1. Introduction

The growth in underground construction, driven by societal demand for better communications and environmental constraints, has enabled the development of large tunnel boring machines (TBMs) for the construction of a larger number of tunnels and for more efficient excavation of heterogeneous terrain.

Tunnel boring machines (TBMs) have become essential tools in the construction of modern underground infrastructure due to their ability to perform continuous excavation, enhance operational safety, and reduce environmental impact compared to conventional methods. Their widespread adoption in large-scale projects, such as high-speed railway lines and urban metro systems, has been driven by advances in automation, cutterhead design, and ground conditioning technologies. Nevertheless, optimal TBM performance is highly dependent on site-specific geotechnical conditions, with rock abrasivity being one of the most critical factors, as it directly affects cutter wear, advance rates, and overall project costs.

Among the various operational parameters, cutter wear is one of the most difficult to predict due to the complex and dynamic interaction between the cutting tools and the ground. This interaction is influenced by multiple factors, including rock mineralogy, grain size, uniaxial compressive strength, and the presence of discontinuities. Cutter wear not only impacts the excavation rate but also contributes significantly to unplanned stoppages, maintenance costs, and operational risks. Therefore, accurate estimation of cutter consumption is essential for improving TBM utilization and minimizing downtime.

The aim of this article is to reduce the complexity of predicting TBM cutter wear, as the large number of parameters involved in predicting the progress of this type of TBM makes its calculation extremely complicated.

The index presented in this article is not intended to replace these existing methods but to act as an additional tool, offering simplicity and low testing costs, making it especially suitable for preliminary design phases. The six-parameter structure enables the CLH to encompass rock mass variability and heterogeneity, providing a more comprehensive view. The re-vision presented in this study demonstrates greater robustness and accuracy in cutter wear time estimation.

The TBM utilization factor U is a key performance indicator, defined as the ratio between the net advance rate Ar (excluding stoppages) and the penetration rate Pr (including stoppages), as expressed in Equation (1):

Typical values of

U range between 30% and 50% [

1]. Stoppages may be planned (e.g., scheduled maintenance, tool inspection) or unplanned (e.g., cutter failure, ground instability), and minimizing the latter requires a strong focus on preventive maintenance and robust predictive models [

2,

3].

Over the past decades, numerous models have been proposed to estimate cutter life and penetration rates, many of which rely on quantifying rock abrasivity through standardized tests such as the Cerchar Abrasivity Index (CAI), the LCPC abrasivity test, and the Sievers’ J-value [

4,

5,

6]. While these models have provided valuable insights, they often exhibit limited applicability outside the specific geological contexts for which they were developed. Moreover, many have been calibrated exclusively for rock excavation, despite the increasing use of TBMs in mixed-face conditions, where soil and rock coexist within the same section [

4,

7].

The technological evolution of TBMs has expanded their use to a wider range of geological environments, complicating machine selection and performance prediction. Engineers must consider not only lithological variability but also operational constraints, cutterhead configuration, and real-time monitoring data. Despite the availability of empirical and semi-empirical models [

2,

8,

9,

10], considerable uncertainty remains in their predictive capability, particularly in heterogeneous and abrasive rock masses [

6].

In this context, the present study aims to contribute to the field by developing a new empirical approach for estimating cutter life, based on laboratory data and field observations. The research is grounded in rock samples collected along more than 120 km of high-speed railway tunnels in Spain, including the following:

Guadarrama Tunnels (Madrid–Segovia): Two parallel tubes, 9.5 m in diameter, 28 km in length.

Das Maceiras Tunnels (Pontevedra): Two parallel tubes, 9.5 m in diameter, 8.5 km in length.

Pajares Tunnels (León–Asturias): Two parallel tubes, 9.5 m in diameter, 24.6 km in length.

These samples were tested at the Rock Mechanics Laboratory of the Higher Technical School of Mining and Energy Engineers (ETSIME-UPM), using a comprehensive suite of geomechanical tests to characterize rock properties and monitor TBM performance. The resulting dataset enabled the development of an empirical formula to estimate the average service life of cutterhead disc cutters, based on a newly proposed index referred to as CLH. It should be noted that “CLH” is not an acronym, but rather a simple label chosen by the authors to represent the model.

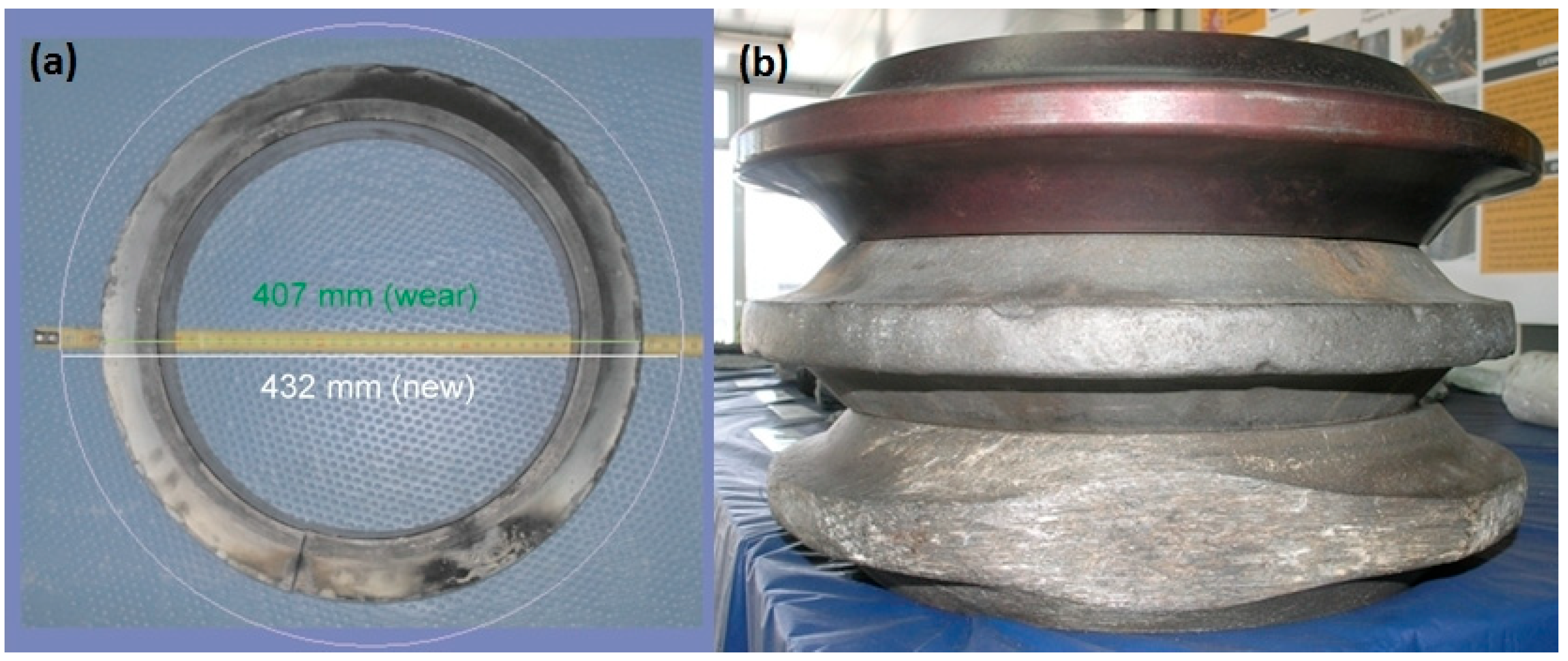

In hard and abrasive rock masses, cutter replacement costs can represent a significant portion of total excavation expenses. As illustrated in

Figure 1a [

11], the wear of a 17″ (432 mm) disc cutter used in the Guadarrama Tunnels exemplifies the impact of sustained contact with abrasive rock. Although TBMs can bore through most natural rock masses, execution costs may become prohibitively high compared to drill-and-blast methods [

12]. As shown in

Figure 1b, cutter replacement may be required due to various factors, including bearing seizure, ring breakage, or wear from prolonged rock contact.

In the Guadarrama Tunnels, wear was identified as the predominant cause of cutter consumption, accounting for 80% and 65% of replacements in the two tubes, respectively [

11]. The main causes of cutter replacement observed in the studied projects include the following:

Wear of the cutter ring during face excavation

Breakage of the ring support due to rockfall

Misalignment of the cutter ring relative to its axis

Accelerated wear of peripheral cutters due to longer travel paths

Loss of bearing lubrication and bearing seizure or fracture

Heterogeneous face conditions and abrupt geological transitions

Fracturing of the excavation face leading to rock block falls or jamming

Excessive torque or thrust resulting in peak loads on individual cutters

Elevated vibration levels and insufficient water flow for cutterhead cooling

Cutter-related stoppages recorded in the Guadarrama Tunnels included cutterhead inspection and verification, cutterhead cleaning, cutter tightening, overcutting for gauge cutter installation, cutter replacement, retaining ring welding, and wedge-related cutter repairs. It is worth noting that some stoppages unrelated to cutter issues were opportunistically used for cutter maintenance or replacement.

By integrating laboratory data, field observations, and operational records, this study proposes a new predictive framework for estimating cutter life, with the aim of improving TBM performance forecasting, reducing maintenance costs, and supporting more efficient excavation in abrasive geological conditions.

The application of the CLH index in multiple Spanish high-speed railway tunnels relies on original datasets compiled for this study from internal technical reports prepared for the joint ventures (UTEs) of the Guadarrama, Das Maceiras, and Pajares tunnels. These reports provided Sievers’ J (SJ), S20, AVS, equivalent quartz content, UCS, and CAI results, together with detailed TBM operation and cutter-consumption records.

2. Materials and Methods

Numerous empirical and analytical models have addressed TBM performance and cost prediction, including penetration rates, cutter wear, and project timelines [

7,

13,

14,

15,

16,

17]. Among the most widely accepted methods are: (i) the Norwegian Method (developed at the Norwegian University of Science and Technology, NTNU) [

15], developed by the Norwegian Institute of Technology; (ii) the Colorado School of Mines Method (CSM) [

18]; (iii) the Rock Mass Excavability Index (RME) developed by Barton [

19]; and (iv) the QTBM method proposed by Bieniawski [

20]. While these methods have been applied successfully in various tunnelling projects, each presents limitations when applied to specific geological settings or mixed-face conditions, thereby motivating the development of alternative predictive tools such as the CLH index [

21,

22].

The NTNU method is based on performance data collected from TBMs operating in a range of rock types, enabling the estimation of cutter wear, penetration rates, and tunnelling times. It accounts for both intact rock properties, using the Drilling Rate Index (DRI), and rock mass characteristics. Originally developed for predicting the penetration rate of percussive drilling hammers, the DRI is now widely regarded as a reliable indicator of TBM advance rates.

The CSM method assesses the influence of rock mechanical properties on TBM cutting performance by determining cutter forces, from which thrust, torque, and cutterhead power are calculated. These calculated parameters are compared against the machine’s design specifications to determine the maximum achievable penetration rate or to verify a target rate.

The QTBM method adapts Barton’s Q-system for rock mass classification to predict TBM net advance rates. It integrates parameters such as joint spacing, rock quality designation, groundwater conditions, and stress factors.

The RME method proposed by Bieniawski incorporates five key parameters describing rock mass behaviour and TBM characteristics to derive an index for predicting excavability. While useful in preliminary feasibility studies, it requires calibration for each geological setting.

2.1. Development of the CLH Index

The CLH index was developed at the ETSIME-UPM Rock Mechanics Laboratory to provide a simple, rapid, and cost-effective method for estimating TBM disc cutter life in hard rock tunnelling. The methodology is underpinned by extensive laboratory testing and statistical analysis of rock samples from over 120 km of TBM-excavated Spanish high-speed railway tunnels, including the Guadarrama, Das Maceiras, and Pajares projects.

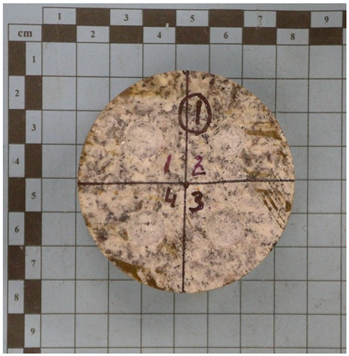

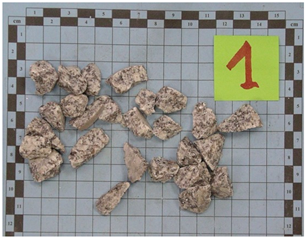

A total of 204 samples, representing various lithologies such as orthogneiss, cataclasites, porphyry, and granite, were collected for testing. All laboratory investigations were performed at the ETSIME-UPM Rock Mechanics Laboratory, equipped with calibrated instruments and testing systems compliant with International Society for Rock Mechanics (ISRM) suggested methods, as well as ASTM and UNE standards where applicable. Procedures were designed to ensure repeatability, comparability, and statistical reliability of results.

Rock samples were collected during core drilling campaigns conducted alongside tunnel excavation. Each specimen was labelled with precise geological and spatial provenance to enable correlation with in situ TBM performance data. Prior to testing, samples were cleaned, dried, and, where required, cut to standardized dimensions. Test sequences were planned to minimize alteration of material properties between procedures. Duplicate or triplicate specimens were tested to assess variability, and anomalous results were re-tested. All results were stored in a centralized database for subsequent calibration of the CLH index.

Six rock properties were identified as the most influential on cutter wear and service life, and were determined using the following standardized laboratory procedures:

Drillability (Sievers’ J miniature drill test, SJ). Quantifies the ease of rock penetration by a steel stylus under controlled conditions. A conical steel point is applied to the rock surface under a specified load, and penetration depth is recorded after a fixed number of revolutions. Lower SJ values indicate harder, less drillable rocks, whereas higher values correspond to softer, more easily drillable lithologies. Drillability influences cutter penetration rate and the energy required for excavation [

23,

24].

Brittleness (Impact test, S20). Measures the tendency of a rock to fracture upon impact. Standardized specimens are subjected to repeated blows from a falling weight, and the resulting grain size distribution is analyzed. Higher S20 values reflect greater brittleness, often linked to increased cutter wear due to sharp-edged fragments accelerating tool degradation [

15,

25].

Rock abrasivity (Abrasion Value Steel, AVS). Evaluates the abrasive effect of rock particles on steel. Rock material, ground to a standardized grain size, is used to abrade a steel specimen under controlled conditions. The weight loss of the steel piece is recorded as the AVS value, with higher values indicating greater potential for cutter ring wear during TBM operation [

26].

Equivalent quartz content. Determined petrographically from thin sections under a polarizing microscope. The Rosiwal method is used to quantify mineral content and relative hardness, yielding an equivalent quartz percentage. Higher quartz content typically correlates with increased abrasivity and reduced cutter wear [

27,

28].

Uniaxial compressive strength (UCS). Represents the maximum axial stress a rock specimen can withstand before failure. Tests are carried out on cylindrical cores (commonly 54 mm diameter) at a constant strain rate until failure. Higher UCS values require greater TBM thrust force for penetration, increasing cutter loading and wear [

29,

30].

Cerchar Abrasivity Index (CAI). Quantifies rock abrasivity by scratching the rock surface with a steel stylus under a specified load (typically 70 N) over a fixed length. The width of the wear flat on the stylus tip is measured; higher CAI values indicate greater abrasivity and a higher likelihood of accelerated cutter-ring wear [

31].

2.2. CLH Index Calculation and Validation

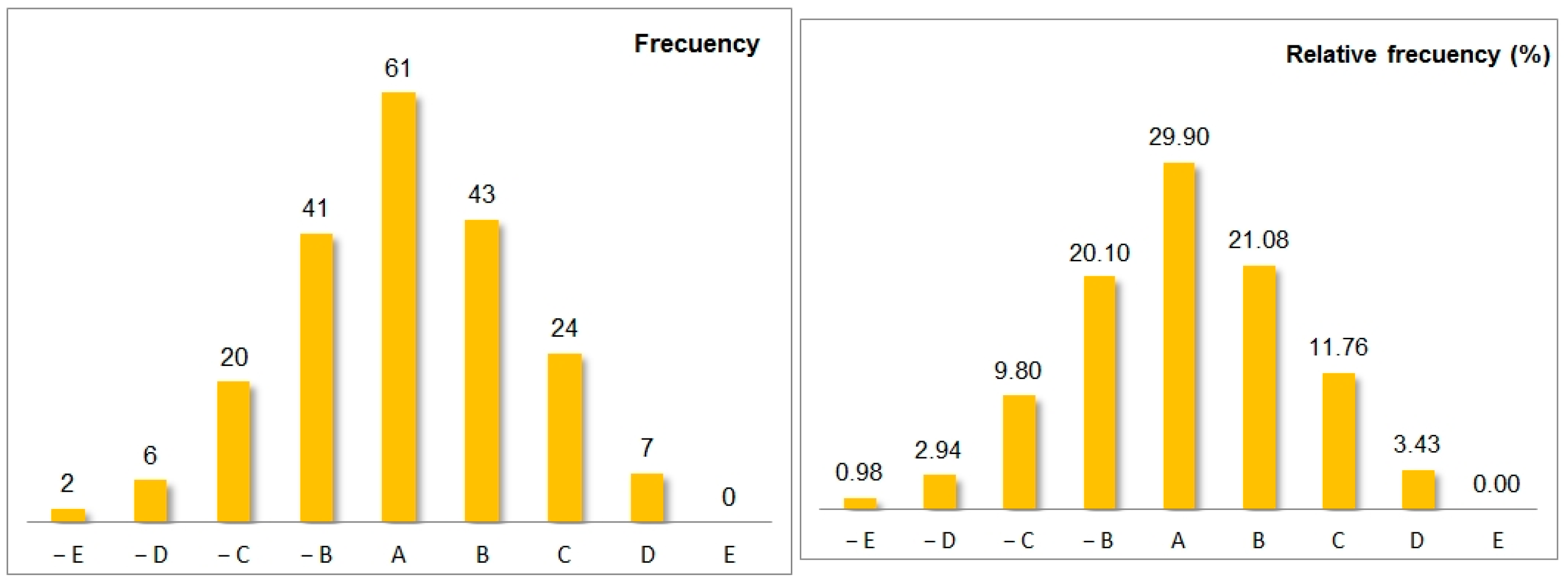

From all the samples evaluated in the ETSIME-UPM Rock Mechanics Laboratory for monitoring various TBM-excavated tunnels in Spain, 204 were selected. These samples had in common the six necessary tests for the calculation of the CLH index. The index is derived from a multivariate statistical correlation between these key rock properties and in-situ measurements of TBM cutter wear.

The data analyzed in

Section 2.2 and

Section 2.3 were obtained from internal technical reports prepared for the joint ventures (UTEs) responsible for the Guadarrama, Das Maceiras, and Pajares tunnels and were made available to the authors through collaboration agreements.

The CLH index is calculated using the following empirical Equation (2):

where

A is the numerical value assigned to drillability (SJ).

B is the numerical value assigned to brittleness (S20).

C is the numerical value assigned to rock abrasivity on steel (AVS).

D is the numerical value assigned to equivalent quartz content.

E is the numerical value assigned to uniaxial compressive strength (UCS).

F is the numerical value assigned to the Cerchar Abrasivity Index (CAI).

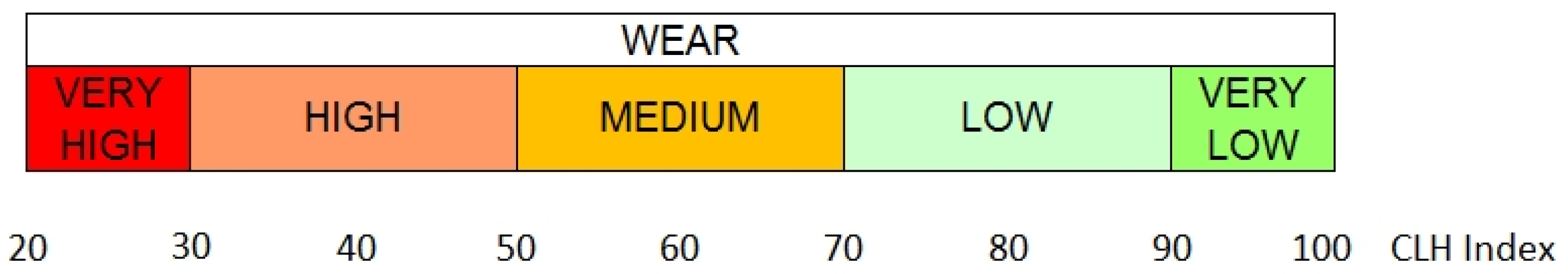

Each of the six test results is mapped to a specific numerical score (

Table 1). These scores were determined empirically through iterative calibration to align, as closely as possible, with the observed service life of the complete set of cutters on the TBM cutterhead. Consequently, the CLH index ranges from 19 to 100, with higher index values indicating a longer expected cutter wear.

Figure 2 illustrates the direct relationship between the CLH index and cutter wear, showing that higher index values correspond to longer observed service life for TBM disc cutters.

2.3. Statistical Analysis

As noted in

Section 2.2, the dataset derives from internal UTE technical reports covering TBM operation, cutter consumption, and geomechanical testing. Analysis of variance (ANOVA) assessed the statistical significance of each predictor, with

p-values below 0.05 indicating a meaningful contribution. Ninety-five percent confidence intervals were computed for all regression coefficients to evaluate their stability and precision.

Outliers and influential observations were identified using Cook’s distance and leverage statistics and were reviewed to distinguish genuine extreme cases from measurement or recording anomalies. Model robustness was further evaluated through cross-validation by partitioning the dataset into training and testing subsets to assess predictive performance.

This statistical framework provided a quantitative measure of the CLH index’s reliability and highlighted the relative importance of each rock property in influencing TBM cutter wear. The coefficient of determination (R2) is used to evaluate the goodness of fit of the regression models developed in this study. R2 measures the proportion of the variance in the dependent variable that is predictable from the independent variable. Higher R2 values indicate a stronger correlation between the predicted and observed data, and thus a more reliable model.