Stress–Strain–Strength Behavior of Hydraulic Asphalt Concrete at Different Bitumen Grades

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

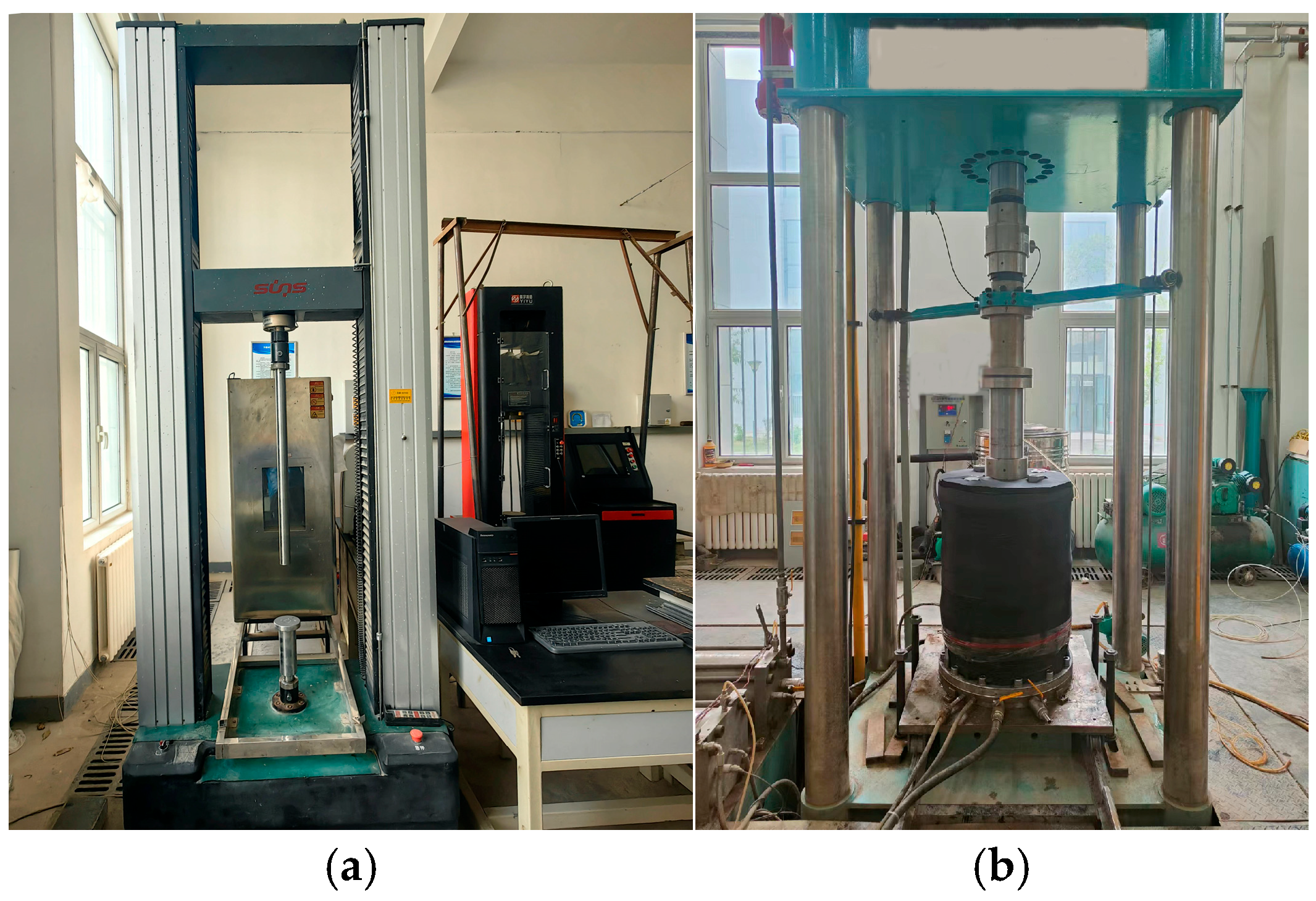

2.2.1. Direct Tension Test

2.2.2. Uniaxial Compression Test

2.2.3. Bending Test

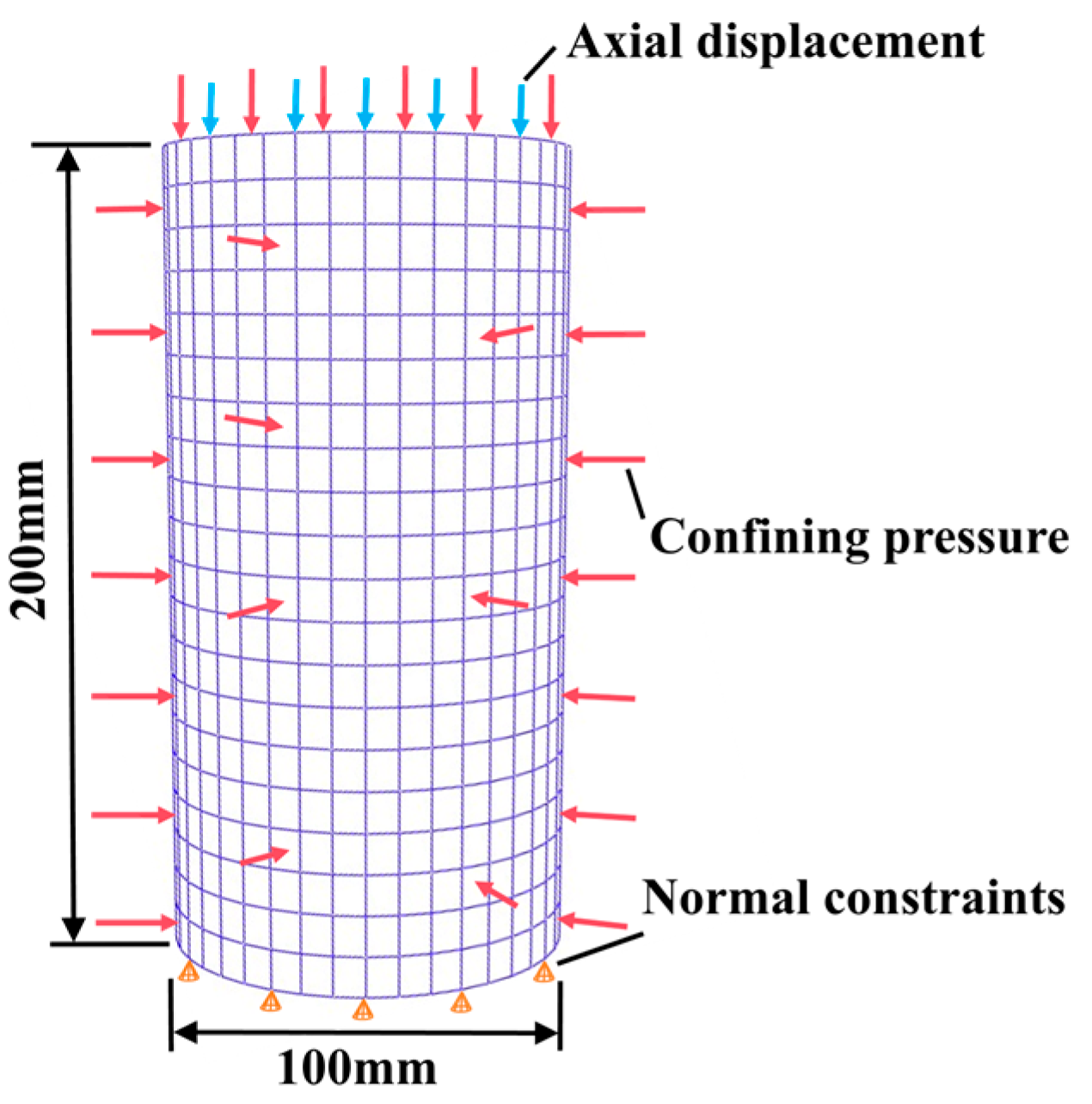

2.2.4. Triaxial Compression Test

3. Results and Analysis

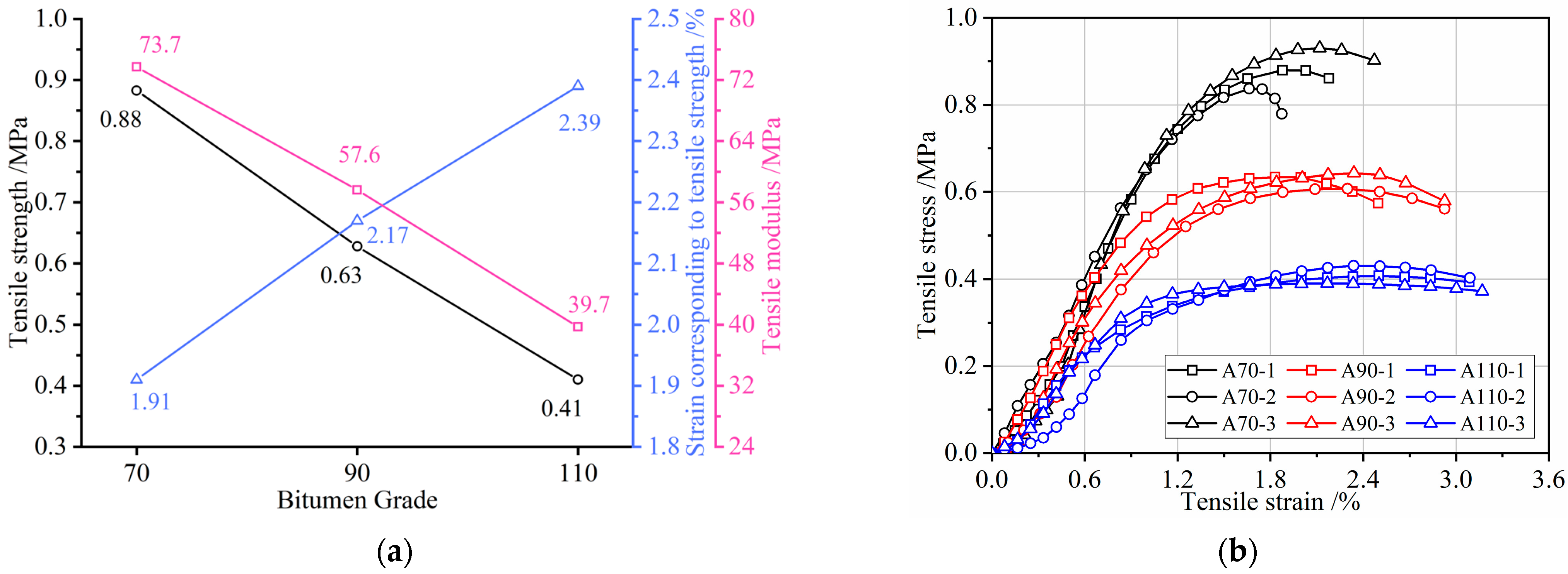

3.1. Analysis of Direct Tension Test Results

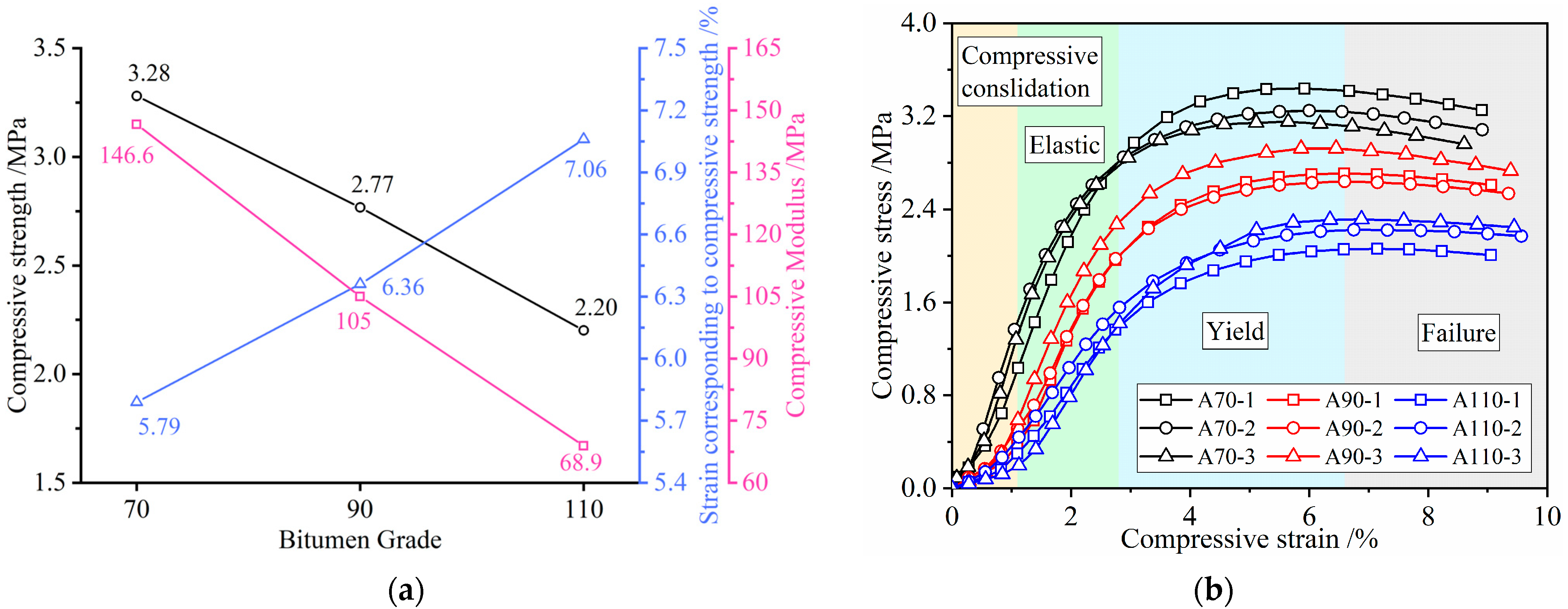

3.2. Analysis of Uniaxial Compression Test Results

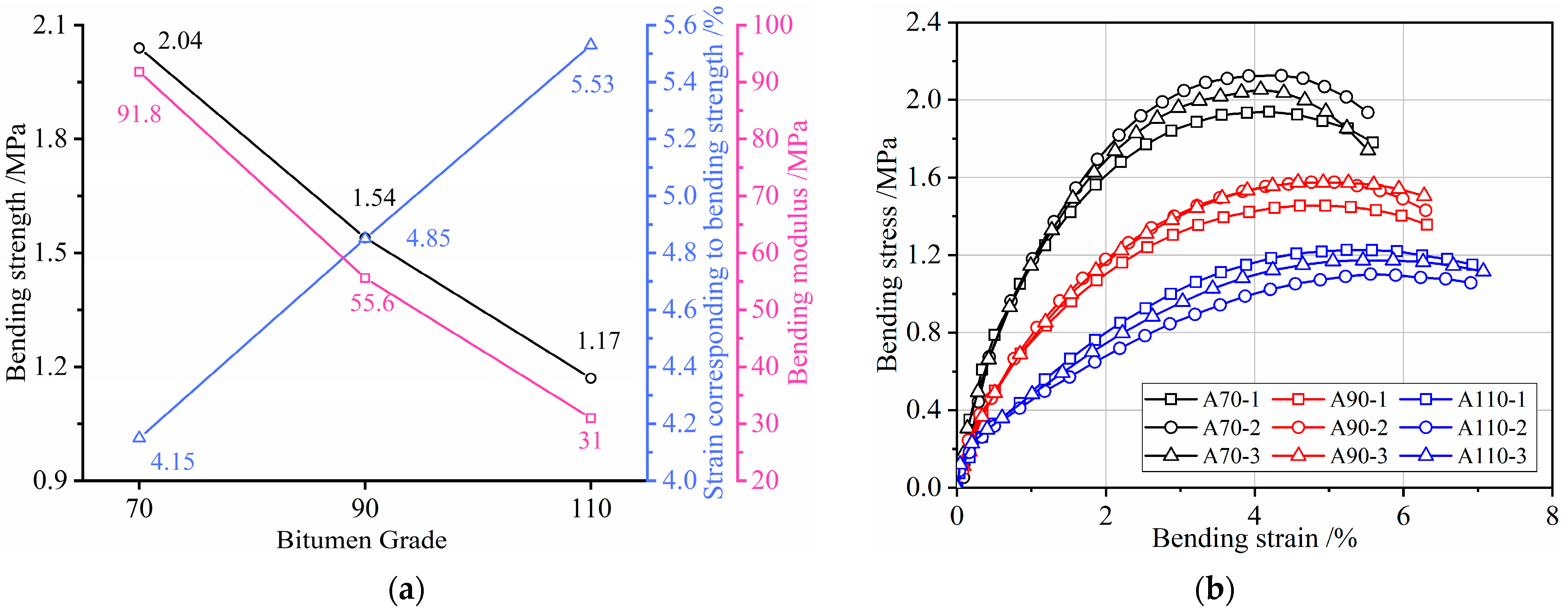

3.3. Analysis of Bending Test Results

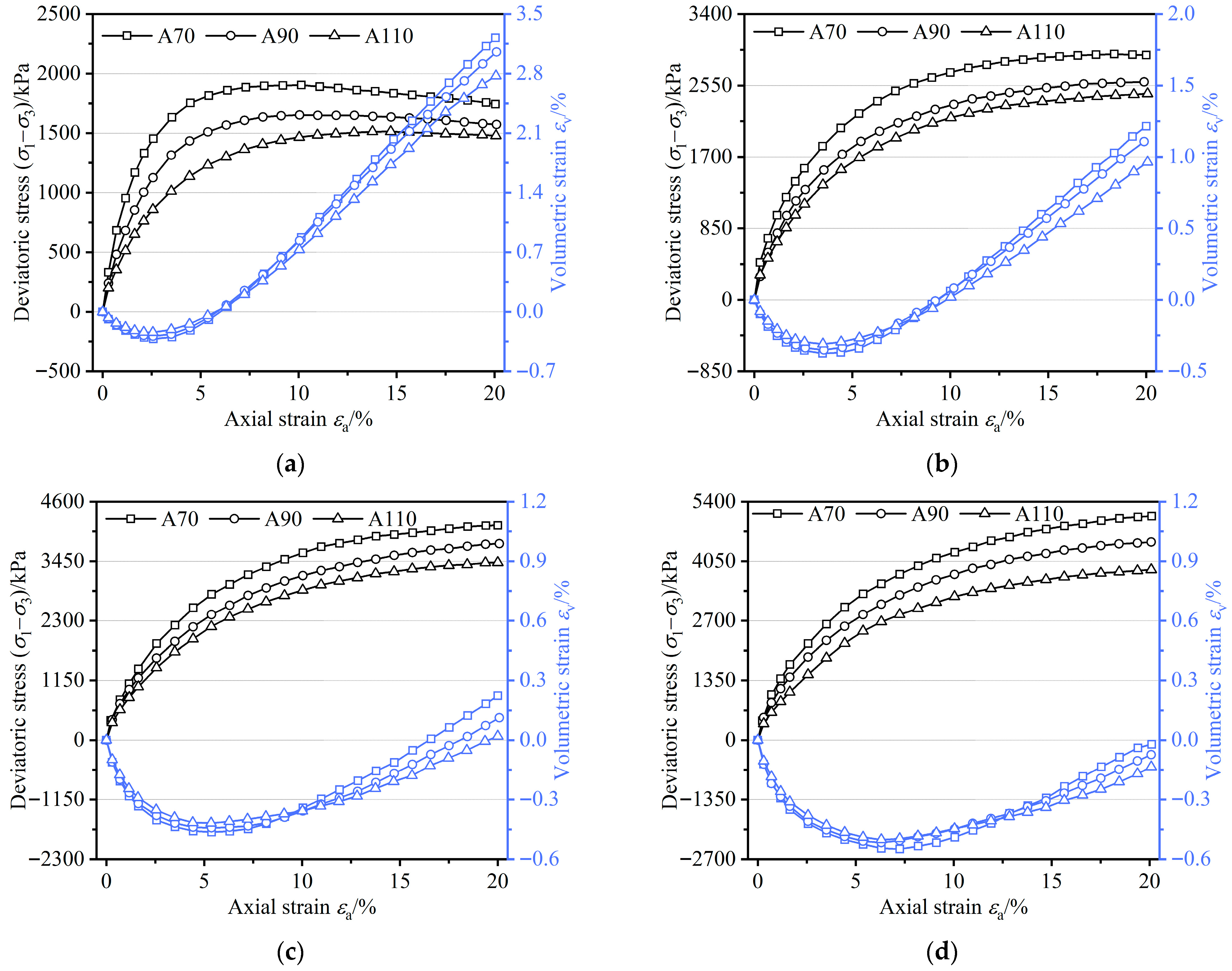

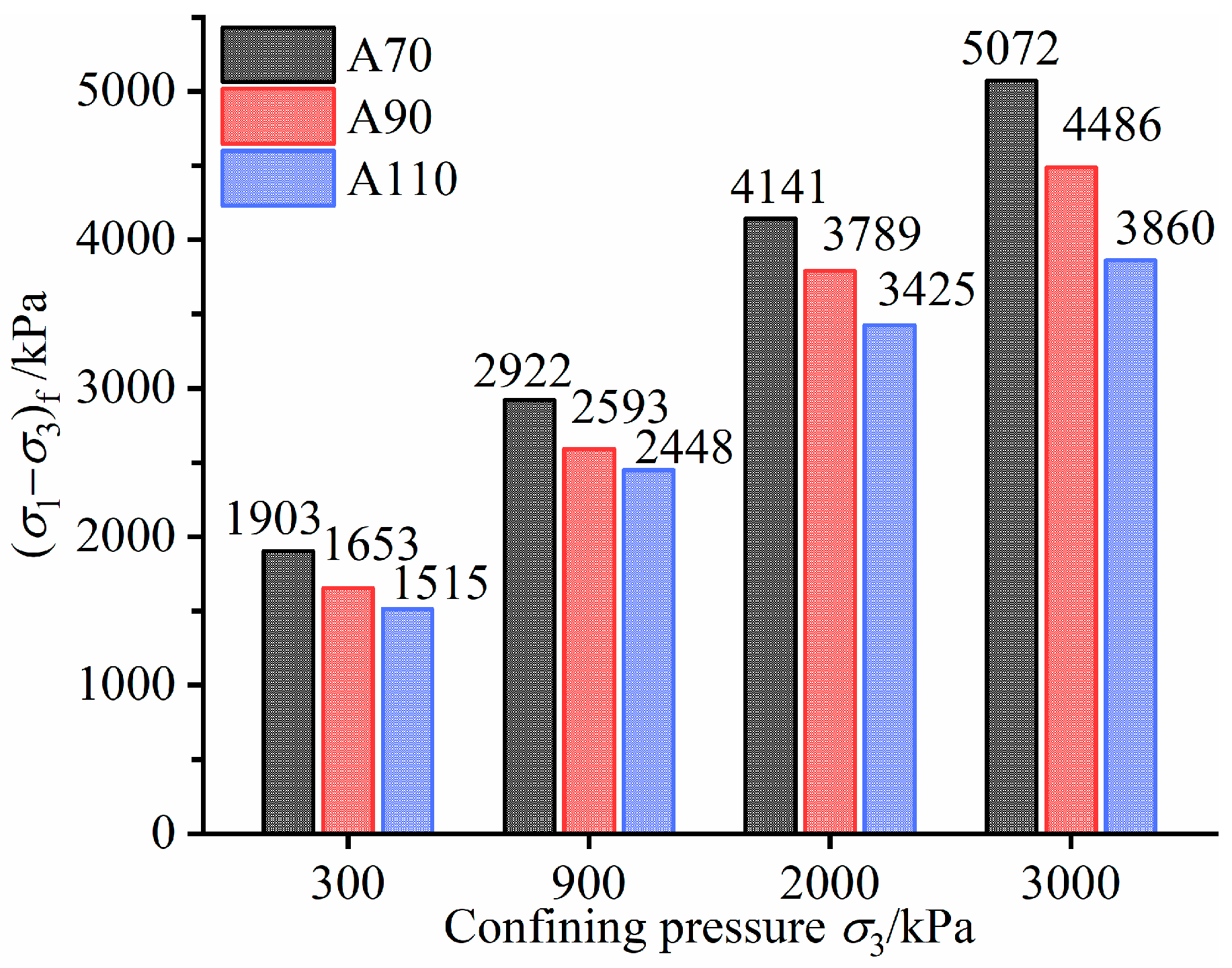

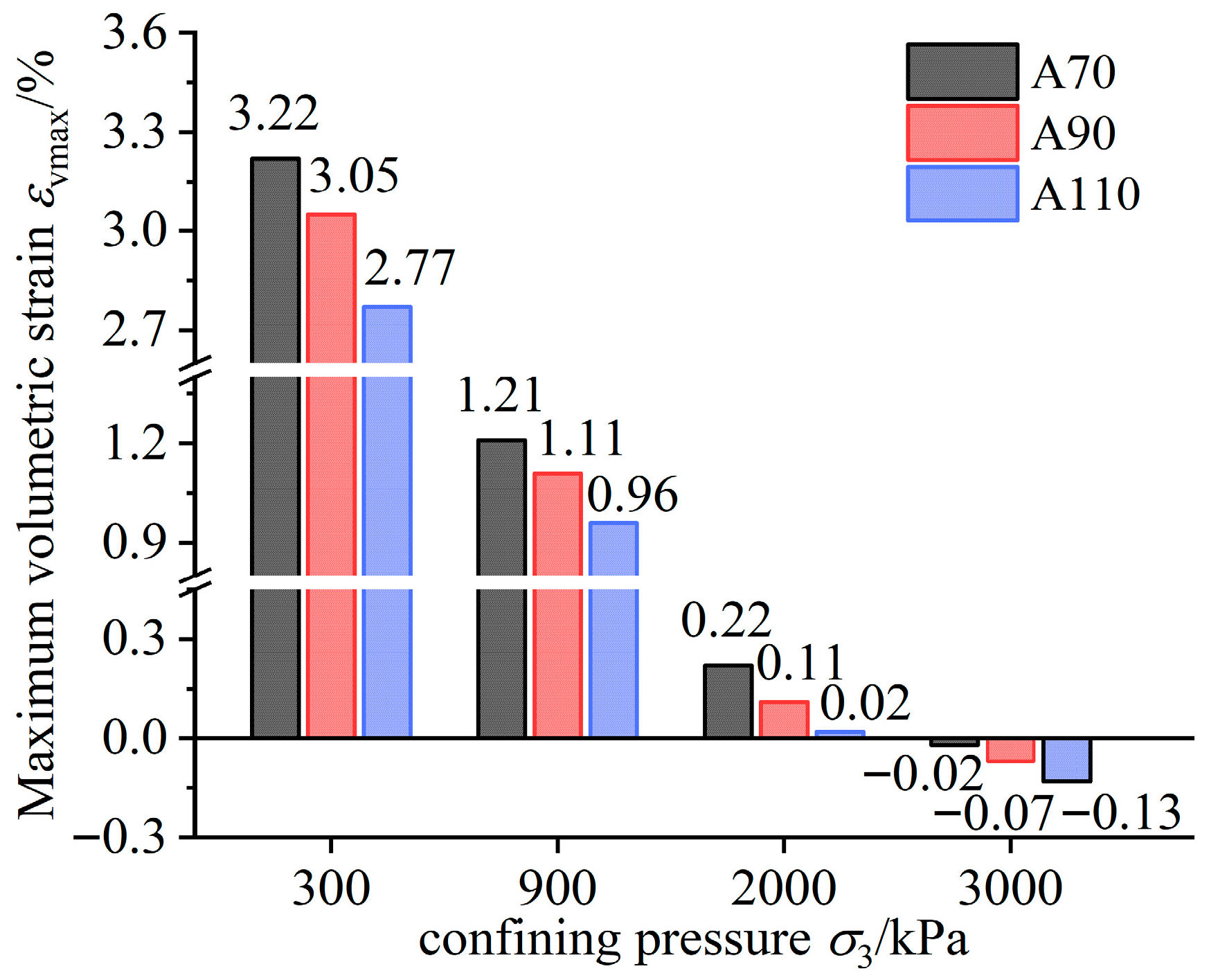

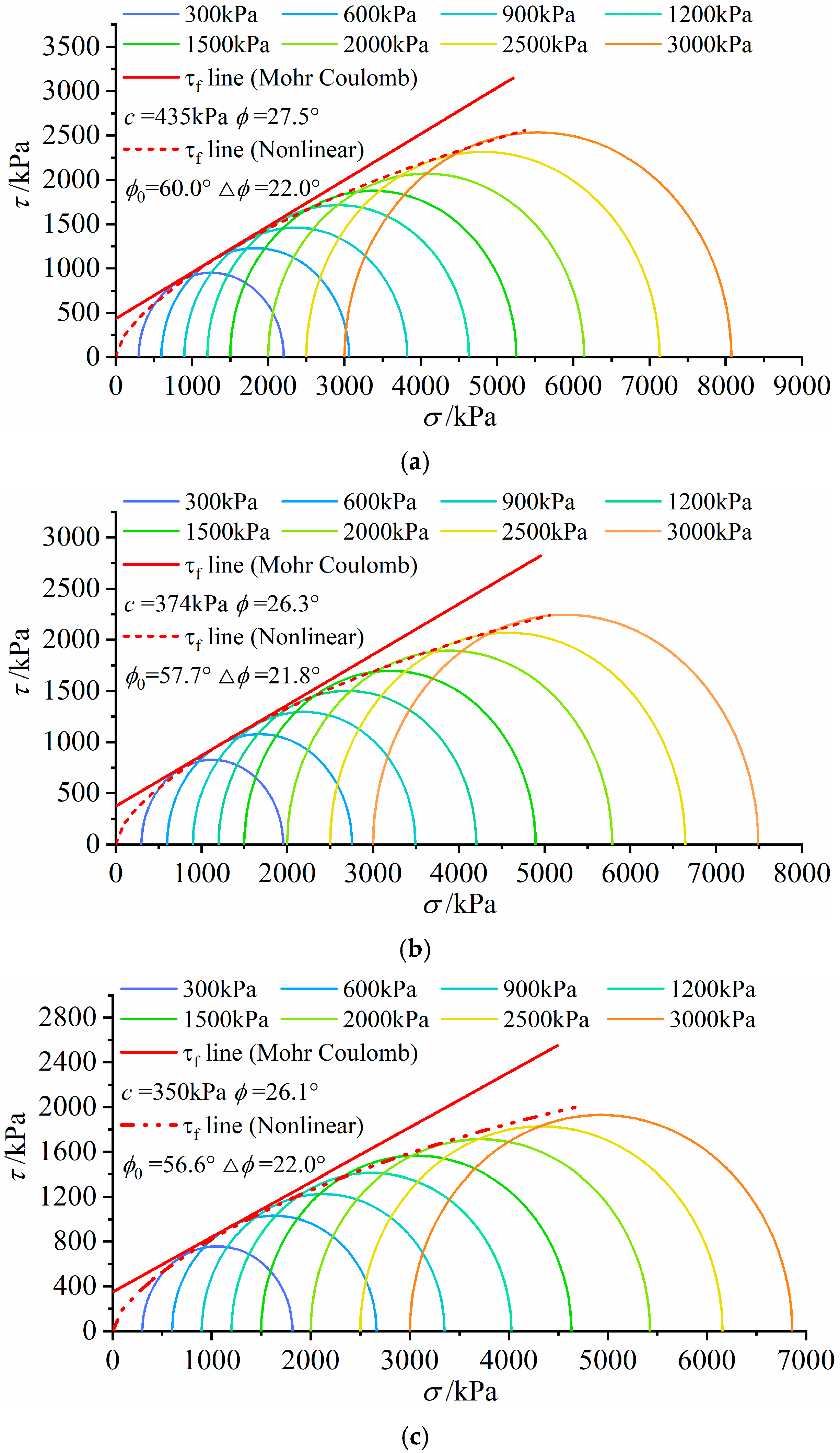

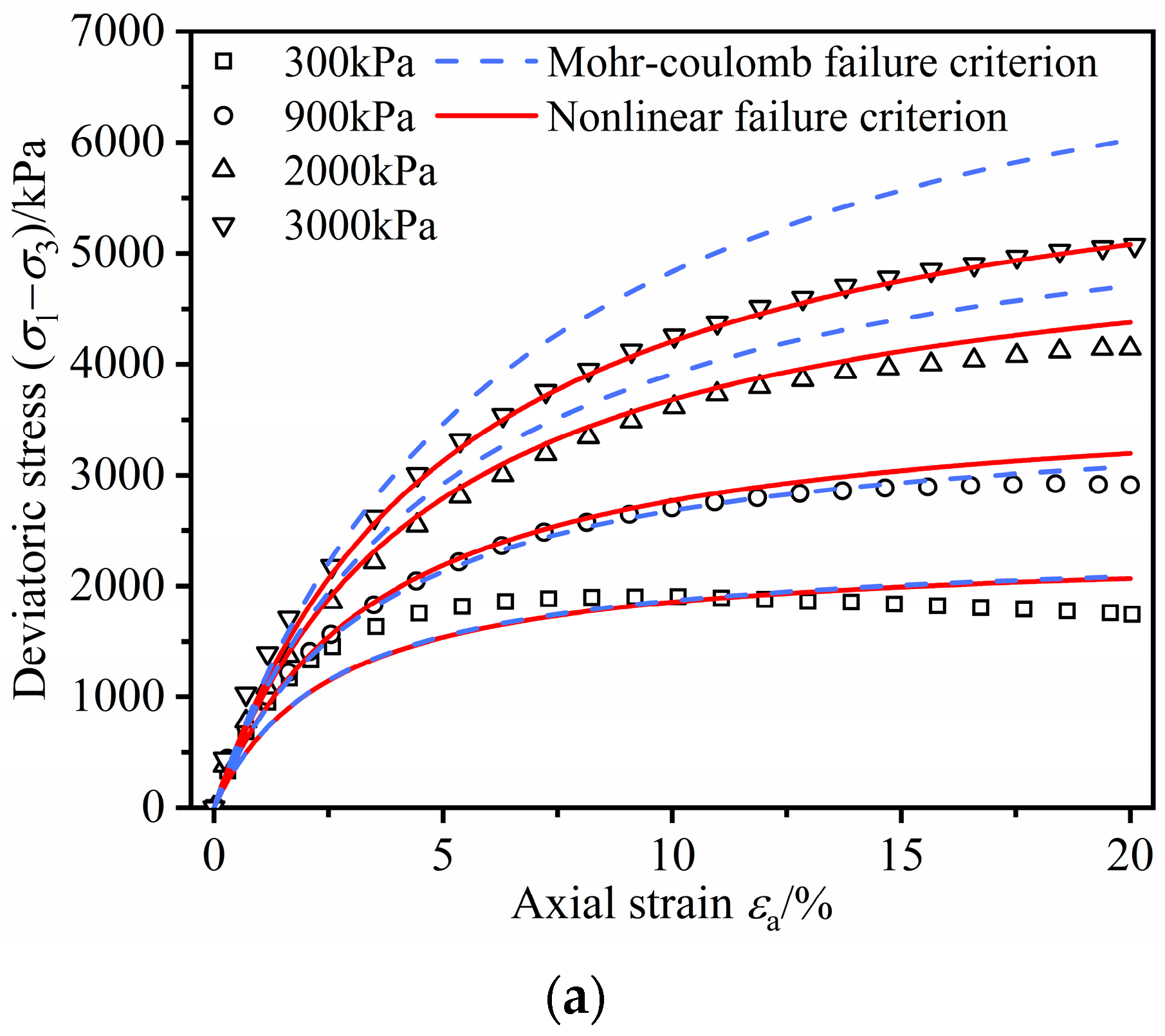

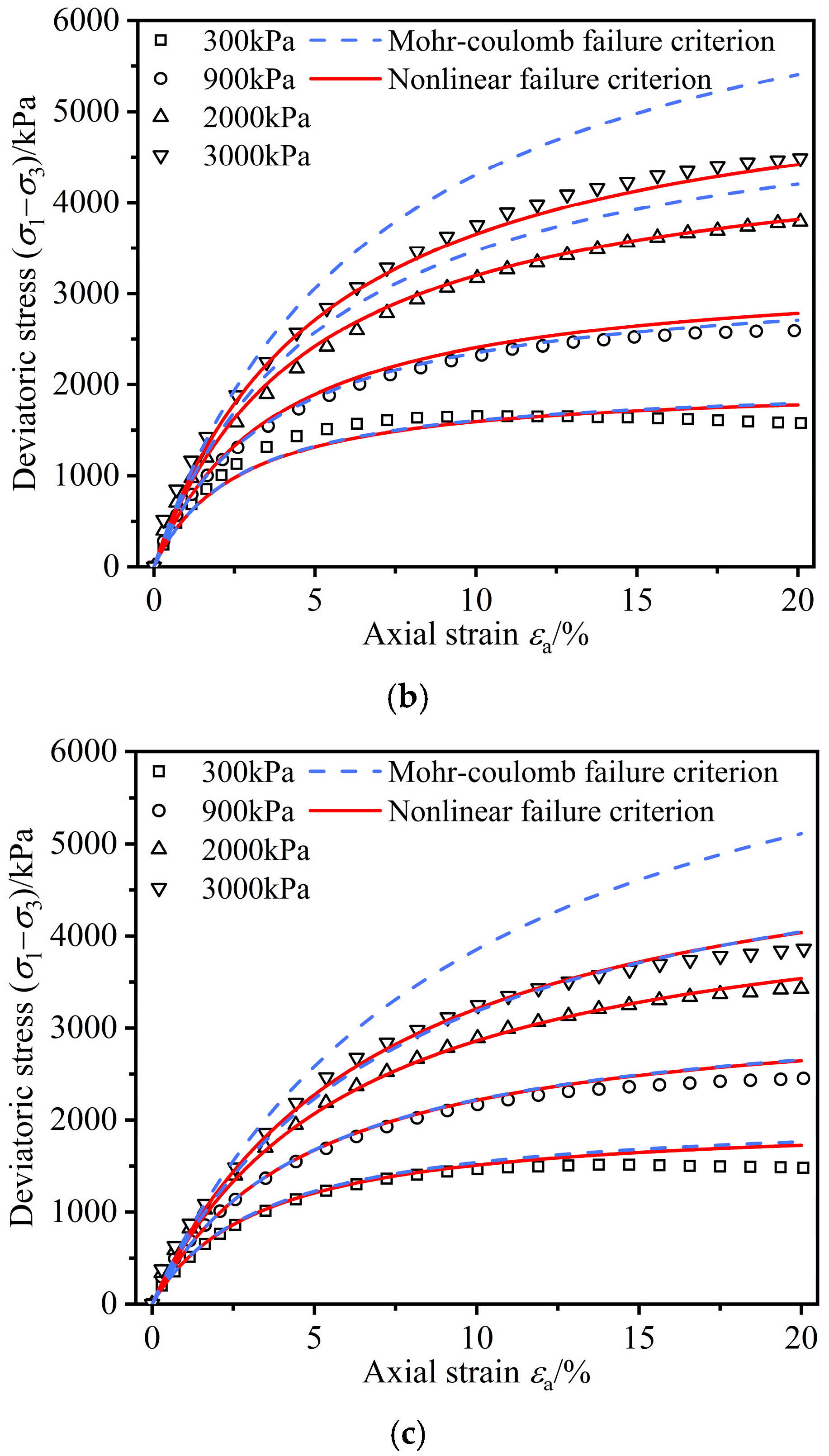

3.4. Analysis of Triaxial Compression Test Results

4. Discussion

5. Conclusions

- Under these loading conditions, the use of high-grade bitumen comprehensively enhances the deformation capacity and ductile behavior of hydraulic asphalt concrete, although it reduces its inherent strength. When the strength of hydraulic asphalt concrete meets design requirements, selecting a higher bitumen grade is advisable to increase the deformation threshold at which the core fails under various load types.

- The volumetric strain curves of hydraulic asphalt concrete at different bitumen grades initially exhibit parabolic variation before gradually transitioning to linear behavior. The slope of the linear segment diminishes as the bitumen grade increases. The use of higher-grade bitumen in hydraulic asphalt concrete reduces its dilatancy, which benefits the impermeability safety of the core.

- As confining pressure increases, the shear strength of hydraulic asphalt concrete with different bitumen grades exhibits pronounced nonlinear behavior. Moreover, with increasing bitumen grade, the nonlinear characteristics of shear strength become more significant. The expression for the elastic modulus, formulated using nonlinear failure criteria, accurately describes the deviatoric stress–axial strain relationship of hydraulic asphalt concrete across different bitumen grades.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, T.; Wang, W.; Höeg, K.; Feng, S.; Zhao, R. 3D analysis of the 174-m high Quxue asphalt-core rockfill dam in a narrow canyon. Soils Found. 2021, 61, 1645–1659. [Google Scholar] [CrossRef]

- Yu, X.; Kong, X.; Zou, D.; Zhou, Y.; Hu, Z. Linear elastic and plastic-damage analyses of a concrete cut-off wall constructed in deep overburden. Comput. Geotech. 2015, 69, 462–473. [Google Scholar] [CrossRef]

- Khalaj, O.; Ayati Ahmadi, A.; Abedin Nejad, S.; Mašek, B.; Štadler, C.; Skála, J. Evaluation of the effect of varying the angle of asphaltic concrete core on the behavior of the Meijaran Rockfill Dam. Coatings 2022, 12, 720. [Google Scholar] [CrossRef]

- Wen, L.; Yang, Y.; Li, Y.; Liu, Y. Effect of Valley Topography on the Behavior of Asphalt Concrete Core Walls in Earthen Dams. Int. J. Geomech. 2024, 24, 04024165. [Google Scholar] [CrossRef]

- Wang, W.; Höeg, K.; Zhang, Y. Design and performance of the Yele asphalt-core rockfill dam. Can. Geotech. J. 2010, 47, 1365–1381. [Google Scholar] [CrossRef]

- ICOLD. Asphalt Concrete Cores for Embankment Dams; Bulletin 179; International Commission on Large Dams (ICOLD): Paris, France, 2018. [Google Scholar]

- Tong, Y.; Shen, B.; Liu, J.; Zhao, J. Characterization of hard-grade asphalt using entropy analysis. Pet. Sci. Technol. 2017, 35, 703–709. [Google Scholar] [CrossRef]

- Tong, Y.; Shen, B.; Liu, J.; Yao, Z.; Fang, W. Preparation and evaluation of 30# hard grade asphalt. Pet. Sci. Technol. 2017, 35, 436–442. [Google Scholar] [CrossRef]

- Song, L.; Xie, X.; Tu, P.; Fan, J.; Gao, J. Study on Aging Mechanism and High-Temperature Rheological Properties of Low-Grade Hard Asphalt. Materials 2023, 16, 5641. [Google Scholar] [CrossRef]

- Qasrawi, H.; Asi, I. Effect of bitumen grade on hot asphalt mixes properties prepared using recycled coarse concrete aggregate. Constr. Build. Mater. 2016, 121, 18–24. [Google Scholar] [CrossRef]

- Hafeez, I.; Kamal, M.A.; Mirza, M.W.; Barkatullah; Bilal, S. Laboratory fatigue performance evaluation of different field laid asphalt mixtures. Constr. Build. Mater. 2013, 44, 792–797. [Google Scholar] [CrossRef]

- Junaid, M.; Irfan, M.; Ahmed, S.; Ali, Y. Effect of binder grade on performance parameters of asphaltic concrete paving mixtures. Int. J. Pavement Res. Technol. 2018, 11, 435–444. [Google Scholar] [CrossRef]

- Zhong, L.; Tong, S.; Li, G. Influence of asphalt grade on flexural performance of asphalt concrete as an impervious core in embankment dam. J. Yangtze River Sci. Res. Inst. 2018, 35, 116–118. (In Chinese) [Google Scholar]

- Höeg, K.; Wang, W. Asphalt Core Embankment Dams; CRC Press: Boca Raton, FL, USA, 2025; pp. 22–28. [Google Scholar]

- Cao, W.; Wen, L.; Li, Y.; Liu, Y.; Si, Z.; Wu, L. Influence of difference in deformation modulus between asphalt concrete core and transition layer on core behavior and difference threshold determination. Comput. Geotech. 2024, 169, 106186. [Google Scholar] [CrossRef]

- Gao, J.; Dang, F.; Ma, Z.; Xue, Y.; Ren, J. Improvement methods for reduction of the high stress of ultra-high asphalt concrete core dams. Appl. Sci. 2019, 9, 4618. [Google Scholar] [CrossRef]

- Gao, J.; Dang, F.; Ma, Z. Investigation for the key technologies of ultra-high asphalt concrete core rockfill dams. Soils Found. 2019, 59, 1740–1757. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhu, Y. Investigation on conditions of hydraulic fracturing for asphalt concrete used as impervious core in dams. Constr. Build. Mater. 2015, 93, 775–781. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Wang, W.; Feng, S. Could Hydraulic fracturing take place for asphalt core in embankment dams through possible cracks in the core? Appl. Sci. 2023, 13, 1523. [Google Scholar] [CrossRef]

- Feng, S.; Wang, W.; Hu, K.; Höeg, K. Stress-strain-strength behavior of asphalt core in embankment dams during construction. Constr. Build. Mater. 2020, 259, 119706. [Google Scholar] [CrossRef]

- Ning, Z.; Liu, Y.; Wang, W.; Dong, J.; Meng, X.; Wang, Q. Crack propagation and non-uniform deformation analysis in hydraulic asphalt concrete: Insights from X-ray CT scanning and digital volume correlation. Constr. Build. Mater. 2024, 411, 134704. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, S.; Wang, W.; Zhu, Y. Effects of test-specimen boundary conditions on the interpretation of stress-strain results for hydraulic asphalt concrete. Arab. J. Sci. Eng. 2025, 50, 8011–8025. [Google Scholar] [CrossRef]

- Ning, Z.; Liu, Y.; Wang, W. Compressive behavior of hydraulic asphalt concrete under different temperatures and strain rates. J. Mater. Civ. Eng. 2021, 33, 04021013. [Google Scholar] [CrossRef]

- Ning, Z.; Liu, Y.; Wang, W. Experimental study on compressive properties and impermeability of hydraulic asphalt concrete under different temperatures. J. Hydraul. Eng. 2020, 51, 527–535. (In Chinese) [Google Scholar]

- Ning, Z.; Liu, Y.; Wang, W.; Dong, J.; Meng, X. Experimental study on effect of temperature on direct tensile behavior of hydraulic asphalt concrete at different strain rates. J. Mater. Civ. Eng. 2022, 34, 04022143. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Wang, W.; Ning, Z.; Feng, S.; Höeg, K. Compressive and tensile stress–strain-strength behavior of asphalt concrete at different temperatures and strain rates. Constr. Build. Mater. 2021, 311, 125362. [Google Scholar] [CrossRef]

- Dong, J.; Ding, Y.; Liu, Y.; Ning, Z.; Qi, Y. Tensile test and discrete element study on recycled aggregate hydraulic asphalt concrete. Constr. Build. Mater. 2024, 450, 138538. [Google Scholar] [CrossRef]

- He, J.; Lu, J.; Liu, L.; Yang, W.; Chen, P.; Ding, X. Bending performance evaluation of large grain hydraulic asphalt concrete based on the coefficient of variation. KSCE J. Civ. Eng. 2024, 28, 3420–3429. [Google Scholar] [CrossRef]

- DL/T 5362-2018; Test Code for Hydraulic Bitumen Concrete. China Electric Power Press: Beijing, China, 2018. (In Chinese)

- Duncan, J.M.; Chang, C.Y. Nonlinear analysis of stress and strain in soils. J. Soil Mech. Found. Div. ASCE 1970, 96, 1629–1653. [Google Scholar] [CrossRef]

- Wang, W.; Høeg, K. Simplified material model for analysis of asphalt core in embankment dams. Constr. Build. Mater. 2016, 126, 199–207. [Google Scholar] [CrossRef]

- He, J.; Li, H.; Yang, W.; Liu, L. Permeability study of asphalt concrete in core wall under shear large deformation conditions. J. Hydraul. Eng. 2024, 55, 686–697. (In Chinese) [Google Scholar]

- Wang, Z.; Hao, J.; Yang, J.; Cao, Y.; Li, X.; Liu, S. Experimental study on hydraulic fracturing of high asphalt concrete core rock-fill dam. Appl. Sci. 2019, 9, 2285. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Wen, L.; Li, W.; Zhang, Y.; Bu, P.; Sun, X. A hybrid approach combining UD and GA-CV-SVM to evaluate shear performance in high asphalt concrete core. Comput. Geotech. 2024, 176, 106812. [Google Scholar] [CrossRef]

- Wang, W. 2024. A material stress-strain-time-temperature creep model for the analysis of asphalt cores in embankment dams. Appl. Sci. 2024, 14, 3399. [Google Scholar] [CrossRef]

| Test Properties | Sieve Size (mm) | ||||

|---|---|---|---|---|---|

| Coarse Aggregate | Fine Aggregate | Filler | |||

| 9.5–19 | 4.75–9.5 | 2.36–4.75 | 0.075–2.36 | 0–0.075 | |

| Density (g/cm3) | 2.71 | 2.71 | 2.72 | 2.73 | 2.73 |

| Water Absorption (%) | 0.50 | 0.64 | 0.72 | 0.93 | — |

| Mud content (%) | 0.0 | 0.0 | 0.0 | 1.1 | — |

| Adhesion to asphalt | 4 | — | — | — | — |

| Durability (%) | 2.8 | 2.5 | — | ||

| Hydrophilicity coefficient | — | — | — | — | 0.76 |

| Moisture content (%) | — | — | — | — | 0.18 |

| Test Properties | Karamay A70 | Karamay A90 | Karamay A110 | |

|---|---|---|---|---|

| Density (g/cm3) | 0.979 | 0.983 | 0.981 | |

| Penetration (100 g, 5 s, 25 °C) (0.1 mm) | 66.5 | 86.4 | 103.8 | |

| Ductility (5 cm/min, 10 °C) (cm) | 55.0 | >100 | >100 | |

| Softening point (°C) | 53.0 | 50.4 | 47.9 | |

| TFOT | Loss by mass (%) | −0.06 | −0.08 | −0.11 |

| Residual penetration (%) | 83.3 | 82.0 | 83.3 | |

| Residual ductility (cm) | 15.1 | 32.8 | 58.1 | |

| Sieve Size (mm) | Bitumen | |||||

|---|---|---|---|---|---|---|

| Coarse Aggregate | Fine Aggregate | Filler | ||||

| 9.5–19 | 4.75–9.5 | 2.36–4.75 | 0.075–2.36 | 0–0.075 | — | |

| Mix proportion (%) | 23.9 | 18.2 | 15.9 | 30.0 | 12.0 | 7.5 |

| Test Type | Bitumen Grade | Temperature (°C) | Loading Rate (mm/min) | Confining Pressure (kPa) |

|---|---|---|---|---|

| Direct tension test | A70, A90, A110 | 8.6 | 2.2 | - |

| Uniaxial compression test | 1.0 | - | ||

| Bending test | 1.67 | - | ||

| Triaxial compression test | 0.3 | 300, 600, 900, 1200 1500, 2000, 2500, 3000 |

| Confining Pressure σ3 (kPa) | A70 | A90 | A110 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (kPa) | Relative Error (%) | (kPa) | Relative Error (%) | (kPa) | Relative Error (%) | ||||

| Test Results | Calculated Results Equation (1) | Test Results | Calculated Results Equation (1) | Test Results | Calculated Results Equation (1) | ||||

| 300 | 1903.1 | 1948.4 | 2.38 | 1652.7 | 1681.1 | 1.72 | 1515.2 | 1594.0 | 5.20 |

| 600 | 2460.1 | 2463.2 | 0.12 | 2156.4 | 2158.4 | 0.09 | 2062.8 | 2065.4 | 0.13 |

| 900 | 2922.3 | 2977.9 | 1.90 | 2592.6 | 2635.7 | 1.67 | 2448.4 | 2536.7 | 3.60 |

| 1200 | 3432.4 | 3492.6 | 1.75 | 3002.8 | 3113.1 | 3.67 | 2825.8 | 3008.0 | 6.45 |

| 1500 | 3752.6 | 4007.3 | 6.79 | 3394.4 | 3590.4 | 5.77 | 3130.5 | 3479.3 | 11.14 |

| 2000 | 4141.4 | 4865.2 | 17.48 | 3788.7 | 4386.0 | 15.77 | 3424.7 | 4264.8 | 24.53 |

| 2500 | 4631.8 | 5723.1 | 23.56 | 4137.8 | 5181.5 | 25.22 | 3662.3 | 5050.3 | 37.90 |

| 3000 | 5072.4 | 6580.9 | 29.74 | 4486.3 | 5977.1 | 33.23 | 3860.1 | 5835.9 | 51.19 |

| Confining Pressure σ3 (kPa) | A70 | A90 | A110 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (kPa) | Relative Error (%) | (kPa) | Relative Error (%) | (kPa) | Relative Error (%) | ||||

| Test Results | Calculated Results Equation (2) | Test Results | Calculated Results Equation (2) | Test Results | Calculated Results Equation (2) | ||||

| 300 | 1903.1 | 1948.4 | 0.85 | 1652.7 | 1681.1 | 1.39 | 1515.2 | 1594.0 | 2.89 |

| 600 | 2460.1 | 2463.2 | 4.64 | 2156.4 | 2158.4 | 5.27 | 2062.8 | 2065.4 | 2.30 |

| 900 | 2922.3 | 2977.9 | 5.37 | 2592.6 | 2635.7 | 5.06 | 2448.4 | 2536.7 | 3.19 |

| 1200 | 3432.4 | 3492.6 | 1.94 | 3002.8 | 3113.1 | 3.17 | 2825.8 | 3008.0 | 1.47 |

| 1500 | 3752.6 | 4007.3 | 2.91 | 3394.4 | 3590.4 | 0.72 | 3130.5 | 3479.3 | 0.86 |

| 2000 | 4141.4 | 4865.2 | 5.69 | 3788.7 | 4386.0 | 2.18 | 3424.7 | 4264.8 | 4.00 |

| 2500 | 4631.8 | 5723.1 | 3.89 | 4137.8 | 5181.5 | 2.68 | 3662.3 | 5050.3 | 6.35 |

| 3000 | 5072.4 | 6580.9 | 2.28 | 4486.3 | 5977.1 | 1.89 | 3860.1 | 5835.9 | 8.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Yang, Z.; Ran, C.; He, J. Stress–Strain–Strength Behavior of Hydraulic Asphalt Concrete at Different Bitumen Grades. Appl. Sci. 2025, 15, 12596. https://doi.org/10.3390/app152312596

Yang X, Yang Z, Ran C, He J. Stress–Strain–Strength Behavior of Hydraulic Asphalt Concrete at Different Bitumen Grades. Applied Sciences. 2025; 15(23):12596. https://doi.org/10.3390/app152312596

Chicago/Turabian StyleYang, Xing, Zhihao Yang, Congyong Ran, and Jianxin He. 2025. "Stress–Strain–Strength Behavior of Hydraulic Asphalt Concrete at Different Bitumen Grades" Applied Sciences 15, no. 23: 12596. https://doi.org/10.3390/app152312596

APA StyleYang, X., Yang, Z., Ran, C., & He, J. (2025). Stress–Strain–Strength Behavior of Hydraulic Asphalt Concrete at Different Bitumen Grades. Applied Sciences, 15(23), 12596. https://doi.org/10.3390/app152312596