1. Introduction

Mining companies face significant challenges due to the high costs of machinery downtime and the complexity of mineral quality assessment [

1,

2]. Equipment breakdowns can halt operations for hours or even days, leading to financial losses and safety concerns. Similarly, accurately determining the quality of extracted minerals is essential for maximizing yield and minimizing waste. Recent advances in AI and sensor technology present opportunities to improve both predictive maintenance and mineral quality assessment in mining [

3,

4,

5]. Predictive maintenance leverages sensor data to forecast equipment failures, enabling timely intervention and preventing unexpected breakdowns [

6,

7]. Deep learning models trained on historical sensor data have shown promising results in predicting failures with high accuracy. Meanwhile, mineral quality assessment traditionally relies on slow and often destructive chemical analyses. However, AI-driven computer vision and spectral analysis techniques can offer real-time, non-destructive alternatives that improve accuracy and efficiency.

Predictive maintenance represents a forward-thinking approach in machinery management, aiming to foresee and prevent potential equipment failures before they occur [

8,

9]. By anticipating issues, predictive maintenance enables more efficient maintenance schedules, reduces unexpected downtimes, and improves overall operational productivity. The foundation of this approach lies in various techniques that monitor the health of machinery components. One such technique is vibration analysis [

10,

11], which involves measuring the vibrations emitted by equipment during operation. Deviations in vibration patterns can reveal early signs of mechanical issues, such as imbalances, misalignments, or worn bearings [

12,

13]. Another essential technique is thermal imaging, which captures the heat signatures of machinery components. Abnormal heat patterns can indicate issues like friction buildup, misalignment, or insufficient lubrication—common precursors to mechanical failure. Acoustic emission monitoring is also widely used, focusing on the sounds generated by machines. Changes in sound signatures, such as increased or erratic noise levels, can indicate wear, cracks, or other structural issues that may lead to future breakdowns. Oil analysis offers insight into internal conditions by monitoring the state of lubricants. Contaminants or particles found in the lubricant may signal wear in critical components, such as gears or bearings, before they impact performance.

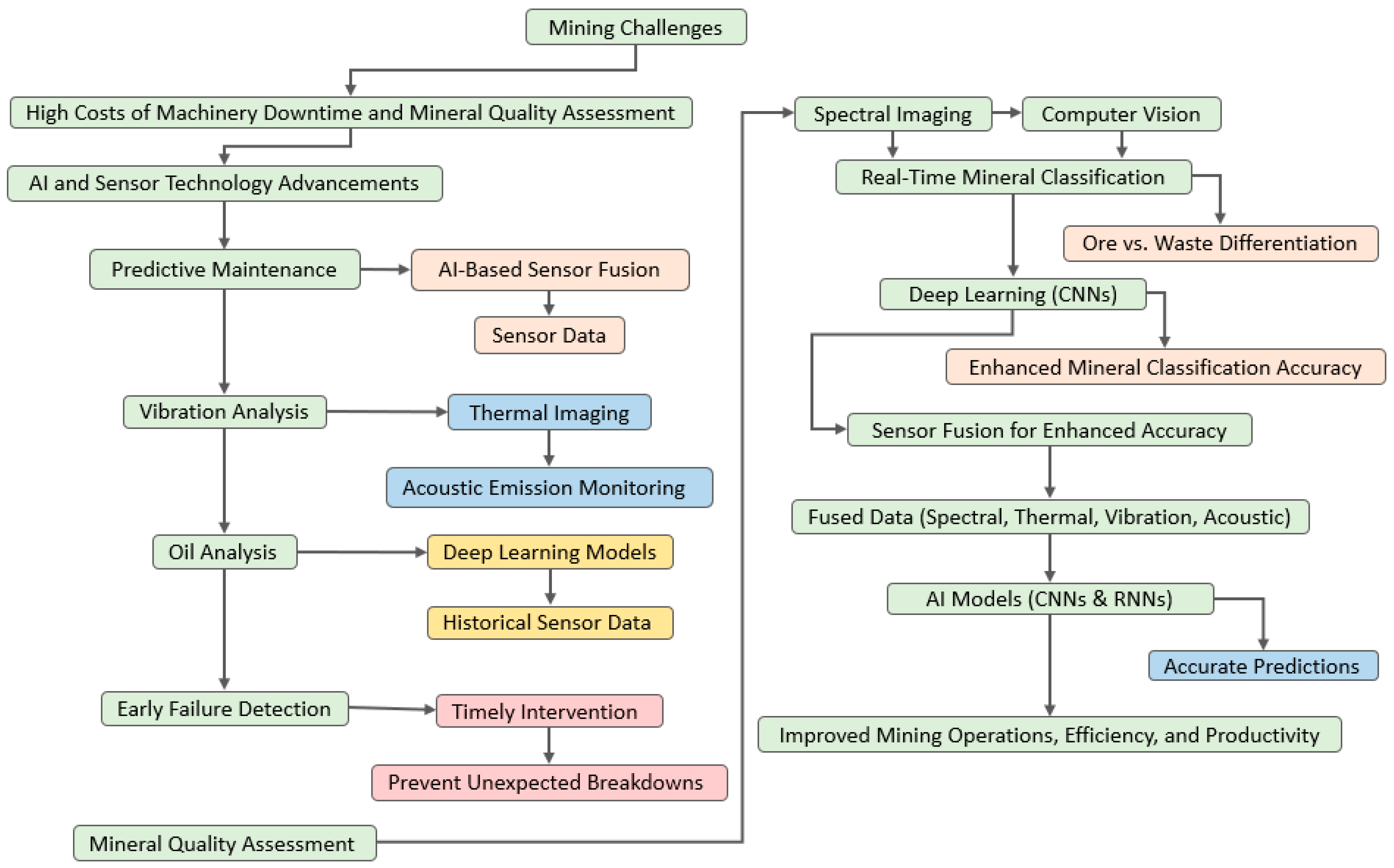

Figure 1 outlines how AI and sensor technologies improve predictive maintenance and mineral quality assessment, integrating multiple sensor inputs through sensor fusion for enhanced accuracy.

In mining, mineral quality assessment is critical for distinguishing valuable ore from waste materials [

14], optimizing the efficiency of processing, and ensuring the final product meets quality standards. Accurate assessment helps mining companies maximize yield while minimizing waste, leading to more cost-effective and environmentally sustainable operations. Two primary techniques that aid in mineral quality assessment are spectral imaging and computer vision. Spectral imaging utilizes spectral reflectance data, where each mineral reflects light at specific wavelengths unique to its composition. By analyzing these unique spectral signatures [

15], spectral imaging can classify minerals in real time, identifying and differentiating ore from waste. This non-destructive, data-rich method is particularly advantageous in mining because it provides rapid and reliable information on mineral composition and distribution. Computer vision is another essential tool in mineral quality assessment, using advanced algorithms to recognize and classify minerals based on observable characteristics, such as color, texture, and morphological features. This technique, often combined with real-time image capture and analysis, allows mining operations to monitor the quality of extracted minerals continuously. When applied to automated sorting systems, computer vision can efficiently direct ore to appropriate processing lines based on quality assessments, enhancing processing accuracy.

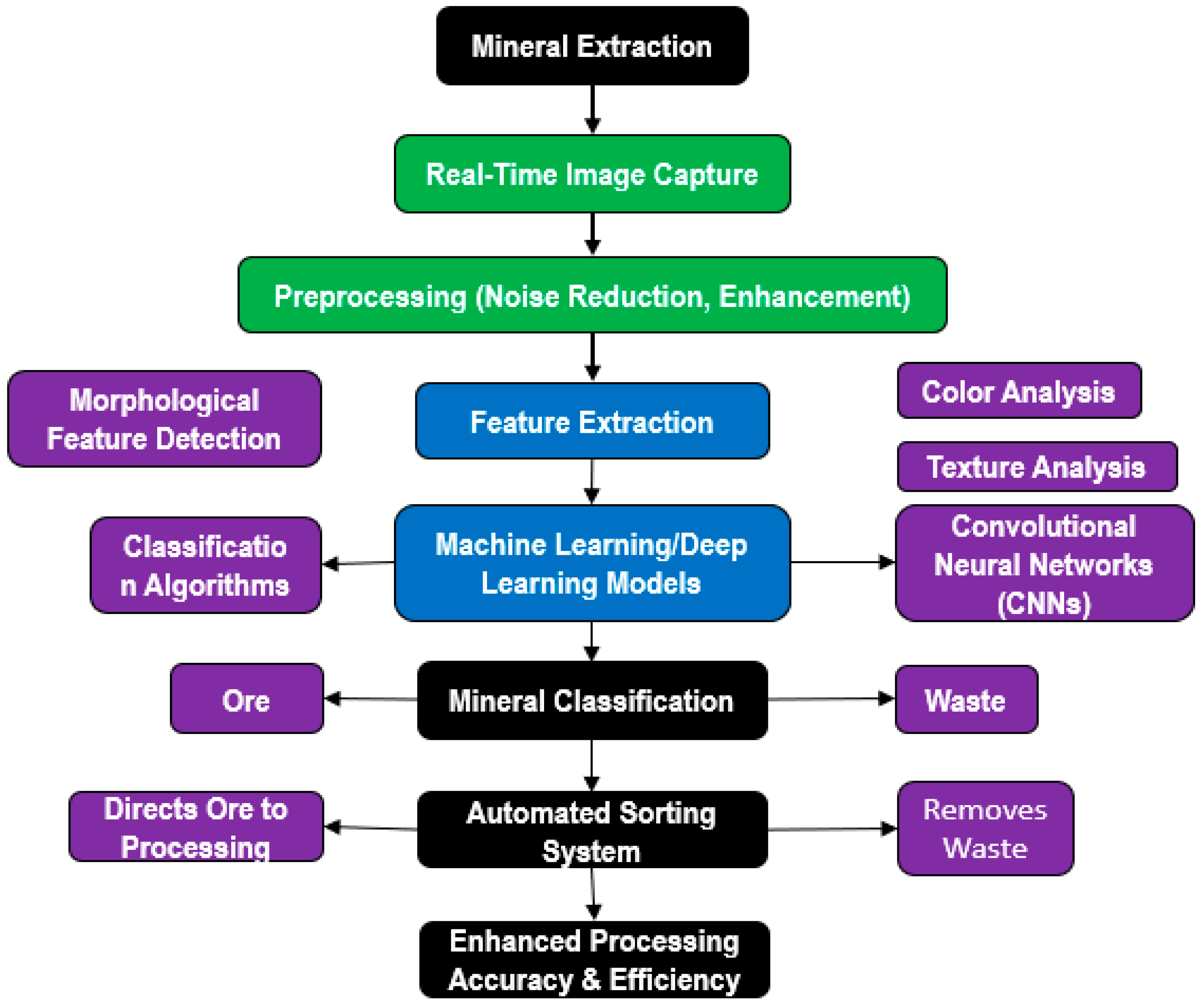

Figure 2 outlines how computer vision is used for mineral classification and automated sorting in mining operations.

Deep learning [

16,

17], especially CNNs, significantly enhances these techniques. CNNs excel in image recognition and can learn complex patterns from spectral and visual data, thereby improving mineral classification accuracy [

18]. By training CNNs on large datasets of labeled mineral samples, the system can quickly and accurately recognize ore qualities, allowing for high precision in real-time quality assessment. This AI-driven approach minimizes errors and accelerates the decision-making process, making mineral quality assessment both more accurate and efficient. Combining multiple sensor inputs through sensor fusion further enhances predictive accuracy by compensating for the limitations of any single sensor. In predictive maintenance and mineral quality assessment, each sensor provides valuable but incomplete information; for instance, thermal sensors detect heat changes, while vibration sensors capture movement irregularities. However, individually, these sensors may miss specific conditions or provide only partial insights. By integrating data from multiple sources, sensor fusion allows for a comprehensive and reliable understanding of both equipment health and mineral composition. Sensor fusion, particularly when integrated with deep learning, provides a holistic view that allows for more nuanced decision-making. For example, in mineral assessment, combining spectral data with computer vision inputs yields richer, multi-dimensional information that improves mineral classification accuracy. Similarly, in predictive maintenance, fusing thermal, acoustic, and vibrational data enables a more thorough assessment of machinery conditions, capturing a wider range of potential issues before they lead to breakdowns. AI-based models, especially those combining convolutional neural networks for image data and recurrent neural networks for time-series sensor data [

19,

20,

21], can process and integrate fused sensor data to make accurate predictions. This robust, multi-sensor approach enhances the precision and reliability of both predictive maintenance and mineral quality assessment, making it an invaluable strategy in modern mining operations.

The fusion of these heterogeneous data streams is a non-trivial challenge. While sophisticated attention mechanisms have been proposed in other domains to dynamically weight the importance of different sensor modalities, their application in the resource-constrained, high-frequency environment of mining processing lines is challenging. These methods, though powerful, introduce significant computational overhead. Therefore, in this initial implementation, we employ a robust, static weighted fusion (Equation (10)) as a computationally efficient baseline that effectively combines features. We acknowledge that this is a simplification compared to dynamic attention models and explicitly discuss the potential of attention-based fusion as a key direction for future work in

Section 4.

To demonstrate the practical applicability of this approach, this study focuses on two critical types of mining equipment: cone crushers and belt conveyors. For crushers, the relevant failure modes include imbalanced rotors, bearing wear, and liner wear, which are effectively captured by vibration and thermal sensors. For conveyors, the focus is on belt misalignment and roller bearing failures, monitored via vibration and acoustic sensors. Concurrently, for mineral quality assessment, we concentrate on iron ore, where quality is defined by Fe (iron) content and the presence of silica (SiO

2) as the primary gangue material. This targeted approach allows for a concrete evaluation of the proposed framework’s capabilities. Furthermore, our work builds upon and extends recent advancements in AI-driven ore characterization, such as those utilizing LiDAR and machine learning for iron ore evaluation [

22], by integrating quality assessment directly with equipment health monitoring within a unified deep learning architecture. While CNN-LSTM architectures are established in deep learning, the novel contribution of this work lies in the tailored fusion of multi-modal, heterogeneous sensor data—including vibration, thermal, acoustic, visual, and spectral inputs—to simultaneously solve two critical, interconnected problems in mining within a single, efficient framework.

Recent works have demonstrated the potential of deep learning in mining applications. For instance, conveyor-scale ore assessment has been advanced using LiDAR and machine learning for iron ore evaluation [

22], while other studies have employed standalone CNNs for rock type classification on conveyor belts. In the domain of predictive maintenance, deep learning models analyzing vibration data for crusher bearing failure prediction and thermal anomalies in conveyor systems have been proposed. However, these systems typically operate in isolation, addressing either quality or maintenance but not both. Furthermore, while multimodal temporal vision systems are emerging in other harsh environments like manufacturing, their application in mining remains limited. This creates a critical gap for an integrated system that can leverage the synergies between equipment health and material quality data in real time. Unlike previous approaches that address predictive maintenance and mineral quality assessment in isolation, our integrated system provides a holistic operational intelligence capability specifically designed for the harsh and variable conditions of mining environments.

4. Discussion

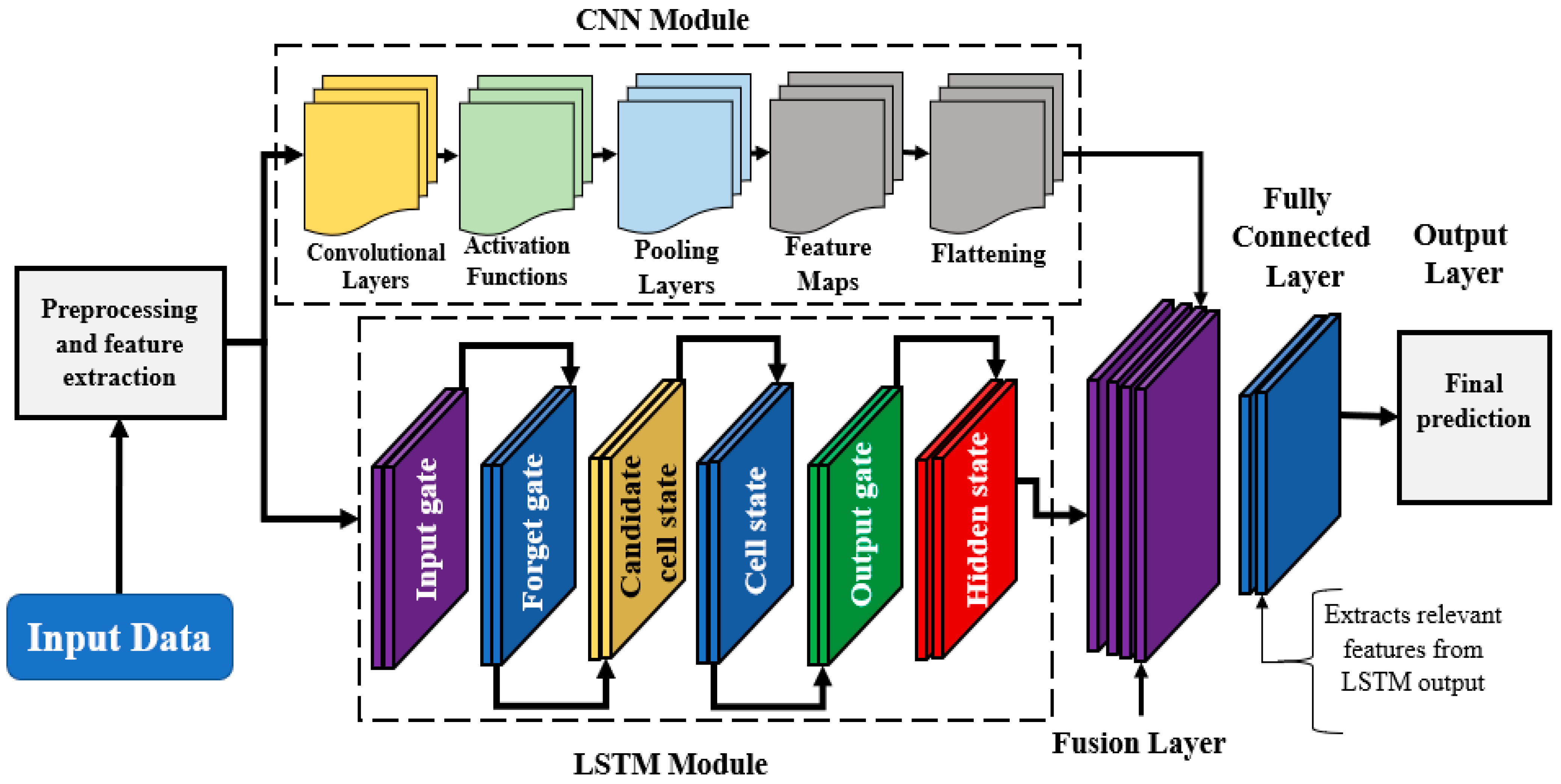

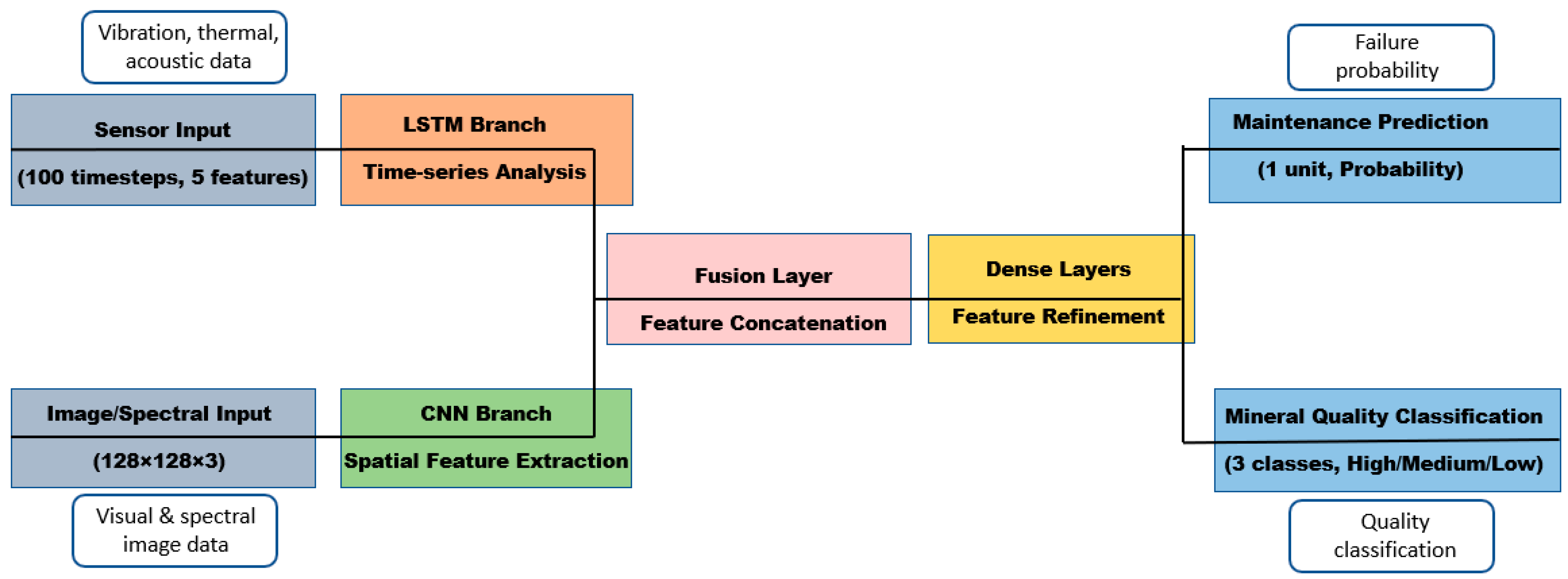

The experimental results demonstrate the effectiveness of the proposed hybrid model in addressing critical challenges in predictive maintenance and mineral quality assessment within mining operations. The integration of LSTM networks for time-series sensor data analysis and Convolutional Neural Networks (CNNs for image-based classification provides a complementary approach that leverages the strengths of both architectures [

43]. This dual capability not only improves prediction accuracy but also enhances operational decision-making in a sector where downtime and inefficiencies can have significant financial and safety implications.

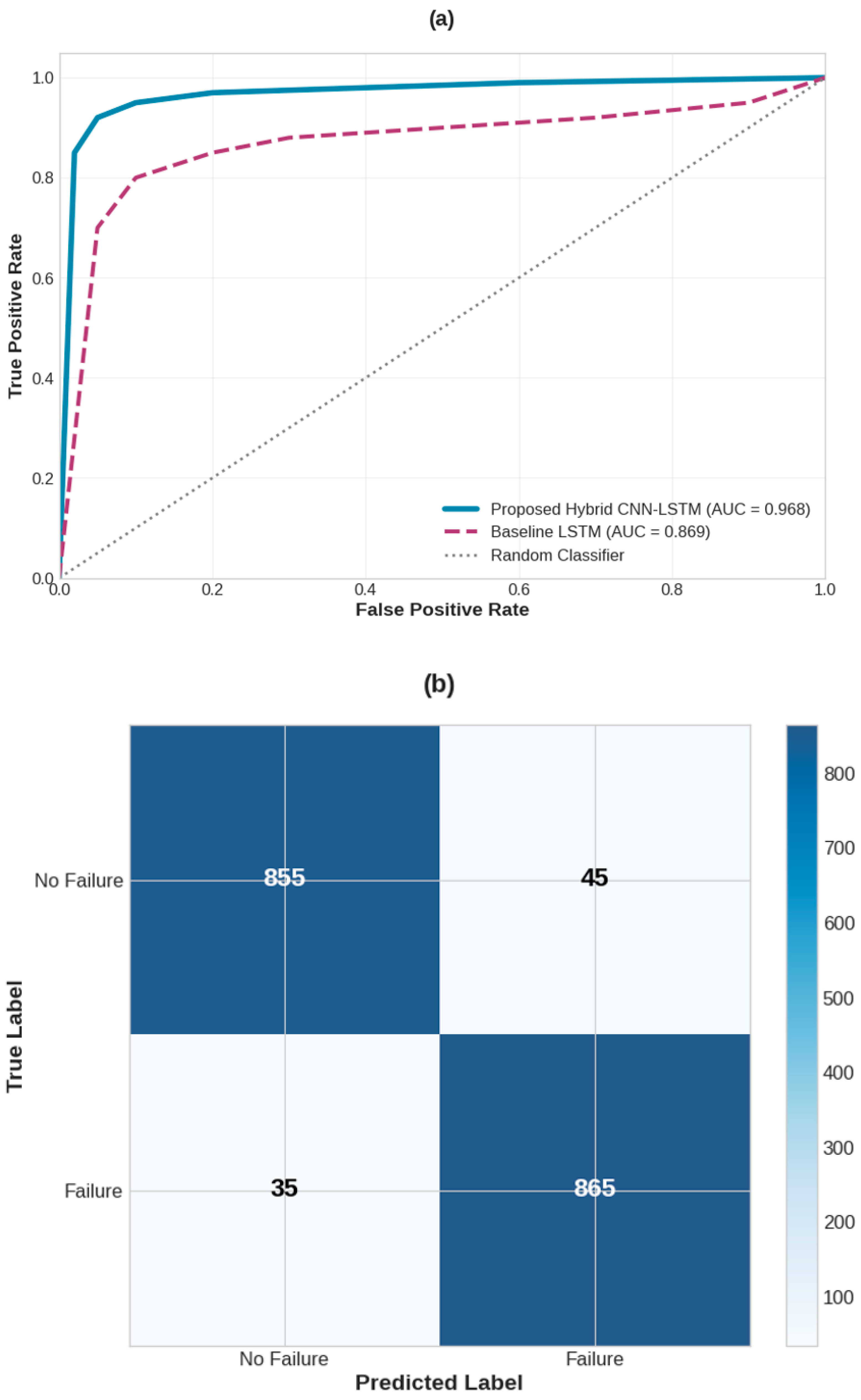

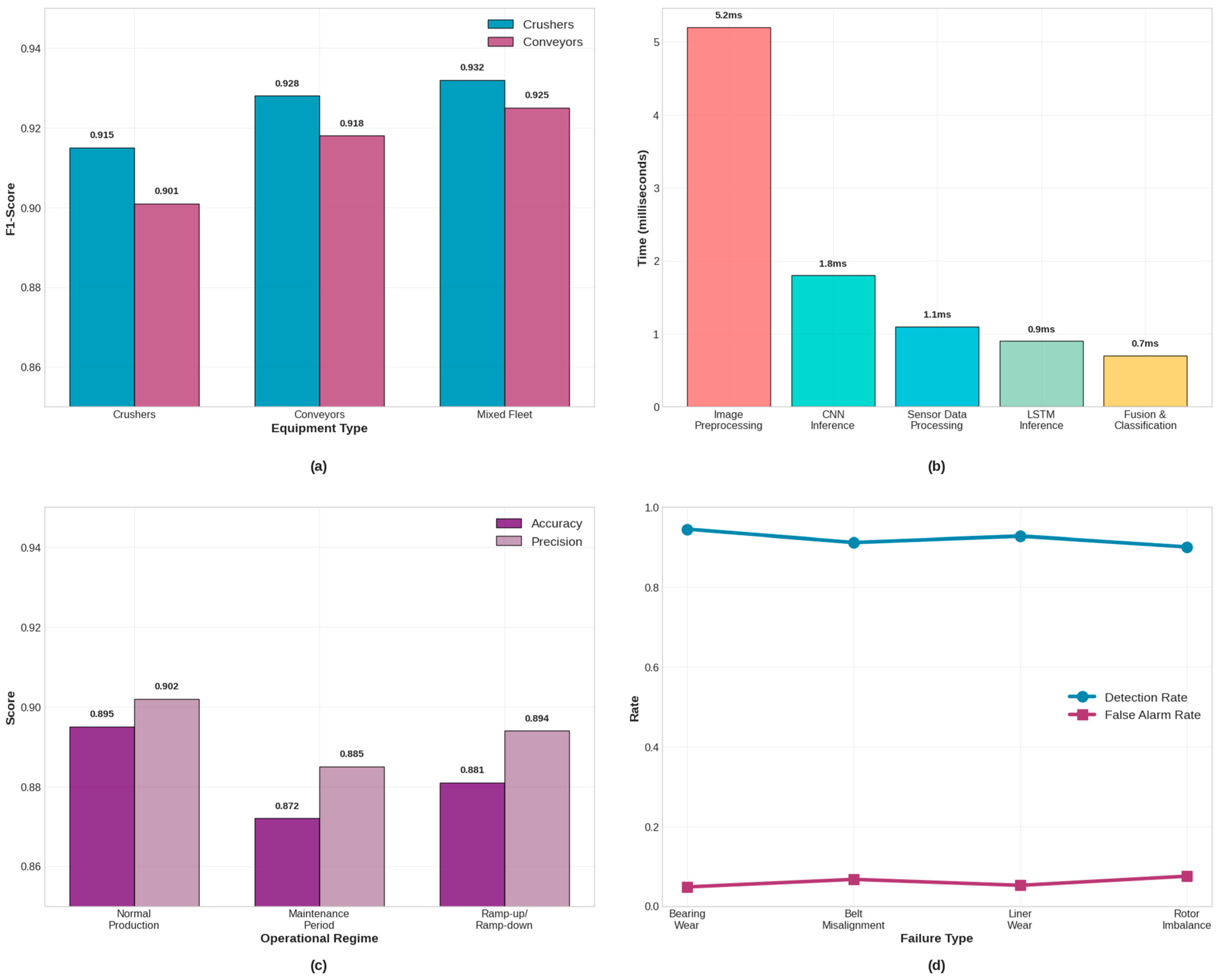

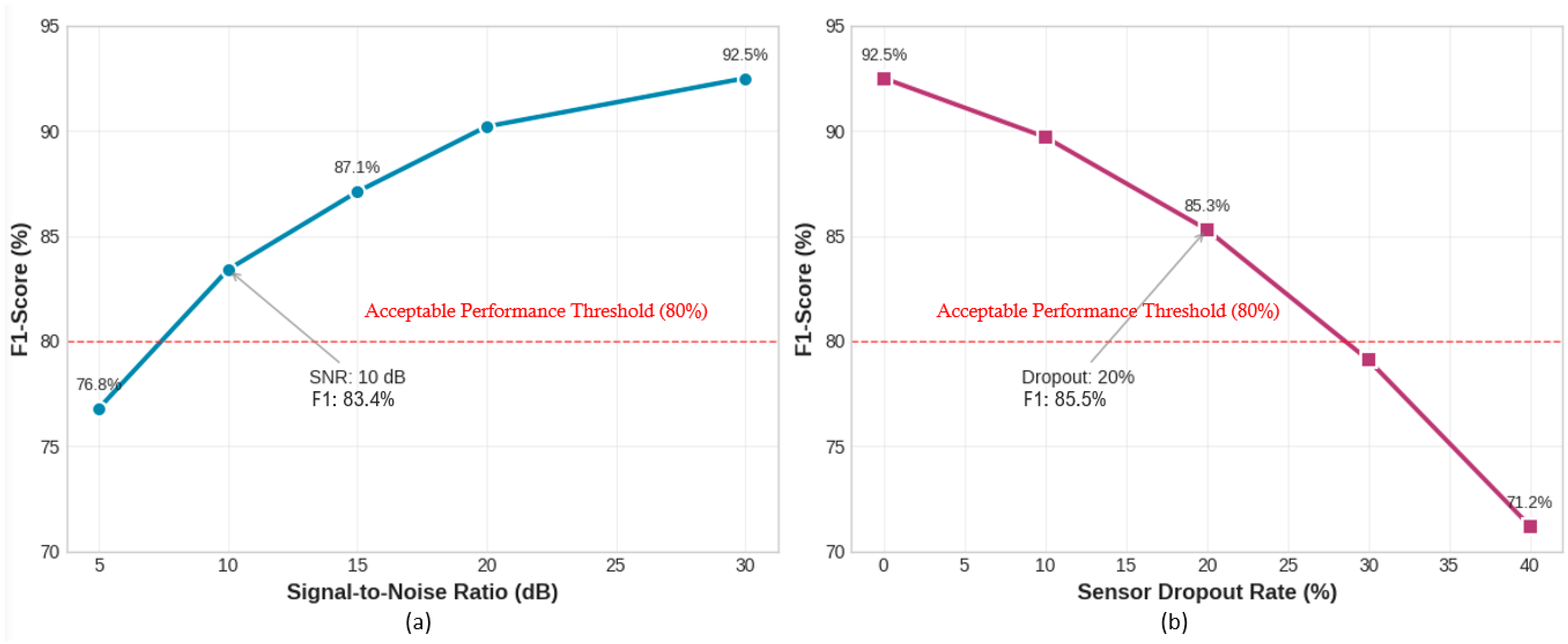

In predictive maintenance, the hybrid model achieved a notable 20–30% reduction in downtime, underlining its capability to predict maintenance needs with high reliability. Such a reduction directly translates into substantial cost savings by minimizing equipment breakdowns and unplanned halts in production. This improvement can be attributed to the LSTM module’s capacity to capture long-term dependencies in vibration, thermal, and acoustic sensor signals, allowing it to detect subtle patterns indicative of emerging faults. The model’s F1-score of 92.50% reflects a well-balanced performance across precision and recall metrics, ensuring that potential failures are identified without triggering excessive false alarms. This balance is crucial in industrial contexts, as unnecessary maintenance interventions can be as disruptive as undetected failures. By providing accurate and timely predictions, the system empowers operators to schedule interventions proactively, thus maximizing equipment utilization and extending asset life cycles.

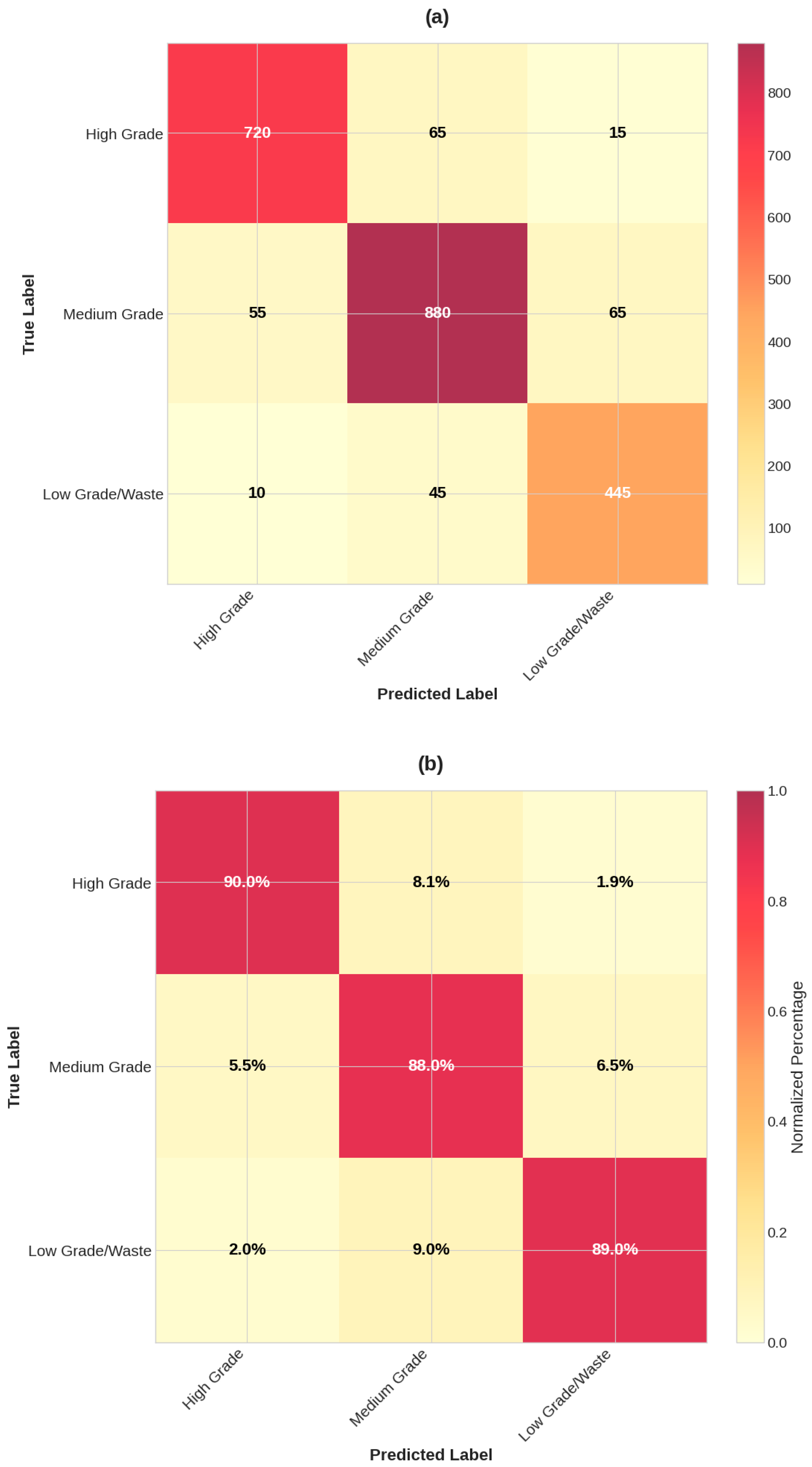

In terms of mineral quality assessment, the CNN module achieved an accuracy of 88.60%, showcasing its strength in image-based mineral classification tasks. The confusion matrix results (TP: 800, FP: 50, FN: 90, TN: 560) provide further evidence of the system’s reliability, with both false positives and false negatives maintained at relatively low levels. Compared with baseline models, the hybrid framework yielded a 15% improvement in classification accuracy, which can be largely attributed to the use of advanced data augmentation techniques and fine-tuning strategies applied to the CNN layers. These improvements have direct operational implications, as more accurate sorting and processing of mineral samples reduce waste, improve throughput, and enhance the overall efficiency of mineral extraction processes. Another significant advantage of the proposed model lies in its real-time prediction capabilities. Achieving a prediction speed of less than 10 ms per inference ensures that the system can be seamlessly integrated into existing mining operations without introducing delays. This responsiveness is particularly vital in dynamic and high-stakes environments such as mining, where timely insights can prevent costly disruptions, improve safety outcomes, and streamline workflow management. The ability to process multimodal data in real time also lays the foundation for further automation, potentially enabling closed-loop control systems that autonomously adjust maintenance schedules or mineral sorting processes based on model outputs.

The successful integration of CNNs and LSTMs into a unified framework highlights the practical utility of hybrid deep learning models for industrial applications [

44,

45]. While the present study demonstrates promising outcomes within mining operations, the model’s architecture is inherently scalable and adaptable. Furthermore, the design of the mineral classification output layer warrants discussion. The decision to employ three distinct mineral quality classes, High Grade, Medium Grade, and Low Grade/Waste, was based on Fe content thresholds determined through XRF analysis, as summarized in

Table 4. This three-class scheme was selected because it aligns with standard industrial practice in iron-ore processing, where materials are operationally categorized into high-yield, mid-grade, and waste streams. It provides a clear balance between classification granularity and dataset representativeness while ensuring that each class contains sufficient examples for robust model training and statistically stable evaluation. Using three categories also facilitates interpretability for mining engineers and aligns the AI system’s outputs with on-site decision-making processes. The consistent adoption of this three-class framework throughout the architecture (

Figure 4), training configuration, and results sections resolves the earlier inconsistency noted by the reviewer and ensures full reproducibility of the findings.

Future research could explore the integration of additional data modalities, such as chemical composition or environmental factors, to further enhance predictive power. Moreover, deploying the framework across diverse industrial settings, such as oil and gas, manufacturing, or energy production, could validate its broader applicability and robustness. The hybrid model demonstrates a strong potential to optimize operational efficiency and enhance resource quality. However, it is important to note that the claimed 20–30% reduction in downtime is a projection based on the model’s high fault-prediction accuracy and standard industry maintenance metrics, rather than a figure from a long-term field trial. A rigorous industrial pilot study is the essential next step to validate these economic benefits in a production environment. Furthermore, the comparative analysis confirms that the hybrid model’s performance gain justifies its increased complexity over simpler baseline models, making a compelling case for its use in tackling these multifaceted predictive tasks. By reducing downtime, improving mineral classification accuracy, and delivering real-time insights, the framework provides tangible benefits that address both economic and operational challenges. As industries continue to adopt AI-driven solutions, such hybrid architectures are poised to play a central role in shaping the future of smart and resilient industrial systems.

5. Conclusions

This paper presents an innovative AI-based framework that seamlessly integrates predictive maintenance and mineral quality assessment using advanced sensor fusion and deep learning techniques. By harnessing the complementary strengths of CNNs for image-based mineral classification and LSTM networks for time-series sensor data analysis, the system addresses two critical challenges in mining operations. The proposed framework not only achieves significant reductions in equipment downtime but also enhances the accuracy of mineral quality classification, demonstrating its capability to optimize operational efficiency and sustainability. The system’s deployment has practical implications for real-world applications, particularly in dynamic mining environments where equipment reliability and resource quality are paramount. The integration of sensor data from multiple modalities, including vibration, thermal, acoustic, and image sources, illustrates the versatility and robustness of the framework. Furthermore, the hybrid model’s ability to perform real-time predictions ensures timely decision-making, which is crucial in minimizing disruptions and maximizing productivity.

Future research directions could explore the incorporation of advanced sensor fusion techniques, such as attention mechanisms, to further enhance data integration and feature extraction. Additionally, the development of multi-objective optimization strategies could balance trade-offs between maintenance costs, operational efficiency, and resource utilization. Addressing real-time deployment challenges, particularly in harsh and remote mining environments, may require the integration of edge computing and energy-efficient AI models. Expanding the framework to include predictive analytics for environmental impact and safety monitoring could also provide a more holistic solution for sustainable mining operations. Overall, this study establishes a foundation for leveraging AI-driven frameworks to address critical challenges in the mining industry, paving the way for smarter, safer, and more efficient practices. The insights gained here have the potential to drive innovation across various industrial sectors facing similar operational complexities.