1. Introduction

Glulam (glued laminated timber—GLT) is a structural engineered product made of solid wood layers with parallel grain orientation to the product length, glued together on their faces with a moisture-resistant adhesive. Such a configuration results in a multi-layer beam-type structure, with characteristics that make it useful as a raw material for structural elements. Glulam is used in most types of construction, namely in columns, beams, arches of medium and large buildings, bridges, canopies, and pavilions. Glulam has excellent advantages regarding its strength, stability, and different length options that facilitate design flexibility [

1], as well as from the viewpoint of sustainability. It allows the use of smaller trees to create large beams, it reduces construction time and costs because of the prefabrication process, it is durable, it requires low maintenance, and it does not require covering with other materials as it is aesthetically pleasing.

The growing concern for the environment and the multiple benefits of using mass timber are leading to an increase in the use of wood in construction applications [

2].

Glulam markets have continued to grow as more residential constructions are adopting the use of this material. The world production of glulam was around 7 million m

3 in 2023 [

3].

Europe remains the largest regional industry with a 47% global industry share in 2024, due to Austria, Germany, and countries in the Nordic area having high glulam production volumes and decades-old policy support. It is followed by North America at 28%, because of advantages created by the increasing adoption of the Type IV solid wood construction code [

4].

Glulam beams have high mechanical strength. The most common classes are GL24, GL28, and GL32. Laminated beams generally have a strength similar to the wood from which they are made.

The durability of the glulam beams should be considered related to the durability of the solid wood they are made from. The species generally used for glulam are softwoods (especially spruce and pine) because they have low density, fast growth rate, good workability, and low price [

5].

Hardwoods have been introduced into glulam production in a smaller proportion. According to a previous study [

6], forming durable bonds with hardwoods is a challenging task in comparison to glueing softwoods. Higher wood density indicates higher cell wall thickness and lower porosity, resulting in less penetration of the adhesive, which can lead to weaker bonds [

7,

8].

However, there is a growing interest in using hardwoods due to their increased availability because of changes in reforestation policies, their superior mechanical properties, and the increasing costs of softwoods.

A series of studies on the application of hardwoods for the production of glulam were conducted [

6,

9,

10,

11,

12]. Species like European beech (

Fagus sylvatica L.), sessile oak (

Quercus petraea L.), pedunculate oak (

Quercus robur L.), chestnut (

Castanea sativa L.), and ash (

Fraxinus excelsior L.) were analysed. These studies show that the flexural strength of glulam made from European hardwood species at least equals and generally exceeds that of the highest strength classes of European softwood glulam.

As far as the dimensional stability is concerned, considering that it is made of solid wood layers kiln-dried down to a moisture content (MC) of 10 ± 2%, glulam does not change its dimensions significantly. In higher humidity conditions, it is considered that the dimensions of laminated beams change by 0.24% for a 1% change in humidity [

13].

The tendency to crack is also smaller in a typical glulam than in solid wood. The presence of cracks due to wood shrinkage, because of exposure to the environment and frequent climate changes, is possible. These cracks are acceptable if they are parallel to the wood grain and have a depth of up to 15% of the beam width for lateral cracks. The cracks near the ends of glulam beams can reduce the shear strength. The shear-critical areas are at each end of a simply supported glulam beam, in a length of 3 times the beam depth, and within the middle half of the beam depth [

13].

The dimensional stability of glulam is guaranteed when using a single, homogenous resinous species such as pine or spruce. However, it is also important to evaluate the behaviour of glulam made with faces and cores from different species, since these mixed glulam structures are more durable than homogeneous resinous glulam, and cheaper than homogeneous hardwood glulam. This approach allows the use of higher-strength species in the outer layers, which are subjected to higher stresses, while using lower-cost species in the core.

The main problem is adhesion when combining different wood species in the glulam structure. Glueing issues are induced mainly by the extractive content of the wood, its anatomical structure, and differences in its swelling and shrinkage coefficients. This variation in swelling and shrinkage coefficients can lead to significant internal stresses that intensify with increases in moisture gradient, the formation of cracks, and delamination of the adhesive joints [

14,

15]. The structural integrity and functionality of glulam members can be affected by delamination, and can also lead to safety hazards in load-bearing applications.

Generally, glulam products are exposed to extreme outdoor conditions during the transportation and installation phase on the construction site when changes in moisture content can occur. Major delamination of the finger-joint bonding in beech glulam, caused by the moisture gradient that occurred between the inner and near-surface wood layer during a three-week alternating climate regime (43% to 85% relative humidity, and 16 °C to 44 °C temperature), was reported in a previous study [

16].

Wetting and drying cycles induce stresses as well as restrained and released strains in glulam, as concluded after tests performed with spruce glulam [

17]. The changing conditions during long-term storage also affect the glulam’s properties. After 30 months of storage of pine glulam, it was observed that the modulus of elasticity (MOE) of the outer lamellas differed significantly from that of the middle layer, due to the fact that the outer layers are more susceptible to stresses resulting from changing conditions [

18].

Previous studies have mostly explored the properties and the behaviour of homogenous glulam structures made of a single species. The main objective of this research was to analyse the behaviour of different mixed glulam structures made of softwood (the core layers) and hardwood (the face layers), when exposed to a humid environment.

2. Materials and Methods

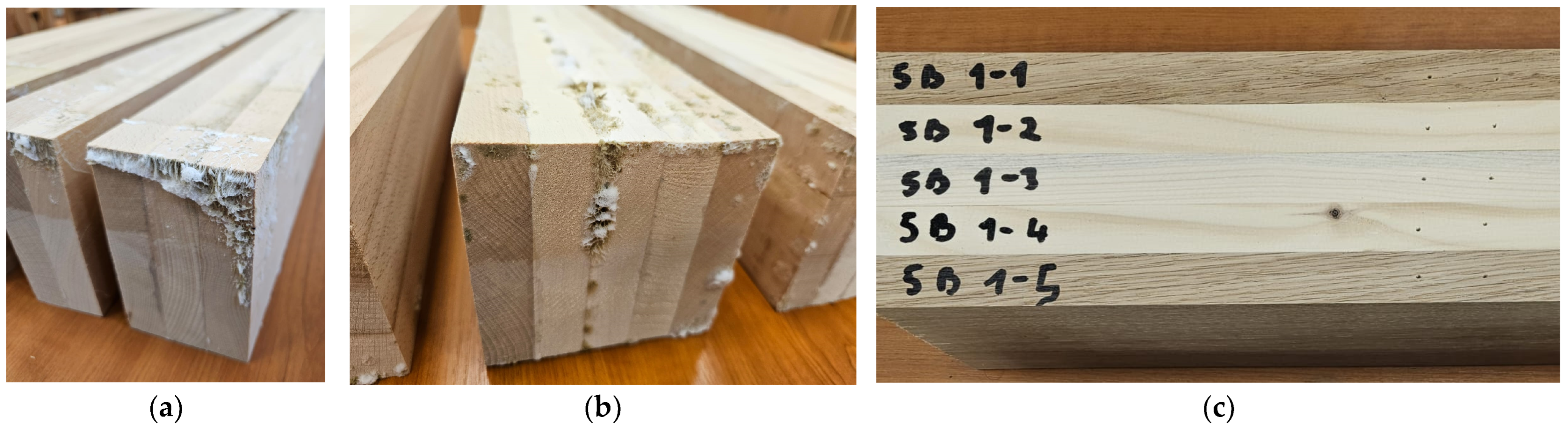

The materials used in this research consisted of fir, lime, beech, and oak lumber boards, previously conditioned at a moisture content of 8%. The dimensions of the solid wood slats prepared for glueing were 500 × 145 × 23 mm, after planing. Thus, the dimensions of the resulting glulam structures were 500 × 145 × 115 mm.

The boards were graded, so that those with small defects (knots, cracks, and inclined fibre) were allowed only for the softwood parts, and used only for the core of the glulam structures. The boards were first straightened, then planed on the faces and edges, and finally cut to length.

Three replicates were made for each mixed structure (coded BF for beech–fir, BL for beech–lime, OF for oak–fir, and OL for oak–lime). Homogeneous structures, using a single species for the faces and the core, were manufactured as well (coded F for fir, L for lime, B for beech, and O for oak), and used as references for the mixed ones.

The adhesive used for bonding the layers was SOUDAL 66A, a one-component polyurethane-based moisture-resistant (D4) adhesive. The adhesive was applied on the lamella faces by brushing. The specific consumption according to the technical sheet was 150 mL/m

2, meaning 8 g/surface. The adhesive is resistant to temperatures between −30 °C and 100 °C. It has an assembly time of 15 min between applying and pressing. The required pressing time is a minimum of 3 h. To avoid movement of the lamellas during pressing, a fixing device was constructed as shown in

Figure 1.

Immediately after glueing, each glulam structure was introduced into a GL6 cold press by Italpresse (Bagnatica, Italy), presented in

Figure 2, and pressed at a pressure of 0.5 MPa for 4 h. After pressing, the Glulam specimens were sized and trimmed to remove the adhesive excess.

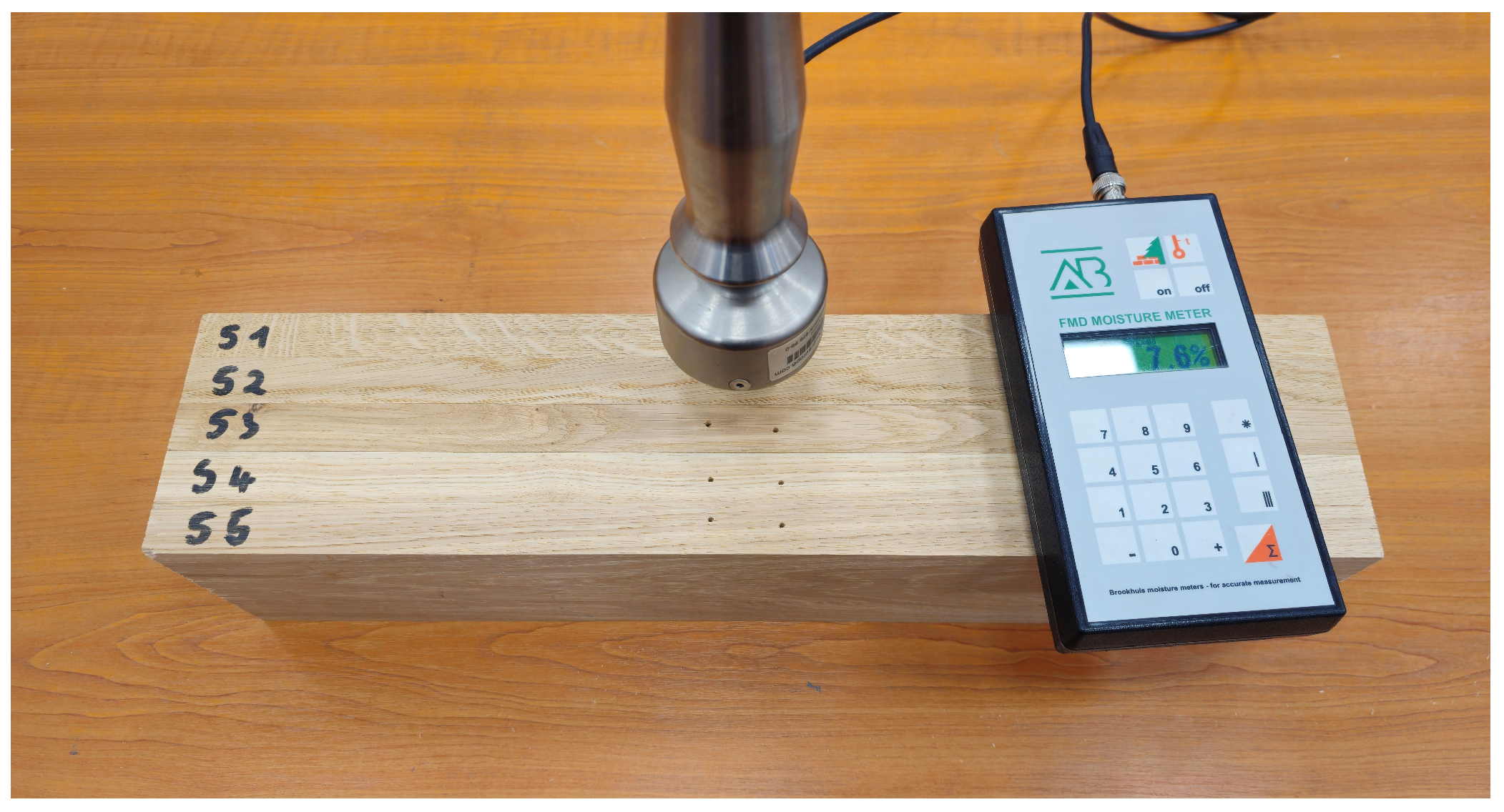

In the next step, the moisture content (MC) of each layer was determined using a resistive moisture meter, type FMD6, from Brookhuis (Almelo, The Netherlands), as shown in

Figure 3. The moisture content was measured at a depth of 30 mm on the edge surface of each layer, and the moisture meter was re-calibrated after each species. Also, all structures were visually analysed to identify any existing delamination before exposure.

Hereinafster, the glulam specimens were placed in a KPK200 climate chamber by FEUTRON (Langenwetzendorf, Germany) (

Figure 4) to be exposed for one month to a climate cycle similar to diurnal/nocturnal exposure in an external environment: a temperature of 30 °C and relative humidity (

RH) of 40% for 12 h, followed by a temperature of 10 °C and

RH = 80% for 12 h.

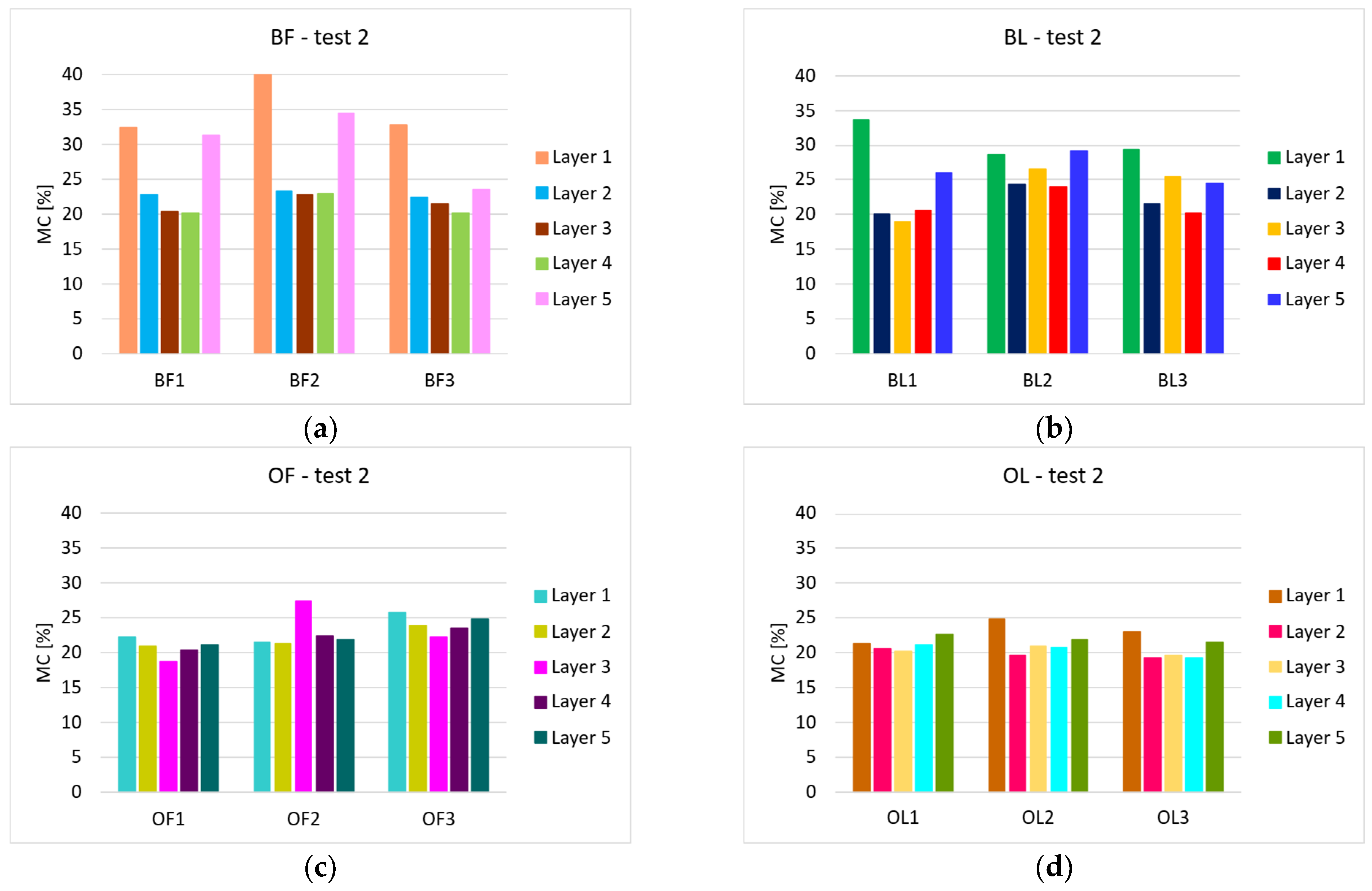

After exposure, the moisture content of each layer of all structures was re-measured with a resistive-type moisture meter, and the structures were visually analysed to identify any delamination.

A second climate test consisted of exposing the same glulam structures to a more aggressive humid environment, with constant parameters of temperature t = 20 °C and a relative air humidity of RH = 90% for 3 weeks. After exposure, the moisture content of each layer was measured again with the same resistive moisture meter and the structures were visually analysed for any delamination. The visual analysis was repeated after 8 weeks of laboratory conditioning.

The difference in moisture content (Δ

MC) between the layer with the highest moisture content (always one of the surface layers) and the one with the lowest moisture content (the core layer) was determined:

This indicator is very important for structural stability. Therefore, it was determined for each structure after each climate test, to create a correlation between the ΔMC values and the degree of delamination.

The Data Analysis ToolPack, Microsoft Excel

®, was used as a statistical tool to reveal if there is a significant difference among analysed groups [

19]. Initially, One-Way Analysis of Variance (ANOVA) was run to reveal if there is a significant difference among the analysed groups. Finally, the

t-test for two independent groups was chosen as a post hoc test. The Bonferroni correction was considered to determine if the mean differences are statistically significant. According to the literature [

20], the Bonferroni correction suggests to divide the significant alpha level (5%) by the number of compared groups. Consequently, the significant alpha level during the post hoc analysis was equal to 0.0125.