1. Introduction

1.1. Background and Research Motivation

Aircraft maintenance delay (AMD) is a fundamental component of aviation safety, operational efficiency, and regulatory compliance, as highlighted by Paidisetty et al. [

1]. As the global aviation industry continues to expand, the demand for timely, accurate and cost-effective maintenance practices has become increasingly critical [

2,

3]. Maintenance-related delays not only affect airline profitability, but also have broader implications for flight schedules, customer satisfaction, and airport operations [

4]. According to Hettiarachchi [

5], a significant proportion of operational delays are directly attributed to maintenance problems [

6], which underscores the urgency to address maintenance inefficiencies [

7].

Despite the implementation of various maintenance management strategies and engineering practices, airlines continue to experience recurring disruptions that lead to financial losses and reputational risks. In this context, the present research proposes the application of contemporary quality management tools and methodologies, aligned with Six Sigma principles, to systematically address maintenance challenges in the aviation sector. This domain is characterized by well-established standards, extensive references, and highly structured and reliable data sources, making it particularly suitable for the deployment of structured problem-solving approaches such as Failure Mode and Effect Analysis (FMEA) integrated with the Define–Measure–Analyze–Improve–Control (DMAIC) framework.

The applicability and effectiveness of the proposed framework are demonstrated through a case study by AFRIQIYAH Airways (AAW), which focuses on the Airbus A320 fleet, which represents the core of the airline’s operations. This study advances existing research by developing a comprehensive and data-driven classification of maintenance delays within the AFRIQIYAH fleet, based on standardized international codes and subcodes, and by proposing targeted improvement projects adapted to the specific regional and operational context. Consequently, the remainder of this introduction is structured as follows: first, it presents the standardized classification systems used to analyze aircraft delays; second, it introduces the Air NAV maintenance system (ANMS), which is used by airlines and the air navigation service; and finally, it outlines the objectives and contributions of the study.

1.2. Standardized Classification Systems for Analyzing Aircraft Delays

In commercial aviation, several standardized systems, including International Air Transport Association (IATA), subcode classifications from International Civil Aviation Organization (ICAO) subcode classifications, ATA chapter numbering from the ATA, and regulations from the European Aviation Safety Agency (EASA) Part M/Part Continuing Airworthiness Management Organization (CAMO) regulations, are widely used to classify, report, and analyze aircraft delays and maintenance problems [

8].

This research focuses on the IATA and ICAO standards, which are widely recognized and widely used by airlines and regulatory authorities. These systems provide a systematic framework to trace the root causes of operational and technical delays. They are implemented internationally in the aviation industry [

9,

10]. They provide structured hierarchical coding systems that enable the precise identification and analysis of delay causes. Their combined application improves operational efficiency and ensures safety compliance in airline maintenance and flight operations.

The IATA delay code system organizes delays into primary categories—including passengers, cargo, technical aircraft problems, maintenance, and flight operations, and subdivides them into specific subcodes, such as technical defects affecting engines, hydraulics, or landing gear [

9].

IATA had developed IATA delay codes to assist carriers in standardizing the cause of delayed departure. Delays could be caused by the following:

Passengers and baggage handling (codes 11–18);

Cargo and mail (codes 21–29);

Aircraft and ramp handling (codes 31–39);

Technical and aircraft equipment (codes 41–47);

Damage to aircraft and Automated Equipment Failure/EDP (computer system) (codes 51–57);

Flight operations and crewing (codes 61–69);

Weather (codes 71–77);

Air Traffic Control Restrictions and airport or governmental authorities (codes 81–89);

Reasons and Miscellaneous (codes 91–99).

IATA delay codes 40, which can be classified as controllable variables, are directly under the responsibility of an airline’s maintenance and engineering division. Finding the underlying causes of events that contribute to airline maintenance delays in airlines is crucial for maintenance and engineering [

11,

12].

Table 1 details all IATA Delay Code 40 (Technical and aircraft equipment): Subcodes 41 to 48 cover delays caused by technical, maintenance, spares, configuration, or aircraft replacement problems [

9].

The ICAO subcode classification system complements IATA codes by providing a global framework for operational and maintenance reporting, as detailed in the ICAO Procedures for Air Navigation Services (PANS-ATM, Doc. 4444). Although the ICAO does not prescribe commercial delay codes, its system standardizes maintenance reporting and integrates operational data for safety and reliability analysis [

10].

1.3. Air NAV Maintenance System (ANMS)

ANMS refers to a computerized or digital platform used by airlines and air navigation service providers to manage, track, and report aircraft maintenance activities and operational events. Integrates maintenance planning, defect reporting, reliability monitoring, and compliance with regulatory standards such as ICAO Annexes, IATA delay codes, and ATA chapter classifications.

The key functions of an ANMS include: (1) maintenance planning: Scheduling preventive and corrective maintenance tasks to ensure continued airworthiness. (2) Report of defects and occurrences: systematically record technical defects, safety-related issues, and operational problems. (3) Regulatory compliance: Ensure maintenance actions and reporting align with ICAO, EASA, and national aviation authority requirements. (4) Data analysis and reliability monitoring: Identifying trends, root causes of delays, and recurring technical issues to support operational efficiency.

Within the ANMS, Airbus operators can optimize maintenance processes and significantly reduce operational costs. ANMS serves as a comprehensive technical data consulting platform that integrates all major technical manuals to support the maintenance and operation of Airbus commercial aircraft worldwide [

13]. Built on an advanced and innovative platform, ANMS dramatically reduces the time required for research, information retrieval, and troubleshooting, while simultaneously reducing the costs of operators [

14]. By streamlining the workflows of maintenance technicians and engineers, the system improves overall efficiency and decision making. One of its key features, ‘problem solving’, uses error codes and electronic centralized aircraft monitor alerts to identify the necessary documentation, allowing rapid access to complete technical data essential for effective maintenance operations [

15,

16].

1.4. Objective and Contributions of the Study

Despite extensive research on maintenance management and reliability engineering, previous studies have largely treated risk analysis and process improvement as distinct areas, with limited attempts to integrate them into a unified framework. Most existing approaches rely on qualitative evaluations or reactive maintenance practices, which often fail to provide long-term sustainable or continuous learning mechanisms. These limitations highlight the need for a comprehensive strategy that combines proactive failure identification with systematic performance improvement. Consequently, this study is motivated by the lack of an integrated data-driven methodology capable of bridging the gap between risk prioritization and process improvement to effectively address AMDs.

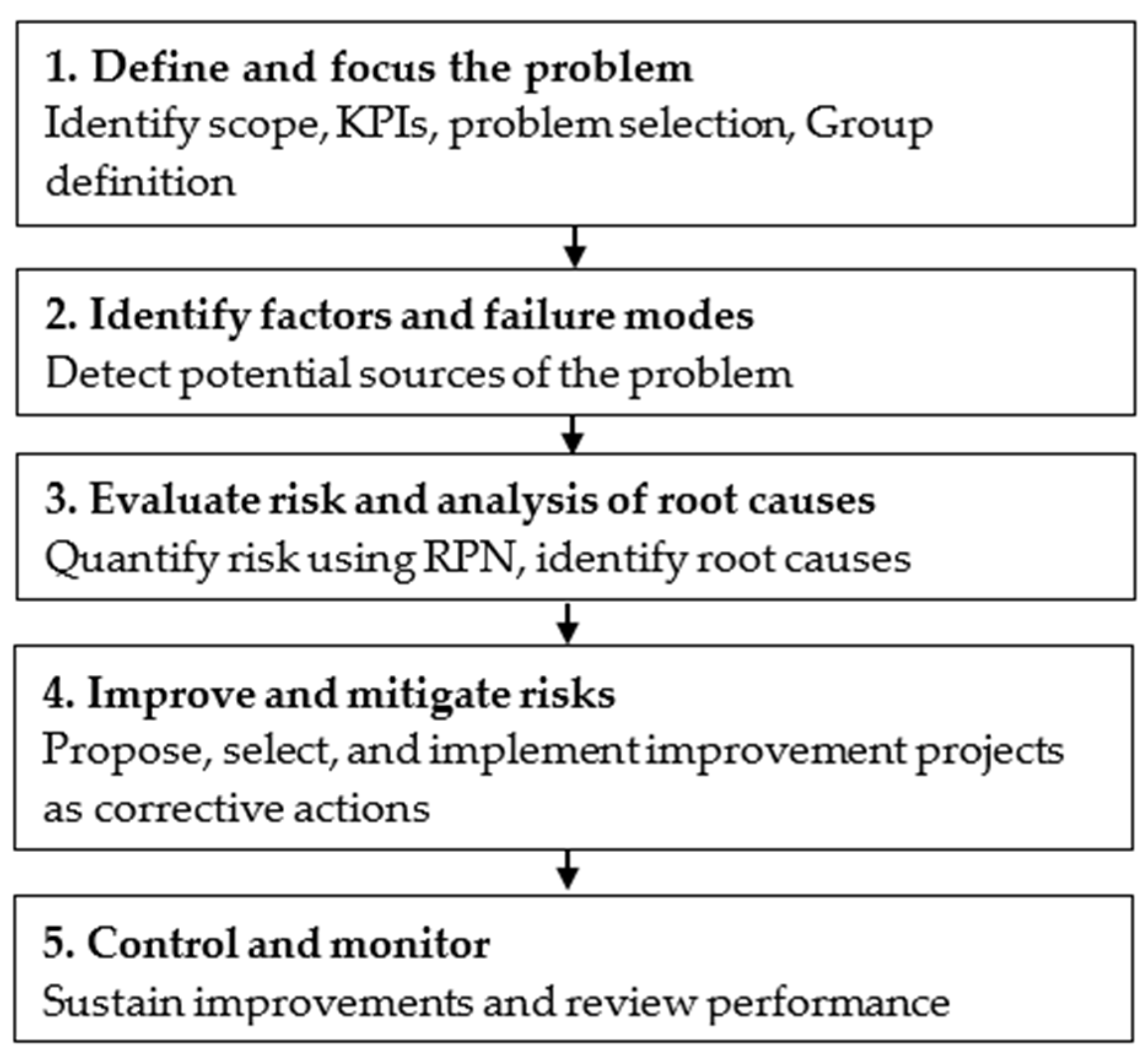

To fill this research gap, the study proposes an integrated five-step framework that merges the strengths of the FMEA technique and the DMAIC methodology. Although FMEA is based independently on the identification and classification of potential failure modes without providing a structured implementation or validation mechanism, DMAIC offers a systematic improvement process, but does not explicitly quantify or prioritize risks. The proposed integration synergizes FMEA’s proactive risk assessment with the structured problem solving and control phases of DMAIC, transforming both mature tools into a dynamic, iterative, and data-driven system. This unified approach aims to identify high-risk maintenance failure modes, assess associated risks, and propose targeted interventions that can improve operational efficiency, reduce delays, and continuously improve overall aircraft reliability.

Following this introduction,

Section 2 presents the review of the literature, discussing delays in aircraft maintenance in commercial aviation, the DMAIC methodology as a structured problem-solving approach, and FMEA as a proactive failure risk mitigation technique.

Section 3 introduces the proposed integrated DMAIC—FMEA framework through five stages: defining the problem, identifying factors and failure modes, assessing risks and root causes, improving and mitigating risks, and controlling and monitoring.

Section 4 presents the results of the case study and the discussion following the same five-step structure, while

Section 5 concludes the article with key findings, managerial implications, and future research directions.

3. The Proposed DMAIC-FMEA Framework

Based on the findings of the above literature review, it has been observed that integrating the proactive risk assessment approach of the FMEA methodology within the structured and data-driven DMAIC framework provides a comprehensive and structured approach to systematically identify, prioritize and mitigate potential failure modes that contribute to reducing AMDs. In fact, DMAIC provides a systematic framework to identify, measure, analyze, improve and control delays, ensuring that maintenance issues are addressed with empirical rigor and data-driven decisions [

34,

39]. Furthermore, FMEA enables early identification and prioritization of possible failure modes by evaluating their severity, occurrence, and detectability, thus reducing the likelihood of operational failures before they occur [

51,

52,

53]. By combining DMAIC’s retrospective problem-solving capabilities with proactive risk mitigation, airlines can improve the reliability of scheduled maintenance, minimize unplanned corrective interventions, and establish robust control mechanisms for sustained improvement [

42,

57]. Although prior studies have applied DMAIC to aircraft maintenance operations [

40,

41,

42] and FMEA to reliability analysis in aerospace systems [

57,

58,

59], to our knowledge, no peer-reviewed research has explicitly integrated DMAIC and FMEA to reduce AMD in commercial aviation. Therefore, this study contributes to a novel methodological framework that bridges this gap, offering analytical and preventive information to improve maintenance efficiency and operational performance. The proposed DMAIC-FMEA framework consists of five successive stages, as illustrated in

Figure 1: (1) defining and focusing the problem, (2) identifying contributing factors and failure modes, (3) evaluating risks and analyzing root causes, (4) implementing improvements and mitigating risks, and (5) controlling and monitoring the results.

3.1. Define and Focus the Problem

The first step involves forming a dedicated problem-solving team composed of responsible individuals tasked with addressing the problem and defining the problem comprehensively. This includes identifying all primary subproblems and collecting relevant statistics and data. In the context of aircraft maintenance, this involves mapping all maintenance processes susceptible to delays, such as line maintenance checks, A-checks, and unscheduled repairs. To investigate the main causes of maintenance delays, data must be recovered from the airline’s information system, commonly known as the Air NAV maintenance system (ANMS), which allows the collection of historical data and the estimation of key performance indicators (KPI). Data collection is carried out according to international standard codifications such as IATA and ICAO.

A KPI in this study is the punctuality index for the delay code 40 (denoted as β

t40), which is used to evaluate flight delays. The index is calculated as shown in Equation (2) [

60,

61]:

where d

fc denotes the total code delay frequency and g denotes the gap time that is equal to the total code delay (in minutes). Equation (2) expresses the percentage of punctuality by comparing the total potential operational time (d

fc × 60) with the actual delay time g. A higher β

t40 value indicates better punctuality performance for the delay code 40.

For historical data collection, the frequency of delays per subcode should be recorded as the number of occurrences, each occurrence representing one hour of theoretical delay. To ensure consistent units for calculation, these values are converted to minutes by multiplying by 60, before subtracting the actual recorded delay time g, which is already in minutes. This procedure ensures an accurate computation of the punctuality rate attributed to maintenance-related interruptions. Historical delay data should be collected for all aircraft in the airline fleet over multiple years. This comprehensive data set is necessary to identify the most relevant subcodes for airline punctuality and to focus on the main maintenance operations responsible for delays.

3.2. Identify the Factors and Failure Modes

Once the main maintenance operations are defined, the FMEA methodology is applied to identify the potential failure modes in each maintenance task. Using structured brainstorming with the problem-solving team and historical maintenance data, every possible source of delay is considered, including human errors, equipment malfunctions, procedural deviations, and environmental factors. The 5M + E categories (Man, Machine, Method, Material, Measurement, Environment) provide a systematic framework to ensure comprehensive coverage. For example, under ‘Man’, technician skill deficiencies or procedural non-compliance are examined, while ‘Machine’ includes failures of specialized tools or aircraft components. This step ensures that no critical failure mode is overlooked, forming the foundation for a subsequent risk assessment.

3.3. Evaluate Risk and Analysis of Root Causes

The next step quantifies the risk associated with each identified factor and the failure mode using the risk priority number (RPN), calculated as the product of O (occurrence/frequency), severity (S), and Detectability (D), as expressed in Equation (1). Historical maintenance delay records are analyzed to validate frequency scores, while severity is assessed based on operational impact, such as delayed departures or increased maintenance costs. Detectability evaluates how likely a failure mode can be identified before causing a delay. By assigning numerical values to each failure mode, the FMEA process allows objective prioritization of the most critical risks, bridging qualitative insights with quantitative data, and guiding focused corrective actions [

52].

High-priority failure modes identified through FMEA undergo a detailed root cause analysis. Tools such as Pareto charts, Ishikawa diagrams, and the 5 Whys method are applied to determine the underlying causes of delays. For example, repeated failures in landing gear inspections may be traced back to insufficient training, an unclear standard operating procedure, or aging equipment. This analysis transforms the risk information from FMEA into actionable insights, highlighting specific process weaknesses, and providing the evidence base for improvement initiatives.

3.4. Improve and Mitigate Risks

In this stage, corrective actions are developed to reduce the RPN of critical failure modes. Potential solutions may include enhanced training programs for maintenance personnel, the implementation of standardized inspection procedures, the optimization of spare parts inventory, or the revision of maintenance schedules. A comprehensive action plan must be formulated that organizes all corrective measures into a coordinated set of improvement projects. Following the implementation (or planned implementation) of these projects, the FMEA is reevaluated to reevaluate the RPN scores and verify that the associated risks have been effectively mitigated. The reduction in RPN is calculated using Equation (3). This iterative process ensures that resources are efficiently focused on the failure modes with the greatest operational impact [

53]. Equation (3) can also be used to estimate the average RPN reduction% using the average initial average RPN and the uptake RPN.

Each selected improvement project should undergo a detailed analysis using quality improvement and project management tools. For example, RACI (Responsible, Accountable, Consulted, Informed) is a commonly used tool that establishes a matrix of responsibility assignment, clarifying roles and responsibilities for each task of the project. Specifically, Responsible denotes the individual performing the work; Accountable refers to the person owning the final outcome and holding decision-making authority; Consulted includes those providing two-way input and expertise; and Informed comprises individuals receiving one-way progress updates.

3.5. Control and Monitoring

The final step focuses on maintaining improvements and ensuring continuous monitoring of maintenance processes. The same KPI used in phase 1, should be evaluated, and the updated RPN trends are regularly tracked. Periodic FMEA reviews are conducted to incorporate new failure modes arising from fleet changes, updated equipment, or evolving procedures. By maintaining this feedback loop, the framework ensures long-term control over aircraft maintenance delays and facilitates continuous process improvement.

4. Case Study Results and Discussion

AFRIQIYAH Airways (AAW) is a licensed commercial airline headquartered in Tripoli and is owned by the Libyan African Aviation Holding Company. Established in 2001, the airline initially operated Boeing 737-400 aircraft before transitioning to an all-Airbus fleet in 2003. Today, its fleet consists exclusively of Airbus models, including nine A320/A330 and three A319 aircraft, which serve both domestic and international routes, as summarized in

Table 1. AFRIQIYAH Airways is a member of the African Airlines Association (AFRAA), the Arab Air Transport Organization (AACO), the International Civil Aviation Organization (ICAO), and the International Air Transport Association (IATA). More details about the airline can be found on its official website: “

https://afriqiyah.aero/en/about/ (accessed on 10 October 2025)”.

4.1. Define and Focus the Problem

4.1.1. Establishment of the Maintenance Improvement Team (MIT)

To ensure effective implementation of all stages of the proposed integrated FMEA–DMAIC framework, a dedicated maintenance improvement team (MIT) was established in AAW. As detailed in

Table 2, this multidisciplinary group consists of seven members, combining academic expertise (two university professors) with operational experience (five technical managers).

The primary objective of the MIT is to systematically identify possible failure modes, assess associated risks, analyze the underlying root causes, and propose targeted improvement actions aimed at reducing aircraft maintenance delays. The methodological approach adopted in the work relied on a series of anonymous and iterative questionnaires, complemented by open-ended survey items and collaborative brainstorming sessions, to ensure comprehensive data collection and informed decision-making. Furthermore, all knowledge contributions and opinions expressed by MIT members were, whenever possible, supported by advanced bibliographic research, reinforcing the scientific validity and reliability of the team’s conclusions.

4.1.2. Fleet Type Selection

Based on the fleet information in

Table 3, the first step is to collect information on the type (A320), as they represent the largest number of aircraft in the fleet compared to the other types.

4.1.3. Fleet-Wide Aggregation of A320 Delay Data

The data set comprises over 3000 delay instances, categorized by aircraft type (e.g., A320, A330, A319), year of occurrence, and subcode classification, as detailed in

Table 1 (the different delay sub-codes are detailed in the first column of

Table 1). Each record includes the flight number, aircraft registration, delay duration (in minutes), subcode, and in some cases, qualitative notes from maintenance personnel regarding the nature of the issue. This level of detail allows for both quantitative and qualitative analyses of delay causes. For each year, β

t40 is estimated for each subcode, for each aircraft, and for each fleet. Flight delay data (code 40 for AAW) are collected from the ANMS of the company named AMSIS—KEOPS, for the years 2007 to 2022 and are illustrated in

Supplementary Tables S1–S7, which presents all collected data for the maintenance delay analysis of A320-ONA, A320-ONB, A320-ONJ, A320-ONL, A320-ONM, A320-ONN and A320-ONO, respectively. All these tables are aggregated within the single

Table 4 as the sum of the seven A320 aircrafts year by year. This is necessary to define the most relevant subcode 40 for the airline’s punctuality. For each year, the number of recorded delays, the total duration of the delays, and the calculated punctuality rate are shown. This aggregation at the fleet level allows for a clearer assessment of the operational performance of the A320s and provides insight into their contribution to the airline’s overall efficiency and profitability.

In terms of time coverage, the data set spans a 6-year period, allowing for the examination of trends and fluctuations in delay occurrences over time. For example, an increase in delays due to unscheduled maintenance was observed in 2020 and 2021, coinciding with reduced availability during the COVID-19 pandemic. On the contrary, a gradual improvement in 2023 and 2024 reflects improved maintenance protocols and investments in fleet modernization.

Table 4 presents data that illustrate various delay subcodes detailed in

Table 1, which correspond to different causes of delays due to maintenance activities (Code 40). During the first years (2007–2012), the number of delays remained relatively low, with slight increases observed in 2008 and 2009. From 2015 onward, there was a marked increase in annual delays, peaking in 2015 with 162 delays, followed by a slight decrease in subsequent years. In specific years, such as 2020—coincident with the COVID-19 pandemic—a sharp decline was recorded (36 delays), likely due to a significant reduction in flight operations.

The gap time, representing the total time lost due to delays throughout the year, shows a substantial upward trend over the observed period. In 2015, the gap time reached a notably high value (52,071 min), corresponding to the high number of delays that year. In more recent years (2019–2022), although the number of delays decreased, the gap time remained relatively high, suggesting that some delays were longer in duration. In particular, in 2020, both the number of delays and the gap time (5468 min) decreased considerably, reflecting the limited flight operations during the pandemic.

It should be noted that the negative βₜ

40 values reported in

Table 4 arise when the total cumulative delay time (g) exceeds the theoretical operational time (d

fc × 60). Since Equation (2) expresses punctuality as the proportion of non-delayed operational time, any excess delay beyond the reference threshold results in negative percentages. Therefore, these negative values indicate extremely poor punctuality performance, where the total duration of delay exceeds the potential operational time associated with that delay category. The lowest punctuality percentage was recorded in 2018 (−404%), followed by 2009 (−363%) and 2015 (−260%). For the entire A320 dataset (2007–2022), the average punctuality index is −157%. Among all subcodes, subcode 41 exhibits the highest frequency, with 1223 occurrences out of a total of 1899, indicating that this category has the greatest impact on the punctuality performance of AF-RIQIAH Airways flights.

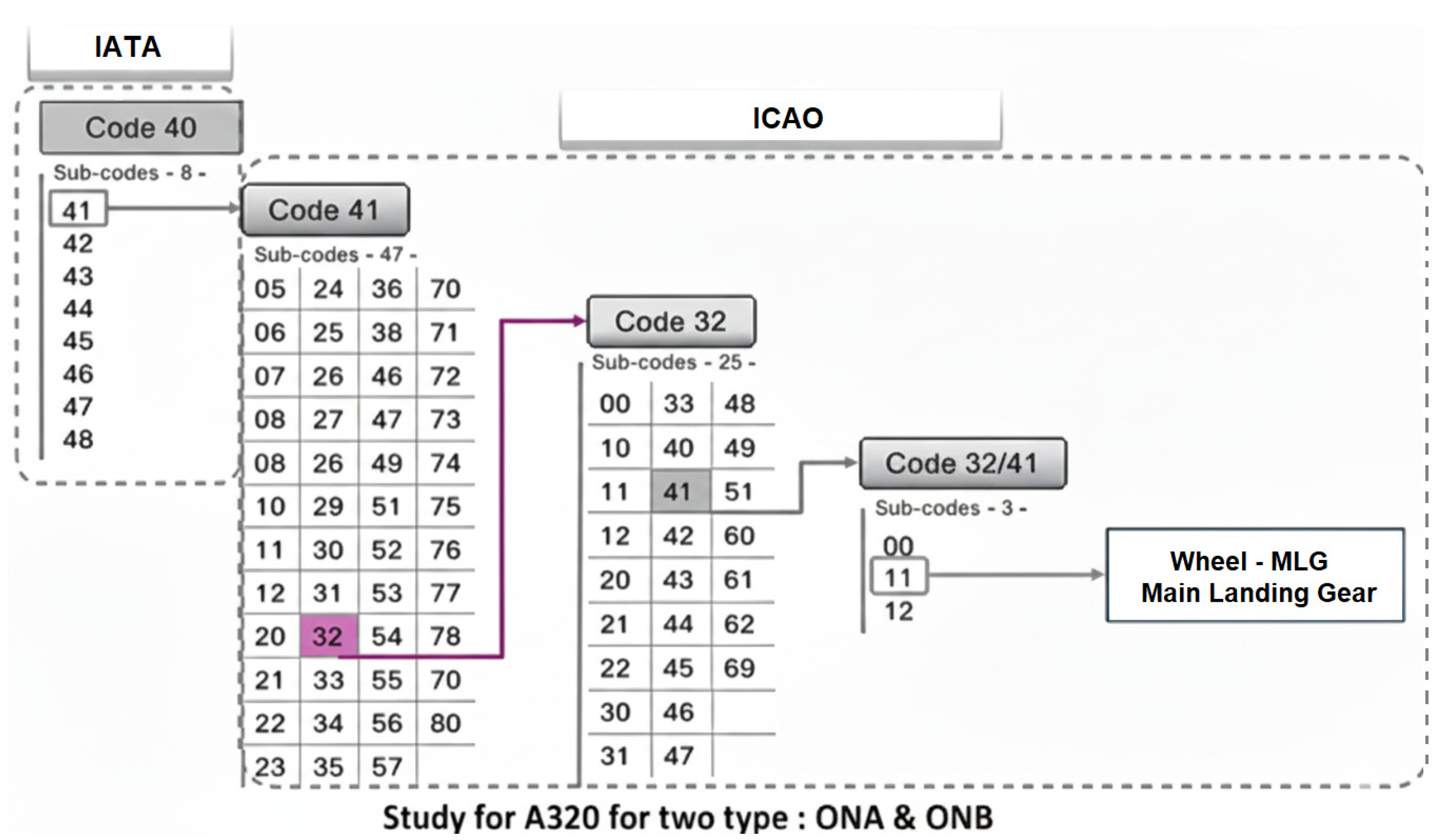

4.1.4. Subcode Tracking and Landing Gear Selection

After reviewing the data in

Table 4, which shows the delay in the departure date for code 40 of Airbus A320 aircraft, and from these data, two aircraft were selected, which have the most delay, which are ONA and ONB, which are shown in sub-code 41. They were chosen as a model for a study in this paper. Therefore, to achieve our objective and determine the maintenance procedure that affects punctuality, we switch from the IATA database to the ICAO database, as shown in

Figure 2. And we will look up the sub-codes progressively.

Code 40 of the IATA, which includes sub-code 41, was used because it clarifies some maintenance issues that cause delays in aircraft departure times. This delay is remedied by using the ANMS of the company. The comparison of the IATA delay codes for the two aircrafts, A320-ONA and A320-ONB, is presented in

Supplementary Table S8. An excerpt of the first six sub-codes with the highest delay times is presented in

Table 5.

The analysis of

Table 5 shows a significant difference in the delay durations associated with Code 40-41 maintenance issues, with total times of 16,886 min for ONA and 14,411 min for ONB. These issues are linked to IATA Code 32, and therefore, the combined classification is identified as Code 40-41-32.

4.2. Identify the Factors and Failure Modes

Aircraft maintenance delays are a critical issue in AAW, as they can lead to operational disruptions, increased costs, and compromised safety. Understanding the factors that contribute to these delays is essential to develop effective problem-solving strategies and improve overall operational efficiency.

Each member of the MIT initially prepared a list of possible causes of maintenance delays, focusing on landing gear. The team leader then consolidated these individual lists into a single comprehensive list by merging causes that conveyed the same meaning but were expressed using different terminology. All identified causes were then validated through a literature review. Numerous research papers were shared among group members to validate all identified factors, including studies by Mofokeng and Marnewick [

32], Deng et al. [

59], Giannikas et al. [

60], Hassan et al. [

62], Liu et al. [

63], Lee et al. [

64], Cao et al. [

65], etc. Finally, an online meeting of the MIT members was held to compile and finalize

Table 6 which categorizes the potential factors that influence maintenance delays related to the traditional 5M + E categories: Man, Machine, Method, Material, Workplace/Infrastructure, and Environment. Each category includes representative causes and detailed descriptions explaining how these elements contribute to increased maintenance time, reduced operational efficiency, and overall delay events.

For WI1, Foreign Object Debris (FOD) refers to any foreign material, debris, or object located on an airport surface or within an aircraft that has the potential to damage equipment or injure personnel. This may include small items such as nuts, bolts, and tools, as well as larger objects, environmental debris, or even wildlife. FOD represents a significant aviation safety hazard, as it can cause severe damage to aircraft engines and components, resulting in costly repairs, operational disruptions, and, in extreme cases, fatal accidents. The problem is further exacerbated by the current political instability in Libyan airports, particularly due to ongoing social unrest and violent clashes between conflicting parties.

4.3. Evaluate Risk and Analysis of Root Causes

For each identified cause presented in

Table 6,

Table 7 illustrates the core application of the FMEA methodology. The primary objective is to identify the failure modes and their corresponding effects on maintenance operations. A failure mode refers to the specific manner in which a component or system fails, while the effect represents the resulting consequence or impact of that failure on the system, the aircraft, or overall operations.

Following this step, three key criteria are evaluated, including the following: O (occurrence/frequency): the likelihood that the cause occurs, rated on a scale from 1 to 5 (1 = Very Low, 2 = Low, 3 = Moderate, 4 = High, 5 = Very High), S (Severity): the severity of the effect, rated from 1 to 5 (1 = Minor, 2 = Low, 3 = Moderate, 4 = Major, 5 = Critical) and D (Detection): the probability of detecting the cause before failure occurs, rated from 1 to 5 (1 = Very High Detection, 2 = High, 3 = Moderate, 4 = Low, 5 = Very Low Detection).

The weighting of the FMEA criteria was established through a structured process involving the seven-member MIT. During a dedicated team meeting, each criterion was discussed in detail, such as severity, occurrence, and detectability, and numerical values were assigned using a consensus building approach to reconcile any divergent assessments. To ensure the robustness of these weights, the team incorporated historical data from maintenance problems similar to those encountered by other airlines around the world and consulted the relevant literature to refine and validate the evaluations.

Once the criteria weights were defined, a weighted selection process was performed for each potential failure mode. Each failure mode was scored according to the defined criteria and these scores were multiplied by the corresponding weights to reflect the relative importance of each factor. The resulting weighted scores were then combined to calculate the risk priority number (RPN) using Equation (1). This approach allows the team to quantitatively prioritize maintenance actions quantitatively, focusing on failure modes with the highest potential impact, and ensuring that limited resources are effectively allocated to mitigate the most critical risks.

The FMEA analysis in

Table 7 reveals various factors that contribute to aircraft maintenance delays, with an RPN of 27 to 100. The most critical causes (RPN = 100) include excessive stress on landing gears due to poor landing techniques (M1), aging components that require frequent maintenance (MA1), delays in spare parts logistics (MT1), low-quality wheels and tires (MT3), and runway debris or surface damage (WI1). These issues significantly increase maintenance complexity, downtime, and operational disruptions. Other high-risk factors, such as design vulnerabilities (MA2), hydraulic system failures (MA4), and political or sanction-related supply chain delays (E2), also pose significant challenges (RPN = 80).

Moderate risks (RPN 36–60) arise from issues such as procedural deviations, additional defects discovered during inspections, planning inefficiencies, communication gaps, and slow troubleshooting. Although lower in risk, pilot experience (M2, RPN = 27) still contributes to maintenance inefficiency. In general, the results show that both technical and operational causes influence maintenance reliability, with high RPN values that highlight areas that need priority attention.

4.4. Improve and Mitigate Risks

4.4.1. Define Targeted Improvement Projects

To address critical failure modes identified with high RPN (RPN = 100), five targeted improvement projects were developed, along with relevant references in the field of aviation maintenance and safety. The objective is to mitigate the main causes of maintenance delays and enhance the reliability of landing gear.

Project P1: Pilot training and optimization of landing technique. This project aims to minimize hard landings that impose excessive stress on the components of the landing gear. Implementation requires advanced pilot training programs, flight simulators, and real-time feedback through flight data monitoring systems.

Project P2: Condition-based and predictive maintenance. Focusing on monitoring and replacing worn or aging components based on actual condition rather than fixed schedules, this project involves sensors for monitoring pressure, temperature and vibration monitoring, a well-selected computerized maintenance management software (CMMS) and trained personnel for data analysis.

Project P3: Quality assurance for critical spare parts. This initiative ensures the timely availability and compliance of landing gear components by working with certified suppliers, using inventory management software, conducting supplier audits and employing quality control personnel.

Project P4: Proactive maintenance of the runway. Designed to reduce premature wear and damage due to suboptimal runway conditions, this project includes regular inspections, FOD detection systems, and scheduled cleaning and maintenance programs.

Project P5: Supplier diversification and inventory management. To mitigate delays caused by supply chain restrictions or sanctions, this project focuses on identifying alternative suppliers, improving inventory tracking and forecasting, and providing procurement teams with appropriate training.

These five projects target direct and indirect causes, representing the main failure modes, while indirectly mitigating other contributing factors through reduced operational stress, enhanced monitoring, and improved resource availability.

Table 8 allows us to map each project to its impact on multiple causes, which supports prioritization in the risk evaluation step.

4.4.2. Prioritize Targeted Improvement Projects

These five improvement projects were presented to AAW top management who were convinced of their value. However, due to time constraints, limited resource availability, and, in particular, a reduced budget allocated for improvement and R&D initiatives, only three projects can realistically be implemented. To prioritize these projects, each MIT team was asked to select three projects from the five proposed. Each selection was weighted according to its priority: first choice = 3 points, second choice = 2 points, and third choice = 1 point.

Table 9 summarizes the selections made by each team member.

The total score for each project, as mentioned in

Table 10, is calculated by summing the weighted votes among all seven MIT members. This approach captures both the intensity of preference and the breadth of support, allowing for a more nuanced prioritization of projects. The resulting scores can also be linked to the expected reduction in RPN. This estimated RPN reduction is simulated in M.S Excel sheets.

Table 10 clearly indicates that the projects to select are P2, P5, and P3. In fact, project P2 (condition-based and predictive maintenance) emerges as the highest priority initiative, scoring 14 points, which confirms that predictive maintenance is expected to have the greatest impact on reducing RPN and overall downtime. Project P2 exhibits the largest isolated effect, estimated at 40–45%, reflecting its direct influence on multiple modes of high-RPN failure, such as MA1, MA5, and MA3. The second most critical project is P5 (Supplier diversification and inventory management), scoring 10 points, highlighting its role in ensuring spare part availability and improving supply chain resilience. Project P5 demonstrates an impact because timely access to components directly reduces downtime and indirectly prevents the accumulation of minor defects. Finally, project P3 (quality assurance for critical spare parts) ranks third with 9 points, indicating that while component quality is important, its impact is slightly lower than the broader systemic projects. Project P3 can potentially reduce RPN by 30–35% when implemented independently, affecting primarily component-related failure modes such as MA3, MA4, and MT3.

4.4.3. Predict the Impact of the Selected Improvement Projects

Table 11 presents the updated FMEA when the three targeted improvement projects (P2, P3, and P5) were applied. Evaluation of each failure mode was carried out by the MIT. For each failure mode, the team reached a consensus on occurrence and detectability, assigning a score from 1 (lowest risk) to 5 (highest risk). After considering the expected impact of the selected improvement projects, the team updated the occurrence and detectability scores to reflect anticipated reductions, while severity remained normally constant. This approach ensured that the risk assessment was comprehensive and collaborative, reflecting the combined judgment and expertise of the multidisciplinary team. The resulting RPN values and percentage reductions provide a clear quantitative measure of effectiveness of the improvement projects and a basis for prioritizing further interventions.

The updated FMEA analysis demonstrates the significant impact of applying the selected improvement projects (P2, P3, and P5) on reducing the delay in maintenance of aircrafts. Line-by-line evaluation reveals that critical failure modes, particularly those related to component age and wear (MA1), hydraulic retraction/extension faults (MA5), spare parts logistics (MT1), wheel/tire quality (MT3), and political/sanctions-induced delays (E2), experienced the highest reductions in RPN, ranging from 85% to 87.5%. These high reductions indicate that the targeted projects effectively mitigate the most severe and frequent maintenance risks, thereby directly contributing to a more reliable and efficient aircraft maintenance process.

Moderate improvements, ranging from 25% to 67%, were observed in failure modes partially affected by projects, including landing technique (M1), design vulnerabilities (MA2), additional defects discovered during inspections (MA4), and planning or operational pressures (ME1, ME2, ME5, WI1). These results show that even partially addressed risks benefit from the intervention, although some residual risk remains and may require future mitigation actions.

Failure modes that were not addressed by the selected projects, such as pilot handling (M2), deviations from the SOP (M3), complex defect rectification (ME3), communication gaps (ME4), runway maintenance delays (WI2), and weather conditions (E1), remained unchanged. These unchanged RPN values emphasize the need for additional projects or measures to cover these residual risks.

Overall, the total RPN was reduced from 1206 (average 60.2) to 492 (average 24.6), corresponding to an approximate 59% reduction in maintenance risk. This substantial reduction indicates that the combined implementation of the selected projects can significantly decrease aircraft downtime, improve operational efficiency, and improve safety outcomes. Analysis also provides a clear prioritization framework, guiding management on where to focus further improvements to maximize maintenance performance and minimize delays.

4.4.4. Example of Critical Spare Part Identification

Once improvement projects have been identified and selected, it is essential—following the same prioritization principle used in Phase 1 of the proposed framework—to focus first on the most critical issues before addressing the less significant ones. For example, considering projects P3 (Quality Assurance for Critical Spare Parts) and P5 (Supplier Diversification and Inventory Management), spare parts should be classified according to their level of importance and criticality. Using the same IATA and ICAO codification approach, as illustrated in

Table 5, the most significant issue is identified under IATA Code 32, which refines the coding sequence to (40-41-32). Specifically, subcode 40-41-32 comprises 25 subcodes.

Table 12 presents data for the A320-ONA and A320-ONB fleets, indicating the total number of delays associated with each maintenance operation. Among these, the subcode 32-41 shows the highest delay frequency (42 for ONA and 68 for ONB), pointing to a recurring issue related to the aircraft wheels.

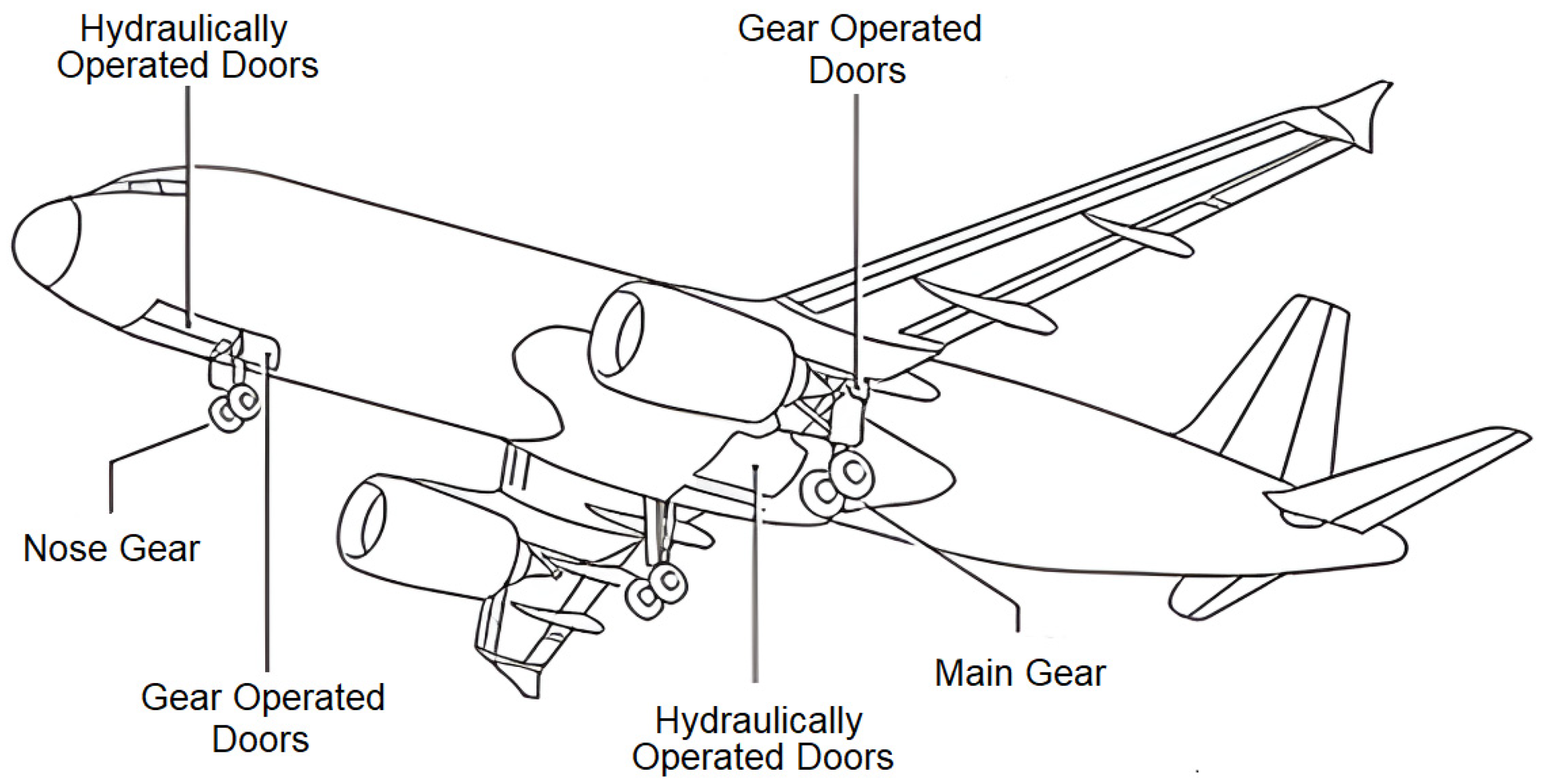

It is evident that the issue concerns the aircraft wheels; however, it is necessary to precisely identify which wheels are most affected.

Table 13, along with

Figure 3, presents data for both the main landing gear and the nose landing gear wheels. Analysis of maintenance-related departure delay data provided by AFRIQIYAH Airways indicates that the main landing gear wheels are generally the most affected, with 31 delays recorded for the A320-ONA and 30 for the A320-ONB. Consequently, the problem can be traced back to Codes 40-41-32-41-11.

This study effectively demonstrated the significant influence of maintenance operations on flight punctuality at AFRIQIYAH Airways, with a focus on Code 40 within the aeronautical maintenance system. Through a systematic and step-by-step analysis of the relevant subcodes, the investigation identified that the primary cause of recurring delays is associated with the main landing gear wheels, specifically captured under subcode 40-41-32-41-11.

By proposing the proposed DMAIC-FMEA framework along with illustrative examples of its application, initiating new studies and launching corresponding improvement projects becomes considerably more feasible. The primary advantage lies in providing a clear, logical and straightforward structure that guides the process and facilitates the achievement of significant and impactful improvement results. Moreover, this framework is applicable not only to AAW but also can be adapted and implemented by other airlines, offering a scalable and transferable approach to systematically improve maintenance operations and overall operational performance.

4.5. Control and Monitoring

The control and monitoring phase constitutes the final stage of the proposed approach, aimed at ensuring that the improvements achieved through the implementation of projects P2, P3, and P5 are maintained over time. In this study, these improvement projects are scheduled to be implemented in 2026; consequently, this phase has not yet been implemented. However, it remains essential, as it focuses on continuously tracking maintenance performance, validating the effectiveness of corrective actions, and preventing the recurrence of high-risk failure modes.

The key actions in this phase include the second estimation of the metrics d

fc, g, and β

t40 metrics, as applied in

Table 4, to rigorously evaluate the actual improvements achieved. Regular audits and inspections are also critical, which involve routine checks of landing gear, hydraulic systems, and spare parts logistics. These inspections ensure that corrective measures continue to be effective and allow for the early identification of emerging failure patterns before they escalate. Another vital element is ongoing team review and feedback. The MIT should convene periodically to examine updated RPN scores, analyze anomalies, and recommend minor adjustments as needed. This iterative process helps institutionalize the lessons learned and reinforces continuous improvement within maintenance operations.

By integrating these control and monitoring activities, the organization can maintain the risk reductions achieved through improvement projects, ensure long-term reliability in maintenance operations, and continuously reduce aircraft maintenance delays in safety and efficiency. Therefore, the Control and Monitoring phase completes the application of the proposed FMEA-DMAIC approach, strengthening a culture of continuous improvement within technical maintenance operations.

Despite the comprehensive design of the proposed FMEA–DMAIC approach, this study has some limitations. The control and monitoring phase has not yet been implemented, as improvement projects are scheduled for the future, so the long-term effectiveness remains to be validated. The study also focuses on a specific aircraft fleet, which may limit its generalizability, and relies primarily on traditional FMEA metrics and expert judgment, which may not fully capture system uncertainties. Future research could extend the methodology to other fleets and operational contexts to assess its adaptability. Integrating fuzzy inference systems, artificial intelligence, or machine learning could improve predictive maintenance, automate risk prioritization, and enable real-time monitoring. Longitudinal studies that track the actual results of improvement projects would further validate the effectiveness and support more reliable maintenance strategies.

5. Conclusions

The application of the newly developed FMEA–DMAIC methodology to maintenance operations demonstrates its effectiveness in systematically identifying and mitigating high-risk failure modes. The selected improvement projects for the AWW company, namely condition and predictive maintenance, supplier diversification and inventory management, and quality assurance for critical spare parts, are projected to reduce overall maintenance by nearly 60%, significantly improving fleet reliability and operational performance.

The study underscores the importance of combining technical, operational, and organizational perspectives in maintenance risk management. Additionally, the control and monitoring phase is essential to maintain improvements, validate corrective actions, and prevent recurrence of high-risk failures. By institutionalizing continuous monitoring, regular audits, and team-based feedback, AAW can reinforce a culture of proactive maintenance, improve aircraft availability, and ultimately achieve greater operational efficiency and passenger satisfaction. This research provides a structured, data-driven framework that can be replicated across other aircraft fleets to optimize maintenance reliability and reduce operational delays.

This study opens multiple avenues for future research and practical applications in the field of aircraft maintenance management. First, the proposed FMEA–DMAIC framework can be extended to additional aircraft fleets and maintenance domains to evaluate its generalizability and adaptability in various operational contexts. Applying the framework to different aircraft types and operational settings would not only validate its robustness, but would also provide information on context-specific modifications required to optimize maintenance processes.

Second, the integration of advanced methodologies, such as a fuzzy inference system, with the FMEA component represents a promising direction to improve risk assessment. Traditional FMEA is based on precise numerical values for severity, occurrence, and detectability, which may not fully capture the inherent uncertainty and subjectivity of expert assessments. Using fuzzy logic, maintenance teams can interpret imprecise and linguistic data from FMEA tables, allowing for more nuanced prioritization of potential failures. Future research could focus on optimizing fuzzy membership functions, inference rules, and aggregation strategies, thus improving the reliability and decision-making efficiency of predictive maintenance strategies. This approach has the potential to strengthen operational safety, optimize resource allocation, reduce maintenance delays, and support proactive decision-making in complex aviation systems.

Third, based on the emerging role of digital twins in aircraft lifecycle management, further research could examine the synergistic integration of predictive maintenance models with digital twin technologies to improve operational efficiency and safety. Digital twins have already shown significant value in maintenance processes by collecting and analyzing real-time status information to optimize aircraft operations [

66]. Incorporating advanced predictive analytics can further improve the identification of high-risk failure modes, enable data-driven maintenance scheduling, and reduce unplanned downtime [

67]. Beyond technical applications, digital twins can also support human-centric training that personalizes instruction, monitors trainee competence, and aligns learning outcomes with regulatory skill benchmarks, as proposed in the recent literature [

68].

Future research could explore a holistic framework in which predictive maintenance models, technical digital twins, and training-oriented digital twins interact, creating a closed-loop system that not only anticipates and mitigates failures, but also continuously improves workforce readiness. Such integrative approaches have the potential to strengthen the resilience of the supply chain, optimize spare parts availability, reduce aircraft turnaround times, and support proactive decision making, ultimately contributing to long-term operational reliability, safety, and cost effectiveness in aviation.

Furthermore, the proposed FMEA–DMAIC approach can be applied and adapted to other airlines and aircraft fleets to improve maintenance efficiency in various operational contexts. Furthermore, future enhancements could take advantage of artificial intelligence techniques to further optimize predictive maintenance. In fact, machine learning algorithms could analyze historical and real-time operational data to detect emerging failure patterns, predict component degradation with greater precision, and recommend optimized maintenance schedules. By considering these perspective tools with the proposed FMEA–DMAIC approach, airlines could achieve more intelligent data-driven maintenance strategies, reduce unplanned downtime, and improve overall safety and cost effectiveness.