Development and Experimental Validation of Active In Situ Temperature-Preserved Coring Testing System for Deep Oil and Gas Reservoirs

Abstract

1. Introduction

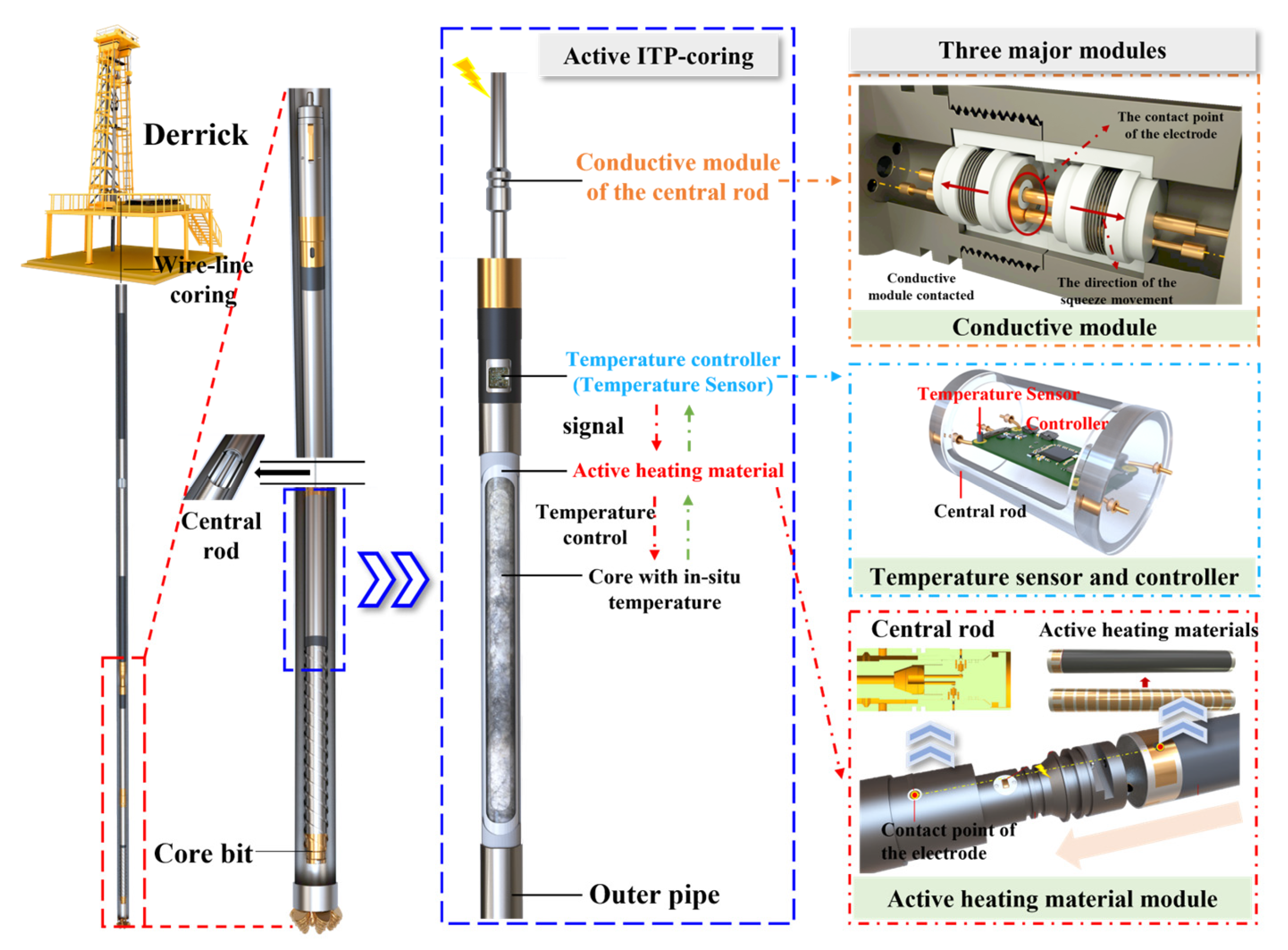

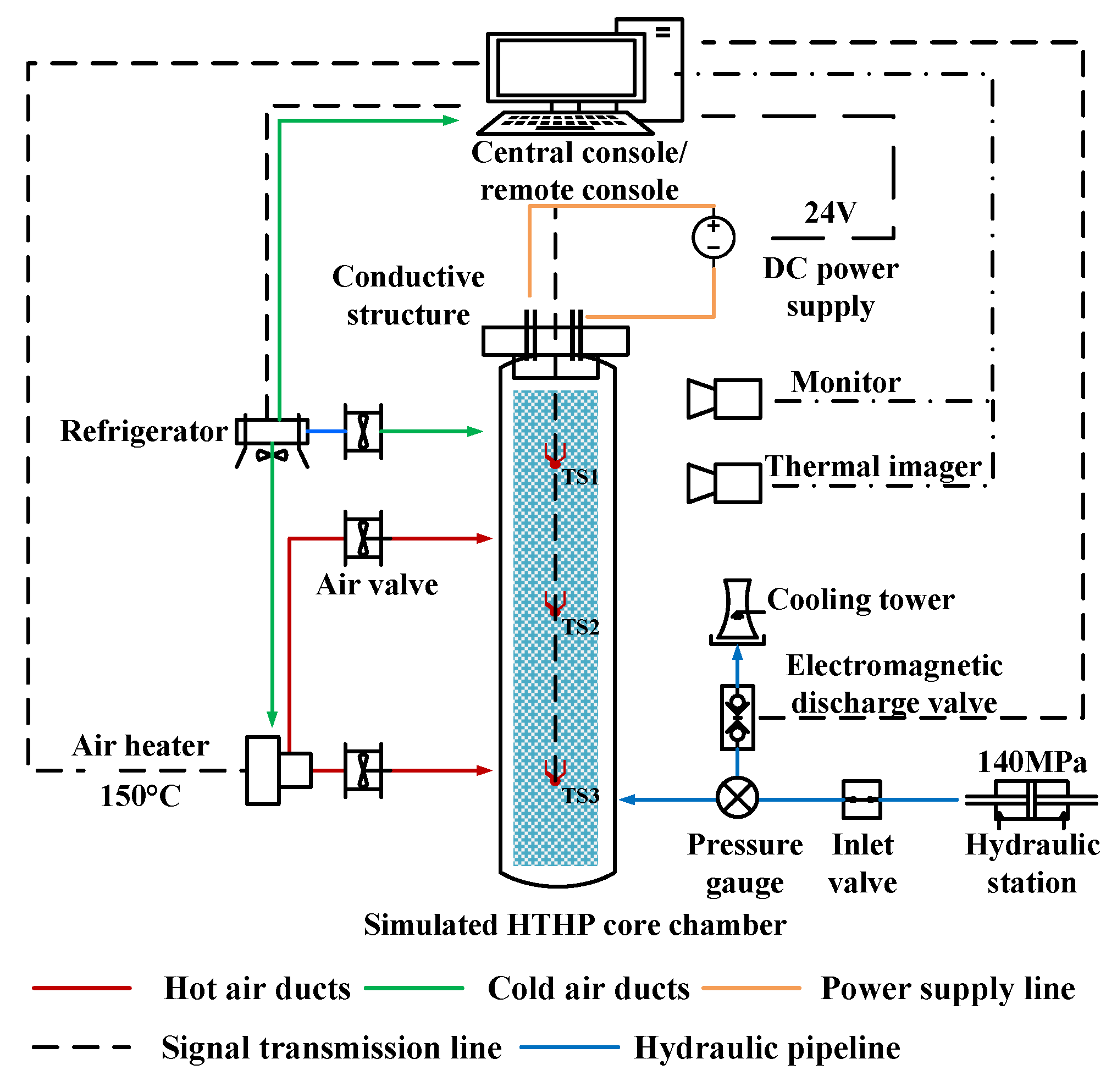

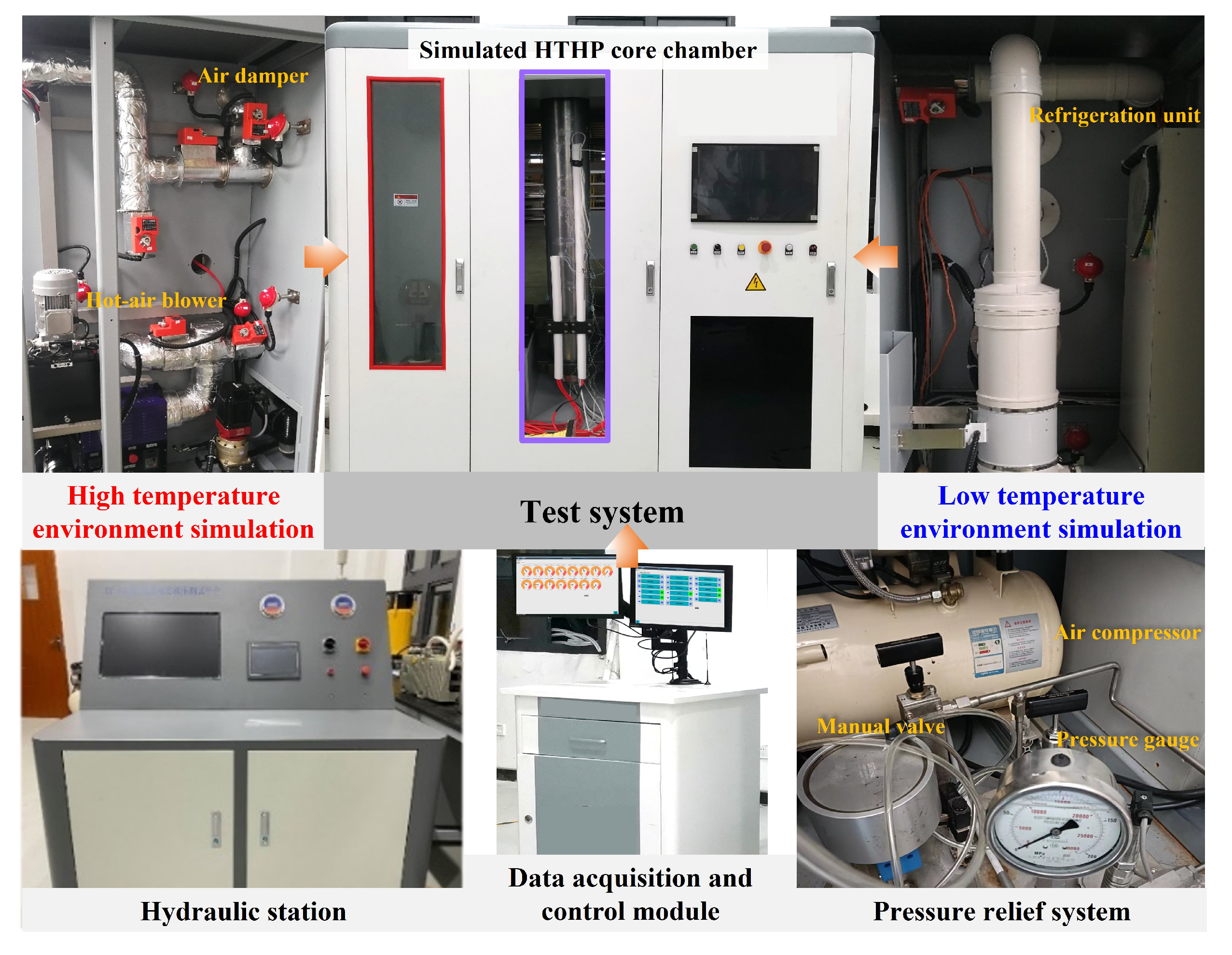

2. Active ITP-Coring Process and Functional Requirements for the Testing System

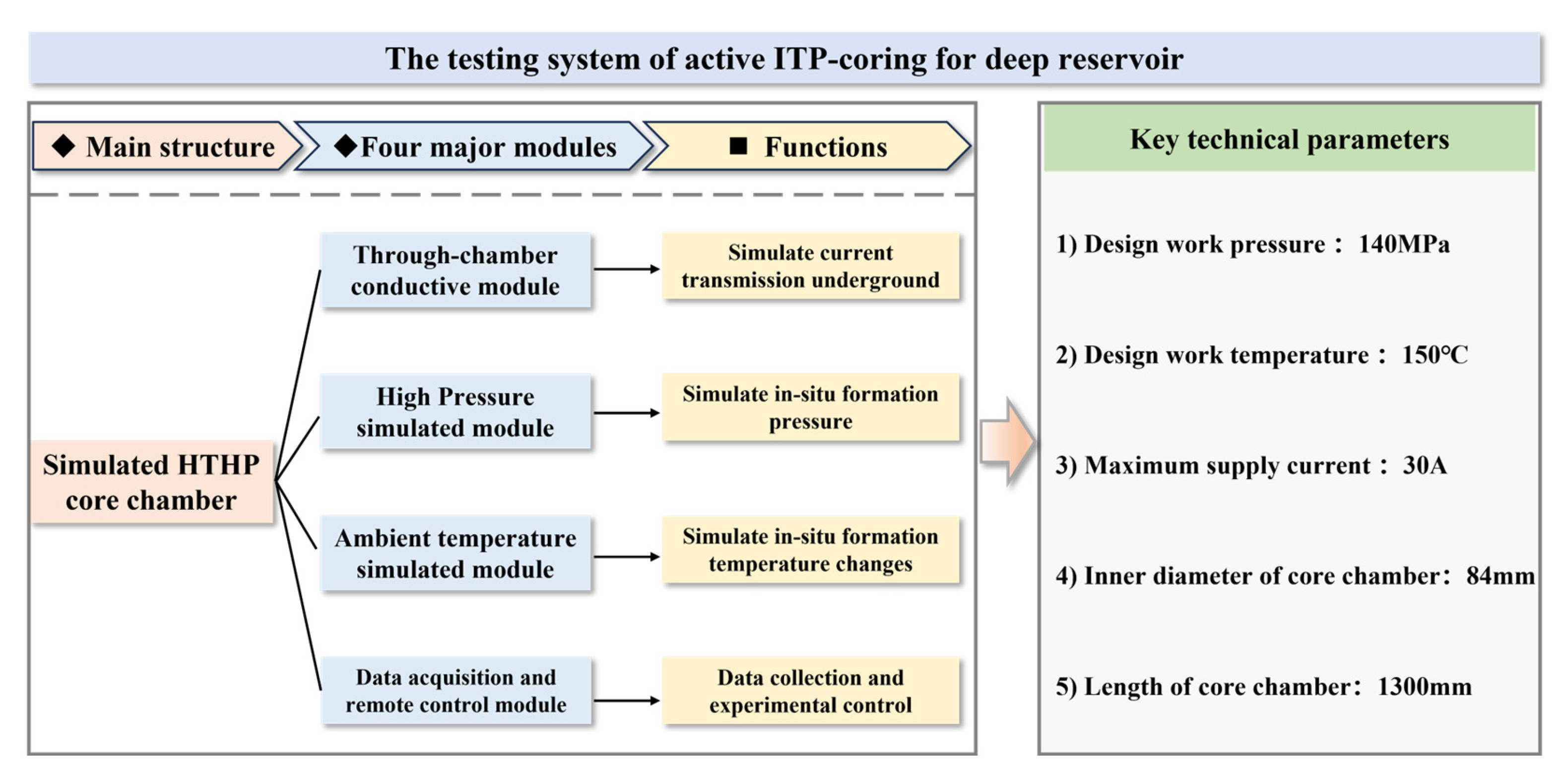

- 1.

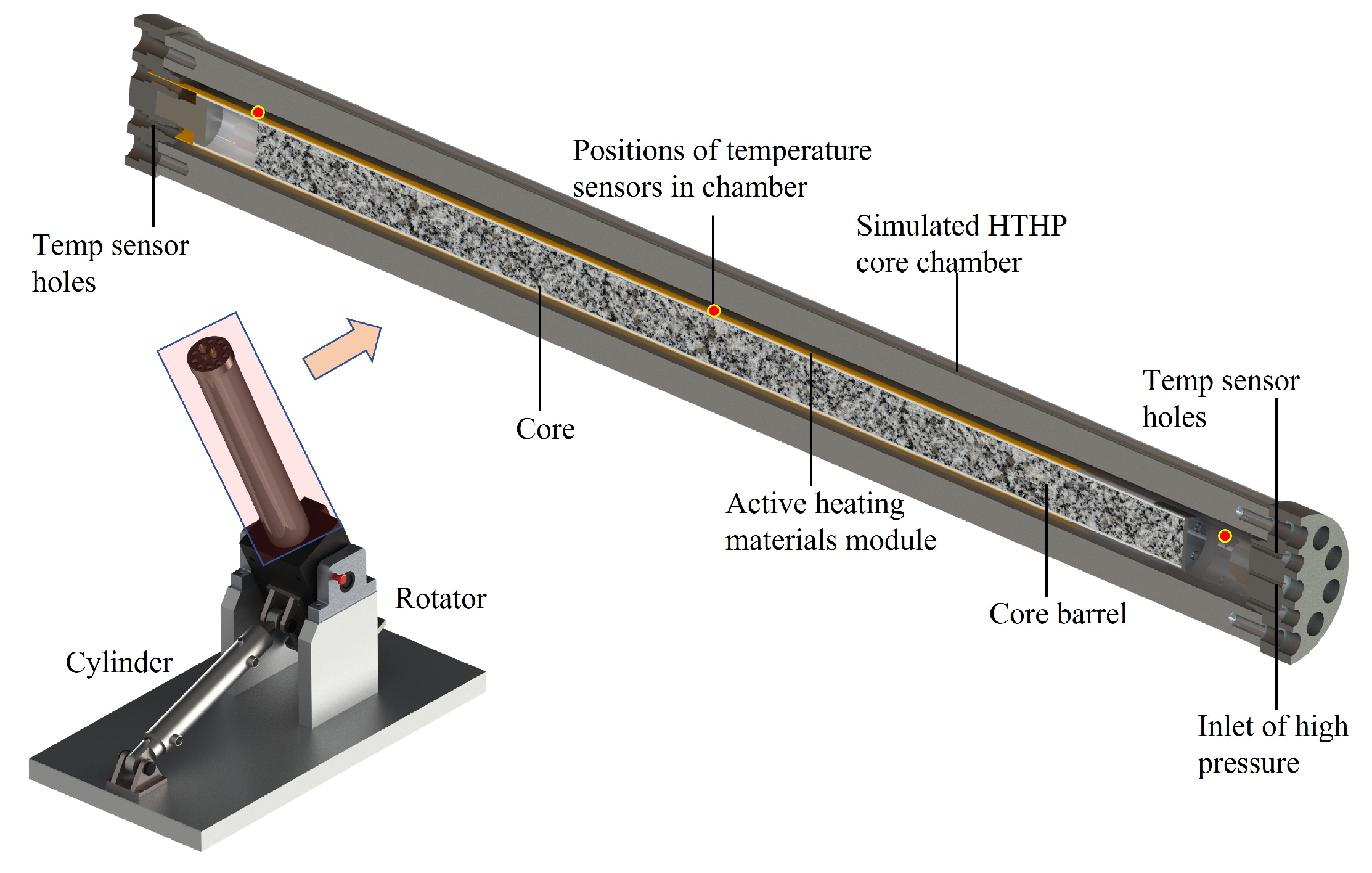

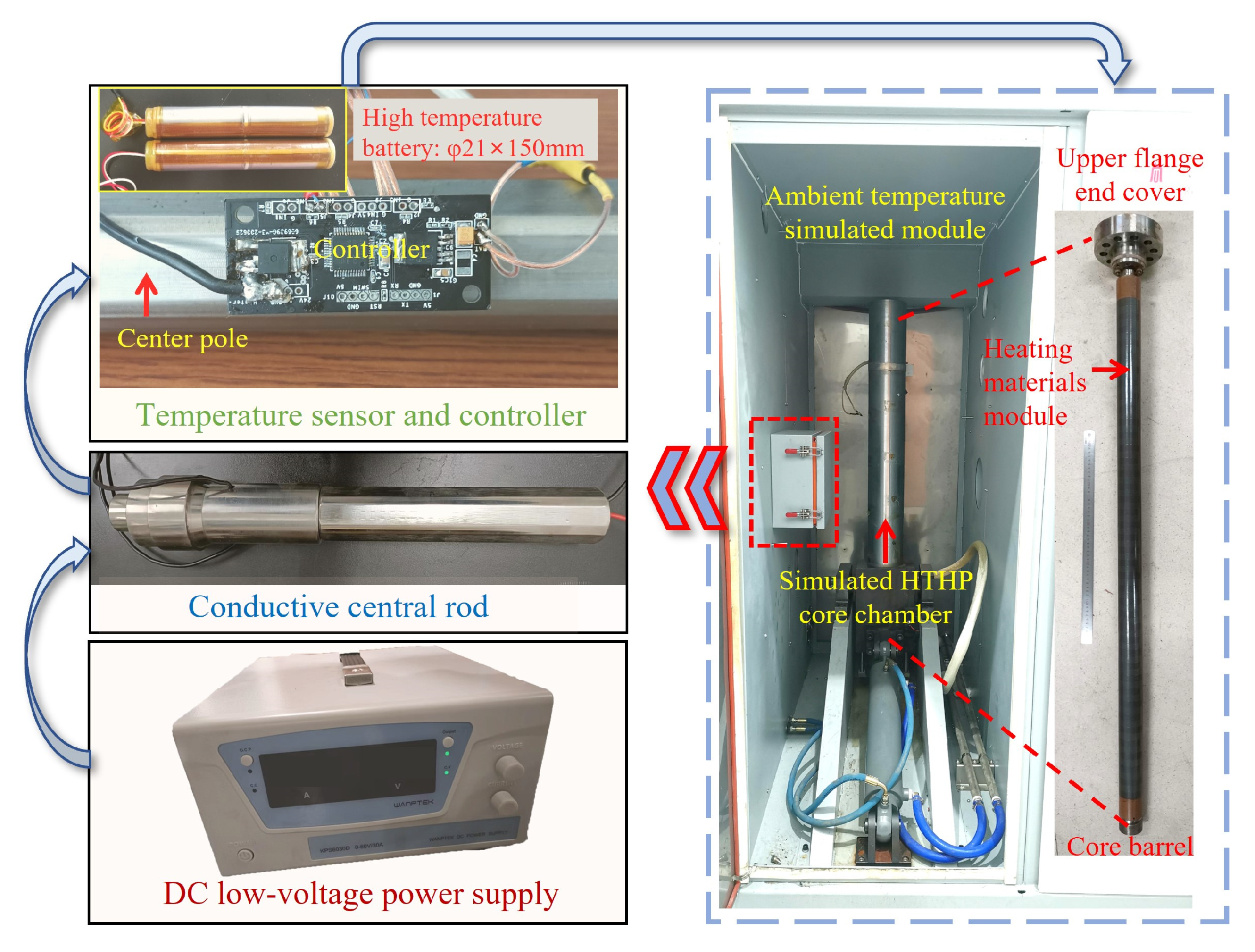

- Simulated HTHP core chamber: Based on the structure of a real corer, the chamber serves as the main body of the testing system and is designed to simulate coupled HTHP conditions of 150 °C and 140 MPa.

- 2.

- HTHP heating and autonomous temperature control: To evaluate the active ITP-coring technology, the system is required to deliver stable power to the heating materials and enable signal transmission from temperature sensors under HTHP environment.

- 3.

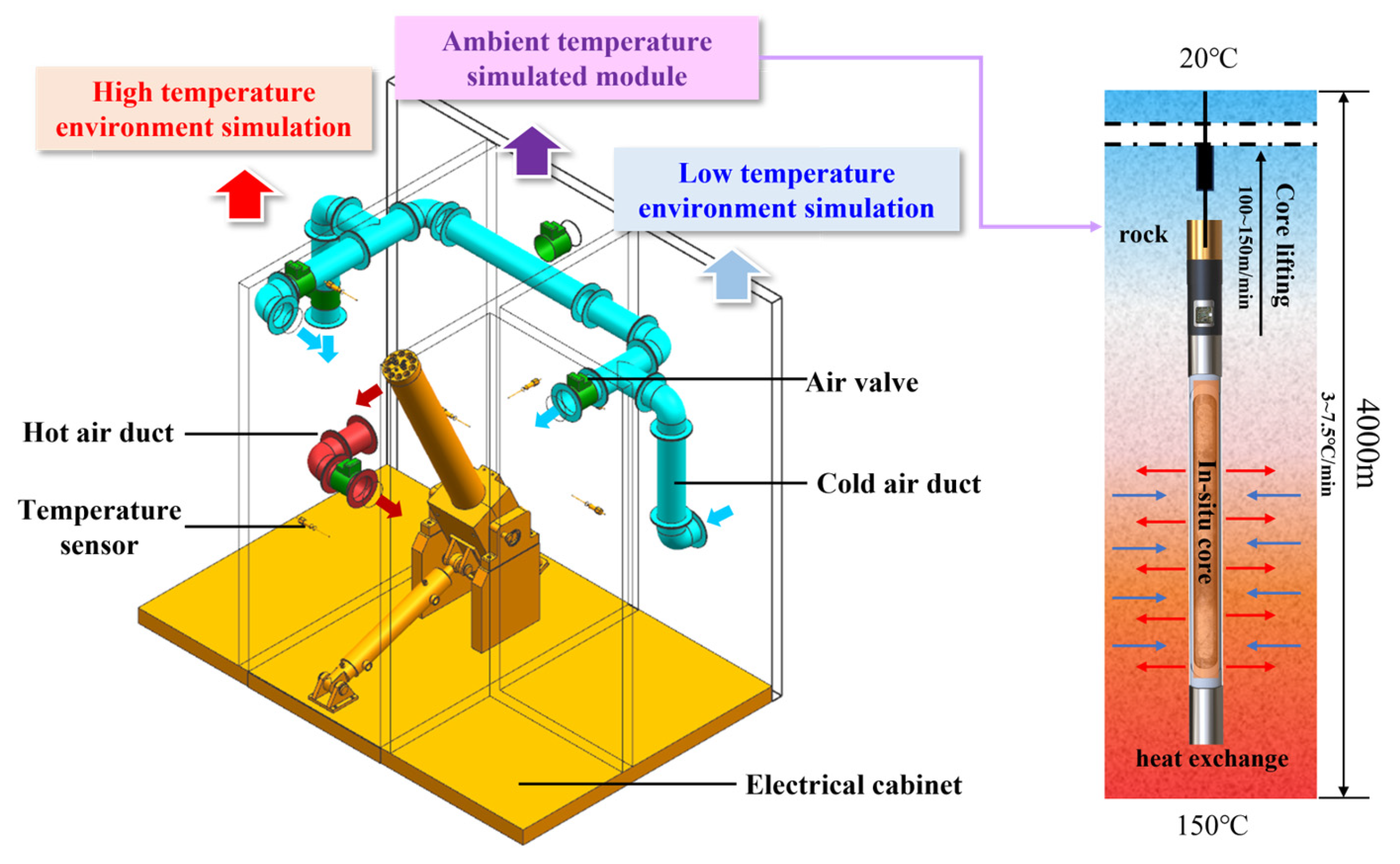

- Environmental temperature simulation: To simulate the temperature variation during core retrieval, the system replicates a continuous temperature decrease of 3–7.5 °C/min, assuming a temperature gradient of 3–5 °C/100 m and a core lifting speed of 100–150 m/min.

- 4.

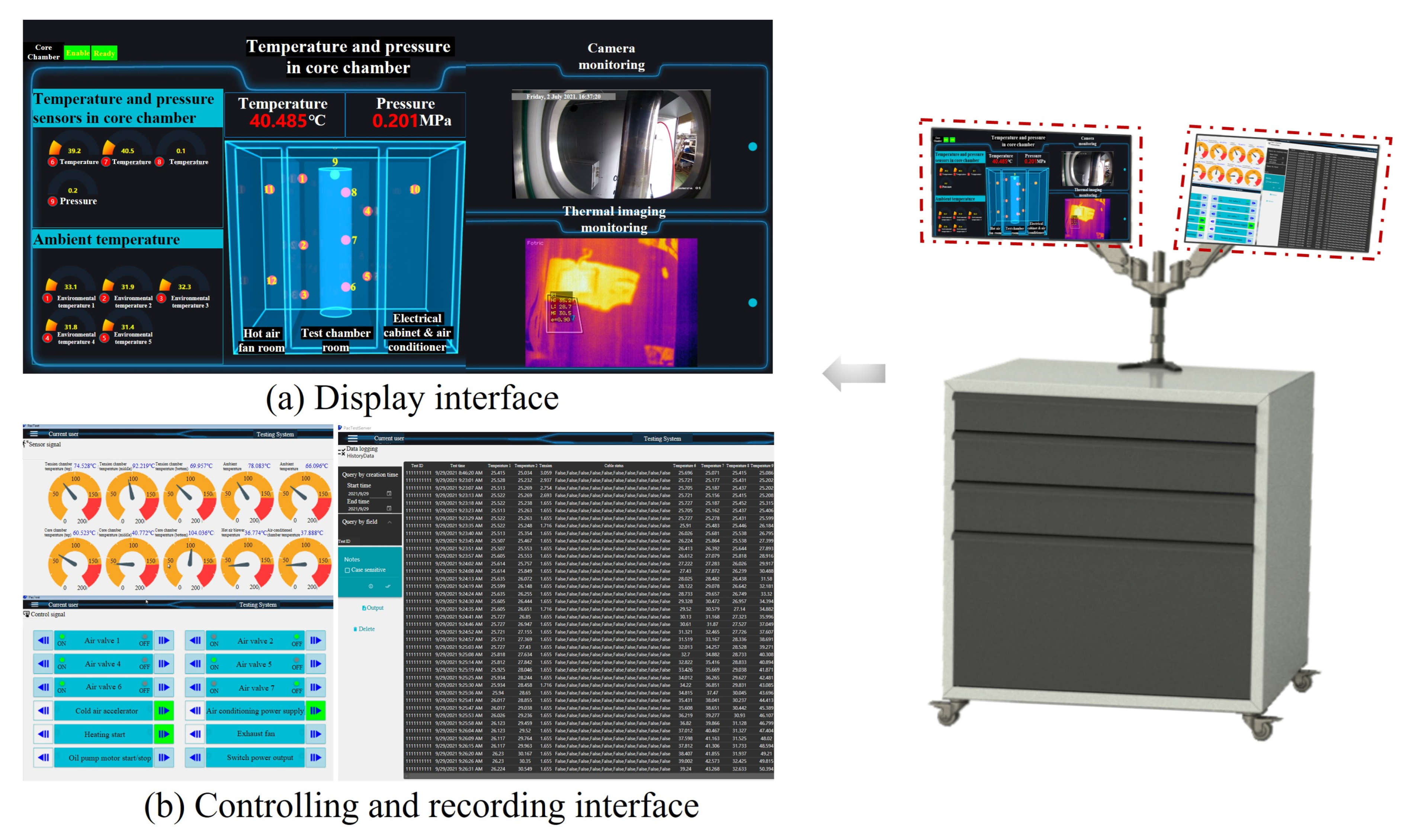

- Data acquisition and remote control: To ensure safe operation and effective data analysis under HTHP conditions, the system is configured to support remote control and data acquisition.

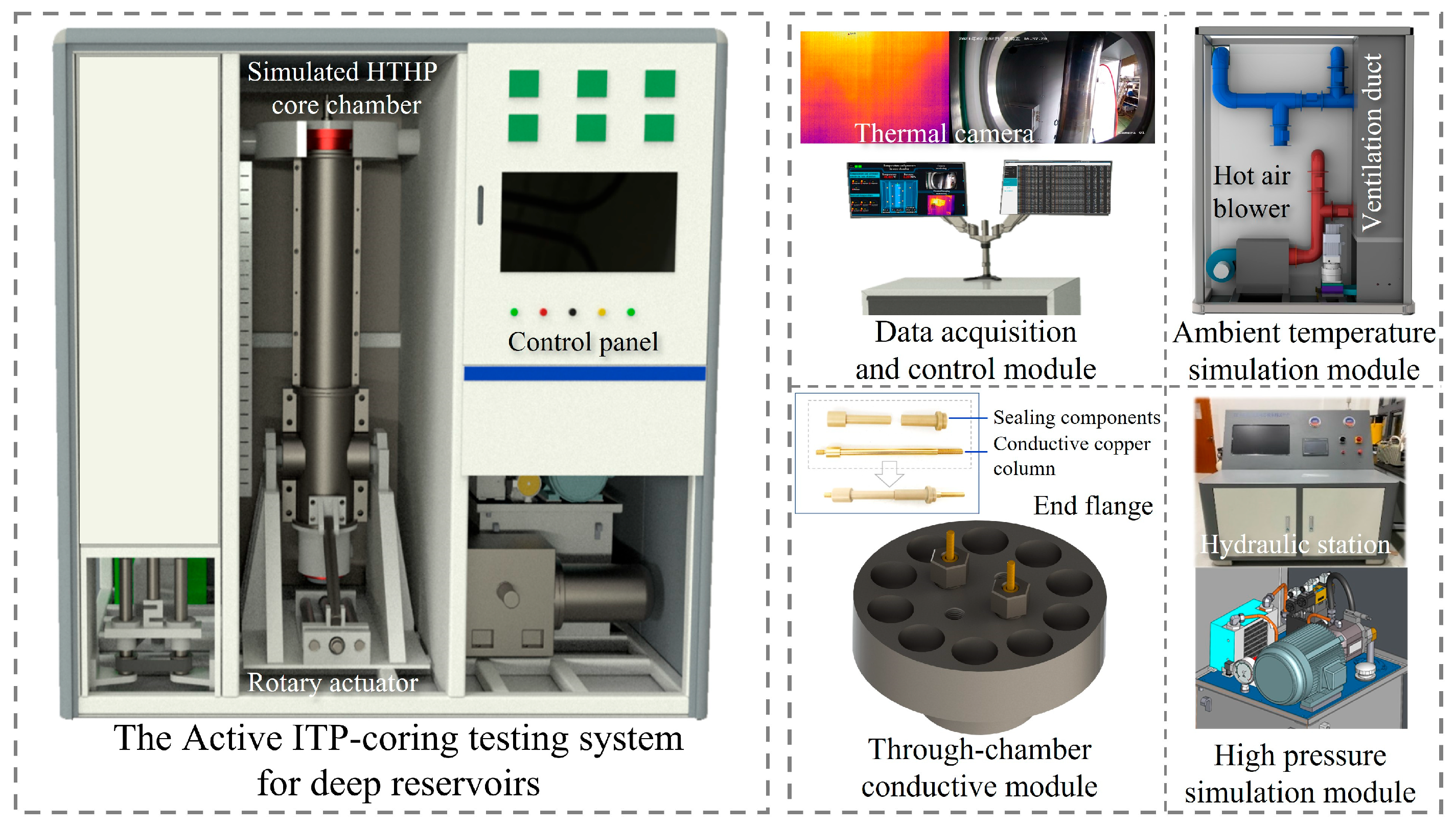

3. Overall and Modular Design of Testing System

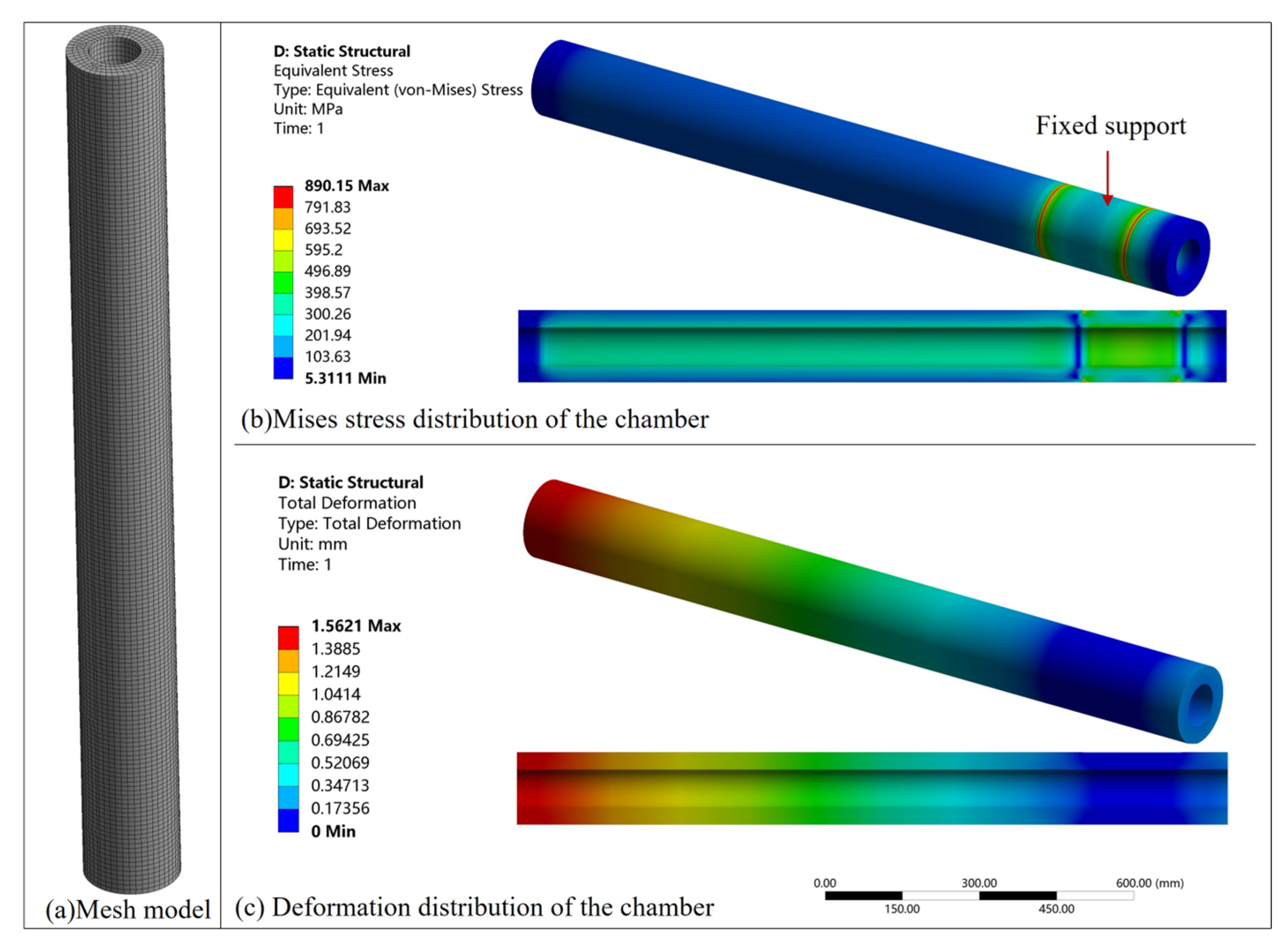

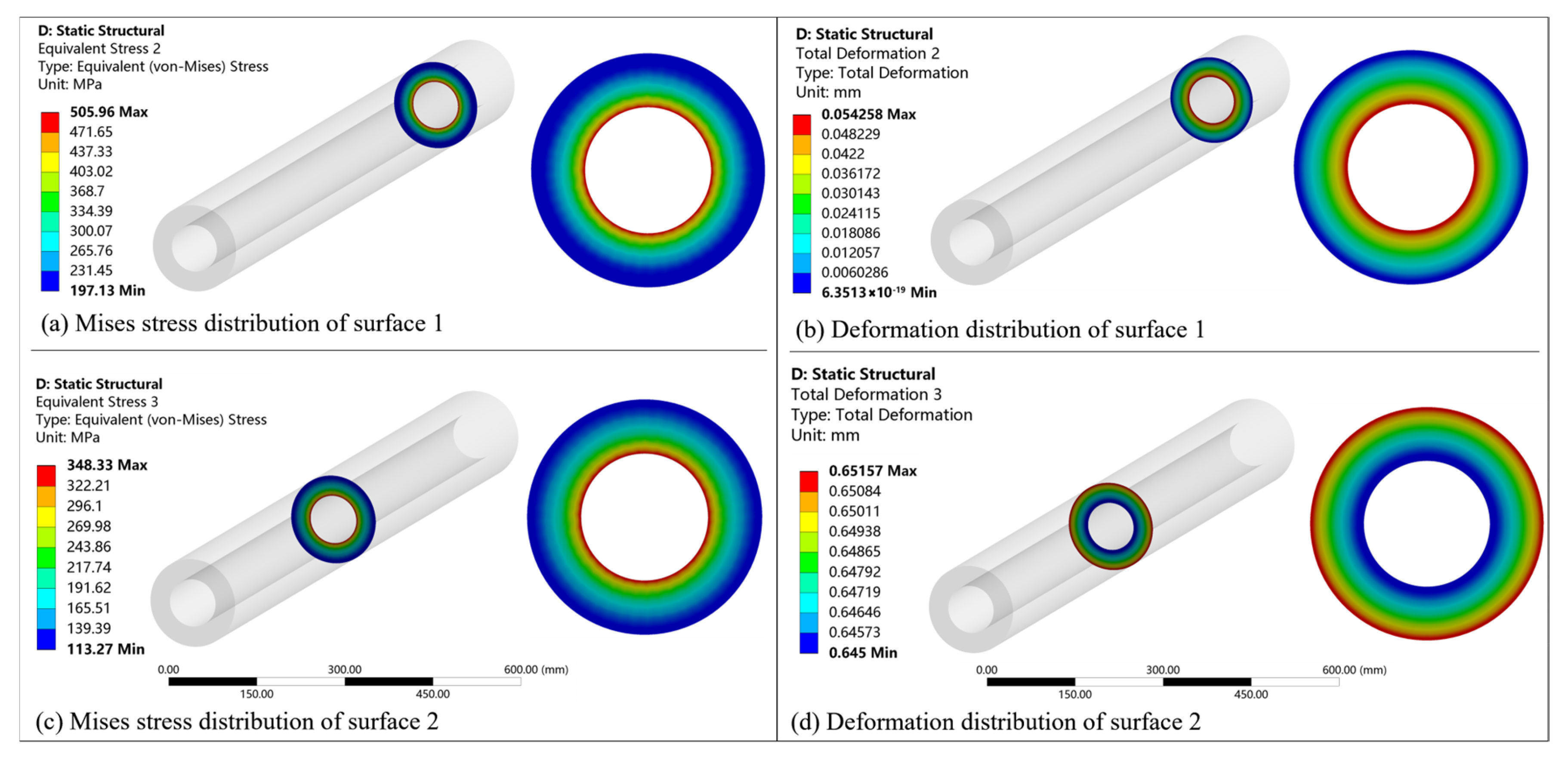

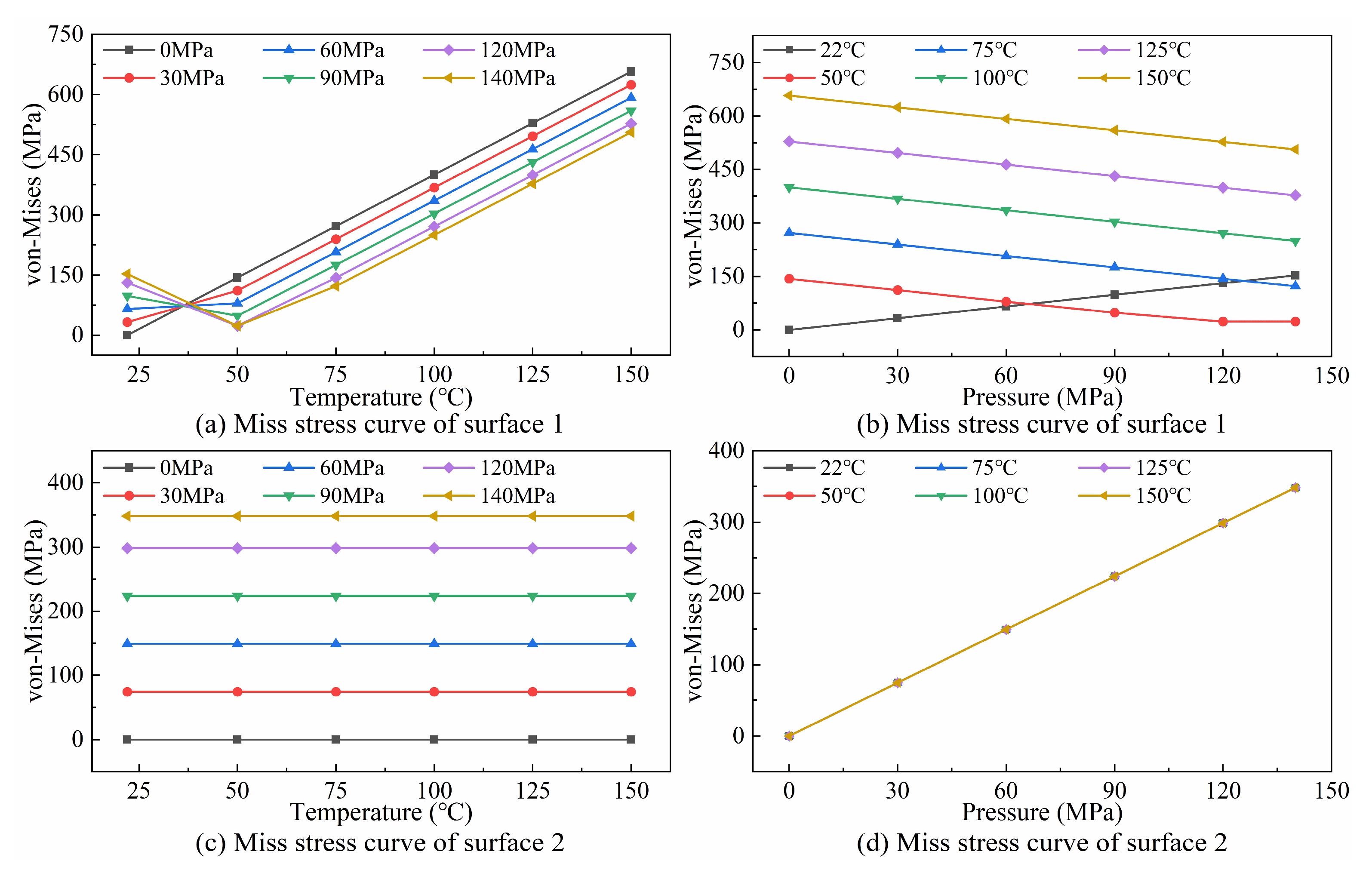

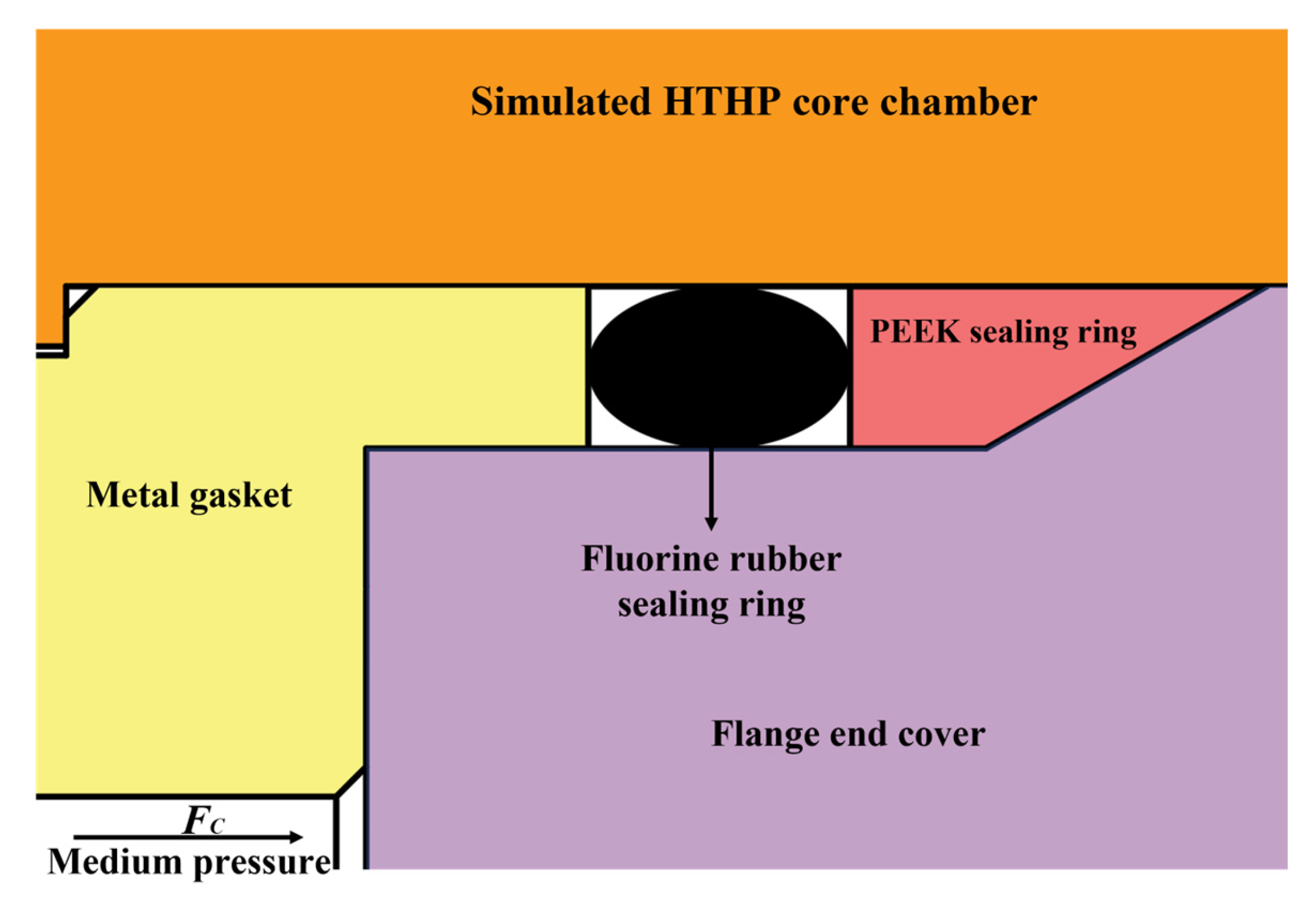

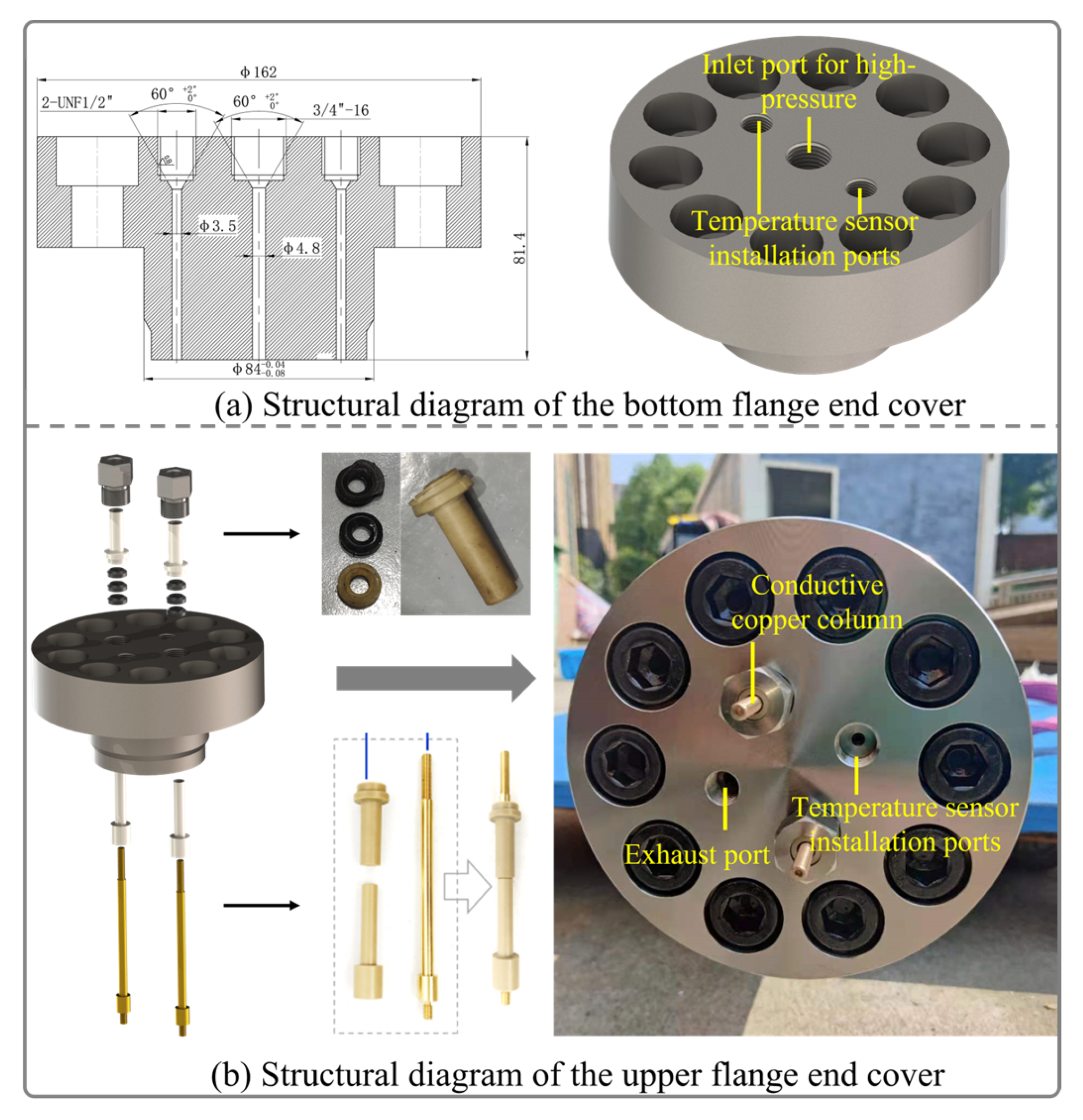

3.1. Simulated HTHP Core Chamber

3.2. Through-Chamber Conductive Module

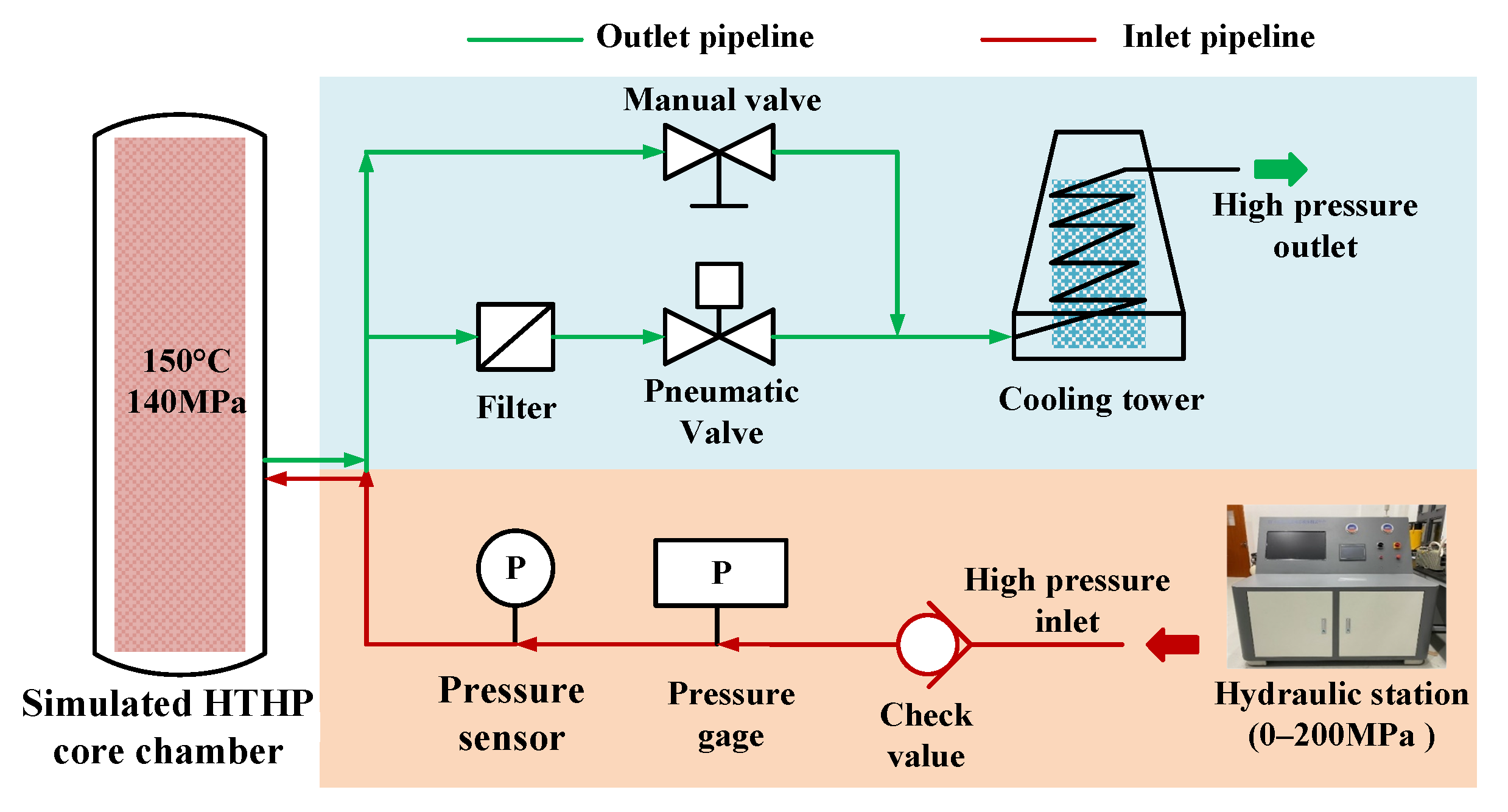

3.3. High-Pressure Simulation Module

3.4. Ambient Temperature Simulation Module

3.5. Data Acquisition and Remote Control Module

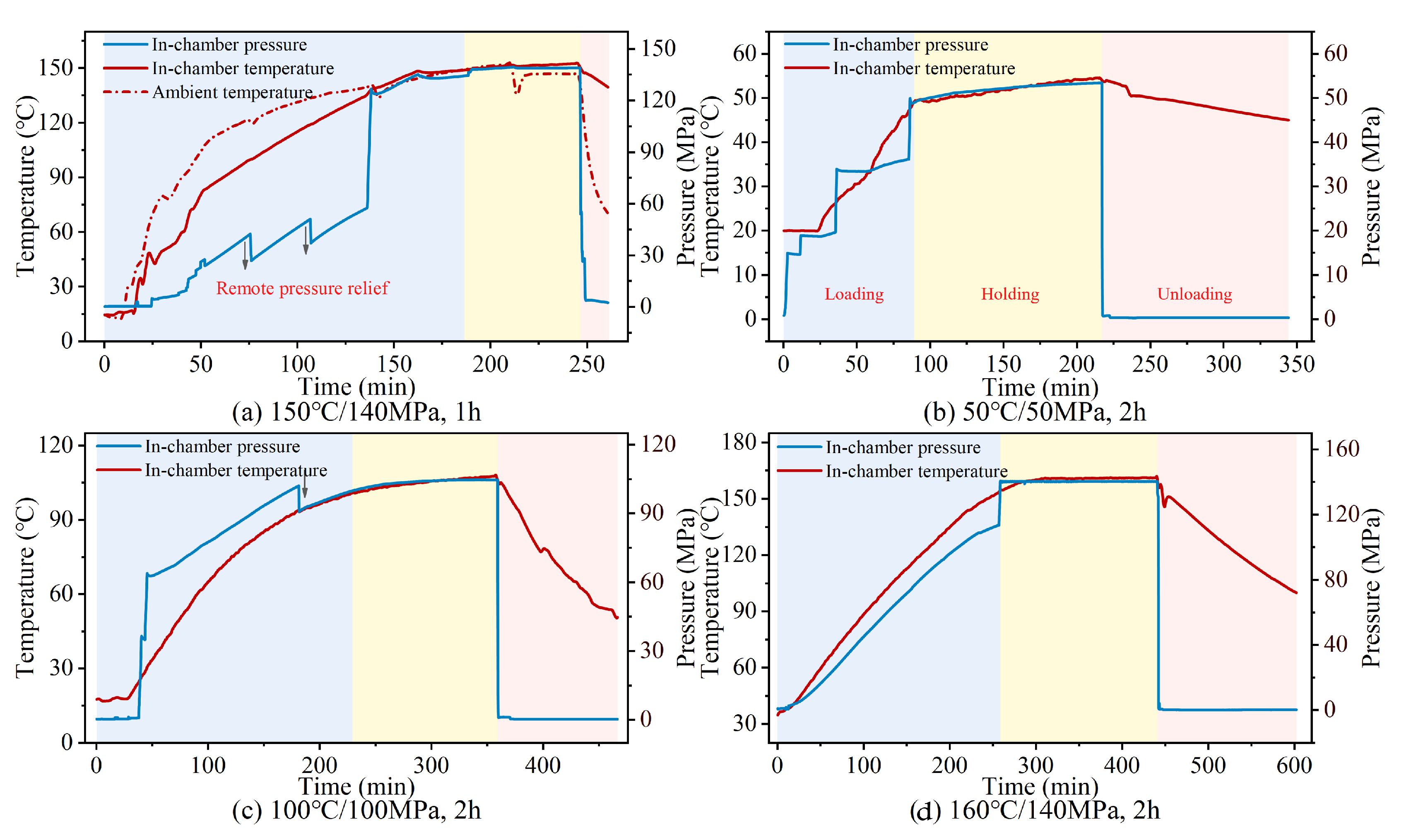

4. Capability Verification of Testing System and Active ITP-Coring System

4.1. Capability Verification of Testing System

- Parameter setting: The target temperature and pressure were set according to each working condition, with allowable fluctuations controlled within ±5 °C and ±1 MPa, respectively.

- System preparation: The flange end caps were installed, and the exhaust port was opened. The simulated core chamber was placed vertically, filled with liquid from the bottom, and pressurized to an initial value of 5 MPa.

- Heating stage: The ambient temperature simulation module was activated to raise the environmental temperature, indirectly heating the internal medium of the simulated chamber to the target in situ temperature. Simultaneously, the active ITP heating module was activated to accelerate the warming process.

- Temperature–pressure coupling: Once the internal temperature reached the target value, hydraulic pressurization was applied to achieve the coupled HTHP state, which was then stably maintained for a designated duration.

- Pressure release and data processing: After the test, remote pressure release and manual drainage were performed. The system data were then exported for post-processing and analysis.

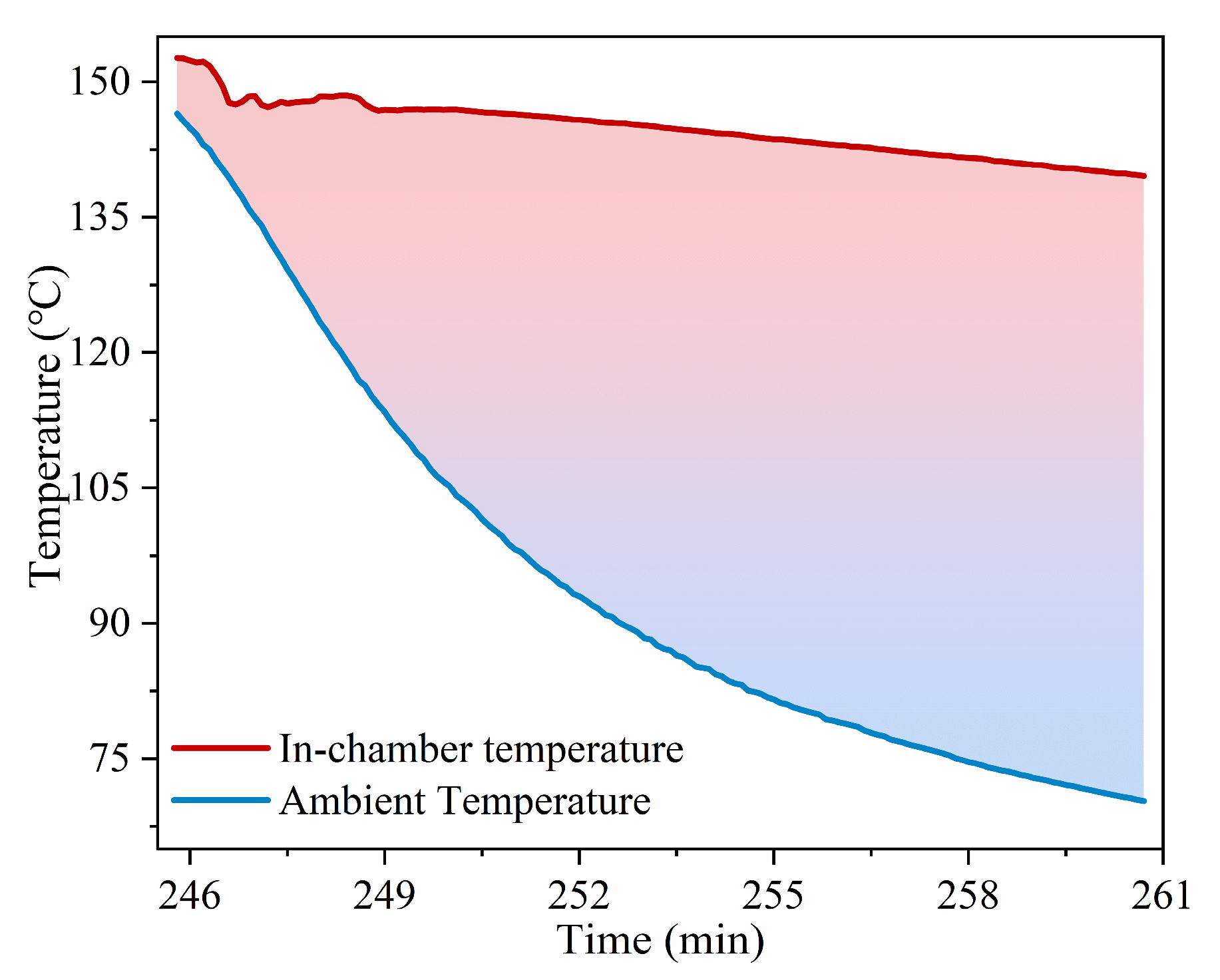

4.2. Capability Verification of Active ITP-Coring System

5. Conclusions

- The system is capable of simulating a coupled HTHP environment of 150 °C and 140 MPa, representing in situ deep reservoir conditions.

- The system can replicate ambient temperature transitions from in situ formation temperatures to ambient surface temperature during the coring process, achieving a maximum cooling rate of 11.22 °C/min and an average rate of 5.11 °C/min.

- The system integrates automated safety control and real-time monitoring functions, enabling secure pressure operation, remote regulation, and real-time transmission of operational data and system status.

- The feasibility and insulation performance of the active ITP-coring system were validated under HTHP conditions (150 °C/140 MPa). During a 40.5 min ambient cooling process, the temperature in the core chamber decreased by only 4.2 °C, achieving an in situ temperature retention of 98.93%. This performance significantly outperforms the 13.1 °C temperature drop observed in 14.9 min without active insulation, demonstrating the crucial role of the active ITP-coring system in preserving in situ thermal conditions during core retrieval.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Gao, M.; Zhang, R.; Zhou, H.; Gao, F.; Chen, L.; Peng, X.; Li, X.; Ju, Y. Application prospects of deep in-situ condition-preserved coring and testing systems. Adv. Geo-Energy Res. 2024, 14, 12–24. [Google Scholar] [CrossRef]

- Xie, H.; Hu, Y.; Gao, M.; Chen, L.; Zhang, R.; Liu, T.; Gao, F.; Zhou, H.; Peng, X.; Li, X.; et al. Research progress and application of deep in-situ condition preserved coring and testing. Int. J. Min. Sci. Technol. 2023, 33, 1319–1337. [Google Scholar] [CrossRef]

- IEA. World Energy Investment 2025; International Energy Agency (IEA): Paris, France, 2025. [Google Scholar]

- Dou, L.; Wen, Z.; Wang, J.; Wang, Z.; He, Z.; Liu, X.; Zhang, N. Analysis of the world oil and gas exploration situation in 2021. Pet. Explor. Dev. 2022, 49, 1195–1209. [Google Scholar] [CrossRef]

- Wang, X.; Lu, Y.; Chen, C.; Yi, X.; Cui, H. Total-factor energy efficiency of ten major global energy-consuming countries. J. Environ. Sci. 2024, 137, 41–52. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Fang, Z.; Xia, X. Analysis of the New Trend of Global Crude Oil Trade. In Annual Report on China’s Petroleum, Gas and New Energy Industry (2022–2023); China International United Petroleum & Chemicals Co., Ltd., Chinese Academy of Social Sciences, Peking University, Eds.; Springer Nature Singapore: Singapore, 2024; pp. 125–136. [Google Scholar]

- Liu, G.; Xie, Y.; Li, C. Design and mechanical optimization of multidirectional pressure-preserved coring system for deep-earth resource exploration. Int. J. Min. Sci. Technol. 2025, 35, 719–735. [Google Scholar] [CrossRef]

- Yang, X.; Tian, J.; Wang, Q.; Li, Y.; Yang, H.; Li, Y.; Tang, Y.; Yuan, W.; Huang, S. Geological understanding and favorable exploration fields of ultra-deep formations in Tarim Basin. China Pet. Explor. 2021, 26, 17. [Google Scholar] [CrossRef]

- Mao, L.; Wei, C.; Jia, H.; Lu, K. Prediction model of drilling wellbore temperature considering bit heat generation and variation of mud thermophysical parameters. Energy 2023, 284, 129341. [Google Scholar] [CrossRef]

- Wang, M.; He, L.; Zhou, Y.; Zhang, J.; Tian, Q.; Hu, R. Practices and understandings on safe drilling technologies for 9000-m-level super deep and ultra high temperature and pressure strata, Sichuan-Chongqing area. Nat. Gas Explor. Dev. 2023, 46, 44–50. [Google Scholar] [CrossRef]

- Liu, K.; Yang, P.; Yang, H.; Liu, J.; Song, Y.; Wei, X. Deep petroleum accumulation models revisited: Case studies from the Tarim basin. Acta Geol. Sin. 2023, 97, 2820–2841. [Google Scholar] [CrossRef]

- Sun, J.; Wang, J. Drilling fluid technology for deep subsurface Tako-1 well. Drill. Fluid Complet. Fluid 2025, 42, 155–166. [Google Scholar] [CrossRef]

- Saif, T.; Lin, Q.; Gao, Y.; Al-Khulaifi, Y.; Marone, F.; Hollis, D.; Blunt, M.J.; Bijeljic, B. 4D in situ synchrotron X-ray tomographic microscopy and laser-based heating study of oil shale pyrolysis. Appl. Energy 2019, 235, 1468–1475. [Google Scholar] [CrossRef]

- Mahanta, B.; Ranjith, P.G.; Vishal, V.; Singh, T.N. Temperature-induced deformational responses and microstructural alteration of sandstone. J. Pet. Sci. Eng. 2020, 192, 107239. [Google Scholar] [CrossRef]

- Kong, L.; Xie, H.; Li, C. Coupled microplane and micromechanics model for describing the damage and plasticity evolution of quasi-brittle material. Int. J. Plast. 2023, 162, 103549. [Google Scholar] [CrossRef]

- Hu, J.; Xie, H.; Li, C.; Liu, G. Evolution mechanism of permeability of hot dry rock under coupled effect of thermal fatigue and seawater interaction during coastal geothermal development. Renew. Sustain. Energy Rev. 2024, 189, 114061. [Google Scholar] [CrossRef]

- Ye, P.; Li, B.; Ren, C.; Song, H.; Fu, J.; Wu, X. Investigation on damage-permeability model of dual-porosity coal under thermal-mechanical coupling effect. Gas Sci. Eng. 2024, 123, 205229. [Google Scholar] [CrossRef]

- Yin, S.; Yang, X.; Chen, W.; Wang, L.; Chen, X. Permeability characteristics of sandstone-type uranium deposits under different temperature and confining pressure. J. Cent. South Univ. 2023, 30, 2302–2312. [Google Scholar] [CrossRef]

- Kahraman, U.; Dincer, I. Development and assessment of an integrated underground gasification system for cleaner outputs. Energy 2023, 285, 128676. [Google Scholar] [CrossRef]

- Li, C.; Xie, H.; Gao, M.; Chen, L.; Zhao, L.; Li, C.; Wu, N.; He, Z.; Li, J. Novel designs of pressure controllers to enhance the upper pressure limit for gas-hydrate-bearing sediment sampling. Energy 2021, 227, 120405. [Google Scholar] [CrossRef]

- Xie, H.; Gao, M.; Zhang, R.; Chen, L.; Liu, T.; Li, C.; Li, C.; He, Z. Study on concept and progress of in situ fidelity coring of deep rocks. Chin. J. Rock Mech. Eng. 2020, 39, 865–876. [Google Scholar] [CrossRef]

- Abegg, F.; Hohnberg, H.J.; Pape, T.; Bohrmann, G.; Freitag, J. Development and application of pressure-core-sampling systems for the investigation of gas- and gas-hydrate-bearing sediments. Deep. Sea Res. Part I Oceanogr. Res. Pap. 2008, 55, 1590–1599. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, Q.; Deng, J.; Wang, G.; Xiao, X.; Jiang, Z.; Zhang, D. Pressure and temperature preservation techniques for gas-hydrate-bearing sediments sampling. Energy 2011, 36, 4542–4551. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, Q.; Wong, G.; Xiao, X.; Zhu, X.; Jiang, Z.; Zhang, D. A Pressure and Temperature Preservation System for Gas-hydrate-bearing Sediments Sampler. Pet. Sci. Technol. 2013, 31, 652–662. [Google Scholar] [CrossRef]

- Shi, X.; Li, C.; Li, J.; He, Z.; Yu, B.; Xie, Y.; Xie, H. Self-sealing control principle and technology of in-situ temperature pressure preserved coring for deep oil and gas. Pet. Sci. 2025, in press. [Google Scholar] [CrossRef]

- He, Z.; Yang, Y.; Yu, B.; Yang, J.; Jiang, X.; Tian, B.; Wang, M.; Li, X.; Sun, S.; Sun, H. Research on properties of hollow glass microspheres/epoxy resin composites applied in deep rock in-situ temperature-preserved coring. Pet. Sci. 2022, 19, 720–730. [Google Scholar] [CrossRef]

- Kabir, C.S.; Hasan, A.R.; Jordan, D.L.; Wang, X. A Wellbore/Reservoir Simulator for Testing Gas Wells in High-Temperature Reservoirs. SPE Form. Eval. 1996, 11, 128–134. [Google Scholar] [CrossRef]

- Morandi, A.C.; Karunakaran, D.; Dixon, A.T.; Baerheim, M. Comparison of Full-Scale Measurements and Time-Domain Irregular Sea Analysis for a Large Deepwater Jack-Up. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1998. [Google Scholar]

- Li, S. Construction of China’s first drilling simulation experimental device. Oil Drill. Prod. Technol. 1990, 3, 91. [Google Scholar] [CrossRef]

- Cai, L.; He, D.; Guo, J. Design of simulation wellbore withstand high temperature and high pressure. Machinery 2008, 35, 19–22. [Google Scholar]

- Xiao, S. Research on the Drilling Tool Structure and Its Supporting Simulate Device of EM-MWD Applied to the Deep Hole. Master’s Thesis, China University of Geosciences, Wuhan, China, 2013. [Google Scholar]

- Yu, B.; He, Z.; Yang, J.; Wei, Z.; Li, C.; Xie, H. Innovative Design of a Conductive Center Pole for an Active Thermal Insulation and Coring System in Deep Rock. Appl. Sci. 2023, 13, 1242. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, W.; Chen, L.; Gao, M.; He, Z.; Hao, W. Innovative design of active insulation system for in-situ fidelity coring in deep strata. Chin. J. Eng. Des. 2020, 27, 407–415. [Google Scholar] [CrossRef]

- He, Z.; Xie, H.; Gao, M.; Chen, L.; Yu, B.; Hu, Y.; Yang, J. Design and Verification of a Deep Rock Corer with Retaining the In Situ Temperature. Adv. Civ. Eng. 2020, 2020, 8894286. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, E.; Wang, Y.; Zhou, X. Development and application of multi-functional test system for coal and gas outburst simulation. Chin. J. Rock Mech. Eng. 2022, 41, 995–1007. [Google Scholar] [CrossRef]

- Li, Z.; Huang, W.; Chen, J.; Cen, J.; Cao, W.; Li, F.; Jiang, F. An enhanced super-long gravity heat pipe geothermal system: Conceptual design and numerical study. Energy 2023, 267, 126524. [Google Scholar] [CrossRef]

- Zheng, J.; Sang, Z. Process Equipment Design, 5th ed.; Chemical Industry Press: Beijing, China, 2020. [Google Scholar]

- Sun, Y.; Hebert, R.J.; Aindow, M. Effect of heat treatments on microstructural evolution of additively manufactured and wrought 17-4PH stainless steel. Mater. Des. 2018, 156, 429–440. [Google Scholar] [CrossRef]

- Namgung, I.; Giang, N.H. Investigation of Burst Pressures in PWR Primary Pressure Boundary Components. Nucl. Eng. Technol. 2016, 48, 236–245. [Google Scholar] [CrossRef]

- Li, T. Research on Key Technologies for Design of Ultra High Pressure Vessels Based on Failure Modes. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2017. [Google Scholar]

- Committee, A.H. Properties and Selection: Irons, Steels, and High-Performance Alloys; ASM International: Almere, The Netherlands, 1990. [Google Scholar]

- Yi, F.; Zhou, M. Research on the Calculation Method of Pre tightening Force of Pressure Vessel Flange Bolts. J. New Ind. 2020, 10, 59–60+64. [Google Scholar] [CrossRef]

- Xie, Y.; Ai, B.; Ren, X.; Zhou, Q.; Bi, L. Analysis and Suggestions on the Design Method of Waters Flange. Petro-Chem. Equip. Technol. 2015, 36, 6–10+15. [Google Scholar] [CrossRef]

- Wang, B.; Yu, S.; Mao, J.; Wang, Y.; Li, M.; Li, X. Effect of basalt fiber on tribological and mechanical properties of polyether-ether-ketone (PEEK) composites. Compos. Struct. 2021, 266, 113847. [Google Scholar] [CrossRef]

- Mo, X.; Zhang, Y.; Li, Y.; Huang, P.; Fu, S. Thermal and Mechanical Properties of Polyetheretherketone/Polyetherimide Alloy. Polym. Mater. Sci. Eng. 2023, 39, 1–9. [Google Scholar] [CrossRef]

- Lin, X.; Liu, Y.; Song, H.; Liu, Y. System design for 700 °C power plants: Integration scheme and performance evaluation. Energy 2023, 267, 126453. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Coefficient of Thermal Expansion | 1.08 × 10−5 | 1/°C |

| Young’s Modulus | 2.06 × 1011 | Pa |

| Poisson’s Ratio | 0.28 | - |

| Tensile Yield Strength | 1.31 × 109 | Pa |

| Compressive Yield Strength | 1.1 × 109 | Pa |

| Isotropic Thermal Conductivity | 16.3 | W/(m·K) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, H.; He, Z.; Wei, Z.; Lan, Y. Development and Experimental Validation of Active In Situ Temperature-Preserved Coring Testing System for Deep Oil and Gas Reservoirs. Appl. Sci. 2025, 15, 12011. https://doi.org/10.3390/app152212011

Bai H, He Z, Wei Z, Lan Y. Development and Experimental Validation of Active In Situ Temperature-Preserved Coring Testing System for Deep Oil and Gas Reservoirs. Applied Sciences. 2025; 15(22):12011. https://doi.org/10.3390/app152212011

Chicago/Turabian StyleBai, Haishu, Zhiqiang He, Zijie Wei, and Yufan Lan. 2025. "Development and Experimental Validation of Active In Situ Temperature-Preserved Coring Testing System for Deep Oil and Gas Reservoirs" Applied Sciences 15, no. 22: 12011. https://doi.org/10.3390/app152212011

APA StyleBai, H., He, Z., Wei, Z., & Lan, Y. (2025). Development and Experimental Validation of Active In Situ Temperature-Preserved Coring Testing System for Deep Oil and Gas Reservoirs. Applied Sciences, 15(22), 12011. https://doi.org/10.3390/app152212011