Modelling of Exploitation Influence on Rock Mass Seismicity in Boundary Coal Pillar Areas—A Single-Longwall Option

Abstract

1. Introduction

2. Materials and Methods

2.1. Assumptions for the Assessment of the Possibility of Activation of Burst-Prone Formations

- –

- If the value of Δ < 0, then the solution of Equation (1) has three different elements, and the expressions defining the principal components describe the following formulas:

- –

- If Δ = 0 and at the same time J3 ≠ 0, then the solution of the equation has one double element and one single element, and the expressions for the principal components are, respectively, as follows:

- –

- If Δ = 0 and J3 = 0, then the solution of the equation has one triple element, and the principal components are as follows:

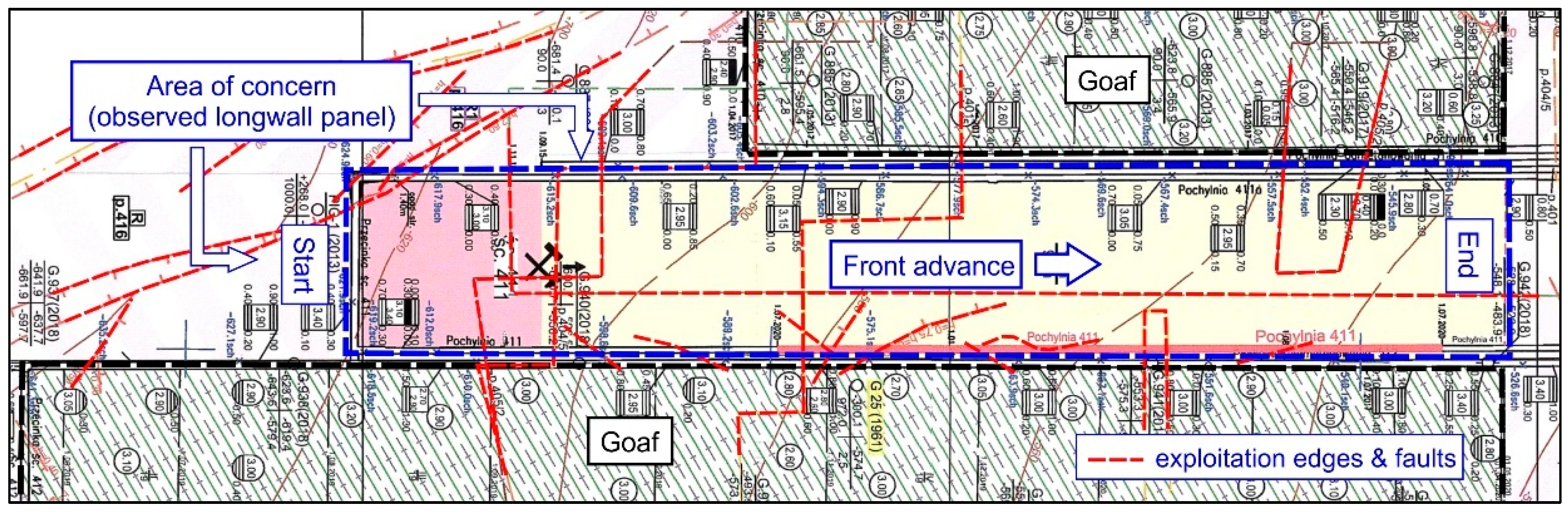

2.2. Geomechanical Models and the Concept of Simulation Studies

- –

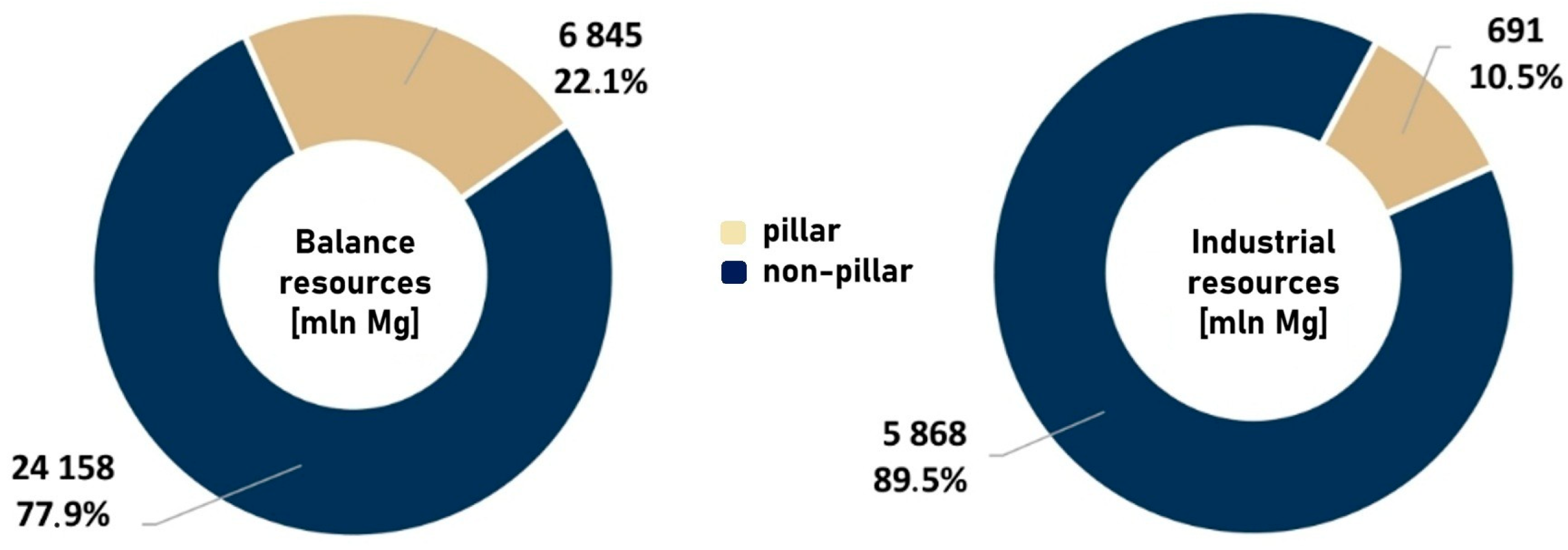

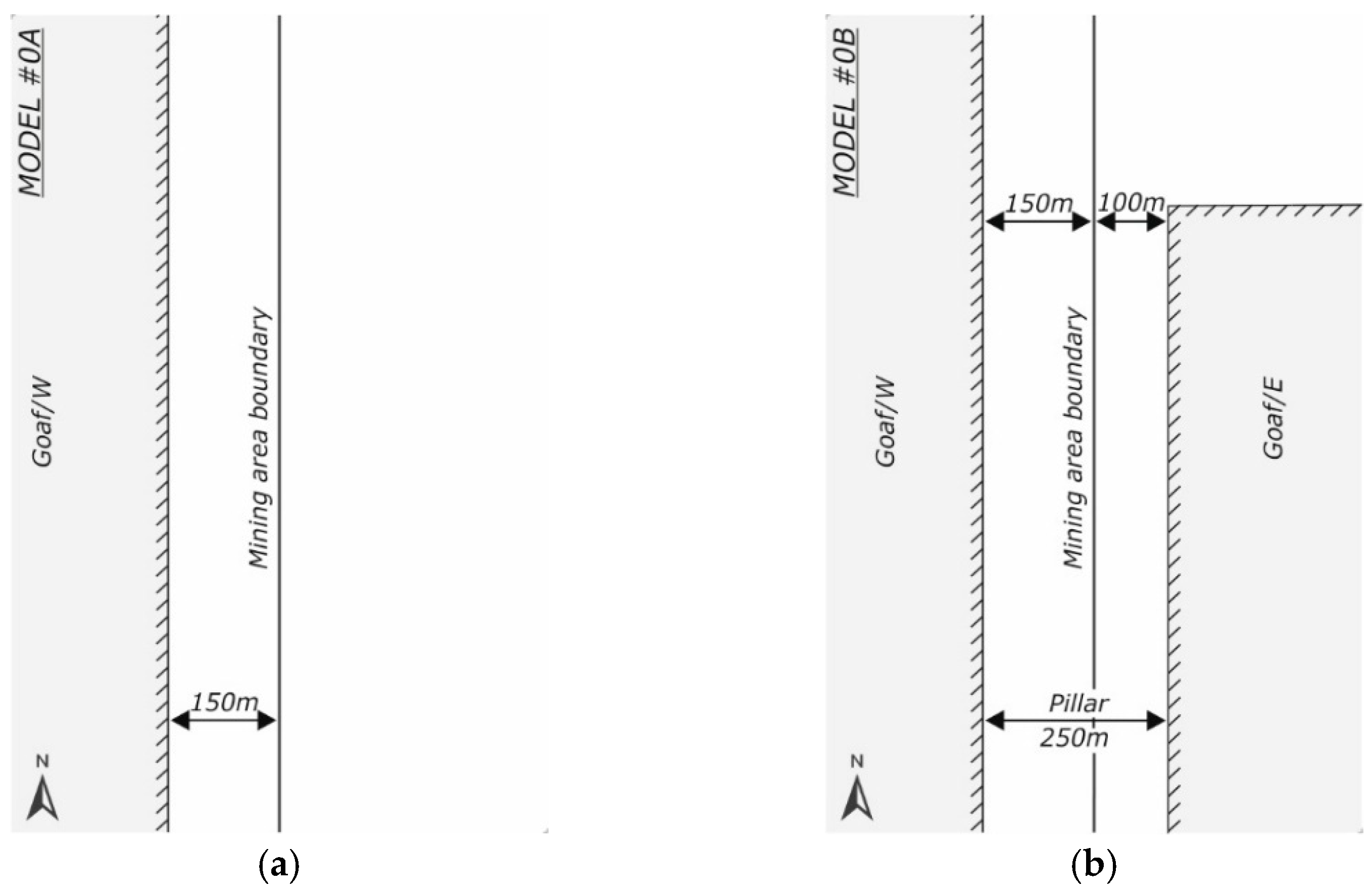

- First step: Development of the goaf surface on the western side (goafW), resulting in the final position of the goaf edges at a distance of 150 m from the MA boundary (Model #0A) (Figure 2a).

- –

- Second step: Further development of the goaf on the eastern side (goafE), resulting in the final position of their edges at a distance of 100 m from the MA boundary (Model #0B) (Figure 2b).

- –

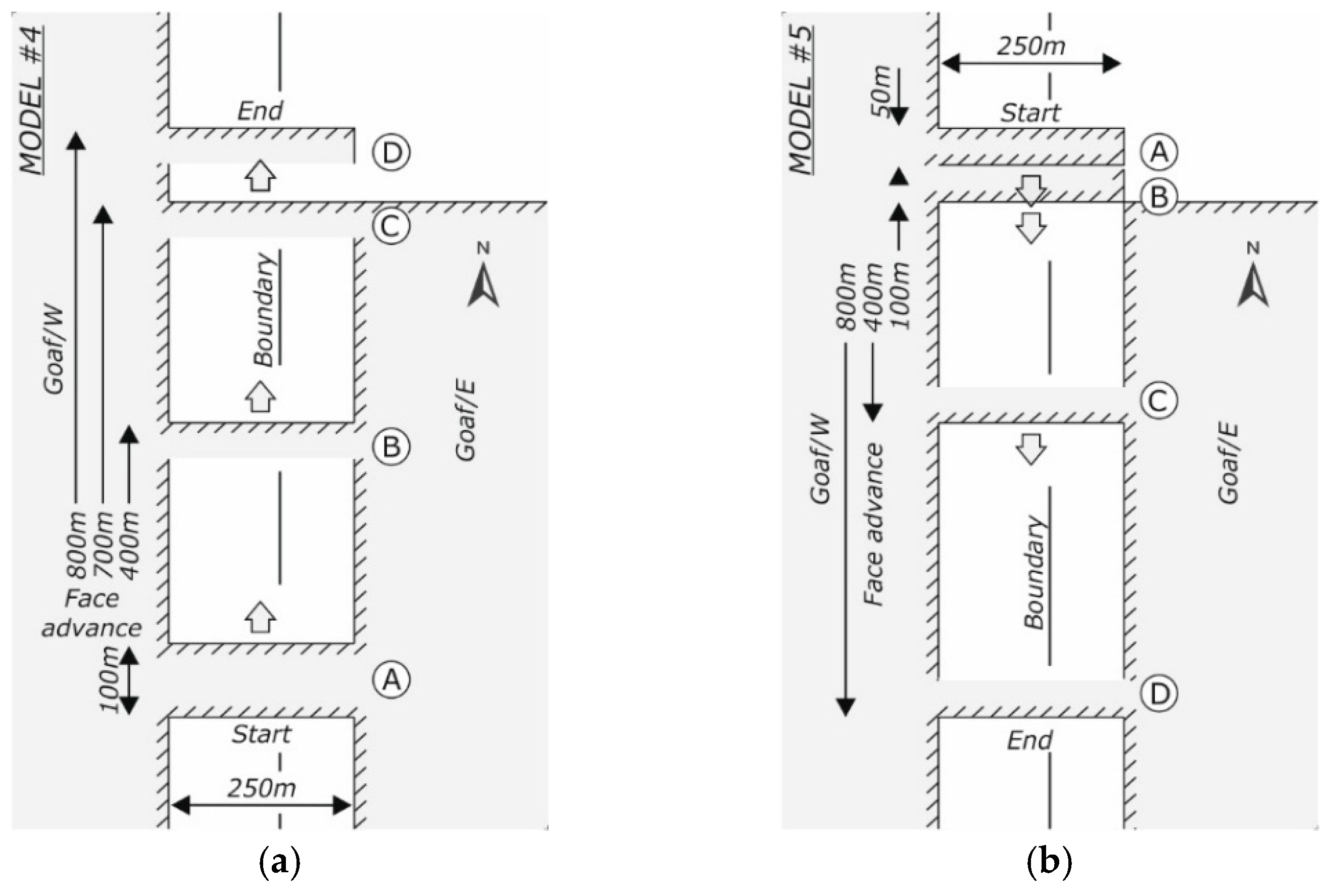

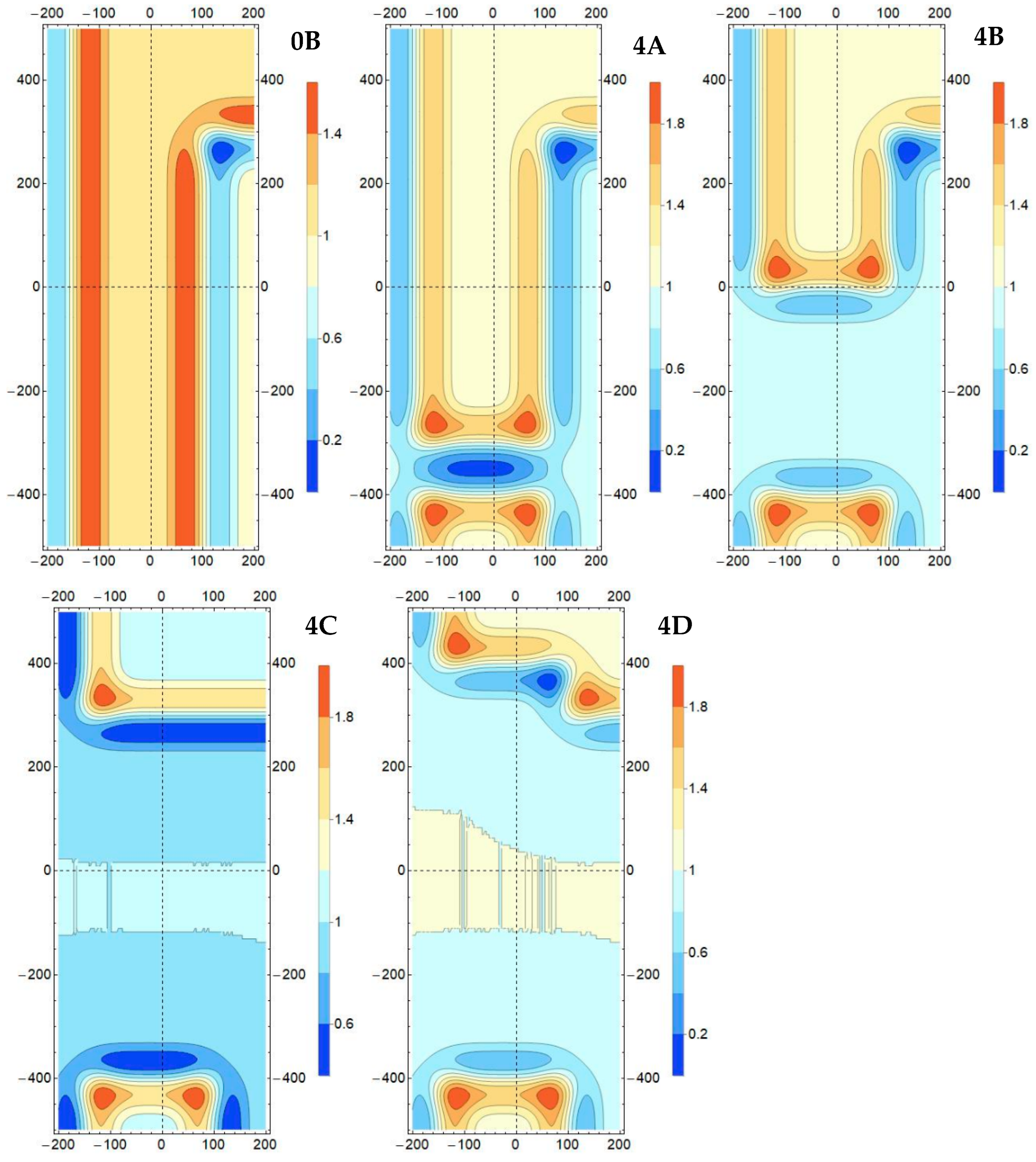

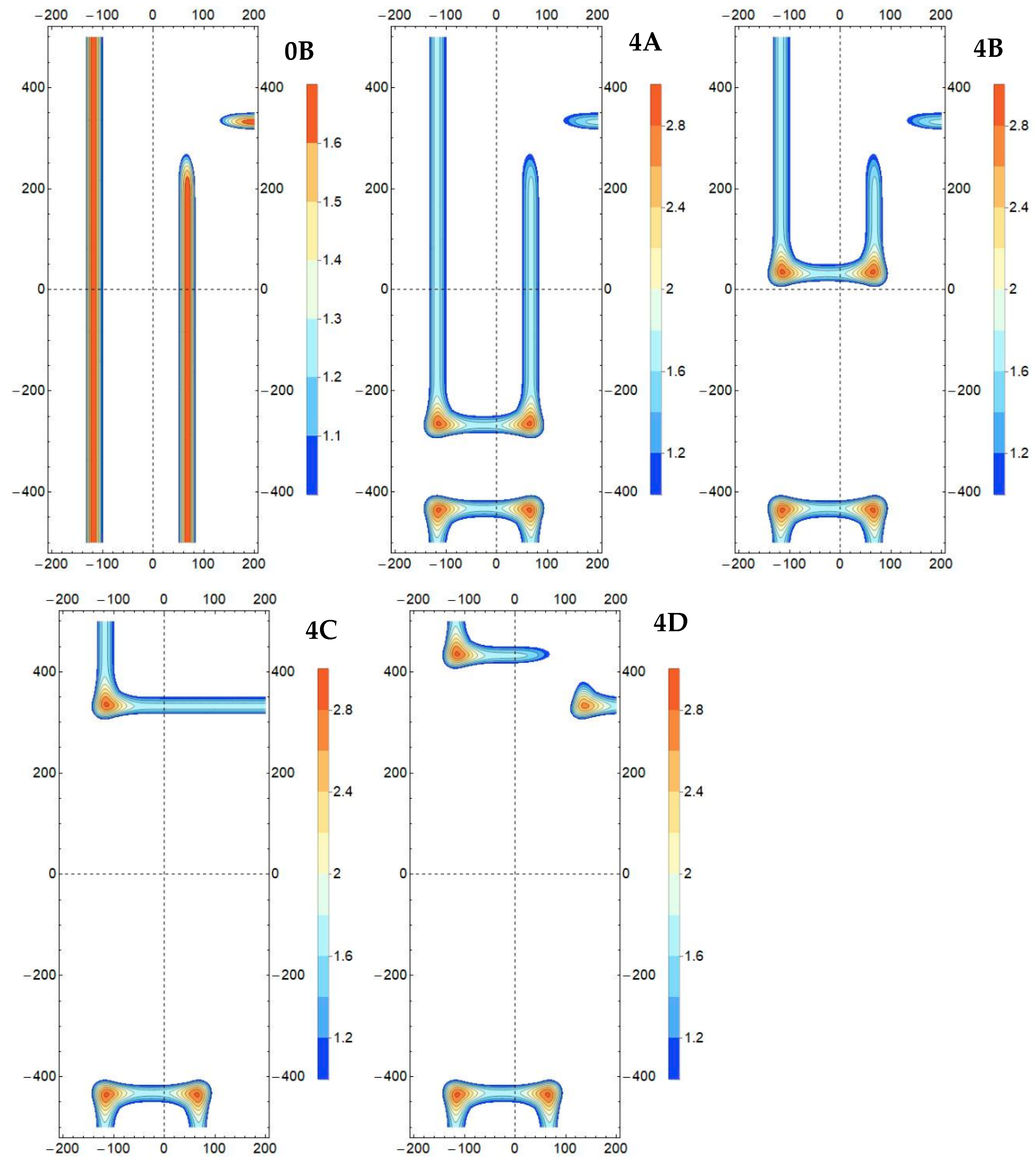

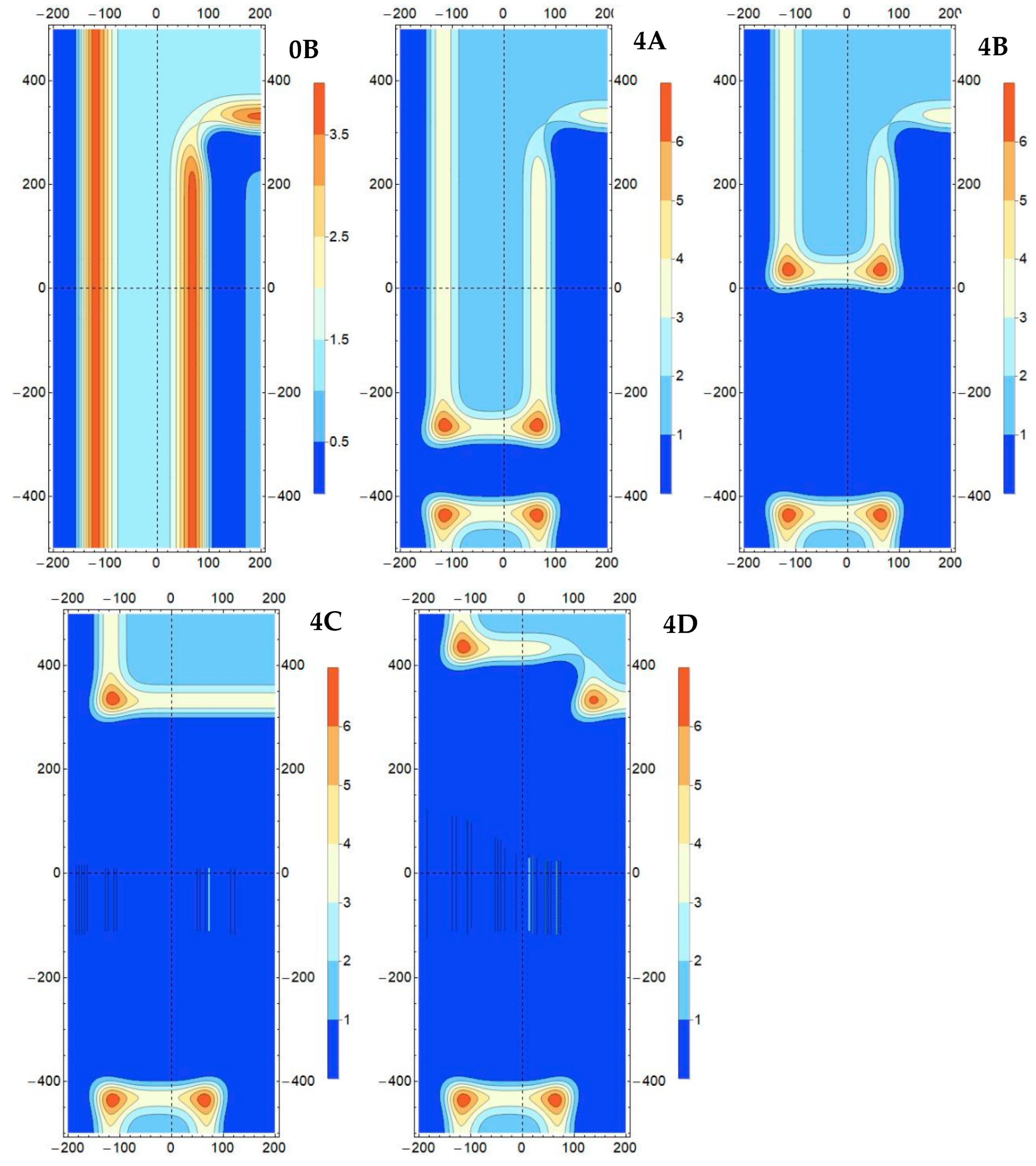

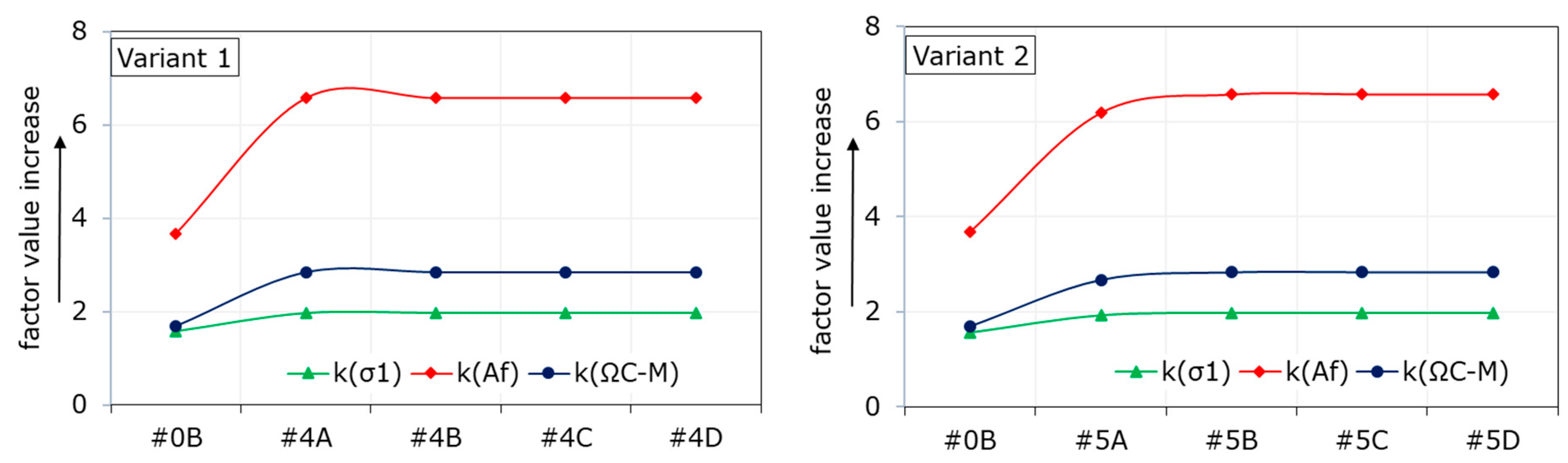

- Variant 1: Exploitation of the deposit in a two-sided environment of the goafs with a working face length of 250 m (Model #4) conducted in the (conventional) northern direction, with an illustration of the results for four instantaneous positions—after achieving a face advance of 100 m (Model #4A), 400 m (Model #4B), 700 m (Model #4C), and 800 m (Model #4D) (Figure 3a);

- –

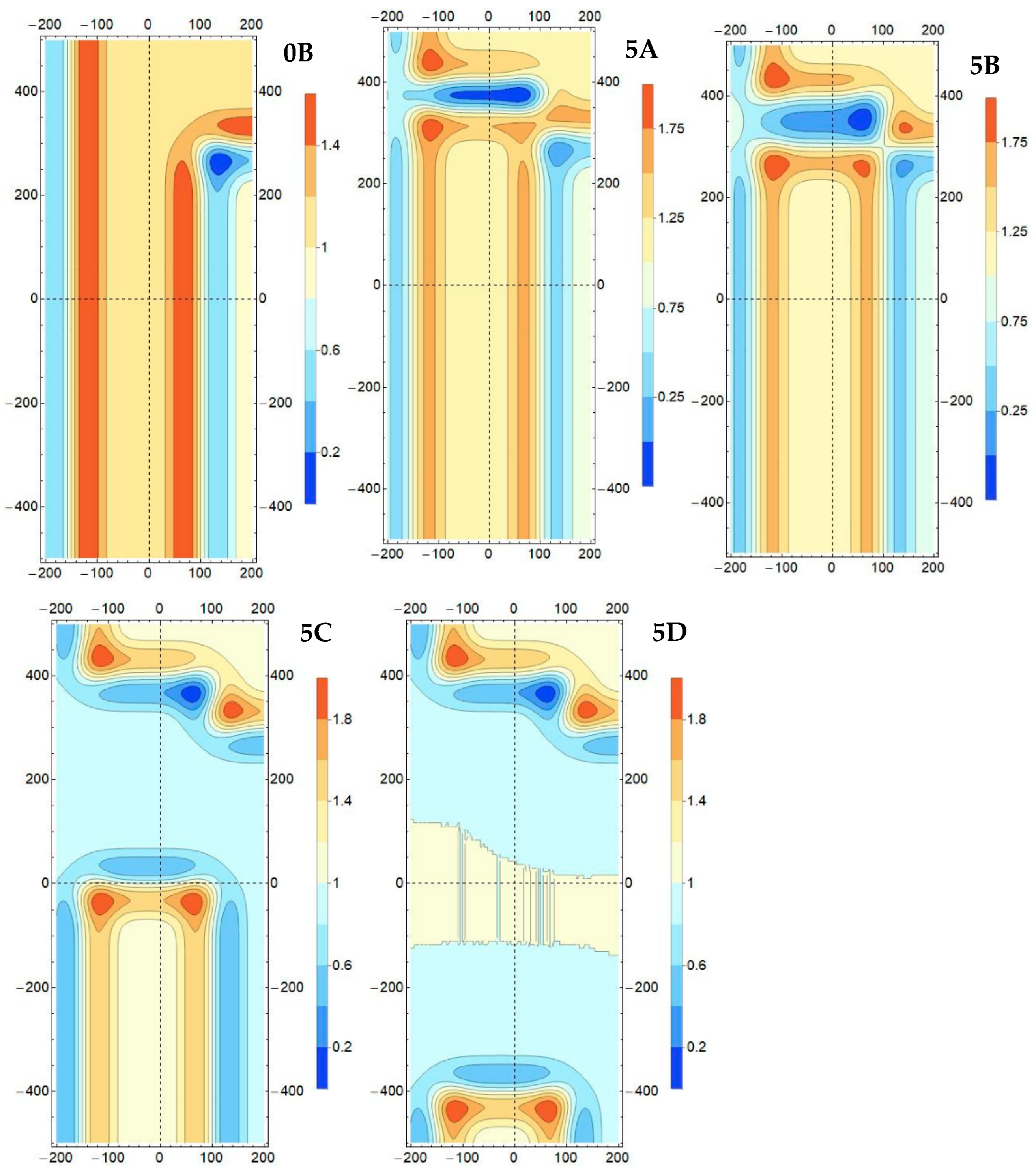

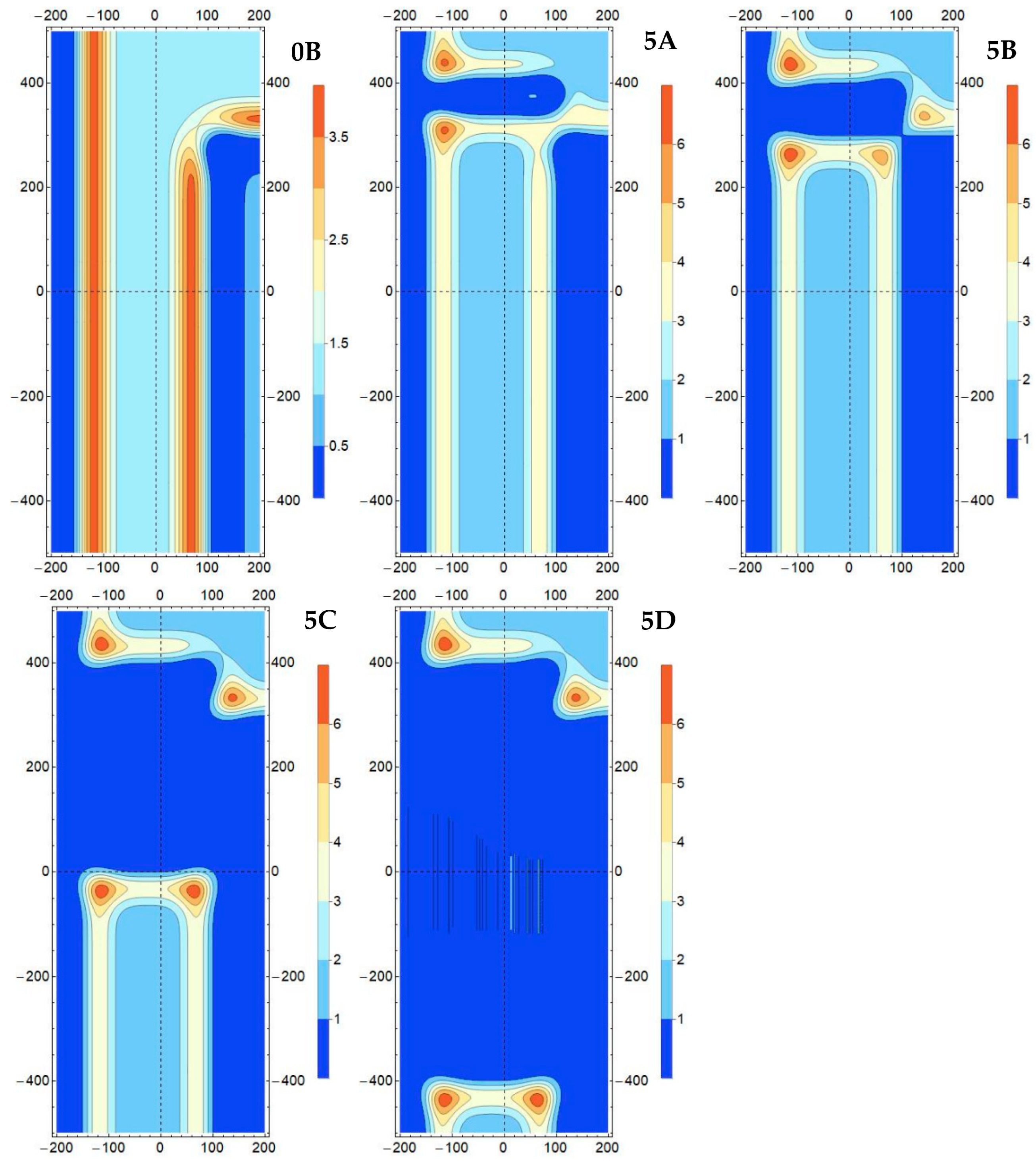

- Variant 2: Exploitation of the deposit in a two-sided environment of the goafs with a working face length of 250 m (Model #5) conducted in the (conventional) southern direction, with an illustration of the results for four of its instantaneous positions—after achieving a face advance of 50 m (Model #5A), 100 m (Model #5B), 400 m (Model #5C), and 800 m (Model #5D) (Figure 3b).

3. Results and Discussion

3.1. Creating a Boundary Pillar

3.2. Deposit Extraction in the Boundary Pillar According to Variant 1

3.3. Deposit Extraction in the Boundary Pillar According to Variant 2

3.4. Comparison of Variant Exploitation in Terms of Potential Seismic Hazard

- –

- Variant 1: May have a smaller number of anomalous zones shaped by the maxima of stress/effort/energy state factors for the face advance, where the face line aligns with the edge of the excavations on the eastern side of the MA boundary (Model 4C),

- –

- Variant 2: May have a smaller scale of percentage increases in the maximum values of computational indicators, favouring the initiation of effort processes for the initial stage of the face advance (Model 5B).

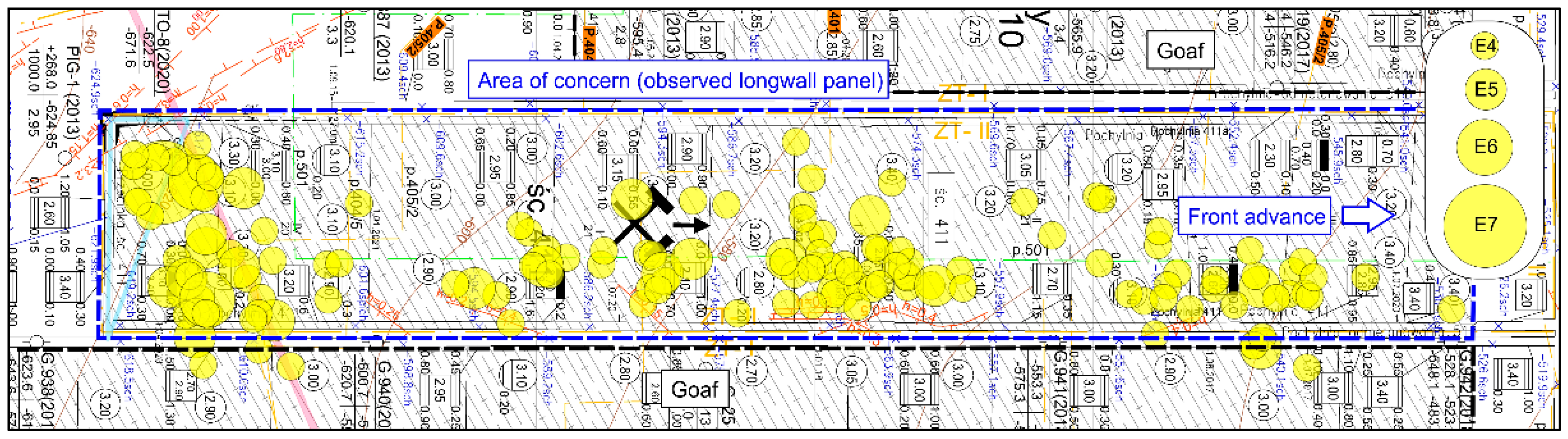

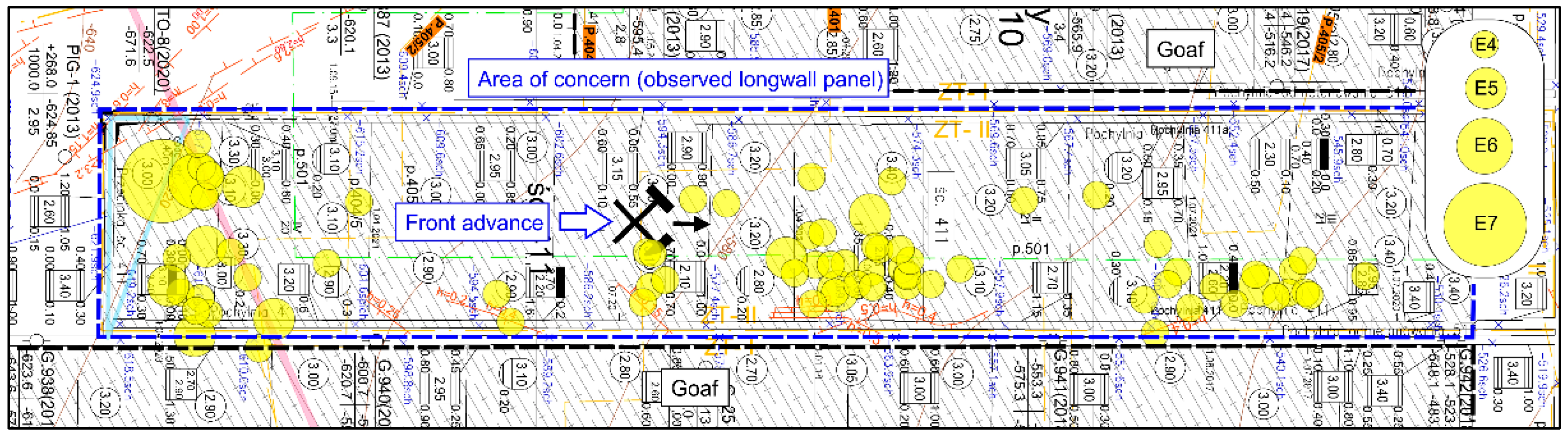

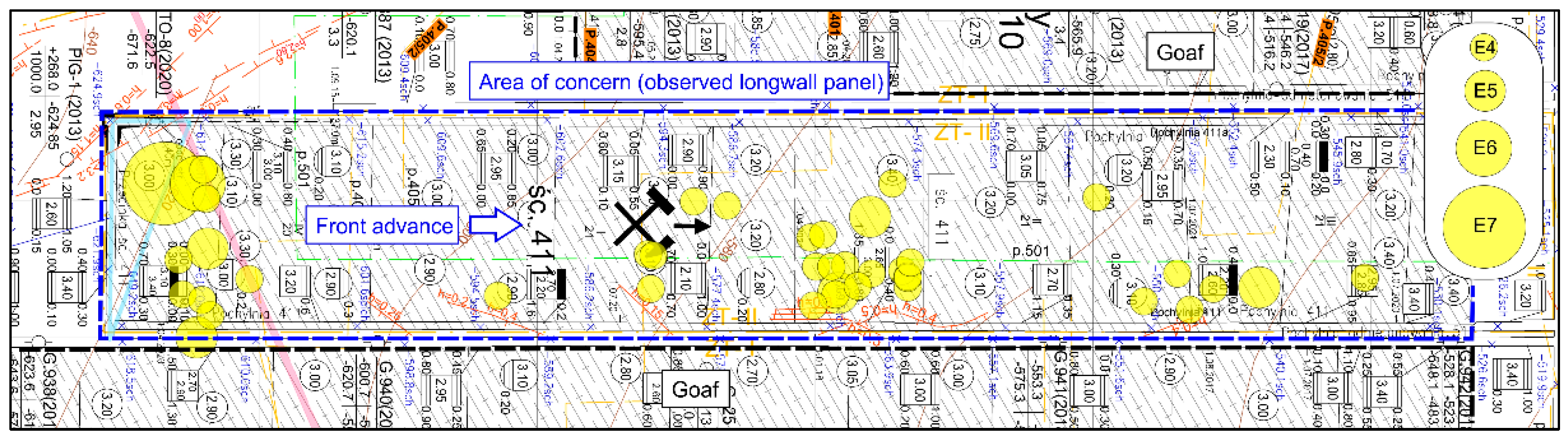

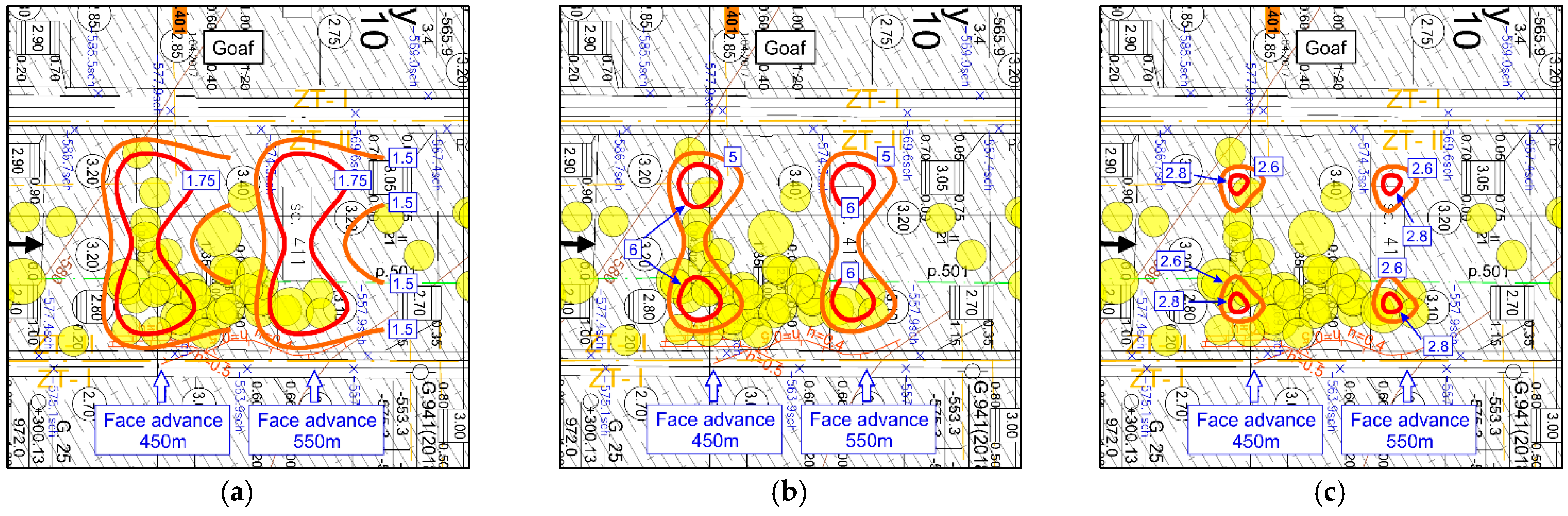

4. Verification of Simulation Results

- –

- Up to 50 m: Out of a total of 140 recorded phenomena, 47 occurred in the forefield (~34%), where their energy expenditure accounted for 9.4% of the total in this distance range (4.1 × 107 J);

- –

- Up to 40 m: Out of a total of 114 recorded phenomena, 37 occurred in the forefield (~32%), where their energy expenditure accounted for 9.0% of the total in this distance range (3.7 × 107 J);

- –

- Up to 30 m: Out of a total of 90 recorded phenomena, 32 occurred in the forefield (~36%), where their energy expenditure accounted for 8.4% of the total in this distance range (3.3 × 107 J);

- –

- Up to 25 m: Out of a total of 75 recorded phenomena, 28 occurred in the forefield (~37%), where their energy expenditure accounted for 7.8% of the total in this distance range (3.1 × 107 J);

- –

- Up to 20 m: Out of a total of 61 recorded phenomena, 23 occurred in the forefield (~38%), where their energy expenditure accounted for 7.5% of the total in this distance range (2.8 × 107 J);

- –

- Up to 15 m: Out of a total of 41 recorded phenomena, 14 occurred in the forefield (~34%), where their energy expenditure accounted for 6.2% of the total in this distance range (2.7 × 107 J).

- –

- –

- –

5. Conclusions

- –

- The geomechanical response of the rock mass to subsequent positions of the extraction face in both variants is at a similar, relatively high level in terms of extreme values of all three calculation indicators;

- –

- The largest fluctuations in the maxima of individual concentration factors are within the range 68–79% and are recorded at the initial stage of the face advance, after which their values asymptotically stabilize at identical levels;

- –

- The greatest risk zones of effort processes in the main roof are local and are located in front of the longwall face in the corners of the solid coal adjacent to the goafs on the sides of the closing field;

- –

- The considered methods of extracting the deposit in the boundary pillar will be associated with a high seismic hazard, but in both cases, it should be comparable, also with regard to the potential effects in the mining excavations;

- –

- The variant with the face advancing on the south is more favourable in the context of the scale of increases in the maximum values of concentration factors, while the variant with the face advancing north is more favourable in the context of the range of anomalous zones on specific sections of the face advance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- State Mining Authority, Report on the Activities of State Mining Authority in 2024. Available online: https://www.wug.gov.pl (accessed on 1 July 2025). (In Polish)

- Report 2020: Hard Coal Mining in Poland. Instytut Gospodarki Surowcami Mineralnymi i Energią PAN.; Kraków. 2021. Available online: https://min-pan.krakow.pl/projekty/wp-content/uploads/sites/8/2018/07/Raport-2020_Górnictwo-węgla-kamiennego-w-Polsce.pdf (accessed on 1 April 2025). (In Polish).

- Konicek, P.; Schreiber, J. Heavy rockbursts due to longwall mining near protective pillars: A case study. Int. J. Min. Sci. Technol. 2018, 28, 799–805. [Google Scholar] [CrossRef]

- Das, R.; Sharma, M.L.; Wason, H.R.; Choudhury, D.; Gonzalez, G. A Seismic Moment Magnitude Scale. Bull. Seismol. Soc. Am. 2019, 109, 1542–1555. [Google Scholar] [CrossRef]

- Das, R.; Das, A. Limitations of Mw and M Scales: Compelling Evidence Advocating for the Das Magnitude Scale (Mwg)-A Critical Review and Analysis. Indian Geotech. J. 2025, 1147, 1–19. [Google Scholar] [CrossRef]

- Cała, M.; Tajduś, A. Stan Naprężenia Pod Pozostawionym Filarem Lub Resztką Pokładu. Conference materials: Tąpania 2001. 2001. (In Polish). Available online: https://home.agh.edu.pl/~cala/papers/2001_03.pdf (accessed on 15 June 2025).

- Kaya, A.; Tarakci, U.C. Stability Investigation of a deep shaft using different methods. Int. J. Geomech. 2020, 21, 05020009. [Google Scholar] [CrossRef]

- Bukowski, P. Determining of safety pillars in the vicinity of water reservoirs in mine workings within abandoned mines in the Upper Silesian Coal Basin. J. Min. Sci. 2010, 46, 298–310. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.K. Water barrier pillar design for safety in underground coal mines: A review. Mine Water Environ. 2025, 44, 203–225. [Google Scholar] [CrossRef]

- Fan, J.; Li, Z.; Feng, G.; Zhang, H.; Qi, C.; Zhang, J. Failure analysis of coal pillars and overburden from underground water reservoir under the mining-water invasion coupling effect. Eng. Fail. Anal. 2023, 151, 107406. [Google Scholar] [CrossRef]

- Wesseloo, J.; Stacey, T.R. A reconsideration of the extension strain criterion for fracture and failure of rock. Int. J. Rock Mech. Rock Eng. 2016, 49, 4667–4679. [Google Scholar] [CrossRef]

- Zakri, R.S.; Wattimena, R.K.; Prassetyo, S.H.; Karian, T. Influence of mining depth and panel length in longwall underground coal mining on the distribution of principal stresses along the barrier pillars. In Proceedings of the IOP Conference Series: Earth and Environment Science, 3rd International Conference on Mining and Environmental Technology, Mataram, Indonesia, 22–24 August 2024; Volume 1422, p. 012014. [Google Scholar] [CrossRef]

- Yadav, A.R.; Islavath, S.R. Numerical investigation for estimation of behaviour of barrier pillars, gateroads and face of a deep longwall mine: A case study. Min. Metall. Explor. 2024, 41, 463–478. [Google Scholar] [CrossRef]

- Eremin, M.; Peryshkin, A.; Esterhuizen, G.; Pavlova, L.; Fryanov, V. Numerical Analysis of Pillar Stability in Longwall Mining of Two Adjacent Panels of an Inclined Coal Seam. Appl. Sci. 2022, 12, 11028. [Google Scholar] [CrossRef]

- Li, W.; Tu, S.; Tu, H.; Li, Y.; Liu, X.; Miao, K. Failure characteristics and control techniques for mining roadway affected by stress accumulation of residual pillars in contiguous coal seams. Eng. Fail. Anal. 2022, 141, 106646. [Google Scholar] [CrossRef]

- Zingano, A.C.; Koppe, J.C.; Costa, J.F. Barrier pillar between production panels in coal mine. Rem Rev. Esc. Minas 2007, 60, 219–226. [Google Scholar] [CrossRef]

- Oraee, K.; Hosseini, N.; Gholinejad, M. Estimation of coal pillar strength by Finite difference model. In Proceedings of the 2009 Coal Operators Conference, Wollongong, Australia, 12–13 February 2009; The AusIMM Illlawarra Branch: Wollongong, Australia, 2009; pp. 54–61. [Google Scholar]

- Wang, H.; Jiang, Y.; Zhao, Y.; Zhu, J.; Liu, S. Numerical Investigation of the Dynamic Mechanical State of a Coal Pillar During Longwall Mining Panel Extraction. Rock Mech. Rock Eng. 2013, 46, 1211–1221. [Google Scholar] [CrossRef]

- Hashikawa, H.; Mao, P.; Sasaoka, T.; Hamanaka, A.; Shimada, H.; Batsaikhan, U.; Oya, J. Numerical Simulation on Pillar Design for Longwall Mining under Weak Immediate Roof and Floor Strata in Indonesia. Sustainability 2022, 14, 16508. [Google Scholar] [CrossRef]

- Rezaei, M.; Hossaini, M.F.; Majdi, A. Development of a time-dependent Energy model to calculate the mining-induced stress over gates and pillars. J. Rock Mech. Geotech. Eng. 2015, 7, 306–317. [Google Scholar] [CrossRef]

- Frith, R.; Reed, G. The limitations and potential design risks when applying empirically derived coal pillar strength equations to real-life mine stability problems. Int. J. Min. Sci. Technol. 2019, 29, 17–25. [Google Scholar] [CrossRef]

- Wang, S.L.; Hao, S.P.; Chen, Y.; Bai, J.B.; Wang, X.Y.; Xu, Y. Numerical investigation of coal pillar failure under simultaneous static and dynamic loading. Int. J. Rock Mech. Min. Sci. 2016, 84, 59–68. [Google Scholar] [CrossRef]

- Lai, X.; Xu, H.; Fan, J.; Wang, Z.; Yan, Z.; Shan, P.; Zhang, S.; Yang, Y. Study on the mechanism and conrol of rockburst od coal pillar under complex conditions. Geofluids 2020, 2020, 8847003. [Google Scholar] [CrossRef]

- Maj, A.; Kortas, G. Wytężenie filarów przy komorowo-filarowej eksploatacji złoża anhydrytu. Przegląd Górniczy 2004, 60, 34–39. (In Polish) [Google Scholar]

- Kumar, A.; Waclawik, P.; Singh, R.; Ram, S.; Korbel, J. Performance of a coal pillar at deeper cover: Field and simulation studies. Int. J. Rock Mech. Min. Sci. 2019, 113, 322–332. [Google Scholar] [CrossRef]

- Chlebowski, D.; Burtan, Z. Geomechanical Analysis of the Main Roof Deformation in Room-and-Pillar Ore Mining Systems in Relation to Real Induced Seismicity. Appl. Sci. 2024, 14, 5710. (In Polish) [Google Scholar] [CrossRef]

- Nguyen, P.; Minh, V.; Litwa, P.; Makówka, J.; Szczerbiński, K.; Phan, V.V. Investigation of the Occurrence of Intensive Seismic Activity at the “Polkowice-Sieroszowice” Copper Ore Mine, Poland. Arch. Min. Sci. 2024, 69, 559–573. [Google Scholar] [CrossRef]

- Bańka, P.; Jaworski, A.; Plewa, F. Analityczne podejście prognostyczne, stosowane do oceny potencjalnego zagrożenia tąpaniami wyrobisk górniczych. Górnictwo Geol. 2011, 6, 23–35. (In Polish) [Google Scholar]

- Chlebowski, D. Analityczne Modelowanie Eksploatacji Skrępowanej w Aspekcie Identyfikacji Stref Zagrożenia Tąaniami; Wydawnictwo AGH: Kraków, Poland, 2013. (In Polish) [Google Scholar]

- Xue, C.; Cao, A.; Liu, Y.; Guo, W.; Wen, Y.; Hu, Y.; Gao, X. Mechanism and prevention practice of coal burst in deep graduał residual coal pillar area: A case study. Arab. J. Geosci. 2022, 15, 195. [Google Scholar] [CrossRef]

- Sałustowicz, A. Tąpania w Świetle Badań Laboratoryjnych i Obserwacji w Praktyce; Wydawnictwo SITG: Katowice, Poland, 1963. (In Polish) [Google Scholar]

- Gil, H.; Drzęźla, B. Metody oceny skłonności węgla do tąpań. Przegląd Górniczy 1973, 12. (In Polish) [Google Scholar]

- Bukowska, M. Kompleksowa Metoda Oceny Skłonności do Tąpań Górotworu w Górnośląskim Zagłębiu Węglowym; Wydawnictwo Główny Instytut Górnictwa: Katowie, Poland, 2009. (In Polish) [Google Scholar]

- Knothe, S. Prognozowanie Wpływu Eksploatacji Górniczej; Wydawnictwo Śląsk: Katowice, Poland, 1984. (In Polish) [Google Scholar]

- Djamaluddin, I.; Mitani, Y.; Esaki, T. Evaluation of ground movement and damage to structure from Chinese coal mining using a new GIS coupling model. Int. J. Rock Mech. Min. Sci. 2011, 48, 380–393. [Google Scholar] [CrossRef]

- Kowalski, A.; Białek, J.; Rutkowski, T. Caulking of Goafs Formed by Cave-in Mining and its Impact on Surface Subsidence in Hard Coal Mines. Arch. Min. Sci. 2021, 66, 85–100. [Google Scholar] [CrossRef]

- Strzałkowski, P. Predicting Mining Areas Deformations under the Condition of High Strength and Depth of Cover. Energies 2022, 15, 4627. [Google Scholar] [CrossRef]

- Blachowski, J. Application of GIS spatial regression methods in assessment of land subsidence in complicated mining conditions: Case study of the Walbrzych coal mine (SW Poland). Nat. Hazards 2016, 84, 997–1014. [Google Scholar] [CrossRef]

- Hejmanowski, R.; Malinowska, A.A. Wykorzystanie metody odwrotnej w estymacji osiadań powierzchni terenu dla złóż soli. Gospod. Surowcami Miner.—Miner. Resour. Manag. 2017, 33, 179–200. (In Polish) [Google Scholar] [CrossRef][Green Version]

- Niedojadło, Z.; Stoch, T.; Jura, J.; Sopata, P.; Wójcik, A.; Mrocheń, D. Monitoring and modelling the deformation state of a dyke of a flotation tailings reservoir of a copper ore mine. Acta Montan. Slovaca 2023, 28, 123–140. [Google Scholar] [CrossRef]

- Tajduś, K. Określenie Wartości Parametrów Odkształceniowych Górotworu Uwarstwionego w Rejonie Wpływów Eksploatacji Górniczej. Ph.D. Thesis, Wydawnictwo AGH, Kraków, Poland, 2008. (In Polish). [Google Scholar]

- Sroka, A.; Knothe, A.; Tajduś, K.; Misa, R. Underground exploitations inside safety pillar shafts when considering the effective use of a coal deposit. Gospod. Surowcami Miner. 2008, 31, 93–110. [Google Scholar] [CrossRef]

- Han, J.; Zou, J.; Hu, C.; Yang, W. Study on Size Design of Shaft Protection Rock/Coal Pillars in Thick Soil and Thin Rock Strata. Energies 2019, 12, 2553. [Google Scholar] [CrossRef]

- Misa, R. Knothe’s theory parameters—Computational models and examples of practical applications. Gospod. Surowcami Miner.—Miner. Resour. Manag. 2023, 39, 157–180. [Google Scholar] [CrossRef]

- Witkowski, W. Implementation of the Least Squares Method in Determining the Parameters of Knothe’s Theory. Geomat. Environ. Eng. 2014, 8, 107–117. [Google Scholar] [CrossRef]

- Polanin, P. Application of the parameter groups of the Knothe-Budryk theory in subsidence prediction. J. Sustain. Min. 2015, 14, 67–75. [Google Scholar] [CrossRef][Green Version]

- Awierszyn, S.G. Sdwiżenije Gornych Porod Pri Podziemnych Razrabotkach; Ugletiechzdat: Moskwa, Russia, 1947. [Google Scholar][Green Version]

- Budryk, W. Wyznaczanie wielkości poziomych odkształceń terenu. Arch. Górnictwa Hut. 1953, 1, 63–74. (In Polish) [Google Scholar][Green Version]

- Kłeczek, Z. Geomechanika Górnicza; Wydawnictwo AGH: Kraków, Poland, 1985. (In Polish) [Google Scholar][Green Version]

- Szeptyński, P. Podstawy Wytrzymałości Materiałów i Mechaniki Układów Prętowych. Creative Commons CC BY-NC-SA 3.0 PL. 2018. Available online: http://limba.wil.pk.edu.pl/kpmoc/images/stories/kpmoc/pracownicy/PSz/WM/konspekty/07-Teoria.pdf (accessed on 15 June 2025).[Green Version]

- Sih, G.C. Methods of Analysis and Solutions of Crack Problems. Recent Developments in Fracture Mechanics. Theory and Methods of Solving Crack Problems. In Mechanics of Fracture; Noordhoff International Publishing: Leyden, The Netherlands, 1973; Volume 1. [Google Scholar][Green Version]

- Drzęźla, B. Zmienność zasięgu wpływów eksploatacji w górotworze. Przegląd Górniczy 1979, 10, 413–418. (In Polish) [Google Scholar][Green Version]

- Dżegniuk, B.; Niedojadło, Z.; Sroka, A. Podstawy wymiarowania i eksploatacji szybowych filarów ochronnych. Mater. Szkoły Eksploat. Podziemnej 2003, 77, 93. (In Polish) [Google Scholar][Green Version]

- Hastings, C.; Mischo, K.; Morrison, M. Hands-on Start to Wolfram Mathematica and Programming with the Wolfram Language; Wolfram Media, Inc.: Champaign, IL, USA, 2016. [Google Scholar][Green Version]

- Own Materials of the USCB Hard Coal Mines, 2020–2023. (Unpublished Materials). (In Polish)[Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chlebowski, D.; Dzik, G. Modelling of Exploitation Influence on Rock Mass Seismicity in Boundary Coal Pillar Areas—A Single-Longwall Option. Appl. Sci. 2025, 15, 12126. https://doi.org/10.3390/app152212126

Chlebowski D, Dzik G. Modelling of Exploitation Influence on Rock Mass Seismicity in Boundary Coal Pillar Areas—A Single-Longwall Option. Applied Sciences. 2025; 15(22):12126. https://doi.org/10.3390/app152212126

Chicago/Turabian StyleChlebowski, Dariusz, and Grażyna Dzik. 2025. "Modelling of Exploitation Influence on Rock Mass Seismicity in Boundary Coal Pillar Areas—A Single-Longwall Option" Applied Sciences 15, no. 22: 12126. https://doi.org/10.3390/app152212126

APA StyleChlebowski, D., & Dzik, G. (2025). Modelling of Exploitation Influence on Rock Mass Seismicity in Boundary Coal Pillar Areas—A Single-Longwall Option. Applied Sciences, 15(22), 12126. https://doi.org/10.3390/app152212126