Study of a High-Power, Long-Pulse-Width Acousto-Optical Q-Switched 1064 nm Laser Based on a Multi-Pass Cavity

Abstract

1. Introduction

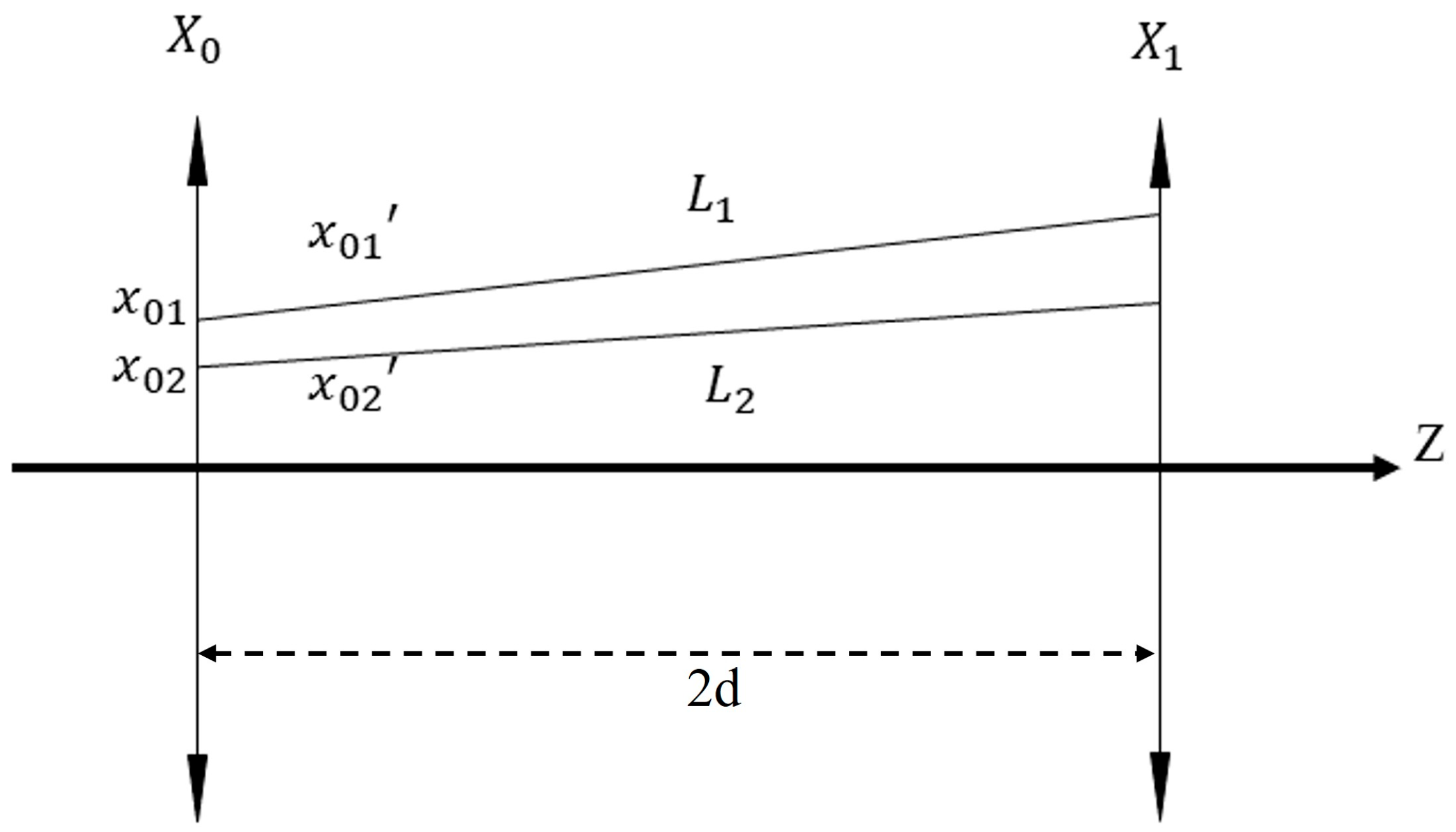

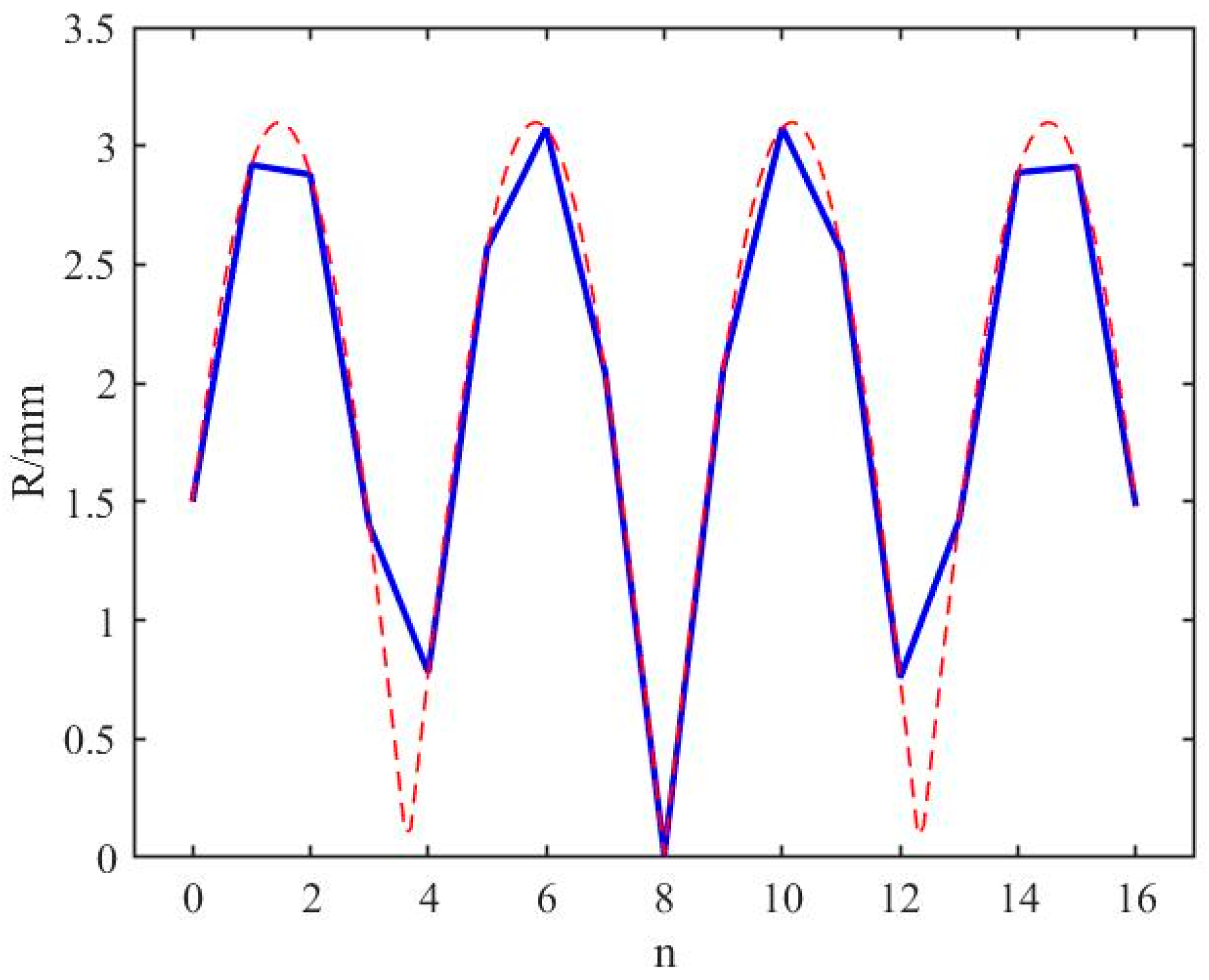

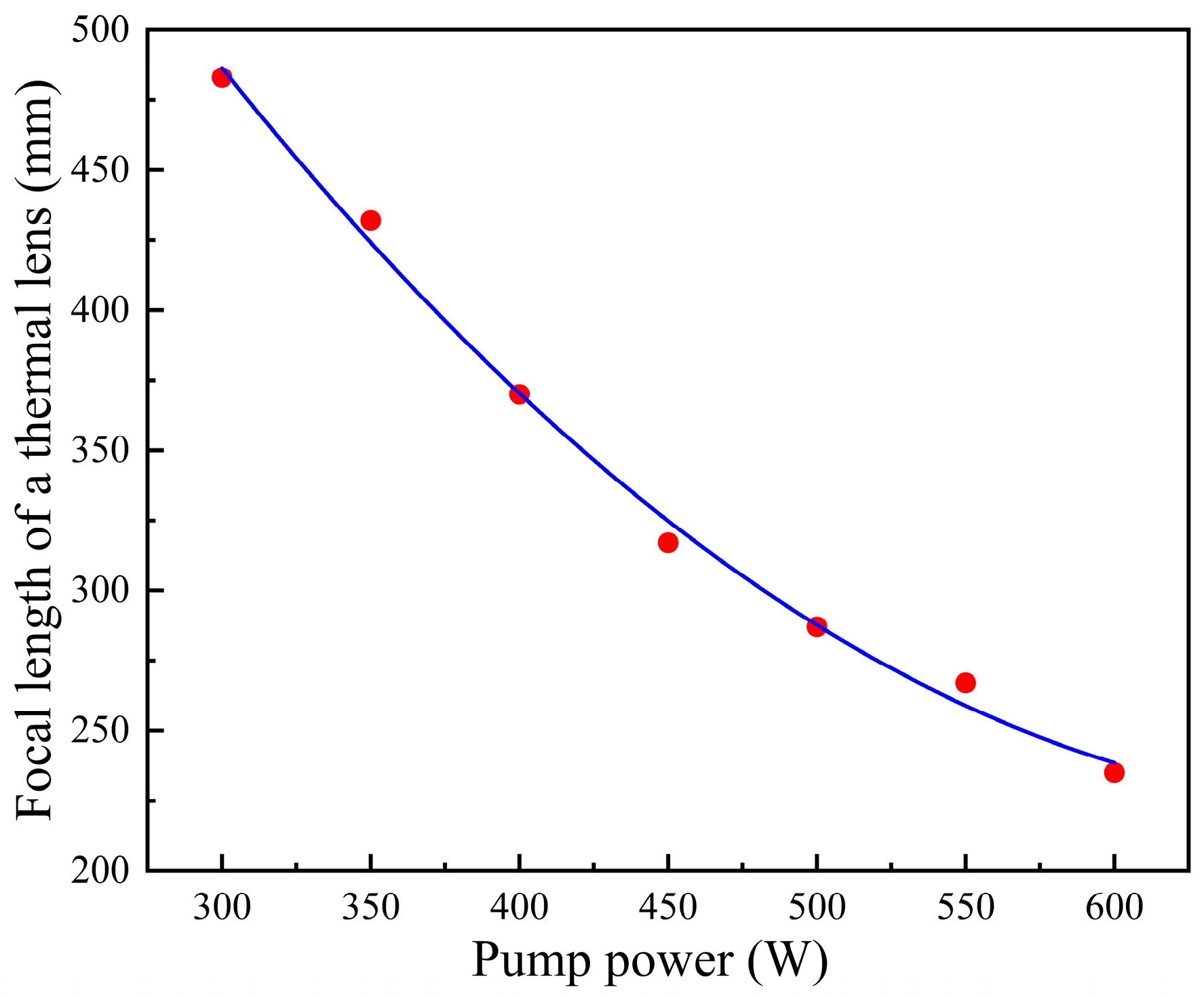

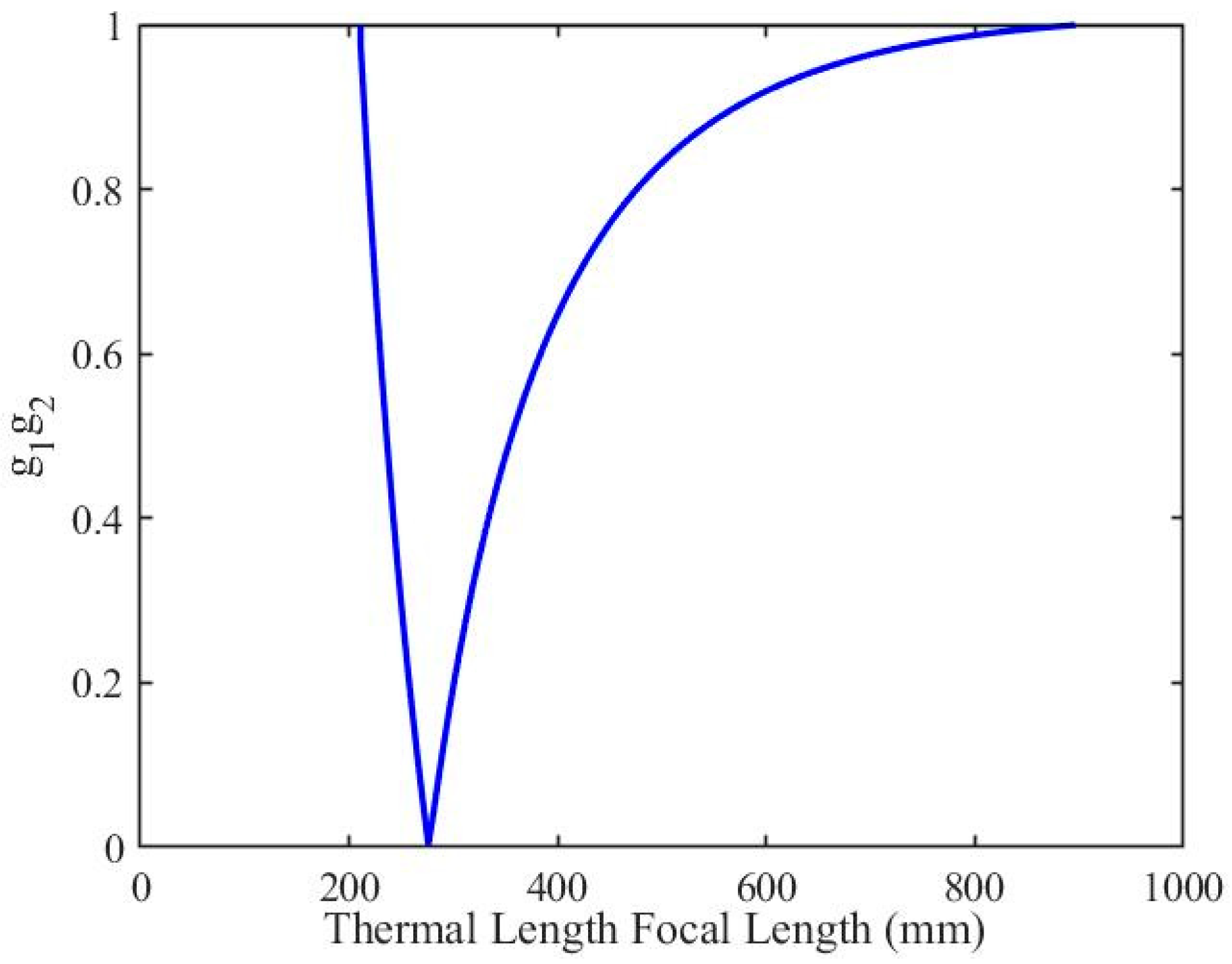

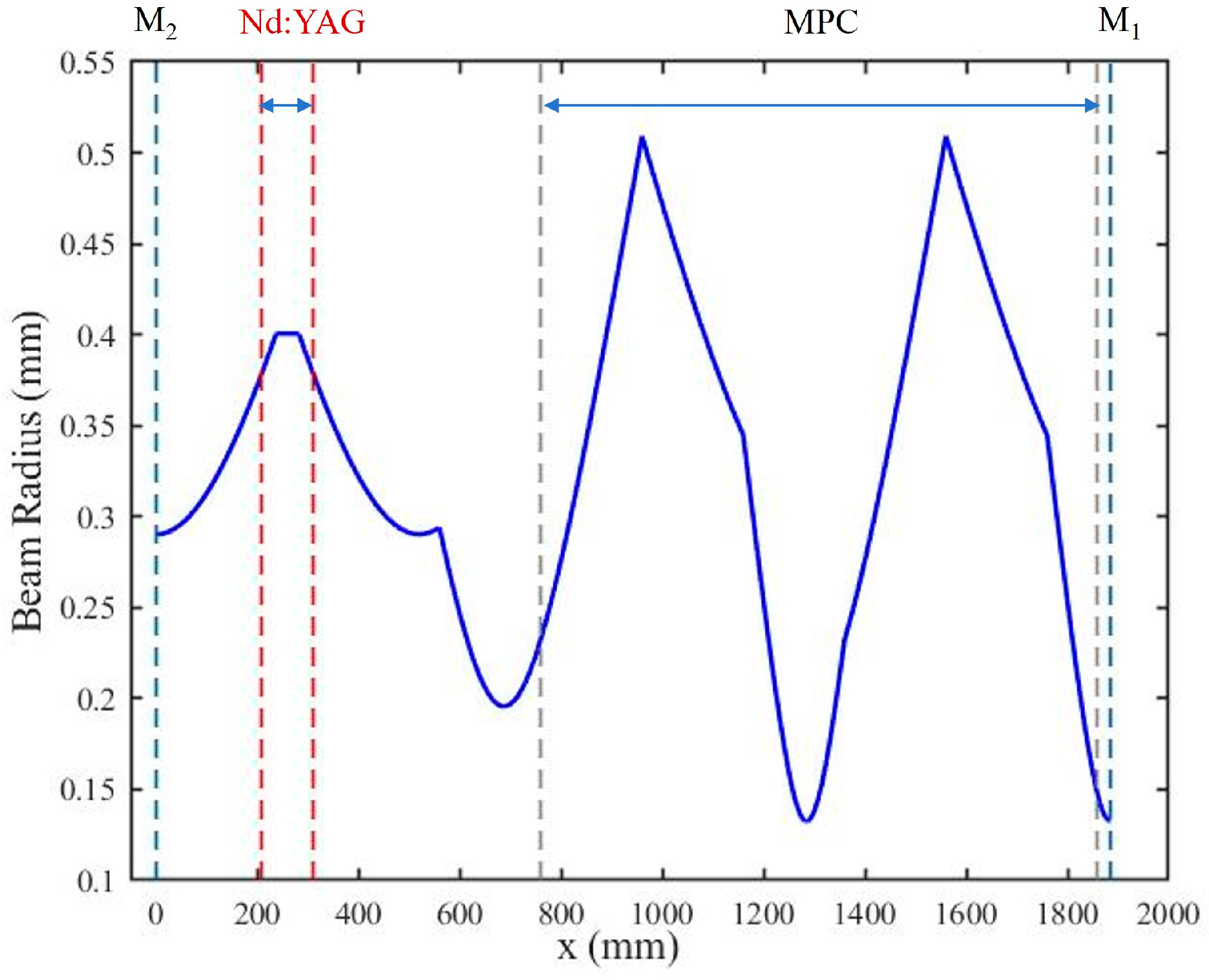

2. Theoretical Analysis

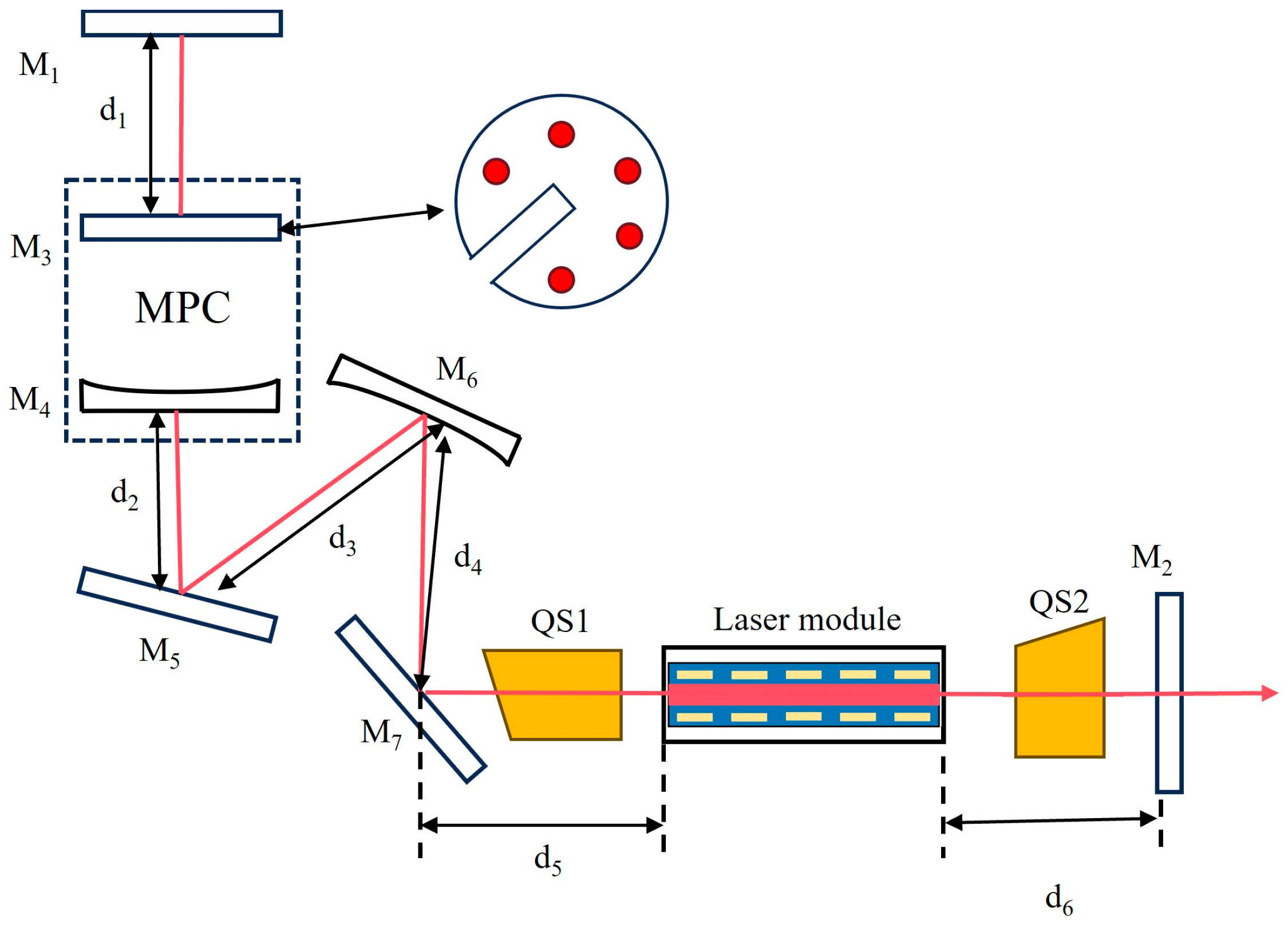

3. Experimental Setup

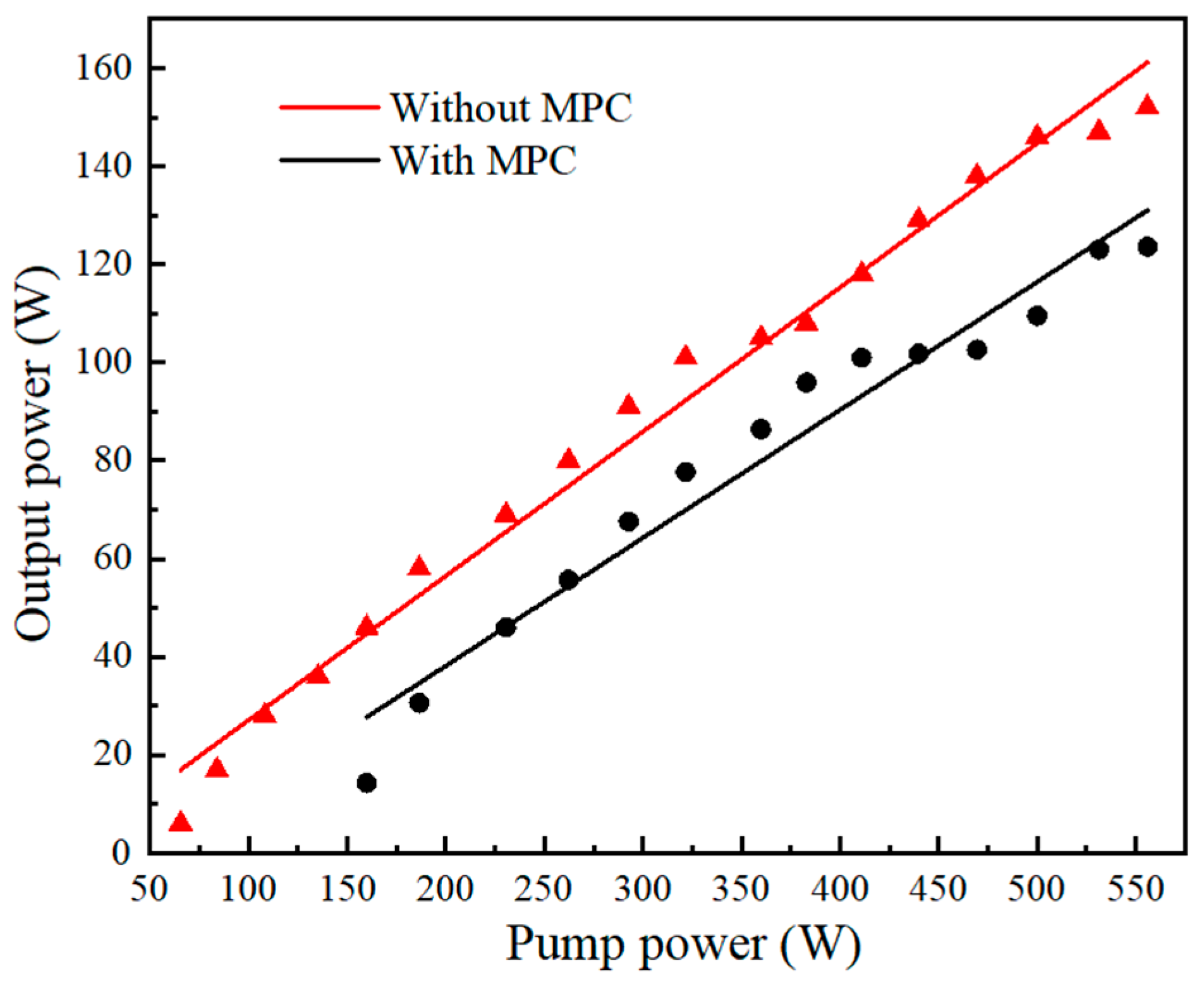

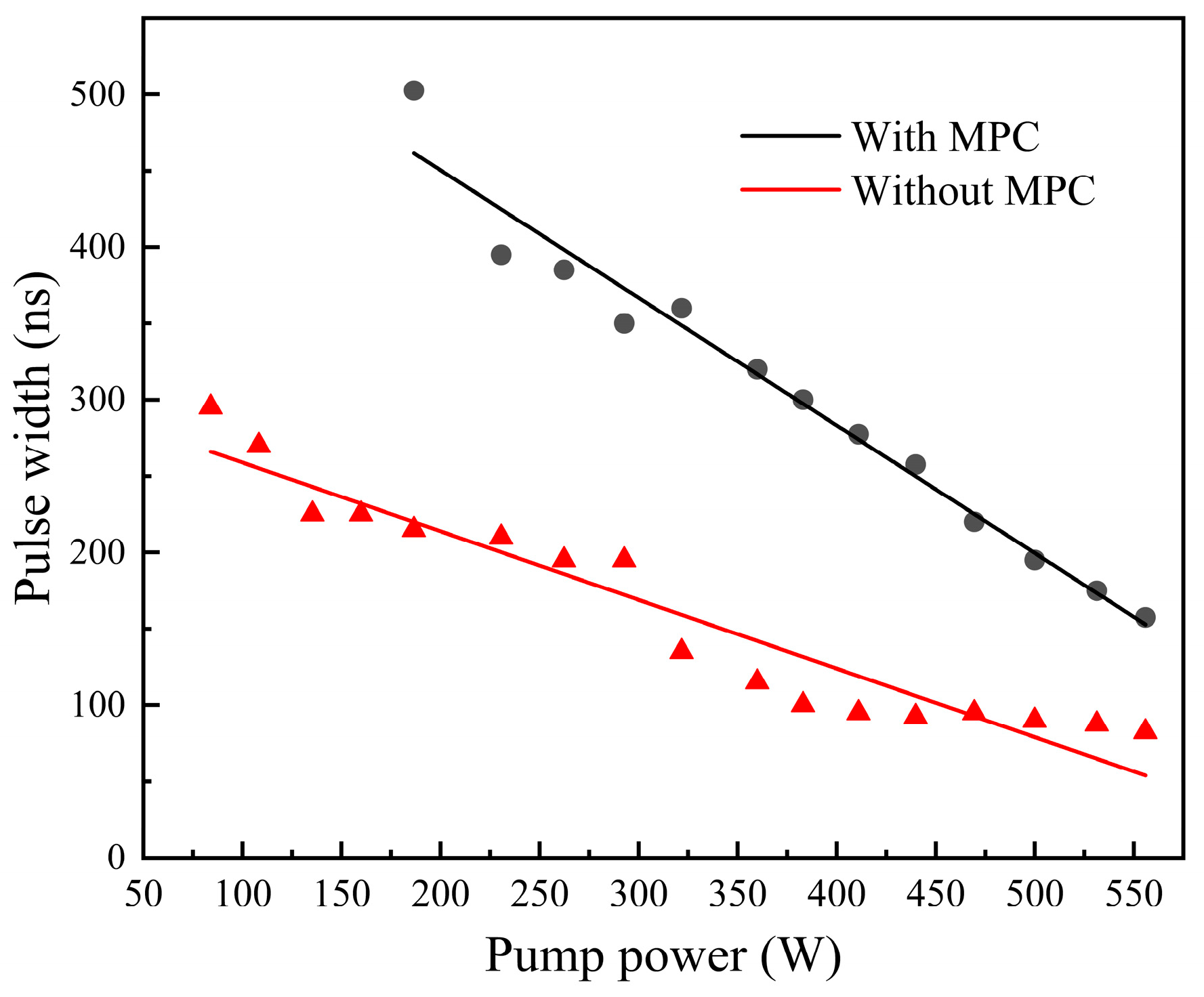

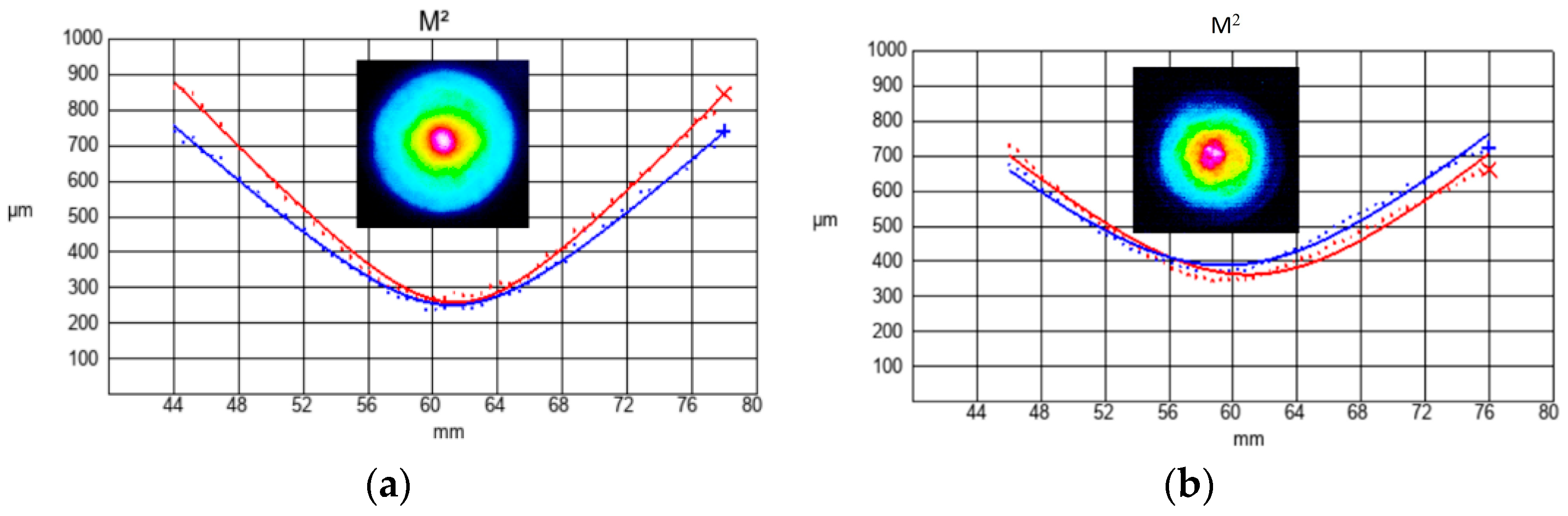

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, X.; Li, L.; Yang, S.; Xu, M.; Zhong, M.; Wang, B.; Jiang, Y. Optimization of nanosecond laser drilling strategy on CFRP hole quality. J. Mech. Work. Technol. 2024, 332, 118559. [Google Scholar] [CrossRef]

- Tang, C.W.; Li, K.M.; Yang, M.; Liao, H.C.; Young, H.T. Improving the dielectric breakdown field of silicon light-emitting-diode sub-mount by a hybrid nanosecond laser drilling strategy. Microelectron. Reliab. 2013, 53, 420–427. [Google Scholar] [CrossRef]

- Li, J.F.; Sun, Y.H.; Wang, W.H.; Bai, H.Y. Nanosecond-pulsed laser welding of metallic glass. J. Non-Cryst. Solids 2020, 537, 120016. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, Y.; Zhang, Y.; Wu, L.; Yang, C.; Yang, X.; Zhang, Z.; Zhao, Y. Signal restoration method for restraining the range walk error of Geiger-mode avalanche photodiode lidar in acquiring a merged three-dimensional image. Appl. Opt. 2017, 56, 3059–3063. [Google Scholar] [CrossRef] [PubMed]

- De Young, R.J.; Barnes, N.P. Profiling atmospheric water vapor using a fiber laser lidar system. Appl. Opt. 2010, 49, 562–567. [Google Scholar] [CrossRef]

- Wright, M.W.; Valley, G.C. Yb-doped fiber amplifier for deep-space optical communications. J. Light. Technol. 2005, 23, 1369. [Google Scholar] [CrossRef]

- Grzes, P.; Michalska, M.; Swiderski, J. Analysis of pulse position modulated fiber-based laser systems for deep space optical communication. In Proceedings of the International Conference on Space Optics—ICSO, Harkiduki, Greece, 9–12 October 2018; SPIE: Bellingham, NJ, USA, 2019; pp. 1953–1963. [Google Scholar]

- He, L.J.; Liu, K.; Bo, Y.; Wang, X.J.; Yang, J.; Liu, Z.; Zong, Q.S.; Peng, Q.J.; Cui, D.F.; Xu, Z.Y. Widely-duration-tunable nanosecond pulse Nd:YVO4 laser based on double Pockels cells. Laser Phys. Lett. 2018, 15, 055004. [Google Scholar] [CrossRef]

- Oztoprak, B.G.; Gonzalez, J.; Yoo, J.; Gulecen, T.; Mutlu, N.; Russo, R.E.; Gundogdu, O.; Demir, A. Analysis and classification of heterogeneous kidney stones using laser-induced breakdown spectroscopy (LIBS). Appl. Spectrosc. 2012, 66, 1353–1361. [Google Scholar] [CrossRef]

- Bai, Z.; Yuan, H.; Liu, Z.; Xu, P.; Gao, Q.; Williams, R.J.; Kitzler, O.; Mildren, R.P.; Wang, Y.; Lu, Z. Stimulated Brillouin scattering materials, experimental design and applications: A review. Opt. Mater. 2018, 75, 626–645. [Google Scholar] [CrossRef]

- Keyes, R.J.; Quist, T.M. Injection luminescent pumping of CaF2:U3+ with GaAs diode lasers. Appl. Phys. Lett. 1964, 4, 50–52. [Google Scholar] [CrossRef]

- Rutten, T.P.; Veitch, P.J.; Munch, J. Efficient pulse stretching of Q-switched lasers. IEEE J. Quantum Electron. 2008, 44, 911–915. [Google Scholar] [CrossRef]

- Schmid, W. Pulse stretching in a Q-switched Nd: YAG laser. IEEE J. Quantum Electron. 1980, 16, 790–794. [Google Scholar] [CrossRef]

- Gao, Z.; Xia, G.; Deng, T.; Lin, X.; Tang, X.; Fan, L.; Wu, Z. Nonlinear Dynamics of a Passively Q-Switched Solid-State Laser. J. Southwest Univ. Nat. Sci. Ed. 2023, 45, 195–203. [Google Scholar]

- Zhou, R.; Li, Y.; Zhu, R.; Zhang, Z.-X. Controlled pulse generation and annihilation dynamics in ultrafast fiber lasers. Acta Physica Sinica 2024, 73, 116–123. [Google Scholar] [CrossRef]

- Hönninger, C.; Paschotta, R.; Morier-Genoud, F.; Moser, M.; Keller, U. Q-switching stability limits of continuous-wave passive mode locking. J. Opt. Soc. Am. B 1999, 16, 46–56. [Google Scholar] [CrossRef]

- Yan, P.; Gong, M.; Xie, T.; Liu, X.-Z. Stabilization of pulse-to-pulse energy and width by gain-controlled prelase in laser-diode-pumped Q-switched laser. Opt. Eng. 2003, 42, 159–162. [Google Scholar] [CrossRef]

- Sennaroglu, A.; Fujimoto, J.G. Design criteria for Herriott-type multi-pass cavities for ultrashort pulse lasers. Opt. Express 2003, 11, 1106–1113. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, H.; Chen, X.; Bi, Y. Design method of variable optical path length multi-pass cell. Appl. Phys. B 2021, 127, 12. [Google Scholar] [CrossRef]

- Omar, A.; Vogel, T.; Hoffmann, M.; Saraceno, C.J. Spectral broadening of 2-mJ femtosecond pulses in a compact air-filled convex–concave multi-pass cell. Opt. Lett. 2023, 48, 1458–1461. [Google Scholar] [CrossRef]

- Li, P.-B.; Teng, H.; Tian, W.-L.; Huang, Z.-W.; Zhu, J.-F.; Zhong, S.-Y.; Yun, C.-X.; Liu, W.-J.; Wei, Z.-Y. Nonlinear pulse compression technique based on inmulti-pass plano-cancave cavity. Acta Phys. Sin. 2024, 73, 142–149. [Google Scholar]

- Song, Y.J.; Liu, K.; Zong, N.; Tu, W.; Bo, Y.; Cui, D.F.; Peng, Q.J.; Xu, Z.Y. Pulse duration adjusted by changing the cavity length with a multi-pass cavity in a Q-switched Nd: YAG laser. Opt. Lett. 2019, 44, 4471–4474. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Yan, Z. Parallel Deviation of Concave Mirrors in Herriott Multipass Cells. In Proceedings of the 2012 International Conference on Industrial Control and Electronics Engineering, Xi’an, China, 23–25 August 2012; IEEE: New York, NY, USA, 2012; pp. 889–892. [Google Scholar]

- Li, Q.; Wang, Z.M.; Wang, Z.Y. Thermal Lens Focal Length Measurement of High Power Lamp Pumped CW Nd:YAG Laser. Chin. J. Lasers 2004, 31, 1117–1120. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Lv, Z.; Ding, Y.; Li, Q.; Hu, J.; Deng, C.; Lan, T.; Yan, A.; Liu, Y.; Liu, X.; et al. Study of a High-Power, Long-Pulse-Width Acousto-Optical Q-Switched 1064 nm Laser Based on a Multi-Pass Cavity. Appl. Sci. 2025, 15, 12536. https://doi.org/10.3390/app152312536

Li W, Lv Z, Ding Y, Li Q, Hu J, Deng C, Lan T, Yan A, Liu Y, Liu X, et al. Study of a High-Power, Long-Pulse-Width Acousto-Optical Q-Switched 1064 nm Laser Based on a Multi-Pass Cavity. Applied Sciences. 2025; 15(23):12536. https://doi.org/10.3390/app152312536

Chicago/Turabian StyleLi, Wenbo, Zhaochen Lv, Yu Ding, Qingxuan Li, Jiapeng Hu, Chenpeng Deng, Tian Lan, Anru Yan, Youqiang Liu, Xuesheng Liu, and et al. 2025. "Study of a High-Power, Long-Pulse-Width Acousto-Optical Q-Switched 1064 nm Laser Based on a Multi-Pass Cavity" Applied Sciences 15, no. 23: 12536. https://doi.org/10.3390/app152312536

APA StyleLi, W., Lv, Z., Ding, Y., Li, Q., Hu, J., Deng, C., Lan, T., Yan, A., Liu, Y., Liu, X., & Wang, Z. (2025). Study of a High-Power, Long-Pulse-Width Acousto-Optical Q-Switched 1064 nm Laser Based on a Multi-Pass Cavity. Applied Sciences, 15(23), 12536. https://doi.org/10.3390/app152312536