Recycling Bitumen for Composite Material Production: Potential Applications in the Construction Sector

Abstract

1. Introduction

1.1. Use on Bitumen Products in Construction Works

1.2. Recycling of BBRM

2. Materials and Methods

2.1. Materials

2.2. Composition of Test Specimen

2.3. Preparation of Bitumen–Plastic Composites

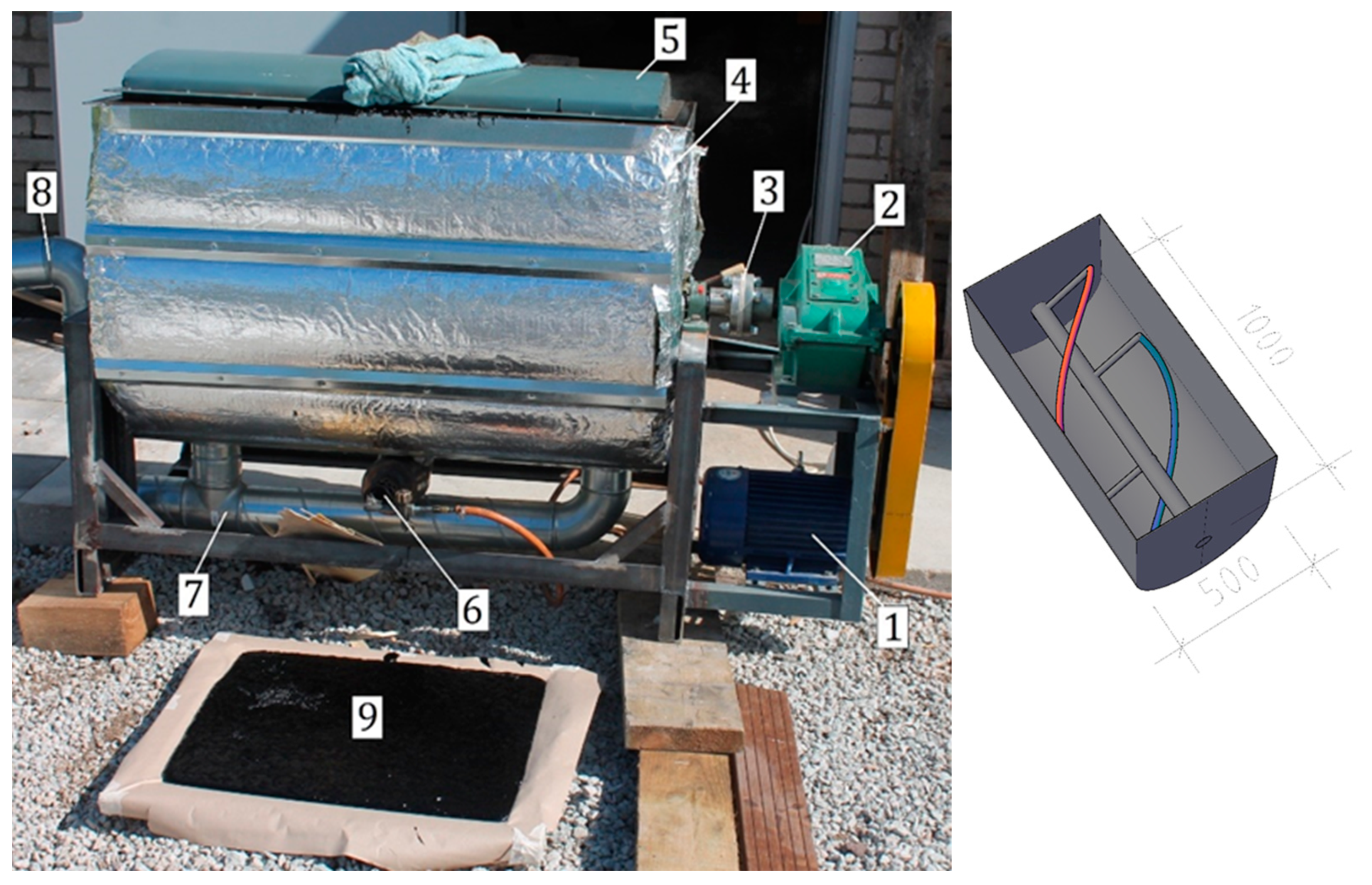

2.4. Pilot Equipment

2.5. Chemical Testing

2.6. Mechanical Testing

2.7. Thermogravimetric Analyses

3. Results

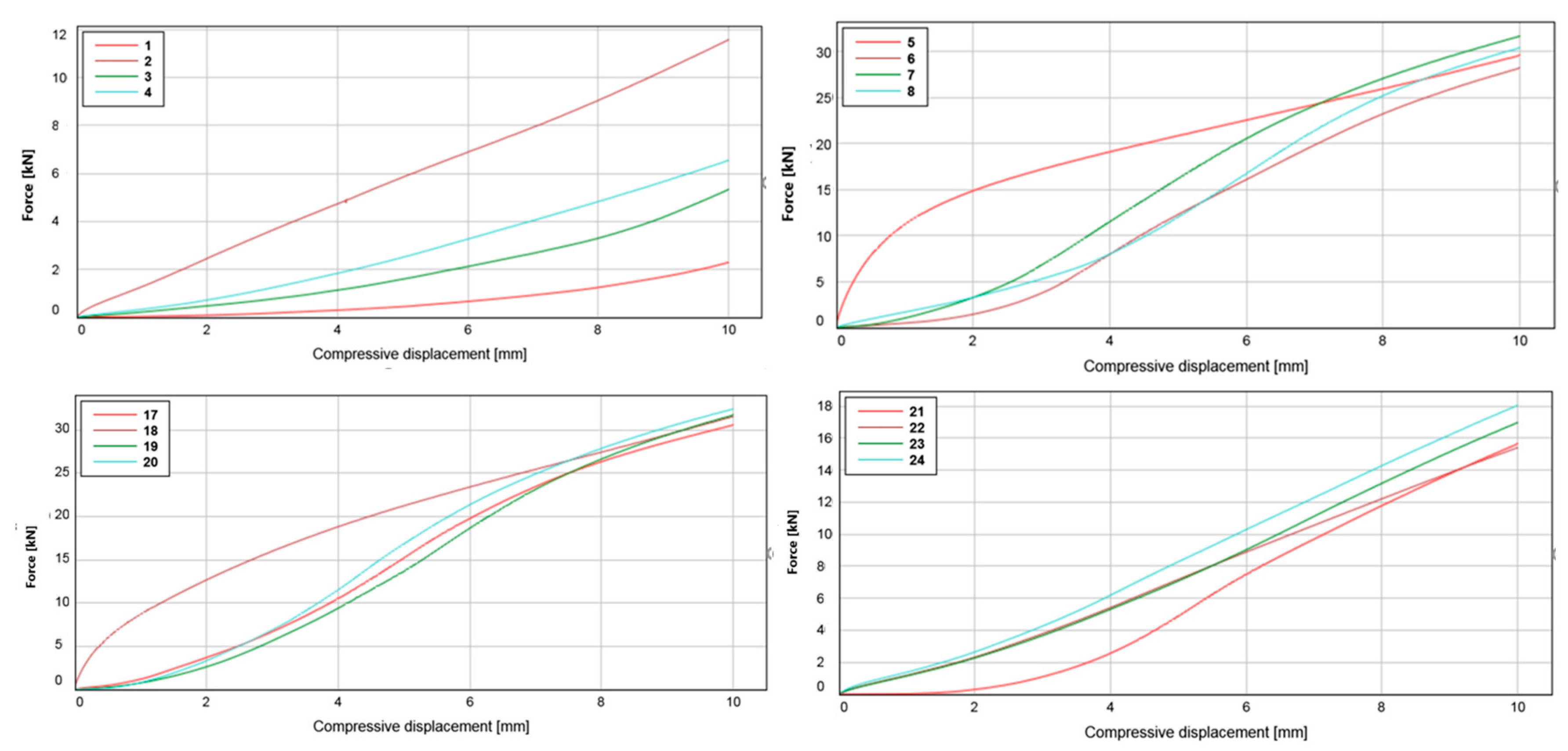

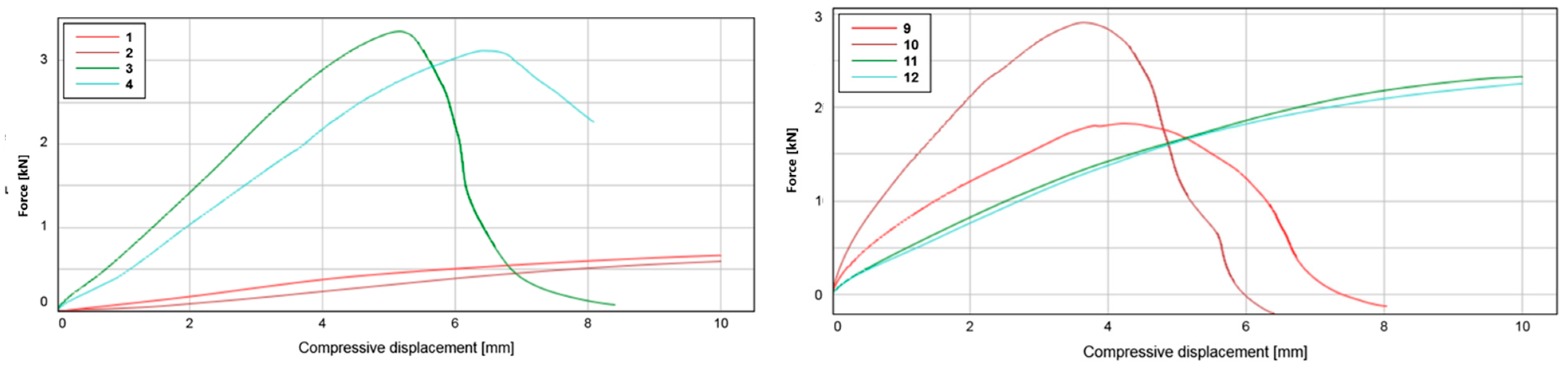

3.1. Mechanical Properties of the Composites

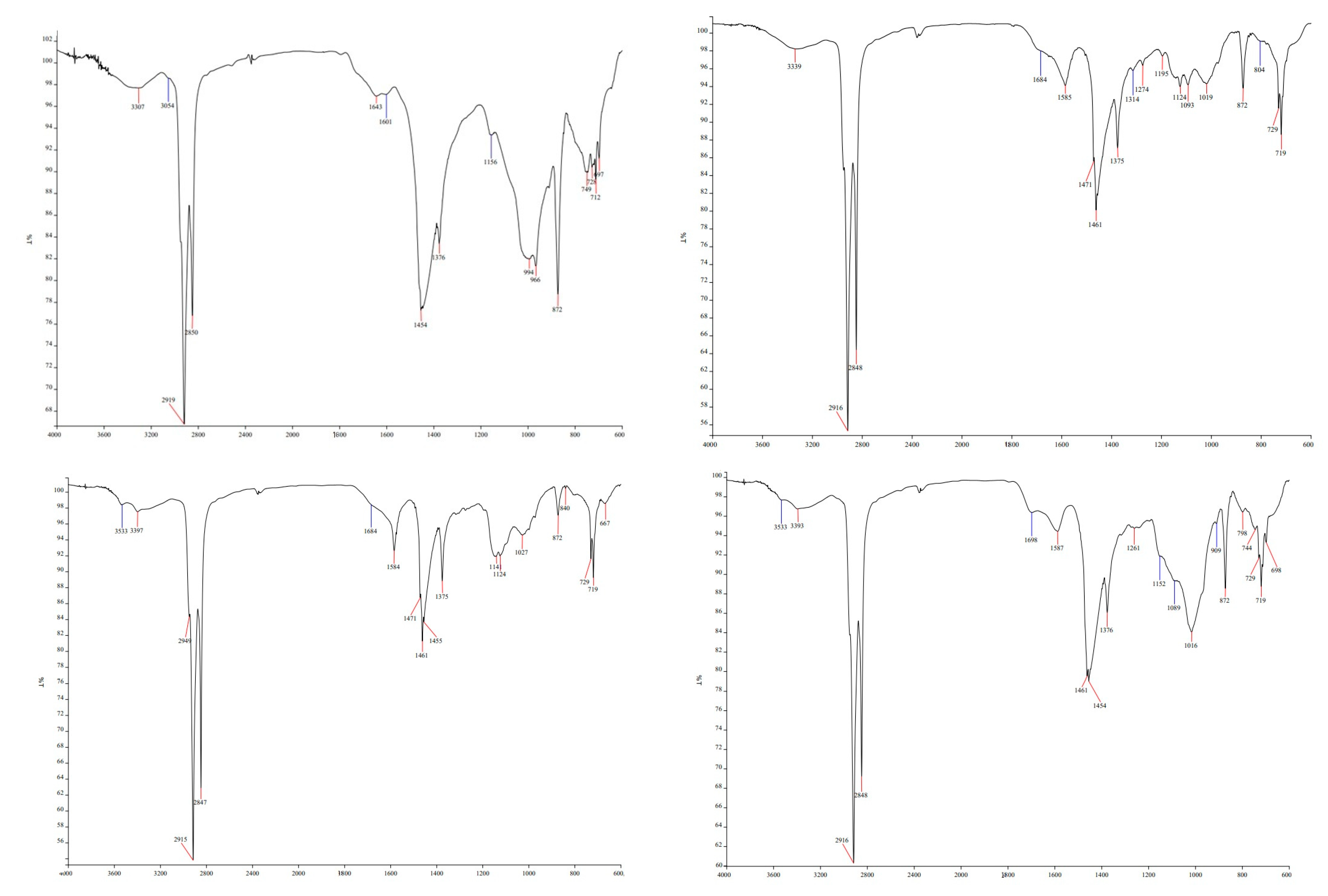

3.2. FTIR-ATR Analyses

3.3. Thermogravimetric Analysis

4. Discussion

- Refining the pilot-scale apparatus for industrial production.

- Exploring alternative polymer blends to further enhance material properties.

- Conducting long-term field studies to evaluate performance under real-world conditions.

- Expanding the range of applications for the composite beyond roofing, such as structural reinforcements or thermal insulation.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fazaeli, H.; Behbahani, H.; Amini, A.A.; Rahmani, J.; Yadollahi, G. High and low temperature properties of FT-paraffin-modified bitumen. Adv. Mater. Sci. Eng. 2012, 1, 406791. [Google Scholar] [CrossRef]

- Pipintakos, G.; Sreeram, A.; Mirwald, J.; Bhasin, A. Engineering bitumen for future asphalt pavements: A review of chemistry, structure and rheology. Mater. Des. 2024, 244, 113157. [Google Scholar] [CrossRef]

- Neşer, G.; Aytekin, V. Modification of bitumen-based roof covering material by glass reinforced polyester recyclate. J. Mater. Cycles Waste Manag. 2015, 17, 583–589. [Google Scholar] [CrossRef]

- Westerbeek, T. Bitumen Roofing Can Be Recycled … But Isn’t. Phys.org. 2013. Available online: https://phys.org/news/2013-09-bitumen-roofing-recycled-isnt.html (accessed on 23 April 2024).

- Fawcett, A.H.; McNally, T.; McNally, G. An attempt at engineering the bulk properties of blends of a bitumen with polymers. Adv. Polym. Technol. 2002, 21, 275–286. [Google Scholar] [CrossRef]

- Pannekens, M.; Voskuhl, L.; Mohammadian, S.; Köster, D.; Meier, A.; Köhne, J.M.; Kulbatzki, M.; Akbari, A.; Haque, S.; Meckenstock, R.U. Microbial Degradation Rates of Natural Bitumen. Environ. Sci. Technol. 2021, 55, 8700–8708. [Google Scholar] [CrossRef] [PubMed]

- Ball, G.F.A.; Herrington, P.A.; Patrick, J.E. Tall oil pitch as bitumen extender. N. Z. J. For. Sci. 1993, 23, 236–242. Available online: https://www.scionresearch.com/__data/assets/pdf_file/0016/17701/NZJFS2321993BALL236-242.pdf (accessed on 27 December 2024).

- Kleinschmidt, R.; Snoke, H.R. Changes in the Properties of an Asphalt During the Blowing Operation. J. Res. Natl. Bur. Stand. 1958, 60, 2835. Available online: https://nvlpubs.nist.gov/nistpubs/jres/60/jresv60n3p169_A1b.pdf (accessed on 27 December 2024). [CrossRef]

- Greenfeld, S.H. Air Oxidation of Asphalt; National Bureau of Standards Report 7420; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1962. [Google Scholar] [CrossRef]

- Wang, W.; Tan, G.; Liang, C.; Wang, Y.; Cheng, Y. Study on Viscoelastic Properties of Asphalt Mixtures Incorporating SBS Polymer and Basalt Fiber under Freeze–Thaw Cycles. Polymers 2020, 12, 1804. [Google Scholar] [CrossRef] [PubMed]

- Yuan, D.; Xing, C.; Jiang, W.; Xiao, J.; Wu, W.; Li, P.; Li, Y. Viscoelastic Behavior and Phase Structure of High-Content SBS-Modified Asphalt. Polymers 2022, 14, 2476. [Google Scholar] [CrossRef] [PubMed]

- APP vs. SBS Roof Membranes—Polyglass U.S.A., Inc. Available online: https://polyglass.us/blog/app-vs-sbs-roof-membranes/ (accessed on 28 December 2024).

- Imanbayev, Y.; Bussurmanova, A.; Ongarbayev, Y.; Serikbayeva, A.; Sydykov, S.; Tabylganov, M.; Akkenzheyeva, A.; Izteleu, N.; Mussabekova, Z.; Amangeldin, D.; et al. Modification of Bitumen with Recycled PET Plastics from Waste Materials. Polymers 2022, 14, 4719. [Google Scholar] [CrossRef] [PubMed]

- Mazzotta, F.; Lantieri, C.; Vignali, V.; Simone, A.; Dondi, G.; Sangiorgi, C. Performance evaluation of recycled rubber waterproofing bituminous membranes for concrete bridge decks and other surfaces. Constr. Build. Mater. 2017, 136, 524–532. [Google Scholar] [CrossRef]

- Jew, P.; Shimizu, J.A.; Svazic, M.; Woodhams, R.T. Polyethlene-modified bitumen for paving applications. J. Appl. Polym. Sci. 1986, 31, 2685–2704. [Google Scholar] [CrossRef]

- Tembe, E.; Tamele, L., Jr.; Buonocore, G.; Madivate, C.; Muiambo, H. Rheological and Thermo-Oxidative Aging Properties of Asphalt Modified with a Combination of Sasobit and Linear Low-Density Polyethylene. Sustainability 2023, 15, 4460. [Google Scholar] [CrossRef]

- Yousefi, A.A. Polyethylene dispersions in bitumen: The effects of the polymer structural parameters. J. Appl. Polym. Sci. 2003, 90, 3183–3190. [Google Scholar] [CrossRef]

- Fuentes-Audén, C.; Sandoval, J.A.; Jerez, A.; Navarro, F.J.; Martínez-Boza, F.J.; Partal, P.; Gallegos, C. Evaluation of thermal and mechanical properties of recycled polyethylene modified bitumen. Polym. Test. 2008, 27, 1005–1012. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Zhang, J.; Jiang, H.; Yao, Z. Comparison of rheological properties and compatibility of asphalt modified with various polyethylene. Int. J. Pavement Eng. 2019, 22, 11–20. [Google Scholar] [CrossRef]

- Eraky, A.; Ayoub, H.S.; Osman, O.; Ouf, M.E.; Mostafa, A.Z.E.A. Improving the Performance Grade and Traffic Loading of Egyptian Asphalt Binders by Recycled Polyethylene Modification. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Cairo, Egypt, 29 March 2021–31 March 2022. [Google Scholar] [CrossRef]

- Asphalt Roofing Manufacturers Association, Low-Slope Asphalt Roofing Recycling. 2024. Available online: www.asphaltroofing.org (accessed on 28 December 2024).

- Icopal, Citumen. Available online: https://citumen.com/ (accessed on 27 November 2024).

- Tarpaper: No more Roofing-Felt Waste!|European Circular Economy Stakeholder Platform. Available online: https://circulareconomy.europa.eu/platform/en/good-practices/tarpaper-no-more-roofing-felt-waste (accessed on 23 April 2024).

- Guillaume, M.; Julien, D.; Caroline, M.; Koen, S.; Patrick, C. Process for Recycling a Bituminous Waste Product such as a Bituminous Waste Membrane. Product. Patent WO2021105451A1, 3 June 2021. Available online: https://patents.google.com/patent/WO2021105451A1/en (accessed on 28 December 2024).

- EVS-EN 772-1:2011+A1:2015 Müürikivide katsemeetodid. Osa 1, Survetugevuse Määramine. Methods of Test for Masonry Units. Part 1, Determination of Compressive Strength|Digar Viewer. Available online: https://www.digar.ee/viewer/et/nlib-digar:252645/222323/page/1 (accessed on 27 November 2024).

- EVS-EN 772-6:2005 Müürikivide katsemeetodid. Osa 6, Betoonmüürikivide Paindetõmbetugevuse Määramine. Methods of Test for Masonry Units. Part 6, Determination of Bending Tensile Strength of Aggregate Concrete Masonry Units|Digar. Available online: https://www.digar.ee/arhiiv/et/raamatud/49042 (accessed on 27 November 2024).

- Silverstein, R.M.; Bassler, G.C.; Morrill, T. Chapter Three: Infrared Spectrometry: In Spectrometric Identification of Organic Compounds, 5th ed.; Sawicki, D., Stiefel, J., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1991; pp. 91–164. [Google Scholar]

| Test Specimen Designation | Dimensions, mm | Area A, mm2 | Destructive Force Fc, N | Compressive Strength fc, N/mm2 | ||

|---|---|---|---|---|---|---|

| Side a, mm | Side b, mm | Value | Average | |||

| 1-1 | 113 | 74 | 8362 | 2288.35 | 0.27 | 8.98 |

| 1-2 | 102 | 72 | 7344 | 11,571.44 | 1.58 | |

| 1-3 | 99 | 72 | 7128 | 5321.50 | 0.75 | |

| 1-4 | 97 | 71 | 6887 | 6542.92 | 0.95 | |

| 2-1 | 101 | 71 | 7171 | 29,620.36 | 3.71 | 3.87 |

| 2-2 | 104 | 73 | 7592 | 28,230.75 | 3.72 | |

| 2-3 | 107 | 73 | 7811 | 31,698.41 | 4.06 | |

| 2-4 | 105 | 73 | 7665 | 30,444.74 | 3.97 | |

| 3-1 | 99 | 70 | 6930 | 30,580.58 | 4.41 | 4.45 |

| 3-2 | 99 | 74 | 7326 | 31,588.61 | 4.31 | |

| 3-3 | 99 | 71 | 7029 | 31,735.71 | 4.51 | |

| 3-4 | 99 | 72 | 7128 | 32,439.21 | 4.55 | |

| 4-1 | 97 | 72 | 6984 | 15,653.25 | 2.24 | 2.24 |

| 4-2 | 100 | 73 | 7300 | 15,415.81 | 2.11 | |

| 4-3 | 103 | 75 | 7725 | 16,984.87 | 2.20 | |

| 4-4 | 102 | 73 | 7446 | 18,051.16 | 2.42 | |

| Test Specimen Designation | Dimensions, mm | Drift. mm | Destructive Force Ff, N | Flexural Strength Ff N/mm2 | ||

|---|---|---|---|---|---|---|

| Side b, mm | Thickness, mm | Value | Average | |||

| 1-1 | 101 | 31 | 10 | 593.77 | 0.92 | 1.24 |

| 1-2 | 107 | 38 | 10 | 666.11 | 1.55 | |

| 2-1 | 104 | 40 | 8 | 3349.28 | 3.02 | 2.84 |

| 2-2 | 110 | 40 | 8 | 3119.39 | 2.66 | |

| 3-1 | 101 | 43 | 8 | 1829.31 | 1.47 | 1.91 |

| 3-2 | 101 | 43 | 6 | 2908.63 | 2.34 | |

| 4-1 | 101 | 43 | 10 | 2329.19 | 1.96 | 2.01 |

| 4-2 | 103 | 40 | 10 | 2254.16 | 2.05 | |

| Sample | Onset, °C | End, °C | Peak, °C | TML 600 1 |

|---|---|---|---|---|

| 1 | 342.8 | 459.0 | 428.9 | 47.4 |

| 2 | 352.3 | 473.2 | 451.3 | 53.5 |

| 3 | 372.5 | 466.1 | 449.4 | 60.7 |

| 4 | 347.2 | 347.2 | 347.2 | 61.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rikmann, E.; Mäeorg, U.; Vaino, N.; Pallav, V.; Järvik, O.; Liiv, J. Recycling Bitumen for Composite Material Production: Potential Applications in the Construction Sector. Appl. Sci. 2025, 15, 1313. https://doi.org/10.3390/app15031313

Rikmann E, Mäeorg U, Vaino N, Pallav V, Järvik O, Liiv J. Recycling Bitumen for Composite Material Production: Potential Applications in the Construction Sector. Applied Sciences. 2025; 15(3):1313. https://doi.org/10.3390/app15031313

Chicago/Turabian StyleRikmann, Ergo, Uno Mäeorg, Neeme Vaino, Vello Pallav, Oliver Järvik, and Jüri Liiv. 2025. "Recycling Bitumen for Composite Material Production: Potential Applications in the Construction Sector" Applied Sciences 15, no. 3: 1313. https://doi.org/10.3390/app15031313

APA StyleRikmann, E., Mäeorg, U., Vaino, N., Pallav, V., Järvik, O., & Liiv, J. (2025). Recycling Bitumen for Composite Material Production: Potential Applications in the Construction Sector. Applied Sciences, 15(3), 1313. https://doi.org/10.3390/app15031313