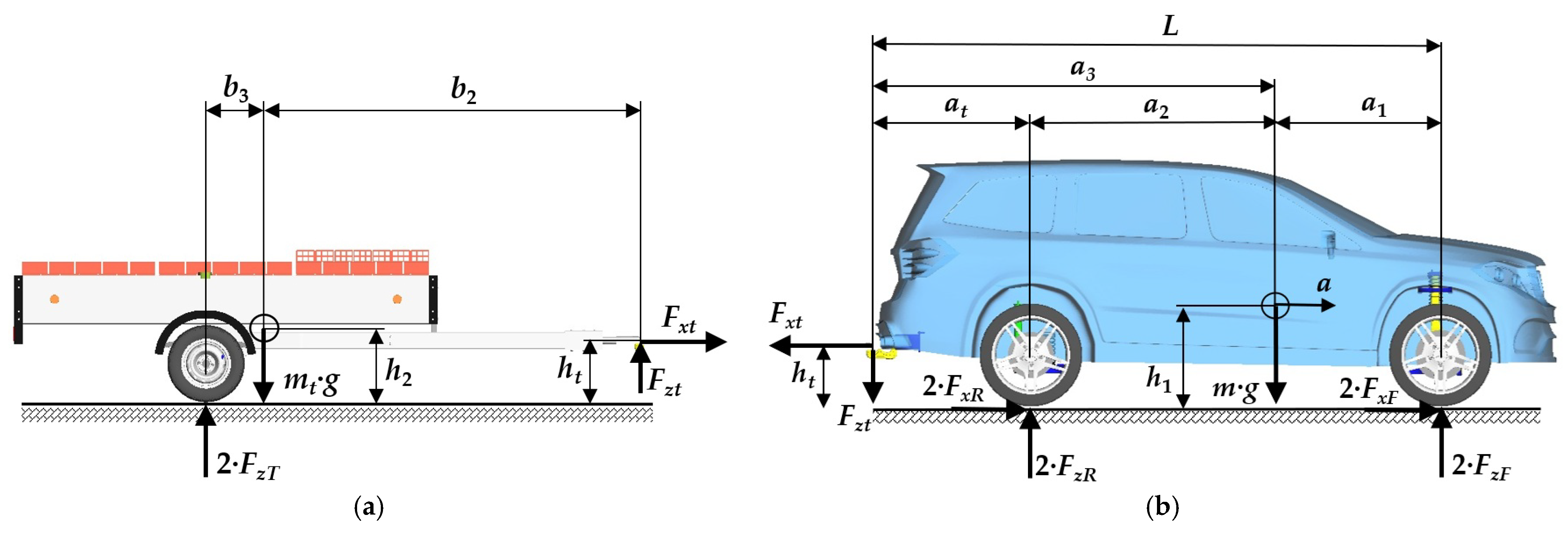

In this section, the research results of the simulation computations of the SUV–trailer driving for the chosen driving maneuvers are presented. Namely, two driving maneuvers were investigated:

The research results are presented in a form of graphs supplemented with illustrations of the SUV–trailer combination in an important time moment. Both driving maneuvers are assessed based on the SUV–trailer combination response for different loading conditions of the trailer.

4.1. Driving the SUV–Trailer Combination While Bypassing an Obstacle on a Lane—Maneuver A

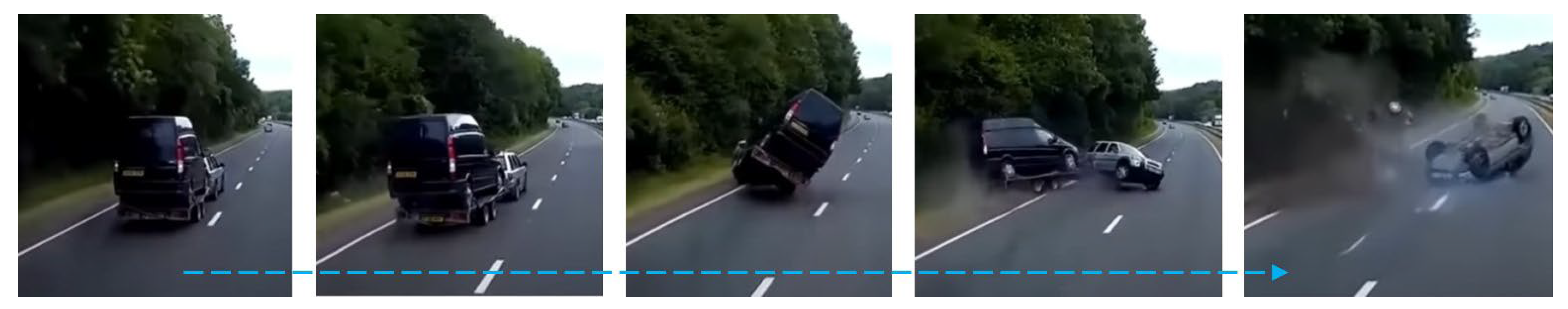

Sudden bypassing of an obstacle on a road lane can be dangerous for a sole car while no trailer is towed. However, when a car tows a trailer (even a loaded trailer), such bypassing of an obstacle can be more dangerous. This is mainly due to the more difficult maneuverability of the car-trailer combination and due to the combination braking (the braking distance is longer).

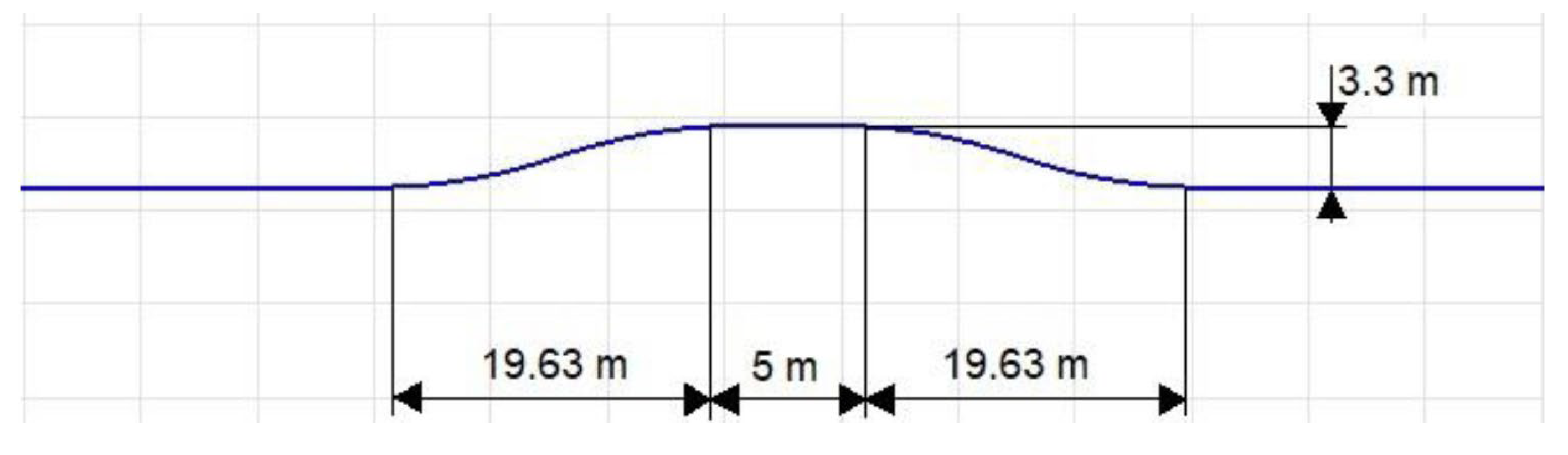

The track geometry for the maneuver was derived from the road geometry for the moose test. The moose test is a driving maneuver that came to public attention in 1997 [ISO 3888-2] [

41]. As the car–trailer combination is not examined only as a sole car, the parameters of the road geometry are slightly changed. This is obvious from

Figure 15 and

Figure 16, where

Figure 15 depicts the track geometry for the moose test and

Figure 16 shows the geometry used in the simulation computations.

Three driving cases were evaluated for the Maneuver A, namely:

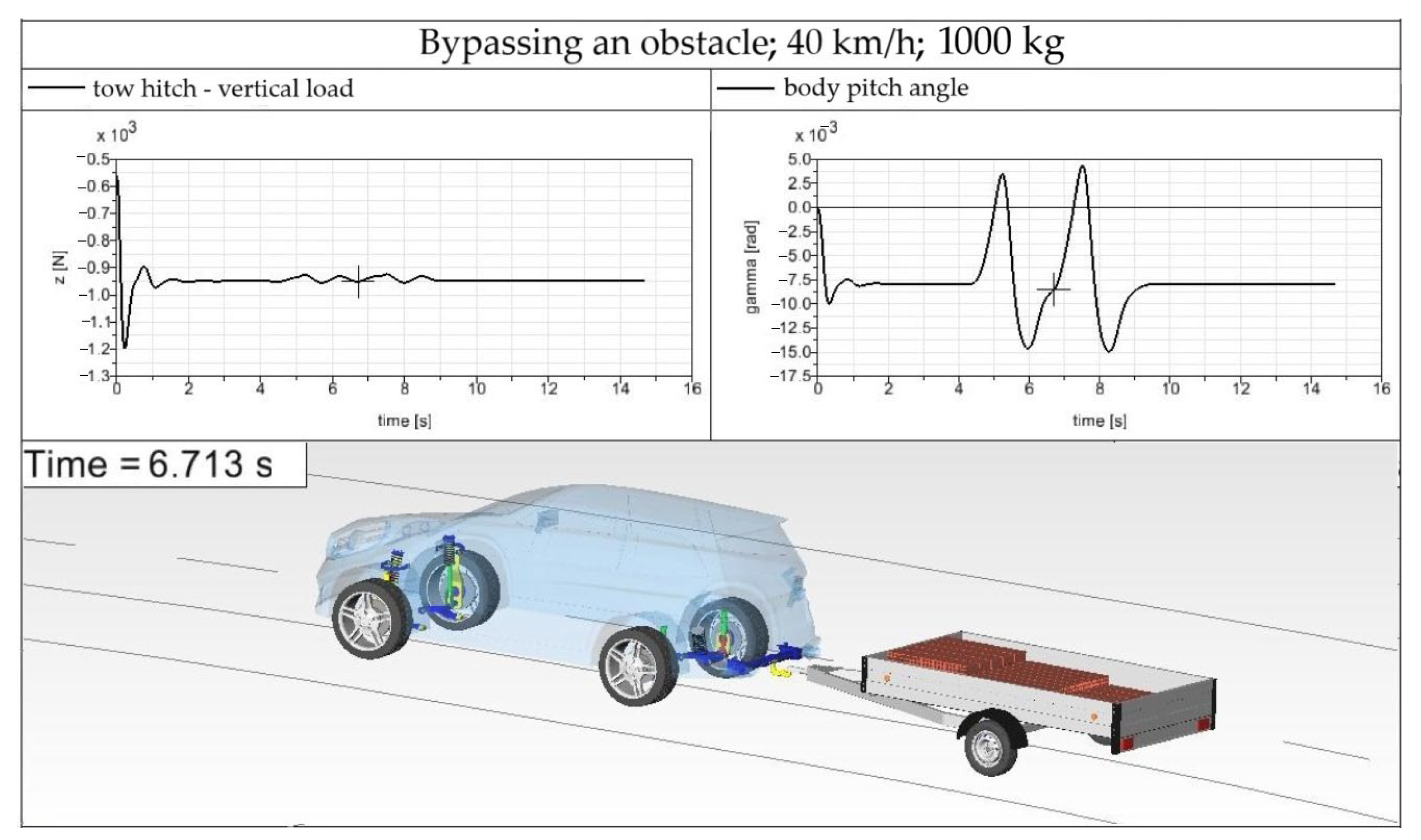

Case 1: the driving speed of 40 km/h, the load of 1000 kg;

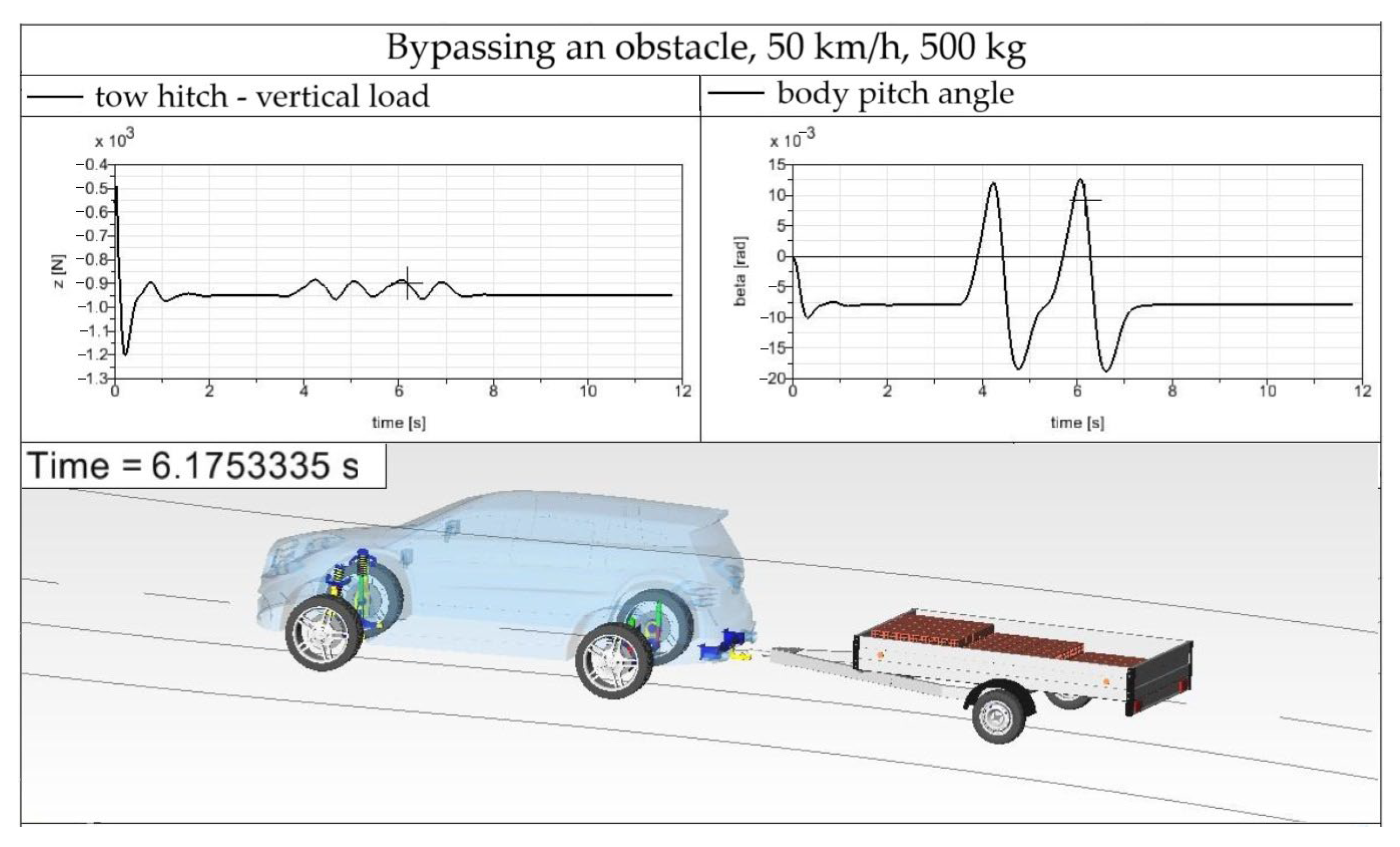

Case 2: the driving speed of 50 km/h, the load of 500 kg;

Case 3: the driving speed of 55 km/h, the load of 500 kg.

These driving cases are evaluated based on the criteria listed in

Table 1.

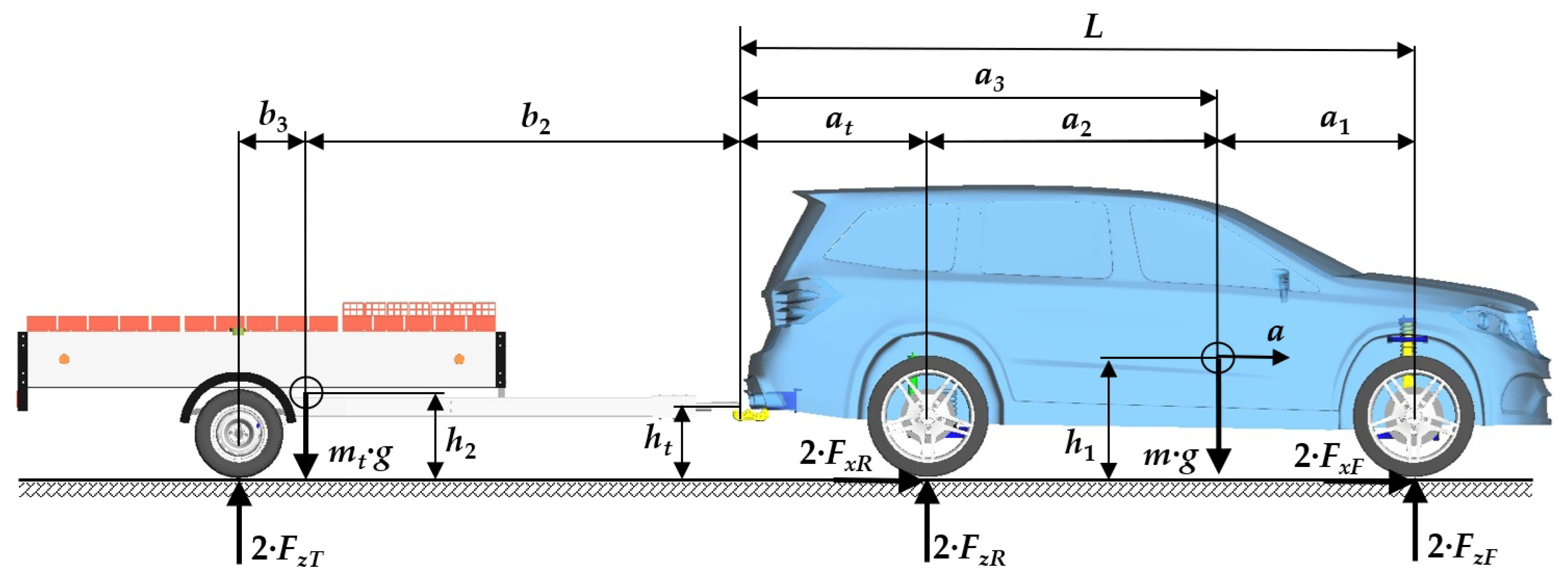

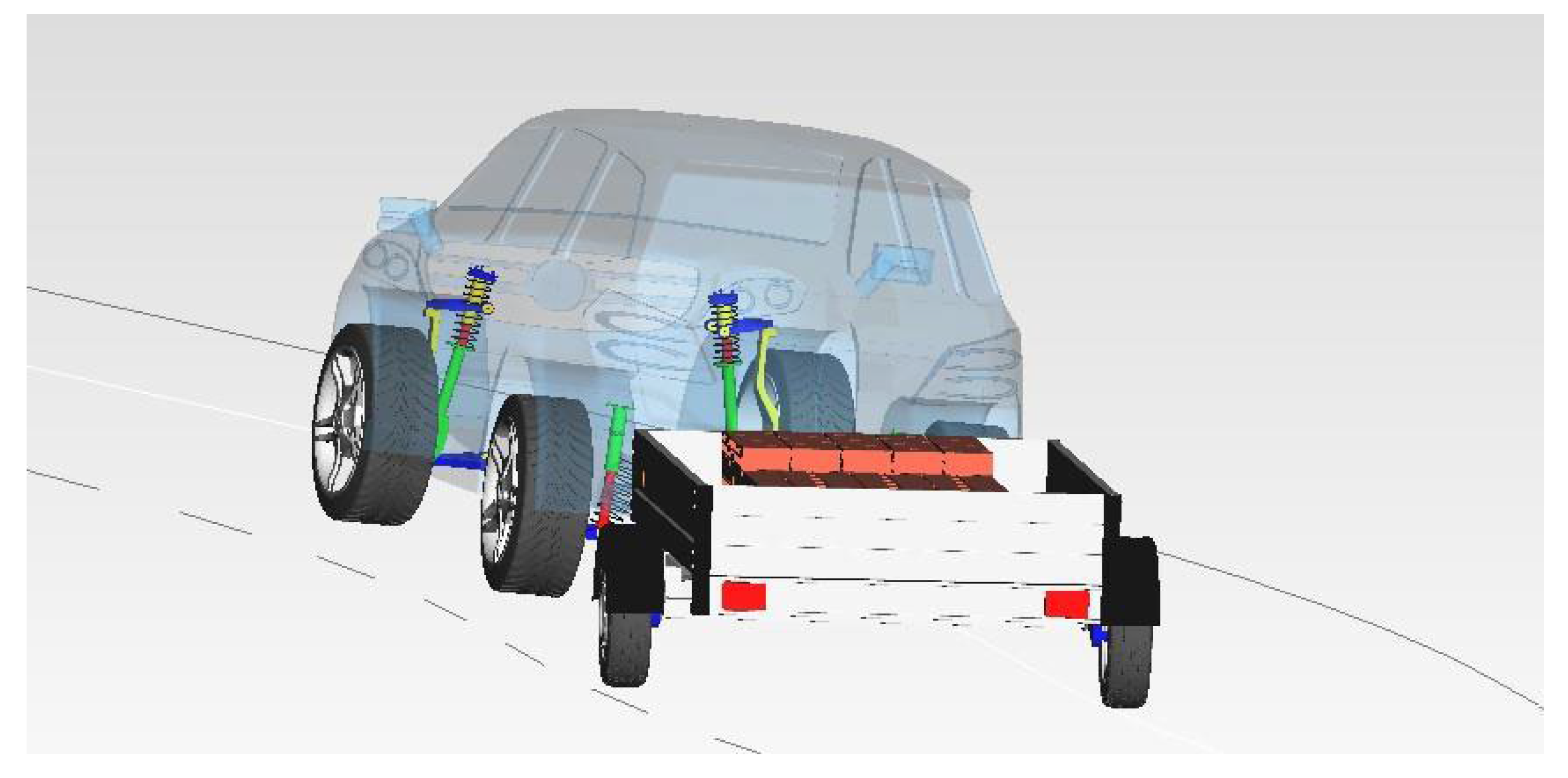

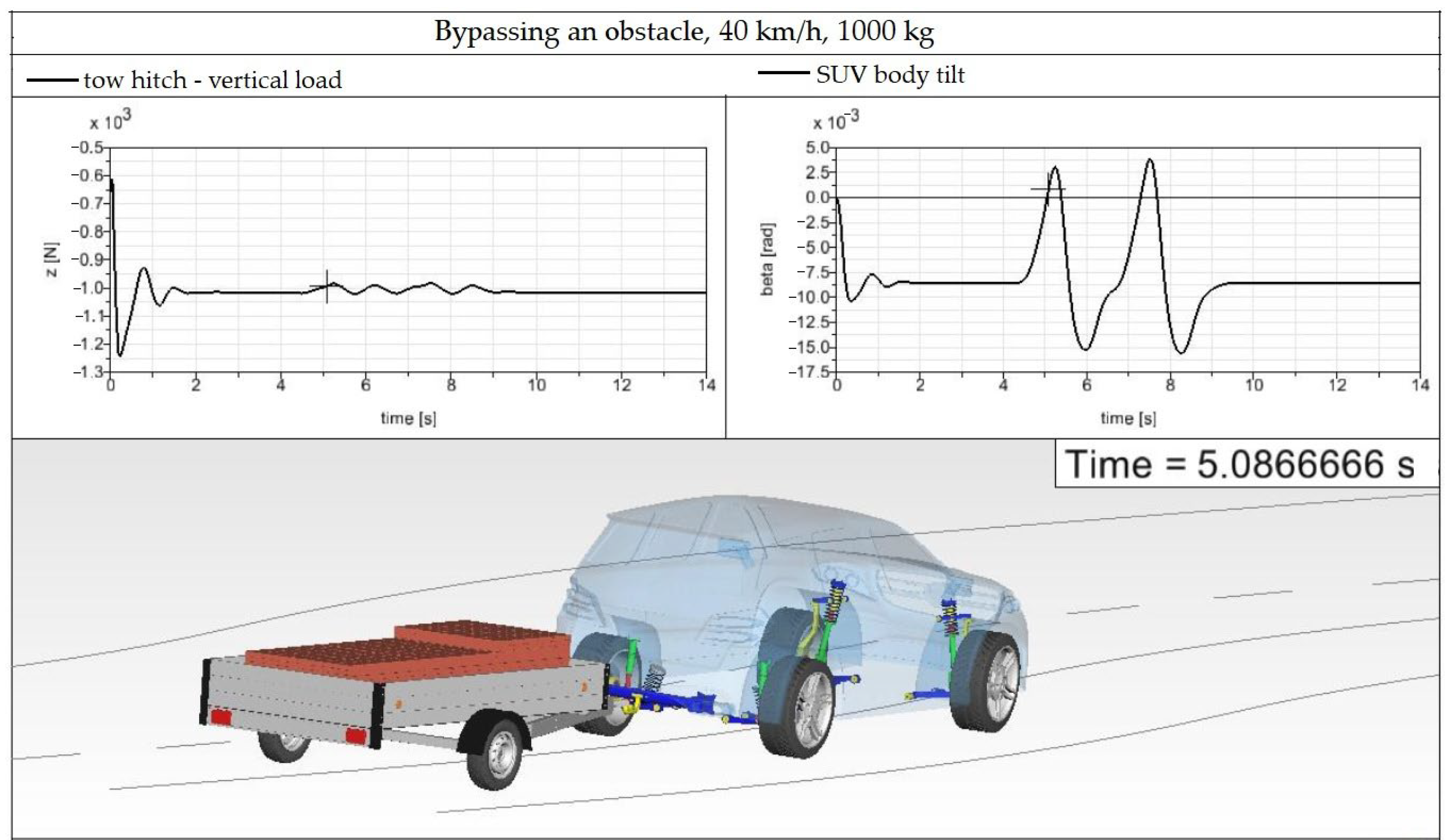

This driving maneuver serving for investigation of the SUV–trailer combination while bypassing an obstacle on a road lane was performed for the driving speed of 40 km/h and the trailer was loaded by the load of 500 kg (a half of the trailer payload). Firstly, the correctness of the load distribution on the trailer loading area is verified. The aim is to find out that the maximal load of the tow hitch in the vertical direction is not exceeded. The driving maneuver is shown in

Figure 17.

The left graph in

Figure 17 depicts the waveform of the vertical load of the tow hitch. The load is 1000 N in the straight road section as well as in a curve (the load has negative values because it acts in the negative direction of the

z-axis, but the absolute value is considered). With the gravitational acceleration of 9.81 m/s

2, the value of 1000 N means the vertical load of the tow hitch is 101.937 N. The maximal permissible load of the tow hitch is 140 kg, i.e., 1373.4 N. This means that the tow hitch is not overloaded, and the load is properly distributed on the trailer loading area.

The right graph of

Figure 17 shows the body pitch angle of the SUV. It is possible to calculate how the trailer load acts on the SUV body, i.e., to calculate the SUV body inclination. During the steady driving, the SUV body is declined by an angle of 0.008 rad (0.4584°). The declination of the rear part of the SUV body is 12.3 mm. During the bypassing of the road obstacle, the SUV body declines by the value of 23.1 mm.

The SUV–trailer combination bypasses the obstacle safely; no skidding is detected.

When the SUV–trailer combination drives this maneuver at a driving speed of 50 km/h, the SUV body’s declination is 28.4 mm. The results are shown in

Figure 18.

The vertical load of the tow hitch is still the same as in the previous driving speed of 40 km/h. The driving maneuver is safe. The left graph in

Figure 18 shows the vertical load of the tow hitch, and the right graph depicts the SUV body pitch for 50 km/h and a trailer load of 500 kg.

When the driving speed is increased to 55 km/h, the evaluated output parameters of the SUV–trailer combination change and are depicted in

Figure 19. The maximal vertical load of the tow hitch is still the same as for the driving speeds of 40 km/h and 50 km/h, or it changes only minimally. The driving speed of 55 km/h is evaluated as the limit speed, at which the car-trailer combination bypasses the road obstacle safely. Higher driving speeds cause skidding, as also follows from

Figure 19. The body pitch angle has a maximal value of 0.0208 rad, which leads to the body declination of 32 mm. As is common for SUVs and it is caused by their design (a higher position of the center of gravity), the examined SUV car also leans in a curve. The body roll angle of the SUV for the driving speed of 55 km/h is shown in

Figure 19. The biggest roll angle of 0.092 rad is detected during bypassing of the road obstacle.

Figure 20 shows the SUV–trailer combination when driving around an obstacle at a speed of 60 km/h to clearly see the behavior of the trailer at a higher driving speed. At this speed, the load acting on the tow hitch, as well as the tilting and leaning of the vehicle, are no longer evaluated. It is already visible at first glance that the trailer is skidding and almost crossing into the other lane. The observation shows that driving the SUV–trailer combination at a speed higher than 55 km/h is dangerous for both the vehicle crew and passing vehicles, as well as all other road users.

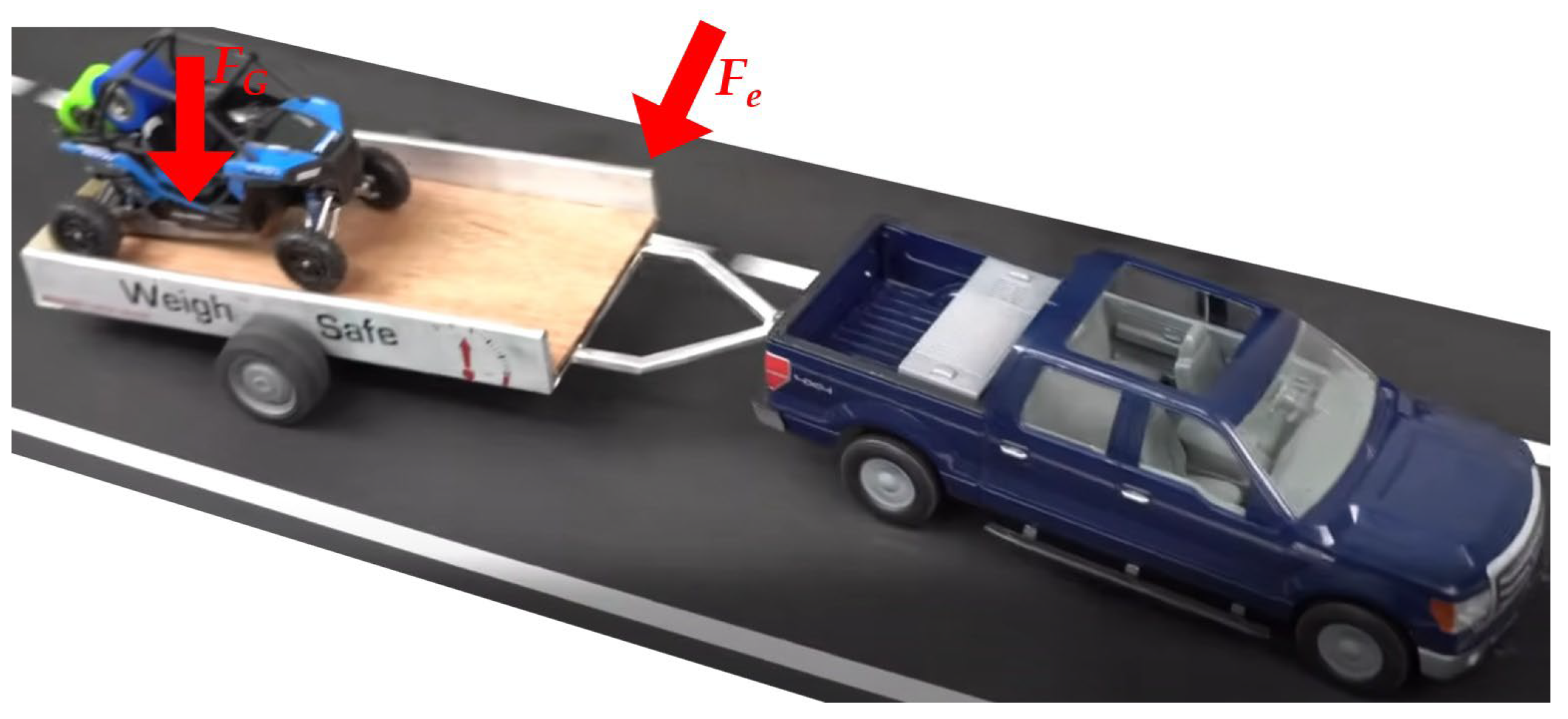

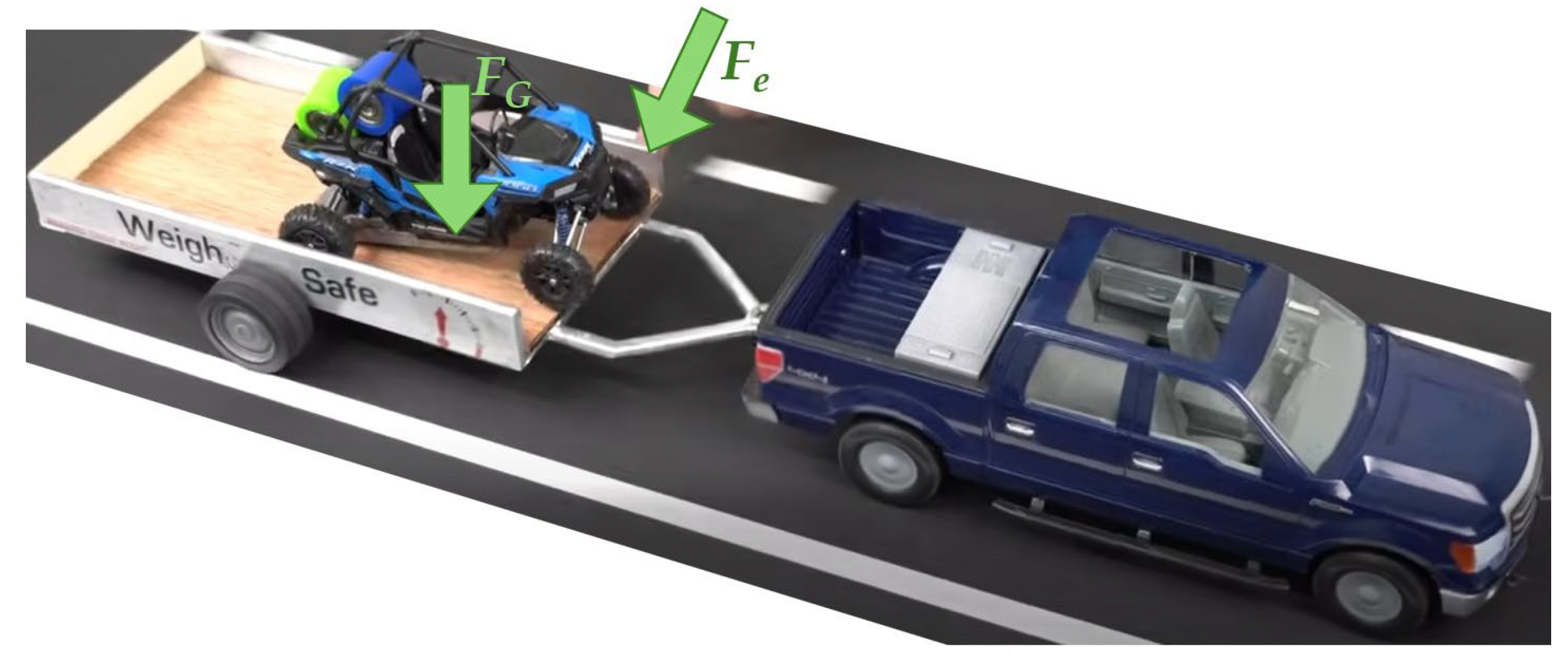

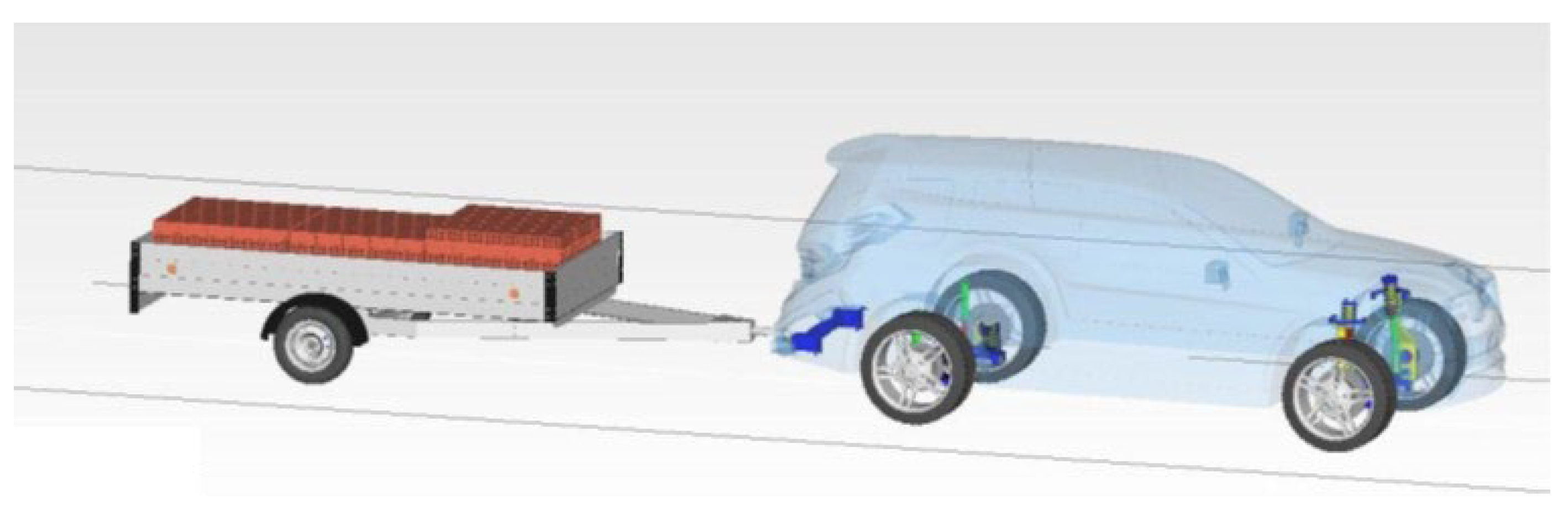

After driving maneuvers in which less than half of the trailer’s payload was loaded, the trailer is loaded with 1000 kg, which is the total load of the trailer. The first pallet weight is 400 kg, the second pallet weight is 300 kg and the third pallet weight is of 300 kg. They are loaded with bricks. A illustration of this configuration of the SUV–trailer combination is shown in

Figure 21.

The first driving maneuver is performed at a driving speed of 40 km/h for both loads of 500 kg as well as 1000 kg. Graphs and visualization of the vehicle–trailer combination entering a curve with the given load and at a driving speed of 40 km/h are depicted in

Figure 22.

The graph of the maximum load acting on the tow hitch shows that pallets with bricks are loaded correctly. The maximum value is at the level of –1244 N. This means that the SUV-car is still pulling the trailer with a reserve. As already explained, this is the value that corresponds to the load at the moment the vehicle–trailer combination lands on the road from the initial, unloaded state. In real life, such a phenomenon does not occur so easily. If pallets with bricks were carelessly loaded onto the trailer (the entire load would be thrown off the forklift), the maximum force acting on the tow hitch could increase at once in 0.23 s of driving, as can be seen in

Figure 22. The maximum load value is important when bypassing an obstacle. This value is around –1000 N, which means that the tow hitch is not overloaded.

The body tilting (the right graph in

Figure 22) shows that the maximum value of the tilt angle is 0.156 rad, which represents the approach of the body at the level of the rear wheels by 24 mm. Compared to the SUV–trailer combination driving at a speed of 40 km/h with the difference that it was loaded with only 480 kg, this value is almost the same (23.1 mm). The SUV–trailer combination bypassed the obstacle without the slightest problem. There was no excessive roll or tilting, and the vehicle combination did not skid.

It can be assessed, after investigation of the driving characteristics of the SUV–trailer combination, that in the case of a modelled road which resembles the bypassing a suddenly created obstacle (the shape of the road shown in

Figure 20), the weight of the loaded load does not play a role in the characteristics of the combination, but its distribution and the speed of the combination. The following figures and graphs show how an incorrectly loaded load can affect the characteristics of the combination. It is evaluated in terms of both the exceeded maximum load acting on the tow hitch (

Figure 23) as well as the loss of control over the vehicle (

Figure 24).

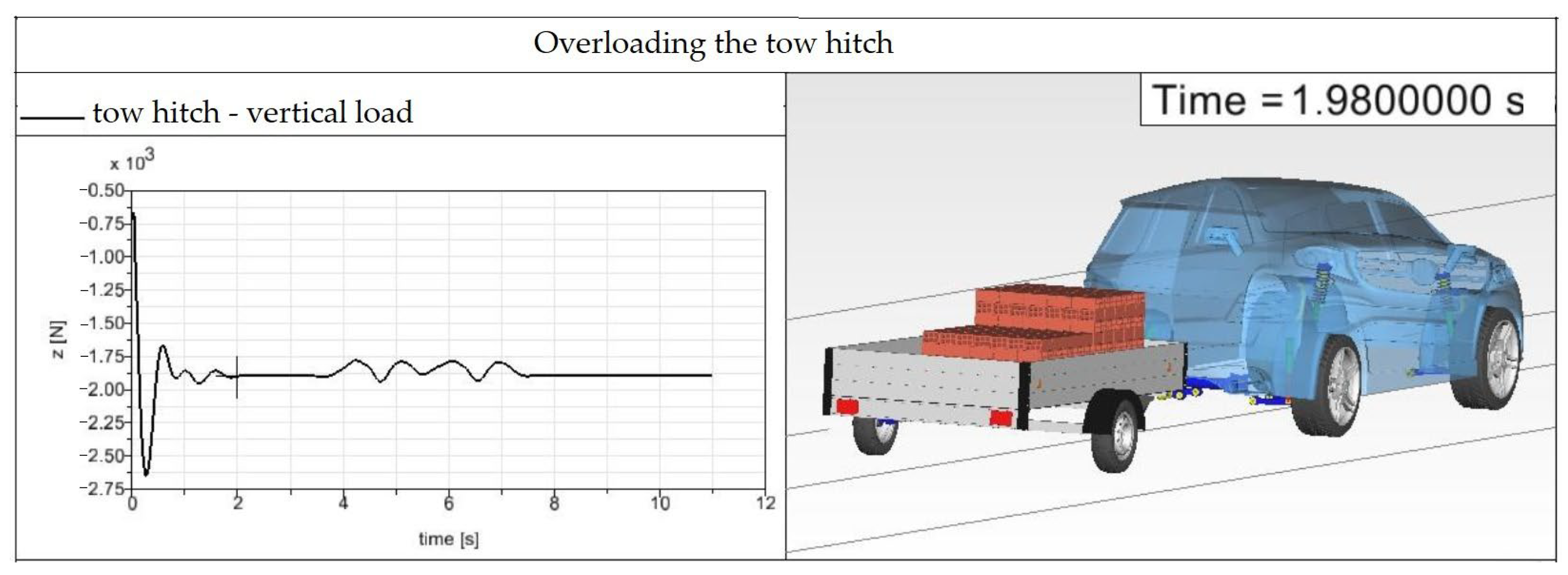

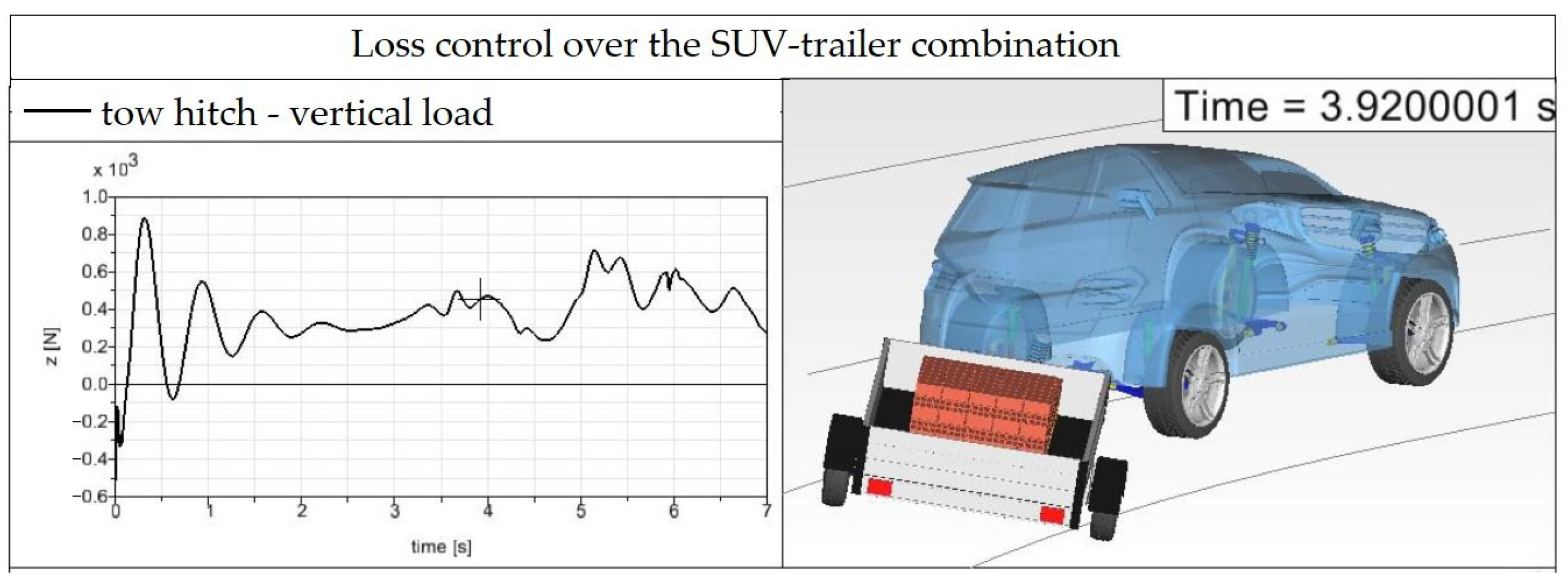

In the case of the driving simulation shown in

Figure 23, the SUV-car is pulling the trailer with the load of 1000 kg (the first pallet weight is 540 kg, the second pallet weight is 300 kg and the third pallet weight is 160 kg). It is not visible directly on the vehicle–trailer combination that there is an overload. However, the graph of the maximum load of the tow hitch shows that it is excessively overloaded. The load values on the horizontal parts of the graph (values of steady-state driving) are at the level of –1900 N, and when bypassing an obstacle and the vehicle combination touches the road up to –2650 N. These values are unacceptable for the operation of the given vehicle (the maximum permissible load is 1373.4 N).

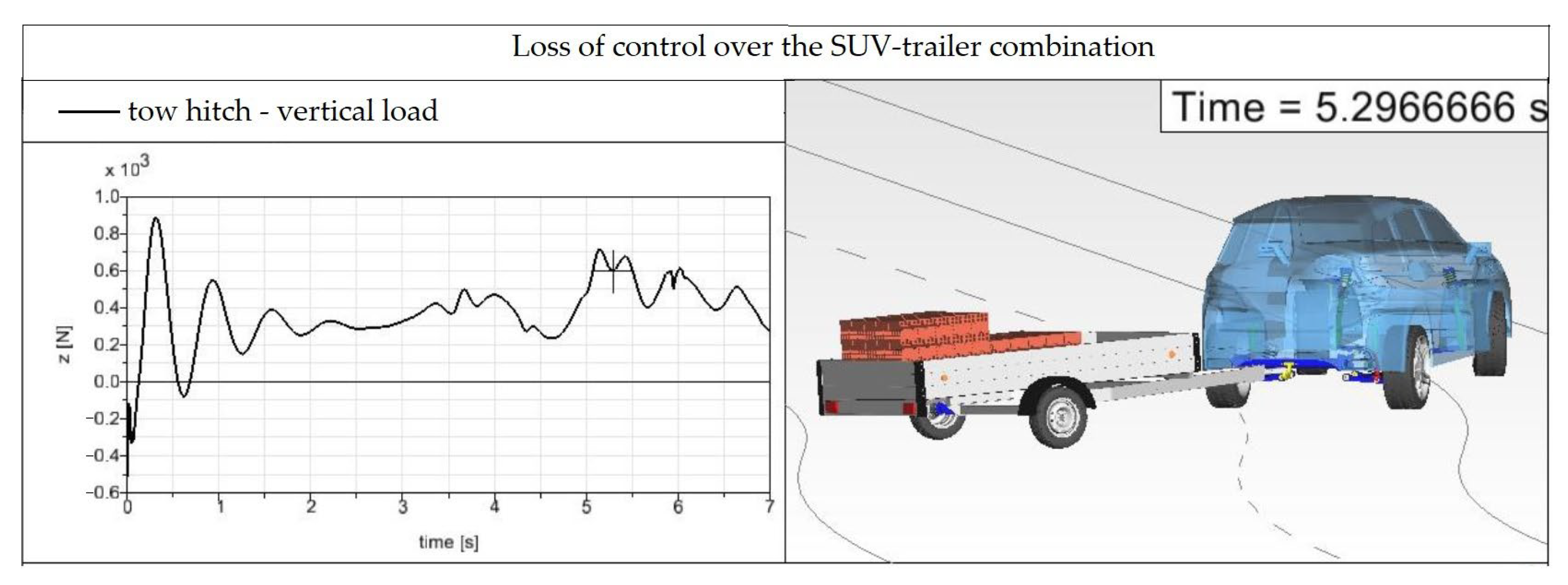

When the pallets are loaded on the trailer mirror-like in the lateral direction in comparison with the loading shown in

Figure 23, namely the first pallet weighing 160 kg, the second pallet weighing 300 kg and the third pallet weighing 540 kg of bricks, the stability of the SUV–trailer combination will be lost (

Figure 24). The center of gravity of the trailer is in the rear part.

The SUV–trailer combination shown in

Figure 24 is located at the transition from the second curve to a five-meter straight section of the road (the geometry of the modeled road is depicted in

Figure 16). It can already be seen in

Figure 24 that the rear wheel of the trailer goes beyond the roadside due to the excessive turning of the trailer. After passing the 5-m straight section of the road to the next two curves, the vehicle gets into a situation as shown in

Figure 25. The trailer gets to the opposite side of the road, and there is a complete loss of control over the SUV–trailer combination. It can be assessed that operating the SUV–trailer combination with such a load distribution would be life-threatening in normal traffic.

4.2. Driving the SUV–Trailer Combination While Changing Lanes—Maneuver B

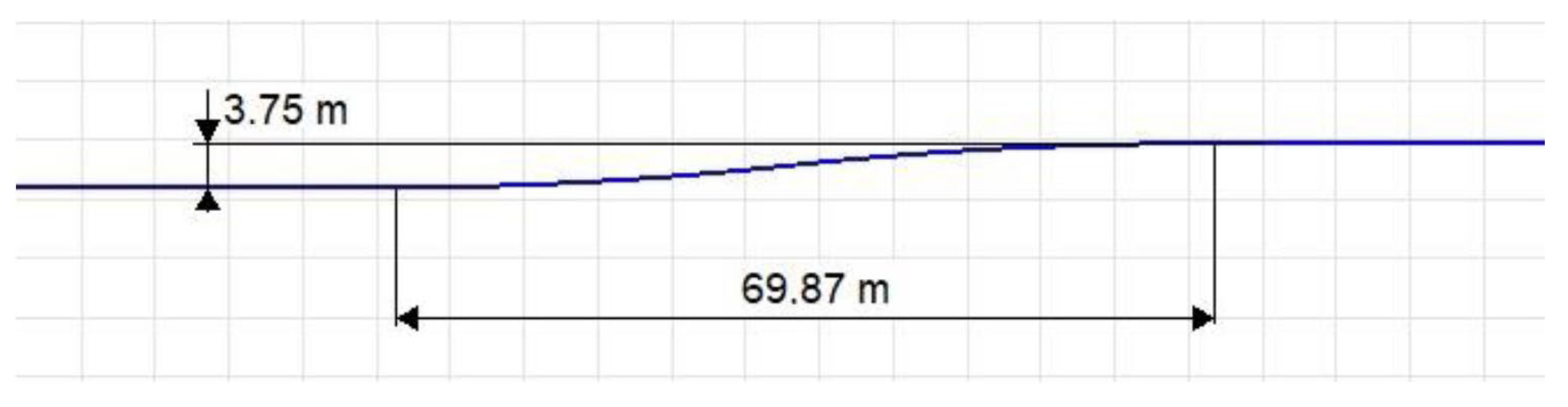

In addition to bypassing an obstacle on the road, which suddenly appeared and had to be bypassed immediately, it is also dangerous to simply go around a vehicle, or rather to change lanes. Such a situation can appear either on a regular two-lane road or on an expressway/motorway. In this section of the work, the difference between driving at a higher speed when changing lanes and driving at a lower speed when bypassing an obstacle is revealed. As was seen in

Section 3.1, bypassing an obstacle with the SUV–trailer combination is dangerous primarily in terms of incorrectly loaded goods on the trailer. As it is already known which load distribution is correct or incorrect for the selected SUV–trailer combination, this section continues with the already used combinations of pallets with bricks. The geometry of the used modeled road is shown in

Figure 26. The roadway consists of a straight section, followed by two curves with a radius of 326 m and a curve length of 35 m, which gradually transition into another straight section. For a better understanding of the shape and longitudinal dimensions of the roadway, the basic dimensions are marked in

Figure 26.

Verification of the maximum load acting on the tow hitch will no longer be carried out. The previous observation of the behavior of the vehicle–trailer combination (

Section 3.1) proved that a correctly distributed load on the trailer does not lead to overloading the tow hitch. The observation also resulted in the fact that the monitored parameters, such as the roll angle and the pitch angle, with the correct load distribution, differ only minimally depending on the load distributed on the trailer (the deviations between the monitored parameters at the same speed and the load of either 500 kg or 1000 kg were insignificant). This observation shows that it is sufficient to consider only one correct load for monitoring the driving characteristics of the SUV–trailer combination when changing lanes. For these driving maneuvers, the load of 1000 kg is chosen.

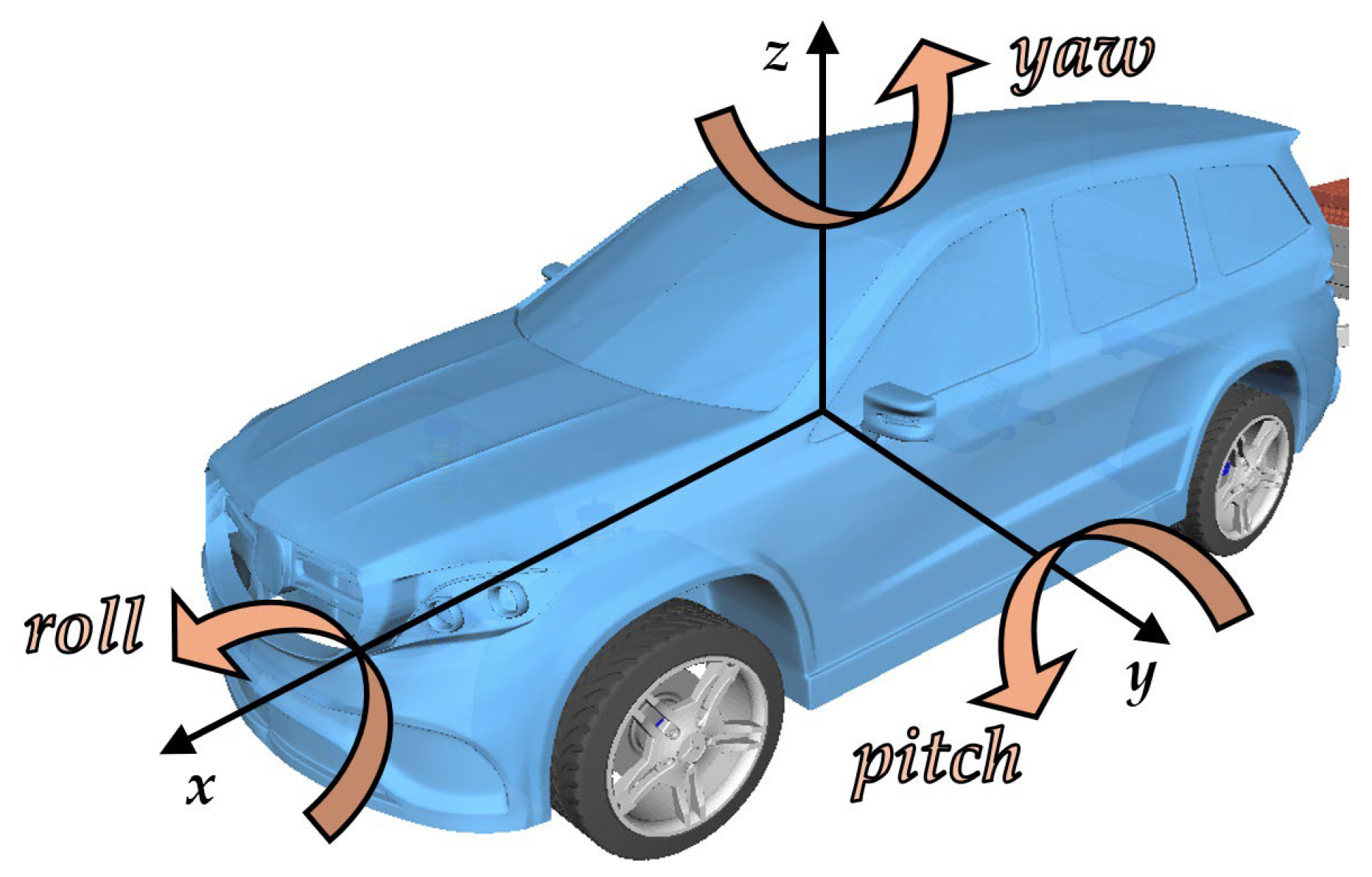

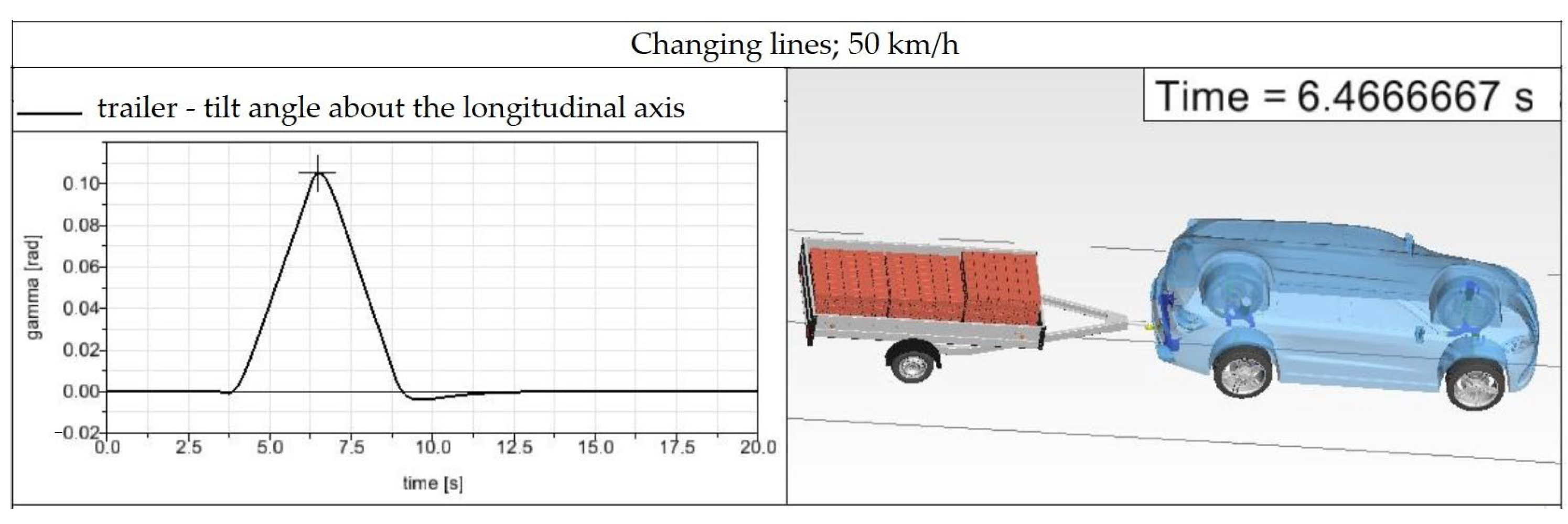

It is also a difference in comparison with

Section 3.1 in the evaluated achieved results. The main monitored parameter is the sway of the trailer (a change of the angle of rotation of the trailer around the vertical

z-axis,

Figure 6). Since the resulting sway angle is evaluated relative to the coordinate axis and not directly to the road, the first step is to create a basic, comparative model with respect to which the turning will be compared (

Figure 27). The turning of this model is performed at a driving speed of 50 km/h. Due to the road geometry (curves with a larger radius), the speed of 50 km/h is taken as the driving speed at which the angle of rotation of the trailer changes only due to the shape of the road and not due to undesirable influences such as loss of traction between the tires of the trailer and the road.

The maximum yaw angle of the trailer is 0.1053 rad, which corresponds to the value of 6.033°. As mentioned above, this angle results from the characteristics of the road.

In addition to the difference in the evaluated quantities, there is also a difference in the observed speeds. The following three driving cases of the Maneuver B were observed in the simulations:

Case 4: 80 km/h—the lowest permitted driving speed on a motorway/expressway, unless the road goes through a village;

Case 5: 110 km/h—the normal driving speed on a motorway if the driver is aware that he is not only driving the vehicle, but also has the load in a trailer;

Case 6: 130 km/h—the maximum permitted driving speed on a motorway/expressway and also the maximum design speed of a trailer.

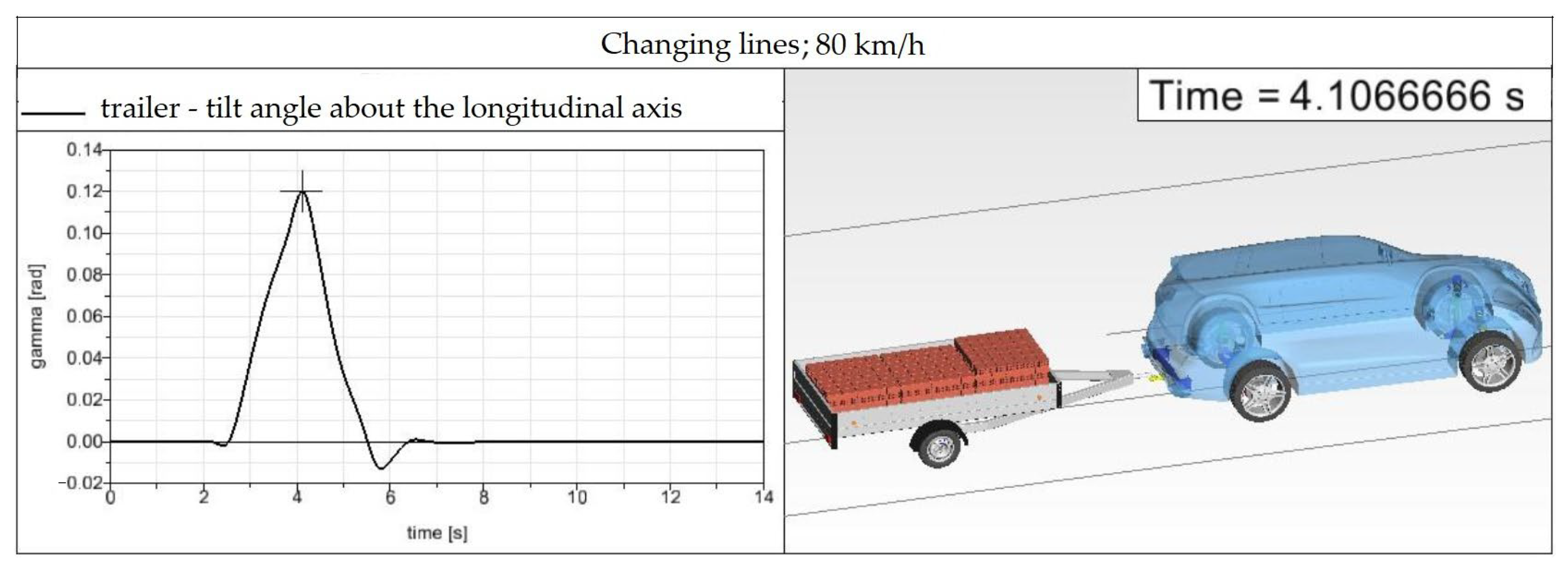

If the SUV–trailer combination drives along the modeled road at the driving speed of 80 km/h (

Figure 28), the yaw angle values differ slightly from the basic model (

Figure 27). The maximum yaw angle value is at the level of 0.12 rad (6.87°), which implies that this speed is safe for driving and does not cause any undesirable effects.

After increasing the driving speed to the value of 110 km/h, the trailer’s yaw rate increases (0.1539 rad = 8.818°), and a slight tilt of the trailer also occurs. The increase in yaw is caused by the higher driving speed, but this value does not have a negative effect on the SUV–trailer combination. In the case of a real vehicle combination, the trailer’s tilt could be a bigger problem, especially when a larger amount of goods is loaded, or cargo with a higher weight. In addition to the higher weight, the behavior of the vehicle–trailer combination could also be affected by loading cargo with a higher center of gravity, and improper securing of the cargo, which could loosen due to centrifugal force in a bend and change the overall behavior of the vehicle combination.

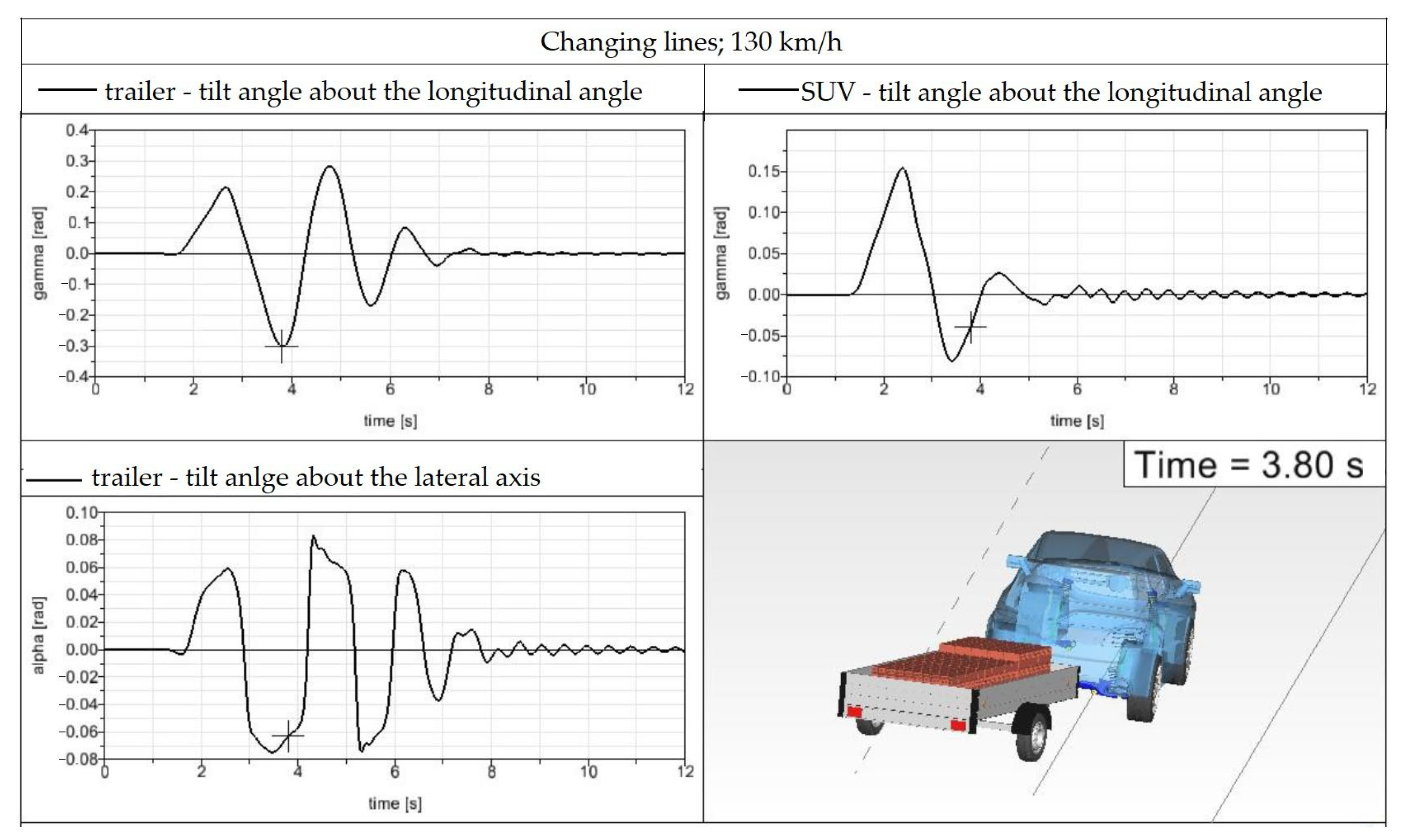

A big difference compared to the basic model can be observed at a speed of 130 km/h. The turning of the trailer reaches almost three-times-higher values, up to 0.301 rad (17.246°), which clearly shows that such a high speed is unacceptable for the investigated SUV–trailer combination. At the driving speed of 130 km/h, traction is lost between the trailer tires and the road, and the trailer starts to skid (

Figure 29).

In addition to the turning of the trailer, its roll is also significant at the driving speed studied (a graph on the bottom left of

Figure 29). The maximum roll value of 0.0832 rad reaches the level of the trailer wheels, the fenders approaching the wheels by 84.7 mm compared to the equilibrium state.

A special phenomenon can be observed when the vehicle is turning (a graph on the top right of

Figure 29). What is interesting is not so much the maximum vehicle roll (0.1536 rad = 8.8°), but the vehicle behavior from the 4th second to the end of the simulation. Both the vehicle and the trailer oscillate around the

z-axis due to the excitation caused by driving through a curve at high speed. This oscillation does not stabilize even after driving a straight section of the road with a length of 350 m. It can be assessed in the case of driving at the driving speed of 130 km/h, that the operation of the vehicle combination with the used load is not permissible for safe driving.

4.3. Discussion of the Resutls

The performed simulation computation with the chosen SUV–trailer combination proved that its driving properties represent a quite complicated phenomenon affected by several factors.

The position of the center of gravity of the trailer can be considered as the first and the most important factor. Its influence on the vehicle–trailer combination driving stability is such that the trailer with the center of gravity positioned behind the trailer axis is very prone to unstable movement. Only a small excitation force is needed, and the vehicle becomes uncontrollable relatively quickly (in a short time).

It is necessary to consider the weight of the trailer itself. A higher weight of the trailer in combination with an improper position of the center of gravity results in unstable movement the entire vehicle–trailer combination [

42,

43,

44,

45].

Driving speed is another factor, which affects the stability of the vehicle–trailer combination during driving. The vehicle–trailer combination is more sensitive to the load distribution at higher driving speeds. At the higher driving speed of the vehicle, only a small excitation force is sufficient to cause uncontrolled movement the vehicle–trailer combination, mainly when the above-described conditions are met. The achieved results of the assessed criteria listed in

Table 1 are summarized in

Table 7 for all six driving cases.

Regarding driving Maneuver A, driving with the load of 1000 kg at the speed of 40 km/h (the driving Case 1) as well as with the load of 500 kg and speed of 50 km/h (the driving Case 2) does not lead to exceeding the limit value of 3.924 m/s2. When the angle ψ is evaluated, it is also below the limit value of 15° for driving cases 1 and 2. However, driving the SUV–trailer combination with the load of 500 kg at the speed of 55 km/h (the driving Case 3) causes exceeding the limit value of the lateral acceleration as well as the ψ angle. The lateral acceleration is exceeded by 2.096 m/s2 and the limit value of the ψ angle by 1.86°. These findings were manifested by unstable driving of the SUV–trailer combination, as is discussed below.

The given criteria evaluated for driving Maneuver B (driving the SUV–trailer combination while changing lanes) are also included in

Table 7. Driving at the speed of 80 km/h (the driving Case 4) and at the speed of 100 km/h (driving Case 5) resulted in lateral accelerations of 1.76 m/s

2 and 2.87 m/s

2, respectively. Both values are lower than the limit value of 3.924 m/s

2. The evaluated

ψ angle was, for the driving speeds of 80 km/h and 110 km/h, under the limit value of 15°. The achieved values were 6.87° and 8.83°, respectively. However, driving the SUV–trailer combination at the speed of 130 km/h (the driving Case 6) was already unstable. This is manifested by the achieved value of the lateral acceleration of 6.04 m/s

2, which is higher by 2.116 m/s

2 than the limit value of 3.924 m/s

2 and also by the achieved value of the

ψ angle, which is higher by 2.27° than the limit value of 15°. This unstable state is also discussed below.

Further, it is possible to express other dependencies of the stability of the vehicle–trailer combination on other factors. An incorrect tow hitch load has negative effects on driving stability. When the tow hitch is loaded with too high a weight, the vehicle–trailer combination has the tendency to preserve a straight direction in a curve [

46,

47,

48]. Too small a weight on the tow hitch has a destabilizing effect, as was investigated and presented above. Next, the tire pressure is inconspicuous but is an important factor affecting the driving stability of the vehicle–trailer combination. It is required to keep the tire air pressure within the prescribed range by the vehicle producer. It is also possible to suppose that weather conditions can affect the safe driving of the vehicle–trailer combination. A slippery road together with sudden changes of driving direction negatively influences the stability of the movement [

49]. Moreover, it was found that driving a vehicle over speed bumps has negative dynamic impacts on the vehicle structure, the passengers in a vehicle as well as the trailer [

50,

51,

52]. In the case of the examined single-axle trailer, rubber deformable components are installed as a suspension between the swinging arms of the axle and the main load-bearing beam of the axle. These elements are dimensioned for the high load of the trailer. Therefore, the empty state of the trailer leads to high vertical displacements and even to loss of tire/road contact. This will also be investigated in future research activities with the vehicle–trailer combination [

31].