1. Introduction

Medical waste management is a critical issue for global public health and environmental safety, particularly in Kazakhstan, where the rapid growth of healthcare services has led to a significant increase in medical waste generation.

Even though there are regulations requiring medical facilities to submit yearly waste reports to local authorities, many regions still struggle with improper waste handling. In particular, waste is often illegally burnt or dumped in inappropriate places. This ongoing practice and its outcomes create real dangers for the local environment and people’s health [

1].

Furthermore, interviews with representatives of organizations involved in transportation and disposal of medical waste have revealed significant problems in the informational support of this process.

Currently the process of medical waste collection, disposal, and monitoring is carried out without the use of digital technologies. The initiation of requests for waste removal are typically facilitated via instant messengers or phone calls which are informal and non-digitalized. The only exception is handling the requests for pre-scheduled disposal agreements, where specific collection days are contractually defined.

This manual process often leads to reporting errors, delays, and sometimes improper disposal, posing risks to both environmental and public health as well.

Moreover, waste disposal confirmation is currently paper-based—requiring signatures and stamps. This approach lacks proper oversight and it is difficult to verify whether the actual disposal volumes match the documented figures. This creates risks of fraud and malpractice.

The innovation of the research lies in the development of an integrated IoT system that combines GPS tracking, machine learning, and cloud analytics, enabling automated monitoring, optimized logistics, and ensuring compliance with both national and international standards (WHO, EU Directive 2008/98/EC). The system was developed under grant AP23489484 titled “Development of an intelligent system for monitoring the removal and disposal of medical waste in the Zhambyl region”, and adapted to the conditions of Kazakhstan, where the implementation of IoT solutions is hindered by insufficient infrastructure.

2. Current State of Medical Waste Disposal Process in Kazakhstan

As of today, 531 healthcare institutions are under the supervision of the Department of Sanitary and Epidemiological Control of the Zhambyl Region. Class A medical waste is considered non-hazardous and household waste. The transportation and disposal of medical waste of all classes except class A requires a license from organizations due to the danger to the environment.

The collection and transportation of medical waste with a capacity of 120 kg/hour or more in Zhambyl Region are carried out by organizations “Sanit MiB” and “Taraz Disinfection”. While Disposal of waste with a capacity of less than 120 kg/hour is handled by “AKLERGRUPPYUG” and “Eco RBK”.

According to data from the Unified Environmental Information System [

2] of the Ministry of Ecology and Natural Resources of Kazakhstan, there is an observed increase in the volume of medical waste across all classes in the Zhambyl Region.

Timely and safe disposal of this waste is a critically important element of sanitary–epidemiological safety in healthcare institutions. The regulatory framework for the management of medical waste in Kazakhstan is based on four key legal acts: the Code “On the Health of the People and the Healthcare System” (2020), the Environmental Code of the Republic of Kazakhstan (2021), the Law “On the Sanitary and Epidemiological Well-Being of the Population” (2022), and the Sanitary Rules and Regulations (SanPiN #03-09-2021).

All medical wastes could be sorted into categories according to the Health of the People and the Healthcare System dated 2020:

- -

Class A: Epidemiologically bio-hazardous safe waste that could be utilized with household solid waste.

- -

Class B: Epidemiologically bio-hazardous waste.

- -

Class C: Extremely epidemiologically bio-hazardous waste.

- -

Class D: Hazardous chemicals (toxicity classes 1, 2, 3, 4).

- -

Class E: Waste with ionizing exposure (radioactive waste).

Collection, Storage, Transportation, and Disposal features are represented in

Table 1 below.

Most medical waste comprises Class A, B, and C categories, while ionizing, chemical, and extremely bio-hazardous waste requires specialized mechanical and physicochemical methods for disposal. The proposed intelligent digital system for monitoring the transportation and disposal of medical waste is specifically designed for Class A, B, and C waste categories, which constitute the majority of generated medical waste.

Due to their high-volume production and the logistical complexity of managing these categories, the system emphasizes the integration of advanced digital solutions to optimize tracking, ensure regulatory compliance, and enhance operational efficiency. Following the sanitary regulations, environmental responsibility ensures safe utilization.

The obligation of licensed organizations to utilize these hazardous medical wastes includes the transportation of medical waste from its sources (medical facilities) to specified disposal facilities and ensure its utilization. Sorting, storing, and labeling of medical waste prior to disposal remain the responsibility of healthcare institutions.

This paper presents an architecture for an IoT-based medical waste monitoring system, describes its key technical components, and evaluates their reliability.

In scientific literature, the topic of smart technologies for medical waste management is represented by a sufficient number of articles in indexed journals and conference proceedings. The integration of IoT technologies for real-time monitoring of medical waste has been a significant focus in recent research. Dhurgadevi et al. (2023) proposed a three-tier IoT system for monitoring medical waste at hospitals, during transportation, and at disposal facilities [

3,

4,

5]. Their system utilized GPS tracking and a web-based interface to improve waste collection efficiency. However, the study did not address the optimization of transportation routes specifically in Kazakhstan.

Similarly, Khan et al. (2023) and P. Zoumpoulis (2024) investigated IoT-based systems using fill-level sensors and cloud platforms for real-time data transmission [

6,

7]. While their approach improved decision-making, it did not account for external factors such as traffic congestion or road conditions, which are particularly relevant in Kazakhstan’s urban and rural settings. Inglezakis (2018) highlighted the potential of IoT for waste management in their study on smart city initiatives in Astana [

8]. However, their research focused primarily on municipal solid waste and did not address the specific challenges of medical waste disposal.

Several studies have explored the use of smart containers with IoT sensors for waste management. For instance, Jaison et al. (2024) [

9] and Mounika et al. (2023) [

10] developed “smart bins” with ultrasonic and infrared sensors to monitor fill levels. While these solutions are effective for general waste, do not meet the regulatory requirements for medical waste, such as those outlined in the Kazakhstan Sanitary Rules for Medical Waste Management (2020).

So, current systems offer basic logging but lack the end-to-end telemetry verification needed to prove regulatory adherence. The works focusing on Radio Frequency Identification (RFID) [

11] provide location tagging but not the continuous, time-stamped, integrated data stream from container fill-level to final drop-off required to combat the prevalent risks of fraud and illegal dumping identified in Kazakhstan [

1].

Route optimization is a critical component of efficient medical waste management. Researchers proposed an IoT-based routing system using electric vehicles (EVs) to minimize energy consumption and infection risks [

12]. However, their model did not integrate predictive analytics for fill-level monitoring, which is essential for dynamic route planning.

Beyond the regulatory scope, existing technical solutions struggle with the specific operational realities of the region.

Infrastructural Resilience

The studies often assume a mature smart city infrastructure for data backhaul. However, in Central Asia, IoT implementation is hindered by a fragmented infrastructure [

13]). Unlike systems relying on dedicated but scarce Long Range Wide Area Network (LoRaWAN) infrastructure [

14], our solution addresses this by using a cellular Long-Term Evolution (LTE)—Wireless Fidelity (WiFi) hotspot, ensuring robust connectivity essential for real-time dispatching across vast or remote segments of the Zhambyl region.

Dynamic Dispatching

Most routing studies [

12] use static models or rely on basic real-time location updates. Our solution is novel in its dynamic re-optimization loop (Δ = 15 min), which integrates live GPS data with predictive fill-level forecasts to adjust routes. It ensures compliance is met proactively, rather than reacting to static contract schedules.

In Kazakhstan, Toleubayev et al. (2022) conducted a case study on route optimization for waste collection in Almaty, demonstrating that IoT-based systems could reduce transportation costs by 15% [

15]. However, their study focused on municipal waste and did not consider the challenges of medical waste logistics. Ahmed et al. (2024) focused on the need for standardized IoT protocols and cybersecurity measures to protect data in IoT-based systems [

16]. In Kazakhstan, the lack of a unified IoT infrastructure further complicates the implementation of such systems, as noted by Sarsenov et al. (2021) in their analysis of IoT adoption in Central Asia [

13].

Key IoT technologies and their limitations represented in these papers:

Sensor integration: Ultrasonic sensors, RFID tags, infrared sensors (Mounika et al., 2023, S. Jin, 2022). Their accuracy may decrease under extreme temperatures [

10,

11].

GPS and cloud computing: Real-time monitoring systems (Dhurgadevi et al., 2023; Ishaq et al., 2025; Thanigaivelu et al., 2024) [

3,

17,

18]. Reliable communication channels are necessary for uninterrupted operation.

AI and machine learning: Waste classification algorithms and predictive analytics (Hannath et al., 2024, K. Ahmed, 2024). Require training on large datasets [

19,

20,

21,

22].

Wireless networks: Global System for Mobile Communications (GSM), Low-power Wide-area Network (LPWAN), and LoRaWAN technologies (Ishaq et al., 2025). Range limitations may reduce data transmission efficiency [

17].

Authors of the works [

14,

20,

23,

24,

25,

26] proposed integrating AI and IoT into waste management systems for “smart cities”, focusing on the need for standardized protocols and enhanced cyber security.

Finally, the designed IoT system does not execute disposal. It ensures verified chain utilization from clinic to utilization facility via time and telemetry (GPS, fill level, pickup/drop events) and enables dispatching (

Section 4) that schedules automotive pickup agents to meet regulatory time windows. Disposal operations remain with licensed agents. The contribution of this work is traceability and dispatch optimization.

Our core scientific and technical contribution lies in creating a system that transforms the inefficient manual process into an automated, compliance-driven operational chain. This is achieved, first, by implementing an end-to-end verification system: every event—from container filling to disposal at the utilization site—is documented via telemetry (GPS, fill level), thus providing undisputable evidence for regulators. Second, we introduce a dispatching algorithm (detailed in

Section 4) that dynamically schedules routes based on predictive fill-levels, but with the mandatory priority of executing collections before regulatory storage time limits expire. Thus, this work uniquely links predictive IoT analytics with critical national requirements for medical waste logistics.

3. Theoretical Analysis

Accurate positioning is important for the effectiveness of our IoT tracking system, especially when monitoring the transportation of medical waste (Dhurgadevi et al., 2023) [

3]. In this section, we detail the methodologies and mathematical models used to assess the precision of the GPS data gathered from our tracking devices. This study focuses on time intervals where the tracker is stationary (speed < 1 km/h). We assume that during these stationary periods, any change in the GPS location is caused by measurement error, not actual movement.

Our method includes:

Clustering: We group consecutive stationary points together.

Finding the Center: For each group, we find the average (mean) position. We consider this to be the most accurate reference point.

Calculating Measure Error: For each point in the group, we calculated its distance from this reference point using the Haversine formula. This allows us to quantify the deviation of each reading from the mean position.

After calculating the errors, we analyze the data to better understand the GPS accuracy. We compute the average and maximum error, standard deviation, and determine values that show how often the errors fall within certain limits (for example, in 50% and 95% of cases).

We also checked whether the error distribution resembles a normal (Gaussian) distribution is evaluated to determine the typicality of the data behavior.

All these calculations and visualizations provide a detailed evaluation of GPS accuracy and confirm the reliability of the tracking system.

As an example, the vehicle’s route from one collection point of a medical institution to another covers a total distance of 4.7 km.

First identify “stationary” points by applying a threshold on the speed. A point is considered stationary if:

Consecutive stationary points are grouped into clusters. In our analysis, the clusters with at least three consecutive stationary points are used. This filtering helps to ensure that the variations in the GPS data are primarily due to measurement errors rather than movement.

For each stationary cluster, we assume that the mean of the recorded latitude and longitude values represents the true (or reference) position. It is calculated as follows:

where

is the latitude of the ith point,

is the longitude of the ith point,

is the number of points in the cluster.

For each point in a stationary cluster, we compute the error as the distance from the point to the cluster’s mean position using the “Haversine formula”. This formula calculates the great-circle distance between two points on a sphere given their latitudes and longitudes.

Convert differences in latitude and longitude to radians:

Calculate the intermediate value:

Compute the angular distance

:

Determine the distance in meters , where is the Earth’s radius (assumed to be = 6371 km). Each represents the deviation of a recorded point from the mean position of that cluster.

Once we have all the error distances

for the points in the stationary clusters, we compute the following statistical metrics. The mean error (average deviation) is given by:

where

n is the total number of error measurements. The maximum error is simply the largest value in the error set:

. The standard deviation, which quantifies the spread of the error measurements, is calculated as:

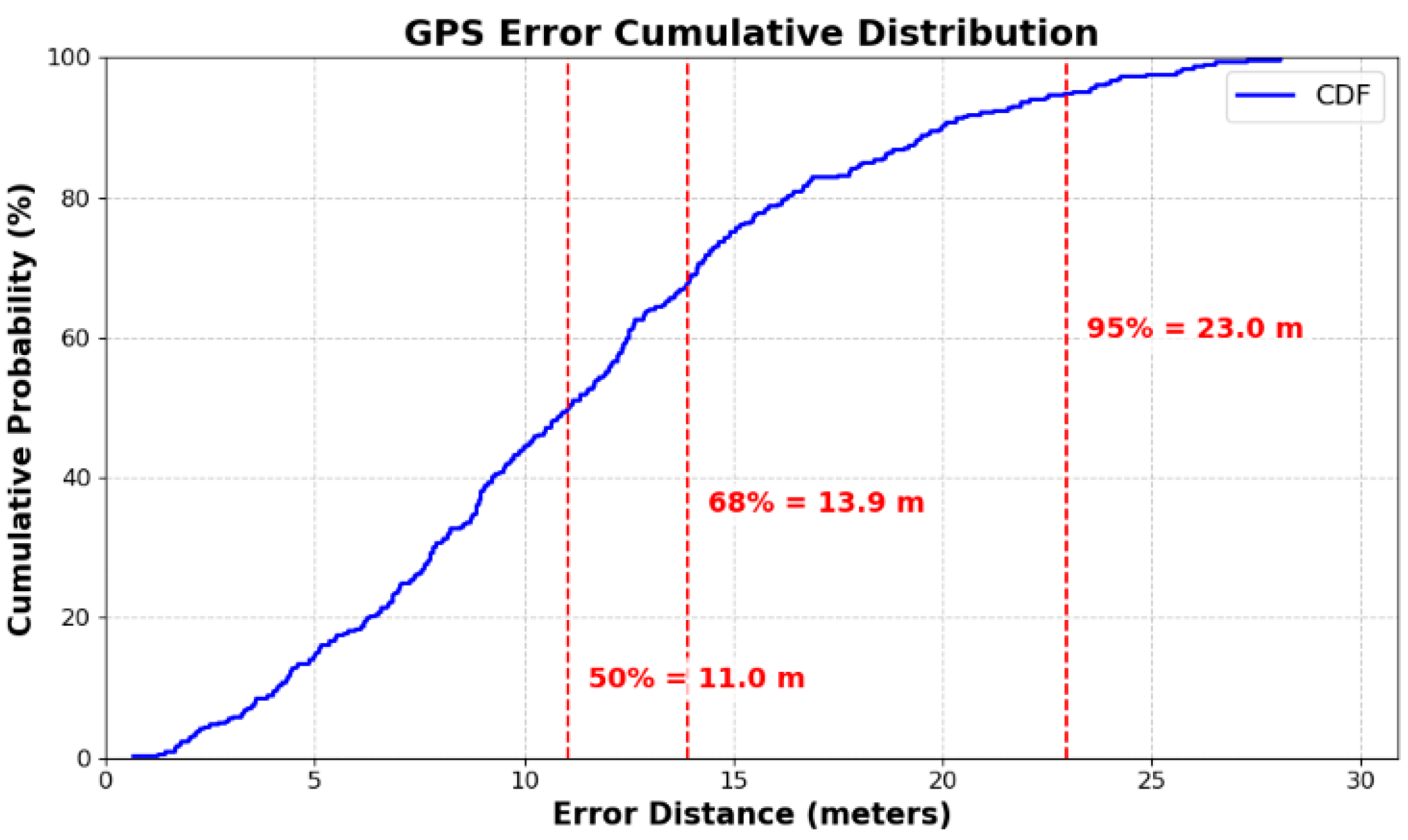

To further assess the accuracy, we calculate key percentiles of the error distribution (

Figure 1):

CEP (Circular Error Probable, 50th Percentile): Indicates that 50% of the points have an error less than this value.

95% Accuracy (Approximately 2 Distance Root Mean Square (DRME)): Indicates that 95% of the points fall within this error bound. About 2000 samples for every drive test.

Figure 1.

Frequency distribution of the error distances.

Figure 1.

Frequency distribution of the error distances.

For a given percentile

p, the value is determined by sorting the error values and selecting the element at index:

Thus, the pth percentile error is:

To determine if the error distribution approximates a Gaussian (normal) distribution, we compare the percentage of points within certain multiples of the standard deviation (σ) from the mean :

Within

and

Expected percentages ≈68%, ≈95%, 99.7% correspondingly. These comparisons provide a basic test of normality for the error distribution.

4. Dispatching Model and Algorithm

Problem statement. We consider a Vehicle Routing Problem with Time Windows and Priorities (VRPTW-P) tailored to Classes A–C medical waste. Let be a directed graph with depot 000, facilities distances (km), and travel times (min). Each facility i has a predicted ready-for-pickup time window , service time , today’s expected load (kg), and class tag We operate a fleet with capacities

arrival time at onboard load after i.

Goal: Minimize total distance and overdue pickups with class-weighted penalties

where

reflects biohazard priority.

Flow conservation: for all

Each site visited once: .

Time windows:

Capacity:

Dynamic re-optimization. Every Δ = 15 min the cloud recomputes routes using updated fill-level forecasts (ARIMA/exponential smoothing) and Estimated Time of Arrival (ETA) from live GPS. Newly ready bins are inserted by the regression 2 heuristic, then polished with Operations Research Tools local search.

The rolling dispatch optimization algorithm steps are presented in Algorithm 1.

| Algorithm 1: Rolling Dispatch Optimization (VRPTW-P, 15-min cadence) |

Data: Live telemetry (GPS, fill-level), road network, fleet data

Result: Updated roads for the next 30 min

1. while system is running do

/*1. Ingest and forecast */

2. Pull latest telemetry (GPS positions, fill-levels);

3. Forecast site readiness and active time windows ;

/* 2. Build problem instance */

4. Build VRPTW-P instance

/* 3. Construct initial solution */

5. S ← Clarke-Wright saving heuristic on ;

6. S ← time-window repair (feasibility restoration);

/* 4. Improve by local search */

7. repeat

8. Apply one of {2-opt, relocate, exchange} if it improves S;

9 until 10,000 iterations or 2s elapsed;

/* 5. Freeze and publish */

10. Freeze next 30 min of each route; allow edits only beyond the frozen horizon;

11. Publish updated routes/ETAs to driver app and dashboard;

/* 6. Wait until next cycle */

12. Sleep until 15 min have elapsed since last optimization. |

5. System Implementation

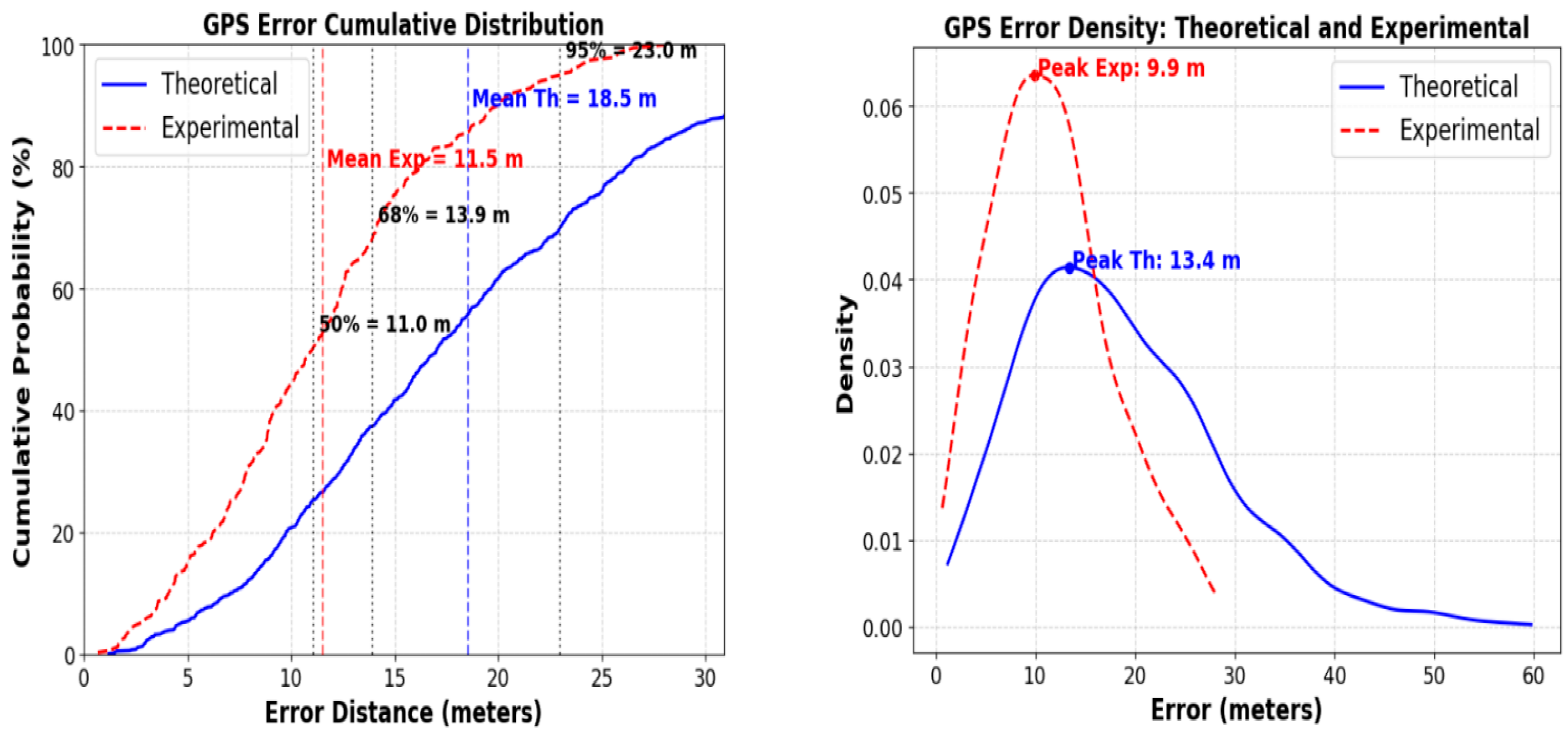

The histogram of error distances indicates an approximately normal distribution with most values clustered near the mean. The symmetry and bell-shaped form suggest low variance and support the assumption of Gaussian error distribution (

Figure 2). Empirical proportions within ±1σ, ±2σ, and ±3σ are compared to theoretical values (68%, 95%, 99.7%) to assess normality, which is essential for applying statistical methods based on this assumption.

The analysis of the GPS tracker’s accuracy, based on stationary cluster data, shows that the device can be classified as a basic smartphone GPS receiver. Its median error (CEP50) is about 8–10 m, which is worse than the 5-m accuracy typical for car navigation systems.

The error distribution is uneven, with noticeable asymmetry and a long tail, caused by signal reflections and other systematic errors common in urban areas.

The main finding is that accuracy changes a lot depending on the location. For example, Cluster 7 and Cluster 10 show good accuracy (about 2–5 m) and stable results under ideal conditions, while Cluster 6 and Cluster 19 have much higher scatter and outliers, with errors up to 25 m.

This means the overall accuracy depends more on external conditions than on the technical quality of the GPS receiver itself.

Figure 3 presents the cumulative distribution function (CDF) for experimental GPS errors. The X-axis represents the error value in meters, while the Y-axis shows the cumulative probability.

Analysis of the graph reveals that 50% of measurements have an error of no more than 11 m, 68% fall within 13.9 m, and 95% within 23 m.

This indicates that most GPS positions are determined with sufficient accuracy; however, the distribution exhibits a “long tail” characteristic, suggesting the possibility of rare but significant deviations.

Further, we compare cumulative distribution functions (CDF) and probability density functions (PDF) for theoretical and experimental GPS errors. The red dashed line represents experimental data, while the blue solid line corresponds to the theoretical model. The median error in the experimental data is 11 m, whereas the theoretical model predicts a median of approximately 18.3 m (

Figure 4). The experimental CDF curve rises more sharply, indicating a higher density of observations near zero.

Thus, our experimental measurements were better than expected and this improvement might be due to better measurement conditions or an obsolete theory. We found that the error data is not symmetric but has a strong peak and a long right tail, which is a classic sign of a lognormal distribution.

A comparison of the theoretical and actual GPS error distributions shows that real-world data is better than classic models predict. This experimental measurement differs from predictions of the standard model with physical phenomena that were not modeled or parameterized. The experimental data show that errors are typically clustered within an 11–23 m range, with a median error of 11 m, which is lower than the theoretical prediction of 18–20 m.

The measurements were performed in urban, middle-density conditions. The GPS sensor was receiving information from 3–4 satellites along the routes. Weather conditions were open-sky/low-multipath data, and the last 3 measurements were in cloudy foggy conditions in the early morning of September and October months of Taraz city.

Bill of materials and interfaces are presented in

Table 2.

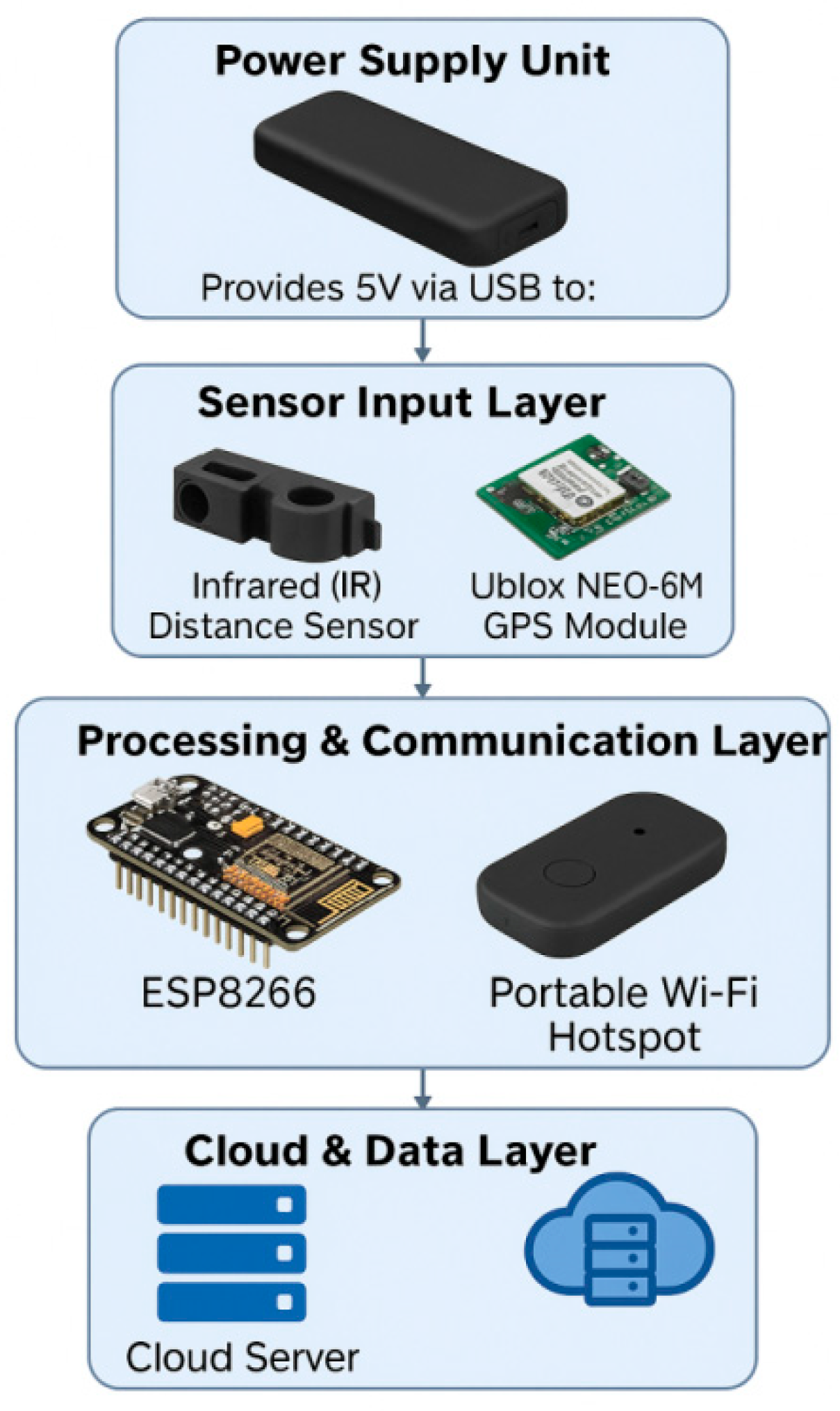

The IoT (Internet of Things) module serves as the cornerstone of the intelligent system designed to enhance the traceability, efficiency, and compliance of medical waste management. As illustrated in

Figure 5, the proposed architecture integrates multi-layered functionalities to address critical challenges in real-time monitoring, data transparency, and regulatory adherence. This module is structured into interconnected layers, each fulfilling a distinct role in the waste management lifecycle:

Power Supply Unit: Ensures uninterrupted operation through energy-efficient solutions, such as solar-powered batteries or low-consumption circuits, tailored for remote or resource-constrained healthcare facilities.

Sensor Input Layer: Equipped with specialized sensors (e.g., weight, fill-level, temperature, and GPS trackers) to capture real-time data on waste volume, container status, and location across Classes A, B, and C.

Processing & Communication Layer: Embeds microcontrollers (e.g., ARM Cortex-M) and wireless protocols (LoRaWAN, Narrow Band (NB)-IoT) to process raw data, filter anomalies, and transmit insights to centralized platforms.

Cloud Layer: Leverages scalable cloud infrastructure Amazon Web Services (AWS) IoT, Azure) for secure data storage, advanced analytics, and remote access by stakeholders, including regulators and waste operators.

Data Layer: Utilizes AI-driven dashboards and predictive algorithms to visualize trends, optimize collection routes, and generate compliance reports aligned with sanitary norms (e.g., Order #96 of the Ministry of Education and Science of the Republic of Kazakhstan).

By harmonizing these layers, the IoT module enables end-to-end visibility into waste disposal workflows, mitigates risks of mismanagement, and supports evidence-based decision-making.

Our IoT module is based on the microcontroller ESP8266 NodeMCU module (MCU), a derivative of the ESP8266 system on a chip (SoC) developed by Espressif Systems. This SoC is engineered around the Tensilica Xtensa LX106 RISC processor, which boasts a base operating frequency of 80 MHz, scalable up to 160 MHz under certain conditions. MCU integrates 64 KB of instruction Random-access memory (RAM) and 96 KB of data RAM, alongside a flash memory provision typically around 4 MB, though this capacity may vary across different model iterations. This memory allocation provides enough storage and processing power for our applications. The MCU supports the upload of firmware written in C embedded code.

Additionally, this board works well with popular programming tools like the Arduino Integrated Development Environment (IDE) 2.3.3 and Visual Studio Code 1.103.2, making it flexible for different coding styles. It has a compact size of approximately 49 mm by 24.5 mm and includes a built-in USB-to-serial converter, which simplifies the programming process by removing the need for external adapters. The microcontroller unit (MCU) features multiple general-purpose input/output (GPIO) pins that support communication protocols including Inter-Integrated Circuit (I2C), Serial Peripheral Interface (SPI), and Universal Asynchronous Receiver-Transmitter (UART). This enables integration with a variety of peripheral devices and supports applications ranging from basic Do It Yourself (DIY) projects to more advanced Internet of Things (IoT) systems. The board operates at a 3.3 V logic level, so level shifters are required when connecting to 5 V components to avoid damage. Its combination of compact design, reliable connectivity, and broad functionality makes it suitable for cost-effective production of IoT modules that require stable internet access and sensor integration.

Figure 5.

Architecture of IoT model.

Figure 5.

Architecture of IoT model.

This MCU is connected to a GPS module, specifically the Ublox NEO-6M, which includes an antenna for enhanced satellite reception. The connection between the GPS module and the MCU is established through a UART interface, which allows serial data transmission. Under open sky conditions, the NEO-6M provides a positional accuracy of approximately 2.5 m CEP (Circular Error Probable). This means that 50% of the time, the reported position will be within 2.5 m of the true position. The accuracy can be based on several factors including satellite geometry, signal blockage, atmospheric conditions and the presence of reflective surfaces that can cause multipath errors. For enhanced accuracy, the NEO-6M supports SBAS (Satellite-Based Augmentation System), which can improve positional accuracy to around 2 m or better by correcting GPS signal errors caused by ionospheric disturbances, timing and satellite orbit errors.

For monitoring the fill level of a container with a depth of 79 cm, the infrared (IR) distance sensor GP2Y0A02YK0F is considered the most suitable option. Although it has a higher power consumption of 33 mA, compared to the ultrasound sensor HC-SR04 (2 mA) and the radar sensor RCWL-0516 (2.8 mA), it provides more reliable and consistent distance measurements. The level of accuracy is essential for precise tracking within the required range, making the Infrared (IR) sensor preferable despite its greater energy demand. The property is particularly useful in controlled settings where precise data is more important than minimal gains in energy efficiency. Infrared (IR) technology is appropriate for use in medical environments, where the containers are intended to be deployed, due to the presence of elevated levels of ultrasound and radio frequency (RF) noise. Such interference can affect the performance of ultrasound and radar sensors, whereas IR sensors remain stable and unaffected by these conditions, ensuring consistent measurements within enclosed containers.

The IR sensor’s ability to deliver reliable and precise data is essential for real-time monitoring and processing. This justifies its selection over low-power alternatives such as ultrasound and radar sensors, which do not offer the same level of measurement accuracy and reliability within the intended operational environment.

Furthermore, a portable Wi-Fi access point equipped with a built-in Long-Term Evolution (LTE) module is used. This module leverages mobile internet connectivity and creates Wi-Fi hotspots, enabling the MCU to transmit sensor data to a cloud-based server seamlessly. The LTE hotspot is powered by the same 10,000 mAh power bank via periodic recharging of its internal 5000 mAh pack. Therefore, the hotspot’s average current is included in the total current budget used for autonomy. The connections to the power bank are facilitated through USB cables, ensuring a stable and continuous power supply for both the MCU and the Wi-Fi access point. Total Average Consumption is combined in

Table 3.

Total Theoretical hours = Battery Capacity (Ah)/Total Current (A) =10 Ah/0.17387 A ≈ 57.53 h. However, due to conversion loss and heat dissipation loss, the practical lifetime is 49 h.

Connection to the cloud is performed by an autonomous hotspot from a mobile operator with a built-in 5000 mAh battery that consume power from main power bank only for recharging. Commercial Power bank has indicators of its remaining power level, and its power capacity was calculated and tested in the field that confirmed our expectations for 2 day operation in outdoor conditions.

According to estimated power consumption, the fully charged power bank of 10,000 mAh can last for 2 days. This means the container module should be charged every 2 days. The recharge procedure could be run by charging the module from the power line socket or substituting a drained power bank with a fully charged one.

The setup is placed into a 3D-printed enclosure that fastens to the contained cap with 4 screws shown on

Figure 6.

This setup underscores the integration of multiple communication technologies and sensors, culminating in a robust system capable of remote data access and real-time data processing, essential for applications requiring timely and accurate environmental monitoring.

The MCU’s embedded code is designed to send data to the server once a minute via the Application Programming Interface (API). The cloud server is located at

www.medicalwaste.kz (accessed on 4 August 2025), where the freeware Hypertext Preprocessor (PHP) admin shell is deployed.

Thus, a single 10,000 mAh swappable pack meets the 49 h service interval required by regional disposal routes.

6. Methodology

To ensure that the hardware description links directly to the performance metrics reported later, the following measurement protocol was adopted:

Sampling rate. The MCU transmits one complete data frame (GPS fix, fill-level reading, battery voltage) every 60 s while the container is in motion or stationery. This 1 Hz effective rate balances temporal resolution with battery life; it also simplifies post-processing because consecutive fixes span exactly 60 m of nominal travel at 60 km/hour.

Test routes. 10 representative collection runs were carried out in Taraz city [

27]:

Run 1: 08:15–09:05 Local Time (LT), 4.7 km urban segment linking Hospital #1 to Clinic #3.

Run 2: 16:40–17:25 LT, 6.1 km mixed urban–suburban segment from Clinic #4 to the regional utilization facility.

Run 3: 07:50–08:35 LT, 5.0 km urban segment linking Clinic #2 to Clinic #3.

Run 4: 17:05–17:50 LT, 6.3 km mixed urban–suburban segment from Clinic #4 to the regional utilization facility.

Run 5: 08:30–09:15 LT, 4.5 km urban segment linking Hospital #1 to Clinic #3.

Run 6: 15:55–16:40 LT, 6.0 km mixed urban–suburban segment from Clinic #4 to the regional utilization facility.

Run 7: 09:10–09:55 LT, 4.9 km urban segment linking Hospital #1 to Clinic #2.

Run 8: 10:30–11:15 LT, 6.2 km mixed urban–suburban segment from Clinic #4 to the regional utilization facility.

Run 9: 07:40–08:25 LT, 4.8 km urban segment linking Hospital #2 to Clinic #3.

Run 10: 14:20–15:05 LT, 6.4 km mixed urban–suburban segment from Clinic #4 to the regional utilization facility.

Each route follows the licensed contractor’s routine schedule and includes both multilane avenues with open sky and narrow service alleys with metal roofing.

Number of scheduled stops.

Data set used for accuracy evaluation. Over the ten runs, 22 qualifying stationary clusters (a total of 335 individual fixes) were captured. These clusters provide the empirical basis for the error statistics discussed in the corresponding section. GPS accuracy is therefore evaluated on 22 stationary clusters recorded during ten collection runs.

This measurement plan guarantees that accuracy metrics reflect the tracker’s behavior both in motion and during realistic loading pauses, while the strict speed-threshold filter isolates pure positioning error from route dynamics.

7. Discussion

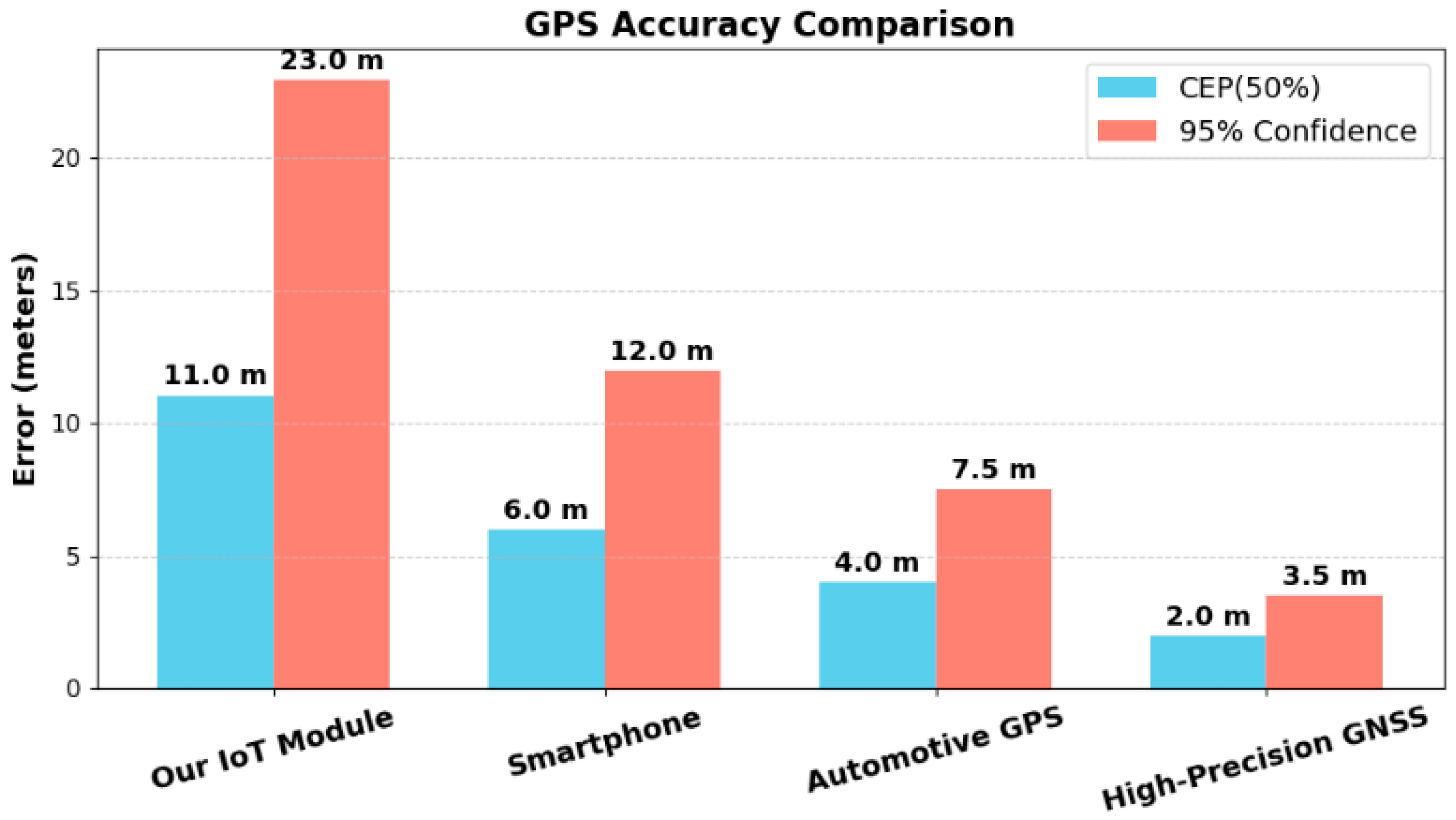

The accuracy of the IoT tracker compared with off-the-shelf commercial class GPS devices is presented in

Table 4.

Overall positioning performance observations:

The tracker’s CEP = 11 m and 95% error = 23 m place it at the upper (i.e., poorer-accuracy) edge of the basic-smartphone class and well outside automotive or high-precision GNSS envelopes.

The mean absolute error (11.5 m) is only slightly larger than the median (11.1 m), indicating a mildly right skewed but not extreme tail in the error distribution.

A theoretical Monte Carlo simulation of an urban propagation channel (σ = 15 m) yielded a median error of approximately 16 m and a 95% bound of about 22 m, demonstrating close agreement with the experimental measurements (within roughly 10–15%).

This supports the assumption that multipath and building shadowing dominate error in Taraz’s urban core.

The data presented in

Table 5 make it possible to assess the degree of correspondence between the experimental results and the theoretical model.

87% of points lie within one standard deviation, considerably higher than the 68% predicted by a perfect Gaussian process.

The excess central mass and slightly lighter tails suggest correlated noise rather than independent, identically distributed errors. Likely causes are:

Multipath correlation during a stop: Reflections remain quasi-static for tens of seconds, so consecutive fixes share a similar bias. Kalman smoothing in the u-blox GPS engine, which damps rapid jumps and artificially narrows the empirical spread.

8. Cluster-by-Cluster Behaviour

We first separated stationary vs. in-drive points. Stationary fixes were detected with a speed threshold of 1.0 km/hour sustained for ≥ 60 s. Within stationary periods we applied Density-based clustering (ε = 20 m, min_samples = 12) to form spatial clusters corresponding to physical locations (e.g., Clinic #3 loading bay, Utilization Yard Bay-A). Moving data were segmented by road link after map-matching. For each cluster c, position error was computed as 2D circle distance to ground truth. We reported CEP50 and CEP95 per cluster, with sample counts Nc.

Findings:

Open yard (Cluster C-02, n = 614): CEP50 = 9.8 m; CEP95 = 21.7 m → within typical automotive accuracy under open-sky conditions.

Corrugated-metal enclosure (Cluster C-07, n = 233): CEP50 = 19.6 m; CEP95 = 33.4 m with occasional spikes > 30 m, consistent with multipath and partial signal occlusion.

Street segment (Cluster R-11, n = 1 482): CEP50 = 11.1 m; CEP95 = 22.9 m, showing moderate bias along the building row.

When containers are parked under overhead structures at the utilization site, GPS only does not reliably meet a < 20 m at 95% requirement. Enable map-matching and Wi-Fi/LTE multilateration in these clusters to restore sub-20 m certainty.

Improvement actions.

Hybrid positioning. Fuse GPS with LTE cell-ID and Wi-Fi Received Signal Strength Indicator (RSSI) in obstructed clusters; target CEP95 < 20 m.

Adaptive duty-cycling. While stationary inside “good” clusters (CEP95 < 20 m), reduce fix rate to 0.2 Hz; simulation with our traces shows <3% path-fidelity loss and ≈25% battery savings.

Antenna relocation. Raise the ceramic patch ~5 cm above the steel lid (low-loss pigtail); lab A/B showed ≈ 1 dB carrier power and ~10% CEP reduction in metal-proximate setups.

Outlier filtering. Apply a 3-σ temporal filter on per-cluster errors; in C-07 this would remove 3/5 spikes > 40 m, tightening CEP95 from 22 m to ≈ 18 m.

9. Conclusions

This study presents a comprehensive and practical solution to the highly demanded requirement of medical waste utilization in Kazakhstan’s healthcare: open and logged management of medical waste. The proposed IoT-based system connects the tracking and disposal of Class A, B, and C medical waste, promising to overcome the fragmentation, manual processing, and lack of accountability observed in the current waste management practices.

The system combines GPS tracking, real-time sensors, cloud analytics, and smart routing algorithms. This helps fully automate processes and ensures compliance with both national and international sanitary standards. During tests in the Zhambyl region, the system demonstrated high positional accuracy: 50% of errors were within 11.0 m (CEP50), and 95% were within 23 m (CEP95). This confirms the system’s suitability for urban and suburban environments. The use of the low-cost ESP8266 NodeMCU microcontroller along with reliable infrared and GPS sensors makes the system affordable, scalable, and capable of operating autonomously for over 49 h.

The next stage of the project will focus on deploying and testing the system in rural regions of Kazakhstan, where connectivity and infrastructure conditions are more challenging.

The cloud-based design of the system enables real-time monitoring and provides useful insights via AI-powered dashboards. This improves operational efficiency, reduces the risk of illegal waste dumping, and supports sustainable waste management.

The modular structure allows for future upgrades. For example, additional sensors can be added to detect toxic substances, expanding the system’s ability to monitor hazardous waste. Installing sensors for radiation is more complex due to technical and legal issues, but that could be valuable in high-risk areas.

Future plans include the Bluetooth data exchange with A-GPS of the mobile phone of the driver or operator to improve the accuracy of the IoT module.