1. Introduction

Over the past five years, the Korean government has actively implemented a variety of traffic safety policies—such as installing additional traffic lights, deploying speed-enforcement cameras, and introducing the Safety Speed 5030 initiative. As a result, the total number of traffic accidents decreased by approximately 6.1%, from 216,335 cases in 2017 to 203,130 cases in 2021 [

1].

However, truck-related accidents showed only a slight decline of 4.6% (from 27,341 to 26,081 cases) during the same period. Trucks continue to have the second-highest casualty rate after passenger cars, with a fatality rate roughly 2.6 times higher. The main causes of these accidents include speeding, overloading, and improper loading, which not only raise fatality risks but also cause significant economic losses such as cargo damage. Therefore, this study specifically targets commercial freight vehicles, where issues of overloading and improper loading are most prevalent.

To address these issues, the Korean government enforces legal restrictions on truck operations. According to the Road Act (Article 59) and its Enforcement Decree (Articles 55 and 60), trucks that exceed an axle load of 10 tons, a total weight of 40 tons, a width of 2.5 m, a height of 4 m, or 110% of the vehicle’s rated length are subject to overloading regulations [

2]. Current enforcement methods, however, rely mainly on low-speed weigh-in-motion (WIM) systems that measure vehicles moving at speeds below 10 km/h, typically at checkpoints or toll booths. In mobile inspections, officers select vehicles for weighing either at random or based on visual judgment. Drivers of large trucks equipped with variable axles often manipulate axle configurations during inspections to avoid accurate weight measurement and may revert to overloaded states afterward. Such practices, combined with limited inspection coverage, result in enforcement inefficiency—the proportion of inspected vehicles on highways remains as low as 0.07–0.09% [

3,

4].

To improve enforcement effectiveness, the high-speed weigh-in-motion (HS-WIM) system has been proposed. The HS-WIM system provides richer data—including speed, length, vehicle classification, and weight—beyond what conventional detection or automatic vehicle classification systems can measure [

5,

6]. Because of its potential role in direct enforcement, system reliability is essential, and many countries have established HS-WIM performance standards to ensure measurement accuracy [

7,

8,

9,

10,

11].

In Korea, the Intelligent Transportation Systems (ITS) Performance Evaluation Standards for Vehicles and Road Traffic are applied, whereas Europe uses the COST 323 standard and the United States follows ASTM E1318. Nevertheless, the Korean standard currently lacks specific provisions for group-axle load tests and offers no criteria for improper-loading detection, underscoring the need for further research in these areas [

12,

13,

14,

15,

16,

17,

18,

19].

Accordingly, this study proposes testing scenarios for evaluating the performance of HS-WIM systems in detecting both overloading and improper loading of commercial vehicles. A dedicated testbed was constructed to validate the proposed scenarios. Domestic and international regulations were analyzed to establish baseline testing conditions, and performance evaluation criteria were refined by referencing global standards. The proposed test framework—covering twelve vehicle types, driving modes, and speed parameters—serves as the foundation for defining performance evaluation criteria for HS-WIM systems, particularly in the accurate detection of overloading and improper loading.

2. Analysis of Overloading and Improper Loading Regulations and Performance Tests in Korea and Abroad

2.1. Standards for Overloading and Improper Loading Regulations in Korea and Abroad

2.1.1. Korean Regulatory Standards

In Korea, regulations governing vehicle overloading are primarily stipulated in Article 77 of the Road Act (Restrictions and Permits for Vehicle Operations), Article 79 of the Enforcement Decree of the Road Act (Vehicle Operation Restrictions), and Article 22 of the Enforcement Decree of the Road Traffic Act (Operational Safety Standards).

According to the Road Act, vehicles with an axle load exceeding 10 tons or a gross vehicle weight (including cargo) exceeding 40 tons are prohibited from operation. Additionally, the Road Traffic Act limits the permissible cargo load to within 110% of the vehicle’s rated load capacity. For example, a truck with a rated load capacity of 10 tons may legally carry a maximum of 11 tons.

These national regulatory standards are summarized in

Table 1. Carriers intending to transport cargo beyond these prescribed limits must obtain an operation permit for restricted vehicles from the relevant authority—either the National Police Agency or the road management authority (e.g., the Ministry of Land, Infrastructure and Transport, or the respective local government).

In recent years, researchers have proposed IoT-based real-time overloading detection frameworks to supplement regulatory enforcement, enabling continuous monitoring and immediate alerting [

20,

21]. These approaches are expected to complement national policies by integrating real-time data collection with advanced WIM infrastructure.

2.1.2. European Regulatory Standards

The European Union follows its own regulations based on Directive 96/53/EC. As shown in

Table 2 and

Table 3, it rigorously inspects and monitors the weight, axle load distribution, and allowable dimensions of cargo vehicles [

22]. These regulations contribute to road safety, control road loads, and help reduce traffic congestion. Moreover, direct enforcement through high-speed WIM systems has been implemented in several EU member states, such as Belgium, demonstrating effective on-road monitoring and penalty automation [

17].

2.1.3. U.S. Regulatory Standards

In the United States, overloading of cargo trucks is regulated by the Federal Motor Carrier Safety Regulations (FMCSRs) [

23]. These regulations apply to all vehicles and drivers engaged in commercial transportation within the U.S. They include various rules to ensure road safety during transportation. As shown in

Table 4, the regulations govern the weight and size of cargo trucks, driving time limits, and other factors, all aimed at improving road safety. Recent developments in the U.S. have also introduced advanced WIM-based systems designed for automatic detection and enforcement, significantly reducing socioeconomic costs due to overweight vehicles [

21].

2.2. Performance Evaluation Standards for HS-WIM Systems

2.2.1. Performance Evaluation Standards in Korea

Key performance criteria are outlined in

Table 5, which shows performance standards by evaluation grade for high-speed WIM systems in Korea, including weight accuracy, avoidance driving detection rate, vehicle number recognition rate, and matching accuracy.

Table 6 displays the number of test runs required per lane for weight accuracy evaluation, while

Table 7 presents the performance evaluation grades for HS-WIM systems. Additionally, the classification of Korea’s 12 vehicle types is illustrated in

Table 8. Emerging studies emphasize the importance of accounting for vehicle dynamic behaviors—such as wheel oscillations and axle vibrations—when calibrating high-speed WIM sensors, as these significantly influence accuracy under real-world conditions [

8,

24].

2.2.2. Performance Evaluation Standards in Europe

The performance evaluation standards for high-speed WIM systems in Europe follow the COST 323 standard. This standard was developed under the COST program to measure vehicle weight in real time on roads, enabling overloading detection and road load monitoring to improve safety. Key details are shown in

Table 9. One main point is that dynamic impacts between the road surface and vehicles affect measurement accuracy. Therefore, the standard considers not only total weight and axle load but also combined axle loads and single axle loads within a combination. The standard categorizes accuracy into seven levels based on allowable tolerances and recommends accuracy levels of A(5) or B+(7) for HS-WIM systems suitable for overloading enforcement.

2.2.3. Performance Evaluation Standards in the United States

The U.S. performance evaluation standards for HS-WIM systems primarily follow ASTM E1318. This standard includes requirements for accuracy classes (such as Type I for enforcement) and prescribes testing methods under various conditions. For example, the California Department of Transportation requires WIM systems to meet pavement smoothness criteria (±3 mm over 12 m) as specified in ASTM E1318. Based on such practices, to ensure reliable enforcement use, the HS-WIM systems must demonstrate high accuracy across different vehicle types and operating conditions.

Type I: A lower-accuracy category (±25% wheel load, ±20% axle load, ±10% gross weight) meant for screening.

Type II: Intermediate, not commonly used in enforcement.

Type III: The standard for enforcement-level systems (e.g., ±6% gross weight, ±10% combined axle weight tolerance).

Type IV: High-precision slow-speed or static systems (nearly equivalent to static scale accuracy).

3. Methodology

This section outlines the methodology used to derive test scenarios, design the HS-WIM testbed, configure sensors, and evaluate data, thereby establishing a structured procedure for detecting overloading and improper loading in commercial vehicles.

3.1. Derivation of Overloading Test Scenarios

A key insight from the international comparison is that Korea’s current ITS performance standards lack provisions for group-axle load assessment and improper loading evaluation. For example, as shown in

Table 10, Korean standards (prior to this study) did not include a category for group-axle load tests (indicated by “×” in the table under combined axle load), whereas international standards like COST 323, OIML R134, and ASTM E1318 do address multi-axle group weights. Additionally, while Korea recently defined basic criteria for improper loading (e.g., legal height, length, width limits), there were no standardized test methods to evaluate a WIM system’s ability to detect such violations. This necessitated developing new evaluation methods for improper loading detection.

Domestic and international WIM standards were reviewed to derive realistic overloading test scenarios for HS-WIM systems. For enforcement purposes, scenarios were defined to challenge the system’s accuracy under varying loads and speeds. Twelve overloading scenarios were established, reflecting combinations of load levels (from no load up to 110% of rated load), vehicle speeds (e.g., 50, 70, 90 km/h), and driving patterns (centered vs. deliberate lateral offset driving). These scenarios also include different environmental conditions (day vs. night, dry vs. wet pavement) to evaluate system robustness.

The overall process for implementing these test scenarios is illustrated in

Figure 1, which outlines the overload vehicle detection test procedure.

The overloading test conditions were defined in compliance with legal thresholds. For instance, scenarios include vehicles loaded to exactly 100% and 110% of their legal load limit to test detection of legal vs. illegal loading. Each scenario was repeated multiple times (typically 10 runs each) to ensure statistical reliability.

Table 11 summarizes the overloading condition test scenarios.

3.2. Derivation of Improper Loading Test Scenarios

There are no existing standardized test conditions for improper loading of cargo vehicles in Korea or abroad. Therefore, we developed test scenarios based on Korea’s regulations on improper loading, as shown in

Table 12. The scenarios address factors such as load shape (oversize dimensions), vehicle speed, driving patterns, sunlight conditions, group driving, and number of repetitions. To verify these scenarios, real vehicle tests were conducted on 12 vehicle types under intentionally improper loading conditions.

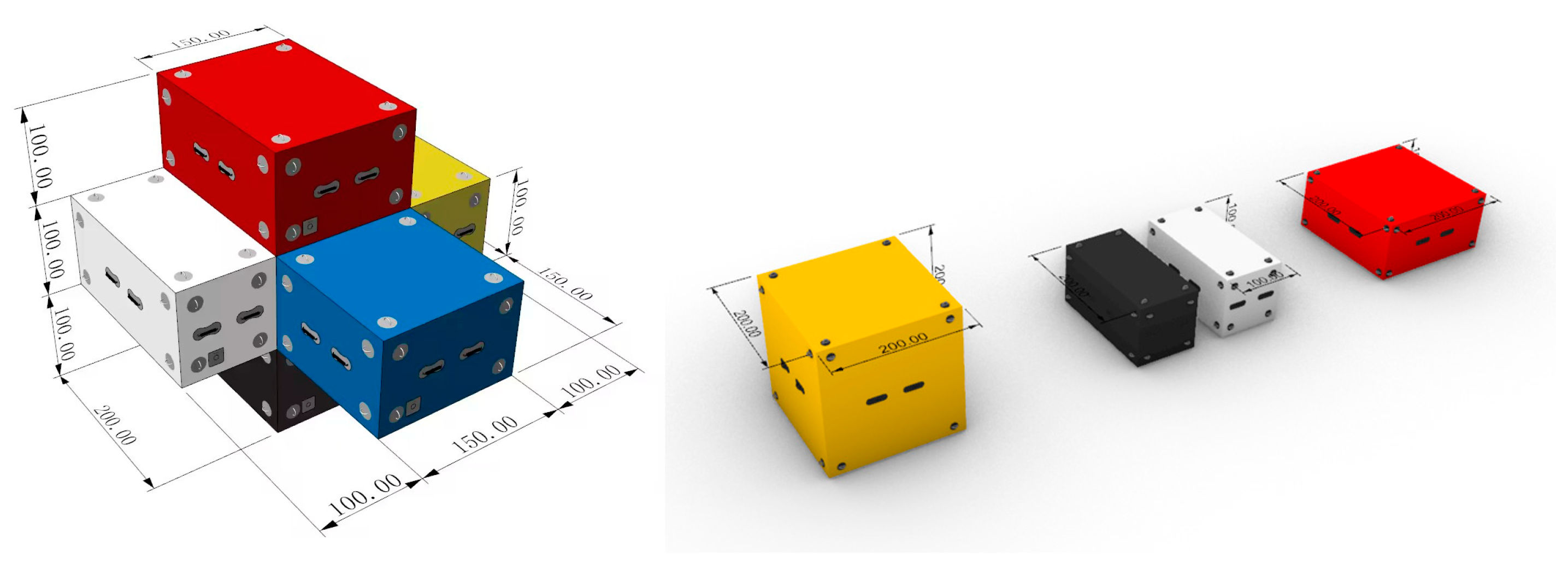

Based on these scenarios, an improper loading model was created (see

Figure 2) to conduct the tests. The tests followed procedures outlined in

Figure 3. Evaluation criteria included vehicle number recognition rate and specification measurement accuracy.

For the improper loading model, we defined quantitative thresholds: a cargo height exceeding 4.0 m, a cargo length exceeding 16.7 m, and a cargo width exceeding 2.5 m. To simulate real-world unbalanced loading, the cargo’s center of gravity in the model is intentionally offset from the vehicle’s centerline. This ensures that the test scenarios adequately represent vehicles with improperly distributed loads.

3.3. Testbed Design and Sensor Configuration

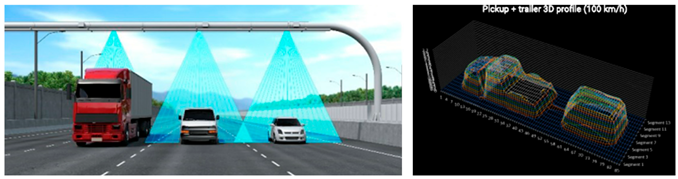

To verify the test scenarios, a testbed was constructed on the Saemangeum Seawall in Gunsan, where vehicle traffic could be controlled and high-speed driving tests could be conducted, as shown in

Figure 4 The overloading detection system installed on the testbed consists of three main components: the WIM system, the AVI (Automatic Vehicle Identification) system, and the VPS (Visual Positioning System). The WIM system is embedded in the road surface and is responsible for measuring the total weight and axle load of passing cargo vehicles. The AVI system uses high-resolution cameras to capture images of all passing vehicles and recognizes their license plates. The VPS measures the dimensions (height, width, length) of the cargo trucks, including the shape and size of the load. The information measured by the installed systems is summarized in

Table 13.

4. Test Results

4.1. Overloading Test Results

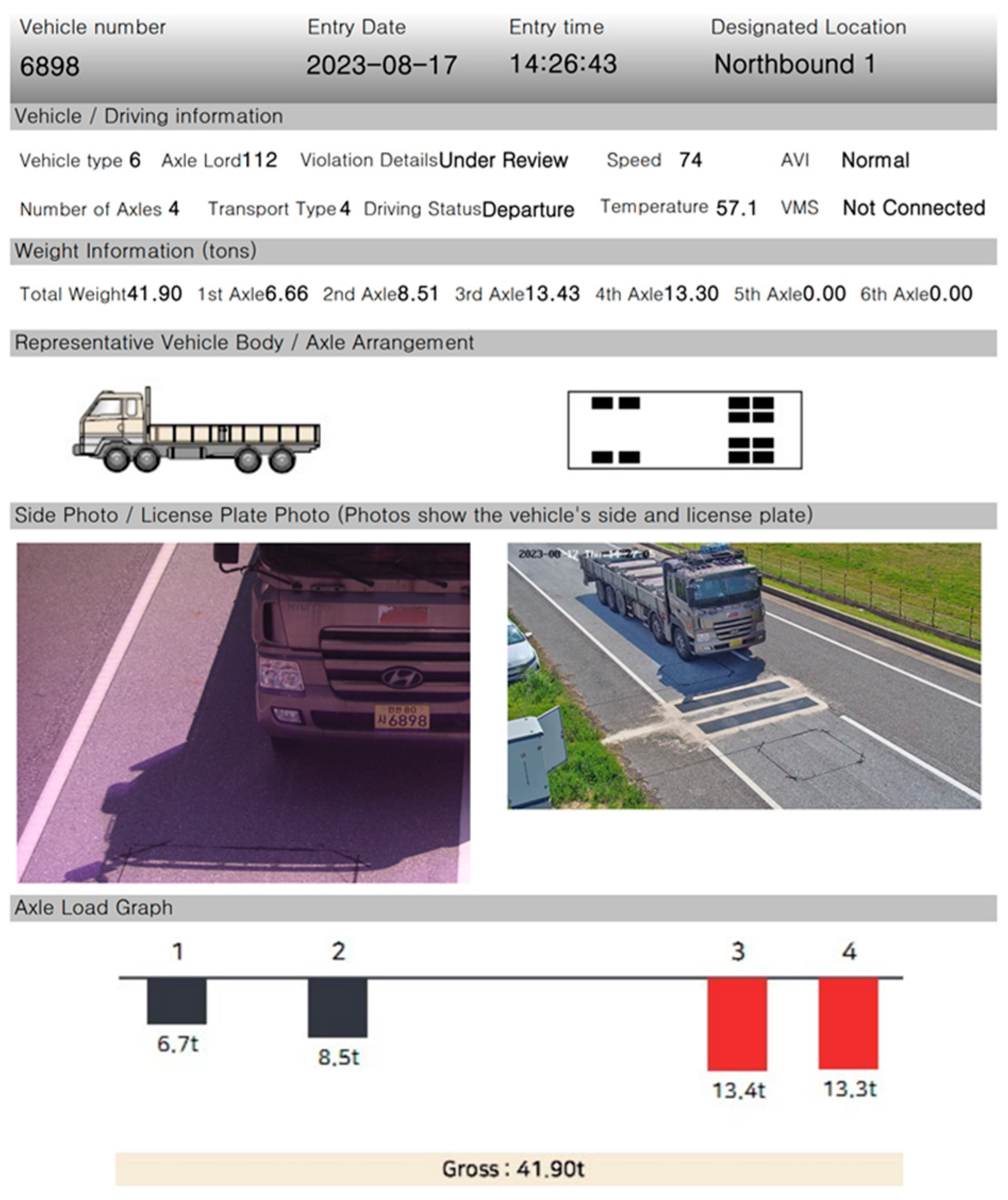

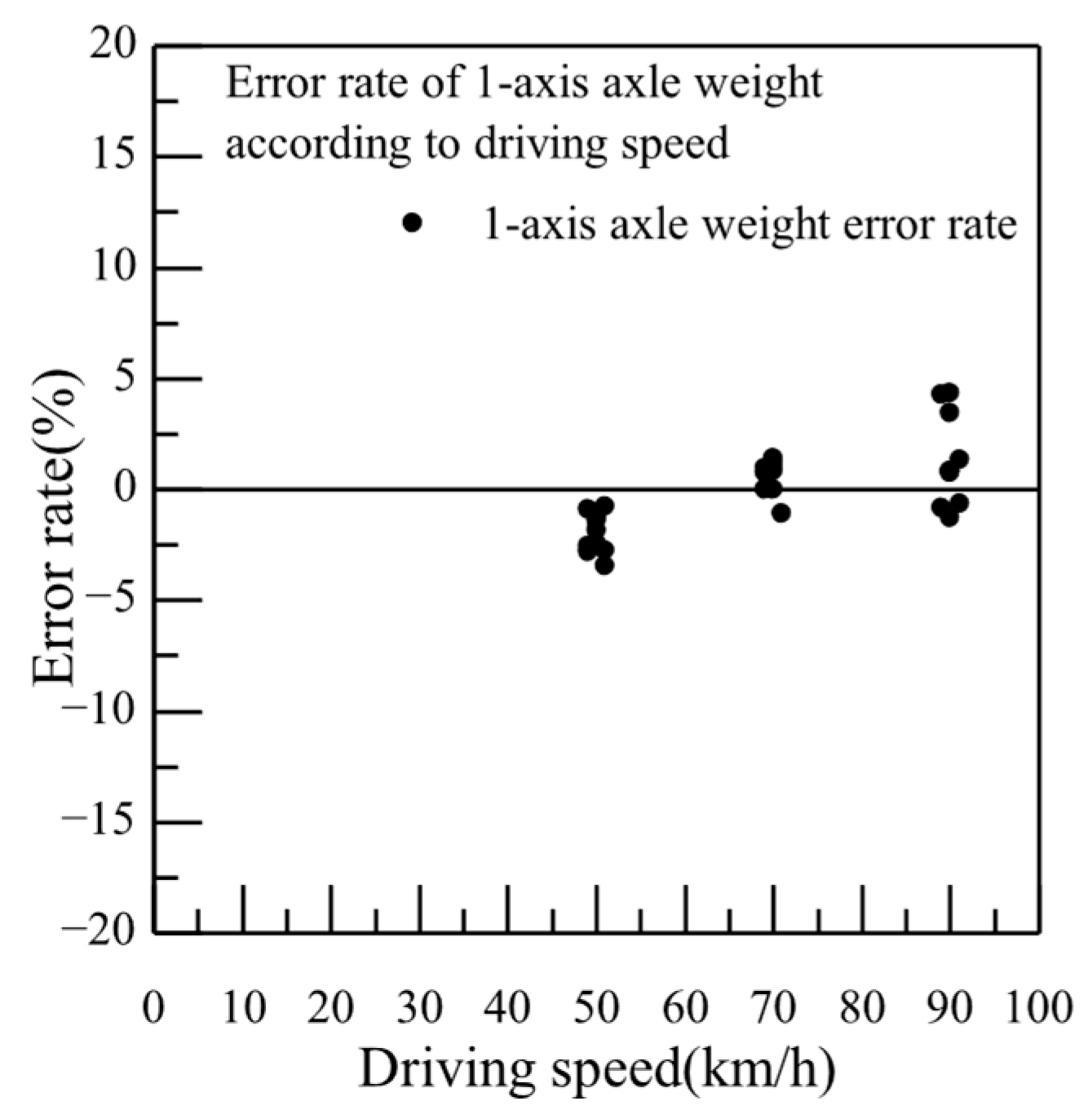

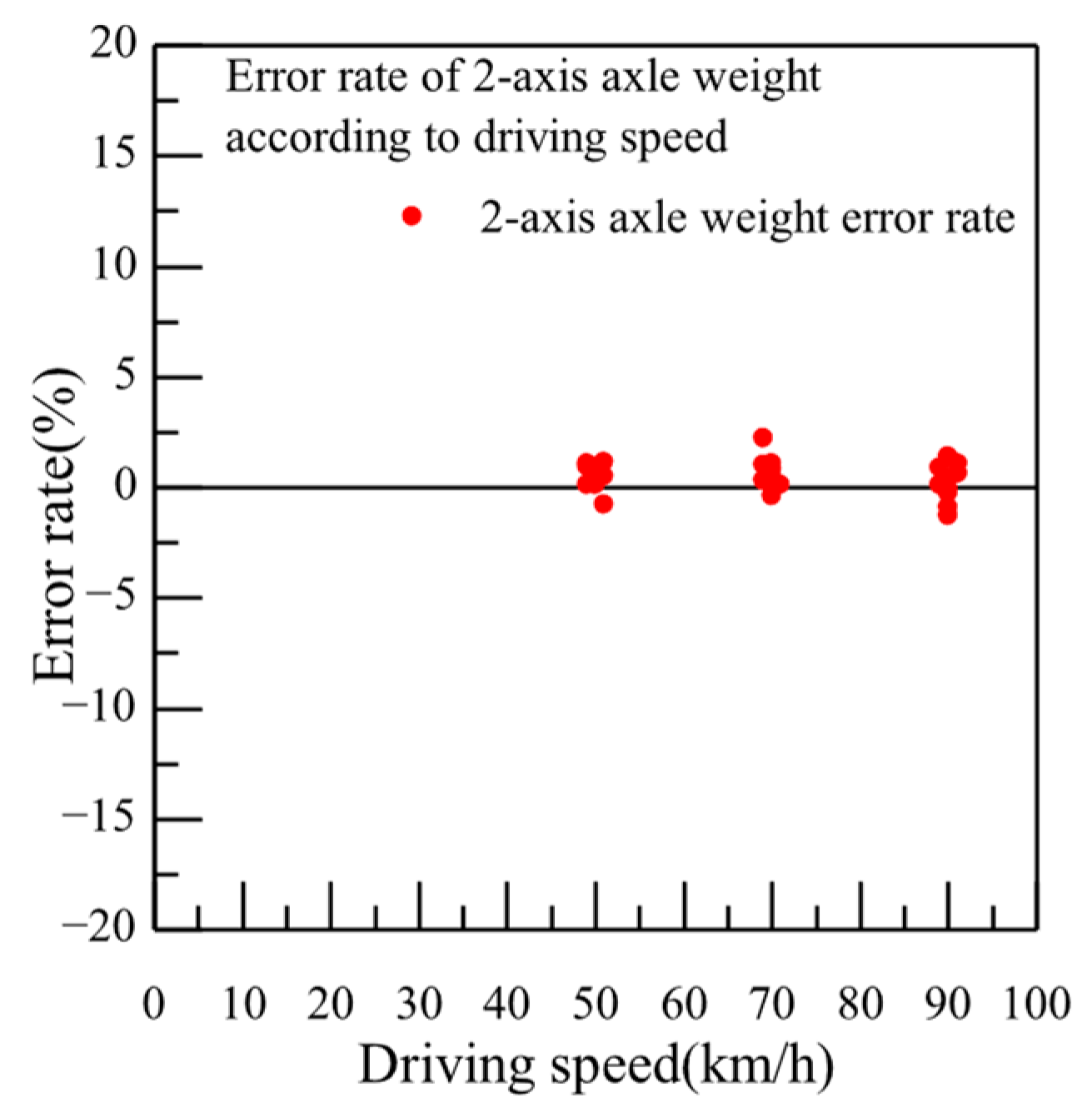

Using the HS-WIM system installed at the testbed (

Figure 5, overloading tests were conducted on cargo vehicles. Real vehicle driving tests were performed to assess basic performance, and indicators such as weight accuracy (total weight and axle load), avoidance driving detection rate, matching accuracy, vehicle number recognition rate, and specification measurement accuracy were evaluated. The results were analyzed by applying the performance evaluation standards outlined in the ITS Performance Evaluation Standards for the Automotive and Road Traffic Sectors.

Additionally, overloading tests considering group driving conditions (

Figure 6 and overloading tests under rain and snow conditions (

Figure 7 were conducted to evaluate HS-WIM performance under various conditions.

Representative results are shown in

Table 14, which summarizes performance evaluation outcomes for a 25-ton cargo truck (7-axle, 5-unit vehicle) under conditions such as 110% load, speeds of 50/70/90 km/h, normal vs. nighttime driving, fair weather, and single-vehicle operation. For weight accuracy, all axles showed over 95% accuracy, achieving the highest grade. For avoidance driving detection, all 10 deliberate lane deviations were correctly identified (100% detection rate). The vehicle number recognition rate was 100%, with all 10 passes correctly recognized. Matching accuracy also reached 100%, as the test vehicle’s number matched the recognized number in all cases. The specification measurement accuracy was 100% for all measured dimensions.

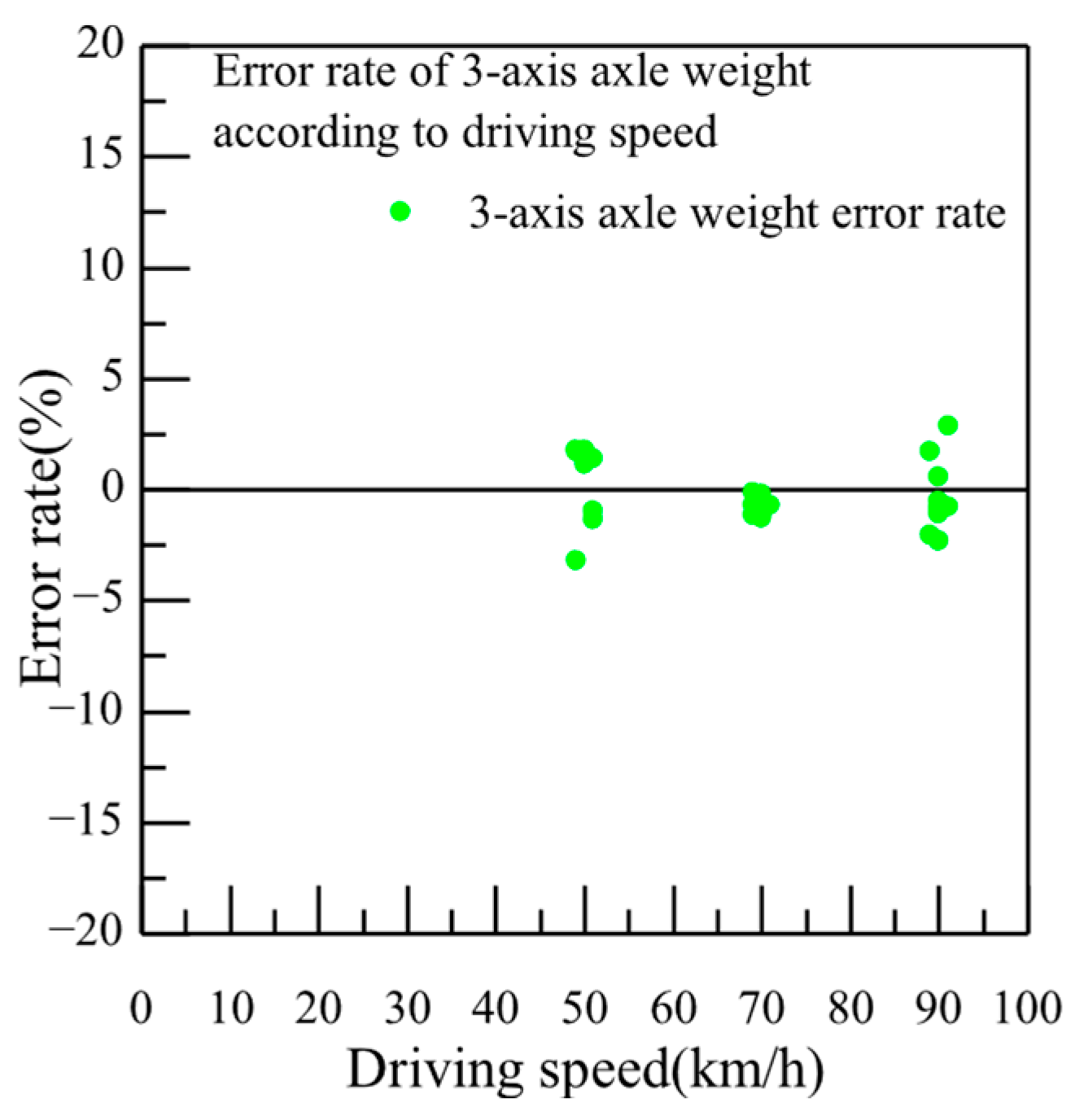

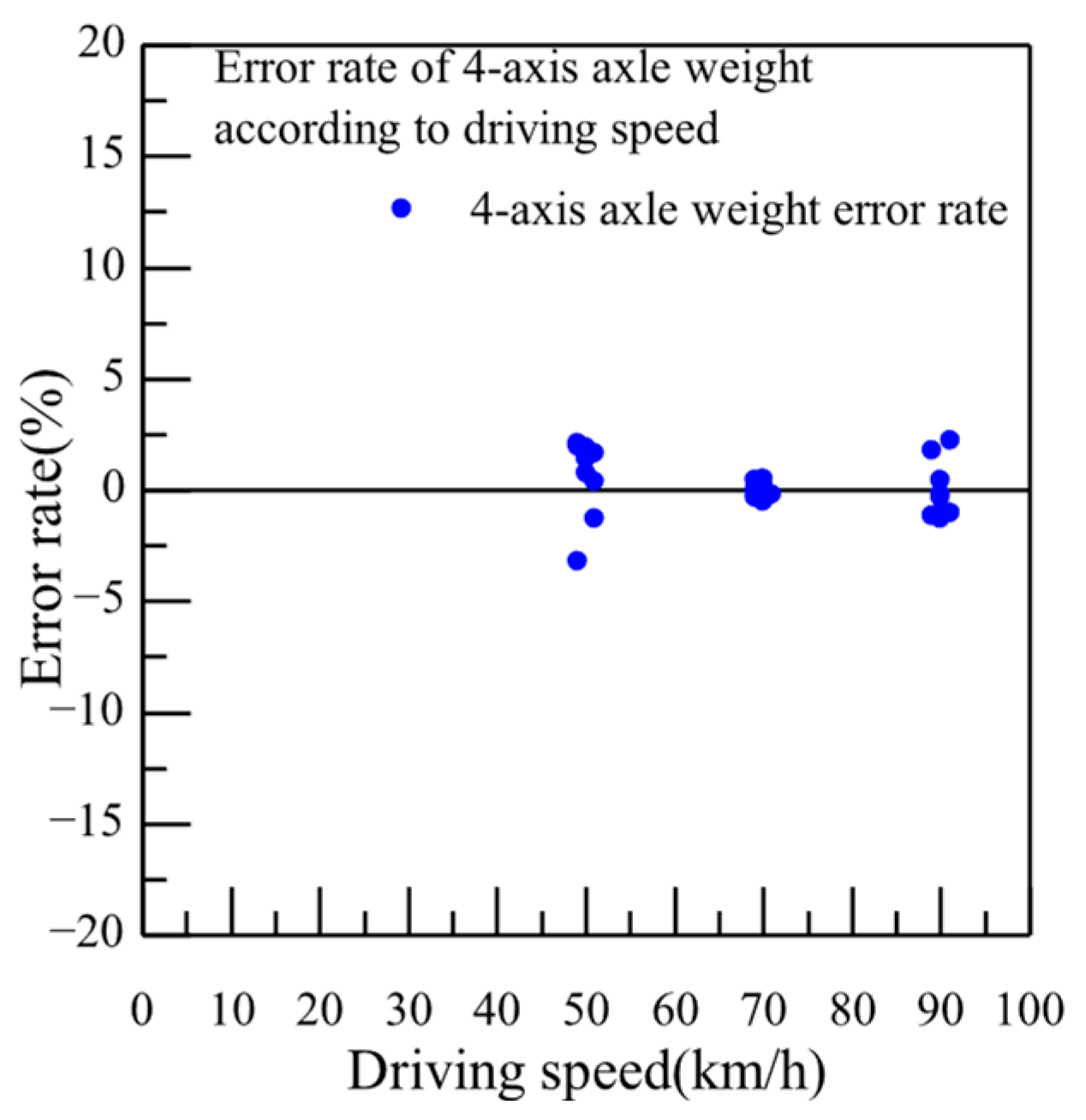

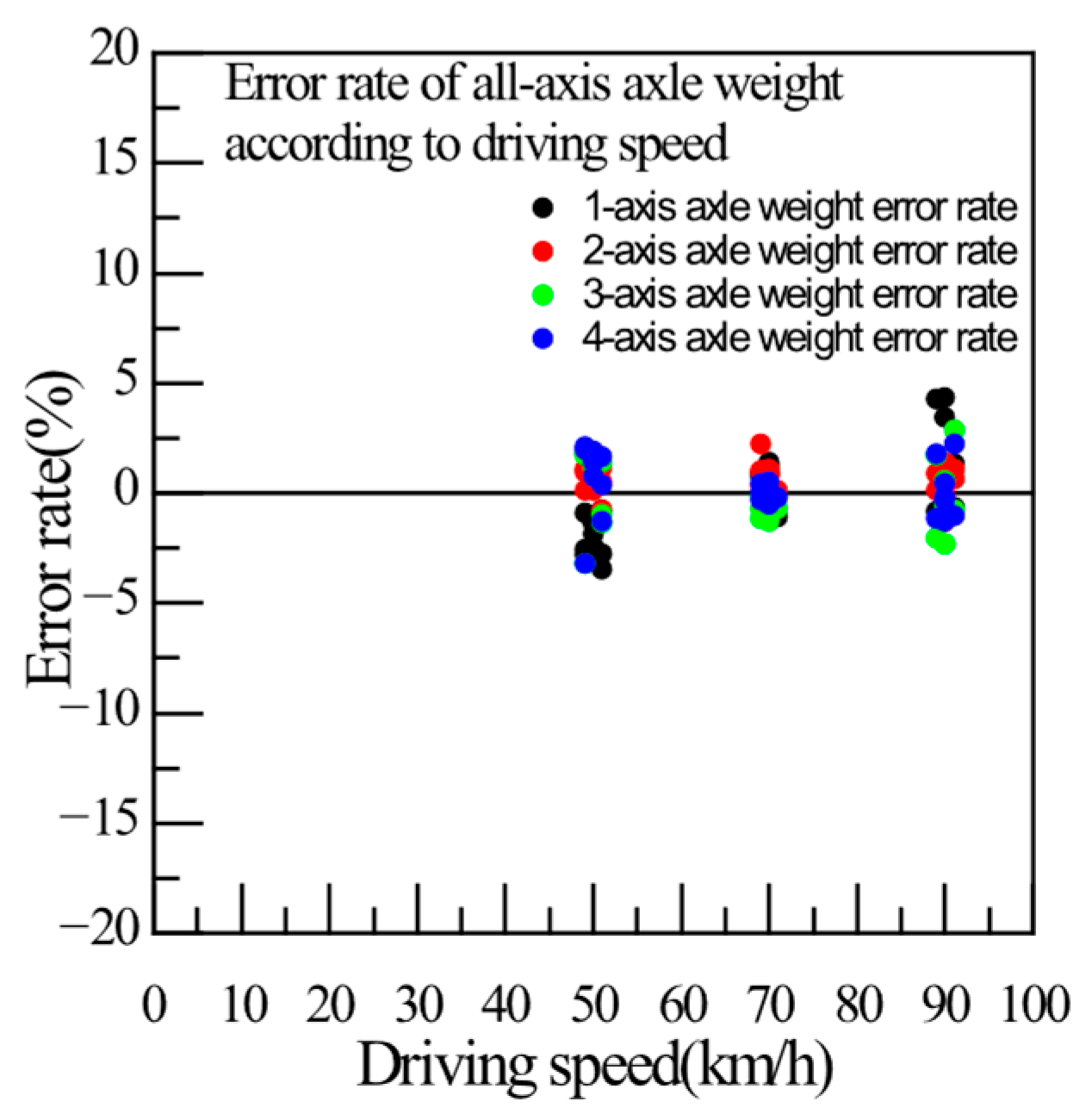

For a more detailed analysis of axle load errors, the measurements are depicted in

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12.

Figure 8 presents the axle load error rate for the first axle under different speed conditions. The maximum error was 3.4% at 50 km/h and 4.3% at 90 km/h, an increase of 0.9% attributed to greater vehicle body vibration at higher speed.

Figure 9 shows the second axle load error rate, which remained within 2.5% across all speeds.

Figure 10 shows the third axle load error rate: 3.2% at 50 km/h, 1.2% at 70 km/h, and 2.8% at 90 km/h. The dip in error at 70 km/h is believed to result from suspension characteristics at that speed.

Figure 11 compares the standard vs. measured axle loads for each axle, and

Figure 12 presents the overall axle load error rates. Overall accuracy was 98.4% for the first axle, 99.2% for the second axle, 98.7% for the third axle, and 99.0% for the fourth axle. The total vehicle weight accuracy was 98.8%, corresponding to the highest performance level.

Based on these results, the effectiveness of the overloading test scenarios using HS-WIM systems for commercial vehicles was confirmed. The scenarios are expected to be highly applicable across various HS-WIM implementations.

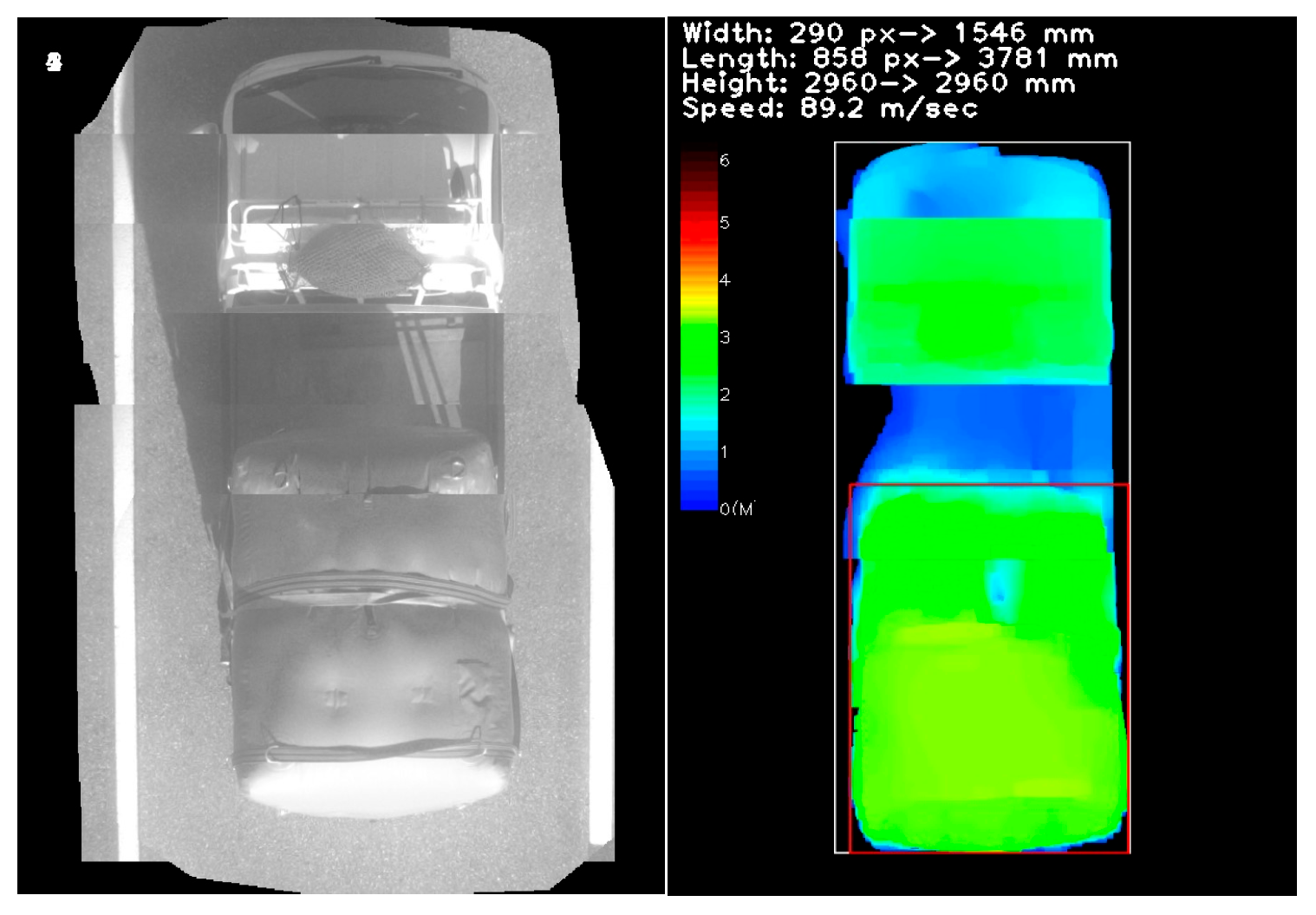

4.2. Improper Loading Test Results

Using the HS-WIM system (

Figure 5), improper loading tests were conducted on cargo vehicles. As shown in

Figure 13, the system measured the specifications of cargo trucks, including the shape and size of the load (height, width, length). To evaluate improper loading detection under various conditions, tests were performed during both day and night, and with single vs. group vehicle scenarios, as shown in

Figure 14.

Representative results from the improper loading tests are summarized in

Table 15. The table provides the performance outcomes for detecting improperly loaded vehicles (e.g., over-height or off-center loads). In these tests, the HS-WIM system correctly identified 100% of instances where loads exceeded legal height or width limits, and it successfully flagged all cases of significant load offset on the vehicle bed. Vehicle identification (plate recognition) remained at 100%, and there were no false positives (vehicles incorrectly flagged as improperly loaded when they were within legal limits).

5. Conclusions

This study developed and validated standardized test procedures for detecting overloading and improper loading in commercial vehicles using a high-speed WIM system, using Korea as a case study. Through designing a dedicated testbed and conducting comprehensive experiments, the following contributions were made:

Establishment of standardized HS-WIM test procedures: We proposed a set of test scenarios and procedures to evaluate HS-WIM system performance in detecting both overloaded and improperly loaded vehicles. These scenarios cover a wide range of conditions (load levels, speeds, driving patterns, weather) and can serve as a framework for evaluating WIM systems in enforcement applications.

Construction of a validated HS-WIM testbed under real-world conditions: We built and utilized a full-scale testbed incorporating road-embedded WIM sensors, AVI cameras, and VPS sensors. The testbed allowed us to simulate enforcement conditions and validate the HS-WIM system’s accuracy and reliability in a controlled yet realistic environment.

Performance evaluation criteria for regulatory development: We proposed quantitative performance criteria (e.g., required accuracy levels, detection rates) based on both domestic standards and international best practices. The findings and criteria from this study can inform national regulations and guidelines for deploying HS-WIM systems in direct enforcement.

Overall, the results demonstrate that a high-speed WIM system, when evaluated and calibrated through the procedures we developed, can reliably identify overloaded and improperly loaded commercial vehicles. The new test procedures and performance metrics introduced in this work provide a foundation for improving enforcement of truck loading regulations, not only in Korea but also in other jurisdictions aiming to adopt advanced WIM technologies for road safety and infrastructure protection.

Future Work: While the developed test scenarios and criteria effectively addressed current gaps (such as group-axle loads and improper loading detection), future studies could explore additional scenarios (e.g., extreme weather or road conditions) and further optimization of sensor fusion algorithms. Collaborative efforts between industry and regulatory bodies will also be important to translate these findings into updated standards and widespread implementation of HS-WIM systems for enhanced enforcement and safety.

Author Contributions

J.-W.J. contributed to conceptualization, formal analysis, investigation, resources, data analysis and visualization. C.-W.C. contributed to conceptualization, methodology, validation, writing—review and editing, supervision, funding acquisition, and project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Korea Agency for Infrastructure Technology Advancement (KAIA) grant funded by the Ministry of Land, Infrastructure and Transport (Grant RS-2022-00142239).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting the reported results, including the questionnaire used in this study, are not publicly available due to privacy concerns and ethical restrictions or proprietary information. However, the data may be made available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jang, S.; Wu, S.; Kim, D.; Song, K.H.; Lee, S.M.; Suh, W. Impact of lowering speed limit on urban transportation network. Appl. Sci. 2022, 12, 5296. [Google Scholar] [CrossRef]

- OECD/ITF. Road Safety Country Profile: Korea 2023; International Transport Forum: Paris, France, 2023.

- Ghisolfi, V.; Ribeiro, G.M.; Chaves, G.D.L.D.; Orrico Filho, R.D.; Hoffmann, I.C.S.; Perim, L.R. Evaluating impacts of overweight in road freight transportation: A case study in Brazil with system dynamics. Sustainability 2019, 11, 3128. [Google Scholar] [CrossRef]

- Gorodnichev, M.G.; Gematudinov, R.A.; Dzhabrailov, K.A.; Potapchenko, T.D. The concept of an automated weight and size control system for measuring the mass of freight vehicles in a traffic flow (Weight-In-Motion). In Proceedings of the 2019 Systems of Signal Synchronization, Generating and Processing in Telecommunications (SYNCHROINFO), Yaroslavl, Russia, 1–3 July 2019; IEEE: New York, NY, USA; pp. 1–5. [Google Scholar]

- Jacob, B.; Cottineau, L.M. Weigh-in-motion for direct enforcement of overloaded commercial vehicles. Transp. Res. Procedia 2016, 14, 1413–1422. [Google Scholar] [CrossRef]

- Burnos, P.; Gajda, J.; Sroka, R.; Wasilewska, M.; Dolega, C. High accuracy weigh-in-motion systems for direct enforcement. Sensors 2021, 21, 8046. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Yang, Z.; Shi, B. Weigh-in-Motion Method Based on Modular Sensor System and Axle Recognition with Neural Networks. Appl. Sci. 2025, 15, 614. [Google Scholar] [CrossRef]

- Hagmanns, M.P.M.; Lamberty, S.; Fazekas, A.; Oeser, M. Enhancing Weigh-in-Motion System Accuracy by Considering Camera-Captured Wheel Oscillations. Sensors 2024, 24, 8151. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Su, J.; Yan, Z.; Gao, Z.; Sun, Y.; Liu, L. Truck model recognition for an automatic overload detection system based on the improved MMAL-Net. Front. Neurosci. 2023, 17, 1243847. [Google Scholar] [CrossRef] [PubMed]

- Tahaei, N.; Yang, J.J.; Chorzepa, M.G.; Kim, S.S.; Durham, S.A. Machine learning of truck traffic classification groups from weigh-in-motion data. Mach. Learn. Appl. 2021, 6, 100178. [Google Scholar] [CrossRef]

- Gajda, J.; Sroka, R.; Burnos, P. Sensor data fusion in multi-sensor weigh-in-motion systems. Sensors 2020, 20, 3357. [Google Scholar] [CrossRef] [PubMed]

- Haider, S.W.; Masud, M.M. Accuracy comparisons between ASTM 1318-09 and COST-323 (European) WIM standards using LTPP WIM data. In Proceedings of the 9th International Conference on Maintenance and Rehabilitation of Pavements—MAIREPAV9, Stockholm, Sweden, 29 June–1 July 2022; Springer: Cham, Switzerland, 2020; pp. 155–165. [Google Scholar]

- Masud, M.M.; Haider, S.W.; Selezneva, O.; Wolf, D.J. Representative Weigh-In-Motion (WIM) System Accuracy and Guidelines for Equipment Selection Based on Sensor, Site, and Calibration-Related Factors. Int. J. Pavement Res. Technol. 2024, 17, 732–749. [Google Scholar] [CrossRef]

- Jacob, B.; O’Brien, E.; Jehaes, S. COST 323: Weigh-in-Motion of Road Vehicles—Final Report; Laboratoire des Ponts et Chaussées: Paris, France, 2002. [Google Scholar]

- OIML R134-1; Automatic Instruments for Weighing Road Vehicles in Motion (OIML Recommendation 134-1). International Organization of Legal Metrology: Paris, France, 2006.

- ASTM E1318-09; Standard Specification for Highway Weigh-in-Motion (WIM) Systems with User Requirements and Test Methods. ASTM International: West Conshohocken, PA, USA, 2017.

- Warscotte, L.; Boreux, J.; Antofie, A.; Corbaye, D. Direct Enforcement in Belgium with High-Speed Weigh-in-Motion (HS-WIM). Electronics 2023, 12, 555. [Google Scholar] [CrossRef]

- Maczyński, A.; Gajda, J.; Burnos, P. A weigh-in-motion system with automatic data reliability estimation. Measurement 2023, 221, 113494. [Google Scholar]

- Jung, Y.; Mizutani, D.; Lee, J. Weigh-In-Motion Placement for Overloaded Truck Enforcement Considering Traffic Loadings and Disruptions. Sustainability 2025, 17, 826. [Google Scholar] [CrossRef]

- Praveena, K.S.; Prajwal, M.; Bhargavi, K.; Darshan, M.R. An automatic overloaded vehicle monitoring and prevention system using iot. In Proceedings of the 2021 International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Bangalore, India, 27 November 2021; IEEE: New York, NY, USA; pp. 788–792. [Google Scholar]

- Nassif, H.; Ozbay, K.; Na, C.; Lou, P.; Demiroluk, S. Development of Advanced Weigh-in-Motion (A-WIM) System for Effective Enforcement of Overweight Trucks to Reduce their Socioeconomic Impact on Major Highways; Connected Cities for Smart Mobility toward Accessible and Resilient Transportation Center (C2SMART): Brooklyn, NY, USA, 2020. [Google Scholar]

- De Ceuster, G.; Breemersch, T.; Van Herbruggen, B.; Verweij, K.; Davydenko, I.; Klingender, M.; Jacob, B.; Arki, H.; Bereni, M. Effects of Adapting the Rules on Weights and Dimensions of Heavy Commercial Vehicles as established within Directive 96/53/EC; European Commission Report; European Union: Brussels, Belgium, 2008.

- Freund, D.M. Motor carrier safety laws and regulations. In The Domain of Truck and Bus Safety Research; Transportation Research Board of the National Academies: Washington, DC, USA, 2007; Volume 25, pp. 1–7. [Google Scholar]

- Godbole, S.; Lam, N.; Muhinadeen, M.M. Vehicle–road interaction analysis for pounding between cargo and trailer-bed. Veh. Syst. Dyn. 2021, 59, 547–567. [Google Scholar] [CrossRef]

Figure 1.

Overload Vehicle Detection Test Procedure. (A). Empty vehicle weight measurement. (B). Incremental load addition. (C). Total vehicle weight measurement. (D). Driving test.

Figure 1.

Overload Vehicle Detection Test Procedure. (A). Empty vehicle weight measurement. (B). Incremental load addition. (C). Total vehicle weight measurement. (D). Driving test.

Figure 2.

Loading defect simulation model. (Illustrates the placement of load blocks to simulate improper loading.).

Figure 2.

Loading defect simulation model. (Illustrates the placement of load blocks to simulate improper loading.).

Figure 3.

Improper Loading Vehicle Detection Test Procedure. (A) Loading of defective models; (B) Shifting load location; (C) Driving test.

Figure 3.

Improper Loading Vehicle Detection Test Procedure. (A) Loading of defective models; (B) Shifting load location; (C) Driving test.

Figure 4.

Overloading Suspected Vehicle Detection System (Depicts the layout of in-road WIM sensors, roadside cameras (AVI), and laser/VPS sensors.).

Figure 4.

Overloading Suspected Vehicle Detection System (Depicts the layout of in-road WIM sensors, roadside cameras (AVI), and laser/VPS sensors.).

Figure 5.

High-Speed Weigh-in-Motion (HS-WIM) System.

Figure 5.

High-Speed Weigh-in-Motion (HS-WIM) System.

Figure 6.

Daytime and Nighttime Overloading Tests Considering Group Driving.

Figure 6.

Daytime and Nighttime Overloading Tests Considering Group Driving.

Figure 7.

Overloading Test Considering Rain and Snow Conditions.

Figure 7.

Overloading Test Considering Rain and Snow Conditions.

Figure 8.

1st Axle Load Error Rate.

Figure 8.

1st Axle Load Error Rate.

Figure 9.

2nd Axle Load Error.

Figure 9.

2nd Axle Load Error.

Figure 10.

3rd Axle Load Error.

Figure 10.

3rd Axle Load Error.

Figure 11.

4th Axle Load Error.

Figure 11.

4th Axle Load Error.

Figure 12.

Total Axle Load Error Rate.

Figure 12.

Total Axle Load Error Rate.

Figure 13.

Poor loading detection.

Figure 13.

Poor loading detection.

Figure 14.

Daytime and Nighttime Considering Group Driving Conditions.

Figure 14.

Daytime and Nighttime Considering Group Driving Conditions.

Table 1.

Overloading Control Standards in Korea.

Table 1.

Overloading Control Standards in Korea.

| Higher Law | Category | Detailed Information |

|---|

| Road Act | Article 71, Paragraph 1 | Vehicles with an axle load exceeding 10 tons or a total weight exceeding 40 tons.

Vehicles with a width exceeding 2.5 m, a height exceeding 4.0 m (4.2 m on designated roads), or a length exceeding 16.7 m.

Vehicles that the road authority deems a particular threat to road structures or traffic safety. |

| Enforcement Decree of the Road Traffic Act | Article 22 | The load capacity of a cargo truck must not exceed 110% of its rated load capacity.

Additionally, the loaded vehicle’s dimensions are restricted to the following limits: length no more than 110% of the vehicle’s length; width within the driver’s rearward field of view (via side mirrors); and height not exceeding 4.0 m from the ground. |

Table 2.

European Cargo Truck Overloading Enforcement Standards (Tons).

Table 2.

European Cargo Truck Overloading Enforcement Standards (Tons).

| Classification | Trailer

(Non-Combination) | Road Train

(Combination) | Articulated Vehicle

(Combination) |

|---|

| 2 axle | 18 | - | - |

| 3 axle | 24 | - | - |

| 4 axle | | 2-axle vehicle + 2-axle trailer: 36 (when axle spacing ≥ 1.3 m and <1.8 m)

2-axle vehicle + 2-axle semi-trailer: 36 (or 38) (when axle spacing ≥ 1.8 m) | 2-axle vehicle + 2-axle semi-trailer: 36 (or 38) (when axle spacing ≥ 1.3 m and <1.8 m

2-axle vehicle + 2-axle semi-trailer: 36 (or 38) (when axle spacing ≥ 1.8 m) |

| 5 axle | 2-axle vehicle + 3-axle trailer: 40 (or 42) | 3-axle vehicle + 2-axle semi-trailer: 40 (or 44) |

| 6 axle | 3-axle vehicle + 3-axle trailer: 40 (or 44) | 3-axle vehicle + 3-axle semi-trailer: 40 (or 44) |

Table 3.

European Cargo Truck Tandem/Tridem Axle Load Standards (Tons).

Table 3.

European Cargo Truck Tandem/Tridem Axle Load Standards (Tons).

Axle Spacing

(d) | Tandem Axle Load | Axle Spacing

(d) | Tridem Axle Load | Single Axle Load |

|---|

| d > 1.0 m | 11 | d ≥ 1.3 m | 21 | Non-drive axle: 10 tons Drive axle: 11.5 tons

(Regardless of axle spacing) |

| 1.0 m ≤ d < 1.3 m | 16 |

| 1.3 m ≤ d < 1.8 m | 18 | d > 1.3 m and ≤1.4 m | 24 |

| d ≥ 1.8 m | 20 | d > 1.4 m |

Table 4.

Cargo Truck Overloading Enforcement Standards (Tons).

Table 4.

Cargo Truck Overloading Enforcement Standards (Tons).

| Classification | Federal Weight Standards | State-Specific Weight Standards |

|---|

| Louisiana | California | Alabama | Minnesota |

|---|

| Gross Vehicle Weight (GVW) | 36.29 | 36.29

(or 37.82, 39.92) | 36.29

(or 34.84) | 36.29

(or 38.1) | 36.29 |

| Single axle load | 9.07 | 9.07

(or 8.16) | 9.07

(or 8.16, 5.67) | 9.07 | 9.07

(4.54 per single tire) |

| Tandem axle load | 15.42 | 15.42

(or 15.24) | 15.42

(or 15.24) | 15.42

(or 16.33) | 15.42 |

Table 5.

Performance Standards by Evaluation Grade for HS-WIM in Korea.

Table 5.

Performance Standards by Evaluation Grade for HS-WIM in Korea.

| Evaluation Criteria | Weight Accuracy (%) | Avoidance Driving Detection Rate (%) | Vehicle Number Recognition Rate (%) | Matching Accuracy |

|---|

| Total Weight | Axle Load |

|---|

| Evaluation grade | Highest grade | ≥95% | ≥90% | ≥90% | ≥95% | 100% |

High

grade | 95>, ≥93 | 90>, ≥85 | 90>, ≥80% | 95>, ≥85% | 100% |

| Medium grade | 93>, ≥90 | 85>, ≥80 | - | 85>, ≥80% | - |

| Lower-medium grade | <90% | <80% | - | <80% | - |

Table 6.

Number of Tests per Lane for Weight Accuracy Evaluation in Korea.

Table 6.

Number of Tests per Lane for Weight Accuracy Evaluation in Korea.

| Classification | Vehicle Type | Evaluation Type |

|---|

| Basic | Completion/Regular/Modification/Relocation |

|---|

| Number of tests | 3-axle, 1-unit | 10 | - |

| 4-axle, 1-unit | 10 | - |

| 5-axle, 1-unit (with variable axle) | 10 | 10 |

| 5-axle, 2-unit | 10 | 10 |

| Total number of tests | 40 | 20 |

Table 7.

Performance Evaluation Grades for HS-WIM in Korea.

Table 7.

Performance Evaluation Grades for HS-WIM in Korea.

| Accuracy Grade | Utilization Plan |

|---|

| Class A(5) | Can be utilized for institutional purposes related to weight limits and other relevant enforcement.

Can be used as a reference to verify loads measured by HS-WIM systems of grade A(5) or lower. |

| Class B+(7) | Can be used for enforcement in cases where the accuracy of grade A is not met, provided legal authority is granted.

Can be used as a reference to verify loads measured by HS-WIM systems of grade B+(7) or lower. |

| Class B(10) | Collected data can be used for the design, maintenance, and evaluation of road pavements and bridge structures (e.g., to assess infrastructure aging and schedule replacements).

Useful for estimating excess weight on axles and for precise vehicle classification based on load. |

Table 8.

Vehicle Types Classification in Korea.

Table 8.

Vehicle Types Classification in Korea.

| Vehicle Class | Vehicle Type & Description | Axle Configuration

(Description) |

|---|

| 1 Class | Passenger cars and mini trucks,

2-axle unit | Small car with 2 axles |

| 2 Class | Buses with 16+ seats, 2-axle unit | Bus with 2 axles |

| 3 Class | Trucks under 2.5 tons, 2-axle unit | Light truck with 2 axles |

| 4 Class | Trucks between 2.5 and 8.5 tons,

2-axle unit | Medium-sized truck with 2 axles |

| 5 Class | 3-axle unit trucks | Heavy truck with 3 axles |

| 6 Class | 4-axle unit trucks | Truck with 4 axles |

| 7 Class | 5-axle unit trucks | Large truck with 5 axles |

| 8 Class | 4-axle semi-trailers, 2-unit vehicles | Semi-trailer with 4 axles

(two units) |

| 9 Class | 4-axle full trailers, 2-unit vehicles | Full trailer with 4 axles

(two units) |

| 10 Class | 5-axle semi-trailers, 2-unit vehicles | Semi-trailer with 5 axles |

| 11 Class | 5-axle full trailers, 2-unit vehicles | Full trailer with 5 axles |

| 12 Class | 6-axle or more semi-trailers,

2-unit vehicles | Semi-trailer with 6 axles or more |

Table 9.

Performance Evaluation Standards for HS-WIM in Europe.

Table 9.

Performance Evaluation Standards for HS-WIM in Europe.

| Classification | Accuracy Grade: Allowable Range of Confidence Interval δ (%) |

|---|

| A(5) | B+(7) | B(10) | C(15) | D+(20) | D(25) | E |

|---|

| Total weight | 5 | 7 | 10 | 15 | 20 | 25 | >25 |

| Combined axle | 7 | 10 | 13 | 18 | 23 | 28 | >28 |

| Single axle | 8 | 11 | 15 | 20 | 25 | 30 | >30 |

| Single axle within a combined axle | 10 | 14 | 20 | 25 | 30 | 35 | >35 |

| Speed | 2 | 3 | 4 | 6 | 8 | 10 | >10 |

Axle distance

(Axle spacing) | 2 | 3 | 4 | 6 | 8 | 10 | >10 |

| Total flow | 1 | 1 | 1 | 3 | 4 | 5 | >5 |

Table 10.

Current Evaluation Criteria for High-Speed Weigh-in-Motion (HS-WIM) Systems in Korea and Abroad. (○ = applicable, × = not included in criteria.)

Table 10.

Current Evaluation Criteria for High-Speed Weigh-in-Motion (HS-WIM) Systems in Korea and Abroad. (○ = applicable, × = not included in criteria.)

| Evaluation Item | Korea ITS | COST 323 | OIML R134 | ASTM E1318 |

|---|

| Total weight measurement | ○ | ○ | ○ | ○ |

| Wheel (single axle) weight | × | × | × | ○ |

| Axle load measurement | ○ | ○ | ○ | ○ |

| Group-axle load measurement | × | ○ | ○ | ○ |

| Single axle within group | × | ○ | × | × |

Table 11.

Overloading Condition Test Scenarios.

Table 11.

Overloading Condition Test Scenarios.

| Parameter | Condition |

|---|

| Load weight | 0%, 50%, 100%, 110% |

| Speed | 50 km/h, 70 km/h, 90 km/h |

| Driving pattern | Normal driving (centered), Eccentric driving (driver-side wheel on the edge) |

| Weather | Normal, Snowfall, Rainfall |

| Group driving | Single vehicle, Same vehicle type, Combination vehicle type |

| Number of repetitions | 10 times |

Table 12.

Improper Loading Condition Test Scenarios.

Table 12.

Improper Loading Condition Test Scenarios.

| Parameter | Condition |

|---|

| Load type | Height exceeding 4.0 m, Length exceeding 16.7 m, Width exceeding 2.5 m |

| Speed | 50 km/h, 70 km/h, 90 km/h |

| Driving pattern | Normal driving (centered), Eccentric driving (driver-side wheel on the edge), Deviation driving (driver-side wheel off the lane) |

| Sunlight conditions | Daytime |

| Group driving | Single vehicle, Same vehicle type, Combination vehicle type |

| Number of repetitions | 10 times |

Table 13.

Specification Data Measurable by Vehicle Specification Measurement Sensor Types.

Table 13.

Specification Data Measurable by Vehicle Specification Measurement Sensor Types.

| Sensor Type | Classification | Detailed Specification Name |

|---|

Road-embedded Contact Sensors

![Applsci 15 11928 i001 Applsci 15 11928 i001]() | Weight Information | Axle load, total weight, combined axle weight, wheel load |

| Axle Information | Number of axles, axle configuration, wheel type |

| Vehicle Information | Vehicle type |

| Length Information | Vehicle length, axle spacing, wheelbase, overhang |

| Driving Information | Speed, acceleration, driving pattern (partial) |

Non-contact Sensors Installed on Pole Structures

![Applsci 15 11928 i002 Applsci 15 11928 i002]() | Vehicle Information | Vehicle number |

| Driving Information | Driving pattern |

| Volume Information | Vehicle length, width, height |

Table 14.

Summary of HS-WIM Performance Test Results for 25-ton Cargo Truck.

Table 14.

Summary of HS-WIM Performance Test Results for 25-ton Cargo Truck.

| Evaluation Criteria | Classification

Total Weight (Gross) | Details

Driving (Times) | 1-Unit Vehicle | Accuracy

(%) |

|---|

| 50 km | 70 km | 90 km |

|---|

| Weight accuracy | 1st axle load (AOW)

2nd axle load (AOW)

3rd axle load (AOW) | Max (%) | 10 | 10 | 10 | 98.7 |

| Min (%) | 0.5 | 1.1 | 1.1 |

| Driving (times) | −0.8 | 0.2 | −0.4 |

4th axle load (AOW)

Vehicle number recognition

Matching accuracy | Max (%) | 10 | 10 | 10 | 96.6 |

| Min (%) | −0.9 | 1.4 | 4.1 |

| Driving (times) | −3.4 | −1.1 | −1.0 |

Avoidance driving detection

Classification | Max (%) | 10 | 10 | 10 | 97.6 |

| Min (%) | 1.1 | 2.3 | 1.4 |

| Driving (times) | −0.7 | −0.4 | −1.3 |

Total weight (Gross)

1st axle load (AOW)

2nd axle load (AOW) | Max (%) | 10 | 10 | 10 | 97.3 |

| Min (%) | 1.1 | −0.1 | 2.8 |

| Driving (times) | −3.2 | 1.1 | −2.1 |

3rd axle load (AOW)

4th axle load (AOW)

Vehicle number recognition | Max (%) | 10 | 10 | 10 | 96.9 |

| Min (%) | 1.9 | 0.5 | 2.2 |

| Driving (times) | −3.0 | −0.5 | −1.2 |

Vehicle number recognition

Avoidance driving detection (Deviation)

Vehicle number recognition | Matching accuracy

Avoidance driving detection | Detection (times) | 10 | 10 | 10 | 100 |

| Driving (times) | 10 | 10 | 10 |

| Specification measurement accuracy Classification | Mismatch (times) | 10 | 10 | 10 | 100 |

| Driving (times) | 0 | 0 | 0 |

| Avoidance driving detection (Deviation) | Total weight (Gross)

1st axle load (AOW) | Detection (times) | 10 | 10 | 10 | 100 |

| Driving (times) | 10 | 10 | 10 |

| Vehicle number recognition | 2nd axle load (AOW) | Detection (times) | 10 | 10 | 10 | 100 |

| Details | 10 | 10 | 10 |

Table 15.

Summary of Improper Loading Detection Performance Evaluation Test Results (7-class, 5-axle, 1-unit Vehicle).

Table 15.

Summary of Improper Loading Detection Performance Evaluation Test Results (7-class, 5-axle, 1-unit Vehicle).

Evaluation Criteria

Improper Loading Detection | Classification

Height Exceeding 4.0 m | Details

Driving (Times) | 5-Class, 3-Axle,

1-Unit Vehicle | Accuracy (%) |

|---|

| 50 km | 70 km | 90 km |

|---|

Vehicle number recognition

Evaluation criteria

Improper loading Detection

Vehicle number recognition | Length exceeding 16.7 m

Width exceeding 2.5 m | Detection rate(%) | 10 | 10 | 10 | 100 |

Driving

(times) | 100 | 100 | 100 |

Vehicle number recognition

Matching accuracy | Detection rate (%) | 10 | 10 | 10 | 100 |

Driving

(times) | 100 | 100 | 100 |

Avoidance driving detection

Classification | Detection rate (%) | 10 | 10 | 10 | 100 |

Driving

(times) | 100 | 100 | 100 |

Evaluation criteria

Improper loading Detection

Vehicle number recognition | Height exceeding 4.0 m

Length exceeding 16.7 m | Detection

(times) | 10 | 10 | 10 | 100 |

Driving

(times) | 10 | 10 | 10 |

Width exceeding 2.5 m

Vehicle number recognition | Mismatch

(times) | 10 | 10 | 10 | 100 |

Driving

(times) | 0 | 0 | 0 |

| Evaluation criteria | Matching accuracy | Detection

(times) | 10 | 10 | 10 | 100 |

| Details | 10 | 10 | 10 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).