Prediction of Tuber Damage from Harvesting and Processing Machine Working Units Based on the Recording of Impact Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Conditions

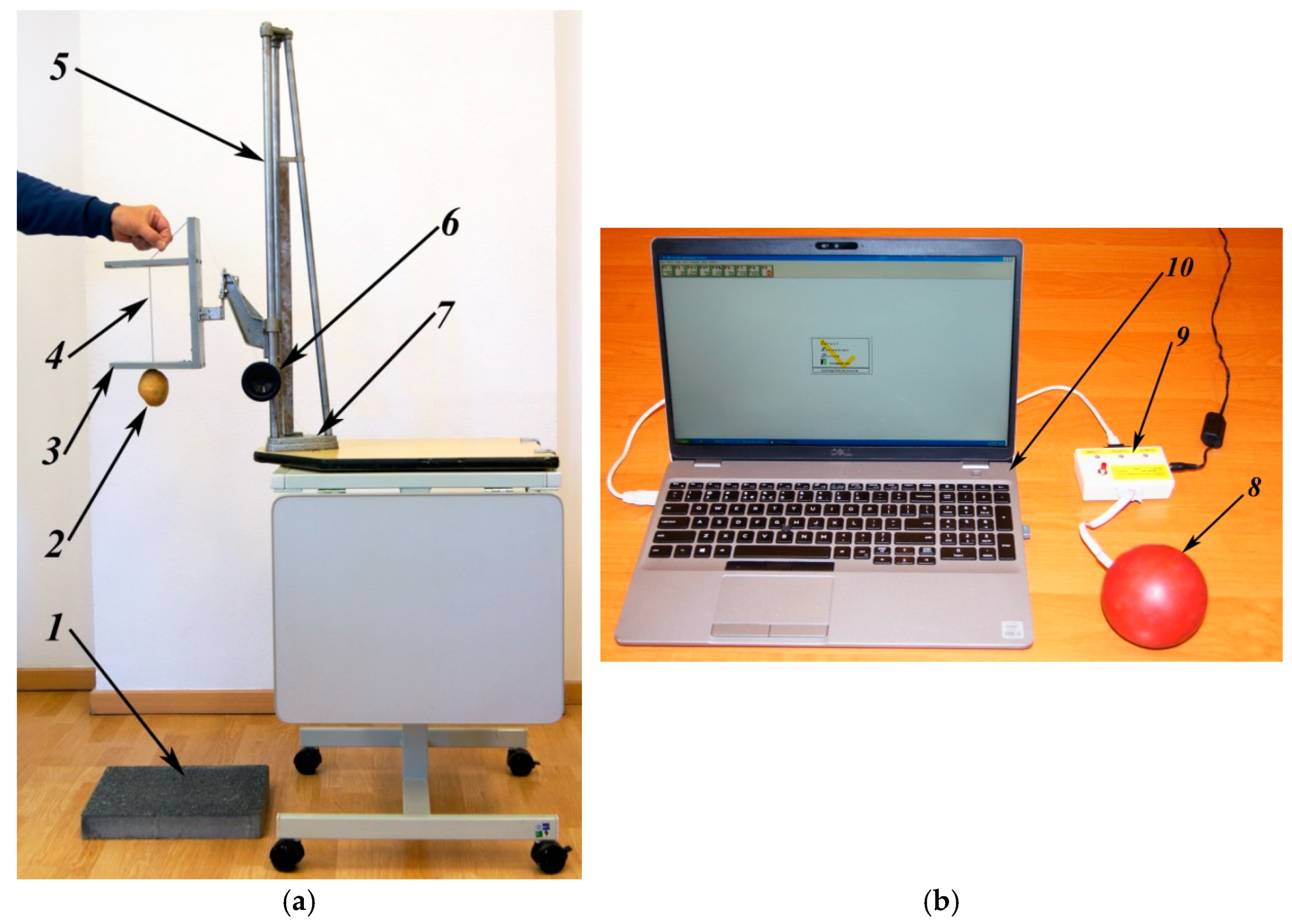

2.2. Free-Fall Test Stand

2.3. Impacts Recording

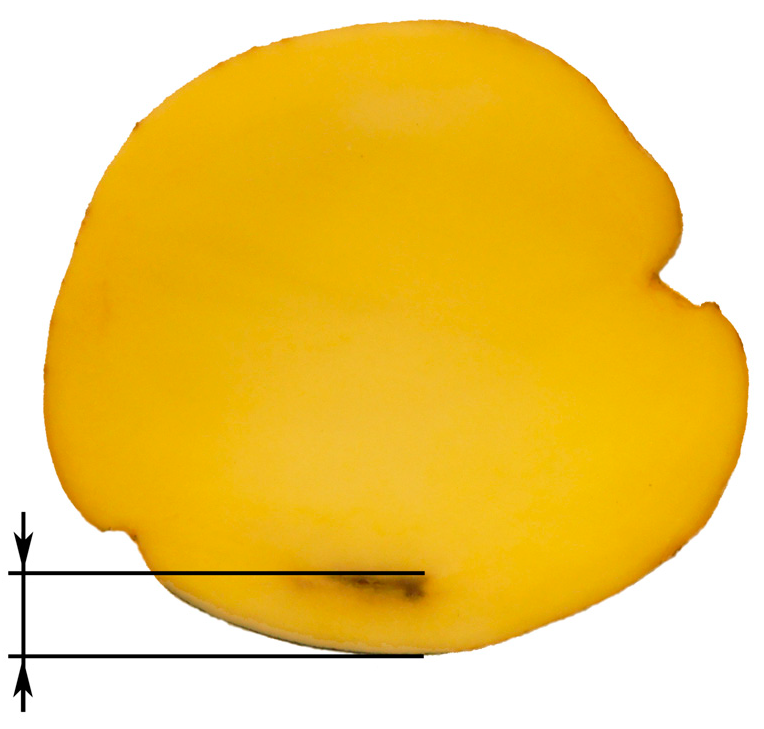

2.4. Damage Assessment

3. Results and Discussion

3.1. Correlations Between Damage Index and Impact Parameters

3.2. Damage Prediction Based on Impact Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bentini, M.; Caprara, C.; Martelli, R. Harvesting damage to potato tubers by analysis of impacts recorded with an Instrumented Sphere. Biosyst. Eng. 2006, 94, 75–85. [Google Scholar] [CrossRef]

- Hyde, G.M.; Brown, G.K.; Timm, E.J.; Zhang, W. Instrumented sphere evaluations of potato packing line impacts. Trans. Am. Soc. Agric. Eng. 1992, 35, 65–69. [Google Scholar] [CrossRef]

- Molema, G.J.; Struik, P.C.; Verwijs, B.R.; Bouman, A.; Klooster, J.J. Subcutaneous tissue discoloration in ware potatoes. 2. Impact measured by an instrumented sphere. Potato Res. 2000, 43, 225–238. [Google Scholar] [CrossRef]

- Van Canneyt, T.; Tijskens, E.; Ramon, H.; Verschoore, R.; Sonck, B. Development of a Predictive Tissue Discolouration Model based on Electronic Potato Impacts. Biosyst. Eng. 2004, 88, 81–93. [Google Scholar] [CrossRef]

- Czerko, Z.; Nowacki, W. Monitorowanie maszyn do obróbki ziemniaków za pomocą bulwy elektronicznej PMS–60. Inżynieria Rol. 2005, 61, 49–55. [Google Scholar]

- Praeger, U.; Surdilovic, J.; Truppel, I.; Herold, B.; Geyer, M. Comparison of electronic fruits for impact detection on a laboratory scale. Sensors 2013, 13, 7140–7155. [Google Scholar] [CrossRef]

- Thomson, G.E.; Lopresti, J.P. Size and temperature characteristics of potatoes help predict injury following impact collisions. New Zealand J. Crop Hort. 2018, 46, 1–17. [Google Scholar] [CrossRef]

- Hendricks, R.L.; Olsen, N.; Thornton, M.; Hatzenbuehler, P. Use of an Impact Recording Device to Determine the Risk of Bruising in Packaged Potatoes. Am. J. Potato Res. 2024, 101, 142–152. [Google Scholar] [CrossRef]

- Corsini, D.; Stark, J.; Thornton, M. Factors contributing to the blackspot bruise potential of Idaho potato fields. Am. J. Potato Res. 1999, 76, 221–226. [Google Scholar] [CrossRef]

- Mathew, R.; Hyde, G.M. Potato impact damage thresholds. Trans. Am. Soc. Agric. Eng. 1997, 40, 705–709. [Google Scholar] [CrossRef]

- Partington, J.C.; Smith, C.; Bolwell, G.P. Changes in the location of polyphenol oxidase in potato (Solanum tuberosum L.) tuber during cell death in response to impact injury: Comparison with wound tissue. Planta 1999, 207, 449–460. [Google Scholar] [CrossRef]

- Xie, S.; Wang, C.; Deng, W. Experimental study on collision acceleration and damage characteristics of potato. J. Food Process Eng. 2020, 43, e13457. [Google Scholar] [CrossRef]

- Noble, R. The relationship between impact and internal bruising in potato tubers. J. Agric. Eng. Res. 1985, 32, 111–121. [Google Scholar] [CrossRef]

- Laerke, P.E.; Christiansen, J.; Veierskov, B. Colour of blackspot bruises in potato tubers during growth and storage compared to their discolouration potential. Postharvest Biol. Tec. 2002, 26, 99–111. [Google Scholar] [CrossRef]

- Lisowski, A.; Klonowski, J. Evaluation of performance of potato combines harvesters with the use of impact recording devices. Ann. Wars. Univ. Life Sci.—SGGW Agric. (Agric. Eng.) 2005, 48, 47–53. [Google Scholar]

- Hollingshead, A.K.; Olsen, N.L.; Thornton, M.; Miller, J.S.; Lin, A.H.M. Potato cultivar susceptibility to Pythium leak as influenced by harvest and early storage temperatures. Am. J. Potato Res. 2020, 97, 393–403. [Google Scholar] [CrossRef]

- Herold, B.; Truppel, I.; Siering, G.; Geyer, M. User’s manual, PMS 60; Institute of Agricultural Engineering: Bornim, Germany, 1994. [Google Scholar]

- Zapp, H.R.; Ehlert, S.H.; Brown, G.K.; Armstrong, P.R.; Sober, S.S. Advanced instrumented sphere (IS) for impact measurements. Trans. ASAE 1990, 33, 955–960. [Google Scholar] [CrossRef]

- Shahbazi, F.; Geyer, M.; Praeger, U.; König, C.; Herold, B. Comparison of Two Impact Detecting Devices to Measure Impact Load on Potatoes. Agric. Eng. Int. CIGR J. 2011, 13, 1–9. [Google Scholar]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Tec. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Vallone, M.; Alleri, M.; Bono, F.; Catania, P. A new wireless device for real-time mechanical impact evaluation in a citrus packing line. Trans. ASABE 2020, 63, 1–9. [Google Scholar] [CrossRef]

- Van Canneyt, T.; Tijskens, E.; Ramon, H.; Verschoore, R.; Sonck, B. Characterisation of a potato–shaped instrumented device. Biosyst. Eng. 2003, 86, 275–285. [Google Scholar] [CrossRef]

- Bajema, R.W.; Hyde, G.M. Instrumented pendulum for impact characterization of whole fruit and vegetable specimens. Trans. Am. Soc. Agric. Eng. 1998, 41, 1399–1405. [Google Scholar] [CrossRef]

- Rady, A.M.; Soliman, S.N. Evaluation of mechanical damage of Lady Rosetta potato tubers using different methods. Int. J. Postharvest Technol. Innov. 2015, 5, 125–148. [Google Scholar] [CrossRef]

- Gancarz, M. Correlation between cell size and blackspot of potato tuber parenchyma tissue after storage. Postharvest Biol. Technol. 2016, 117, 161–167. [Google Scholar] [CrossRef]

- Stropek, Z.; Gołacki, K. Studies concerning the response of potatoes to impact. Int. Agrophys. 2022, 36, 115–122. [Google Scholar] [CrossRef]

- Blahovec, J.; Židová, J. Potato bruise spot sensitivity dependence on regimes of cultivation. Res. Agric. Eng. 2004, 50, 89–95. [Google Scholar] [CrossRef]

- Thornton, R.E.; Timm, H. Influence of fertilizer and irrigation management on tuber bruising. Am. Potato J. 1990, 67, 45–54. [Google Scholar] [CrossRef]

- Baritelle, A.L.; Hyde, G.M. Commodity conditioning to reduce impact bruising. Post. Biol. Technol. 2001, 21, 331–339. [Google Scholar] [CrossRef]

- Surdilovic, J.; Praeger, U.; Herold, B.; Truppel, I.; Geyer, M. Impact characterization of agricultural products by fall trajectory simulation and measurement. Comput. Electron. Agric. 2018, 151, 460–468. [Google Scholar] [CrossRef]

- Lisowski, A. Process of soil separation on the chain web. Inz. Rolnicza. 2001, 1, 197–203. [Google Scholar]

- McGarry, A.; Hole, C.C.; Drew, R.L.K.; Parsons, N. Internal damage in potato tubers: A critical review. Postharvest Biol. Technol. 1996, 8, 239–258. [Google Scholar] [CrossRef]

- Marks, N. Mechaniczne Uszkodzenia Bulw Ziemniaka; Polskie Towarzystwo Inżynierii Rolniczej: Cracow, Poland, 2009. [Google Scholar]

- Deng, W.; Wang, C.; Xie, S. Impact peak force measurement of potato. Int. J. Food. Prop. 2020, 23, 616–626. [Google Scholar] [CrossRef]

- Hendricks, R.L.; Olsen, N.; Thornton, M.K.; Hatzenbuehler, P. Susceptibility of potato cultivars to blackspot and shatter bruise at three impact heights. Am. J. Potato Res. 2022, 99, 358–368. [Google Scholar] [CrossRef]

- Xie, S.; Wang, C.; Deng, W. Model for the prediction of potato impact damage depth. Int. J. Food Prop. 2018, 21, 2517–2526. [Google Scholar] [CrossRef]

- Krzysztofik, B.; Sułkowski, K. Wpływ wybranych czynników na wartość indeksu mechanicznych uszkodzeń bulw ziemniaka przeznaczonego do przetwórstwa spożywczego. Biul. Inst. Hod. I Aklim. Roślin 2012, 266, 235–243. [Google Scholar] [CrossRef]

- Fluck, R.C.; Ahmed, E.M. Impact testing of fruits and vegetables. Trans. ASAE 1973, 16, 660–666. [Google Scholar] [CrossRef]

| Variable | Tuber Damage Index | Peak Impact Acceleration of the IRD 400 | ||

|---|---|---|---|---|

| Factor | Fisher–Snedecor coefficient, F | critical significance level, p | Fisher–Snedecor coefficient, F | critical significance level, p |

| Variety | 102.17 | <0.0001 | – | – |

| Surface | 470.08 | <0.0001 | 1443.45 | <0.0001 |

| Impact velocity | 148.86 | <0.0001 | 147.72 | <0.0001 |

| Factor | Factor Level | No. | Tuber Damage Index, % | Peak Impact Acceleration |

|---|---|---|---|---|

| Impact velocity, m·s−1 | 2.43 | 120 | 0.65 a ± 1.12 | 142.0 a ± 5.3 |

| 2.80 | 160 | 14.2 b ± 0.94 | 209.0 b ± 4.5 | |

| 3.13 | 120 | 22.5 c ± 1.12 | 242.2 c ± 5.3 | |

| 3.43 | 160 | 23.7 c ± 0.94 | 271.8 d ± 4.5 | |

| 3.71 | 120 | 28.6 d ± 1.12 | 293.5 e ± 5.3 | |

| 3.96 | 160 | 30.5 d ± 0.94 | 296.0 e ± 4.4 | |

| 4.20 | 100 | 34.4 e ± 1.23 | 309.0 f ± 5.3 | |

| 4.43 | 140 | 42.9 f ± 1.02 | 318.5 g ± 4.5 | |

| Variety | Saturna | 540 | 21.0 a ± 0.53 | – |

| Hermes | 540 | 28.4 b ± 0.54 | – | |

| Surface | Bulk potatoes | 160 | 0.4 a ± 1.02 | 67.4 a ± 4.8 |

| Rod | 320 | 20.1 b ± 0.67 | 214.4 b ± 3.2 | |

| Concrete | 300 | 37.1 c ± 0.69 | 370.7 c ± 3.2 | |

| Steel | 300 | 41.2 d ± 0.69 | 388.4 d ± 3.2 |

| Surface | Model | R-Squared (R2) |

|---|---|---|

| Concrete | a = 55.12 Δv + 13.77 | 0.959 |

| Rod | a = 95.32 Δv − 128.13 | 0.810 |

| Steel | a = 60.41 Δv − 29.23 | 0.961 |

| Bulk potatoes | a = 18.70 Δv + 18.21 | 0.963 |

| Surface | Model | R-Squared, (R2) |

|---|---|---|

| Steel | a = −21.10v2 + 237.78v − 195.15 | 0.662 |

| Concrete | a = −71.22v2 + 575.43v − 723.75 | 0.750 |

| Rod | a = −16.38v2 + 201.63v − 282.31 | 0.755 |

| Bulk potatoes | a = −2.3626v2 + 42.965v − 44.56 | 0.444 |

| Characteristic | Surface | Impact Velocity, v | Peak Acceleration, a | Change in Velocity, Δv | Damage Index, DI | a × Δv |

|---|---|---|---|---|---|---|

| Saturna Variety | ||||||

| Impact velocity, v | Concrete | 1 | ||||

| Peak acceleration, a | Concrete | 0.8064 | 1 | |||

| Change in velocity, Δv | Concrete | 0.7938 | 0.7534 | 1 | ||

| Damage Index, DI | Concrete | 0.5944 | 0.5412 | 0.5322 | 1 | |

| a × Δv | Concrete | 0.8415 | 0.9165 | 0.9474 | 0.5518 | 1 |

| Impact velocity, v | Rod | 1 | ||||

| Peak acceleration, a | Rod | 0.8387 | 1 | |||

| Change in velocity, Δv | Rod | 0.6240 | 0.6632 | 1 | ||

| Damage Index, DI | Rod | 0.8466 | 0.7758 | 0.5007 | 1 | |

| a × Δv | Rod | 0.7667 | 0.9074 | 0.8928 | 0.6633 | 1 |

| Impact velocity, v | Steel | 1 | ||||

| Peak acceleration, a | Steel | 0.8069 | 1 | |||

| Change in velocity, Δv | Steel | 0.8598 | 0.7456 | 1 | ||

| Damage Index, DI | Steel | 0.9020 | 0.7943 | 0.8046 | 1 | |

| a × Δv | Steel | 0.8785 | 0.9343 | 0.9247 | 0.8325 | 1 |

| Impact velocity, v | Bulk potatoes | 1 | ||||

| Peak acceleration, a | Bulk potatoes | 0.6653 | 1 | |||

| Change in velocity, Δv | Bulk potatoes | 0.8592 | 0.5739 | 1 | ||

| Damage Index, DI | Bulk potatoes | 0.2047 | −0.0206 | 0.1841 | 1 | |

| a × Δv | Bulk potatoes | 0.8336 | 0.8993 | 0.8424 | 0.0854 | 1 |

| Hermes Variety | ||||||

| Impact velocity, v | Concrete | 1 | ||||

| Peak acceleration, a | Concrete | 0.7806 | 1 | |||

| Change in velocity, Δv | Concrete | 0.7836 | 0.7521 | 1 | ||

| Damage Index, DI | Concrete | 0.4147 | 0.5402 | 0.4206 | 1 | |

| a × Δv | Concrete | 0.8240 | 0.9134 | 0.9481 | 0.4817 | 1 |

| Impact velocity, v | Rod | 1 | ||||

| Peak acceleration, a | Rod | 0.8103 | 1 | |||

| Change in velocity, Δv | Rod | 0.5894 | 0.6789 | 1 | ||

| Damage Index, DI | Rod | 0.7787 | 0.5647 | 0.4659 | 1 | |

| a × Δv | Rod | 0.7491 | 0.9089 | 0.8918 | 0.5701 | 1 |

| Impact velocity, v | Steel | 1 | ||||

| Peak acceleration, a | Steel | 0.8061 | 1 | |||

| Change in velocity, Δv | Steel | 0.8702 | 0.7337 | 1 | ||

| Damage Index, DI | Steel | 0.9477 | 0.7284 | 0.8155 | 1 | |

| a × Δv | Steel | 0.8877 | 0.9340 | 0.9180 | 0.8203 | 1 |

| Impact velocity, v | Bulk potatoes | 1 | ||||

| Peak acceleration, a | Bulk potatoes | 0.6653 | 1 | |||

| Change in velocity, Δv | Bulk potatoes | 0.8592 | 0.5739 | 1 | ||

| Damage Index, DI | Bulk potatoes | 0.2668 | 0.3174 | 0.2420 | 1 | |

| a × Δv | Bulk potatoes | 0.8336 | 0.8993 | 0.8424 | 0.3947 | 1 |

| Variety | Surface | Coefficient λm,%·s·m−1 | Determination Coefficient R2, % | The Root Mean Squared Error (RMSE), % |

|---|---|---|---|---|

| Saturna | bulk potatoes | 0.0057 | 49.87 | 3.15 |

| rod | 0.02821 | 77.22 | 13.23 | |

| concrete | 0.0132 | 87.03 | 12.58 | |

| steel | 0.0163 | 93.02 | 10.91 | |

| Hermes | bulk potatoes | 0.0145 | 55.31 | 7.21 |

| rod | 0.0415 | 76.76 | 19.72 | |

| concrete | 0.0158 | 87.57 | 15.33 | |

| steel | 0.0205 | 92.91 | 13.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sypuła, M.; Lisowski, A.; Klonowski, J.; Nowakowski, T.; Chlebowski, J.; Dąbrowska, M. Prediction of Tuber Damage from Harvesting and Processing Machine Working Units Based on the Recording of Impact Parameters. Appl. Sci. 2025, 15, 1161. https://doi.org/10.3390/app15031161

Sypuła M, Lisowski A, Klonowski J, Nowakowski T, Chlebowski J, Dąbrowska M. Prediction of Tuber Damage from Harvesting and Processing Machine Working Units Based on the Recording of Impact Parameters. Applied Sciences. 2025; 15(3):1161. https://doi.org/10.3390/app15031161

Chicago/Turabian StyleSypuła, Michał, Aleksander Lisowski, Jacek Klonowski, Tomasz Nowakowski, Jarosław Chlebowski, and Magdalena Dąbrowska. 2025. "Prediction of Tuber Damage from Harvesting and Processing Machine Working Units Based on the Recording of Impact Parameters" Applied Sciences 15, no. 3: 1161. https://doi.org/10.3390/app15031161

APA StyleSypuła, M., Lisowski, A., Klonowski, J., Nowakowski, T., Chlebowski, J., & Dąbrowska, M. (2025). Prediction of Tuber Damage from Harvesting and Processing Machine Working Units Based on the Recording of Impact Parameters. Applied Sciences, 15(3), 1161. https://doi.org/10.3390/app15031161