A Review on Piezoelectric Ultrasonic and Peristaltic Methods for Precision Motion and Measurement

Abstract

1. Introduction

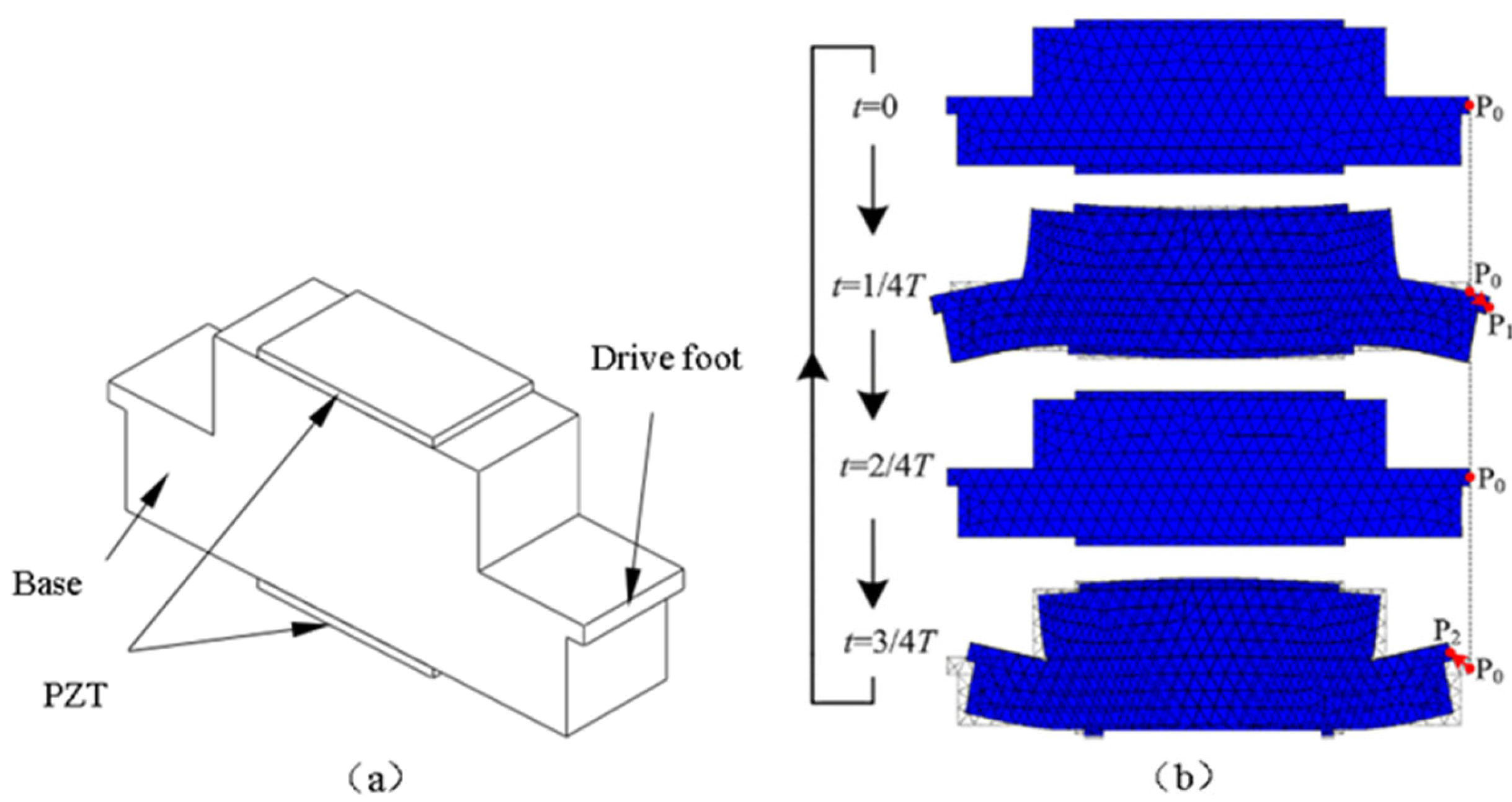

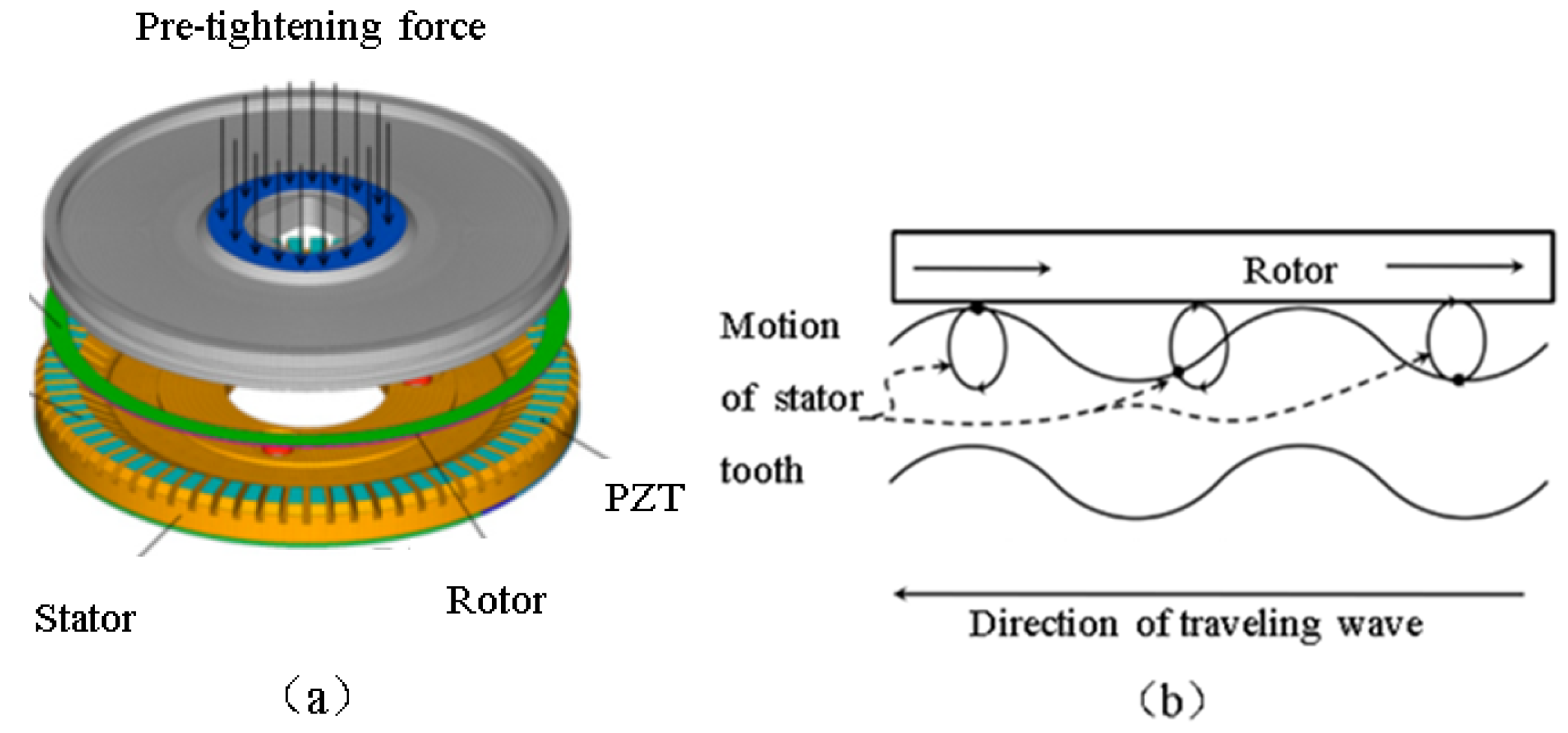

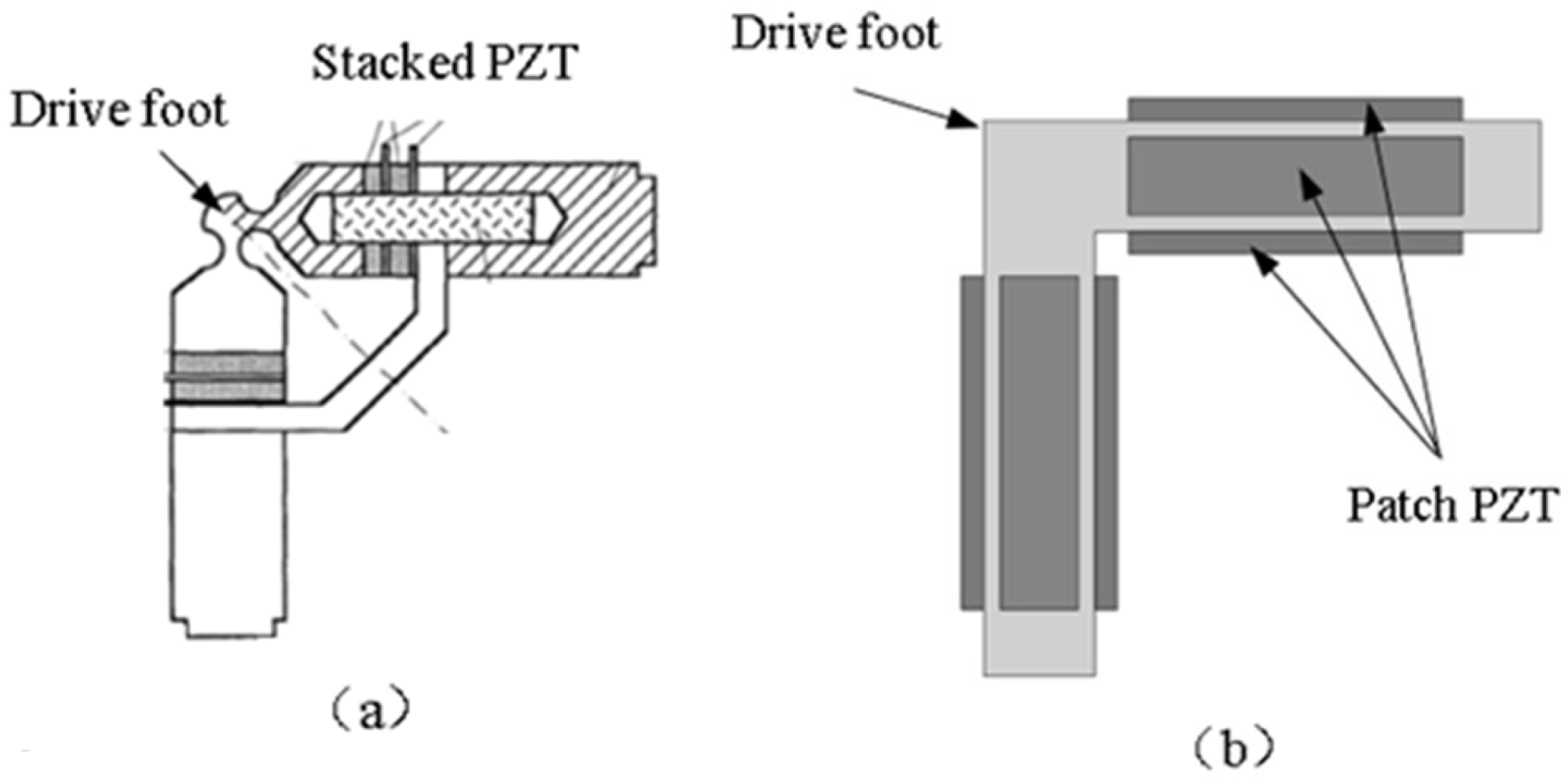

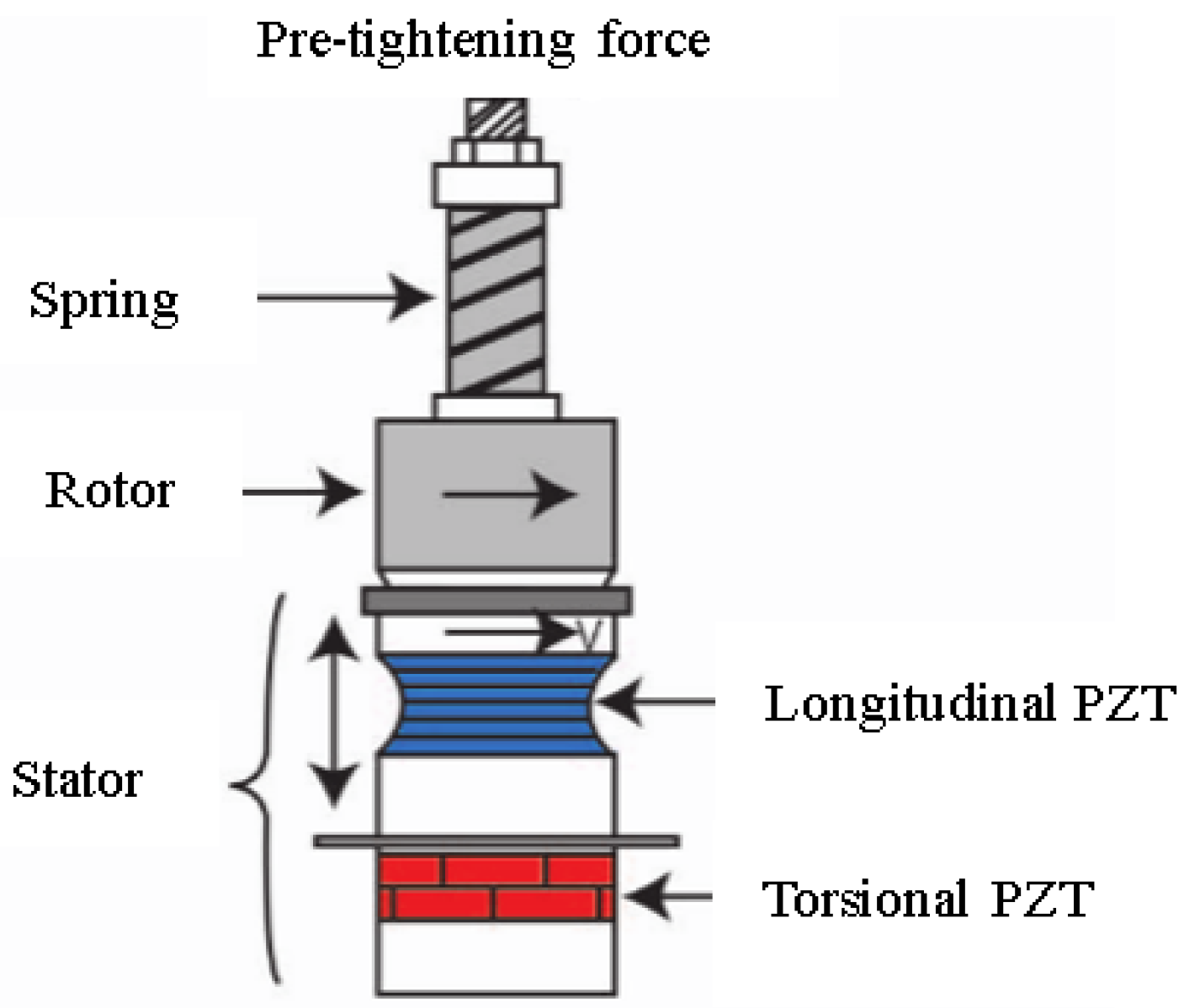

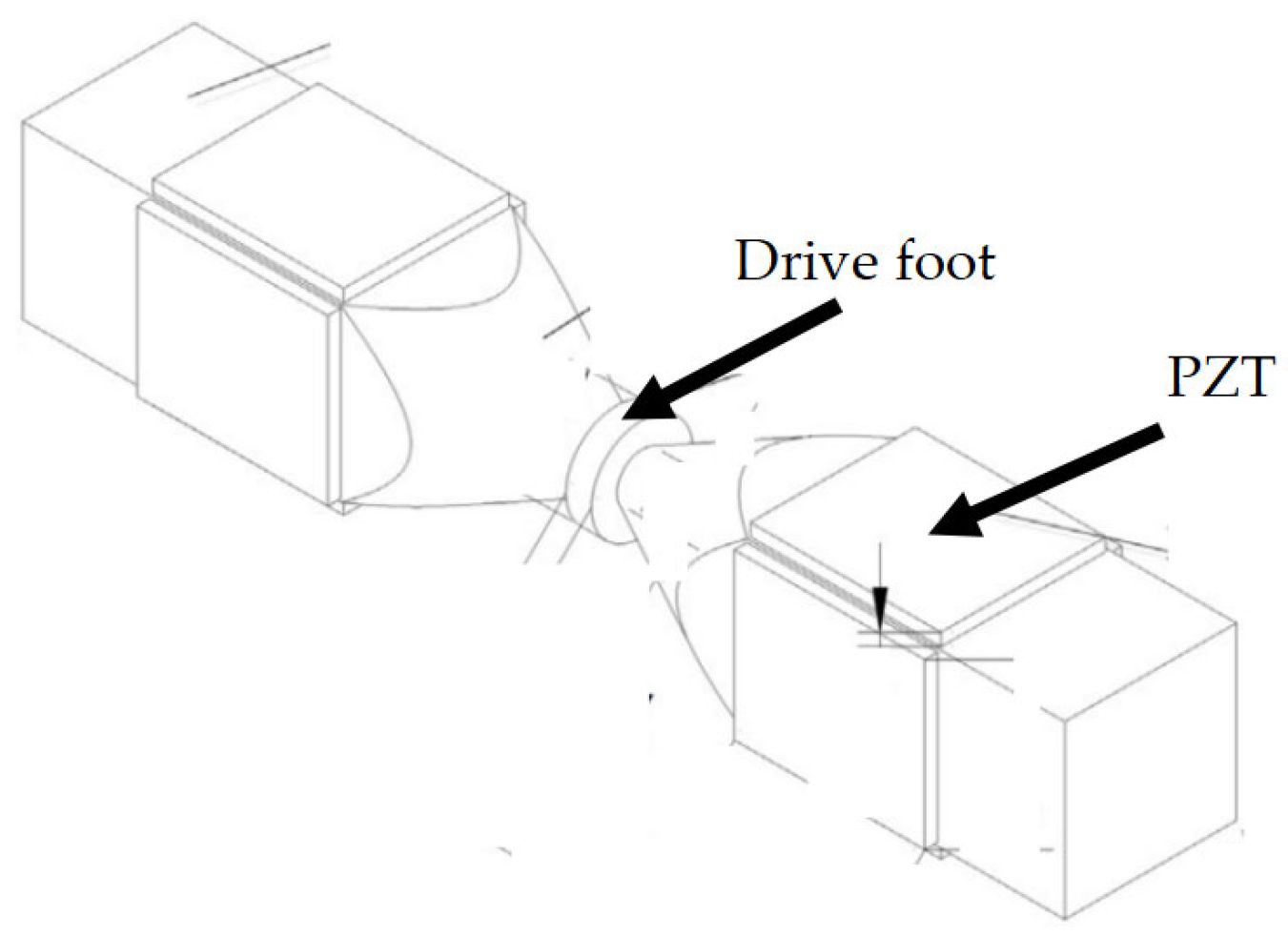

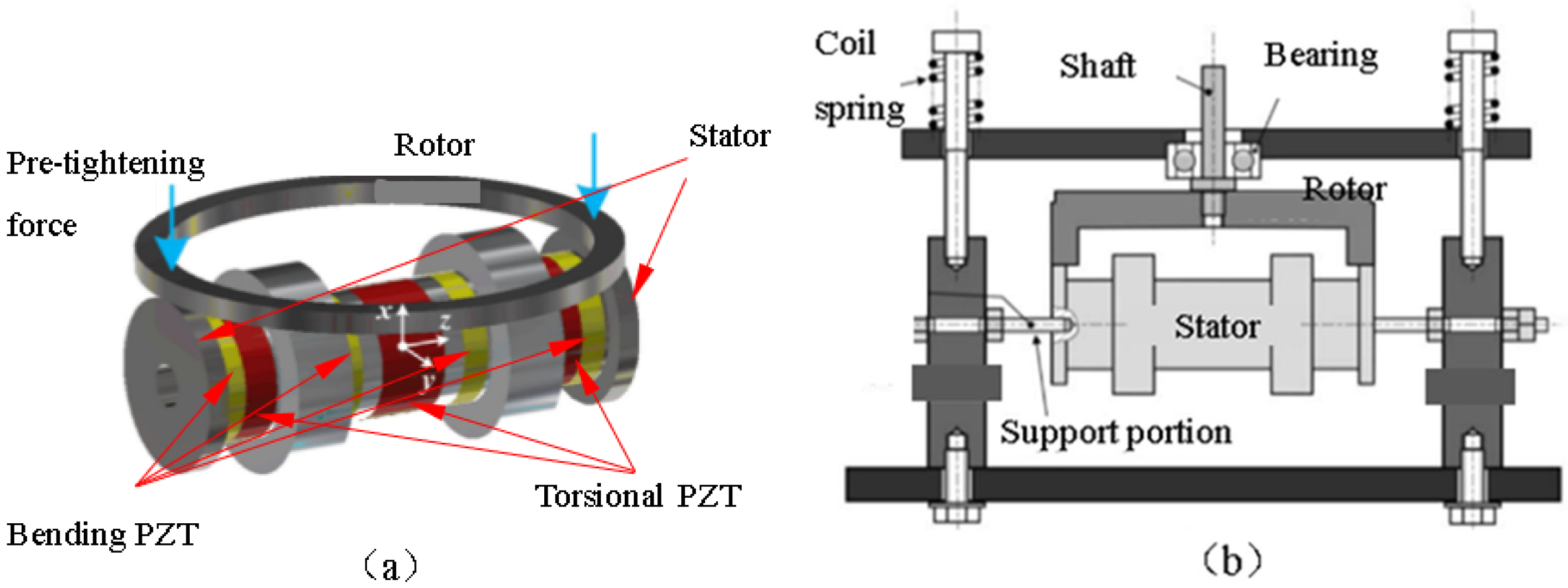

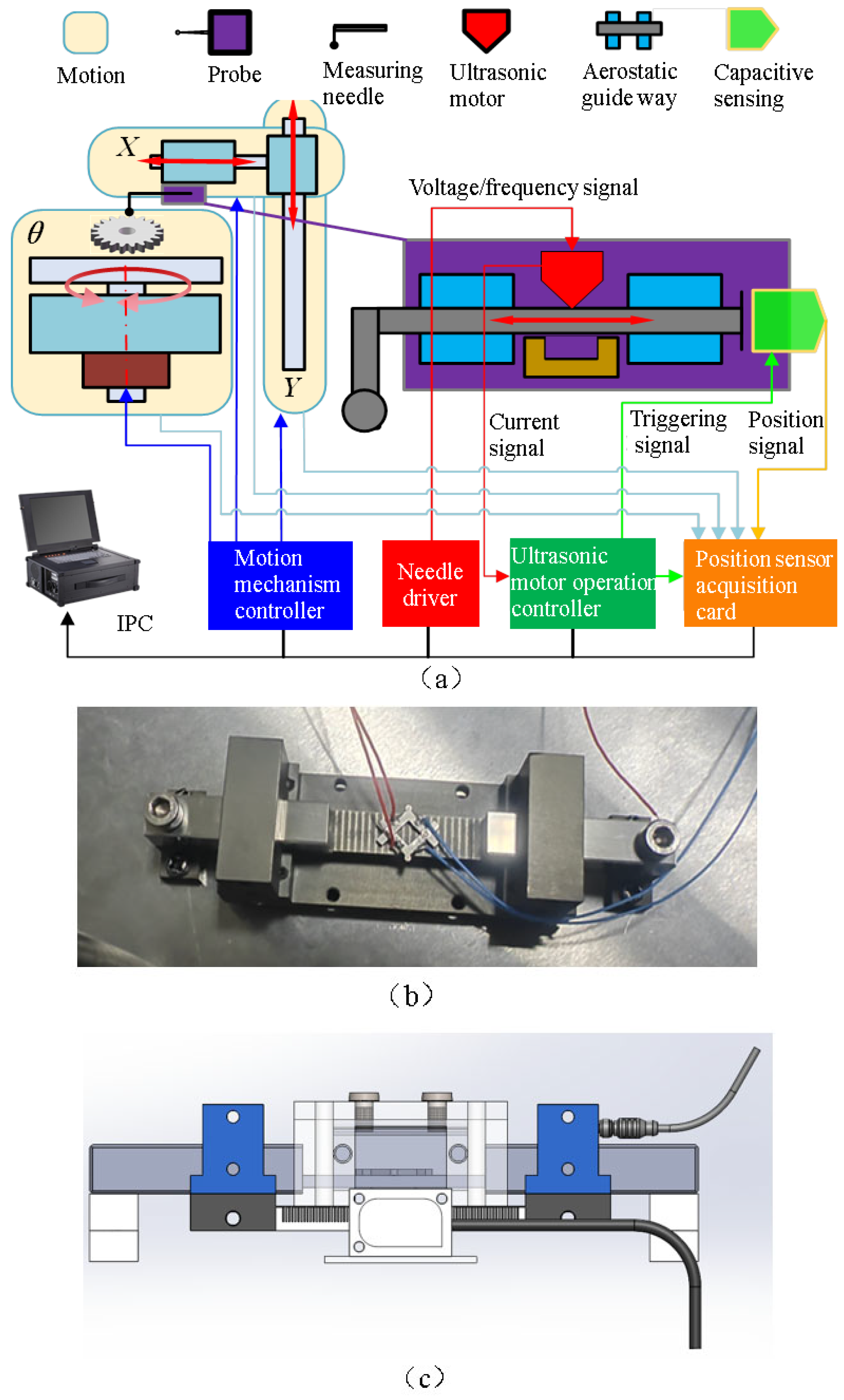

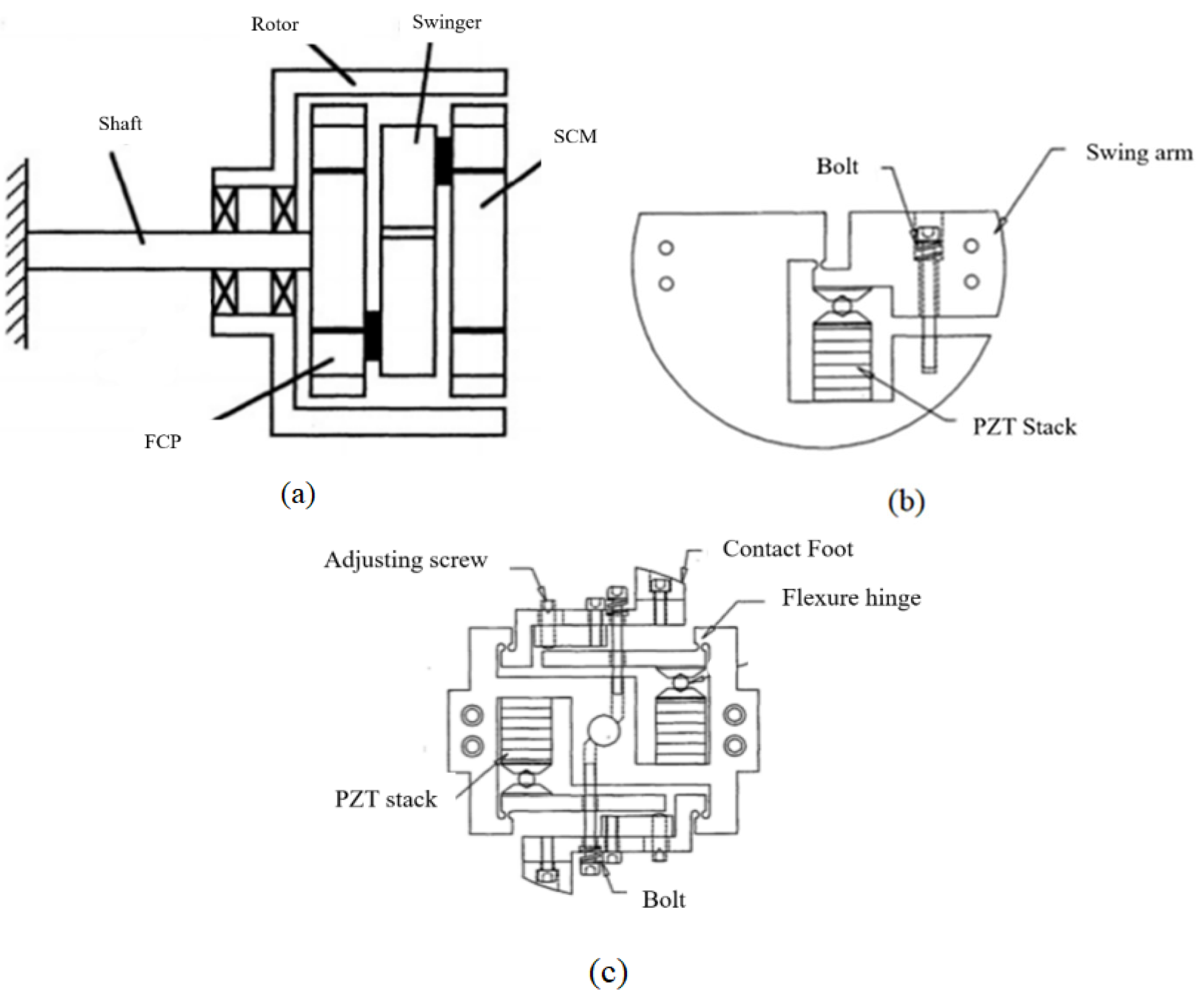

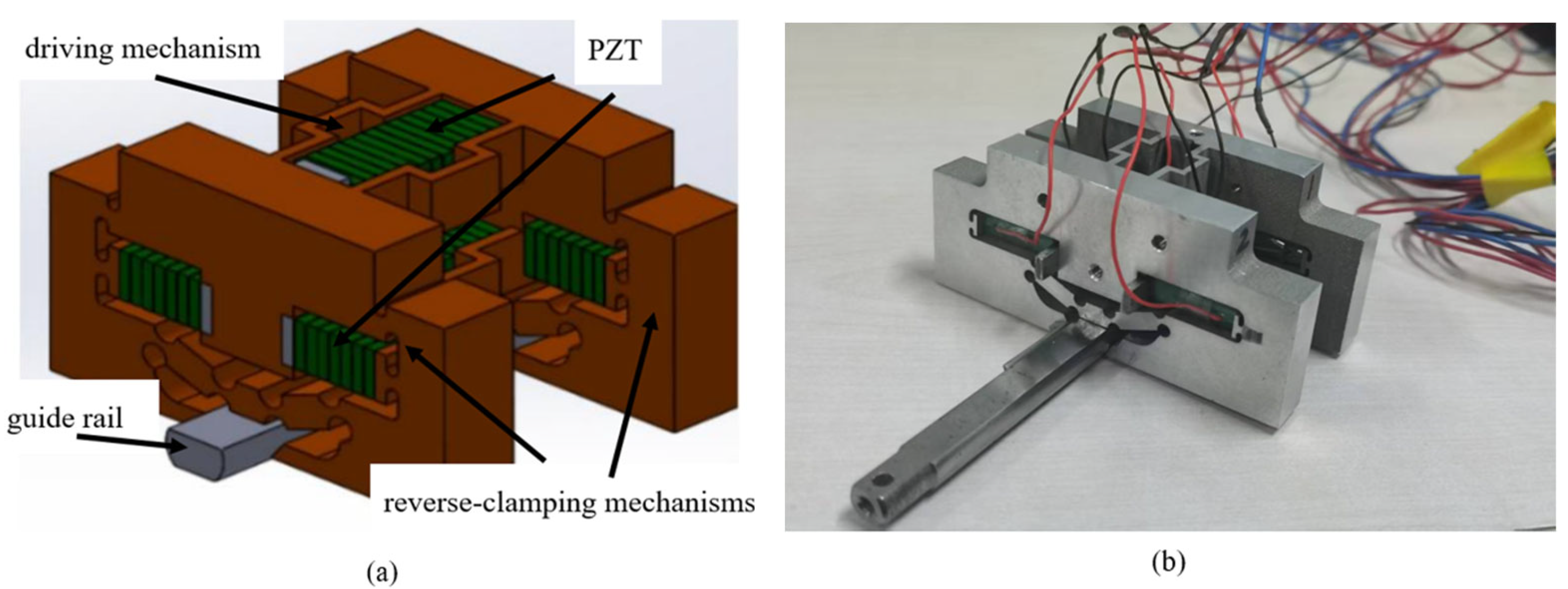

2. Ultrasonic Motor

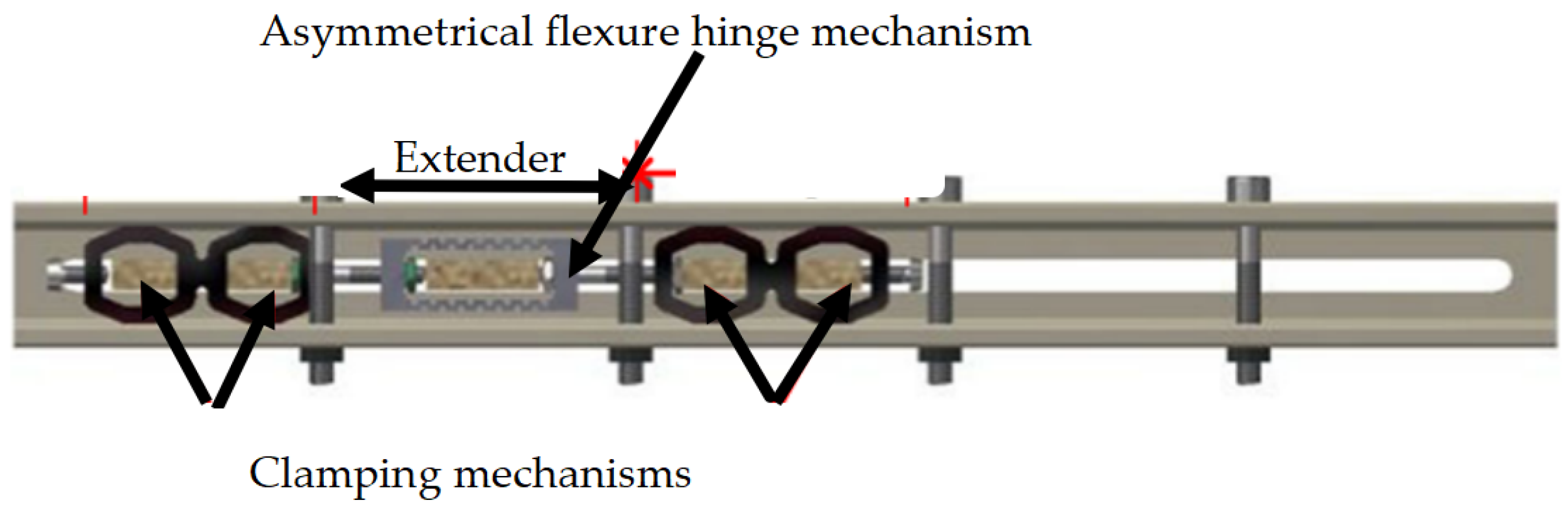

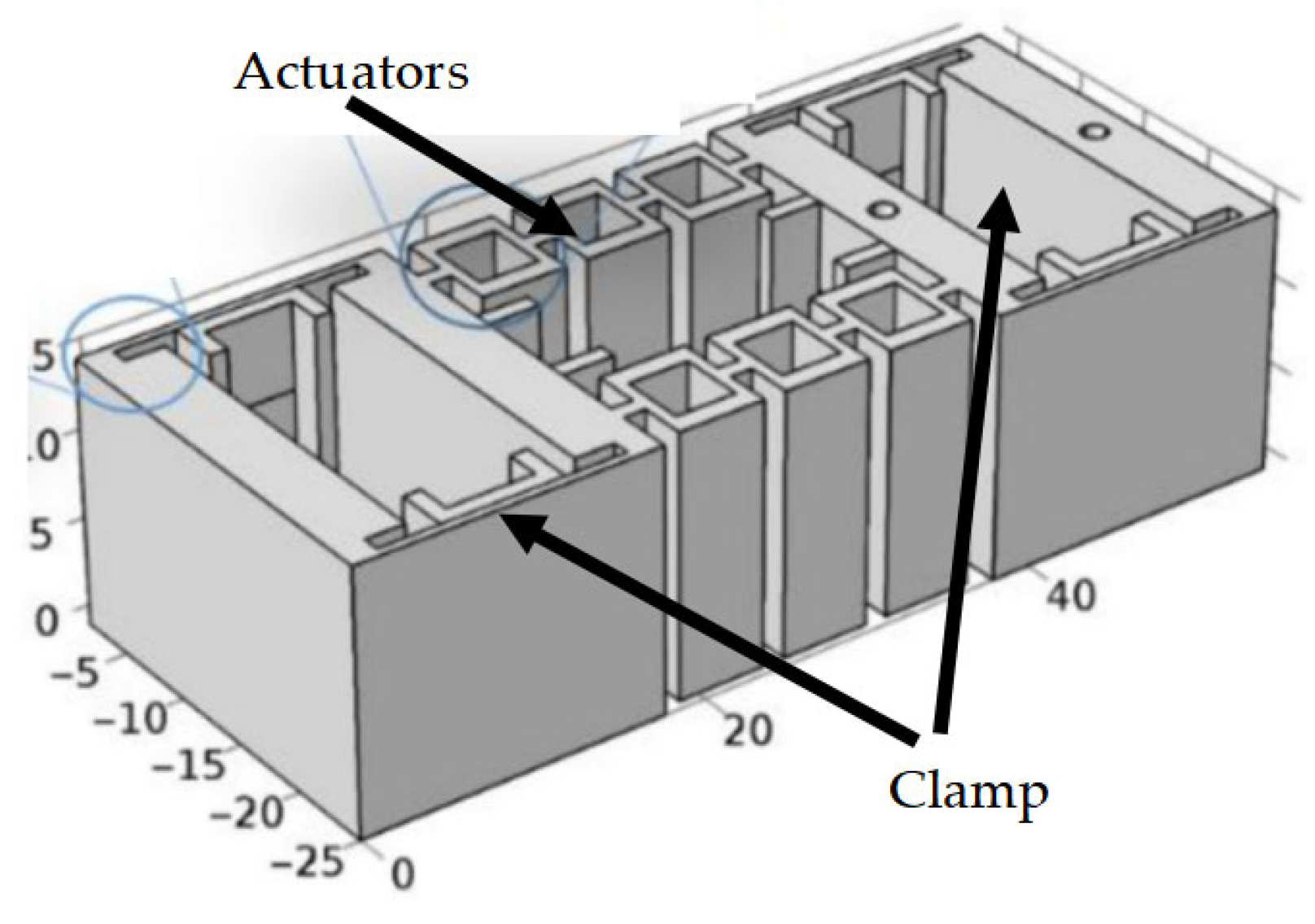

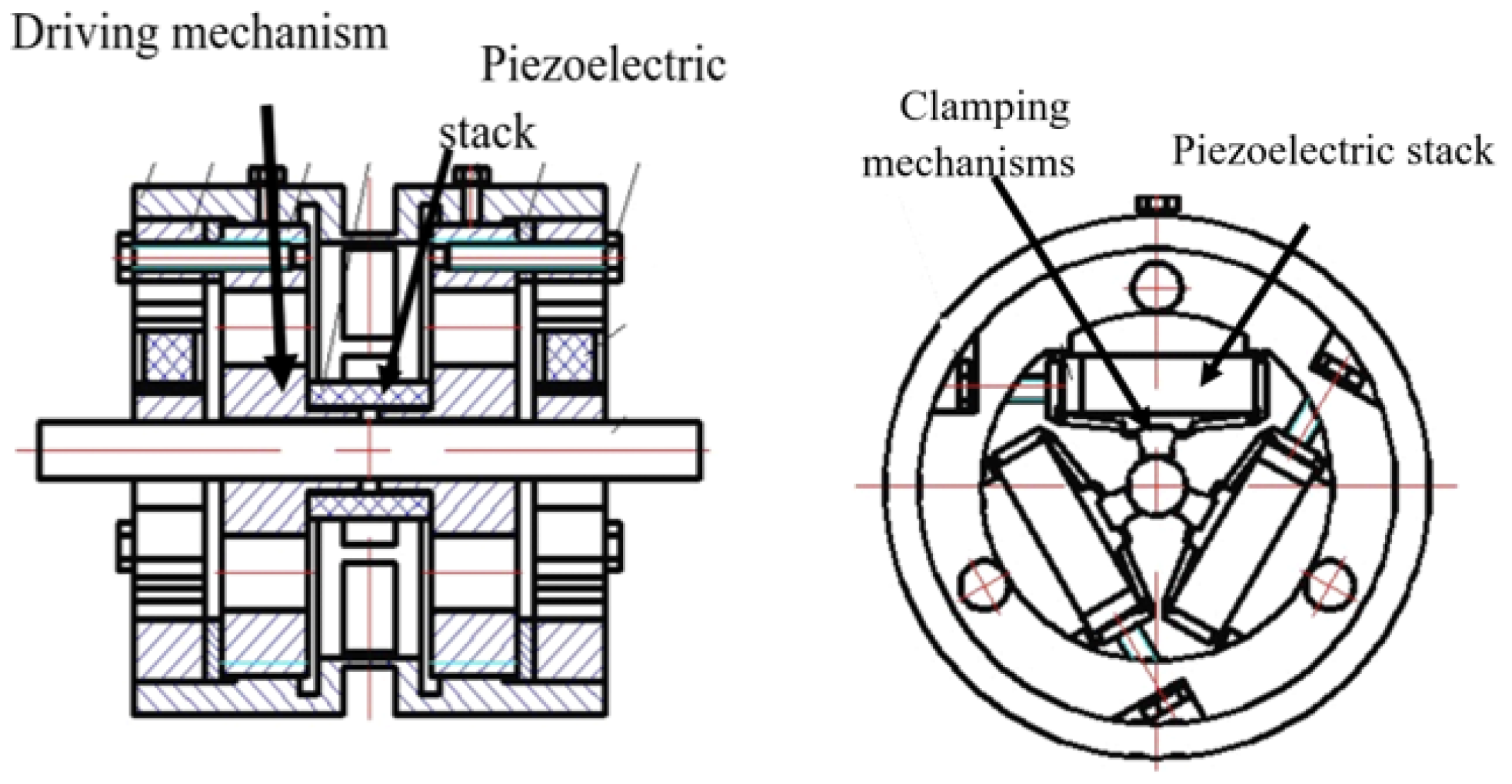

3. Peristaltic Motor

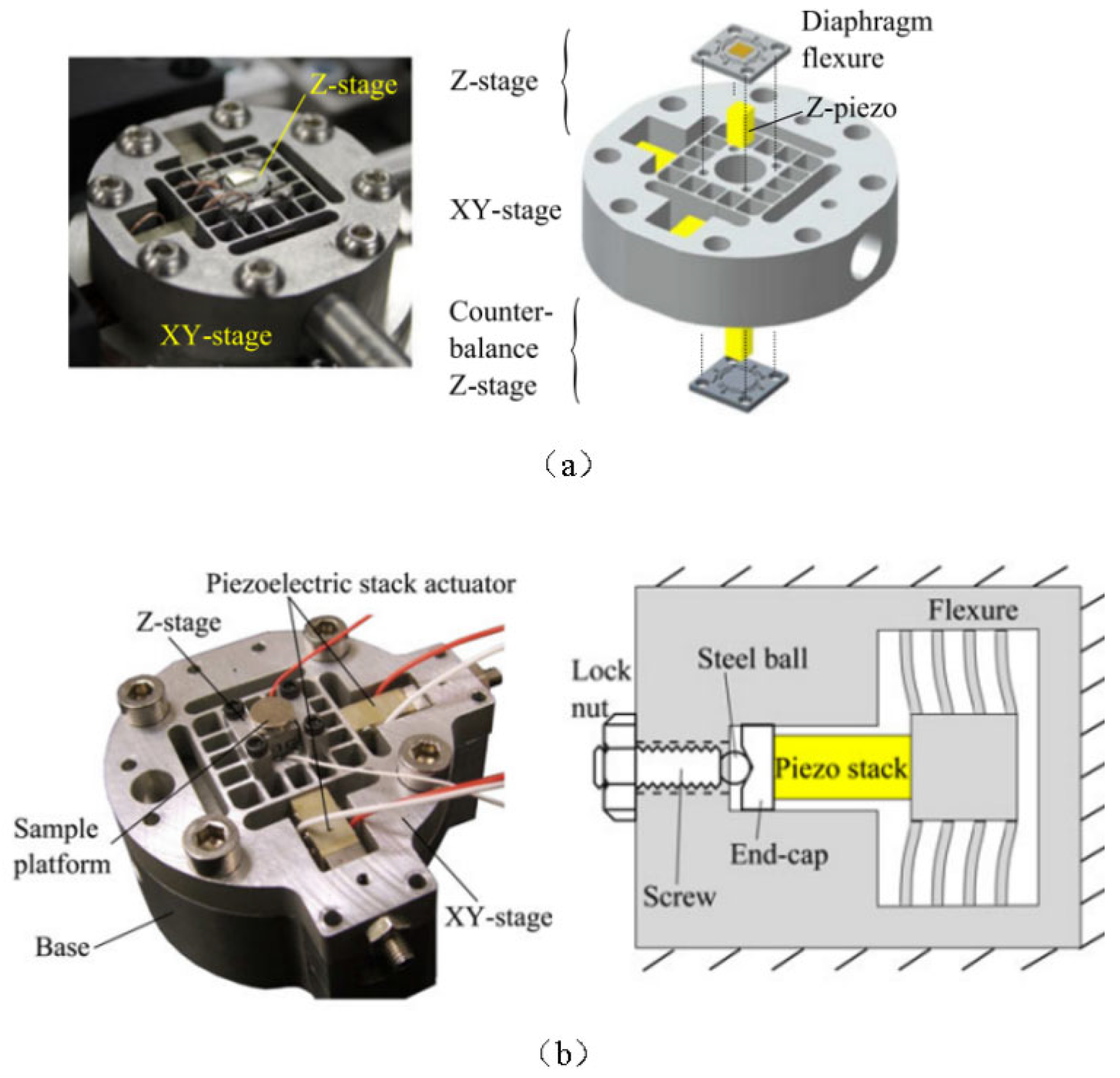

4. Other Piezoelectric Motors

5. Discussion

6. Conclusions and Trends

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Chang, S.; Wu, H. Research on Radial Dynamic Performance of Air Float supported Contact Needle Measurement System. Aviat. Manuf. Technol. 2021, 64, 48–54. [Google Scholar]

- Morita, T. Miniature piezoelectric motors. Sens. Actuators A Phys. 2003, 103, 291–300. [Google Scholar] [CrossRef]

- Spanner, K.; Koc, B. Piezoelectric motors, an overview. Actuators 2016, 5, 6. [Google Scholar] [CrossRef]

- Chen, W.; Liu, Y.; Liu, Y.; Tian, X.; Shan, X.; Wang, L. Design and experimental evaluation of a novel stepping linear piezoelectric actuator. Sens. Actuators A Phys. 2018, 276, 259–266. [Google Scholar] [CrossRef]

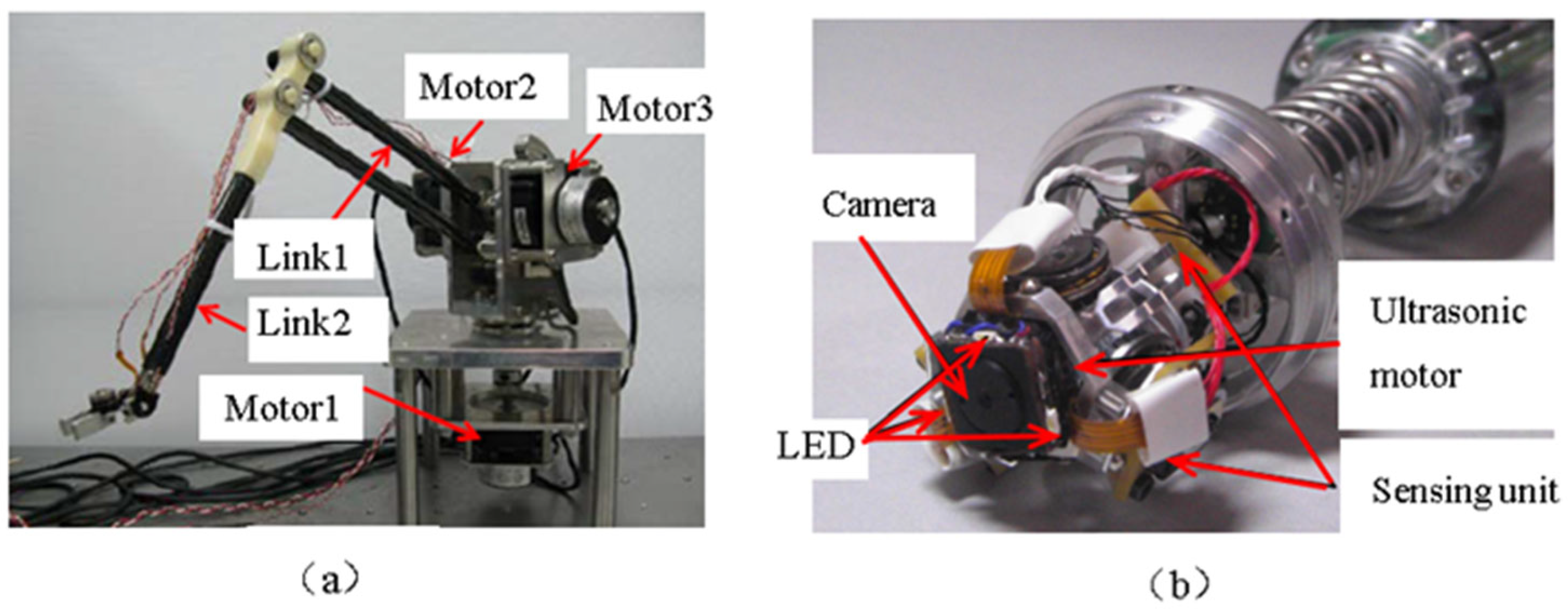

- Shi, S.; Huang, Z.; Yang, J.; Liu, Y.; Chen, W.; Uchino, K. Development of a compact ring type MDOF piezoelectric ultrasonic motor for humanoid eyeball orientation system. Sens. Actuators A Phys. 2018, 272, 1–10. [Google Scholar] [CrossRef]

- Kuhne, M.; Rochin, R.G.; Cos, R.S.; Astorga, G.J.R.; Peer, A. Modeling and two-input sliding mode control of rotary traveling wave ultrasonic motors. IEEE Trans. Ind. Electron. 2018, 65, 7149–7159. [Google Scholar] [CrossRef]

- Zhao, G.; Wu, C.; Zhang, L.; Song, J.; Ding, Q. Friction and wear behavior of PI and PTFE composites for ultrasonic motors. Polym. Adv. Technol. 2018, 29, 1487–1496. [Google Scholar] [CrossRef]

- Yang, L.; Wang, F.; Zhang, J.; Ren, W. Remaining useful life prediction of ultrasonic motor based on Elman neural network with improved particle swarm optimization. Meas. J. Int. Meas. Confed. 2019, 143, 27–38. [Google Scholar] [CrossRef]

- Qu, H.; Wen, Z.; Qu, J.; Song, B. Study on effects of ultrasonic vibration on sliding friction properties of PTFE composites/phosphor bronze under vacuum. Vacuum 2019, 164, 1–6. [Google Scholar] [CrossRef]

- Yin, Z.; Dai, C.; Cao, Z.; Li, W.; Chen, Z.; Li, C. Modal analysis and moving performance of a single-mode linear ultrasonic motor. Ultrasonics 2020, 108, 106216. [Google Scholar] [CrossRef]

- Tian, X.; Liu, Y.; Deng, J.; Wang, L.; Chen, W. A review on piezoelectric ultrasonic motors for the past decade: Classification, operating principle, performance, and future work perspectives. Sens. Actuators A Phys. 2020, 306, 111971. [Google Scholar] [CrossRef]

- Deng, J.; Liu, Y.; Liu, J.; Xu, D.; Wang, Y. Development of a planar piezoelectric actuator using bending-bending hybrid transducers. IEEE Trans. Ind. Electron. 2019, 66, 6141–6149. [Google Scholar] [CrossRef]

- Wu, J.; Mizuno, Y.; Nakamura, K. Polymer-based ultrasonic motors utilizing high-order vibration modes. IEEE/ASME Trans. Mechatron. 2018, 23, 788–799. [Google Scholar] [CrossRef]

- Wang, L.; Quan, Q.; Xue, K.; Li, H. Development of a three-DOF piezoelectric actuator using a thin cross-beam vibrator. Int. J. Mech. Sci. 2018, 149, 54–61. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, Y.; Hua, X.; Quan, L.; Qu, J. Wear debris of friction materials for linear standing-wave ultrasonic motors: Theory and experiments. Wear 2020, 448–449, 203216. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, L.; Jin, J. A novel robotic arm driven by sandwich piezoelectric transducers. Ultrasonics 2018, 84, 373–381. [Google Scholar] [CrossRef]

- Mohith, S.; Upadhya, A.R.; Navin, K.P.; Kulkarni, S.M.; Rao, M. Recent trends in piezoelectric actuators for precision motion and their applications: A review. Smart Mater. Struct. 2021, 30, 053001. [Google Scholar] [CrossRef]

- Gao, X.; Yang, J.; Wu, J.; Xin, X.; Li, Z.; Yuan, X.; Shen, X.; Dong, S. Piezoelectric actuators and motors: Materials, designs, and applications. Adv. Mater. Technol. 2020, 5, 1900716. [Google Scholar] [CrossRef]

- Wang, L.; Hofmann, V.; Bai, F.; Jin, J.; Twiefel, J. Modeling of coupled longitudinal and bending vibrations in a sandwich type piezoelectric transducer utilizing the transfer matrix method. Mech. Syst. Signal Process. 2018, 108, 216–237. [Google Scholar] [CrossRef]

- Hariri, H.; Bernard, Y.; Razek, A. 2-D traveling wave driven piezoelectric plate robot for planar motion. IEEE/ASME Trans. Mechatron. 2018, 23, 242–251. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, Y.; Hua, X.; Quan, L.; Qu, J. Characteristics and attenuation mechanism of linear standing-wave piezoelectric motors with ceramics-mated friction couples. Tribol. Int. 2021, 153, 106580. [Google Scholar] [CrossRef]

- Ryndzionek, R.; Sienkiewicz, Ł. A review of recent advances in the single- and multi-degree-of-freedom ultrasonic piezoelectric motors. Ultrasonics 2021, 116, 106475. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Liu, Y.; Chen, W.; Deng, J.; Liu, J. Development and experiment evaluation of an H-shape linear piezoelectric actuator operated in stepping mode. Ceram. Int. 2018, 44, S246–S249. [Google Scholar] [CrossRef]

- Li, J.; Huang, H.; Zhao, H. A piezoelectric-driven linear actuator by means of coupling motion. IEEE Trans. Ind. Electron. 2018, 65, 2458–2466. [Google Scholar] [CrossRef]

- Qu, H.; Liu, C.; Zhang, L.; Qu, J.; Song, B. A longitudinal-bending hybrid linear ultrasonic motor and its driving characteristic. Shock Vib. 2022, 2022, 5701014. [Google Scholar] [CrossRef]

- Peled, G.; Yasinov, R.; Karasikov, N. Performance and applications of L1B2 ultrasonic motors. Actuators 2016, 5, 6. [Google Scholar] [CrossRef]

- Li, X.; Kan, C.; Cheng, Y.; Chen, Z.; Ren, T. Performance evaluation of a bimodal standing-wave ultrasonic motor considering nonlinear electroelasticity: Modeling and experimental validation. Mech. Syst. Signal Process. 2020, 141, 106475. [Google Scholar] [CrossRef]

- Jian, Y.; Yao, Z.; Silberschmidt, V.V. Linear ultrasonic motor for absolute gravimeter. Ultrasonics 2017, 78, 54–61. [Google Scholar] [CrossRef]

- Izuhara, S.; Mashimo, T. Design and characterization of a thin linear ultrasonic motor for miniature focus systems. Sens. Actuators A Phys. 2021, 329, 112797. [Google Scholar] [CrossRef]

- Uchino, K. Piezoelectric ultrasonic motors: Overview. Smart Mater. Struct. 1998, 7, 273–285. [Google Scholar] [CrossRef]

- Wu, J.; Mizuno, Y.; Nakamura, K. Structural parameter study on polymer-based ultrasonic motor. Smart Mater. Struct. 2017, 26, 115022. [Google Scholar] [CrossRef]

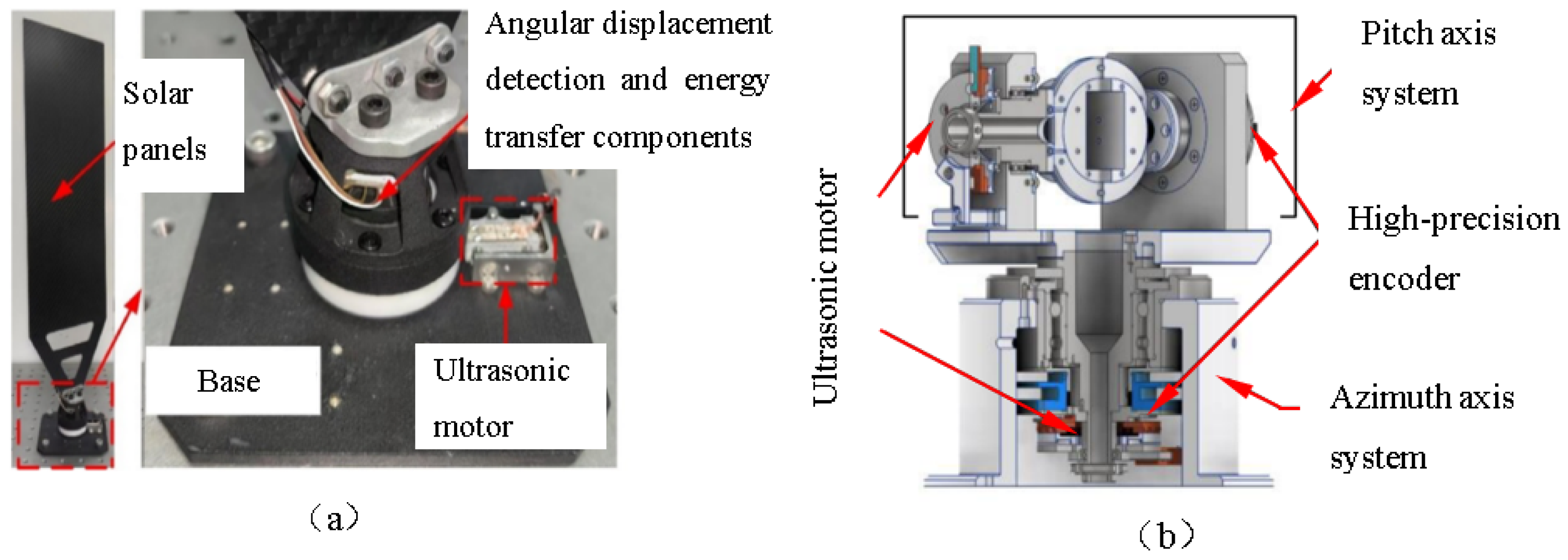

- Li, X.; Li, X.; Li, T.; Zhang, Y. Development of a compact solar array drive assembly based on ultrasonic motor for deep space micro-nano satellites. Acta Astronaut. 2025, 228, 865–874. [Google Scholar] [CrossRef]

- Liang, Y.; Pan, S.; Chen, L. Design of optoelectronic tracking platform driven by ultrasonic motor with a novel limiter. Micromachines 2023, 14, 13. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, J.; Liu, Y.; Tian, X.; Yan, J. A novel single-mode linear piezoelectric ultrasonic motor based on asymmetric structure. Ultrasonics 2018, 89, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Ma, C.; Ren, W.; Zhang, J. Beat traveling wave principle and its verification on rotating ultrasonic motor. J. Vib. Control 2020, 27, 2354–2367. [Google Scholar] [CrossRef]

- Yamashita, T.; Mashimo, T.; Takesue, N.; Terashima, K. Safeness of a robot arm using ultrasonic motors with high responsiveness and backdrivability. In Proceedings of the IEEE/SICE International Symposium on System Integration, Tokyo, Japan, 14–17 December 2014; pp. 13–18. [Google Scholar]

- Toyama, S. Spherical Ultrasonic Motor for Pipe Inspection Robot. Appl. Mech. Mater. 2012, 186, 3–11. [Google Scholar] [CrossRef]

- Liu, C.D. Study on Rhombic Linear Ultrasonic Motor. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2022. [Google Scholar]

- Kurosawa, M.K.; Kodaira, O.; Tsuchitoi, Y.; Higuchi, T. Transducer for high speed and large thrust ultrasonic linear motor using two sandwich-type vibrators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1998, 45, 1188–1196. [Google Scholar] [CrossRef]

- Jeong, S.S.; Park, T.G.; Kim, M.H.; Song, T.K. Characteristics of a V-type ultrasonic rotary motor. Curr. Appl. Phys. 2011, 11, 364–367. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.; Yang, M. A novel large thrust-weight ratio V-shaped linear ultrasonic motor with a flexible joint. Rev. Sci. Instrum. 2017, 88, 065003. [Google Scholar] [CrossRef]

- Qiu, W.; Mizuno, Y.; Koyama, D.; Nakamura, K. Efficiency improvement of hybrid transducer-type ultrasonic motor using lubricant. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 786–794. [Google Scholar] [CrossRef]

- Yan, J.; Liu, Y.; Liu, J.; Xu, D.; Chen, W. The design and experiment of a novel ultrasonic motor based on the combination of bending modes. Ultrasonics 2016, 71, 205–210. [Google Scholar] [CrossRef]

- Wu, J.; Mizuno, Y.; Nakamura, K. A rotary ultrasonic motor operating in torsional/bending modes with high torque density and high power density. IEEE Trans. Ind. Electron. 2021, 68, 6109–6120. [Google Scholar] [CrossRef]

- Li, X.; Wen, Z.; Jia, B.; Wu, D. A review of application and development trends in ultrasonic motors. ES Mater. Manuf. 2020, 12, 3–16. [Google Scholar] [CrossRef]

- Liu, W.; Yang, Z.; Jiang, S.; Feng, D.; Zhang, D. Design and implementation of a new cable-driven robot for MRI-guided breast biopsy. Int. J. Med. Robot. Comput. Assist. Surg. 2020, 16, e2063. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Li, C.; Zuo, W.; Zhang, H.; Liu, J.; Wen, W.; Ouyang, Z. Lunar farside to be explored by Chang’e-4. Nat. Geosci. 2019, 12, 222–223. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, T.; Zhang, H.; Jia, Y.; Zhang, H.; Chen, J.; Wu, X.; Shen, Z. The technical design and achievements of Chang’E-3 probe. Sci. China Technol. Sci. 2014, 4, 13. [Google Scholar]

- Jana, S.; Shome, S.K.; Nandi, A.K. A novel four-legged linear piezoelectric peristaltic motor with high thrust force. Microsyst. Technol. 2024, 31, 161–175. [Google Scholar] [CrossRef]

- Sangchap, M.; Tahmasebipour, M.; Tahmasebipour, Y. A linear peristaltic piezomotor with a new configuration: Design considerations, fabrication and characterization. Iran. J. Sci. Technol. Trans. Mech. Eng. 2022, 46, 149–160. [Google Scholar] [CrossRef]

- Yu, Y.; Li, W. A high-thrust peristaltic piezoelectric linear motor. Small Spec. Electr. Mach. 2001, 05, 29–31. [Google Scholar]

- Huang, H. Research on Cylindrical Passive Clamping Piezoelectric Peristaltic Linear Motor. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

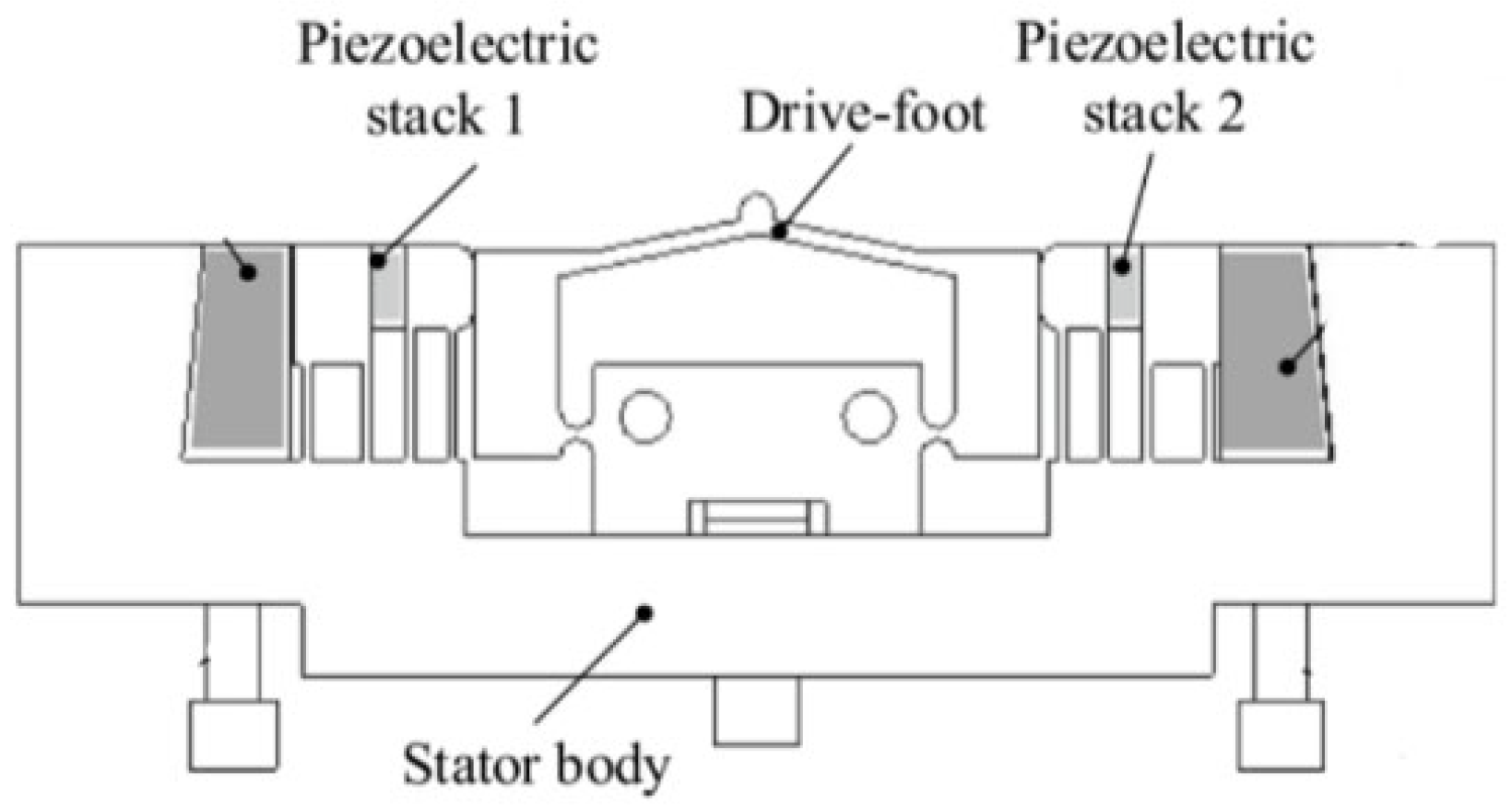

- Chen, X.; Li, M.; Zhang, H.; Lu, Q.; Lyu, S. Improvement on the structure design of a kind of linear piezoelectric motor with flexible drive-foot. Int. J. Precis. Eng. Manuf. 2020, 21, 81–89. [Google Scholar] [CrossRef]

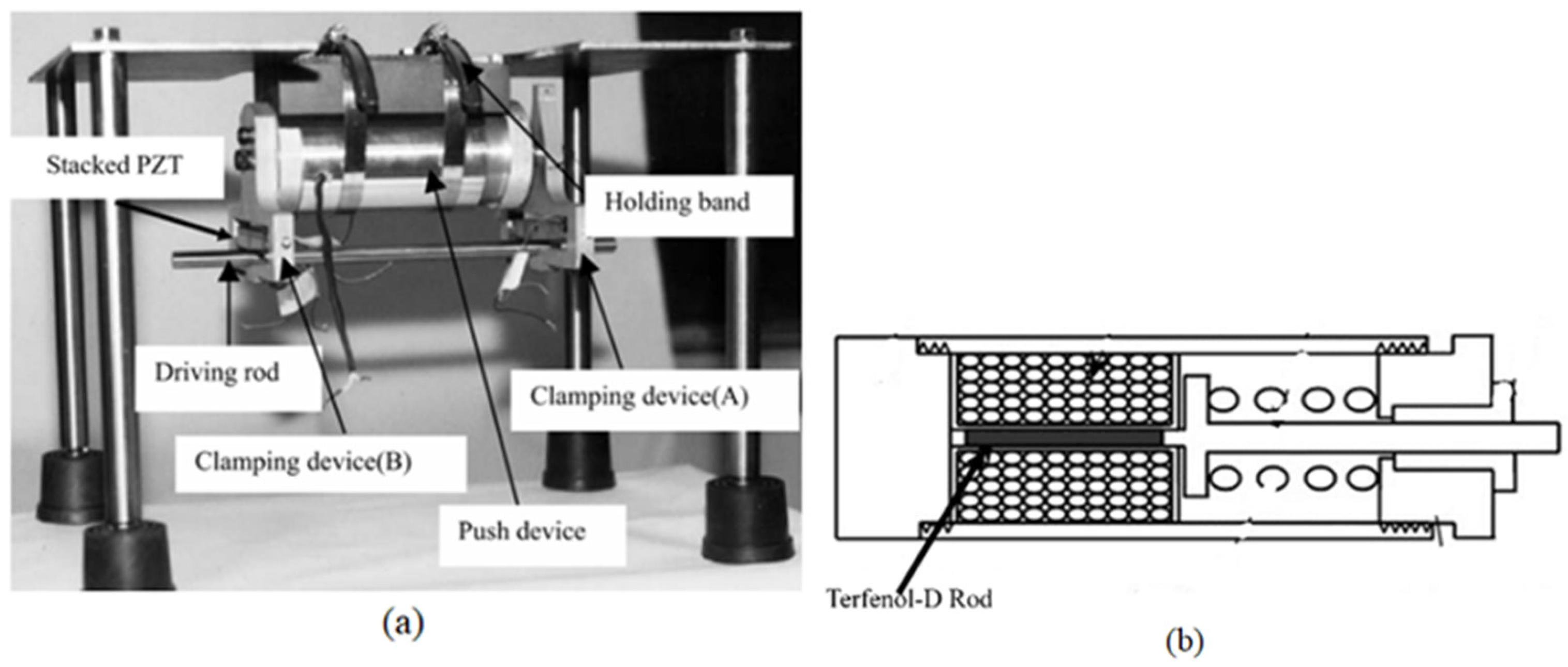

- Kim, J.; Kim, H.-K.; Choi, S.-B. A hybrid peristaltic linear motor. Mechatronics 2002, 12, 525–542. [Google Scholar] [CrossRef]

- Williams, E.; Loveday, P.; Theron, N. Design of a large-force piezoelectric peristaltic motor with a force duplicator. In Proceedings of the 2013 6th Robotics and Mechatronics Conference (RobMech), Durban, South Africa, 30–31 October 2013; pp. 46–51. [Google Scholar]

- Kwon, K.; Cho, N.; Jang, W. The design and characterization of a piezo-driven peristaltic linear motor with a reduction-lever mechanism. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2004, 47, 803–811. [Google Scholar]

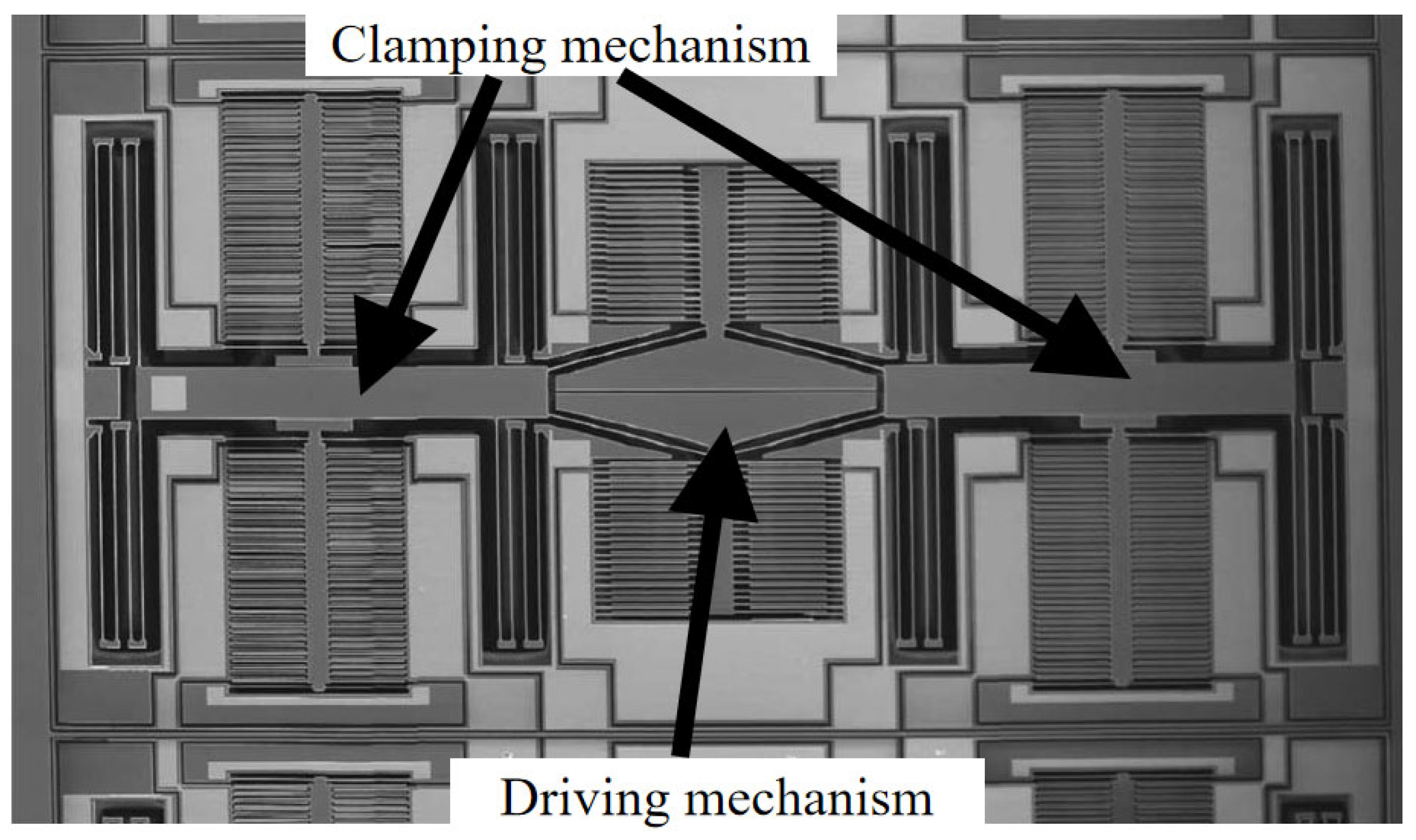

- Erismis, M.A. A low-voltage large-displacement large-force peristaltic actuator. J. Microelectromechanical Syst. 2008, 17, 1294–1301. [Google Scholar] [CrossRef]

- Gu, Y.; Xing, J. Dynamics analysis for the clamping mechanisms of a rotary peristaltic piezoelectric motor. J. Vibroengineering 2016, 18, 2229–2239. [Google Scholar] [CrossRef]

- Li, J. A piezoelectric-driven rotary actuator by means of peristaltic motion. Sens. Actuators A Phys. 2013, 194, 269–276. [Google Scholar] [CrossRef]

- Duong, K.; Garcia, E. Design and performance of a rotary motor driven by piezoelectric stack actuators. Jpn. J. Appl. Phys. 1996, 35, 6334–6341. [Google Scholar] [CrossRef]

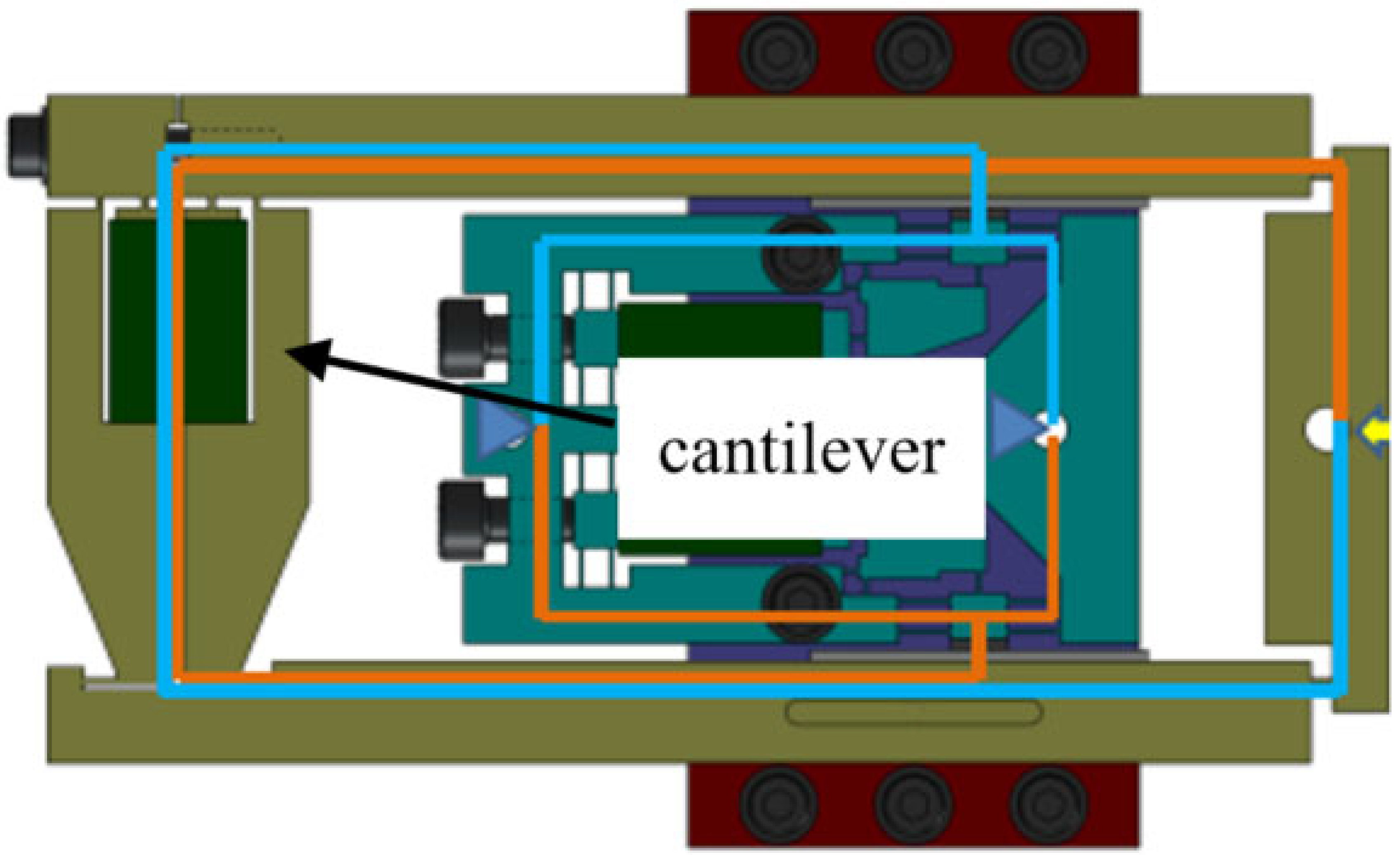

- Hu, M.M. Research on a Compound Amplified Passive-Clamping Piezoelectric Peristaltic Linear Actuator. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2018. [Google Scholar]

- Yong, Y.K.; Moheimani, S.O.R. Collocated Z-axis control of a high-speed nanopositioner for video-rate atomic force microscopy. IEEE Trans. Nanotechnol. 2015, 14, 338–345. [Google Scholar] [CrossRef]

- Yong, Y.K.; Bhikkaji, B.; Moheimani, S.O.R.R. Design, modeling, and FPAA-based control of a high-speed atomic force microscope nanopositioner. IEEE/ASME Trans. Mechatron. 2013, 18, 1060–1071. [Google Scholar] [CrossRef]

| Principle | Ultrasonic Motor | Inertial Motor | Peristaltic Motor |

|---|---|---|---|

| Trip | Large itinerary | Large itinerary | Large itinerary |

| Running speed | Extremely high (200 mm/s) | Medium | Medium (0.5 mm/s) |

| Resolution | 100 nm | 100 nm | 20 nm |

| Positioning stability | Medium | Low | High |

| Load | Medium | Low | High |

| Frequency | High | Medium | Low |

| Friction | High friction | Frictional | Slight friction |

| Fever | Fever | Mild fever | No fever |

| Energy efficiency | Inefficient | Relatively high efficient | High efficient |

| Structural complexity | Relatively high | Relatively Low | High |

| Control characteristics | Specific waveform | Specific waveform | Specific timing sequence |

| Control difficulty | Complex | Easy | Complex |

| Curve trajectory | Supporting | Forbidden | Supporting |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, Z.; Shi, H.; Chi, Y. A Review on Piezoelectric Ultrasonic and Peristaltic Methods for Precision Motion and Measurement. Appl. Sci. 2025, 15, 12510. https://doi.org/10.3390/app152312510

Wen Z, Shi H, Chi Y. A Review on Piezoelectric Ultrasonic and Peristaltic Methods for Precision Motion and Measurement. Applied Sciences. 2025; 15(23):12510. https://doi.org/10.3390/app152312510

Chicago/Turabian StyleWen, Zhongpu, Haoyang Shi, and Yuchen Chi. 2025. "A Review on Piezoelectric Ultrasonic and Peristaltic Methods for Precision Motion and Measurement" Applied Sciences 15, no. 23: 12510. https://doi.org/10.3390/app152312510

APA StyleWen, Z., Shi, H., & Chi, Y. (2025). A Review on Piezoelectric Ultrasonic and Peristaltic Methods for Precision Motion and Measurement. Applied Sciences, 15(23), 12510. https://doi.org/10.3390/app152312510