Surface-Roughness Prediction Based on Small-Batch Workpieces for Smart Manufacturing: An Aerospace Robotic Grinding Case Study

Abstract

1. Introduction

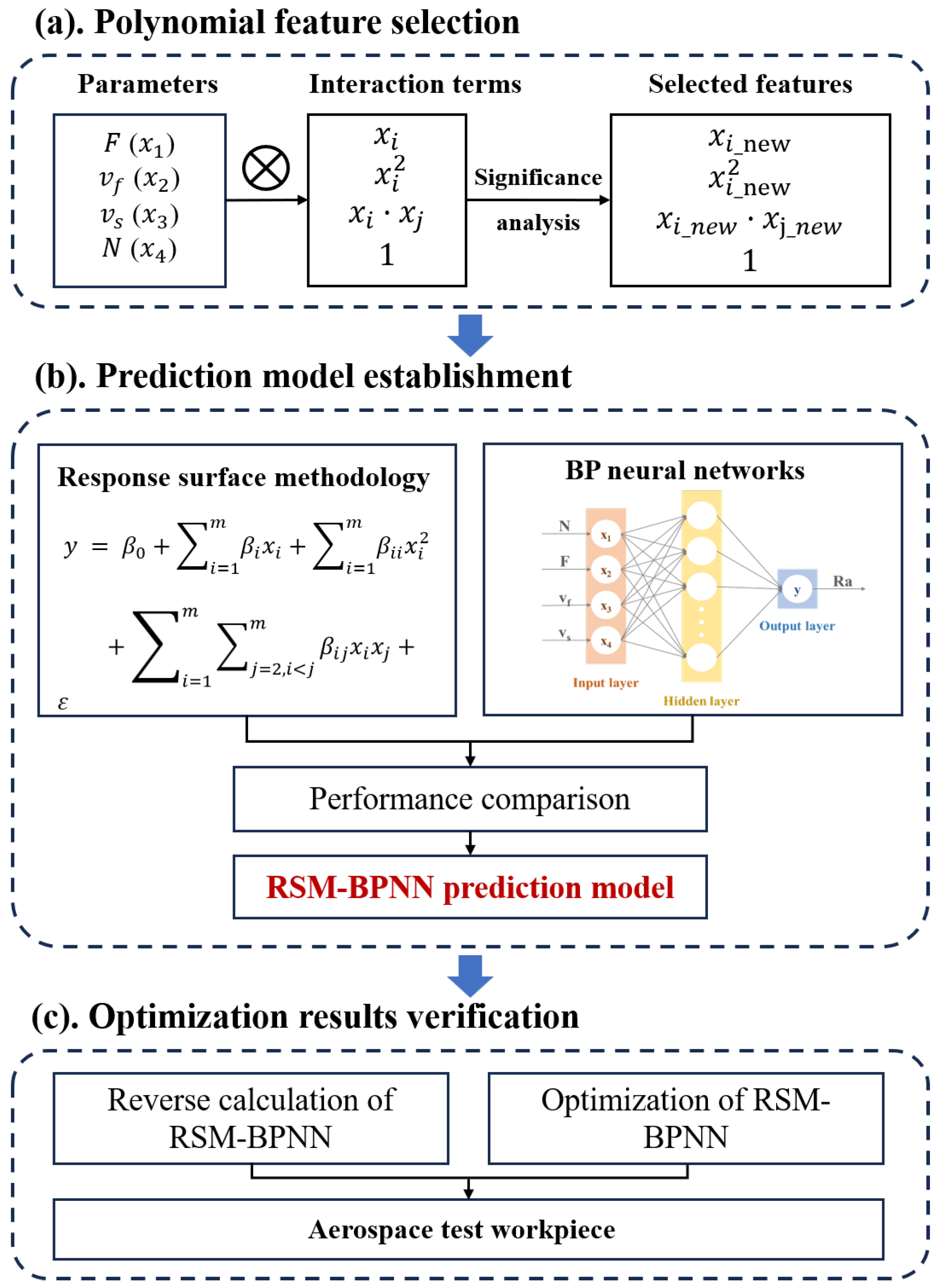

- (a)

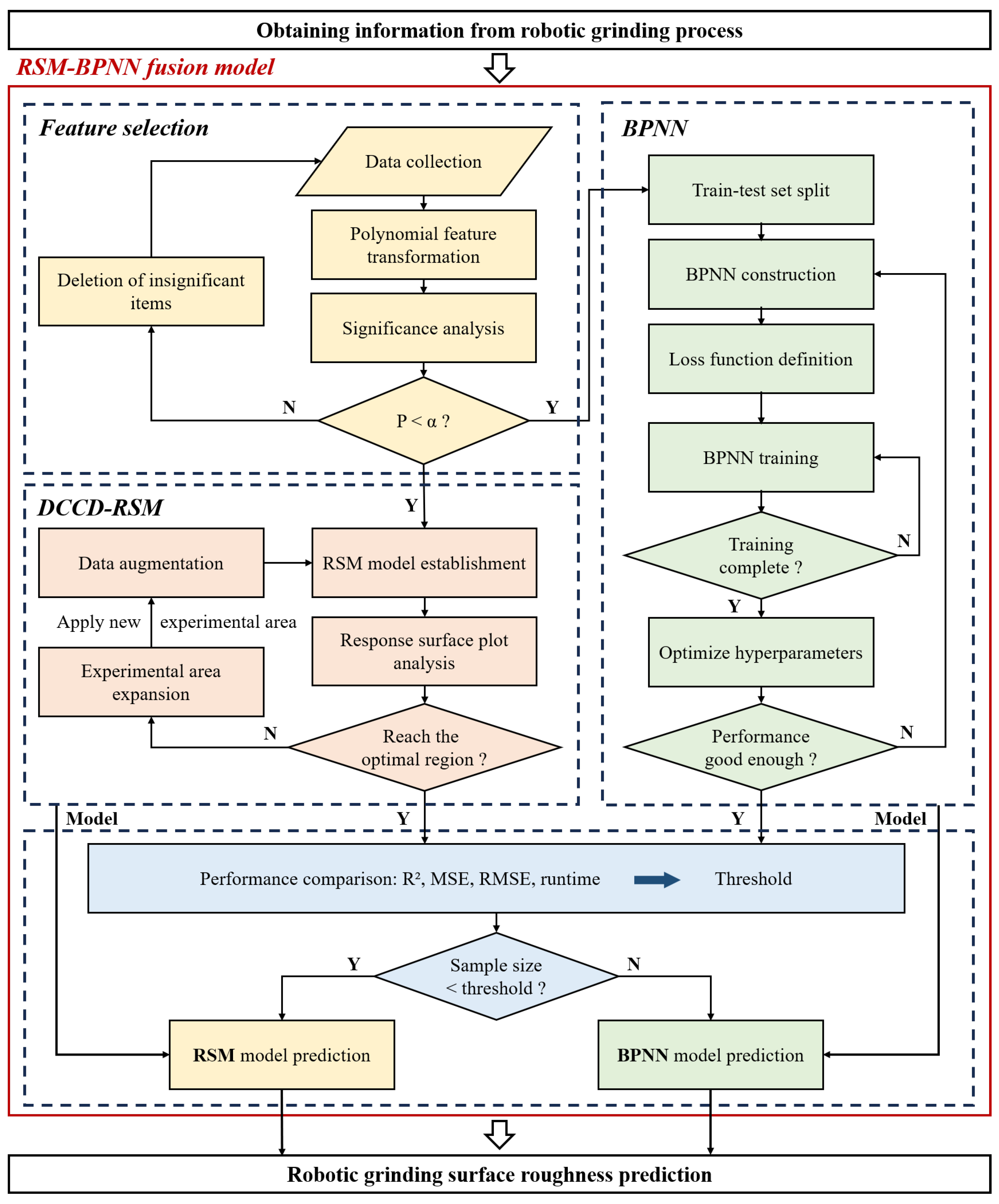

- Polynomial feature transformation and significance analysis were performed on the proposed parameters. Data preprocessing, including normalization and feature selection, was conducted to ensure the significance of features’ impact on prediction results.

- (b)

- By incorporating model training time into the evaluation metrics and using the acquired experimental data sample size as a horizontal parameter for comparison, this method ensures compatibility of the model with industrial production requirements.

- (c)

- A Data-Model-Verification(DMV) architecture for grinding is proposed, which has obvious accuracy and practicality in modeling and predicting the roughness of ground surfaces.

2. Literature Review

2.1. Smart Manufacturing System Quality Modeling and Optimization

2.2. Statistical Fitting Model

2.3. Data-Driven Model

2.4. Research Gaps

- (a)

- Existing grinding studies mostly focus on specific scenarios, and the selected process parameters vary accordingly. Currently, there is no systematic parameter selection for the case of robotic grinding, where the workpiece is fixed, and the tool serves as the end-effector.

- (b)

- At the modeling method level, traditional statistical methods often suffer from insufficient prediction accuracy when dealing with large sample sizes. On the other hand, data-driven methods face challenges such as high computational complexity, long runtime, and overfitting when dealing with small sample sizes. Moreover, existing studies lack considerations for selecting methods based on different data sample sizes, neglecting the training time requirements of the model, which affects data adaptability and the practical feasibility in production environments.

- (c)

- Some prediction tasks rely on theoretical modeling, simulation, or are limited to dataset validation, without subsequent parameter optimization and real-machine verification. Theoretical or simulation results may differ from actual production environments, resulting in suboptimal model performance under real working conditions.

3. Methodology

3.1. Overall Framework of BPNN Fusion Model

3.1.1. Selection of Polynomial Transformation Feature

- and represent the between-group mean square and within-group mean square, respectively,

- and represent the sum of squares for between-group and within-group variances, respectively,

- and are the corresponding degrees of freedom.

3.1.2. Design and Establishment of DCCD-RSM

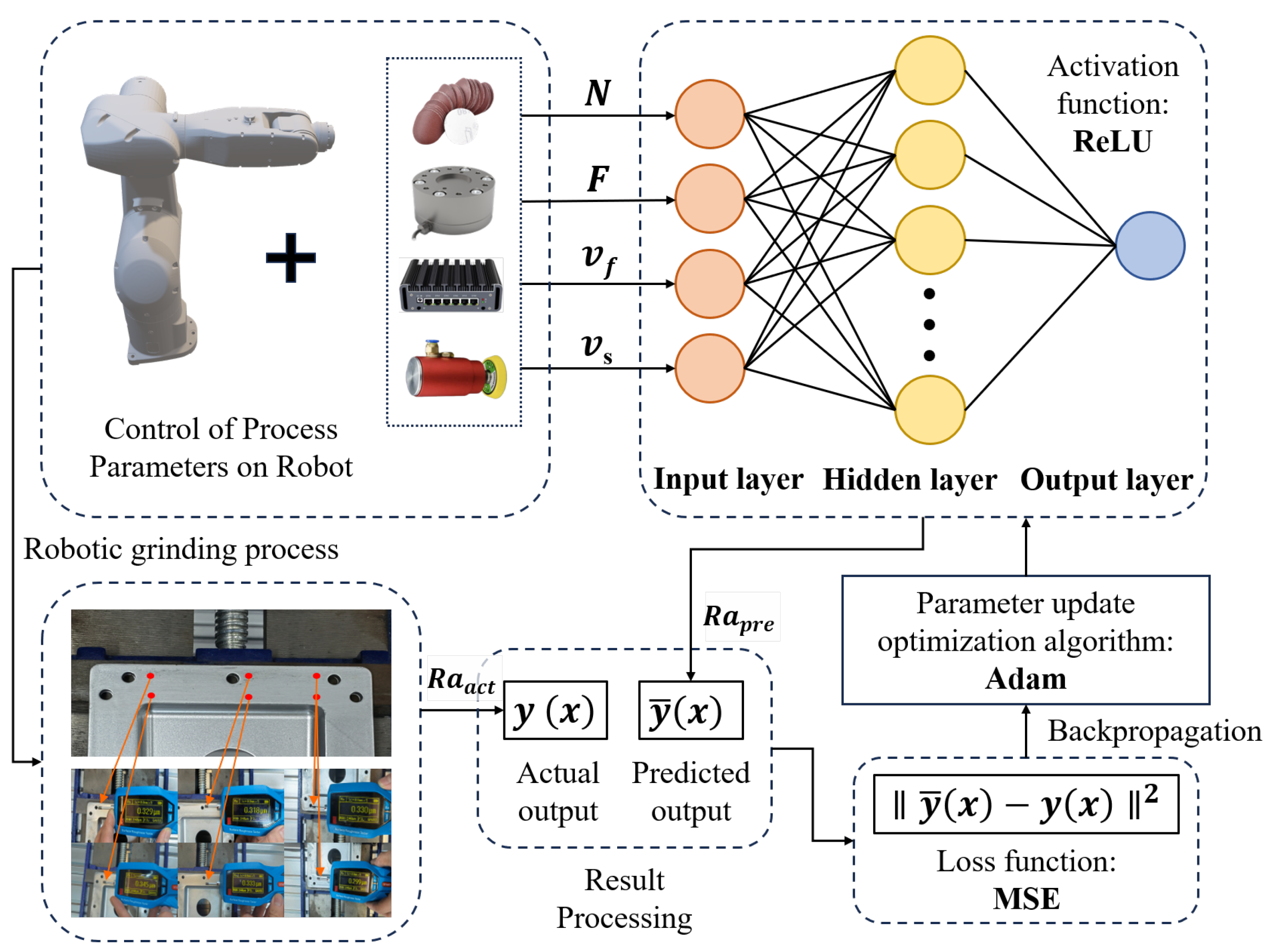

3.1.3. Structure and Training Design of BPNN

3.2. Robotic Grinding Process Parameters Optimization

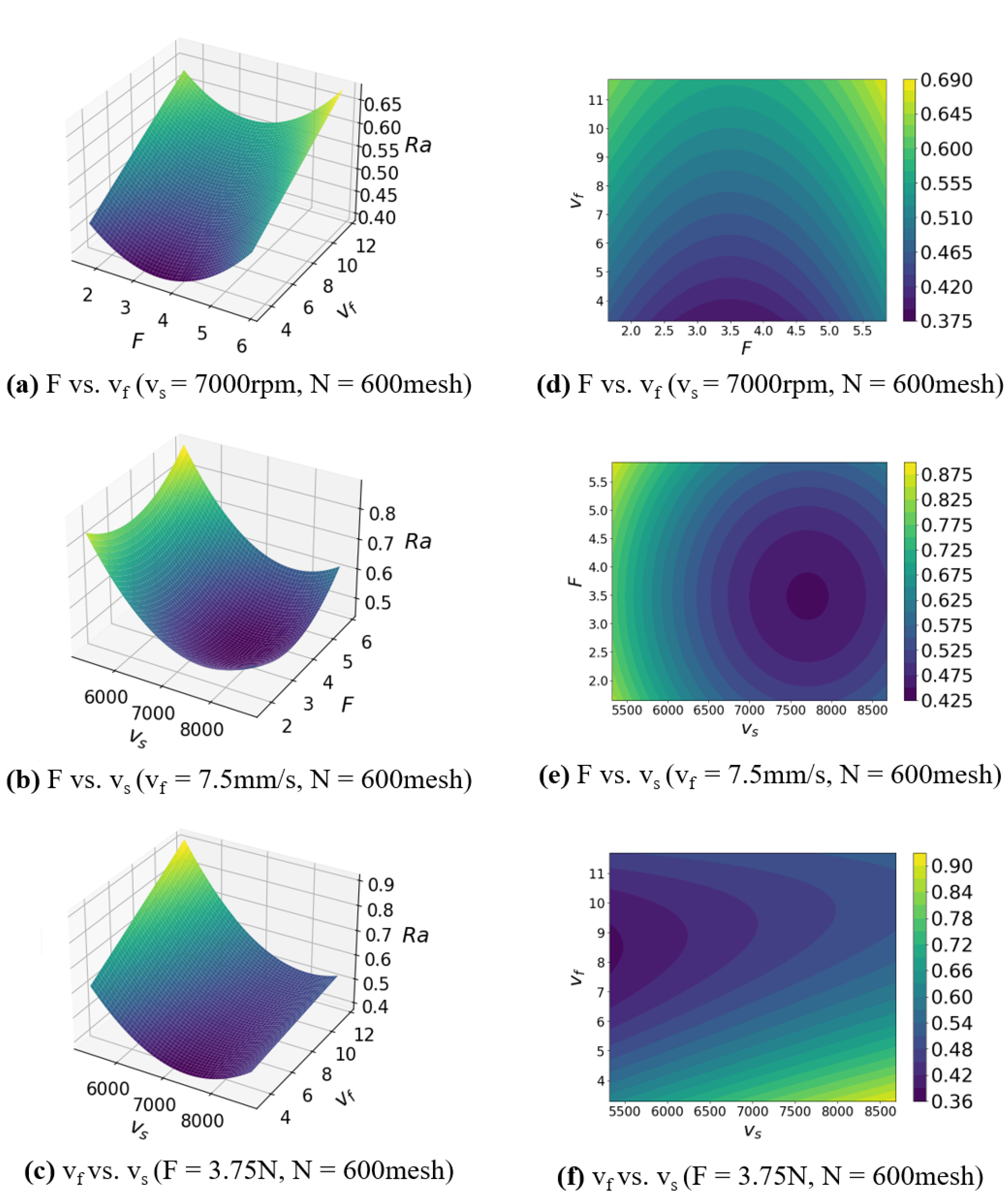

3.2.1. Robotic Parameters Optimization on RSM

3.2.2. Robotic Parameters Optimization on BPNN

4. Experimental Platform Setup

5. Results

5.1. Polynomial Feature Selection

5.2. Prediction Model Establishment

5.2.1. Result and Analysis of DCCD-RSM

5.2.2. Training Process and Results of BPNN

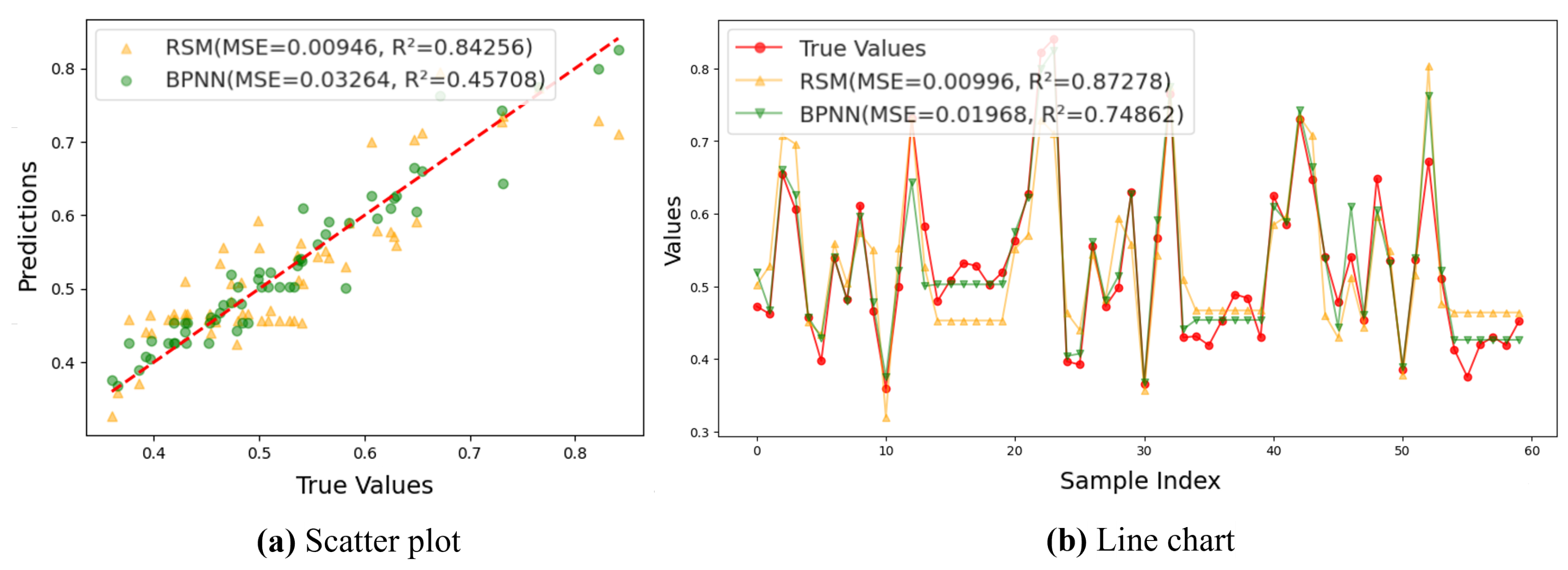

5.2.3. Prediction Comparison Between RSM and BPNN of 60 Sets Data

5.3. Optimization Results Verification

5.3.1. Parameters Reverse Calculation and Optimization of BPNN

5.3.2. Applications and Verification in Robotic Grinding of Aerospace Test Workpiece

6. Discussions

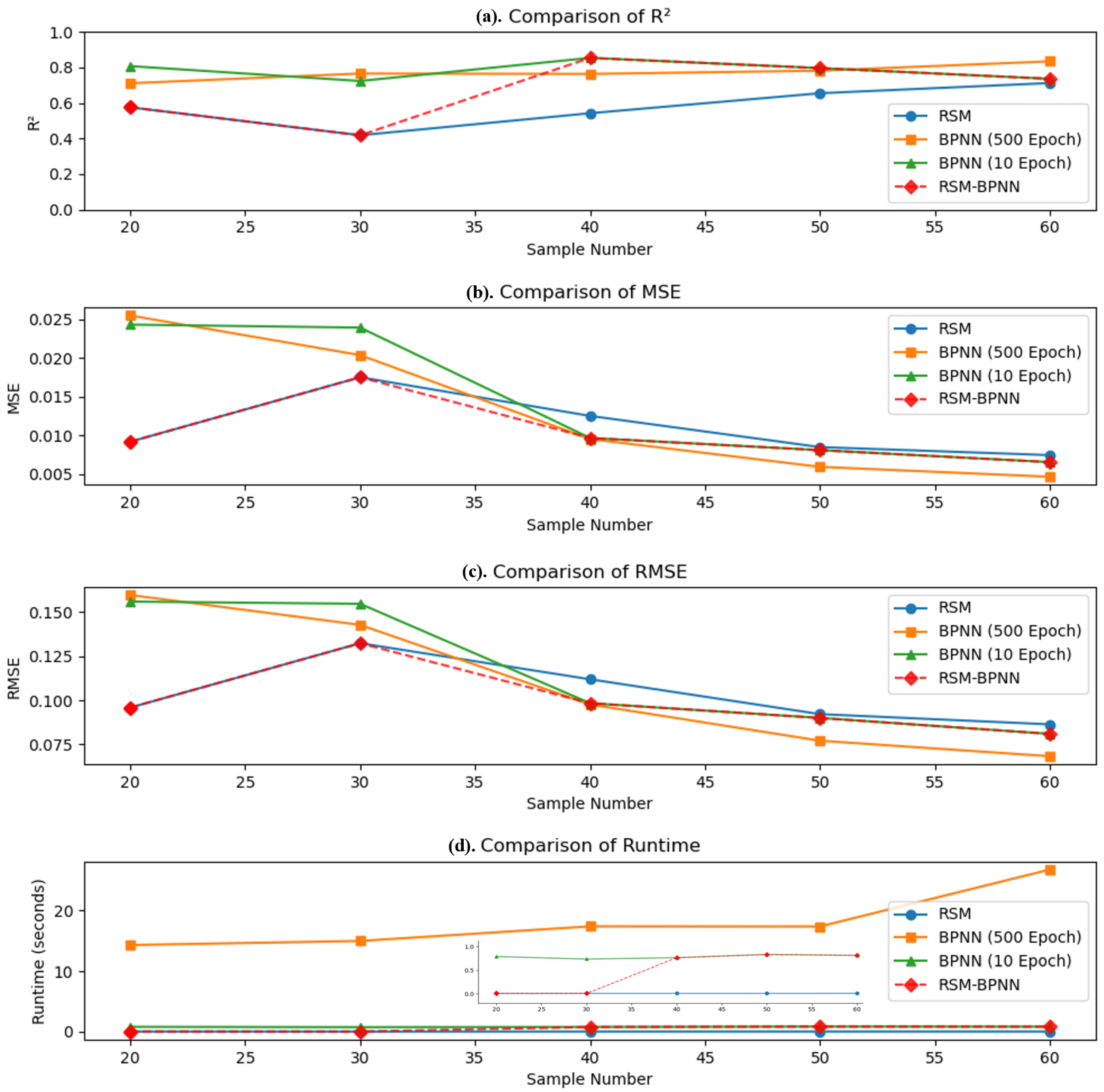

Evaluation Results of BPNN Fusion Method on Variable Small-Sample Data

7. Conclusions

- (a)

- During the selection of polynomial features after dimensional expansion, ANOVA is adopted to evaluate the significance of process features. Features with p-values exceeding the significance threshold are eliminated, resulting in polynomial interaction features based on four experimental process parameters: grinding force, feed speed, wheel speed, and sandpaper grit size.

- (b)

- Based on the RSM and BPNN prediction models, an BPNN fusion model is designed. This model combines the reliability of RSM for small sample sizes and the accuracy of BPNN for large sample sizes under varying sample sizes. Taking into account the training time and fitting efficiency, this model is better suited to handle data modeling for single-piece and small-batch workpieces under varying experimental conditions, meeting industrial requirements for efficient model establishment.

- (c)

- After performing reverse computation and parameter optimization on the model, the optimized parameters are used to calculate the selected feature results for real-machine validation. The experiments validate the applicability of this method in predicting the surface roughness of single-piece and small-batch workpieces in industrial robotic grinding applications.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DCCD | Dynamic Central Composite Design |

| RSM | Response Surface Methodology |

| BPNN | Back Propagation Neural Network |

| DMV | Data-Model-Verification |

References

- Li, S.; Yue, X.; Li, Q.; Peng, H.; Dong, B.; Liu, T.; Yang, H.; Fan, J.; Shu, S.; Qiu, F. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Kiran, M.; Khanna, N.; Pintaude, G.; Vasco, M.C.; da Silva, L.R.R.; Giasin, K. Review of improvement of machinability and surface integrity in machining on aluminum alloys. Int. J. Adv. Manuf. Technol. 2023, 129, 4743–4779. [Google Scholar] [CrossRef]

- Li, H.; Zou, L.; Wang, W.; Li, M. Investigation of Undeformed Chip Thickness Model and Surface Roughness Prediction in Belt Grinding. In Proceedings of the ASME 2022 International Mechanical Engineering Congress and Exposition, Columbus, OH, USA, 30 October–3 November 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 86632, p. V02AT02A040. [Google Scholar]

- Xie, Y.; Chang, G.; Yang, J.; Zhao, M.; Li, J. Process optimization of robotic polishing for mold steel based on response surface method. Machines 2022, 10, 283. [Google Scholar] [CrossRef]

- Yin, F.; Ji, Q.; Cun, C. Data-driven modeling and prediction analysis for surface roughness of special-shaped stone by robotic grinding. IEEE Access 2022, 10, 67615–67629. [Google Scholar] [CrossRef]

- Li, R.; Wang, Z.; Yan, J. Multi-Objective Optimization of the Process Parameters of a Grinding Robot Using LSTM-MLP-NSGAII. Machines 2023, 11, 882. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- You Li, S.L.; Yang, L. Experimental study of wet and dry milling effect on surface roughness of TC4 titanium alloy. Mach. Sci. Technol. 2024, 28, 984–1005. [Google Scholar] [CrossRef]

- Zhu, C.; Gu, P.; Wu, Y.; Liu, D.; Wang, X. Surface roughness prediction model of SiCp/Al composite in grinding. Int. J. Mech. Sci. 2019, 155, 98–109. [Google Scholar] [CrossRef]

- Umamaheswara Raju, R.; Ravi Kumar, K.; Vargish, K.; Bharath Kumar, M. Machine learning based surface roughness assessment via CNC spindle bearing vibration. Int. J. Interact. Des. Manuf. 2025, 19, 477–494. [Google Scholar] [CrossRef]

- Pandremenos, J.; Doukas, C.; Stavropoulos, P.; Chryssolouris, G. Machining with robots: A critical review. In Proceedings of the DET2011, 7th International Conference on Digital Enterprise Technology, Athens, Greece, 28–30 September 2011; pp. 1–9. [Google Scholar]

- Zhu, D.; Feng, X.; Xu, X.; Yang, Z.; Li, W.; Yan, S.; Ding, H. Robotic grinding of complex components: A step towards efficient and intelligent machining–challenges, solutions, and applications. Robot. Comput.-Integr. Manuf. 2020, 65, 101908. [Google Scholar] [CrossRef]

- Ke, X.; Yu, Y.; Li, K.; Wang, T.; Zhong, B.; Wang, Z.; Kong, L.; Guo, J.; Huang, L.; Idir, M. Review on robot-assisted polishing: Status and future trends. Robot. Comput.-Integr. Manuf. 2023, 80, 102482. [Google Scholar] [CrossRef]

- Pervez, M.R.; Ahamed, M.H.; Ahmed, M.A.; Takrim, S.M.; Dario, P. Autonomous grinding algorithms with future prospect towards SMART manufacturing: A comparative survey. J. Manuf. Syst. 2022, 62, 164–185. [Google Scholar] [CrossRef]

- Xiao, Q.; Gao, M.; Chen, L.; Goh, M. Multi-variety and small-batch production quality forecasting by novel data-driven grey Weibull model. Eng. Appl. Artif. Intell. 2023, 125, 106725. [Google Scholar] [CrossRef]

- Lestari, W.D.; Adyono, N.; Faizin, A.K.; Haqiyah, A.; Sanjaya, K.H.; Nugroho, A.; Kusmasari, W.; Ammarullah, M.I. Optimization of the cutting process on machining time of ankle foot as transtibial prosthesis components using response surface methodology. Results Eng. 2024, 21, 101736. [Google Scholar] [CrossRef]

- Khalilpourazari, S.; Khalilpourazary, S. Optimization of time, cost and surface roughness in grinding process using a robust multi-objective dragonfly algorithm. Neural Comput. Appl. 2020, 32, 3987–3998. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Huang, Y.; Lv, J.; Wang, K. Multi-objective optimization of milling process: Exploring trade-off among energy consumption, time consumption and surface roughness. Int. J. Comput. Integr. Manuf. 2023, 36, 219–238. [Google Scholar] [CrossRef]

- Chen, C.C.; Liu, N.M.; Chiang, K.T.; Chen, H.L. Experimental investigation of tool vibration and surface roughness in the precision end-milling process using the singular spectrum analysis. Int. J. Adv. Manuf. Technol. 2012, 63, 797–815. [Google Scholar] [CrossRef]

- Li, L.; Haghighi, A.; Yang, Y. A novel 6-axis hybrid additive-subtractive manufacturing process: Design and case studies. J. Manuf. Process. 2018, 33, 150–160. [Google Scholar] [CrossRef]

- Fry, N.R.; Richardson, R.C.; Boyle, J.H. Robotic additive manufacturing system for dynamic build orientations. Rapid Prototyp. J. 2020, 26, 659–667. [Google Scholar] [CrossRef]

- Wu, X.; Su, C.; Zhang, K. 316L Stainless Steel Thin-Walled Parts Hybrid-Layered Manufacturing Process Study. Materials 2023, 16, 6518. [Google Scholar] [CrossRef]

- Sahoo, S.; Lo, C.Y. Smart manufacturing powered by recent technological advancements: A review. J. Manuf. Syst. 2022, 64, 236–250. [Google Scholar] [CrossRef]

- Ozay, C.; Ballikaya, H.; Savas, V. Application of the Taguchi method to select the optimum cutting parameters for tangential cylindrical grinding of AISI D3 tool steel. Mater. Tehnol. 2016, 50, 81–87. [Google Scholar] [CrossRef]

- Fan, M.; Zhou, X.; Chen, S.; Jiang, S.; Song, J. Study of the surface roughness and optimization of machining parameters during laser-assisted fast tool servo machining of glass-ceramic. Surf. Topogr. Metrol. Prop. 2023, 11, 025017. [Google Scholar] [CrossRef]

- Krajnik, P.; Kopac, J.; Sluga, A. Design of grinding factors based on response surface methodology. J. Mater. Process. Technol. 2005, 162, 629–636. [Google Scholar] [CrossRef]

- Zhujani, F.; Abdullahu, F.; Todorov, G.; Kamberov, K. Optimization of Multiple Performance Characteristics for CNC Turning of Inconel 718 Using Taguchi—Grey Relational Approach and Analysis of Variance. Metals 2024, 14, 186. [Google Scholar] [CrossRef]

- Kahraman, M.F.; Öztürk, S. Experimental study of newly structural design grinding wheel considering response surface optimization and Monte Carlo simulation. Measurement 2019, 147, 106825. [Google Scholar] [CrossRef]

- Heininen, A.; Santa-aho, S.; Röttger, J.; Julkunen, P.; Koskinen, K.T. Grinding optimization using nondestructive testing (NDT) and empirical models. Mach. Sci. Technol. 2024, 28, 98–118. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Le, T.T. Predicting surface roughness in machining aluminum alloys taking into account material properties. Int. J. Comput. Integr. Manuf. 2024, 0, 1–22. [Google Scholar] [CrossRef]

- Kim, G.; Park, S.; Choi, J.G.; Yang, S.M.; Park, H.W.; Lim, S. Developing a data-driven system for grinding process parameter optimization using machine learning and metaheuristic algorithms. CIRP J. Manuf. Sci. Technol. 2024, 51, 20–35. [Google Scholar] [CrossRef]

- Nguyen, V.-H.; Le, T.-T.; Le, M.V.; Minh, H.D.; Nguyen, A.T. Multi-objective optimization based on machine learning and non-dominated sorting genetic algorithm for surface roughness and tool wear in Ti6Al4V turning. Mach. Sci. Technol. 2023, 27, 380–421. [Google Scholar] [CrossRef]

- Shao, H.; Xia, M.; Wan, J.; de Silva, C.W. Modified stacked autoencoder using adaptive Morlet wavelet for intelligent fault diagnosis of rotating machinery. IEEE/ASME Trans. Mechatronics 2021, 27, 24–33. [Google Scholar] [CrossRef]

- Lai, J.Y.; Lin, P.C. Grinded surface roughness prediction using data-driven models with contact force information. In Proceedings of the 2022 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Sapporo, Japan, 11–15 July 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 983–989. [Google Scholar]

| Feature Type | Selected Features |

|---|---|

| Constant Term | 1 |

| Linear Terms | |

| Quadratic Terms | |

| Interaction Terms |

| Factor | Coded Symbol | Low Level | High Level |

|---|---|---|---|

| Grinding force (N) | F | 2.5 | 5 |

| Feed rate (mm/s) | 5 | 10 | |

| Wheel speed (rpm) | 6000 | 8000 | |

| Grit size | N | * | * |

| Sample Size | F(N) | (mm/s) | (rpm) | N | (m) |

|---|---|---|---|---|---|

| 30 | 4.1474 | 3.0000 | 7312.7826 | 400 | 0.3472 |

| 60 | 5.4593 | 3.4935 | 7122.5485 | 600 | 0.3449 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Wen, K.; Qu, Y.; Mao, Y.; Pan, Y. Surface-Roughness Prediction Based on Small-Batch Workpieces for Smart Manufacturing: An Aerospace Robotic Grinding Case Study. Appl. Sci. 2025, 15, 1349. https://doi.org/10.3390/app15031349

Xiao Y, Wen K, Qu Y, Mao Y, Pan Y. Surface-Roughness Prediction Based on Small-Batch Workpieces for Smart Manufacturing: An Aerospace Robotic Grinding Case Study. Applied Sciences. 2025; 15(3):1349. https://doi.org/10.3390/app15031349

Chicago/Turabian StyleXiao, Yi’nan, Ke Wen, Yuanju Qu, Yanxi Mao, and Yang Pan. 2025. "Surface-Roughness Prediction Based on Small-Batch Workpieces for Smart Manufacturing: An Aerospace Robotic Grinding Case Study" Applied Sciences 15, no. 3: 1349. https://doi.org/10.3390/app15031349

APA StyleXiao, Y., Wen, K., Qu, Y., Mao, Y., & Pan, Y. (2025). Surface-Roughness Prediction Based on Small-Batch Workpieces for Smart Manufacturing: An Aerospace Robotic Grinding Case Study. Applied Sciences, 15(3), 1349. https://doi.org/10.3390/app15031349