Comparative Study of Supporting Methods for a Deep Mine Shaft Using Similar Physical Model Tests Under True Triaxial Stresses

Abstract

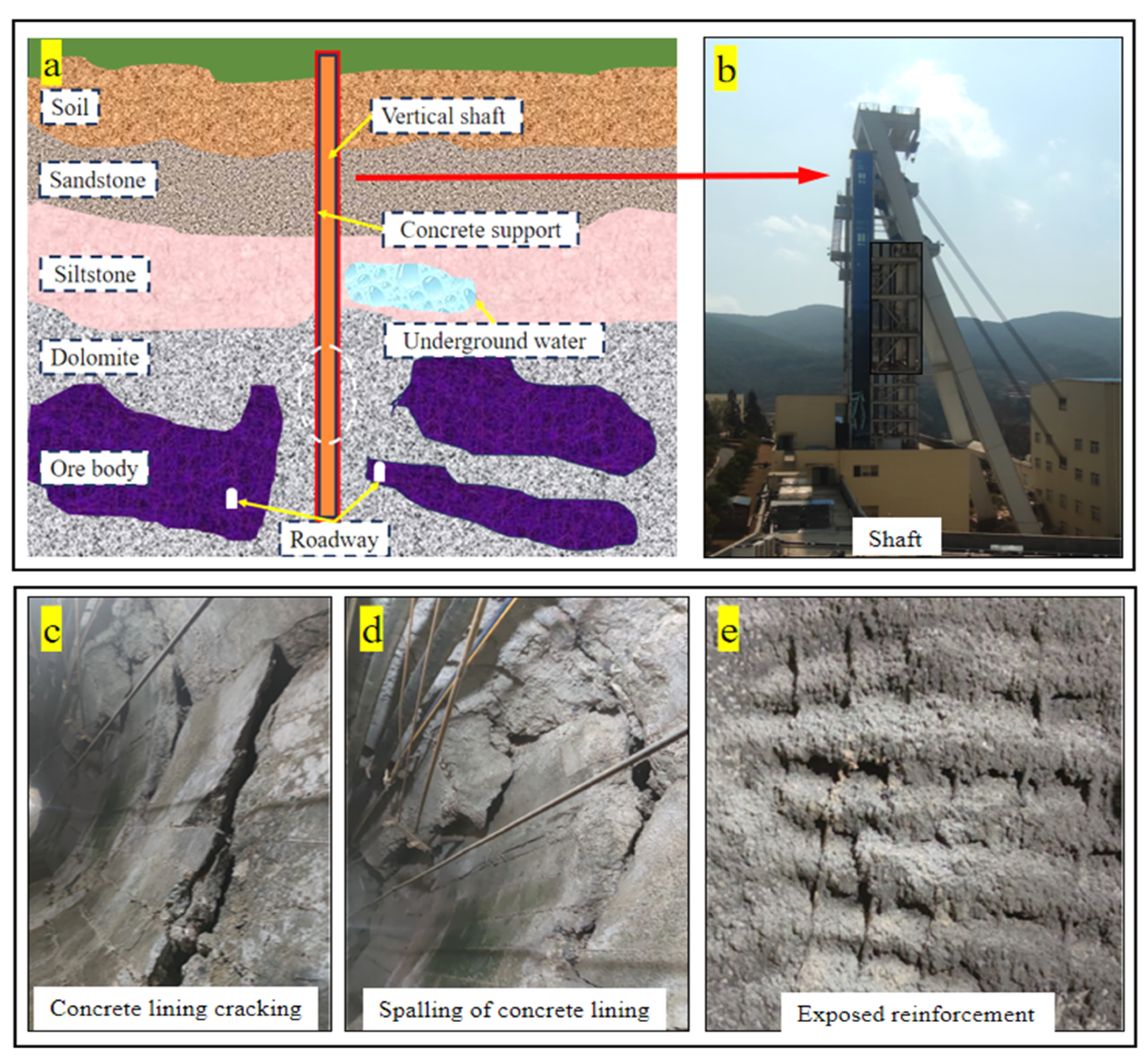

1. Introduction

| No. | Nationality | Research Content and Conclusion |

|---|---|---|

| 1 | China | Vertical force is the main factor causing the peeling and instability of the lining of the mine shaft; using optical fiber to monitor the deformation of the shaft. |

| 2 | USA | Exploring the causes of severe deformation in the vertical shaft of Haikela coal mine, optimizing the excavation shape of the shaft, and reducing the later deformation of the shaft. Simultaneously analyzed the causes of collapse and preventive measures. |

| 3 | Australia | Constructing Telfer, the largest vertical shaft in Australia, and exploring the effect of concrete lining support on the shaft. Research and analysis on the stability of vertical shafts and surrounding rock masses. |

| 4 | Canada | In response to the problem of concrete lining support peeling and degradation in X41 mine shaft, this study investigates the shaft damage factors and designs a long-term stability maintenance plan for the shaft. |

| 5 | Republic of Korea | A study was conducted on the deformation of the vertical shaft and the stress distribution around the shaft. The theory of soil pressure distribution was proposed to guide the construction of shafts in mines. |

| 6 | Japan | Taken Yatani mine as the research object, the influence of faults and seepage on the stability of vertical shaft was studied. At the same time, as grouting treatment for shaft damage, there will be repeated force on the shaft, affecting its stability. |

| 7 | South Africa | Stability analysis and improvement of steel structure support for vertical shafts in Driefontein and Kloof gold mines. The Bambanani mine was the research object. Based on lining support and steel structure support, the mining layout and the addition of filling materials between regional pillars had a positive impact on delaying the expected deformation of the shaft cylinder. |

| 8 | Poland | Conduct statistical analysis and design prevention plans for water inrush incidents in the shaft and predict the stability of the shaft after lining support. |

2. Materials and Methods

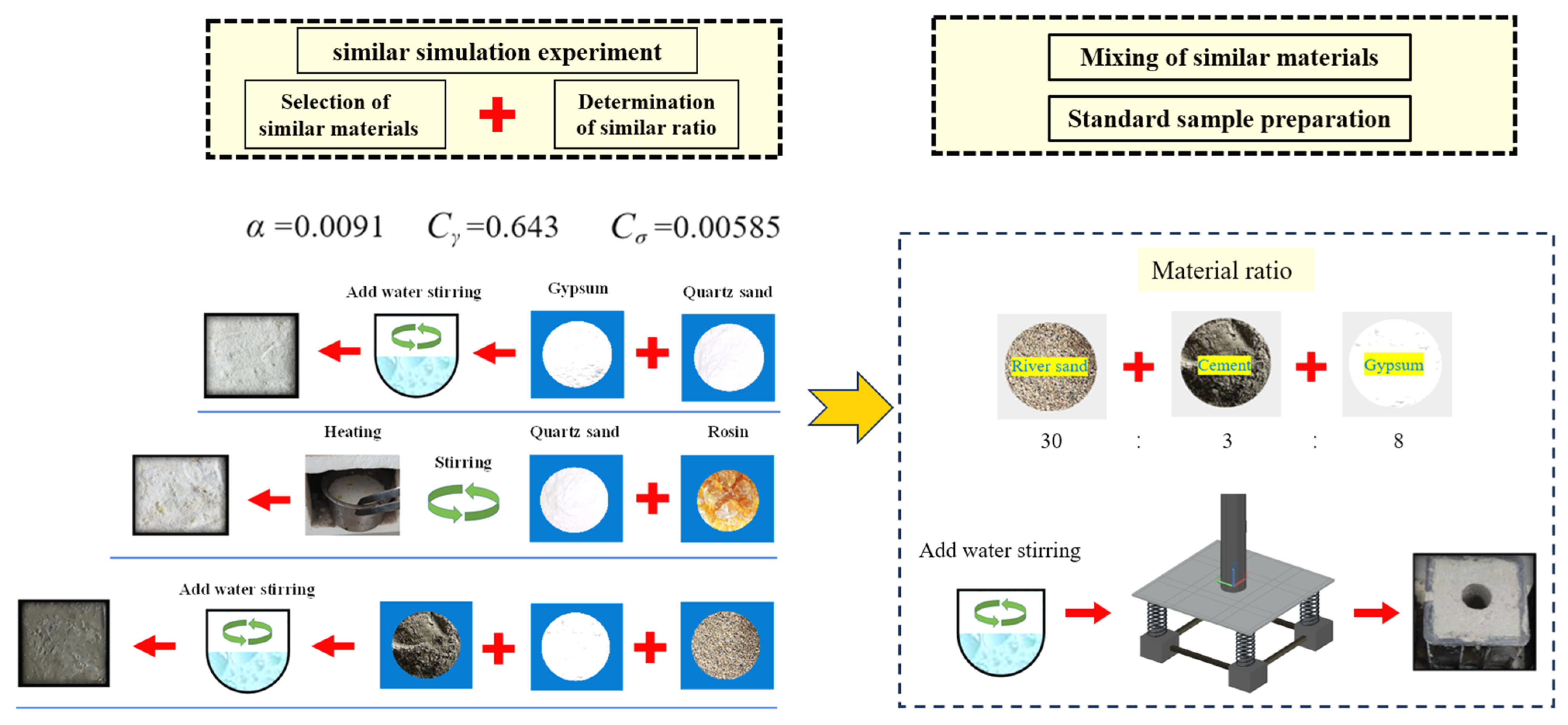

2.1. Preparation of Specimens

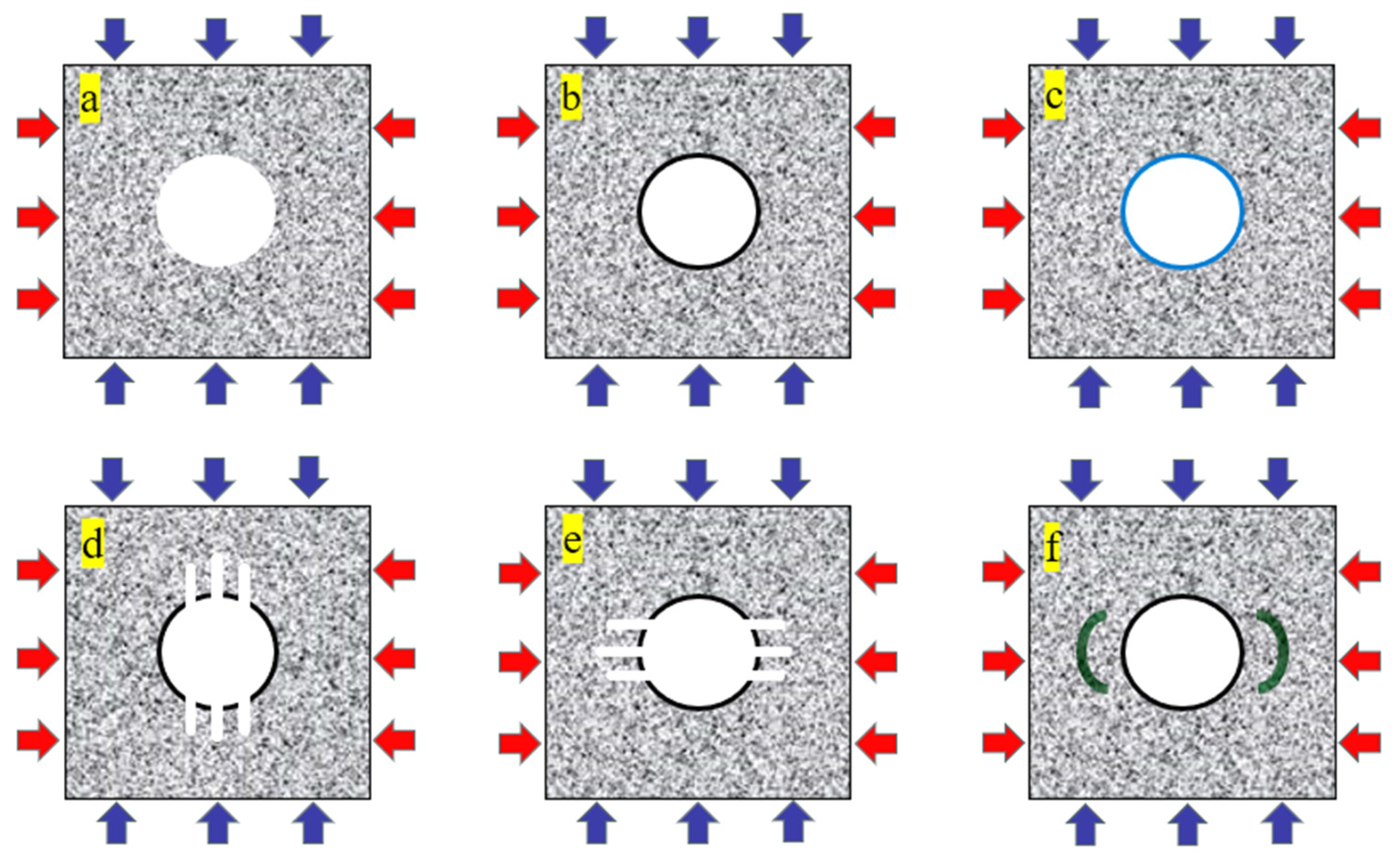

2.2. Experimental Procedure

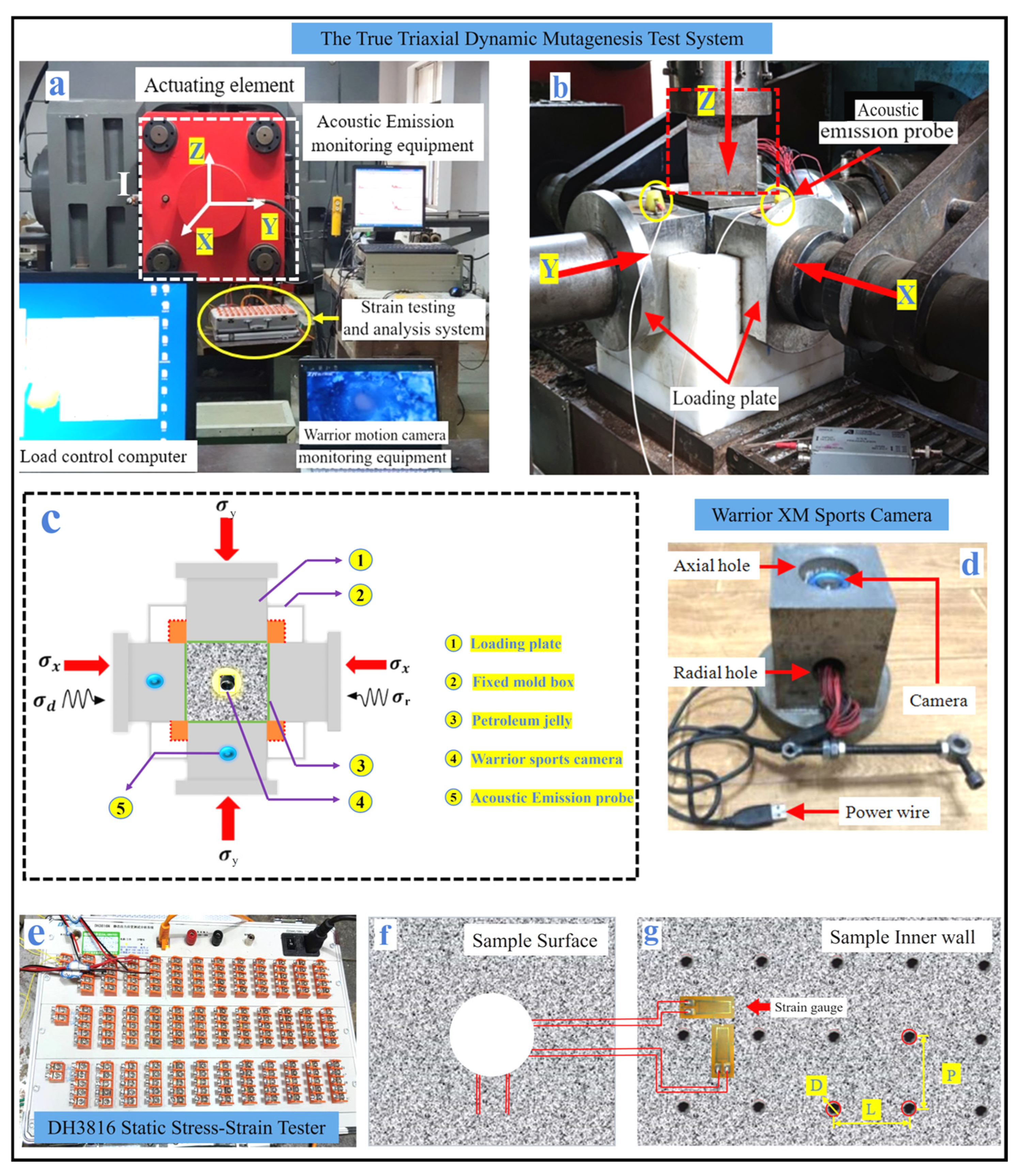

2.2.1. Experimental Equipment

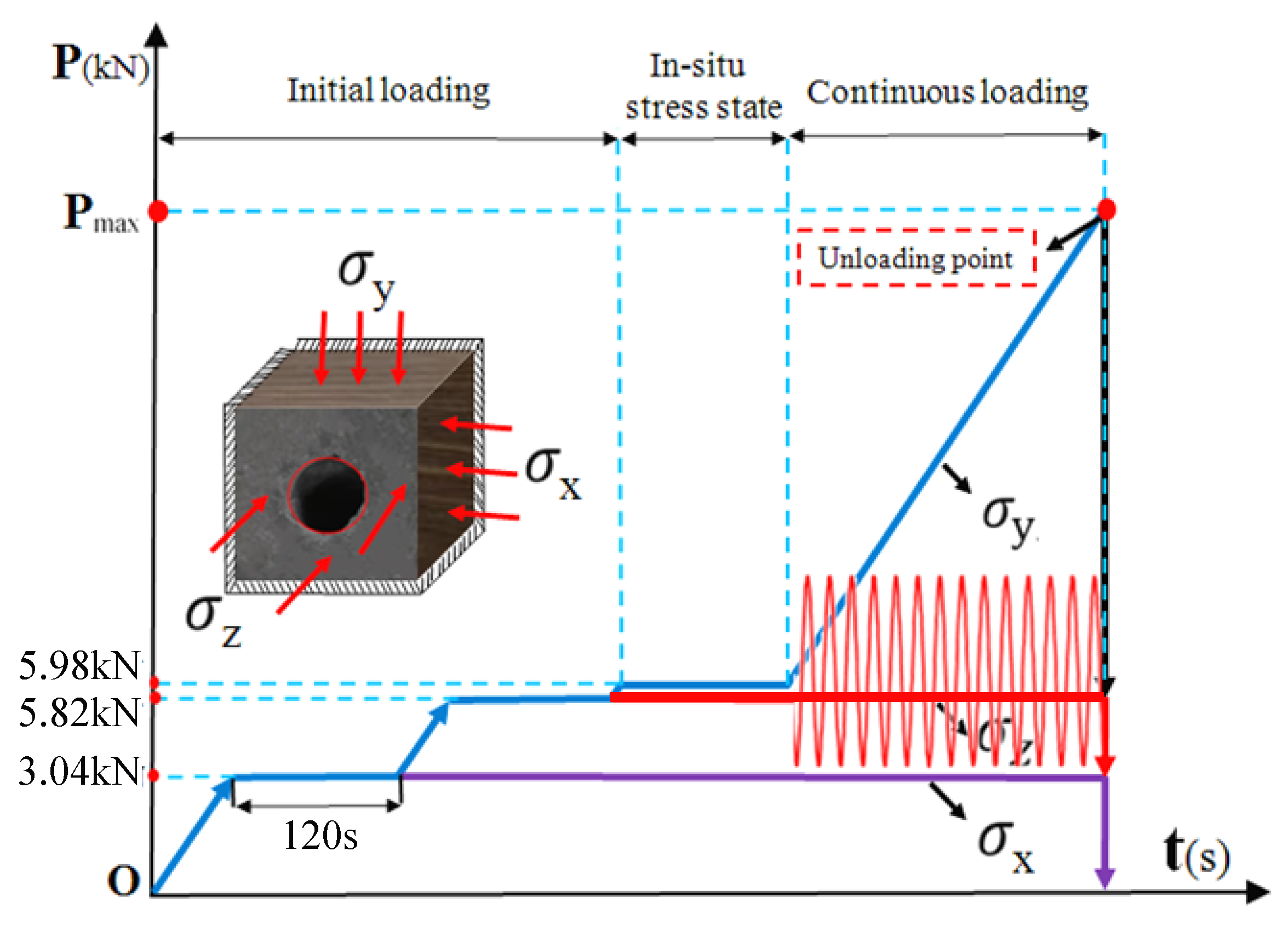

2.2.2. Loading Paths

3. Results

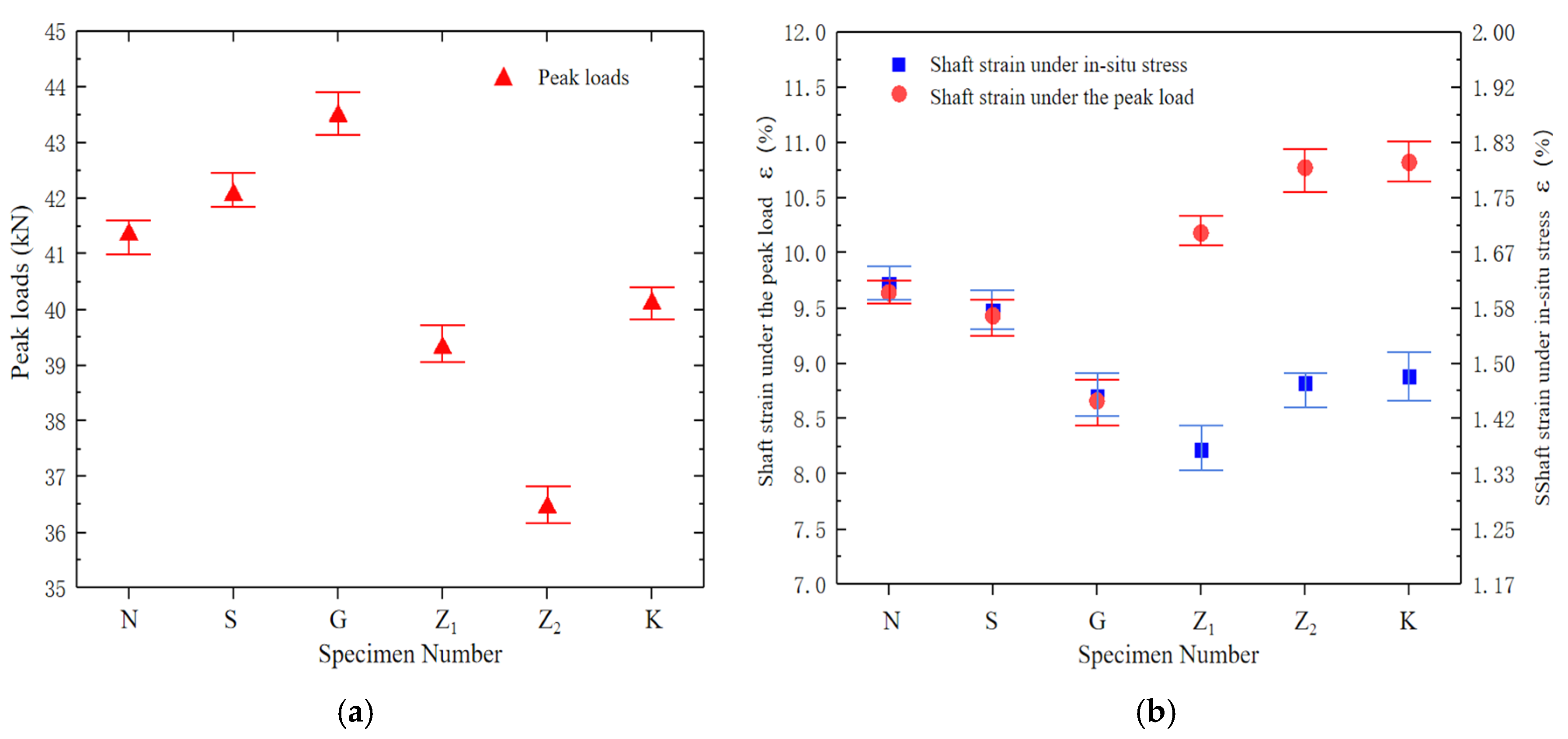

3.1. Mechanical Properties

3.1.1. Stress–Strain Behavior

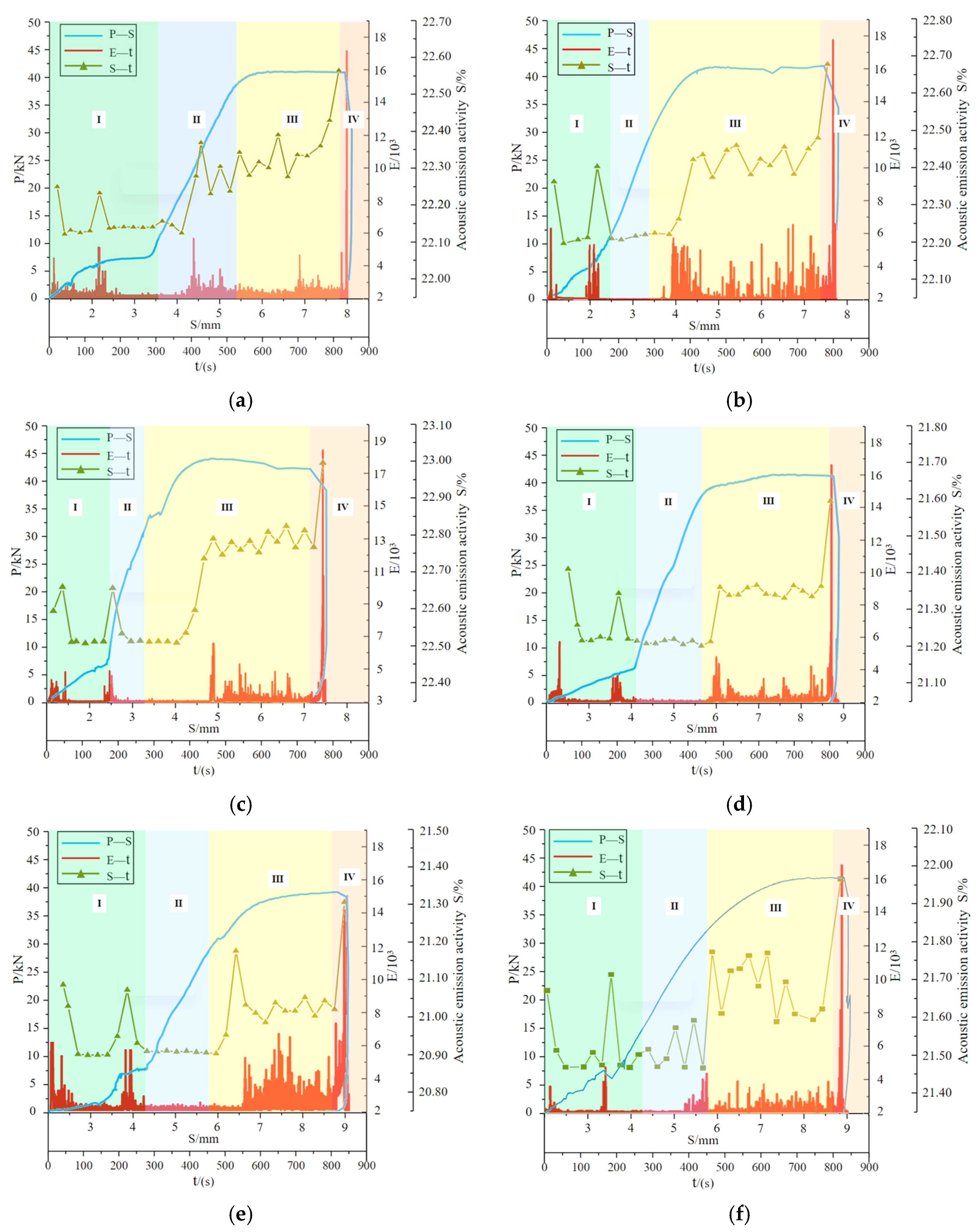

3.1.2. AE Characteristics

3.2. Failure Characteristics

3.2.1. Vertical Shaft Failure Characteristics

3.2.2. Fractal Dimension Statistics

4. Discussion

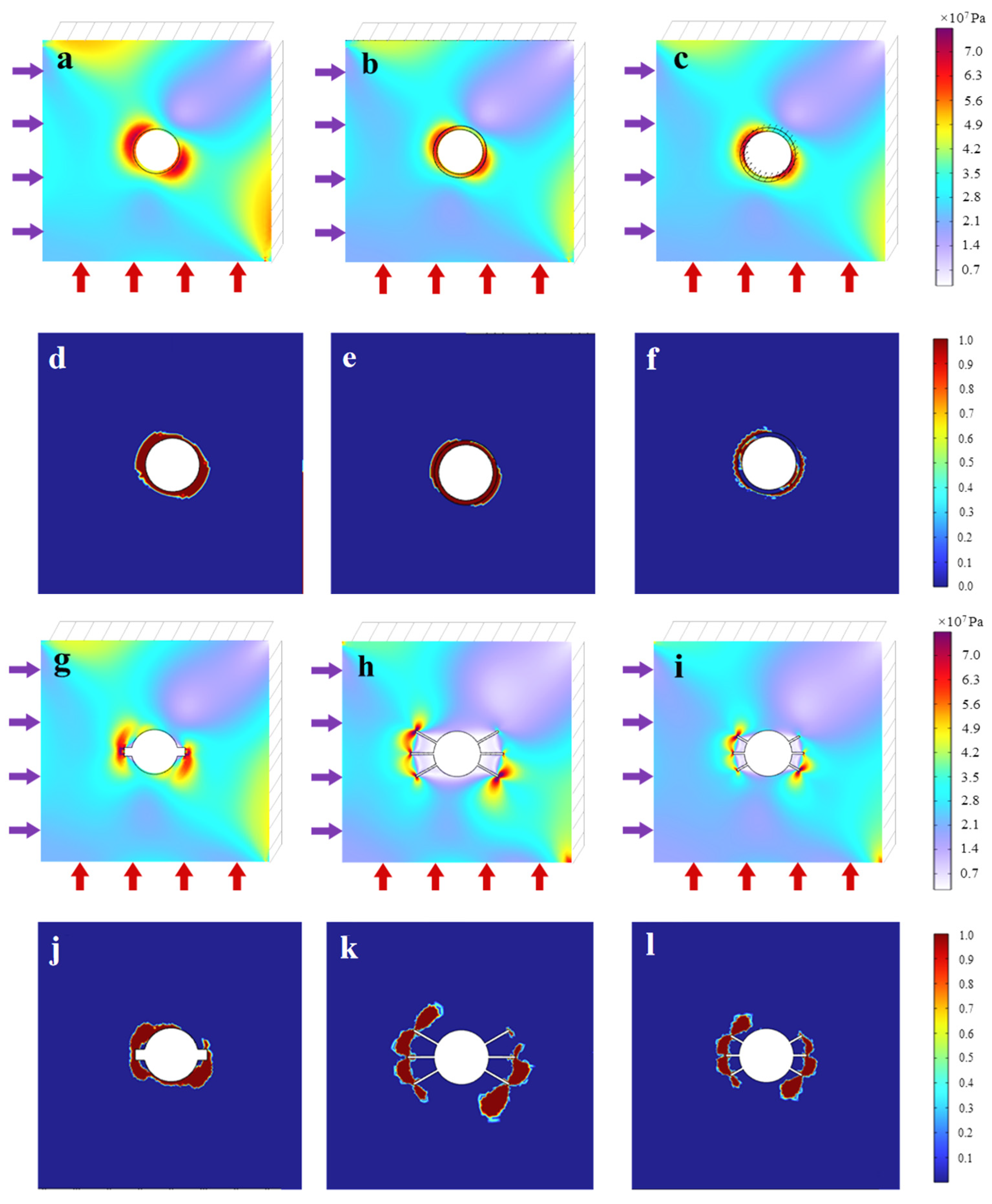

4.1. Numerical Simulation Verification of Shaft Support Methods

4.2. Effect of Shaft Support Methods Under Engineering Disturbance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, X. Basic Theory and Development Trends of Ultra-deep Shaft Construction. Chin. J. Met. Mine 2018, 4, 1–10. [Google Scholar] [CrossRef]

- He, M.; Xie, H.; Peng, S.; Jiang, Y.D. Study on Rock Mechanics in Deep Mining Engineering. Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Li, X.; Zhou, J.; Wang, S.; Liu, B. Review and practice of deep mining for solid mineral resources. Chin. J. Nonferrous Met. 2017, 27, 1236–1262. [Google Scholar]

- Wu, A.; Wang, Y.; Zhang, M.; Yang, G.F. New Development and Prospect of Key Technology in Underground Mining of Metal Mines. Chin. J. Met. Mine 2021, 535, 1–13. [Google Scholar]

- Yang, W.; Cui, G.; Zhou, G. Research on the Mechanism and Prevention Technology of Well Wall Fracture under Special Formation Conditions. J. China Univ. Min. Technol. 1996, 1–5. [Google Scholar]

- Wang, W. Discussion on the Stress Analysis and Design Problems of the Wall of a Kilometer Vertical Well. J. China Coal Soc. 1993, 63–72. [Google Scholar]

- He, Y.; Jing, L.W. Stability Analysis of the Surrounding Rock in Deep Shaft. China Min. Mag. 2006, 15, 61–64. [Google Scholar]

- Liu, Z.; Song, C.; Ji, H.; Liu, S.; Tan, J.; Cheng, S.; Ning, F. Basic Construction mode and key technology of mining shaft engineering for deep mineral resources. J. China Coal Soc. 2021, 46, 826–845. [Google Scholar]

- Akopyan, Z.S. Nonaxisymmetric loss of stability in a vertical shaft mine. Int. Appl. Mech. 1976, 12, 517. [Google Scholar] [CrossRef]

- Guz, A.N. Establishing the Fundamentals of the Theory of Stability of Mine Workings. Int. Appl. Mech. 2003, 39, 20–48. [Google Scholar] [CrossRef]

- Konstantinova, S.A.; Chernopazov, S.A. Mathematical modeling of pressure on the strengthening vertical shaft support in Mirmine located in the Charsk saliferous rock series. J. Min. Sci. 2006, 42, 113–121. [Google Scholar] [CrossRef]

- Su, G.; Hu, L.; Feng, X.T.; Wang, J.H.; Zhang, X.H. True triaxial experimental study of rockburst process under low frequency cyclicdisturbance load combined with static load. Chin. J. Rock Mech. Eng. 2016, 35, 1309–1322. [Google Scholar]

- Chen, L. A Study of Physical Model-Test Technology and Application in Geotechnical Engineering. Ph.D. Thesis, Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, Beijing, China, 2006. [Google Scholar]

- Feng, F.; Chen, S.J.; Wang, Q. Experimental Study on Failure Characteristics of Natural and Saturated Sandstone under True Triaxial Unloading and Dynamic Disturbance Condition. Chin. J. Rock Mech. Eng. 2022, 41, 2240–2253. [Google Scholar]

- Cui, G. Mechanism and Prevention Technology of Shaft Lining Failure Under Special Stratum Conditions. Mine Constr. Technol. 1998, 28–32. [Google Scholar]

- Xu, Y. Theory and Application of Shaft Lining Design for Ultra Kilometer Deep and High Water Pressure in Jiaodong Gold Mine. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2021. [Google Scholar]

- Han, T. Study on the Loads and Design Theory of the Monolayer Freezing Shaft Lining in Water-rich Bedrock. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2011. [Google Scholar]

- Bruneau, G.; Tyler, D.B.; Hadjigeorgiou, J.; Potvin, Y. Influence of faulting on a mine shaft—A case study: Part I—Background and instrumentation. Int. J. Rock Mech. Min. Sci. 2003, 40, 95–111. [Google Scholar] [CrossRef]

- Kun, M.; Onargan, T. Influence of the fault zone in shallow tunneling: A case study of Izmir Metro Tunnel. Tunn. Undergr. Space Technol. 2013, 33, 34–45. [Google Scholar] [CrossRef]

- Dong, J.; Yang, J.; Yang, G.X.; Wu, F.Q.; Liu, H.S. Research on Similar Material Proportioning Test of Model Test Based on Orthogonal Design. J. China Coal Soc. 2012, 37, 44–49. [Google Scholar]

- Xiao, J. Selection of Similar Materials for Model Test & Research on Similar Material Proportioning Test. Ph.D. Thesis, Beijing Transportation University, Beijing, China, 2013. [Google Scholar]

- Du, K.; Li, X.; Li, D.; Weng, L. Failure Properties of Rocks in True Triaxial Unloading Compressive Test. Trans. Nonferrous Met. Soc. China 2015, 25, 571–581. [Google Scholar] [CrossRef]

- Lu, J.; Yin, G.; Gao, H.; Li, M.; Deng, B. Experimental Study on Compound Dynamic Disaster and Drilling Pressure Relief of Gas-Bearing Coal under True Triaxial Loading. J. China Coal Soc. 2020, 45, 1812–1823. [Google Scholar]

- Du, K.; Li, X.; Ma, C. Development of Rock True Triaxial Dynamic Disturbance Test System and its Application. Exp. Technol. Manag. 2014, 31, 35–40. [Google Scholar]

- Du, K.; Li, X.; Dong, L.J.; Tao, M.; Zhou, J. Fracture Mechanism of Rock Induced by True-Triaxial unloading and Heterology Dynamic Disturbance. Chin. J. Rock Mech. Eng. 2015, 34, 4047–4053. [Google Scholar]

- Dong, L.; Sun, Y.; Sun, D.; Chen, Y.C.; Tang, Z. Stage Characteristics of Acoustic Emission and Identification of Unstable Crack State for Granite Fractures. Chin. J. Rock Mech. Eng. 2022, 41, 120–131. [Google Scholar]

- Wu, C.; Gong, F.; Luo, Y. A new quantitative method to identify the crack damage stress of rock using AE detection parameters. Bull. Eng. Geol. Environ. 2021, 80, 519–531. [Google Scholar] [CrossRef]

- Li, D.; Charlie, C.; Li, X. Influence of sample height-to-width ratios on failure mode for rectangular prism samples of hard rock loaded in uniaxial compression. Rock Mech. Rock Eng. 2011, 44, 253–267. [Google Scholar] [CrossRef]

- He, M.; Xia, H.; Jia, X.; Gong, W.; Zhao, F.; Liang, K. Studies on classification, criteria and control of rockbursts. J. Rock Mech. Geotech. Eng. 2012, 4, 97–114. [Google Scholar] [CrossRef]

- Wang, M.; Wang, X.; Xiao, T. Borehole Destressing Mechanism and Determination Method of its Key Parameters in Deep Roadway. J. China Coal Soc. 2017, 42, 1138–1145. [Google Scholar]

- Lin, B.; Zou, Q.; Shen, C.; Xu, Y.P.; Dai, H.M.; Yang, W. Investigation on Highly Effective Depressurization Property of Dual-Power Drilling and its Application. J. China Coal Soc. 2013, 38, 911–917. [Google Scholar]

- Xu, J.; Liu, S. Research on Fractal Characteristics of Marble Fragments Subjected to Impact Loading. Rock Soil Mech. 2012, 33, 3225–3229. [Google Scholar]

- Ji, J.; Li, H.; Wu, F.; Yao, Q. Fractal Characteristics of Rock Fragmentation under Impact Load. J. Vib. Shock 2020, 39, 176–183. [Google Scholar]

| Parameters | Rock Strength (MPa) | Shaft Diameter (mm) | Support Thickness (mm) | Concrete (C30) (MPa) | Disturbance Amplitude (kN) |

|---|---|---|---|---|---|

| Prototype | 45.9 | 5500 | 450 | 34.87 | |

| Model | 0.269 | 50 | 4.1 | 0.204 | 20 |

| Parameters | Filling Body Strength (MPa) | Fiber-Reinforced Concrete Strength (MPa) | Maximum Principal Stress (Mpa) | Minimum Principal Stress (MPa) | Intermediate Principal Stress (MPa) |

| Prototype | 18.00 | 41.54 | 45.44 | 44.23 | 23.11 |

| Model | 0.105 | 0.243 | 0.266 | 0.259 | 0.135 |

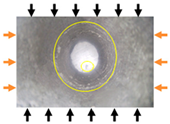

| Parameters | Drilling Spacing (mm) | Drilling Diameter (mm) | Drill Depth (mm) | Slot Width (mm) | Slot Arc Length (mm) |

| Prototype | 1600 | 220 | 4400 | 825 | 1.33πR |

| Model | 20 | 2 | 40 | 7.5 | 36π |

| NO. | Size/mm | Shaft Support Method | Shaft Strain (In Situ Stress) | Peak Loads (kN) | Shaft Strain (the Peak Load) | Energy (J) | Value S (%) |

|---|---|---|---|---|---|---|---|

| N-1 | 150 × 150 × 150 | / | 1.62 | 41.35 | 9.64 | 1.73 × 104 | 22.57 |

| N-2 | 150 × 150 × 150 | / | 1.65 | 41.42 | 9.58 | 1.71 × 104 | 22.61 |

| S-1 | 150 × 150 × 150 | concrete | 1.58 | 42.06 | 9.43 | 1.79 × 104 | 22.71 |

| S-2 | 150 × 150 × 150 | concrete | 1.49 | 41.57 | 8.85 | 1.75 × 104 | 22.65 |

| G-1 | 150 × 150 × 150 | Fiber concrete support | 1.45 | 43.48 | 8.66 | 1.89 × 104 | 23.02 |

| G-2 | 150 × 150 × 150 | Fiber concrete support | 1.51 | 42.12 | 9.12 | 1.82 × 104 | 23.08 |

| Z1-1 | 150 × 150 × 150 | concrete + destressing boreholes | 1.37 | 39.31 | 10.18 | 1.64 × 104 | 21.66 |

| Z1-2 | 150 × 150 × 150 | concrete + destressing boreholes | 1.42 | 38.56 | 10.44 | 1.61 × 104 | 21.57 |

| Z2-1 | 150 × 150 × 150 | concrete + destressing boreholes | 1.47 | 36.45 | 10.77 | 1.52 × 104 | 21.27 |

| Z2-2 | 150 × 150 × 150 | concrete + destressing boreholes | 1.44 | 37.87 | 10.56 | 1.58 × 104 | 21.42 |

| K-1 | 150 × 150 × 150 | concrete + cutting groove destressing | 1.48 | 40.11 | 10.82 | 1.68 × 104 | 21.92 |

| K-2 | 150 × 150 × 150 | concrete + cutting groove destressing | 1.41 | 40.92 | 10.51 | 1.71 × 104 | 22.31 |

| No Support | Concrete Support | Steel Fiber Concrete Support | |

|---|---|---|---|

| 0 |  |  |  |

| In situ stress states |  |  |  |

| 60%σmax |  |  |  |

| 80%σmax |  |  |  |

| 100%σmax |  |  |  |

| Destressing Boreholes A | Destressing Boreholes B | Destressing by Cutting Groove | |

|---|---|---|---|

| 0 |  |  |  |

| In situ stress states |  |  |  |

| 60%σmax |  |  |  |

| 80%σmax |  |  |  |

| 100%σmax |  |  |  |

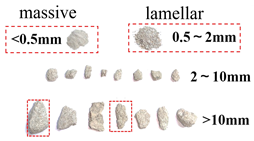

| No. | Sample Number | Total Debris Mass/g | Average Fragmentation | Displacement/mm | Peak Loads/kN |

|---|---|---|---|---|---|

| 1 | N | 116.7 | 2.96 | 4.62 | 41.35 |

| 2 | S | 96.4 | 2.88 | 4.52 | 42.06 |

| 3 | G | 102.6 | 2.25 | 4.13 | 43.48 |

| 4 | Z1 | 106.5 | 5.54 | 4.89 | 39.31 |

| 5 | Z2 | 109.8 | 6.17 | 5.19 | 37.87 |

| 6 | K | 110.4 | 5.73 | 5.21 | 40.11 |

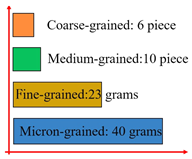

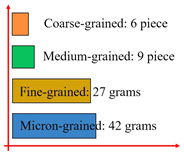

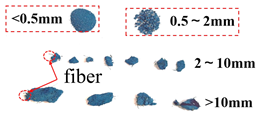

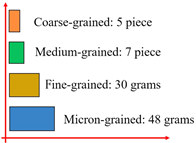

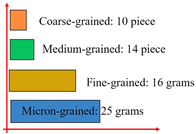

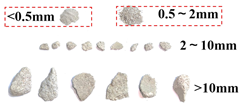

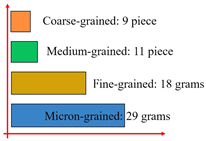

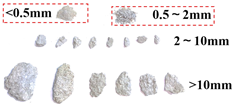

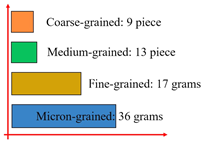

| Support Method | Shaft Debris | Fragmentation Statistical Diagram of Shaft Destruction | Brief Summary |

|---|---|---|---|

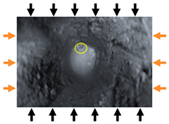

| Non-Support |  |  | There are many large blocks falling from the wall of the shaft, and the maximum size is up to 18 mm. At the same time, the amount of fine and particulate debris is larger, accumulating 96 g. |

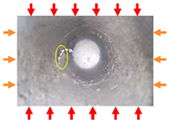

| Concrete Support |  |  | The number of large blocks dropped in the shaft was relatively reduced, and the size of the largest block dropped was increased to 25 mm. The whole concrete is mainly spalled, and there are fewer fine particles and fine particle debris. |

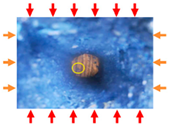

| Steel Fiber Concrete Support |  |  | Fewer blocks dropped from shafts. The amount of fine particles and particulate debris dropped is 1/3 of that without support. |

| Borehole Pressure Relief Support K1 |  |  | The amount of fine and fine particle debris dropped is greatly reduced, but the phenomenon of large peeling is obvious. |

| Borehole Pressure Relief Support K2 |  |  | The spalling block is the block between the pressure relief holes, and the flaking block is the main peeling block. Borehole deformation is large and the borehole integrity is low. |

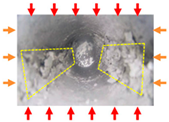

| Cutting Groove Destressing Support |  |  | The maximum blockage is 46 mm, borehole failure shows that compared with the non-supporting sample, the initial state of this support method has caused damage to the shaft. |

| Material | Elastic Modulus | Density | Internal Friction Angle | UCS | Cohesion | M and S |

|---|---|---|---|---|---|---|

| Dolomite | 2.6 GPa | 2.5 g/cm3 | 38.5° | 36.5 MPa | 4.5 MPa | 22/0.88 |

| Peak Loads/kN | Non-Support | Non-Fiber Concrete | Steel Fiber Concrete Support | Borehole Pressure Relief Support K1 | Borehole Pressure Relief Support K2 | Cutting Groove Destressing Support |

|---|---|---|---|---|---|---|

| Non-support disturbance | 41.35 | 42.06 | 43.48 | 39.31 | 36.45 | 40.11 |

| 41.42 | 41.57 | 42.12 | 38.56 | 37.87 | 40.92 | |

| Disturbance in the direction of the maximum principal stress | 39.2 | 41.08 | 42.83 | 37.26 | 36.25 | 38.22 |

| 41.27 | 39.41 | 43.93 | 38.55 | 35.90 | 38.79 | |

| Disturbance in the direction of the minimum principal stress | 41.78 | 42.94 | 44.82 | 39.84 | 38.11 | 40.27 |

| 41.56 | 41.92 | 44.48 | 38.82 | 37.13 | 41.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Yu, Y.; Jiang, J.; Ma, J. Comparative Study of Supporting Methods for a Deep Mine Shaft Using Similar Physical Model Tests Under True Triaxial Stresses. Appl. Sci. 2025, 15, 12997. https://doi.org/10.3390/app152412997

Li D, Yu Y, Jiang J, Ma J. Comparative Study of Supporting Methods for a Deep Mine Shaft Using Similar Physical Model Tests Under True Triaxial Stresses. Applied Sciences. 2025; 15(24):12997. https://doi.org/10.3390/app152412997

Chicago/Turabian StyleLi, Diyuan, Yisong Yu, Jingtai Jiang, and Jinyin Ma. 2025. "Comparative Study of Supporting Methods for a Deep Mine Shaft Using Similar Physical Model Tests Under True Triaxial Stresses" Applied Sciences 15, no. 24: 12997. https://doi.org/10.3390/app152412997

APA StyleLi, D., Yu, Y., Jiang, J., & Ma, J. (2025). Comparative Study of Supporting Methods for a Deep Mine Shaft Using Similar Physical Model Tests Under True Triaxial Stresses. Applied Sciences, 15(24), 12997. https://doi.org/10.3390/app152412997