Research on the Stability of Tailings Dams Under the Combined Stacking of Waste Rock Pillars and Tailings

Abstract

1. Introduction

2. Physical Model Testing of Waste Rock Pillars

2.1. Project Overview

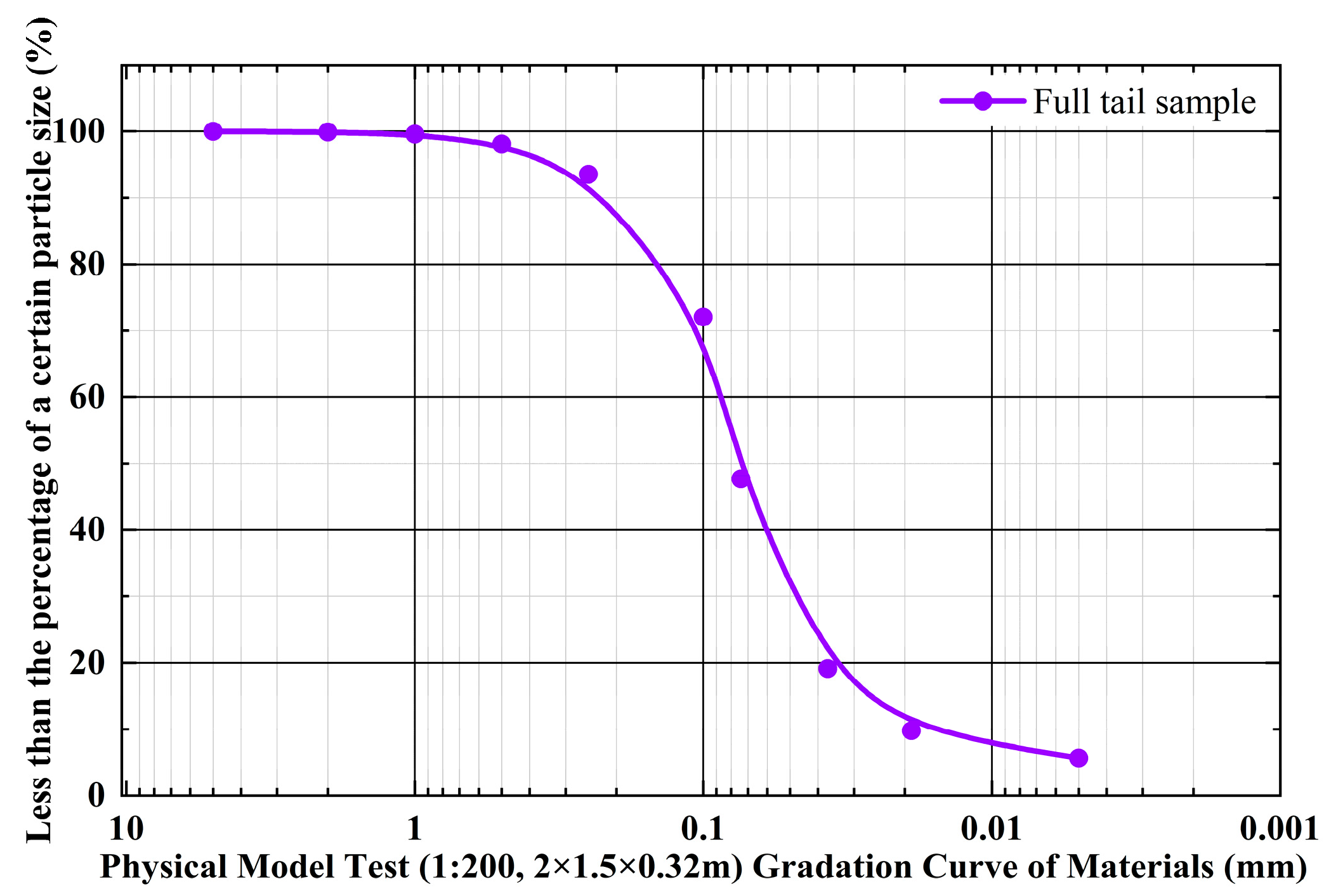

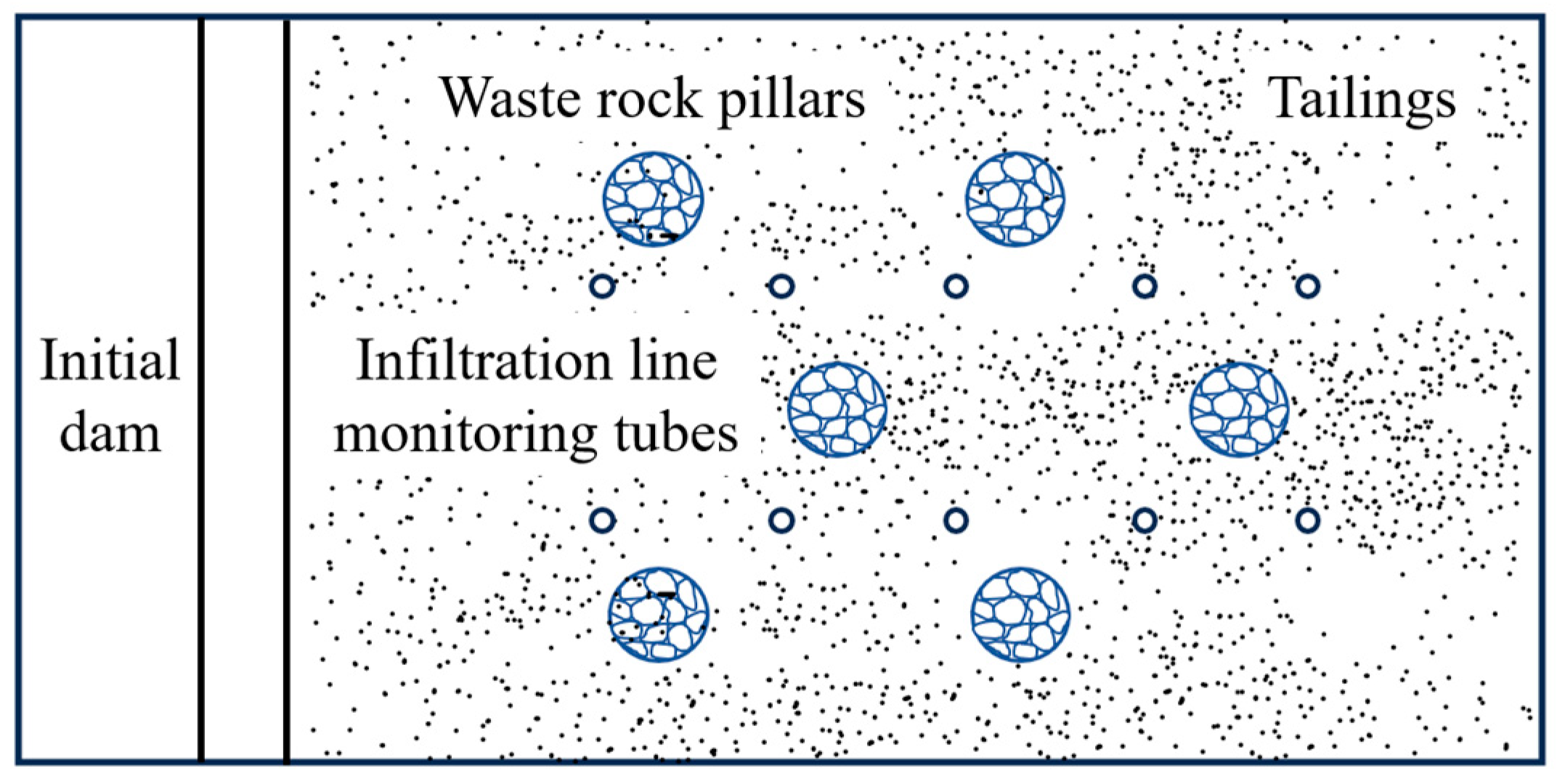

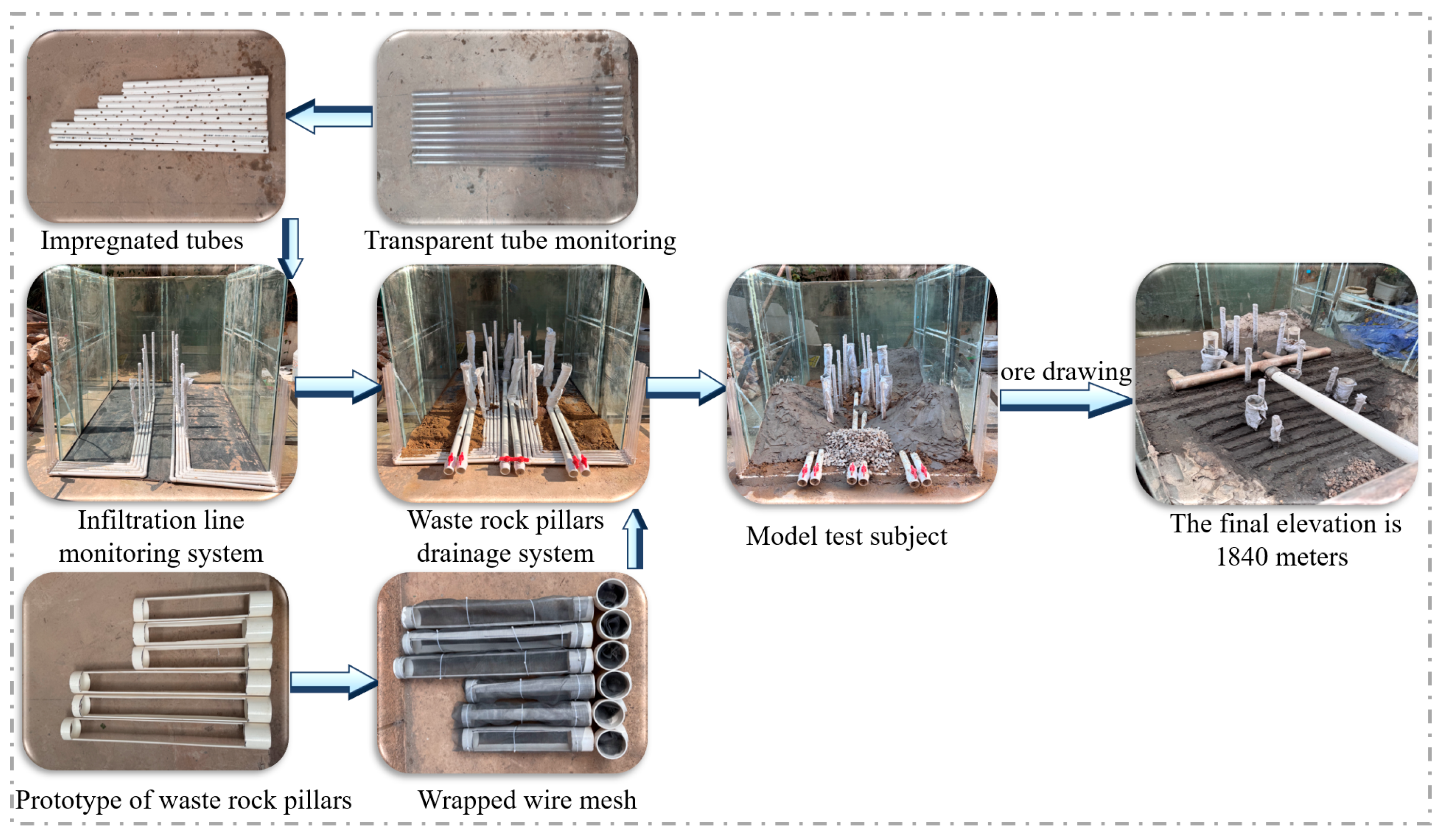

2.2. Model Test Design and Process

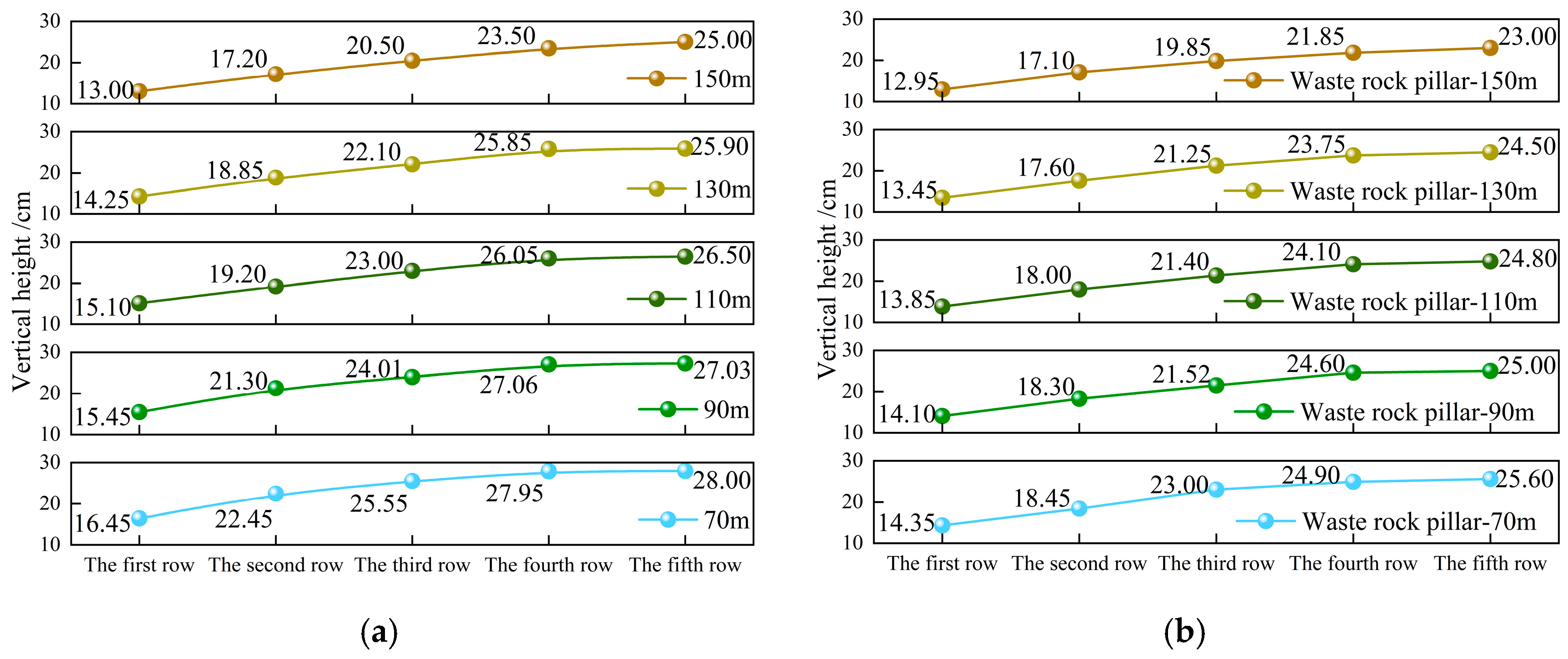

2.3. Analysis of Model Test Results

2.3.1. Seepage Analysis of Tailings Dams Without Waste Rock Pillars

2.3.2. Seepage Analysis of Tailings Dams Containing Waste Rock Pillars

3. Stability Analysis of Tailings Dams Under the Influence of Waste Rock Pillars

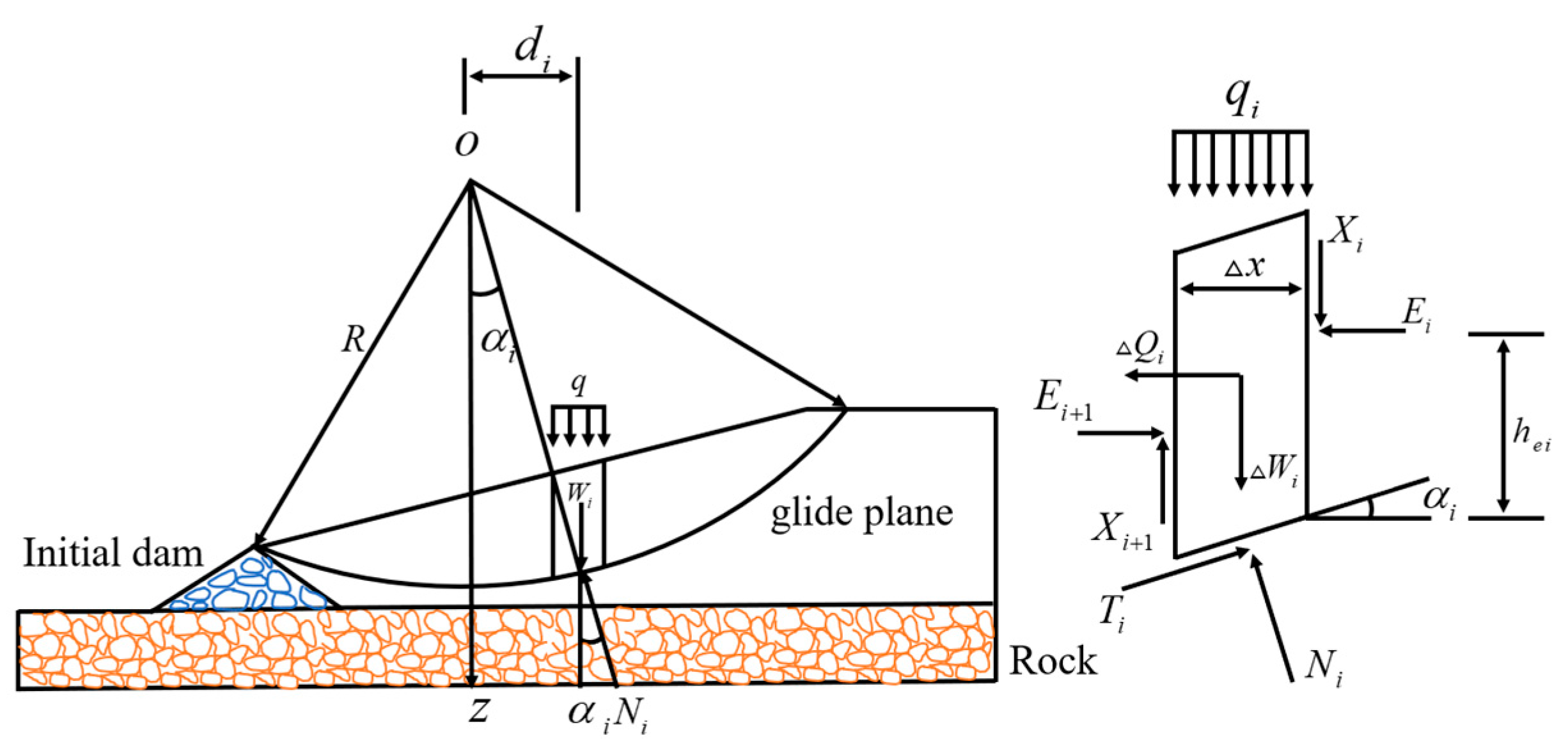

3.1. Theory of Stability Calculation

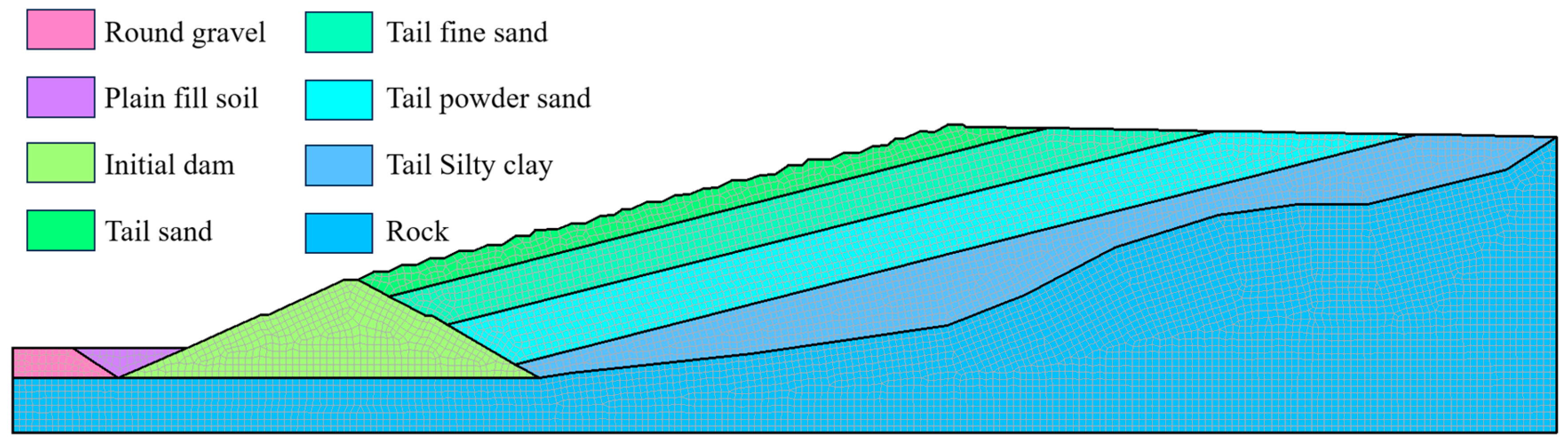

3.2. Model Establishment

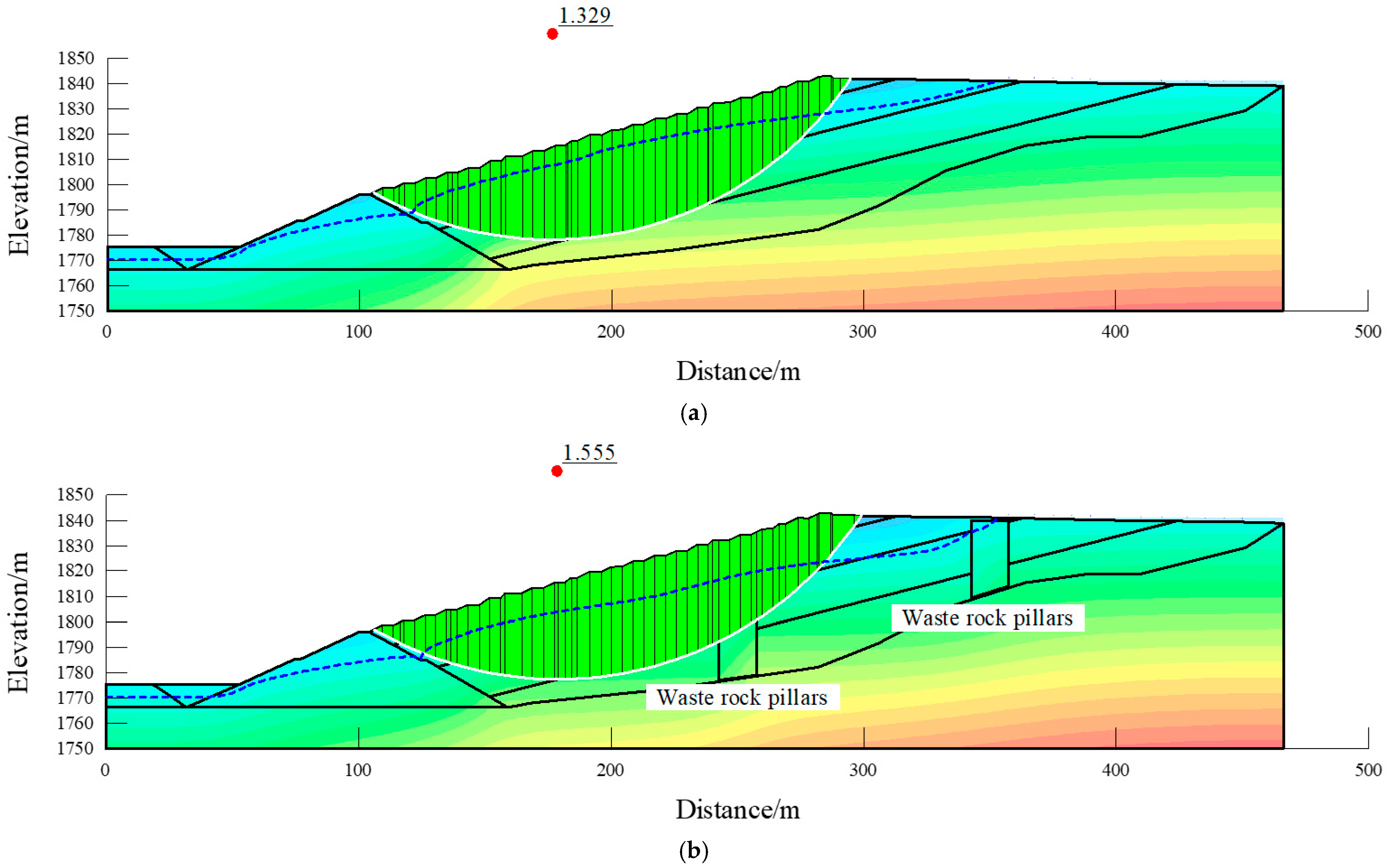

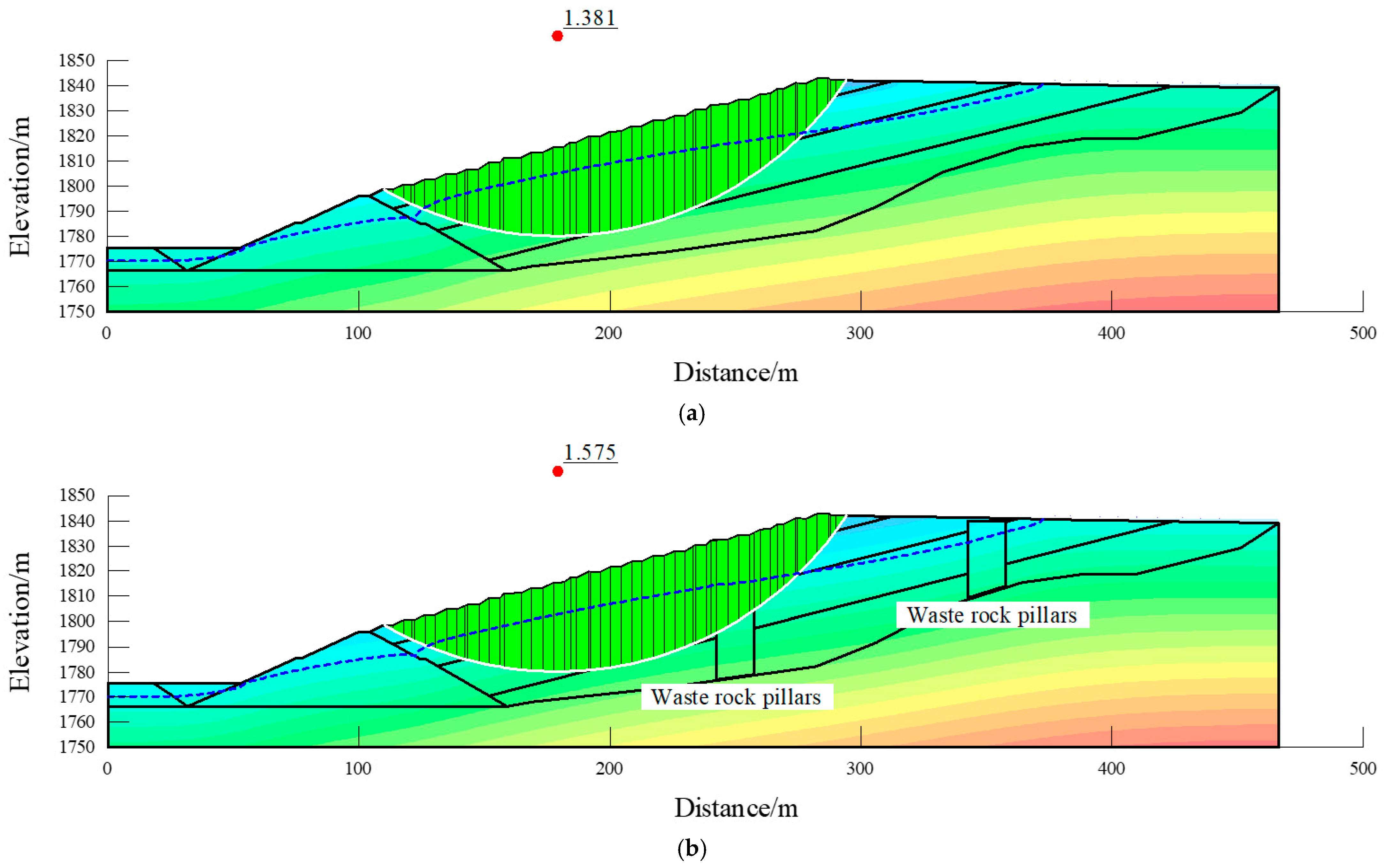

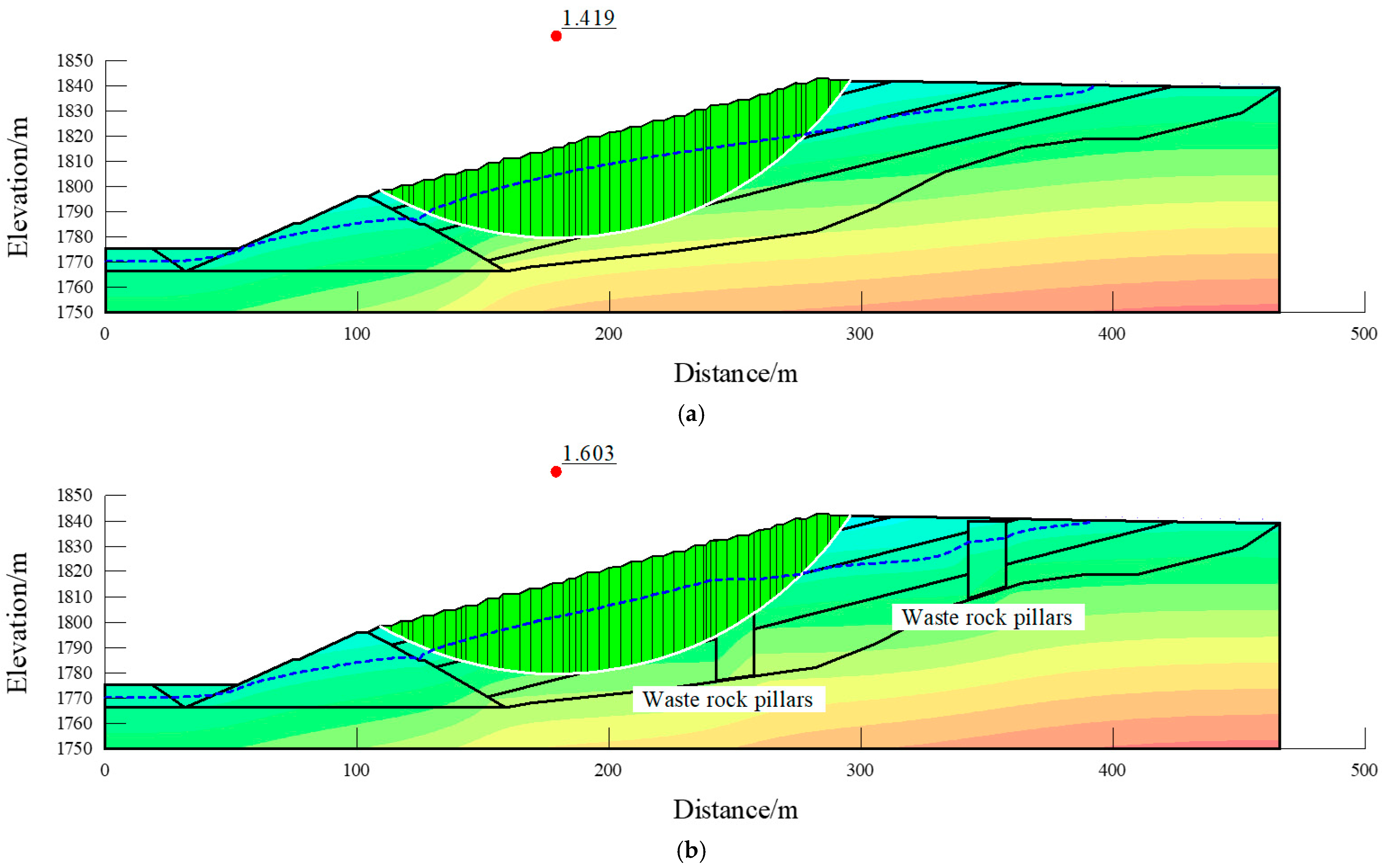

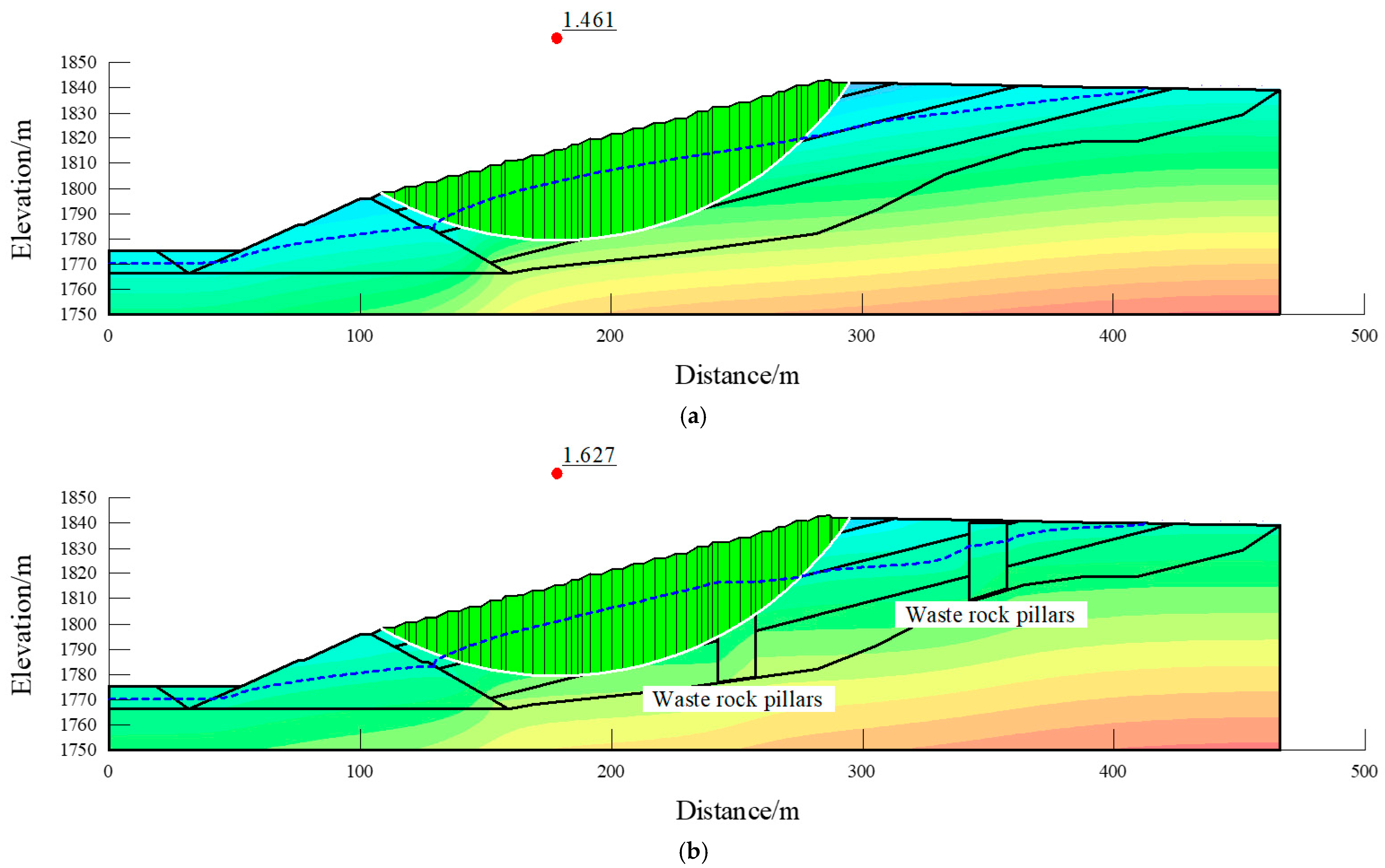

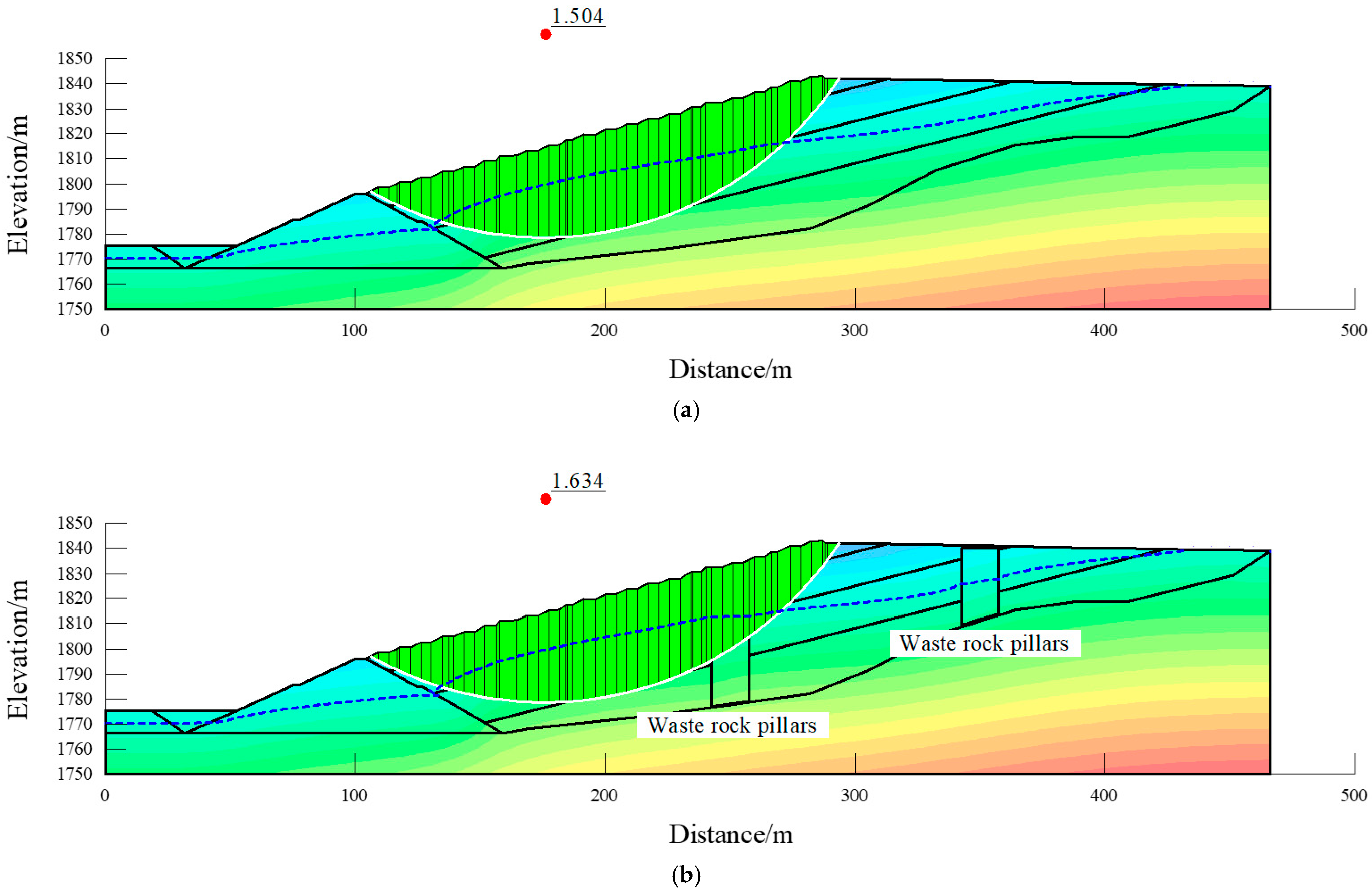

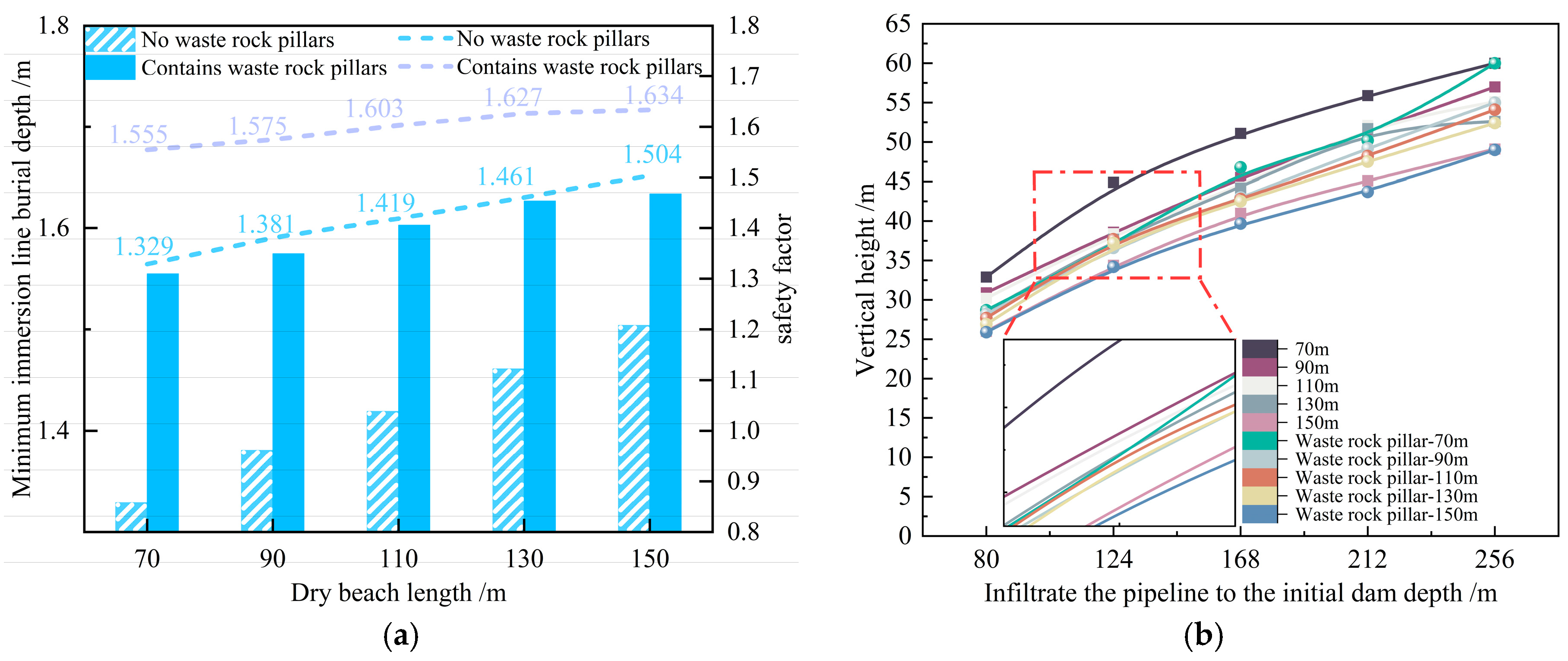

3.3. Simulation Analysis of Stability for Tailings Dams with Waste Rock Pillars at Different Dry Beach Lengths

3.4. Simulation Analysis of Seepage Stability

4. Discussion

5. Conclusions

- (1)

- For tailings dams without waste rock pillars, reducing the dry beach length from 150 m to 70 m caused the phreatic line to rise by 3.00–5.25 cm in the physical model. In contrast, dams incorporating waste rock pillars showed a smaller rise of only 1.35–3.15 cm under the same conditions. These results demonstrate that the proposed structure effectively deepens the burial depth of the phreatic line

- (2)

- The safety factor decreases as the dry beach shortens; however, incorporating waste rock pillars significantly enhances dam stability. Numerical results show that the safety factor increased from 1.329 to 1.555 at a 70 m dry beach length and from 1.504 to 1.634 at 150 m, representing improvements of 20.0% and 8.6%, respectively.

- (3)

- The waste rock pillars provide a substantially larger seepage area and greater resistance to clogging than traditional drainage pipes, resulting in enhanced drainage efficiency, reduced pore-water pressure, and improved downstream shear strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zare, M.; Nasategay, F.; Gomez, J.A.; Moayedi Far, A.; Sattarvand, J. A Review of Tailings Dam Safety Monitoring Guidelines and Systems. Minerals 2024, 14, 551. [Google Scholar] [CrossRef]

- Al-Janabi, A.M.S.; Dibs, H.; Sammen, S.S.; Yusuf, B.; Ikram, R.M.A.; Alzuhairy, S.H.; Kisi, O. Comparison Analysis of Seepage Through Homogenous Embankment Dams Using Physical, Mathematical and Numerical Models. Arab. J. Sci. Eng. 2025, 50, 8143–8152. [Google Scholar] [CrossRef]

- Contreras, C.A.; Yniesta, S.; Aubertin, M. Improvement of Tailings Impoundment Seismic and Post-Seismic Stability Using Densification and Waste Rock Inclusions. Can. Geotech. J. 2023, 60, 1629–1644. [Google Scholar] [CrossRef]

- Zeng, K.; Dai, H.; Yao, H. Fine Tailings Heap High Levels of Radiation Seepage Drainage Wells Application. IOP Conf. Ser. Earth Environ. Sci. 2019, 283, 012022. [Google Scholar]

- Zhang, H.; Shen, Z.; Liu, D.; Xu, L.; Gan, L.; Long, Y. A Suggested Equivalent Method for a Drainage Structure to Analyze Seepage in Tailings Dam. Materials 2022, 15, 7154. [Google Scholar] [CrossRef]

- Du, S.; Liu, P.; Wang, W.; Shi, W.; Li, Q.; Li, J.; Li, J. Numerical Simulation and Analysis of the Influencing Factors of Foundation Pit Dewatering under a Coupled Radial Well and Curtain. Water 2023, 15, 1839. [Google Scholar] [CrossRef]

- Jin, S.L.; Xu, H.D.; Zhang, W.; Yan, H.; Wu, Z.X. Research on Calculation Method and Drainage Mechanism of Slotted Pipe in Fine-Grained Tailings Dam. Metal Mine 2013, 03, 42–44+48. [Google Scholar]

- Zhang, S.M.; Cui, X. Analysis of the influence of three-dimensional drainage facilities in the soft beach on the seepage field of tailings pond. China Min. 2024, 33 (Suppl. 1), 157–163. [Google Scholar]

- Yang, H.; Wu, J.; Guo, C.; Li, H.; Wu, Z. Effects of Geotextile Envelope and Perforations on the Performance of Corrugated Drain Pipes. Int. J. Agric. Biol. Eng. 2023, 16, 36–44. [Google Scholar] [CrossRef]

- Xie, S.; Liu, H.; Huang, H.; Ye, F. Experimental Study on Effect of Geotextile Filter Layer on Flow of Perforated Pipe. J. Drain. Irrig. Mach. Eng. 2022, 40, 576–581. [Google Scholar]

- Yang, C.H.; Li, Z.H.; Mao, H.J.; Yang, J.; Zhang, C. Experimental study on the clogging mechanism of drainage system in tailings dam. J. Guangxi Univ. (Nat. Sci. Ed.) 2019, 44, 845–854. [Google Scholar]

- Wu, H.M.; Wang, W.S.; Yang, L.; Zhang, Z.; Ou, Z. Research on the Permeability Characteristics of Iron Tailings-Geotextile Filter Under Vacuum Conditions. J. Hohai Univ. (Nat. Sci. Ed.) 2025, 1–10. [Google Scholar]

- Du, C.; Tao, H.; Yi, F. Seepage Stability Analysis of Geogrid Reinforced Tailings Dam. Sci. Rep. 2024, 14, 1814. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Shen, Z.; Gan, L.; Xu, L.; Zhang, K.; Jin, T. The Seepage and Stability Performance Assessment of a New Drainage System to Increase the Height of a Tailings Dam. Appl. Sci. 2018, 8, 1840. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Feng, D. Experimental study on drainage characteristics of new composite drainage pipes in tailings pond. Chin. J. Geotech. Eng. 2019, 41, 2360–2366. [Google Scholar]

- Wang, C.; Li, L.; Wen, J.H.; Cai, F.Z.; Xu, L. Influence of single-row horizontal drainage pipe layout at top of initial dam on stability of tailings dam. China Saf. Prod. Sci. Technol. 2024, 20, 125–131. [Google Scholar]

- Chen, J.H.; Liu, X.W. Influence of different drainage pipe arrangement schemes on the seepage line of seepage field in tailings reservoir. Light Metal. 2020, 2, 1–8. [Google Scholar]

- Deni, M.C.N.; Afandi, K.; Sinamo, B.; Satriawan, A. Co-Disposal as an Alternative Method for Waste Rock and Tailings Management—A Review of Geochemical Aspects. IOP Conf. Ser. Earth Environ. Sci. 2024, 1422, 012003. [Google Scholar] [CrossRef]

- Saleh-Mbemba, F.; Aubertin, M. Physical and Numerical Modelling of Drainage and Consolidation of Tailings near a Vertical Waste Rock Inclusion. Can. Geotech. J. 2021, 58, 1263–1276. [Google Scholar] [CrossRef]

- Nguyen, N.D.; Pabst, T. Acceleration of Consolidation of Tailings in a Pit Using Waste Rocks Co-Disposal. Geotech. Geol. Eng. 2024, 42, 1593–1609. [Google Scholar] [CrossRef]

- Burden, R.; Wilson, G.W. Commingling of Waste Rock and Tailings to Improve “Dry Stack” Performance: Design and Evaluation of Mixtures. Minerals 2023, 13, 295. [Google Scholar] [CrossRef]

- Han, Y.; Wang, G.; Zhang, X.; Zhao, B. Numerical Simulation of Seepage Surface and Analysis of Phreatic Line Control from a Fine-Grained Tailings High Stacked Dam under Complicated Geography Conditions. Appl. Sci. 2023, 13, 12859. [Google Scholar] [CrossRef]

- Yang, J.; Hu, J.; Wu, Y.; Zhang, B. Numerical Simulation of Seepage and Stability of Tailing Dams: A Case Study in Ledong, China. Sustainability 2022, 14, 12393. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, G.J.; Liu, W.L.; Wu, S.; Xu, H. Numerical Simulation and Experimental Analysis of Three-dimensional Seepage Field of Tailings Dam Body. Nonferrous Met. Eng. 2020, 10, 99–106. [Google Scholar]

- Rocha, A.H.; Becker, L.D.B. Development of an Apparatus for Physical Modeling of Tailings Dams: Preliminary Tests. In Proceedings of the 5th European Conference on Physical Modelling in Geotechnics, Delft, The Netherlands, 2–4 October 2024. [Google Scholar]

- Bella, G.; Freire, C.; Lameiras, F.; Giani, M. Numerical Investigation on Tailing Dams Stability: A Preliminary, Parametric Analysis of Some Key Factors. In Proceedings of the 8th World Congress on Civil, Structural, and Environmental Engineering (CSEE’23), Lisbon, Portugal, 29–31 March 2023. [Google Scholar]

- Wang, K.; Zhang, Z.; Yang, X.; Wang, D.; Zhu, L.; Yuan, S. Enhanced Tailings Dam Beach Line Indicator Observation and Stability Numerical Analysis: An Approach Integrating UAV Photogrammetry and CNNs. Remote Sens. 2024, 16, 3264. [Google Scholar] [CrossRef]

- Li, Q.; Ma, G.; Lu, Y. An Experimental and Theoretical Study on the Tailings Dam with Geotextile Bags. Sustainability 2023, 15, 4768. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard Test Methods for Geotechnical Engineering. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- GB 50863-2013; Design Specifications for Tailings Facilities. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2013.

- Khanal, M.; Shi, J.; Qu, Q. Effect of Stepwise Increase in Tailings Deposition on Tailings Dam Stability. Minerals 2025, 15, 346. [Google Scholar] [CrossRef]

| Physical Quantity/Unit | Similarity Scale | Model Test Parameters |

|---|---|---|

| Length/m | 1:200 | 2.00 |

| Width/m | 1:200 | 1.50 |

| Height/m | 1:200 | 0.32 |

| Flow velocity/(cm/s) | 1:13.96 | 9.60 |

| Gravity acceleration/(m/s2) | 1:1 | 9.80 |

| Name | Natural Weight (kN/m3) | Cohesion (kPa) | Internal Friction Angle (°) | Permeability Coefficient (cm/s) |

|---|---|---|---|---|

| Round gravel | 22.0 | 1.0 | 35.0 | 3.0 × 10−3 |

| Plain fill soil | 19.0 | 5.0 | 12.0 | 3.0 × 10−3 |

| Initial dam | 24.0 | 5.4 | 35.0 | 5.0 × 10−3 |

| Tail sand | 19.9 | 2.4 | 25.2 | 1.4 × 10−3 |

| Tail fine sand | 20.2 | 4.1 | 23.4 | 1.0 × 10−4 |

| Tail powder sand | 20.4 | 5.4 | 21.6 | 8.6 × 10−4 |

| Tail Silty clay | 18.9 | 23.5 | 15.5 | 1.2 × 10−6 |

| Rock | 23.0 | 5.0 | 40.0 | 3.0 × 10−7 |

| Waste Rock Pillars | 20.0 | 43.5 | 36.0 | 9.5 × 10−2 |

| Calculation Method | Operating Conditions | Dam Classification | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4, 5 | ||

| Simplified Bishop’s Law | Normal operation | 1.50 | 1.35 | 1.30 | 1.25 |

| Flood Run | 1.30 | 1.25 | 1.20 | 1.15 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Zhao, B.; Lan, R.; Liu, M. Research on the Stability of Tailings Dams Under the Combined Stacking of Waste Rock Pillars and Tailings. Appl. Sci. 2025, 15, 12348. https://doi.org/10.3390/app152312348

Wu S, Zhao B, Lan R, Liu M. Research on the Stability of Tailings Dams Under the Combined Stacking of Waste Rock Pillars and Tailings. Applied Sciences. 2025; 15(23):12348. https://doi.org/10.3390/app152312348

Chicago/Turabian StyleWu, Shengfeng, Bing Zhao, Rong Lan, and Mingsheng Liu. 2025. "Research on the Stability of Tailings Dams Under the Combined Stacking of Waste Rock Pillars and Tailings" Applied Sciences 15, no. 23: 12348. https://doi.org/10.3390/app152312348

APA StyleWu, S., Zhao, B., Lan, R., & Liu, M. (2025). Research on the Stability of Tailings Dams Under the Combined Stacking of Waste Rock Pillars and Tailings. Applied Sciences, 15(23), 12348. https://doi.org/10.3390/app152312348