Designing a Conceptual Digital Twin Architecture for High-Temperature Heat Upgrade Systems

Abstract

1. Introduction

- Proposing a digital twin architecture aimed at thermal energy systems.

- Provide the process modeling perspective of such systems, together with the data flow.

- Instantiate the proposed architecture on a complex industrial high-temperature heat upgrade system.

- The digital twin instance is used during the create and build phases of the product life cycle, which is rare in the literature.

2. Related Work

2.1. Architecture

2.2. Industrial Relevance

2.3. Renewable Heat Systems Optimization

3. Digital Twin Architecture for Heat Upgrade Systems

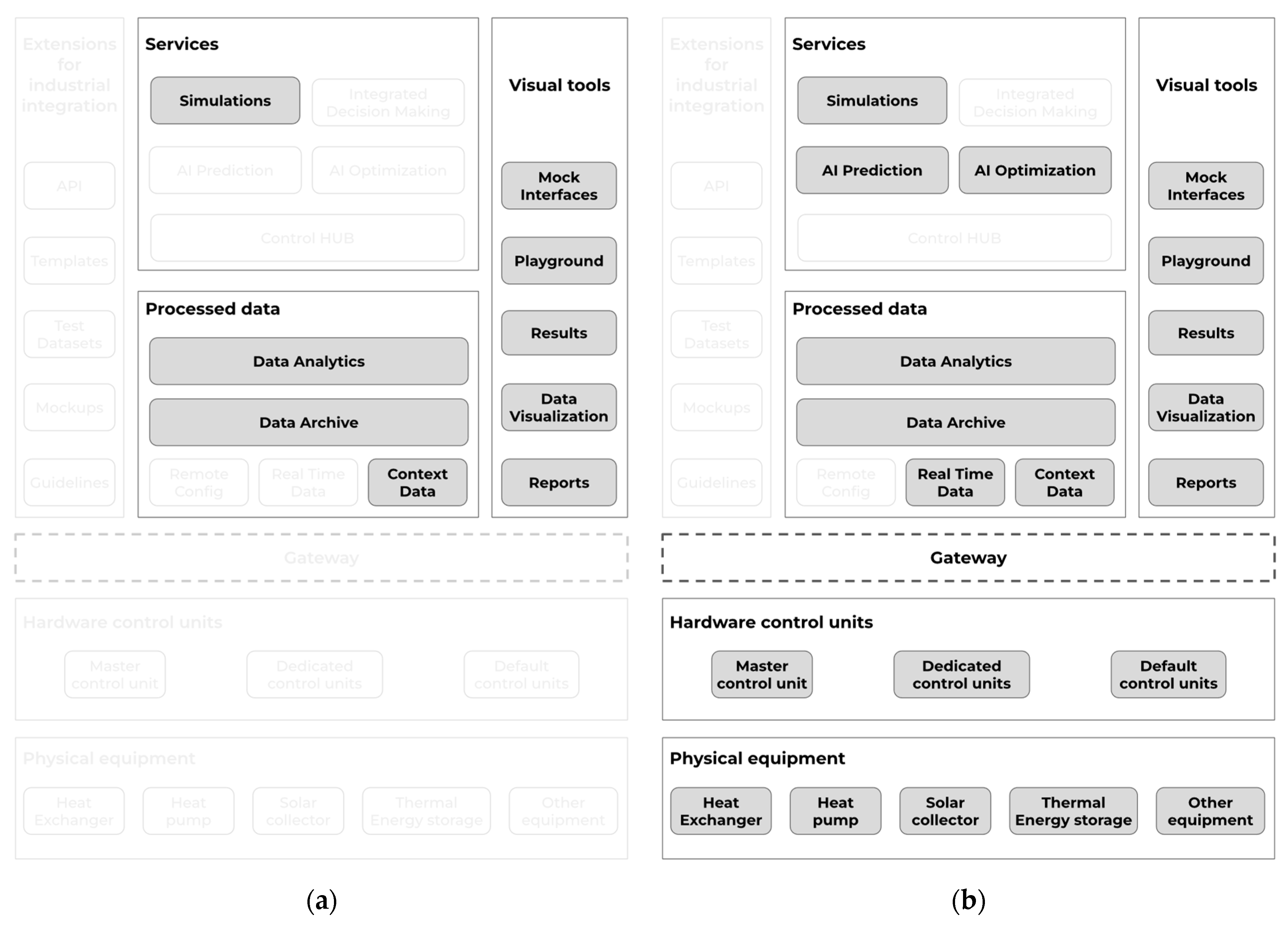

- Default control units—these units represent and control physical equipment that already has an IoT compatible controller or there is an API available. Interfacing and controlling these devices will require low effort and financial costs due to their digital readiness.

- Dedicated control units—we expect that some of the physical equipment have a closed-source controller, or a controller without communication capabilities. This type of device requires the augmentation of the specific physical unit with a dedicated controller. Usually, this is the case when the physical equipment is old, and replacing it with a new one that has IoT capabilities is not economically feasible. This is usually costly in terms of time and effort, as it requires domain knowledge about the device and additional sensors and computing hardware to acquire the device state.

- Master controller unit—while the previous two types of control units are responsible for single physical devices, this control unit is responsible for reactive, time-critical operations, supervision, and orchestration of the system in case connection to higher control levels is not available temporarily due to a disruption in the network.

- Remote config—this module is responsible for translating high-level commands, configuration parameters, and goals received from the Service layer into coordinated sequences of machine-understandable commands for the physical layer devices that are delivered through the Gateway layer.

- Real-Time data—this is a high throughput input module that ingests and processes the real-time data generated by the physical layer devices.

- Context data—represents the specific global parameters of the physical devices together with relations between them. Contextual data consists of information such as geospatial data, physical characteristics, physical relationship to other objects, or environmental conditions. Contextual data is usually represented as knowledge graphs and ontologies.

- Data Archive—represents a module with database-like responsibilities that saves historical data for retrieval and further analysis at a later date.

- Data Analysis—this is a complex module enabled by statistical data analysis methods, including simpler machine learning and AI algorithms.

- Simulation—this module will perform different types of simulations of different physical assets, either individually or in combination with several assets. It is used together with the AI modules to provide results in what if analysis by doing performance simulation, stress testing simulation, control system simulation, or thermal and fluid dynamics simulation.

- AI Prediction and AI Optimization—these two modules will mainly operate with archived data, contextual data, and simulation data to anticipate what will happen in the near or far future. As manual fine-tuning of a complex system is not feasible in a reasonable time, this will be done automatically with the help of Simulation and AI Optimization modules that will find the best parameter value for the system.

- Integrated decision-making—using machine learning algorithms and advanced optimization techniques, this module evaluates potential courses of action under various scenarios and constraints, presenting decision-makers with prioritized options and recommended strategies. This functionality is particularly valuable in time-sensitive or high-stakes environments, where rapid and accurate decision-making is essential to maintaining continuity and achieving operational goals.

- Control HUB—this module enables all the necessary Application Programming Interface (API) instances to connect to the system control. Its main role is to manage and coordinate data flow and control signals between the Service layer, and the underlying Processed Data and Gateway layers, translating them into actionable commands for the physical devices or intermediate control units.

- A simulation Playground where users can simulate various scenarios and explore the behavior of the twinned system under different conditions. Having an interactive risk-free environment, operators can experiment several “what-if” scenarios, exploring the effects of the parameter changes.

- Data Visualization, Results, and Reports represent the main user interface for real-time monitoring and historical data review. Through dynamic graphs, charts, and heatmaps, the dashboard presents complex datasets in an intuitive format, enabling operators to monitor the system.

- Mock Interfaces are included within the user interaction modules to provide a testing environment for connectivity and functionality. These interfaces simulate connectivity to different control units and devices within the digital twin system, allowing operators to test system behavior and diagnose potential connectivity issues without engaging the actual hardware.

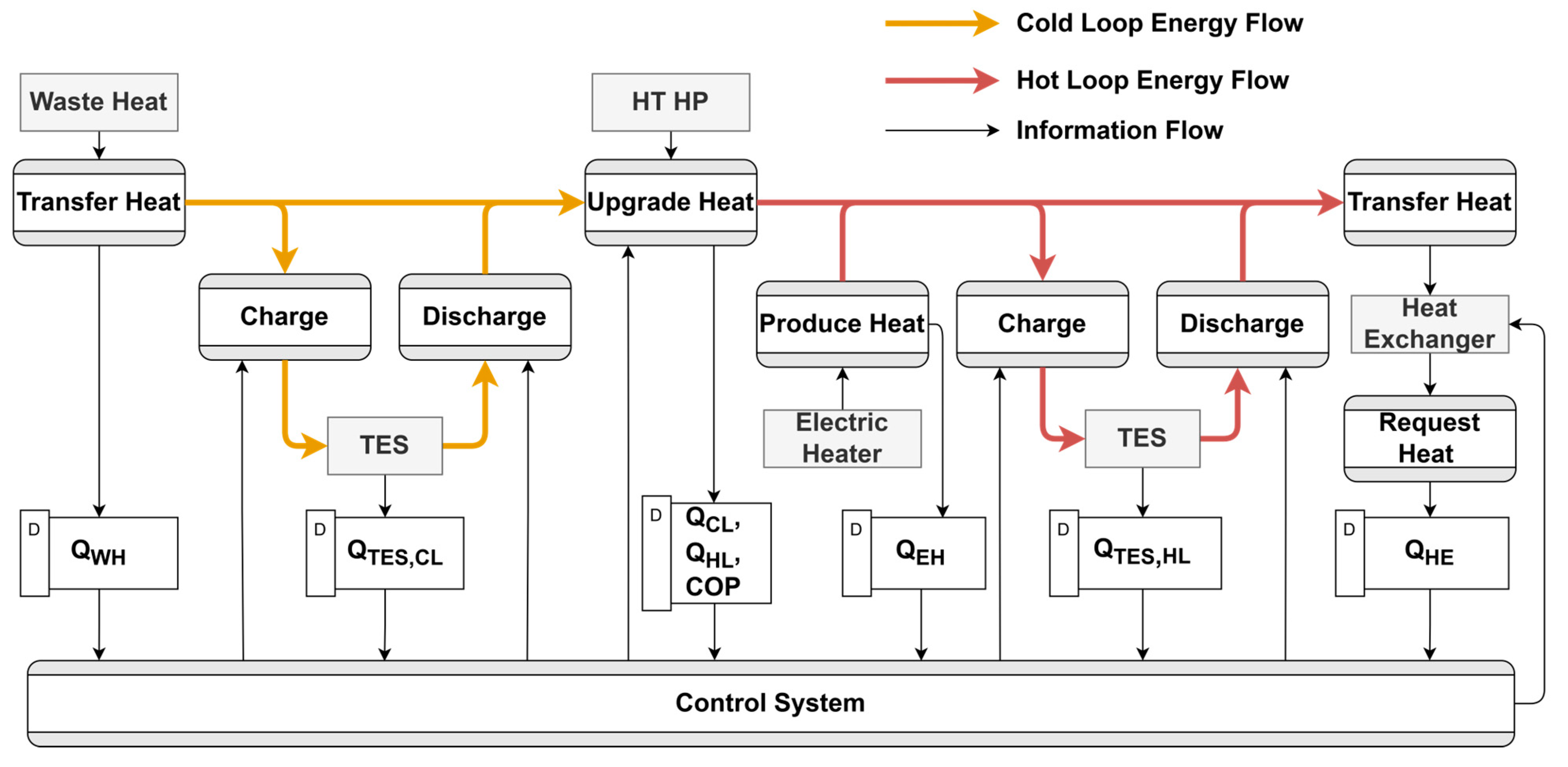

3.1. Digital Twin Process Modeling Perspective

3.2. Tech Stack and Implementation Considerations

4. High-Temperature Heat Upgrade Use Case

4.1. Physical System Perspective

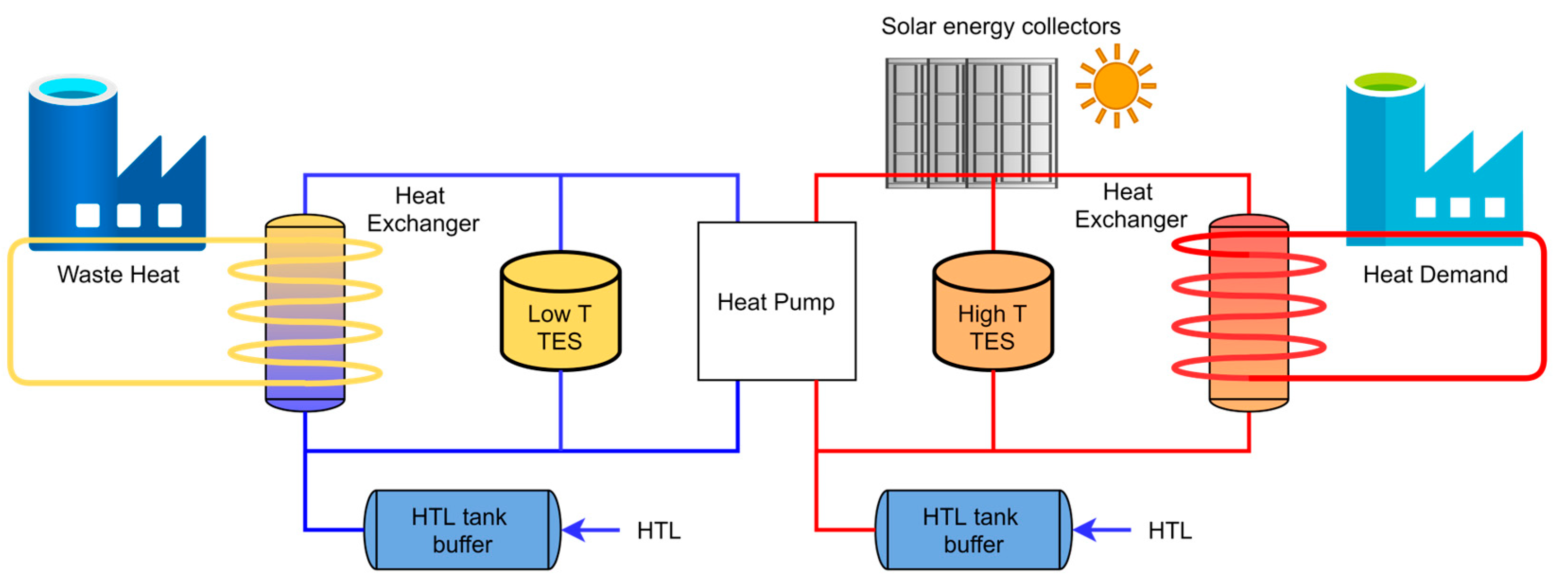

- Waste heat—represents a low-temperature energy source. SUSHEAT targets industrial processes that generate residual heat that is usually lost in the environment.

- Low and High T Thermal Energy Storage—these are two Thermal Energy Storage (TES) devices for the two loops of the system: the cold loop and the hot loop. Useful in situations where there is no high heat demand and the waste energy can be stored in TESes, or when there is no waste heat available, the energy can be extracted from TESes. Two approaches are currently used to find a suitable TES design for the SUSHEAT prototype. One direction explores the use of biomimicry inspiration optimized by genetic algorithms [40] and built using additive manufacturing [41], while the other direction is to use a U-net CNN-based network [42]. The Low T TES is designed for 15 kWh, while the High T TES is aimed for 30 kWh.

- Heat exchangers—two heat exchangers, one for capturing the waste heat into the system, and one to transfer the high-temperature heat to the heat demand process.

- Heat pump—a custom-made heat pump that can output high temperature. Currently, a prototype of a Stirling-cycle heat pump designed for normal operation at 200 kWh with a maximum heat capacity of 400 kW is being tested in a biogas facility, and is able to provide heat up to 200 °C using a source as low as 10 °C with high efficiency, having a COP of up to 3 [43,44]. The SUSHEAT heat pump prototype aims at temperatures up to 250 °C to meet the demands of multiple industries.

- HTL tank buffers—two heat transfer liquid (HTL) buffers, one for each system loop. They are necessary for system safety and pressure damping, ensuring full system flexibility with different types of HTLs across different temperature ranges.

- Solar energy collectors—provide additional energy into the system. Depending on the heat demand, medium or high-temperature collectors can be used. In our case, Fresnel collectors, a type of high-temperature collector, will be used.

- Heat demand—this represents an industrial process that requires a high temperature to operate, usually between 150 °C and 250 °C, considering the current heat pump capabilities and market needs [11].

4.2. Mathematical Modeling

4.3. System Simulation

4.4. 3D Modeling of the System

4.5. Data Flow and Process Modeling

5. Discussion

5.1. Digital Twin Iteration Process

5.2. Digital Twin Architectural Modularity

5.3. Digital Twin Benefits

5.4. Research Gaps

6. Industrial Renewable Energy Upgrade System Cases

6.1. Fish Oil Industry

- Increased energy efficiency compared to traditional steam boilers.

- Environmental sustainability by decreasing the greenhouse gas emissions.

- Cost savings by reducing the carbon dioxide quota.

- Process optimization as the transition from steam boilers to heat pumps will necessitate a more proactive approach to equipment operation and maintenance.

6.2. Dairy Production Industry

- Precise estimations of head-demand and heat production to allow more flexibility for the production planning, worker shifts, and product diversification.

- Parametrization of the system based on different manufacturing processes and products.

- Faster studies and research for new products.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- The European Green Deal—European Commission. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 30 December 2024).

- Deng, X.; Lv, T. Power System Planning with Increasing Variable Renewable Energy: A Review of Optimization Models. J. Clean. Prod. 2020, 246, 118962. [Google Scholar] [CrossRef]

- Thirunavukkarasu, M.; Sawle, Y.; Lala, H. A Comprehensive Review on Optimization of Hybrid Renewable Energy Systems Using Various Optimization Techniques. Renew. Sustain. Energy Rev. 2023, 176, 113192. [Google Scholar] [CrossRef]

- Fan, Z.; Yan, Z.; Wen, S. Deep Learning and Artificial Intelligence in Sustainability: A Review of SDGs, Renewable Energy, and Environmental Health. Sustainability 2023, 15, 13493. [Google Scholar] [CrossRef]

- Pandey, V.; Sircar, A.; Bist, N.; Solanki, K.; Yadav, K. Accelerating the Renewable Energy Sector through Industry 4.0: Optimization Opportunities in the Digital Revolution. Int. J. Innov. Stud. 2023, 7, 171–188. [Google Scholar] [CrossRef]

- Talari, S.; Shafie-khah, M.; Osório, G.J.; Aghaei, J.; Catalão, J.P.S. Stochastic Modelling of Renewable Energy Sources from Operators’ Point-of-View: A Survey. Renew. Sustain. Energy Rev. 2018, 81, 1953–1965. [Google Scholar] [CrossRef]

- Ould Amrouche, S.; Rekioua, D.; Rekioua, T.; Bacha, S. Overview of Energy Storage in Renewable Energy Systems. Int. J. Hydrogen Energy 2016, 41, 20914–20927. [Google Scholar] [CrossRef]

- Ammari, C.; Belatrache, D.; Touhami, B.; Makhloufi, S. Sizing, Optimization, Control and Energy Management of Hybrid Renewable Energy System—A Review. Energy Built Environ. 2022, 3, 399–411. [Google Scholar] [CrossRef]

- Rovira, A.; Guedez, R.; Trevisan, S.; Høeg, A.; Vérez, D.; Cabeza, L.F.; Butean, A.; Enríquez, J.; Law, R.; Muegge, M.; et al. Smart Integration of Waste and Renewable Energy for Sustainable Heat Upgrade in the Industry (SUSHEAT). 2023. Available online: https://zenodo.org/records/8367412 (accessed on 2 October 2024).

- Horizon EU SUSHEAT. Available online: https://susheat.eu/ (accessed on 10 November 2024).

- Marcos, J.D.; Golpour, I.; Barbero, R.; Rovira, A. Decarbonizing European Industry: A Novel Technology to Heat Supply Using Waste and Renewable Energy. Appl. Sci. 2024, 14, 8994. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Kahlen, F.-J., Flumerfelt, S., Alves, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 85–113. ISBN 978-3-319-38754-3. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Nee, A.Y.C. Five-Dimension Digital Twin Modeling and Its Key Technologies. In Digital Twin Driven Smart Manufacturing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 63–81. ISBN 978-0-12-817630-6. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Steindl, G.; Stagl, M.; Kasper, L.; Kastner, W.; Hofmann, R. Generic Digital Twin Architecture for Industrial Energy Systems. Appl. Sci. 2020, 10, 8903. [Google Scholar] [CrossRef]

- Adolphs, P.; Bedenbender, H.; Dirzus, D.; Ehlich, M.; Epple, U.; Hankel, M.; Heidel, R.; Hoffmeister, M.; Huhle, H.; Kärcher, B.; et al. Reference Architecture Model Industrie 4.0 (Rami4.0). ZVEI and VDI, Status Report 2015. Available online: https://www.zvei.org/fileadmin/user_upload/Presse_und_Medien/Publikationen/2016/januar/GMA_Status_Report__Reference_Archtitecture_Model_Industrie_4.0__RAMI_4.0_/GMA-Status-Report-RAMI-40-July-2015.pdf (accessed on 5 November 2024).

- Kasper, L.; Birkelbach, F.; Schwarzmayr, P.; Steindl, G.; Ramsauer, D.; Hofmann, R. Toward a Practical Digital Twin Platform Tailored to the Requirements of Industrial Energy Systems. Appl. Sci. 2022, 12, 6981. [Google Scholar] [CrossRef]

- Robles, J.; Martín, C.; Díaz, M. OpenTwins: An Open-Source Framework for the Development of next-Gen Compositional Digital Twins. Comput. Ind. 2023, 152, 104007. [Google Scholar] [CrossRef]

- Functional Mock-Up Interface. Available online: https://fmi-standard.org/ (accessed on 28 November 2024).

- Infante, S.; Martín, C.; Robles, J.; Rubio, B.; Díaz, M.; Perea, R.G.; Montesinos, P.; Poyato, E.C. Integrating FMI and ML/AI Models on the Open-source Digital Twin Framework OpenTwins. Softw. Pract. Exp. 2024, 54, 1470–1490. [Google Scholar] [CrossRef]

- You, M.; Wang, Q.; Sun, H.; Castro, I.; Jiang, J. Digital Twins Based Day-Ahead Integrated Energy System Scheduling under Load and Renewable Energy Uncertainties. Appl. Energy 2022, 305, 117899. [Google Scholar] [CrossRef]

- Van Dinter, R.; Tekinerdogan, B.; Catal, C. Reference Architecture for Digital Twin-Based Predictive Maintenance Systems. Comput. Ind. Eng. 2023, 177, 109099. [Google Scholar] [CrossRef]

- Gourisetti, S.N.G.; Bhadra, S.; Sebastian-Cardenas, D.J.; Touhiduzzaman, M.; Ahmed, O. A Theoretical Open Architecture Framework and Technology Stack for Digital Twins in Energy Sector Applications. Energies 2023, 16, 4853. [Google Scholar] [CrossRef]

- Semeraro, C.; Olabi, A.G.; Aljaghoub, H.; Alami, A.H.; Al Radi, M.; Dassisti, M.; Abdelkareem, M.A. Digital Twin Application in Energy Storage: Trends and Challenges. J. Energy Storage 2023, 58, 106347. [Google Scholar] [CrossRef]

- Kasper, L.; Schwarzmayr, P.; Birkelbach, F.; Javernik, F.; Schwaiger, M.; Hofmann, R. A Digital Twin-Based Adaptive Optimization Approach Applied to Waste Heat Recovery in Green Steel Production: Development and Experimental Investigation. Appl. Energy 2024, 353, 122192. [Google Scholar] [CrossRef]

- Ontop. Available online: https://ontop-vkg.org/ (accessed on 28 November 2024).

- Guo, Y.; Tang, Q.; Darkwa, J.; Wang, H.; Su, W.; Tang, D.; Mu, J. Multi-Objective Integrated Optimization of Geothermal Heating System with Energy Storage Using Digital Twin Technology. Appl. Therm. Eng. 2024, 252, 123685. [Google Scholar] [CrossRef]

- Aguilera, J.J.; Meesenburg, W.; Markussen, W.B.; Zühlsdorf, B.; Elmegaard, B. Real-Time Monitoring and Optimization of a Large-Scale Heat Pump Prone to Fouling—Towards a Digital Twin Framework. Appl. Energy 2024, 365, 123274. [Google Scholar] [CrossRef]

- Aguilera, J.J.; Padullés, R.; Meesenburg, W.; Markussen, W.B.; Zühlsdorf, B.; Elmegaard, B. Operation Optimization in Large-Scale Heat Pump Systems: A Scheduling Framework Integrating Digital Twin Modelling, Demand Forecasting, and MILP. Appl. Energy 2024, 376, 124259. [Google Scholar] [CrossRef]

- Seifert, J.; Haupt, L.; Schinke, L.; Perschk, A.; Hackensellner, T.; Wiemann, S.; Knorr, M. Digital Twin for Heat Pump Systems: Description of a Holistic Approach Consisting of Numerical Models and System Platform. In Proceedings of the CLIMA2022 | The 14th REHVA HVAC World Congress, Rotterdam, The Netherlands, 22–25 May 2022; pp. 2201–2207. [Google Scholar] [CrossRef]

- Savage, T.; Akroyd, J.; Mosbach, S.; Hillman, M.; Sielker, F.; Kraft, M. Universal Digital Twin—The Impact of Heat Pumps on Social Inequality. Adv. Appl. Energy 2022, 5, 100079. [Google Scholar] [CrossRef]

- The World AvatarTM. Available online: https://theworldavatar.io/ (accessed on 28 November 2024).

- Lv, R.; Yuan, Z.; Lei, B. A High-Fidelity Digital Twin Predictive Modeling of Air-Source Heat Pump Using FCPM-SBLS Algorithm. J. Build. Eng. 2024, 87, 109082. [Google Scholar] [CrossRef]

- Tepsa, T.; Haavikko, M.; Li, O.; Ruismaki, V.-M.; Kangas, S.; Kattelus, J.; Vaataja, H. A Digital Twin of a Heat Pump with a Game Engine for Educational Use. In Proceedings of the 2022 45th Jubilee International Convention on Information, Communication and Electronic Technology (MIPRO), Opatija, Croatia, 23 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1341–1346. [Google Scholar]

- Khan, T.; Yu, M.; Waseem, M. Review on Recent Optimization Strategies for Hybrid Renewable Energy System with Hydrogen Technologies: State of the Art, Trends and Future Directions. Int. J. Hydrogen Energy 2022, 47, 25155–25201. [Google Scholar] [CrossRef]

- He, P.; Almasifar, N.; Mehbodniya, A.; Javaheri, D.; Webber, J.L. Towards Green Smart Cities Using Internet of Things and Optimization Algorithms: A Systematic and Bibliometric Review. Sustain. Comput. Inform. Syst. 2022, 36, 100822. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A Systematic Literature Review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- West, T.D.; Blackburn, M. Demonstrated Benefits of a Nascent Digital Twin. Insight 2018, 21, 43–47. [Google Scholar] [CrossRef]

- Mehraj, N.; Mateu, C.; Zsembinszki, G.; Kala, S.M.; Risco, S.; Cabeza, L.F. Biomimicry-Inspired Design Optimization of a Latent Thermal Energy Storage System Using Phase Change Materials. In Proceedings of the 16th IEA ES TCP International Conference on Energy Storage (ENERSTOCK 2024), Lyon, France, 5–7 June 2024; pp. 58–62. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Mani Kala, S.; Zsembinszki, G.; Vérez, D.; Risco Amigó, S.; Borri, E. Development of a Bio-Inspired TES Tank for Heat Transfer Enhancement in Latent Heat Thermal Energy Storage Systems. Appl. Sci. 2024, 14, 2940. [Google Scholar] [CrossRef]

- Cala, E.F.R.; Bejar, R.; Borri, E.; Mateu, C.; Cabeza, L.F. Modelling of Thermal Storage Systems Using Artificial Intelligence. In Proceedings of the 16th IEA ES TCP International Conference on Energy Storage (ENERSTOCK 2024), Lyon, France, 5–7 June 2024; pp. 366–369. [Google Scholar] [CrossRef]

- Høeg, A.; Løver, K.; Gunnar, V. Performance of a High-Temperature Industrial Heat Pump, Using Helium as Refrigerant. In Proceedings of the High-Temperature Heat Pump Symposium 2024, Copenhagen, Denmark, 23–24 January 2024; Available online: https://www.enerin.no/s/Hoeg-etal-2024_HTHPSymposium.pdf (accessed on 11 November 2024).

- Høeg, A.; Løver, K.; Asphjell, T.-A.; Lümmen, N. Performance of a New Ultra-High Temperature Industrial Heat Pump. In Proceedings of the 14th IEA Heat Pump Conference, Chicago, IL, USA, 15–18 May 2023. [Google Scholar]

- Butean, A.; Enriquez, J.; Matei, A.; Rovira, A.; Barbero, R.; Trevisan, S. A Digital Twin Concept for Optimizing the Use of High-Temperature Heat Pumps to Reduce Waste in Industrial Renewable Energy Systems. Procedia Comput. Sci. 2024, 237, 123–128. [Google Scholar] [CrossRef]

- Sanclemente, M.; Trevisan, S.; Guedez, R. Integrated High Temperature Heat Pump and Thermal Energy Storage Laboratory Rig—Engineering Considerations and Preliminary Design. In Proceedings of the 16th IEA ES TCP International Conference on Energy Storage (ENERSTOCK 2024), Lyon, France, 5–7 June 2024; pp. 285–288. [Google Scholar] [CrossRef]

- Zhang, M.; Tao, F.; Huang, B.; Liu, A.; Wang, L.; Anwer, N.; Nee, A.Y.C. Digital Twin Data: Methods and Key Technologies. Digitaltwin 2021, 1, 2. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in Manufacturing: A Categorical Literature Review and Classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Grieves, M.W. Digital Twins: Past, Present, and Future. In The Digital Twin; Crespi, N., Drobot, A.T., Minerva, R., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 97–121. ISBN 978-3-031-21342-7. [Google Scholar]

- Baldwin, C.Y.; Clark, K.B. Design Rules: The Power of Modularity; The MIT Press: Cambridge, MA, USA, 2000; ISBN 978-0-262-26764-9. [Google Scholar]

- Brusoni, S.; Henkel, J.; Jacobides, M.G.; Karim, S.; MacCormack, A.; Puranam, P.; Schilling, M. The Power of Modularity Today: 20 Years of “Design Rules”. Ind. Corp. Change 2023, 32, 1–10. [Google Scholar] [CrossRef]

- van der Valk, H.; Haße, H.; Möller, F.; Arbter, M.; Henning, J.-L.; Otto, B. A Taxonomy of Digital Twins. In Proceedings of the AMCIS 2020 Proceedings, Salt Lake City, UT, USA, 10–14 August 2020; p. 4. [Google Scholar]

- Pelagia. Available online: https://www.pelagia.com/ (accessed on 3 January 2025).

- Mandrekas. Available online: https://www.mandrekas.gr/en/ (accessed on 3 January 2025).

| Architecture | Target Domain | Abstraction Level | Structure |

|---|---|---|---|

| 3D-DT [12]—2017 | general | Conceptual | 3 components |

| 5D-DT [13,14]—2018 | manufacturing | Conceptual | 5 components |

| GDTA [16]—2020 | energy system | Logical | 6 layers |

| DT-IES [18]—2022 | energy system | Concrete | 5 layers |

| MVES-DT [22]—2022 | energy system | Concrete | 2 components |

| OpenTwins [19,21]—2023 | general | Concrete | 12 components |

| RA-DT-PdM [23]—2023 | general | Logical | 5 layers |

| D-Arc [24]—2023 | energy system | Concrete | 7 layers |

| Requirement | Potential Technology | Purpose |

|---|---|---|

| Bidirectional connection | MQTT, OPC-UA | Collecting real-time data from sensors and IoT devices, and pushing it to a cloud for further processing; Receive commands and control parameters |

| Protocol translation | Eclipse Hono | Connect a large number of IoT devices in a unified way |

| Data Storage | InfluxDB, Prometheus | Time series database |

| Data analysis, AI, and ML | Tensorflow (v2.16.1), Pytorch (v.2.4) | Prediction and optimization |

| Simulation Interface | FMI standard | Integration of multiple simulation tools |

| 3D Modeling and Rendering | Unity (v.6), Unreal Engine (v.5.3) | Real-time 3D visualization of the physical system, interactive interfaces |

| Data Visualization | Grafana (v.10.4) | Real-time data dashboards and monitoring metrics |

| Deployment and Orchestration | Docker (v.28.0.0), Kubernetes (v.1.32.1) | Containerization, orchestration, scaling, and management of distributed apps |

| Cloud Infrastructure | AWS, Microsoft Azure, Google Cloud | Cloud-based processing, storage, and infrastructure for digital twin |

| Component | Variable | Type | Symbol | Unit |

|---|---|---|---|---|

| Heat Pump | HL—Inlet Temperature | Input | Celsius | |

| HL—Outlet Temperature | Input | Celsius | ||

| CL—Inlet Temperature | Input | Celsius | ||

| CL—Outlet Temperature | Input | Celsius | ||

| HL—Mass Flow Rate | Input | L/s | ||

| CL—Mass Flow Rate | Input | L/s | ||

| Electric Power to the Motor | Input | kW | ||

| Coefficient of Performance | Output | |||

| Power from CL | Output | kW | ||

| Power to HL | Output | kW | ||

| Thermal Energy Storage | Inlet Temperature | Input | Celsius | |

| Outlet Temperature | Input | Celsius | ||

| Mass Flow Rate | Input | L/s | ||

| Liquid Fraction | Output | - | % | |

| PCM Temperature | Input | Celsius | ||

| Coefficient of Heat Loss | Output | - | % | |

| Power | Output | kW | ||

| Electric Heater and Heat Sink | Inlet Temperature | Input | Celsius | |

| Outlet Temperature | Input | Celsius | ||

| Mass Flow Rate | Input | L/s | ||

| Power | Output | kW | ||

| Pressure Vessel | Pressure | Input | Bar | |

| Level | Output | - | % |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matei, A.; Butean, A.; Zamfirescu, C.-B.; Marcos, J.D. Designing a Conceptual Digital Twin Architecture for High-Temperature Heat Upgrade Systems. Appl. Sci. 2025, 15, 2350. https://doi.org/10.3390/app15052350

Matei A, Butean A, Zamfirescu C-B, Marcos JD. Designing a Conceptual Digital Twin Architecture for High-Temperature Heat Upgrade Systems. Applied Sciences. 2025; 15(5):2350. https://doi.org/10.3390/app15052350

Chicago/Turabian StyleMatei, Alexandru, Alex Butean, Constantin-Bala Zamfirescu, and José Daniel Marcos. 2025. "Designing a Conceptual Digital Twin Architecture for High-Temperature Heat Upgrade Systems" Applied Sciences 15, no. 5: 2350. https://doi.org/10.3390/app15052350

APA StyleMatei, A., Butean, A., Zamfirescu, C.-B., & Marcos, J. D. (2025). Designing a Conceptual Digital Twin Architecture for High-Temperature Heat Upgrade Systems. Applied Sciences, 15(5), 2350. https://doi.org/10.3390/app15052350