1. Introduction

Cervical spondylosis, arising from the degeneration of the cervical intervertebral disc and its secondary changes, manifests as clinical symptoms and signs when the adjacent structures such as nerve roots, spinal cord, blood vessels, and esophagus are stimulated or compressed by the degenerated disc [

1]. As a prevalent health issue in contemporary society, its current situation is alarming. With the acceleration of modern life rhythms and changes in work patterns, factors such as prolonged maintenance of poor posture, lack of exercise, and aging have collectively contributed to the annual increase in the incidence of cervical diseases [

2]. According to epidemiological statistics, the incidence rate of cervical spondylosis is approximately 10% among people over 30 years old, 25% among those aged 40 to 50, and exceeds 50% among middle-aged and elderly individuals aged 50 to 70 [

3]. This situation not only severely impacts patients’ quality of life but also imposes tremendous pressure on societal medical resources. Among the various treatment methods for cervical diseases, total disc replacement (TDR) has gradually emerged as one of the primary treatment modalities due to its effectiveness in restoring spinal function, alleviating pain, and improving patients’ quality of life [

4,

5,

6].

TDR surgery still faces some significant issues in practical application, among which the material selection and molding method of the core artificial intervertebral disc product are key factors restricting its further development. Currently, there is a wide variety of artificial intervertebral disc materials available, but different materials exhibit marked differences in mechanical properties, biocompatibility, wear resistance, and other aspects, making it challenging to find an ideal material that meets all requirements [

7]. The artificial intervertebral disc materials on the market include metals, ceramics, polymers, etc., among which polycarbonate-based polyurethane (PCU) is highly favored due to its excellent biocompatibility, wear resistance, and elasticity [

8,

9,

10,

11]. However, PCU materials of different hardness demonstrate varying mechanical properties and long-term stability when used in artificial intervertebral discs. PCU materials with higher hardness may suffer from issues such as stress concentration and material fatigue due to excessive stiffness, while those with lower hardness may lead to deformation and failure of the artificial intervertebral disc due to insufficient support [

12,

13]. Therefore, finding the optimal balance among PCU materials of different hardness is an urgent issue that needs to be addressed. Due to the wide range of properties exhibited by polyurethane materials, they hold potential applications in numerous medical scenarios, such as medical catheters, heart valves, and artificial joints. To better meet the specific requirements of different medical applications, researchers employ various methods to modify polyurethane materials and alter their properties. For instance, some researchers can enhance the stiffness and tensile strength while reducing the cost of nanocomposites [

14], or develop tailored strategies to functionalize solid surfaces with other materials through isocyanate–polyol reactivity [

15]. If the properties of the PCU in this study deviate significantly from those of natural intervertebral discs, further adjustments to the material’s properties will be considered to meet the requirements of the intervertebral disc field.

Meanwhile, the choice of molding technique also exerts a significant influence on the performance of artificial intervertebral discs. Although traditional molding methods such as injection molding and hot pressing are technologically mature, they have limitations in terms of mold cost and consistency, making it difficult to meet the manufacturing requirements for high-precision artificial intervertebral discs [

16]. On the other hand, while emerging 3D printing technology offers advantages in high precision and customizability, it still faces challenges in material compatibility and precision control [

17]. Different molding techniques have their own advantages and disadvantages in terms of precision, consistency, and cost. Therefore, selecting the appropriate molding technique to meet the manufacturing requirements of artificial intervertebral discs remains a challenging problem that needs to be addressed.

Based on the current situation, this study aims to compare the comprehensive performance of PCU materials with different hardness and molding techniques, with the goal of identifying the optimal combination of material hardness and processing method for application in artificial intervertebral discs. This will further enhance the performance of intervertebral disc products, promote the development of TDR technology, and improve clinical treatment outcomes. This research not only holds significant theoretical importance but also promises to provide better treatment options and enhance the quality of life for patients with cervical diseases.

2. Materials and Methods

2.1. Material Preparations and Processing

The raw materials used in this study were all medical-grade PCU pellets purchased from Lubrizol, belonging to the Carbothane™ PC Series (Lubrizol, Wickliffe, OH, USA). We ultimately selected four grades of pellets with different hardness: PC-3575A, PC-3585A, PC-3595A, and PC-3555D. PC-3575A was classified as a low-hardness material, while PC-3585A and PC-3595A were medium-hardness materials, and PC-3555D was a high-hardness material. The difference in hardness among these four PCU grades essentially stemmed from varying contents of hard segments. As the material’s hardness increased, so did its rigidity, tensile strength, and compressive strength, but its elasticity might decrease. Conversely, lower-hardness materials were softer and more elastic, typically exhibiting better elongation but possibly lacking in rigidity. Natural intervertebral discs required both sufficient stiffness to support the weight of the head and maintain cervical spine height, as well as elasticity to cushion and absorb shock, thereby protecting the cervical spine. Therefore, to explore the potential application of PCU in artificial cervical discs, we conducted a comprehensive study encompassing materials from low to high hardness, with a focus on the mechanical properties of PCU, such as tensile and compressive performance, in order to identify a PCU material with properties close to those of natural intervertebral discs. For better differentiation, we classified the four materials based on their hardness and grade: 75A for PC-3575A, 85A for PC-3585A, 95A for PC-3595A, and 55D for PC-3555D. The processing methods employed in the study encompassed three of the most used molding techniques at present [

18]: injection molding (IM), compression molding (CM), and fused deposition modeling in three-dimensional printing (3D).

Thermoplastic polyurethane products are susceptible to the detrimental effects of moisture when in a molten state. To achieve optimal results, all pellets were dried in a vacuum oven at 65 °C (150 °F) for at least four hours prior to processing, ensuring a moisture content of 0.05% by weight or less. Subsequently, the dried PCU particles were introduced into the machinery for further processing.

For the injection-molded specimens, the dried PCU pellets were loaded into the hopper of the injection molding machine (MA 900 III; HaiTian Plastics Machinery, Ningbo, Zhejiang, China). The pellets were then melted and injected at a speed of 40 mm/s. Referring to the parameter ranges provided in the Lubrizol technical sheet and considering the actual operating environment, the final temperatures for the mold, rear, middle, front, and nozzle are shown in

Table 1 below.

For the compression-molded specimens, a large-scale hot press machine (KSH R100; Dongguan Kesheng Industry, Dongguan, Guangdong, China) was employed. During the hot-press molding process, the temperatures of the upper and lower platens were both set to 200 °C for 75A and 85A materials, while 210 °C was applied for 95A and 55D. The pressure was uniformly maintained at 20 MPa. The preheating phase lasted for 8 min, followed by a hot-pressing duration of 10 min, and subsequently, air cooling for 10 min. The dried pellets were placed into standard molds and pressed into thin sheets or cylinders of specified thickness for subsequent experimental research and applications.

For the 3D-printed specimens, a precision 3D printing filament extruder (SESL-20/02; Guangzhou Putong Experimental Analysis Instrument, Guangzhou, Guangdong, China) was used to process the pellets into filaments. The filaments were then printed and shaped using a 3D printer (RAISED 3D-E2; Shanghai Fuzhi Information Technology, Shanghai, Jiangsu, China). The dried PCU pellets were fed into the filament extruder, where they underwent melting extrusion, water cooling, and winding, ultimately being extruded into a 1.75 mm-diameter filament coil for 3D printing. During the 3D printing process, the printer nozzle temperature was set to 220 °C, the bed temperature to 40 °C, and the printing speed of the samples to 10 mm/s.

2.2. Hardness

The hardness test of the material was conducted using a Shore hardness tester (LX-A-1; Dongguan Sanliang Precision Measuring Instrument, Dongguan, Guangdong, China), with the test method following the standard ISO 868-2003 [

19]. A flat sample was placed on the test surface, and the Shore hardness tester was pressed into the material being tested. After pressing for 1 s, the value displayed on the dial was read. Five tests were repeated at different locations on each sample, specifically selected from the front, middle, and back positions. The values were recorded, and the average was calculated as the final Shore hardness value of the sample.

2.3. Morphology and Element

The surface morphology of the samples was observed and investigated using a scanning electron microscope (SEM). Energy-dispersive X-ray spectroscopy (EDS) was employed to study the elemental composition of the sample surfaces. Prior to testing, the samples were first immersed in deionized water and ultrasonically cleaned for 20 min, followed by drying in a vacuum oven for at least 5 h to prevent any impurities or moisture on the PCU material surface from affecting subsequent observations. The sample surfaces were then coated with gold, and imaging was performed using a TESCAN Mira3 Schottky field-emission scanning electron microscope (TESCAN Orsay Holding, Brno, Moravian, Czech Republic). In this study, the acceleration voltage of the SEM was set at 10 KV, a fixed value used to ensure that the electron beam had sufficient energy to penetrate the sample surface and produce high-quality images. Throughout the entire experimental process, the acceleration voltage remained unchanged. Energy spectra were acquired using an Esprit 1.9 EDS spectrometer (Bruker Corporation, Billerica, MA, USA).

2.4. Fourier-Transform Infrared Spectroscopy

Attenuated total reflection Fourier-transform infrared (ATR-FTIR) spectroscopy was utilized to examine the interactions and structural differences among PCU samples of different hardness grades as well as those processed through various molding methods. In this study, ATR-FTIR spectroscopy was employed to perform spectral analysis on the synthesized PCU elastomers, aiming to identify the characteristic functional groups of these materials. Measurements were carried out using a Nicolet Is 50 FTIR spectrophotometer (Thermo Fisher Scientific, Waltham, MA, USA), with each sample being scanned 32 times within the range of 4500–400 cm−1. The resolution for this scanning was set at 2 cm−1.

2.5. Tensile Tests

The tensile testing procedure for the materials followed the standards ISO 527-1:2012 and ISO 527-2:2012 [

20,

21]. All material specimens were dumbbell-shaped type-1A samples, and testing was conducted using an Instron universal testing machine (Instron Corporation, Norwood, MA, USA) equipped with a 10 kN load cell. The tensile speed was set at 50 mm/min. A minimum of 5 specimens were tested for each group, and all results were calculated as the mean ± standard deviation. Excel software (Microsoft version 2021, Washington DC, USA) was used for data analysis, and an unpaired student’s

t-test was applied to statistically evaluate the significance of differences in the data (

p < 0.05).

2.6. Compression Tests

The compressive testing of the material was conducted in accordance with the standard ISO 604:2002 [

22]. Cylindrical specimens with dimensions of 15 mm in diameter and 6 mm in height were used. The tests were performed using an Instron universal testing machine (Instron Corporation, Norwood, MA, USA) equipped with a 10 kN load cell, and compression was applied at a rate of 1 mm/min [

23]. A minimum of five specimens were tested per group, and all results were calculated as the mean ± standard deviation. By further processing the data, stress–strain curves for PCUs of gradient hardness and different molding methods were derived, along with the corresponding stress level values at 15% strain. These were used to assess the compatibility of PCUs with different hardness levels and molding techniques in relation to the compression performance of natural intervertebral discs.

2.7. Water Contact Angle

To evaluate the surface wettability of materials, hydrophilicity tests were conducted. One of the commonly used methods for measuring hydrophilicity is the water contact angle (WCA) method. The static contact angles between different materials of varying hardness, processed through different molding techniques, and deionized water at room temperature were measured using a static contact angle measuring instrument (Data Physics Corporation, Santa Rosa, CA, USA). For each measurement, a 3 μL aliquot of the test liquid was dispensed onto the sample surface using an automatic piston syringe. Then, the static contact angle was measured, and the contact angle value was directly read from the instrument equipment. Three parallel specimens were used for each material of different hardness, and each specimen was measured five times to obtain an average value. Prior to the experiments, all samples were cleaned with detergent for 10 min using ultrasonic cleaning, followed by rinsing with pure water for another 10 min using ultrasonic cleaning. The samples were then dried in an oven at 75 °C for 30 min. After removal from the oven, the samples were placed on the contact angle stage for contact angle testing.

2.8. Data and Statistical Analysis

The software Matlab (version 2021a; MathWorks, Natick, MA, USA) was utilized to process the collected raw data and subsequently output the target data. IBM SPSS Statistics software (version 26.0; IBM Corp, Armonk, NY, USA) was employed to perform one-way ANOVA among different groups of data. A significant statistical difference between two groups was considered to be present when the p-value was less than 0.05; otherwise, no significant statistical difference was deemed to exist between the two groups.

4. Discussion

The main objective of this study is to identify a combination of PCU material hardness and molding method that exhibits comprehensive properties more suitable for replacing the natural intervertebral disc. To this end, four PCU materials with different hardness were molded using the commonly employed molding methods of IM, CM, and 3D. Various material performance studies were then conducted to assess the impact of different molding methods and material hardness on the overall properties of the PCUs.

This study found that the three molding methods did not affect the material hardness. The results convincingly demonstrated that none of the aforementioned molding methods significantly impacted the hardness characteristics of the PCU material, thereby validating the rationality of these molding processes in terms of temperature settings and processing procedures. No degradation, resynthesis, or other reactions that could alter the original properties of the material were triggered by improper processing conditions. Furthermore, an interesting trend emerged from the hardness data: IM > CM > 3D. Although slight differences existed among the three, these differences were not statistically significant, indicating comparable hardness properties of the materials produced by these three molding methods. This finding aligned with previous research results, and the work by Pompe et al. [

27] also emphasized the importance of selecting molding techniques in maintaining material performance, yet similarly found no significant differences in hardness within their specific material system. In summary, our findings further support the notion that appropriate molding techniques can reliably produce materials with consistent hardness properties, regardless of the specific method employed. Although the molding method itself has little influence on the hardness of PCU, when pursuing high-precision applications, it is still necessary to consider the minor hardness variations that may arise from different molding processes, in order to make the optimal choice based on specific requirements.

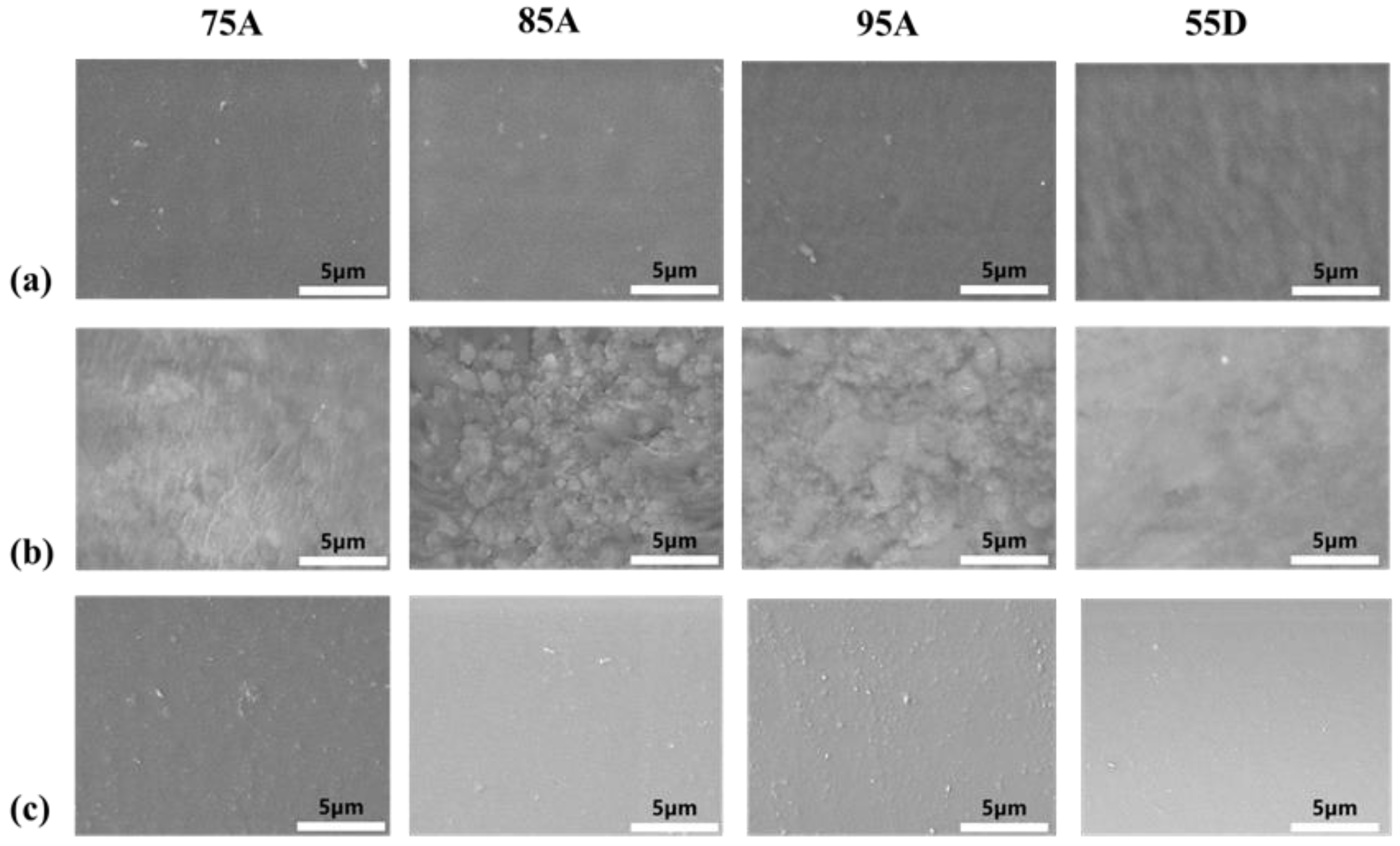

The PCU materials selected for this study are intended for future use as nucleus pulposus materials in artificial intervertebral discs. Consequently, there are specific requirements for the microstructure of PCUs to minimize failure factors such as stress concentration, fatigue cracks, and wear debris in subsequent practical applications due to unsatisfactory surface morphology, thereby enhancing the service life of artificial intervertebral discs. Lestari et al. [

24] observed during the processing of PCU specimens using the CM method that an inappropriate melting temperature during the compression process likely caused the surface of the obtained PCU specimens to appear rough under SEM examination, with the presence of incompletely melted particles. The SEM results of this study differed from theirs; through appropriate temperature control, a uniform distribution of the material on the specimen surface was achieved without the presence of incompletely melted particles. However, possibly due to excessively high demolding speed or insufficient cooling time, minor flocculent marks were present on the surface of the CM specimens.

The observations from this study revealed that although all three molding methods could produce dense and essentially defect-free PCU samples, there were still subtle differences in surface morphology. The surface smoothness of IM and 3D samples was superior to that of CM samples. These subtle differences might arise from the unique processing conditions and mechanisms associated with each molding method. The smoother surface of IM samples might be attributed to the higher processing pressure and more controlled cooling rate employed in this technique. In contrast, despite the layer-by-layer construction process of 3D, it still achieved a relatively smooth surface, with only occasional granular features that might be related to specific printing parameters and material deposition mechanisms [

28]. The reduction of demolding-related defects in CM samples highlighted the importance of optimizing processing temperatures and demolding strategies.

ATR-FTIR spectroscopy was employed to identify the characteristic chemical groups present in the chemical structure of the processed PCUs. On the other hand, it was also used to examine potential structural changes that may occur during the reprocessing of PCUs. The FTIR results in this study revealed that the final specimens of PCUs with different hardness, obtained through three different molding methods, exhibited the same functional groups without any damage. These results were consistent with the PCU molecular structure reported in the literature [

29,

30,

31,

32], indicating that the material did not undergo degradation or introduce impurities during the molding process, and the molded specimens were identical. Miller et al. [

33] also conducted a study on different PCU grades using various molding methods and found that there was no significant difference in the degree of phase separation between IM and 3D-molded PCU materials for any hardness of PCU. This suggested that different molding methods did not cause damage to the material’s functional groups, which agreed with the findings of this study.

All tensile tests in this study utilized A1 specimens. Due to the measurement range limitations of the testing equipment, the specimens reached the maximum capacity of the equipment at a 300% elongation. Therefore, all data processing was conducted using 300% strain as the upper limit. Fracture testing could not be performed, and thus, the ultimate tensile strength and elongation at break of the PCUs could not be obtained. However, the stress–strain curves of the PCUs processed through different molding methods within 300% elongation were consistent with the research by Jahanmardi et al. [

34]. The modulus of the PCUs significantly increased with the increase in hard segment content. Furthermore, the PCUs exhibited classic elastomer behavior, with the typical plateau region diminishing as the hard segment content increased, which also validated the findings of Oelsch et al. [

35] that the mechanical behavior of the PCU materials was the same under IM and 3D processing. A comparison of the elongation in our study revealed that the tensile properties of PCU processed by IM were inferior to those of PCU processed by CM and 3D printing. Additionally, the tensile properties of PCU processed by CM were inferior to those of PCU processed by 3D printing. Therefore, considering tensile properties, 3D printing was found to be the optimal molding method, followed by CM and IM. This was consistent with the findings of Miller et al. [

33], which demonstrated that 3D-processed specimens exhibited significantly larger failure strain during tension compared to IM-processed specimens.

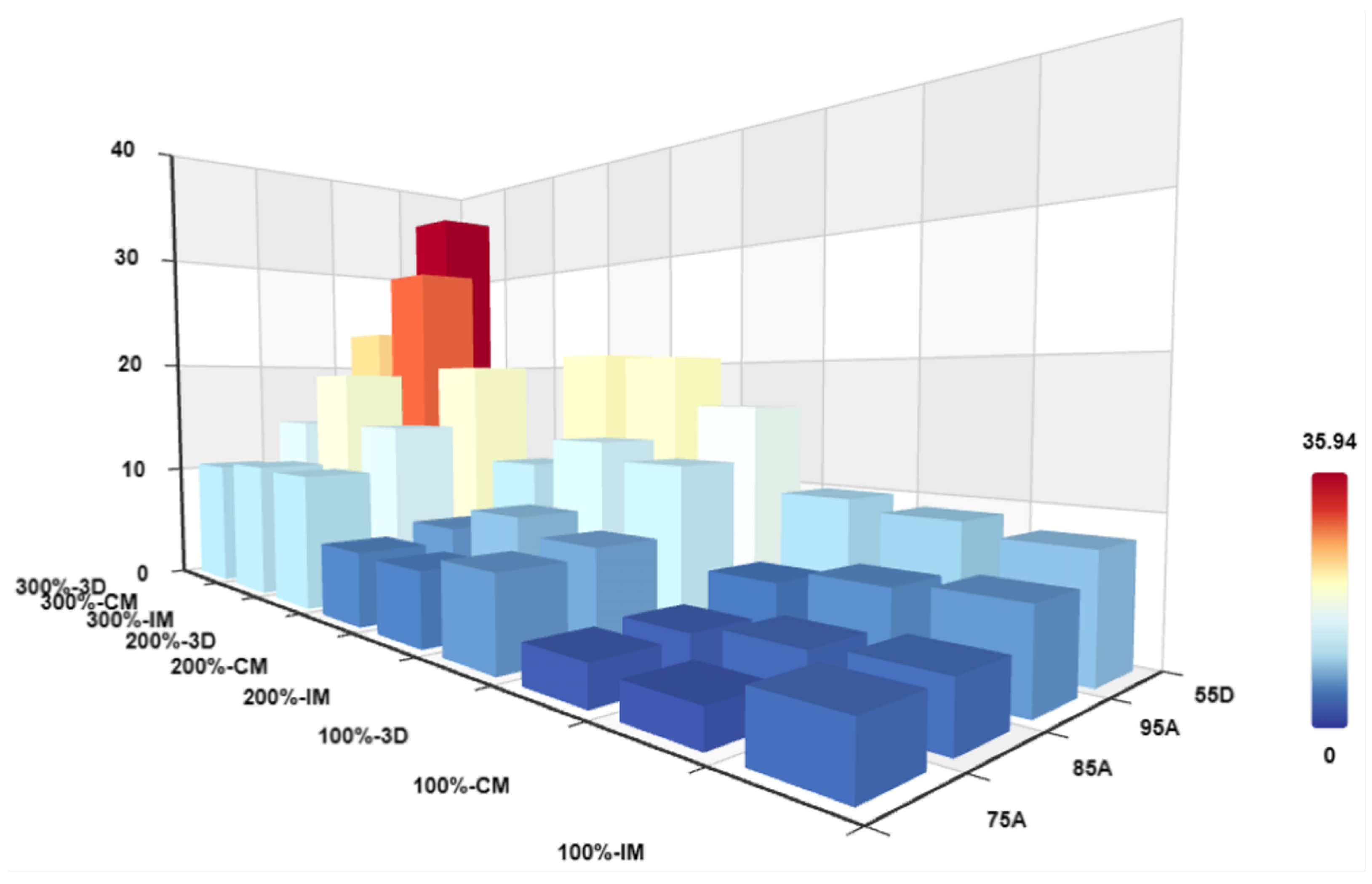

In the compression process of this study, PCU exhibited linear behavior before reaching 40% strain, but subsequently demonstrated non-linear behavior, with a rapid increase in compressive modulus. This was somewhat inconsistent with the findings of Shepherd et al. [

36], who observed that PCU material exhibited linear behavior throughout the entire compression process. The possible reason for this discrepancy is that their study primarily focused on the application of PCU in cartilage and did not investigate the material’s behavior under larger compressive strains. In our study, when processed by IM, the average stress levels of PCU with all hardness levels were above 0.9 MPa, theoretically satisfying the load-bearing requirements of the intervertebral disc. However, the stress level of 55D was excessively high, failing to meet the shock absorption requirements of the disc, and thus it was excluded from material selection. Additionally, the average stress levels of 75A PCU processed by CM and 3D were found to be below 0.9 MPa, failing to meet the load-bearing requirements, which was consistent with the findings of Alvarez et al. [

37] that some PCU materials had insufficient compressive stiffness to satisfy the load-bearing requirements of the intervertebral disc. Therefore, from the perspective of mimicking the load-bearing capacity of the natural intervertebral disc, 85A and 95A materials, when processed by IM, CM, and 3D, were considered the preferred choices that could meet the load-bearing requirements of the disc material. As for the slightly higher stress levels, common methods, such as doping with silicon, could be employed to appropriately reduce the compressive stiffness to better adapt to the requirements of the natural intervertebral disc.

Due to the direct influence of chemical bonds, the molecular angle on a smooth surface was smaller than that on a rough surface, as the smoothness of the surface reduced wetting hysteresis [

38]. The hydrophilicity and hydrophobicity of the material surface affected its biocompatibility; a surface with higher hydrophilicity had better affinity for cells and exhibited better blood compatibility [

39]. For artificial intervertebral disc products, hydrophobicity was a favorable factor, and the greater the surface roughness, the more it could resist the adsorption of blood proteins, theoretically reducing the likelihood of platelet adhesion and thrombus formation [

40]. In this study, it was found that PCU materials processed by the CM method had a relatively larger WCA and greater surface roughness compared to those processed by other methods. Under certain hardness conditions, they even exhibited significant differences compared to IM and 3D-processed materials of the same hardness. Therefore, materials processed by the CM method had relatively better hydrophobicity. Studies by Julien et al. [

41] also found that PCU processed by IM exhibited excellent hydrophobic properties, which was consistent with the results of this study. However, for materials processed by IM and 3D methods, the surface smoothness of different hardness grades was similar, showing no significant differences.

5. Conclusions

In summary, we drew the following conclusions: (1) In terms of hardness, SEM, EDS, ATR-FTIR, and WCA, PCUs with the same hardness processed through IM, CM, and 3D exhibited similar comprehensive performance. That is, given a reasonable temperature setting, all three molding methods could be applied for the processing and molding of PCU pellets. (2) Regarding mechanical properties, PCUs with 85A and 95A hardness, processed through IM, CM, and 3D methods, demonstrated tensile and compressive properties that were more akin to those of natural intervertebral discs. However, there remained a gap between their performance and that of natural discs, necessitating further improvements in material properties before they could be fully utilized in intervertebral disc products as replacements for natural discs.

Therefore, the ultimate conclusion of this study was that PCU materials with 85A and 95A hardness, processed by IM, CM, and 3D, exhibited comprehensive properties more consistent with the requirements of natural intervertebral discs, making them the most promising candidates for replacing natural discs in intervertebral disc products. Based on the current research findings, further performance optimization studies on PCU are still needed in the future to fully align its properties with those of the natural intervertebral disc, thereby achieving an effective replacement of the natural disc with artificial intervertebral disc products made of PCU material.