Increase of Efficient at Aerated Concrete Compositions Based on Mineral Powders

Abstract

1. Introduction

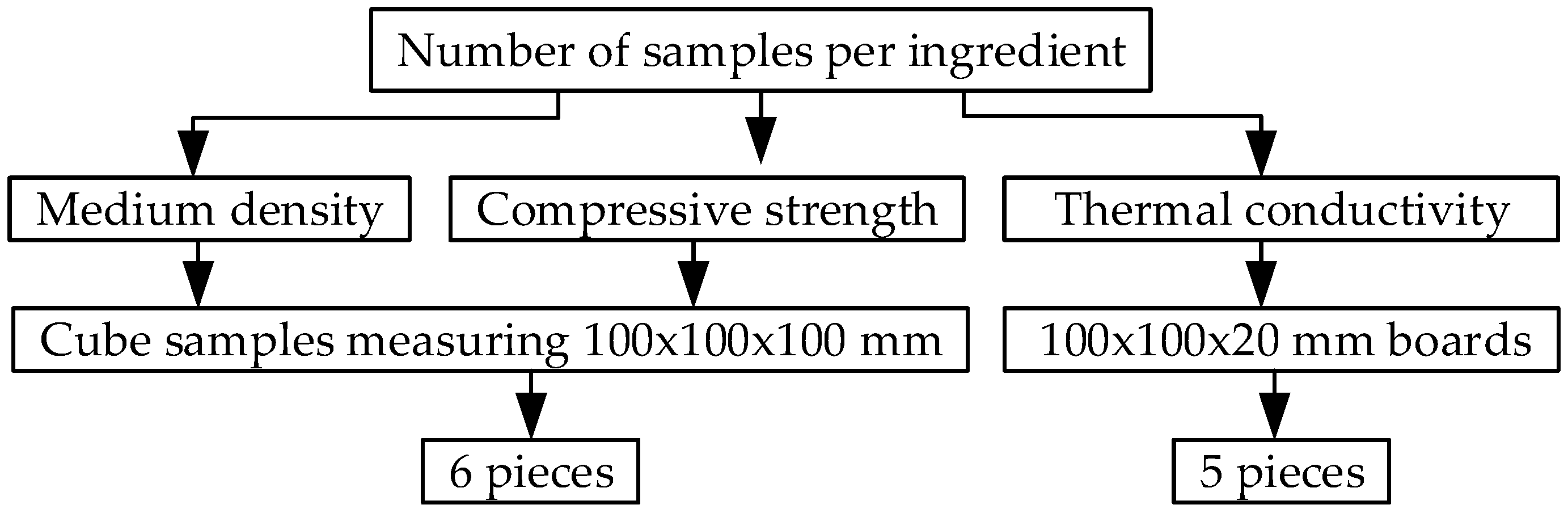

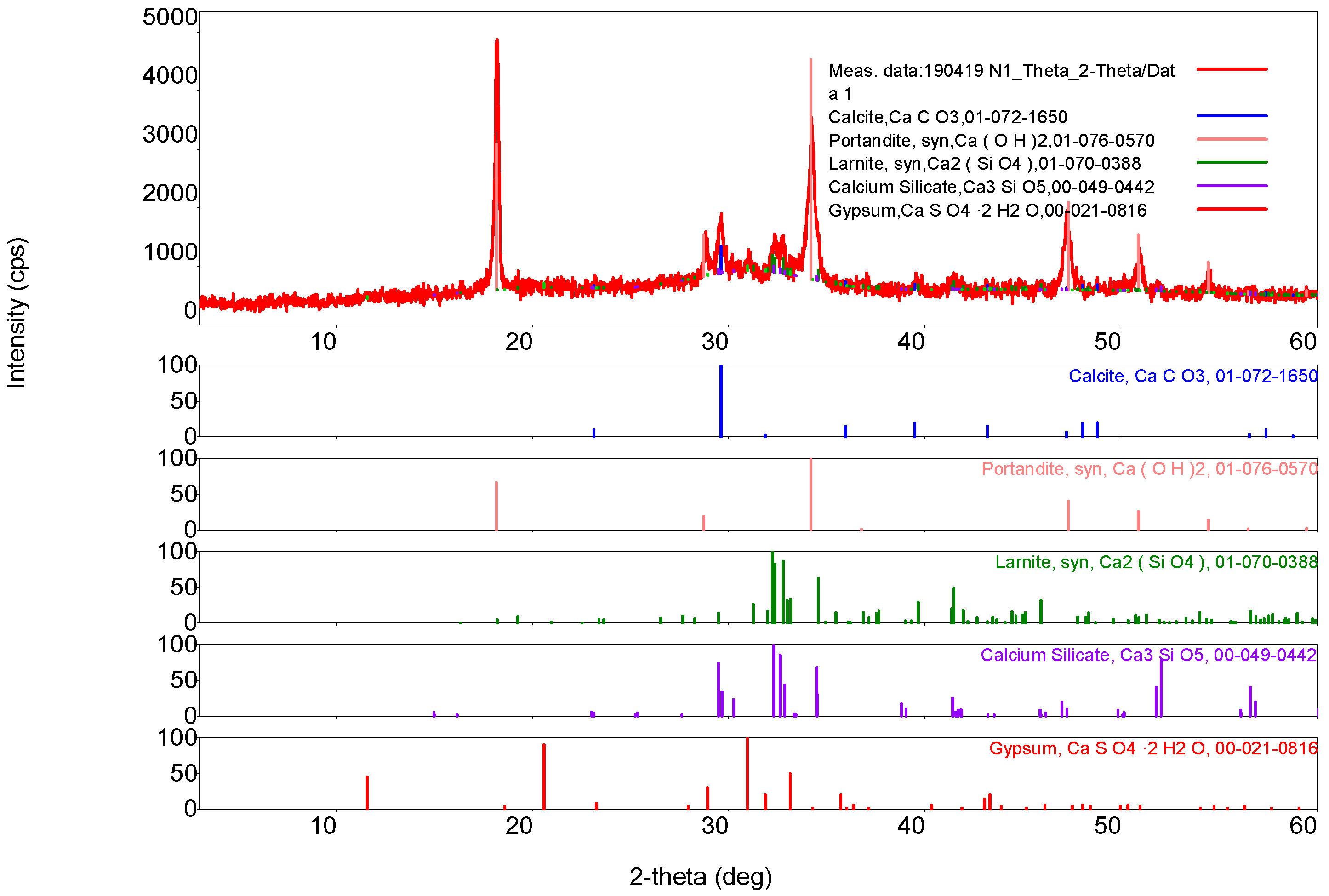

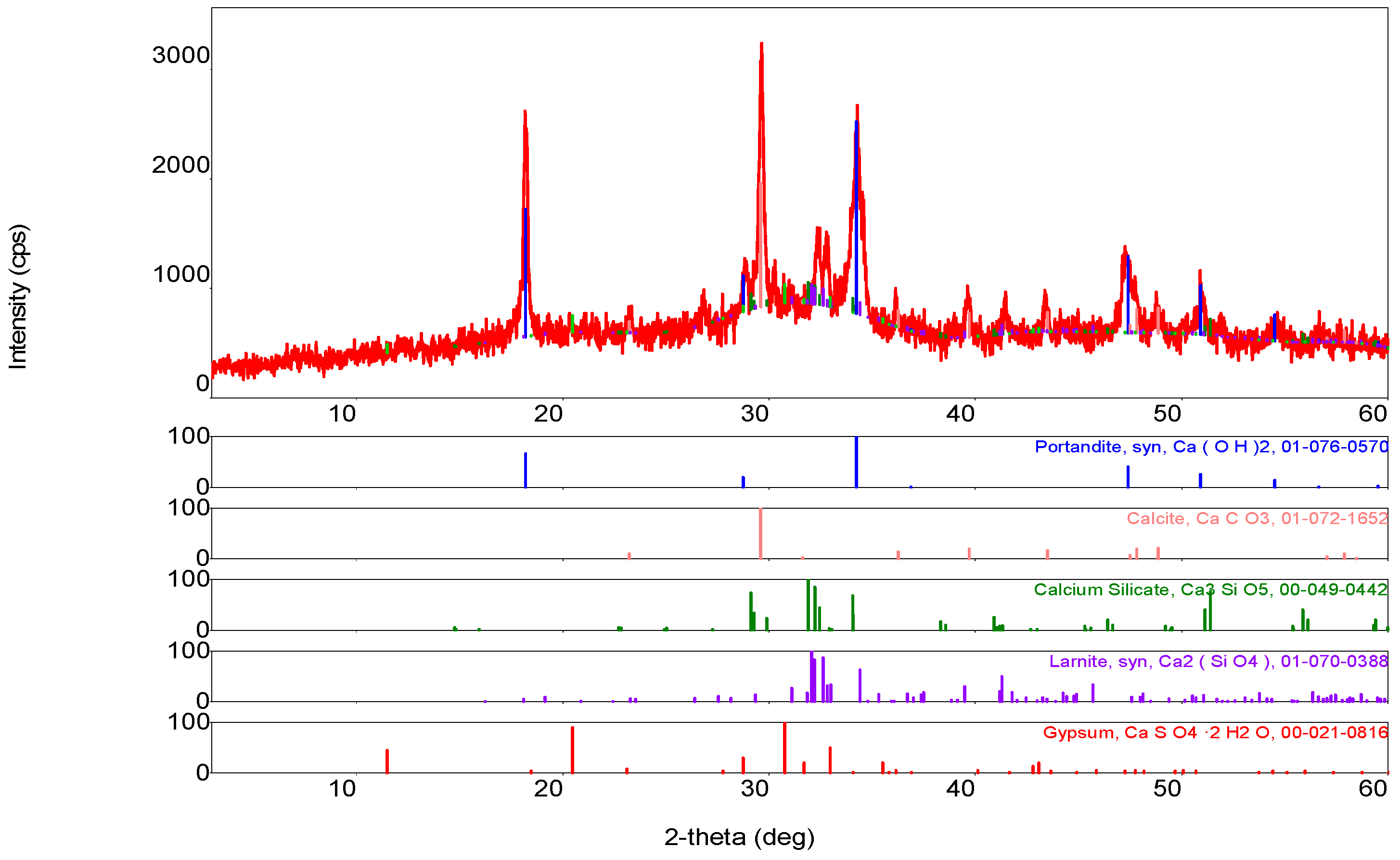

2. Materials and Methods

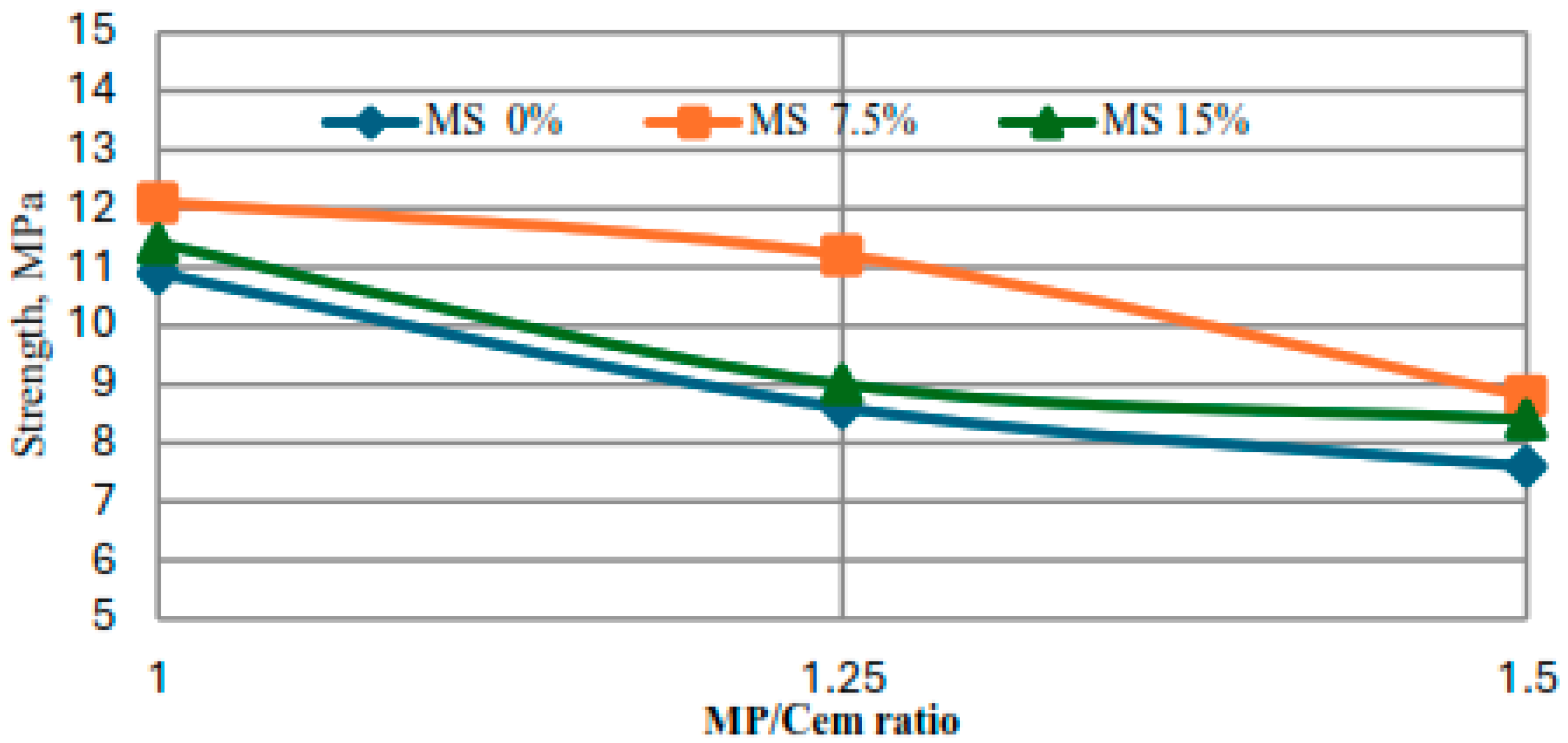

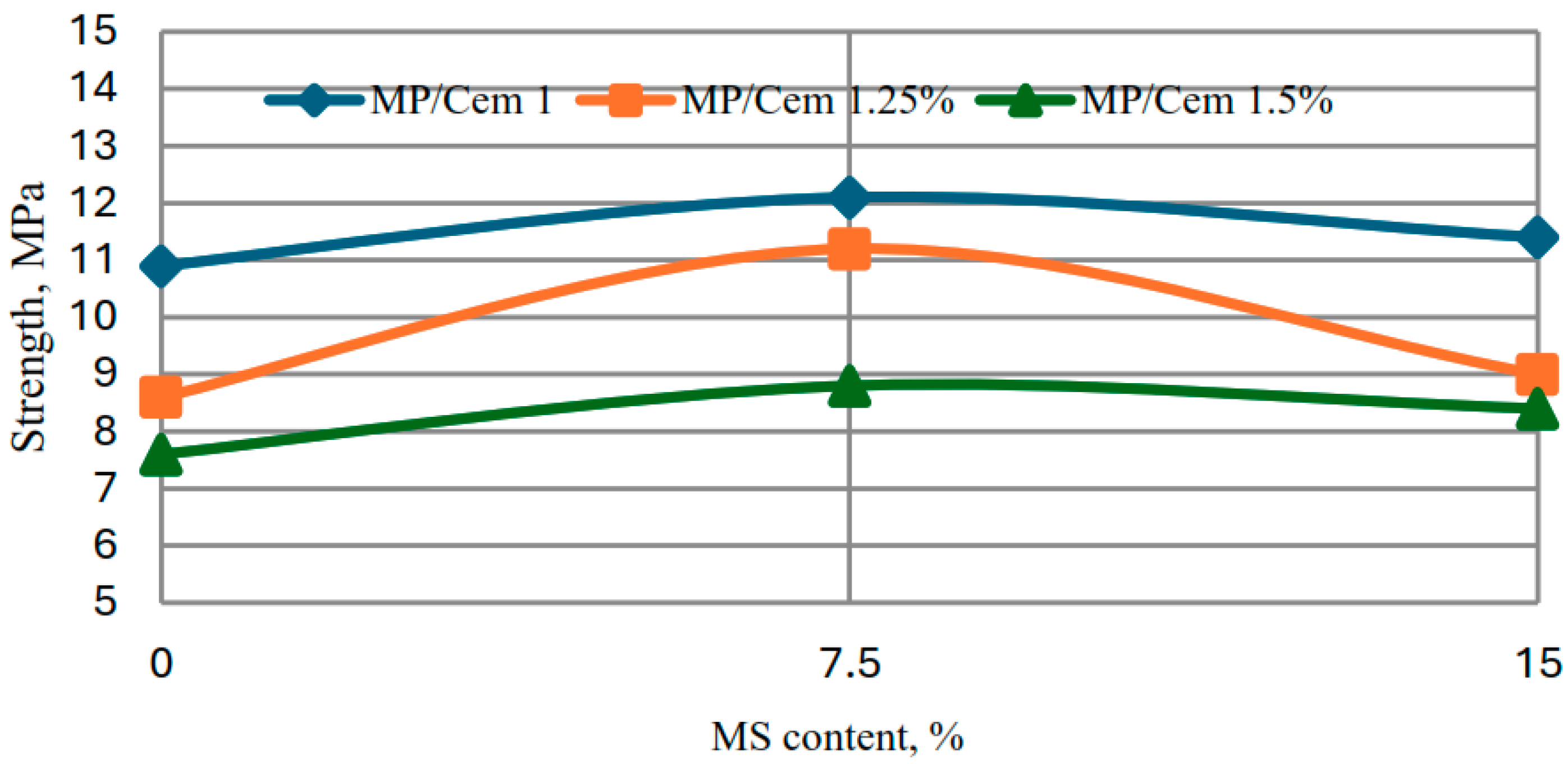

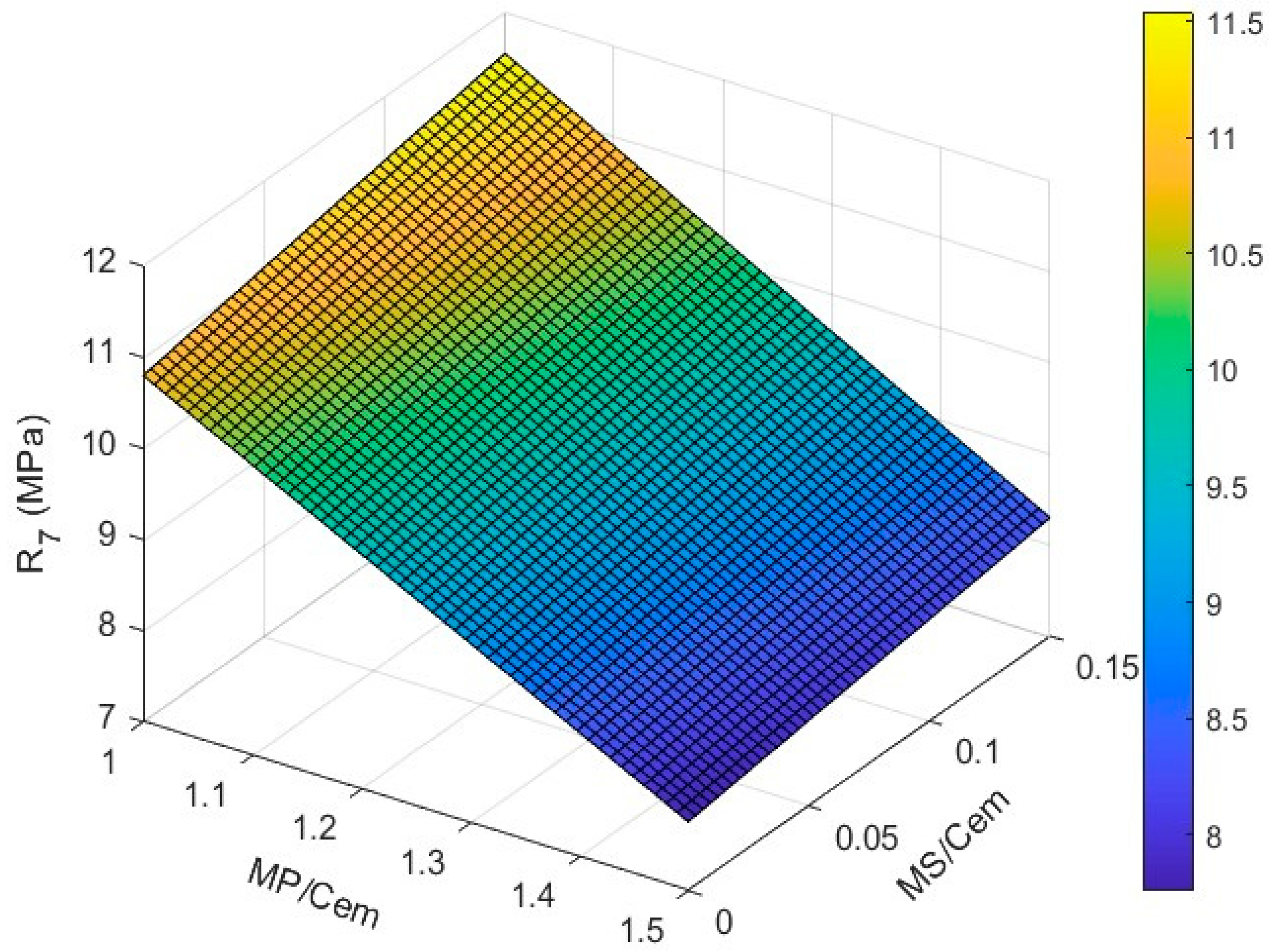

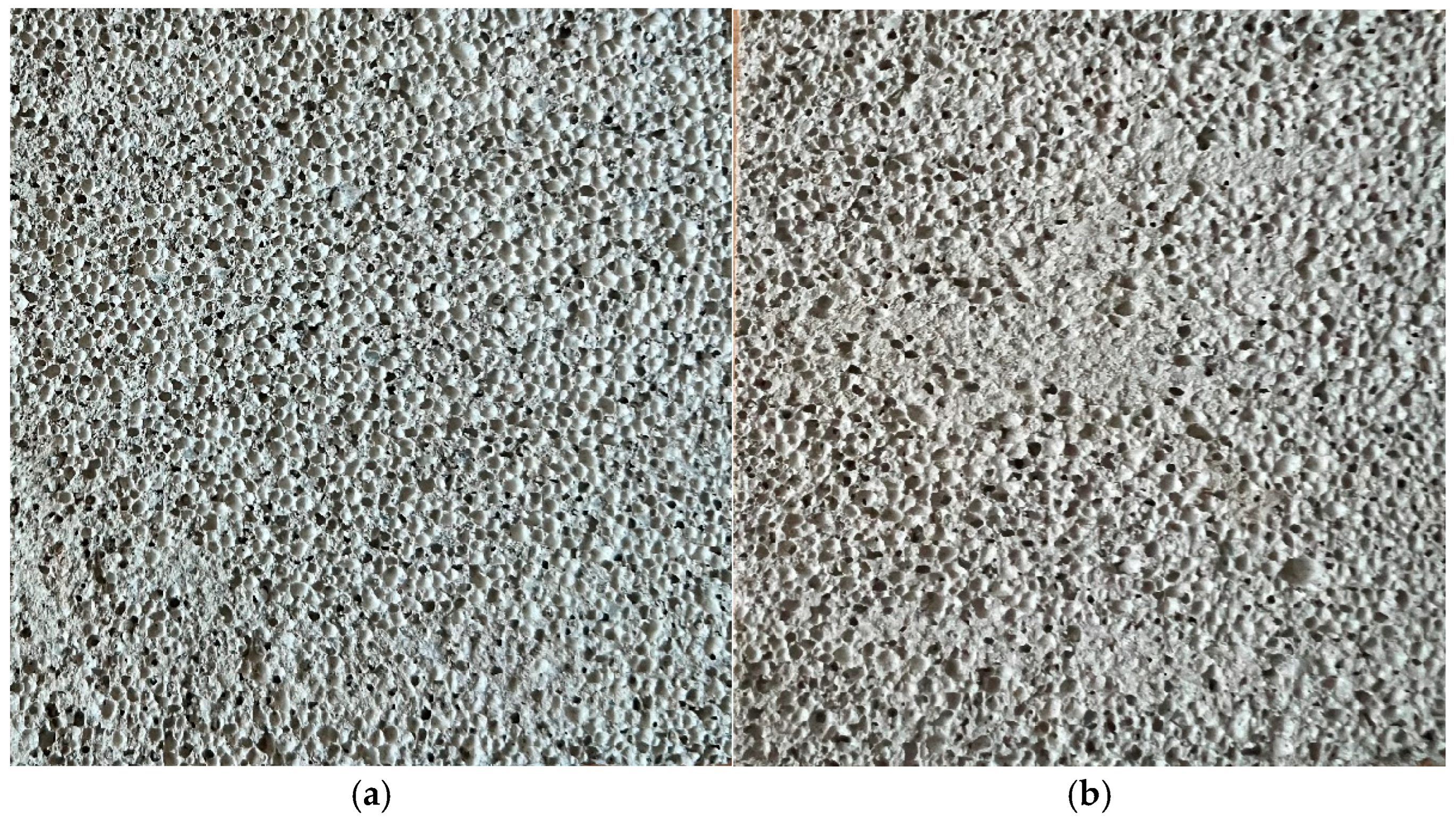

3. Experimental Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pestsov, V.I.; Otsokov, K.A.; Pinsker, V.V.P. Efficiency of using cellular concrete in construction in Russia. Constr. Mater. 2004, 3, 7–8. [Google Scholar]

- Khaliq, A.; Verma, A. Strength Analysis of Aerated Concrete. Int. J. Sci. Res. Eng. Trends 2022, 8, 321–327. [Google Scholar]

- Jain, D.; Hindoriya, A.K.; Bhadauria, S.S. Evaluation of properties of cellular lightweight concrete. AIP Conf. Proc. 2019, 2158, 020034. [Google Scholar]

- Loganina, V.I.; Pylaev, V.S.; Klyuev, S.V.; Shambina, S.L.; Trukhanov, S.V.; Shodiev, B.N.; Hasanov, K. Influence of polysaccharide additives on carbonization of lime coatings. In Proceedings of the 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering 2024 (ISCEIE 2024), Tashkent, Uzbekistan, 22–23 February 2024. [Google Scholar] [CrossRef]

- Ferraa, N.; Ouakki, M.; Alaoui, K.; Cherkaoui, M.; Ziatni, M.B. Sustainable enhancement of steel corrosion inhibition in saline environments using Ca2.7Mg6.3(HPO4)(PO4)5(OH) and Ca3Mg7(PO4)6(OH)2: Synthesis, characterization, electrochemical and chemometric investigations. J. Mol. Struct. 2025, 1348, 143480. [Google Scholar] [CrossRef]

- Davidyuk, A.A.; Fiskind, E.S.; Gusar, O.A.; Balakireva, V.V. Advantages in the production and use of cellular concrete block. Constr. Mater. 2018, 12, 41–43. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2020, 22, 321–329. [Google Scholar] [CrossRef]

- Abdel-Gawwad, H.A.; Mohammed, M.S.; Arif, M.A.; Shoukry, H. Reuse of lead glass sludge in the fabrication of thermally insulating foamed glass with outstanding properties and high Pb-stabilization. Environ. Sci. Pollut. Res. 2022, 29, 47209–47224. [Google Scholar] [CrossRef]

- Sarje, H.K.; Autade, A.S. Study of performance of lightweight concrete. Int. J. Latest Trends Eng. Technol. 2014, 4, 336–340. [Google Scholar]

- Azghay, I.; Dikici, B.; Zannagui, C.; Dalouh, M.; Aktaş, A.; Gök, Y.; Lahhit, A.; Elyoussfi, A.; Ahari, M.; El Barkany, S.; et al. Corrosion inhibition of mild steel in acidic media using benzimidazolium salts: An experimental and computational approach. Colloids Surf. A Physicochem. Eng. Asp. 2025, 726, 137815. [Google Scholar] [CrossRef]

- Almetwally, E.M.; Attia, M.E.H.; Elazab, M.; Bassyouni, M.; Kabeel, A. Improving thermal efficiency and water production in conical solar stills through integrating pistachio shells and paraffin wax phase change material. Energy Convers. Manag. 2025, 346, 120462. [Google Scholar] [CrossRef]

- Shon, C.S.; Mukangali, I.; Zhang, D.; Ulykbanov, A.; Kim, J. Evaluation of Non-Autoclaved Aerated Concrete for Energy Behaviors of a Residential House in Nur-Sultan. Buildings 2021, 11, 610. [Google Scholar] [CrossRef]

- Walcza, P.; Szymański, P.; Różycka, A. Autoclaved aerated concrete based on fly ash in density 350 kg/m3 as an environmentally friendly material for energy-efficient constructions. Procedia Eng. 2015, 122, 39–46. [Google Scholar] [CrossRef]

- Jones, M.; Mc Carthy, A. Utilising unprocessed low-lime coal fly ash in foamed concrete. Fuel 2005, 84, 1398–1409. [Google Scholar] [CrossRef]

- Raman, M.; Ryan, T.; Olfman, L. Designing knowledge management systems for teaching and learning with wiki technology. J. Inf. Syst. Educ. 2005, 16, 311–320. [Google Scholar]

- Alexiou Ivanova, T.; Paramonova, K.; Talipov, O.; Tanyrbergenov, N.; Zhakupov, T.; Akayev, A. Assessment of common reed (Phragmites australis (Cav.) Trin. ex Steud.) biomass suitability for solid biofuels production. Sustainability 2024, 16, 7378. [Google Scholar] [CrossRef]

- Prokhorov, S.B. Development prospects and features of the use of Russian specialized aluminum blowing agents. Constr. Mater. 2013, 4, 94–95. [Google Scholar]

- Annand, P.; Sinha, A.K.; Rajhans, P. Enhancing the performance of aerated concrete through accelerated curing waste material integration Available to Purchase. Adv. Cem. Res. 2024, 36, 406–426. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the long-term performance of aerated concrete containing mineral admixtures. J. Build. Eng. 2024, 86, 108892. [Google Scholar]

- Sadenova, M.A.; Kulenova, N.A.; Rudenko, O.V.; Anop, D.K. Features of Producing Non-Autoclaved Aerated Concrete With Additives of Mineral and Technogenic Raw Materials. Chem. Eng. Trans. 2024, 114, 217–222. [Google Scholar] [CrossRef]

- Shaumarov, S.; Kandakhorov, S.; Babaev, A.; Kodirov, B. Modeling development of optimal composition of non-autoclaved aerated concrete based on industrial waste. E3S Web Conf. 2023, 401, 03011. [Google Scholar] [CrossRef]

- Ding, X.; Chen, C.; Jiu, S.; Song, Q.; Chen, Y. Preparation and Characterization of a Novel Nonautoclaved Aerated Concrete Based on Magnesium Phosphate Cement. J. Mater. Civ. Eng. 2025, 37, 04025286. [Google Scholar] [CrossRef]

- Chen, C.; Ding, X.; Wang, Y.; Luo, Z.; Zhai, P. Fractal dimension analysis of structure and bending strength of porous alumina prepared using starch and carbon fiber as pore-forming agents. Fractal Fract. 2022, 6, 574. [Google Scholar] [CrossRef]

- Muxtorov, A.; Toshev, A.; Kodirov, T. Innovative leather composites in construction: Environmental performance of modified silk hydrolysate fillers. E3S Web Conf. 2025, 648, 03006. [Google Scholar] [CrossRef]

- Dyikanbaeva, N.A. Non-claved aerated concrete from natural and man-made raw materials of Kyrgyzstan. Bull. KRSU 2017, 17, 123–126. [Google Scholar]

- Guvalov, A.A.; Abbasova, S.I. Effect of stone dust on properties of cement composition. Sci. Work. Azerbaijan Univ. Archit. Constr. 2018, 1, 60–64. [Google Scholar]

- Liu, B.; Yu, R. Properties of aerated concrete prepared from steel slag and ground granulated blast furnace slag. Cem. Concr. Res. 2022, 151, 106609. [Google Scholar]

- Ganasen, N.; Bahrami, A.; Loganathan, K. Experimental investigation and optimization of lightweight concrete with vermiculite. Front. Mater. 2023, 10, 1117138. [Google Scholar] [CrossRef]

- Wang, Z.; Li, G. Mechanical properties and microstructure of aerated concrete based on nickel slag. J. Clean. Prod. 2023, 387, 135823. [Google Scholar]

- Jiang, Y.; Sun, Z. Development of eco-friendly aerated concrete using copper slag and lime. Constr. Build. Mater. 2024, 411, 134467. [Google Scholar]

- Matyeva, A.; Melibaev, S.; Sardarbekova, E.; Kyzy, E.M.; Asanalieva, Z. Development of the composition and properties of a wall block made of non-autoclaved aerated concrete based on secondary raw materials of the Kyrgyz Republic. Arch. Stud. 2024, 1, 46–58. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Elshaeva, D.; Chernil’nik, A.; Razveeva, I.; Panfilov, I.; Kozhakin, A.; Madenci, E.; Aksoylu, C.; et al. Porosity Analysis and Thermal Conductivity Prediction of Non-Autoclaved Aerated Concrete Using Convolutional Neural Network and Numerical Modeling. Buildings 2025, 15, 2442. [Google Scholar] [CrossRef]

- Bakr, M.A.; Singh, B.K.; Deifalla, A.F.; Pandey, S.; Hussain, A.; Ragab, A.E.; Alvi, S.S.; Hasnain, S.M. Assessment of the mechanical and durability characteristics of bio-mineralized Bacillus subtilis self-healing concrete blended with hydrated lime and brick powder. Case Stud. Constr. Mater. 2023, 19, e02672. [Google Scholar] [CrossRef]

- Rudenko, O.; Galkina, D.; Sadenova, M.; Beisekenov, N.; Kulisz, M.; Begentayev, M. Modelling the properties of aerated concrete on the basis of raw materials and ash-and-slag wastes using machine learning paradigm. Front. Mater. 2024, 11, 1481871. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Dotsenko, N.; Kotenko, M. Influence of Recipe Factors on the Structure and Properties of Non-Autoclaved Aerated Concrete of Increased Strength. Appl. Sci. 2022, 12, 6984. [Google Scholar] [CrossRef]

- Il’iNa, L.V.; Rakov, M.A. Non-Autoclaved Aerated Concrete with Mineral Additives. In Proceedings of the Advanced Materials in Technology and Construction (AMTC-2015) Proceedings of the II All-Russian Scientific Conference of Young Scientists “Advanced Materials in Technology and Construction”, Tomsk, Russia, 6–9 October 2015; Volume 1698, p. 070007. [Google Scholar] [CrossRef]

- Gvalov, A.A.; Abbasova, S.I. Composite Materials Technology; Azerbaijan Education Ministry: Baku, Azerbaijan, 2019; 196p. [Google Scholar]

- Omran, Ş. A Review of Lightweight Concrete in Civil Engineering. J. Civ. Eng. Urban. 2024, 14, 378–404. [Google Scholar] [CrossRef]

- Shinkevich, E.S.; Lutskin, E.S. Technological features of production of non-autoclaved licata products. Constr. Mater. 2008, 11, 54–56. [Google Scholar]

- Amran, M.; Huang, S.; Debbarma, S.; Rashid, R.S.M. Utilization of fly ash in aerated concrete: A review on durability and mechanical properties. J. Build. Eng. 2022, 45, 103556. [Google Scholar]

- Zhang, P.; Wang, K.; Wang, J.; Guo, J. Mechanical and thermal properties of high-volume fly ash aerated concrete. Constr. Build. Mater. 2021, 301, 124337. [Google Scholar]

- Liu, J.; Wang, D.; Tang, W. Synergistic effect of fly ash and silica fume on the autoclaved aerated concrete performance. Case Stud. Constr. Mater. 2023, 18, 114–126. [Google Scholar]

- Stelmakh, S.A.; Shcherban, E.O.; Lotoshnikova, A.V.; Yanovskaya, N.A.; Dotsenko. Influence of complex additives on physical and mechanical properties of non-autoclaved gas concrete. Bull. Belgorod State Technol. Univ. Named After V. G. Shukhov 2017, 9, 15–18. (In Russian) [Google Scholar] [CrossRef]

- Esmaily, H.; Nuranian, H. Non-autoclaved high strength cellular concrete from alkali activated slag. Constr. Build. Mater. 2012, 26, 200–206. [Google Scholar] [CrossRef]

- Guvalov, A.A.; Abbasova, S.İ. Influence of Rheological Active Additives on the Properties of Self-compacting Concrete. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2021, 3, 381–386. [Google Scholar] [CrossRef]

- Ahmed, S.; Khan, M. Performance enhancement of aerated concrete by limestone filler and silica fume. Mater. Today Proc. 2024, 78, 110–119. [Google Scholar]

- Bekkaliev, N.; Sabitov, Y.; Lukpanov, R.; Zhumagulova, A.; Jexembayeva, A. Optimised Hydration and Durabilityof Non-Autoclaved Aerated Concretevia Lignin-Based Ionic Additive. Eng 2025, 6, 249. [Google Scholar] [CrossRef]

- Sabitov, Y.; Dyussembinov, D.; Zhumagulova, A.; Bazarbayev, D.; Lukpanov, R. Composite non-autoclaved aerated concrete based on an emulsion. Mag. Civ. Eng. 2021, 106, 10605. [Google Scholar]

- Ashtar, S. Al-Luhybi, Diyar Altalabani The Influence of Nano-Silica on the Properties and Microstructure of Lightweight Concrete: A Review. Mater. Sci. Eng. 2021, 1094, 012075. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, H.; Wang, Y. Microstructure and mechanical performance of lightweight concrete with microsilica. J. Build. Eng. 2023, 74, 107091. [Google Scholar]

- Fatullayev, R.F. Optimal short duration of flow construction production. Sci. Work. 2024, 2, 146. [Google Scholar]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Evtushenko, A.; El’shaeva, D.; Chernil’nik, A. Improving the Physical and Mechanical Characteristics of Modified Aerated Concrete by Reinforcing with Plant Fibers. Fibers 2023, 11, 33. [Google Scholar] [CrossRef]

- Zhong, D.; Wei, S.; Zhou, H.; He, X.; Qian, B.; Ma, B.; Hu, Y.; Ren, X. The Influence of Retreated Lithium Slag with a High Content of Alkali, Sulfate and Fluoride on the Composition and the Microstructure of Autoclaved Aerated Concrete. Materials 2024, 17, 2569. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zhu, R.; Xu, B. Rehydration Activity of High-Temperature Calcined Recycled Sand Autoclaved Aerated Concrete. Processes 2023, 11, 422. [Google Scholar] [CrossRef]

- Peng, F.; Chen, C.; Jiu, S.; Song, Q.; Chen, Y. Preparation and Characterization of Novel Sulfoaluminate-Cement-Based Nonautoclaved Aerated Concrete. Materials 2024, 17, 836. [Google Scholar] [CrossRef] [PubMed]

- Rudenko, O.V.; Charykov, N.A.; Kulenova, N.A.; Sadenova, M.A.; Anop, D.K.; Kuldeyev, E. Aerated Concrete, Based on the Ash of Thermal Power Plants, Nanostructured with Water-Soluble Fullerenols. Processes 2024, 12, 2139. [Google Scholar] [CrossRef]

- AZS EN 197-1; Cement. Part 1: Composition, Technical Requirements and Conformity Criteria for General Purpose Cements. Azerbaijan Standardization Institute: Bakı, Azerbaijan, 2021.

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Shuyskiy, A.; Beskopylny, N.; Dotsenko, N. Mathematical Modeling and Experimental Substantiation of the Gas Release Process in the Production of Non-Autoclaved Aerated Concrete. Materials 2022, 15, 2642. [Google Scholar] [CrossRef] [PubMed]

| № | Composition of the Mixture | Spread According to Suttard, sm | Compressive Strength, 7 Days, MPa | |

|---|---|---|---|---|

| MP/Cem | MS, % by Mass | |||

| 1 | 1.0 | 0 | 16 | 10.9 |

| 2 | 1.25 | 0 | 16 | 9.0 |

| 3 | 1.5 | 0 | 16 | 7.6 |

| 4 | 1.0 | 7.5 | 16 | 12.1 |

| 5 | 1.25 | 7.5 | 16 | 11.2 |

| 6 | 1.5 | 7.5 | 16 | 8.8 |

| 7 | 1.0 | 15 | 16 | 11.4 |

| 8 | 1.25 | 15 | 16 | 9.0 |

| 9 | 1.5 | 15 | 16 | 8.4 |

| № | FL | FV | X1X2 | SS, cm | W/C | CS, 7 Days, MPa | AD y, kg/m3 | ||

|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | MP/Cem | MS/Cem | ||||||

| 1 | −1 | −1 | 1 | 0 | +1 | 16 | 0.40 | 10.9 | 1630 |

| 2 | +1 | −1 | 1.5 | 0 | −1 | 15 | 0.38 | 7.6 | 1565 |

| 3 | −1 | +1 | 1 | 0.15 | −1 | 16 | 0.42 | 11.4 | 1640 |

| 4 | +1 | +1 | 1.5 | 0.15 | +1 | 16 | 0.41 | 8.4 | 1605 |

| 5 | −1 | 0 | 1 | 0.075 | 0 | 16 | 0.40 | 12.1 | 1700 |

| 6 | +1 | 0 | 1.5 | 0.075 | 0 | 15 | 0.39 | 8.8 | 1610 |

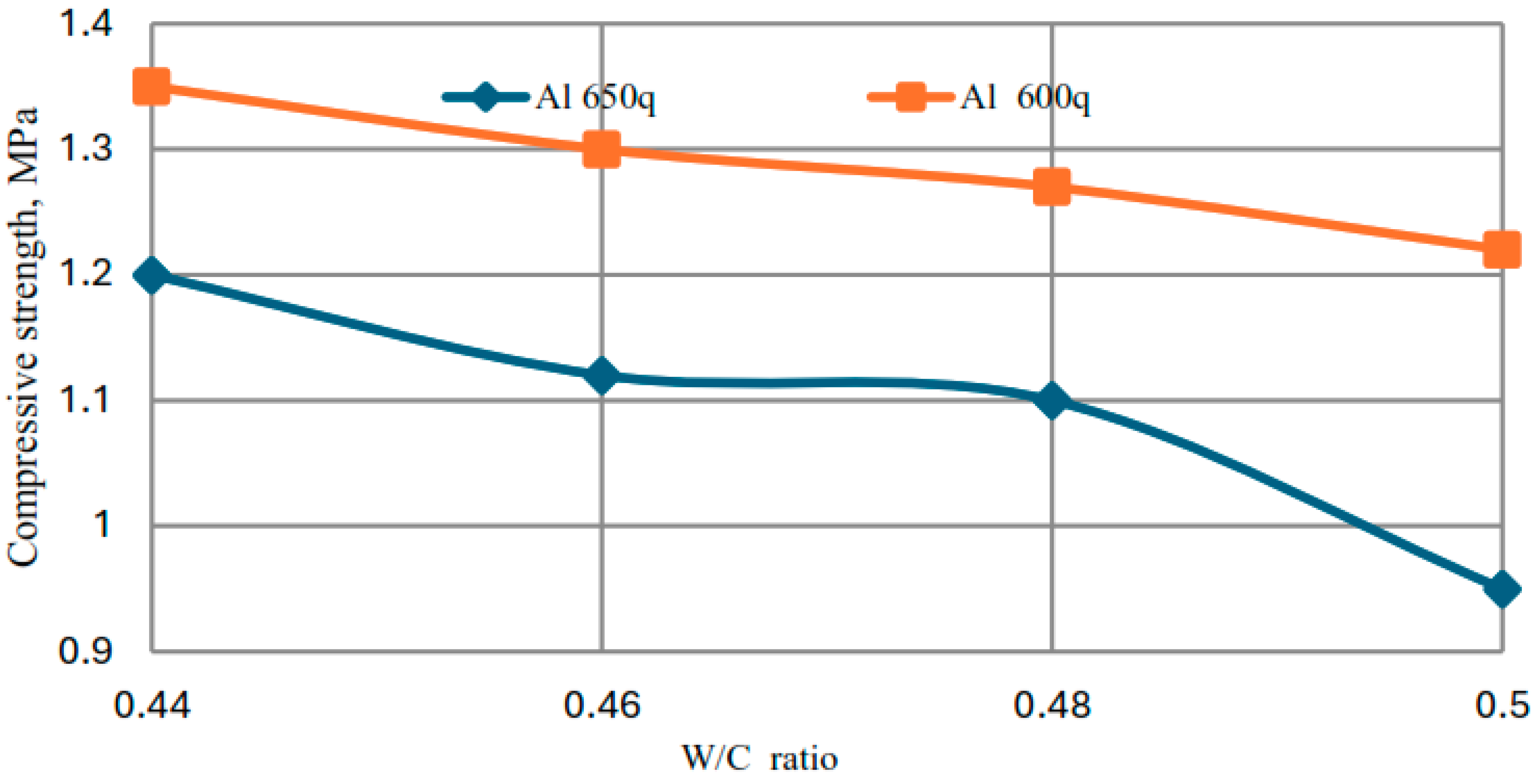

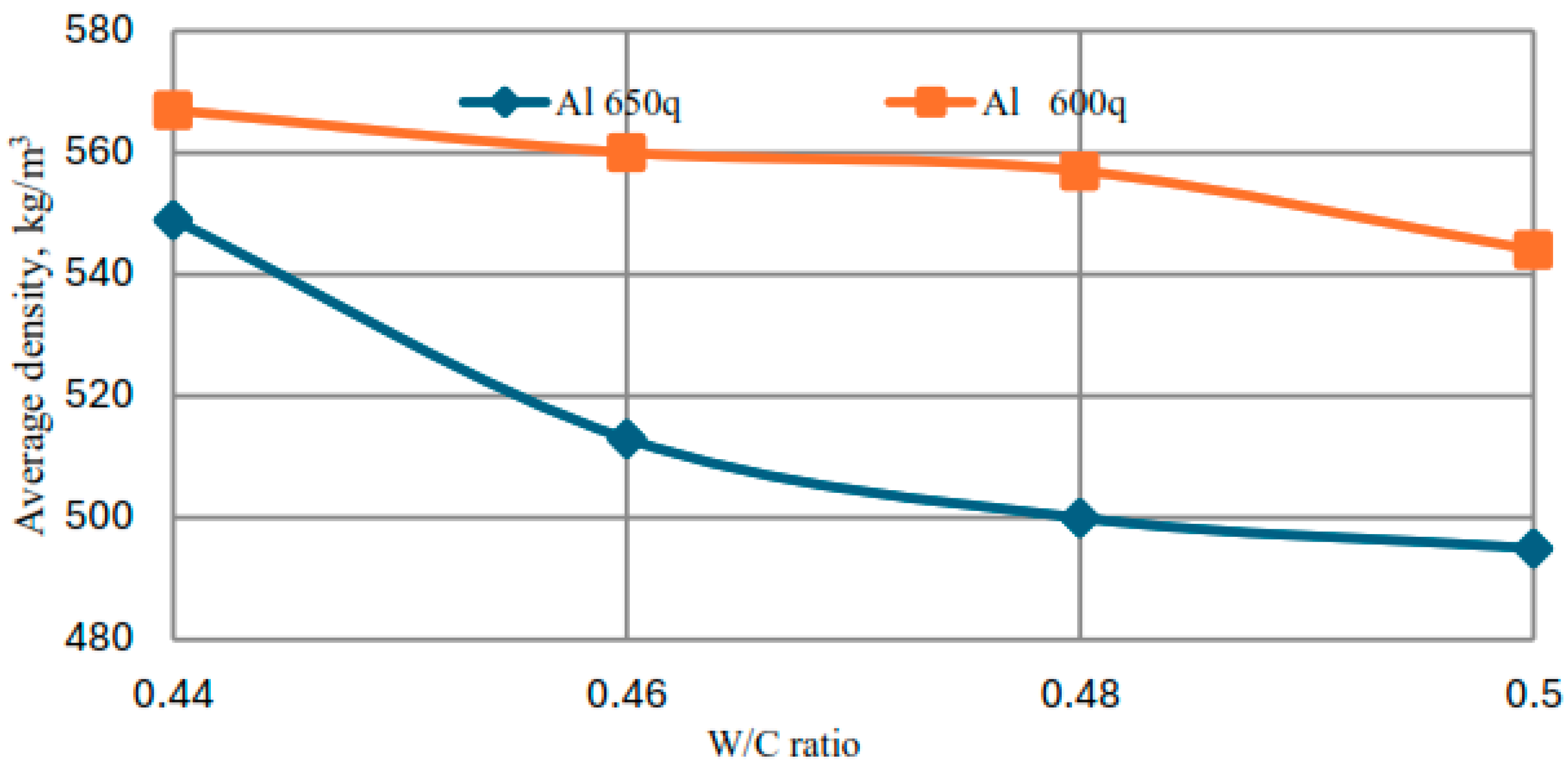

| № | FVs | ToM (°C) | Foaming Time, min | CS, (MPa) | AD (kg/m3) | ||

|---|---|---|---|---|---|---|---|

| W/S | 1 m3 Al Content (g) | 7 Days | 28 Days | ||||

| 1 | 0.50 | 650 | 40 | 8 | 0.62 | 0.95 | 495 |

| 2 | 0.48 | 650 | 41 | 10 | 0.65 | 1.10 | 500 |

| 3 | 0.46 | 650 | 40 | 11 | 0.67 | 1.12 | 513 |

| 4 | 0.44 | 650 | 39 | 12 | 0.70 | 1.20 | 549 |

| 5 | 0.48 | 600 | 41 | 11 | 0.78 | 1.27 | 557 |

| 6 | 0.44 | 600 | 41 | 11 | 0.80 | 1.35 | 567 |

| 7 | 0.50 | 600 | 42 | 11 | 0.74 | 1.15 | 544 |

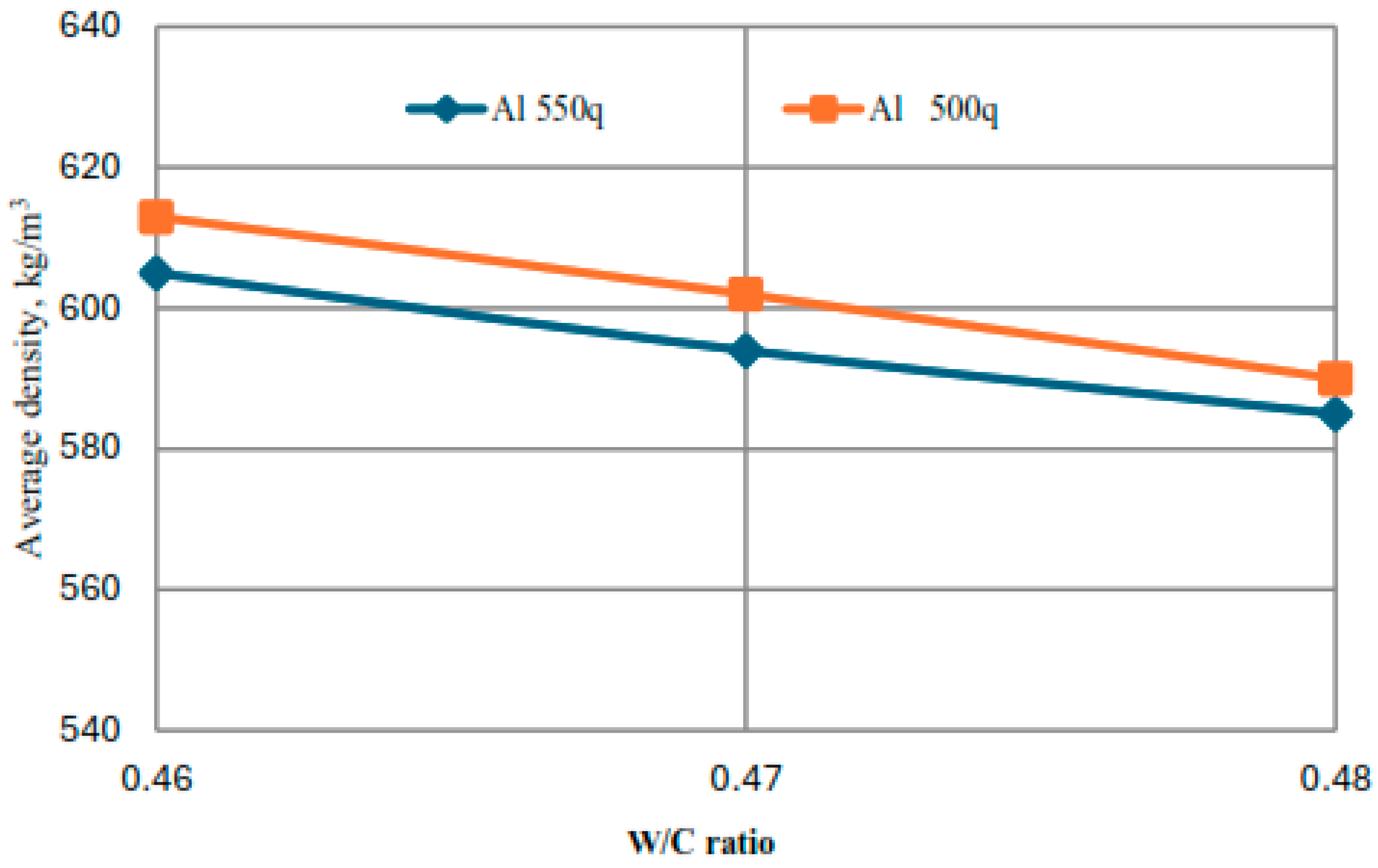

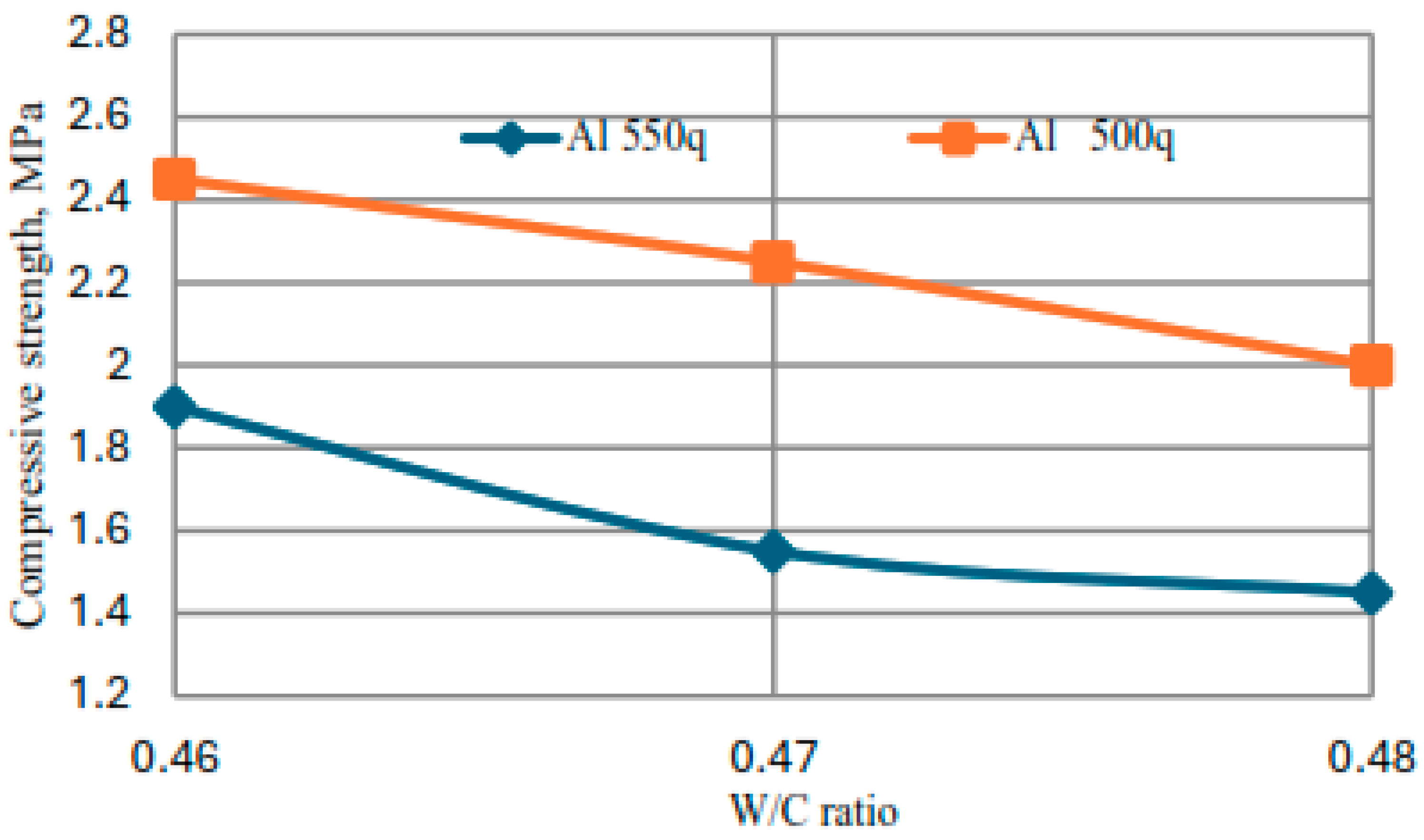

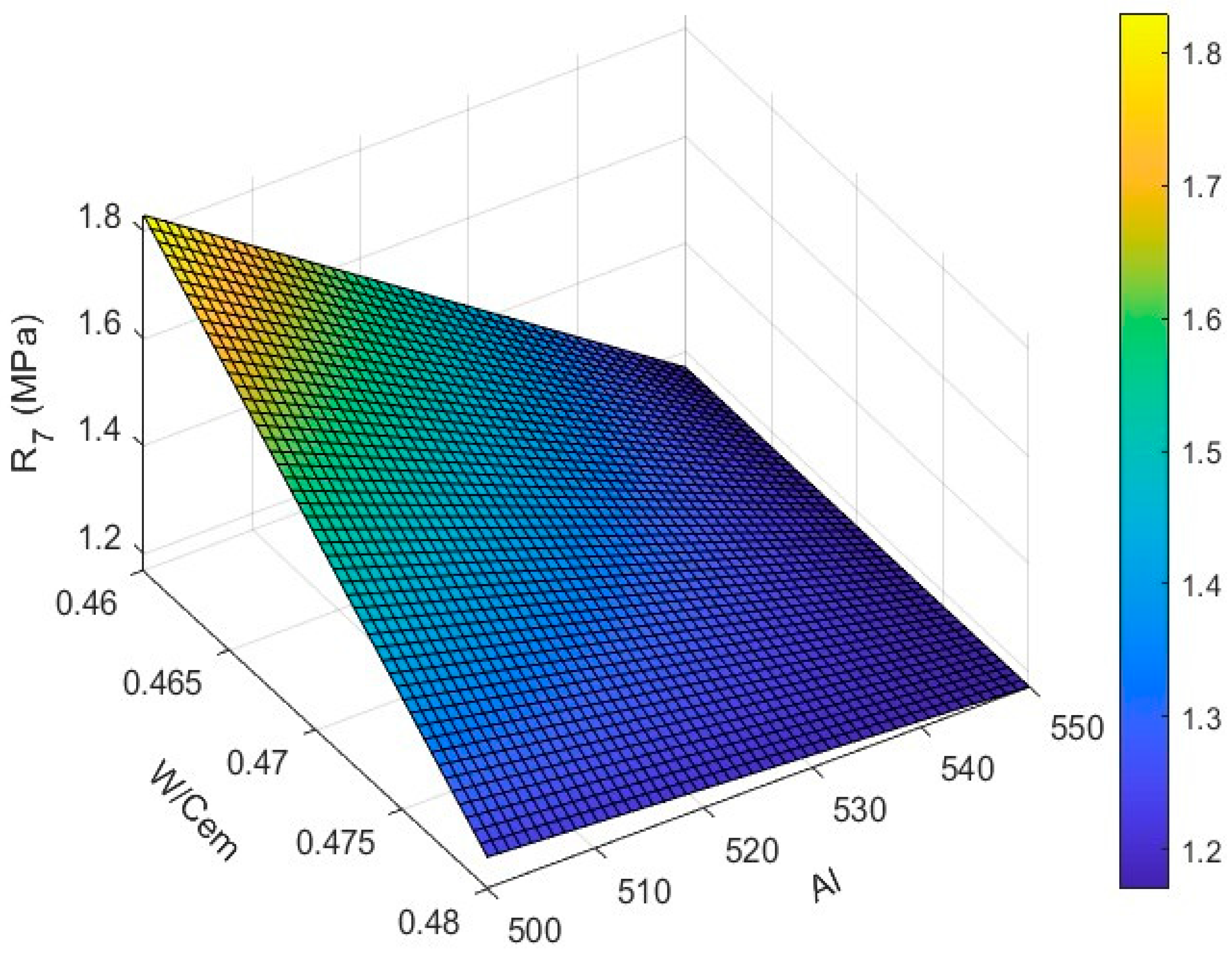

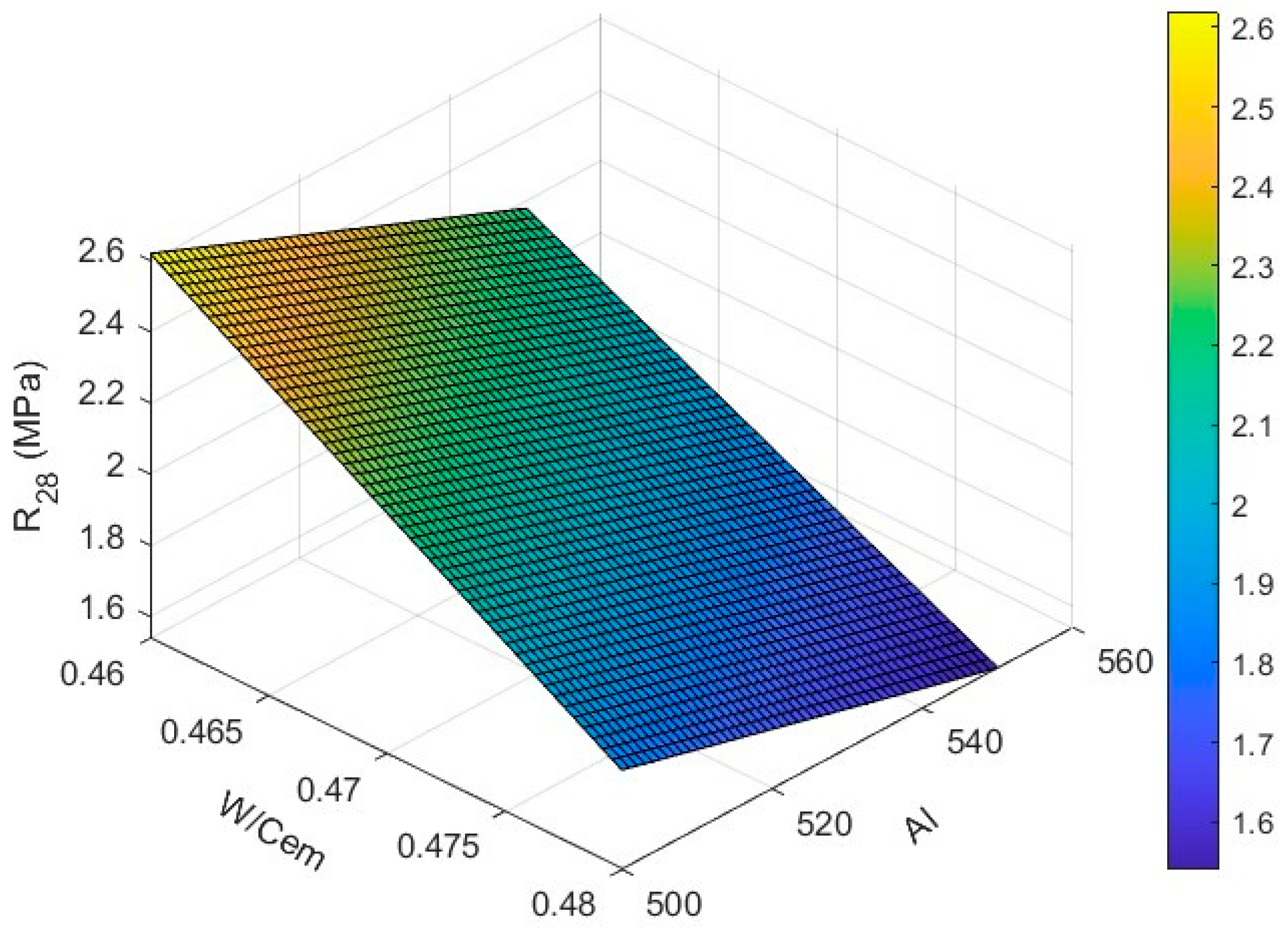

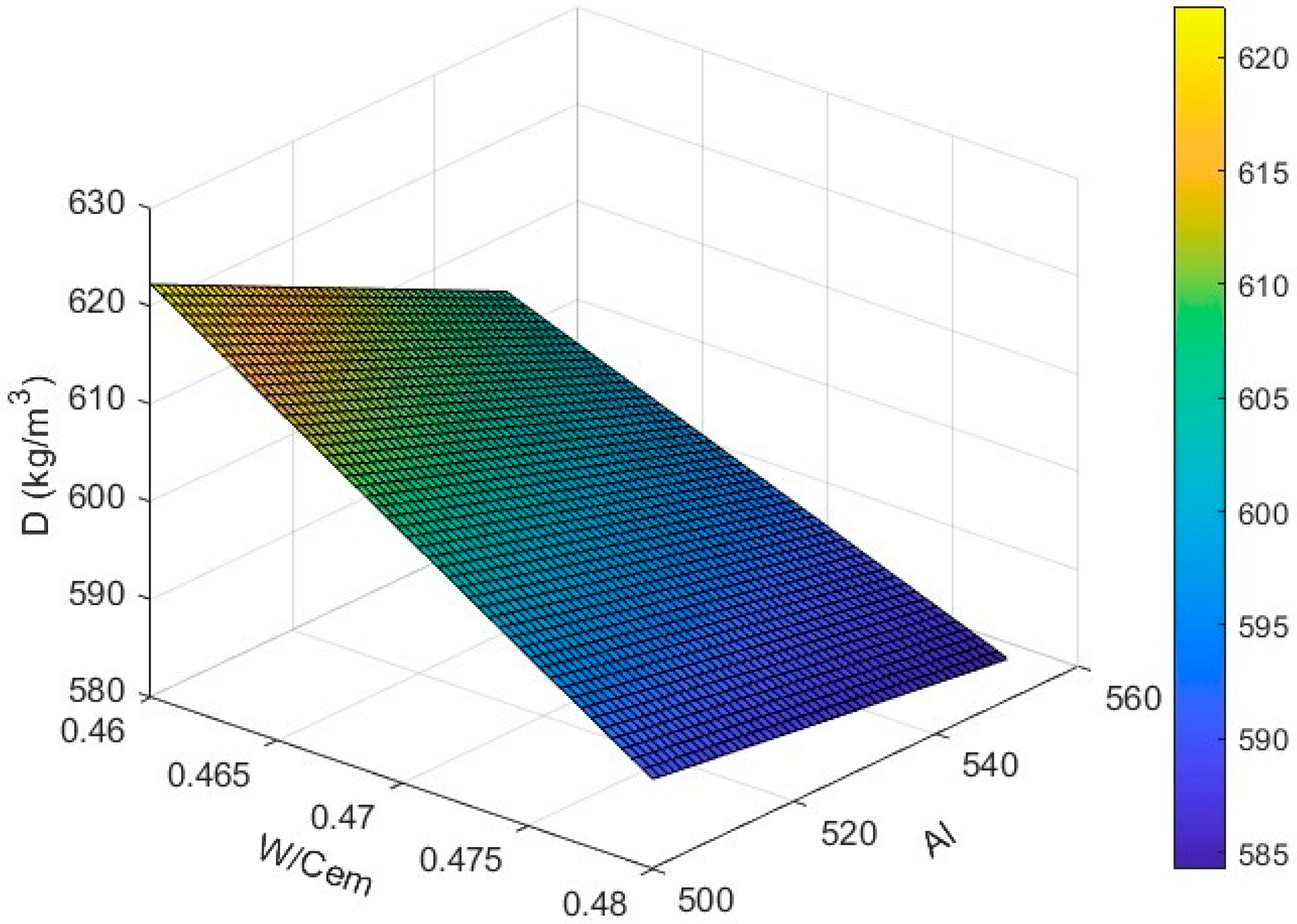

| № | The Value of Factors in Coded Form | The Price of Factors in Their Natural State | Foaming Time, min | Compressive Strength, MPa | Average Density, kg/m3 | |||

|---|---|---|---|---|---|---|---|---|

| W/C | Al Content in 1 m3 Mixture | W/C | 7 Days | 7 Days | 28 Days | |||

| 1 | −1 | −1 | 0.46 | 500 | 11 | 1.62 | 2.45 | 623 |

| 2 | +1 | −1 | 0.48 | 500 | 11 | 1.24 | 2.00 | 590 |

| 3 | −1 | +1 | 0.46 | 550 | 11 | 1.38 | 2.15 | 605 |

| 4 | +1 | +1 | 0.48 | 550 | 10 | 1.15 | 1.55 | 585 |

| 5 | 0 | 0 | 0.47 | 525 | 10 | 1.35 | 2.24 | 600 |

| № | Settings | D600 |

|---|---|---|

| 1 | MP/Cem | 1.25 |

| 2 | MS/Cem | 0.075 |

| 3 | W/Sem ratio | 0.47 |

| 4 | Amount of Al powder, g/m3 | 525 |

| 5 | Superplasticizer CORSO RMX, % | 0.6 |

| 6 | Na2SO4, % | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

, A.G.; Dursun, M. Increase of Efficient at Aerated Concrete Compositions Based on Mineral Powders. Appl. Sci. 2025, 15, 12364. https://doi.org/10.3390/app152312364

AG, Dursun M. Increase of Efficient at Aerated Concrete Compositions Based on Mineral Powders. Applied Sciences. 2025; 15(23):12364. https://doi.org/10.3390/app152312364

Chicago/Turabian Style(Kapanakchi), Abbas Guvalov, and Mahir Dursun. 2025. "Increase of Efficient at Aerated Concrete Compositions Based on Mineral Powders" Applied Sciences 15, no. 23: 12364. https://doi.org/10.3390/app152312364

APA Style, A. G., & Dursun, M. (2025). Increase of Efficient at Aerated Concrete Compositions Based on Mineral Powders. Applied Sciences, 15(23), 12364. https://doi.org/10.3390/app152312364