Abstract

Asphalt mixtures designed with an elevated air void content are intended to lower traffic noise as well as to improve traffic safety and quality by improving rainwater evacuation through the layer of the surface mixture, not just on top of it. While undoubtedly mixtures with high air voids have significant advantages, the durability of such mixes could be an issue. In the research presented in this paper, a performance evaluation case study of asphalt mixes with medium and high air void content was investigated, in both the laboratory and the trial section. The study assessed asphalt mixtures intended for so-called quiet pavements in terms of selected properties (such as water and frost resistance, low temperature cracking, fatigue life, and water permeability) that significantly impact the durability of the pavement surface course under traffic loads and climatic conditions. Five different mixtures were designed, which differed in the proportion of individual components, grain size, asphalt content, and void content. The conducted research indicates that mixtures with increased void content may exhibit lower durability parameters. In addition, the surface drainage performance can be effectively managed by selecting the appropriate mixture type, maximum aggregate size, and target air void content, depending on the functional requirements for macrotexture and pavement type. This should be considered both in the mix design process, by using the best possible materials and conducting additional testing, and also when selecting the mixture type to find an optimum between durability and acoustic parameters of the pavement layer.

1. Introduction

High air voids in asphalt mixtures allow water to drain through the top, surface layer of asphalt pavement, improving traffic safety [1]. In addition to improving friction, pavements with such mixtures reduce tyre/pavement noise. Unfortunately, traffic and weather actions detrimentally affect such pavement, typically with a higher extent as compared to the dense graded asphalt mixtures. While clogging is a major factor that limits the effectiveness of water drainage and noise reduction [2,3,4,5], the functional and mechanical characteristics of such mixtures should also be preserved.

Prediction of the coefficient of permeability of asphalt mixtures was studied with various methods, including the lattice Boltzmann method to simulate fluid flow in porous materials [6] and with a customised testing method focused on the anisotropic effect of permeability of open-graded friction course (OGFC) mixture [7]. Meso-scale study [8] also includes evaluation of porous asphalt stress induced effects on environmental functions, even with discrete [9] data processing methodology.

An interesting investigation based on 15 years of observation of porous asphalt mixture was conducted in the city of Chicago, IL (USA), in seven trial sections close to the lake, where cold regions with freeze–thaw cycles and heavy wind affect the pavement. Performance of pavement was studied based on the findings derived from non-destructive analyses of the cores’ texture and internal structure, as well as from multi-scale tests performed both to asphalt binders and mixtures. It was found that in surface texture, consistent change over time was noticed, such as increase in mean profile due to ravelling. Analysis of internal structure using a Computed Tomography (CT) scan revealed that there is also a lack of homogeneity in the air void distributions. Also, binder ductility shows a drastic and consistent reduction throughout the layer as ageing increases [10].

Another recent study on low-temperature cracking (LTC) behaviour of asphalt binders and mixtures concluded that the prediction of LTC in asphalt mixtures includes the following approaches: traditional mechanical model, finite element, and discrete element model prediction at the fine scale. They further summarised that mechanical models are difficult to fully explain material behaviour at smaller scales, and that the complex geometrical characteristics with material properties of asphalt pavement materials are essential for the mechanical response of asphalt pavement, the damage process, and the sensitivity of anti-cracking parameters [11]. The selection of binder in the context of low-temperature resistance should consider local climatic conditions, which is crucial for the durability of the wearing course [12].

Durability, permeability, low-temperature performance, and functionality of porous asphalt were recently examined, including the impact of porosity, pore structure, and temperature variations on the low-temperature cracking resistance of porous asphalt, together with the influence of pore characteristics, water flow directions, clogging processes, and pavement designs. They observed that the permeability of porous asphalt mixtures is primarily influenced by pore structure, including porosity, pore connectivity, and pore size distribution. Enhancing permeability is possible by optimising pore structure to increase interconnected porosity. Further, it was found that the large pore structure of porous asphalt mixtures effectively absorbs and disperses sound energy. Increasing porosity, texture depth, and using rubber asphalt can further enhance noise reduction; however, porous asphalt mixtures with smaller porosity are recommended for cold regions [13]. This also includes reclaimed asphalt pavement (RAP) and wax, affecting compaction temperature and mechanical properties [14], and steel slag application [15]. Studies were also directly focused on stiffness, fatigue, and cracking under freeze–thaw (F-T) cycles [16].

Another study on the mitigation of high air voids in asphalt mixtures deterioration due to rainfall, snowfall, rapid temperature change, large temperature difference, and freeze–thaw cycles was also recently conducted [17]. In the laboratory programme, heating, cooling, freeze–thaw, and uniaxial compression tests were performed to evaluate the temperature regulation capability of asphalt mixtures with different contents of microencapsulated phase change materials. A strong positive influence on pavement durability of this additive was proved. In another study, researchers investigated shear strength parameters [18] and cohesion loss [19].

A recent three-year, field-oriented study from Spain [20] on porous asphalt mixture pavement showed satisfactory mixture durability in terms of resistance to abrasion, accelerated ageing, frost, and humidity. Asphalt mixture contained ladle furnace slag. Pavement proved its drainage capacity, durability, and low environmental impact, being a good solution for roads in high-rainfall areas with medium traffic loads. Other authors [21] found that the cohesion value of porous mixture is greatly affected by the number of freeze–thaw cycles, and with the increase in the number of freeze–thaw cycles, the anti-reflection cracking performance decreases gradually. The aforementioned cohesion phenomenon was also studied with the addition of zirconium dioxide to mitigate water sensitivity [22] and directed to porous asphalt healing with magnetic induction [23].

Based on the conducted extensive literature review, it can be concluded that the specific research gap in asphalt mixtures designed with an elevated air void content intended to lower traffic noise is related to performance evaluation case study of asphalt mixes with medium and high air void content, in both the laboratory and the trial section, in terms of selected properties (such as water and frost resistance, low temperature cracking, fatigue life, and water permeability) that significantly impact the durability of the pavement surface course under traffic loads and climatic conditions. The main challenge is related to the selection of the mixture parameters to find high durability for quiet pavements.

2. Materials and Experimental Sections

2.1. Materials and Mix Design

Five asphalt mixtures were designed for the study, including one reference Stone Mastic Asphalt (SMA 5) with a typical (medium) air voids content and gap-graded structure and four mixtures with a high air voids content and an open-graded structure, i.e., Very Thin Bituminous Concrete (BBTM 8 and BBTM 11, from French Béton Bitumineux Très Mince) and Porous Asphalt (PA 8 and PA 11). All mixtures were intended to exhibit noise-reducing properties. The noise reduction mechanism in the SMA 5 mixture is attributed to its surface texture, whereas in the BBTM and PA mixtures, the high air void content plays a key role in noise reduction.

The mixtures were designed using crushed sand and coarse crushed aggregate from gabbro rock, along with polymer-modified bitumen (PMB) 45/80-55. The basic characteristics of the materials are provided in Table 1 and Table 2.

Table 1.

Physical properties of polymer-modified bitumen PMB 45/80-55.

Table 2.

Density of mineral-aggregate (following EN 933-1).

All designed mixtures featured a gap-graded aggregate gradation and were developed using the control points method, with the target air void content as the primary criterion. The key properties assessed for the designed mixtures included maximum and bulk density, air void content, water sensitivity, aggregate loss for open-grade mixtures, and mastic drainage. A comparison of the aggregate gradation curves is presented in Figure 1.

Figure 1.

Grading curves of asphalt mixtures.

The mixtures can be categorised based on their porosity and intended functionality. The reference mixture SMA 5 has a developed macrotexture but low porosity; the open-graded mixtures BBTM 8 and BBTM 11 have a developed macrotexture and intermediate porosity; and the porous mixtures PA 8 and PA 11 have a developed macrotexture and high porosity.

For each mixture, three series of asphalt mix specimens were prepared to provide the needed replicates. The summary of the basic property test results for the mixtures is presented in Table 3. The last column also includes the results of the air void content in the layer obtained from the test sections, which are used further for the analysis of in situ permeability. The test results confirmed the appropriate selection of materials (binder, aggregates, and additives). The Cantabro test, conducted as an aggressive particle loss assessment, yielded favourable results at the PL 10 class level, with only one exception at PL 30 class level for the PA 11 mixture. These results suggest that, under field conditions, the asphalt mixtures should exhibit resistance to ravelling and provide the necessary compactness required for quiet and permeable pavements.

Table 3.

Basic physical properties of asphalt mixtures.

Based on the conducted tests, the mixtures were selected for further experimental verification, including industrial-scale test production and the construction of a test section. The mixtures chosen for the test section exhibited target air voids porosities: SMA 5: 4.1% (target range: 3.5–4.0%), BBTM 8: 13.8% (target range: 12–15%), BBTM 11: 18.6% (target range: 15–20%), PA 8: 23.4% (target range: 20–25%), and PA 11: 25.8% (target range: 25–28%).

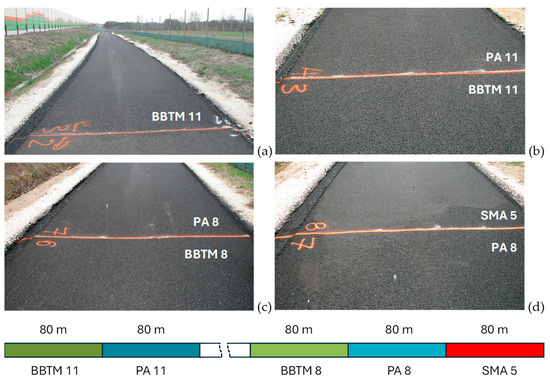

2.2. Experimental Sections Construction

The mixtures were produced on an industrial scale at an asphalt plant and incorporated into an experimental road pavement on a service road adjacent to the highway. This road is closed to regular traffic, with only occasional technical vehicle movement related to highway maintenance.

The pavement structure consisted of the following:

- 20 cm-thick sub-base layer made of crushed aggregate 0–31.5 mm,

- 6 cm-thick and 3.2 m-wide binder coarse made of asphalt concrete,

- 4 cm-thick and 3.0 m-wide surface coarse made of the experimental mixtures.

Figure 2 presents the layout of the experimental road sections. The sections were arranged according to aggregate gradation. From west to east, the first two sections consisted of pavements with a maximum aggregate size of 11 mm: BBTM 11 and PA 11. These were followed by sections with a maximum aggregate size of 8 mm: BBTM 8 and PA 8. At the end of the test section, the SMA 5 reference section was placed. At both the beginning and the end of the entire experimental sections, technical sections were constructed to facilitate test vehicle turnaround and braking. A ≥ 2.5% one-sided transverse slope was applied, while longitudinal slopes did not exceed 5%.

Figure 2.

Schematics and overall views on experimental sections: (a) overall view and starting of BBTM 11, (b) transition from BBTM 11 to PA 11, (c) transition from BBTM 8 to PA 8, and (d) transition from PA 8 to SMA 5.

3. Testing Methods

3.1. Specimen Preparation and Curing

At the laboratory testing stage, the asphalt mixtures were prepared using the same materials as those available at the asphalt plant. In the second stage, the mixtures were produced on an industrial scale at the asphalt plant, and 50 kg of each mixture was collected and stored in steel trays. In the laboratory, the mixtures were then reheated at 140 °C for two hours to ensure proper compaction of the test specimens.

For basic property testing, specimens were compacted using the Marshall hammer, applying 50 blows per side. For performance testing, slabs were compacted using a slab compactor, from which beams were cut for four-point bending (4PB) fatigue and Thermal Stress Restrained Specimen Test (TSRST).

At the laboratory stage, short-term ageing (STOA) was simulated to replicate the ageing process occurring at the asphalt plant. The asphalt mixture, produced in a laboratory mixer at approximately 150 °C, was spread evenly in a loose (non-compacted) state on a metal tray, ensuring a layer thickness of approximately 1.5 cm. The tray was then placed in a ventilated oven at 135 °C ± 1 °C. The mixture was conditioned in the oven for four hours, with periodic stirring every 60 min to ensure uniform ageing. After removal from the oven, the mixture was preheated to the compaction temperature 140 °C, and specimens were compacted accordingly.

Specimens that were not aged were labelled as Non-Aged (NA), while those subjected to short-term ageing were labelled as STOA.

3.2. Water Sensitivity

Water resistance is considered a fundamental property with significant implications for pavement durability. The test was conducted in accordance with EN 12697-12 Bituminous mixtures - Test methods - Part 12: Determination of the water sensitivity of bituminous specimens, incorporating a single freeze cycle at −18 °C for 16 h. The specimens were compacted using the Marshall hammer, applying 35 blows per side, to simulate insufficient compaction under unfavourable conditions (the standard compaction level is 50 blows per side). For each mixture, five dry and five wet specimens were prepared. Water sensitivity was assessed using the Indirect Tensile Strength Ratio (ITSR), calculated as the ratio of the Indirect Tensile Strength (ITS) of the wet specimens after the freeze cycle to the tensile strength of the dry specimens. This is a standard procedure used in Poland, adapted to local climatic conditions.

3.3. Resistance to Low Temperature Cracking

The TSRST test was performed in accordance with EN 12697-46 Bituminous mixtures - Test methods - Part 46: Low temperature cracking and properties by uniaxial tension tests. A rectangular prismatic specimen was cooled at a rate of 10 °C/h, starting from +20 °C. The loading frame was designed to prevent deformation (contraction) of the specimen. Throughout the test, temperature and tensile force were continuously recorded. As the temperature dropped below freezing, the specimen stiffened, transitioning from a viscoelastic to an elastic–brittle state, leading to an increase in tensile stress. Cracking occurred once the tensile strength limit was exceeded. The key results of this test were the cracking temperature (Tc) and the maximum stress at cracking (σc).

3.4. Resistance to Fatigue

Fatigue life was evaluated using the four-point bending beam test, in accordance with EN 12697-24 Bituminous mixtures - Test methods - Part 24: Resistance to fatigue. The test was performed on rectangular prismatic beam specimens. The beams were subjected to cyclic sinusoidal bending under a controlled constant strain mode. During the test, the applied load, beam deflection, and phase angle shift were recorded as a function of the number of loading cycles. Fatigue testing was conducted at a frequency of 15 Hz, a strain level of 350 µm/m, and a temperature of 10 °C. The fatigue life was determined based on the conventional stiffness reduction criterion (N), defined as a 50% decrease in stiffness, and the energy-based criterion (N1), which is considered a more objective measure of fatigue performance.

3.5. Complex Modulus

Rheological properties were determined using the complex modulus test, also based on the 4-point bending (4PB) configuration, in accordance with the EN 12697-26 Bituminous mixtures - Test methods - Part 26: Stiffness standard. The test was conducted at temperatures of 0, 10, 20, and 30 °C, over a frequency range from 0.5 to 15 Hz. The primary outputs of the test were the stiffness modulus, i.e., the absolute value of the complex modulus and the phase angle. Based on the test results and applying the time–temperature superposition principle; the master curves for these parameters were developed.

3.6. Water Drainage

Tests for vertical permeability (Kv) and horizontal permeability (Kh) were conducted under laboratory conditions in accordance with EN 12697-19 Bituminous mixtures - Test methods - Part 10: Permeability of specimen. In contrast, field permeability tests were carried out on the experimental road section following the Tex 246-F “Permeability or Water Flow of Hot Mix Asphalt” procedure. Figure 3 presents the measurement devices used for both permeability tests. Each measurement was repeated three times, and the average value was calculated.

Figure 3.

Testing facilities for water permeability tests: (a) laboratory permeability column, (b) Texas field permeability column, and (c) field measurement.

The laboratory permeability test involved pre-conditioning the specimen by allowing water to flow through it for approximately two minutes while maintaining a constant water column height of 300 ± 1 mm. The test was conducted on cylindrical specimens compacted using the Marshall method, which was subsequently trimmed to a uniform height of 50 mm. The measurement process consisted of determining the volume of water (Qv or Qh) that passed through the specimen under controlled conditions within a 60 ± 1 s timeframe. The permeability coefficients Kv or Kh (in m/s) were calculated based on that.

The field permeability test measured the time required for the water column to drop from the initial level (365 mm) to the end level (110 mm) within the measurement apparatus.

4. Results and Discussion

4.1. Mechanical and Performance Tests

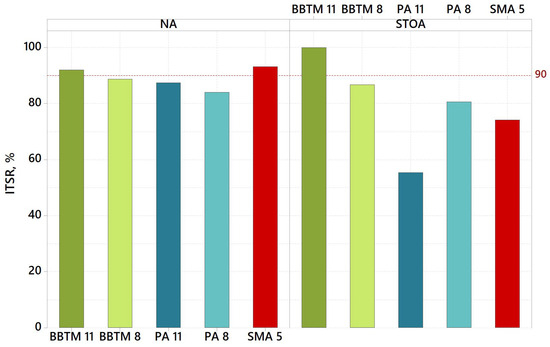

Water resistance assessment is a standard method employed to evaluate the durability of asphalt mixtures. In the testing procedure adopted in this study, an additional freeze–thaw cycle was incorporated, reflecting practices used in regions where pavements are subject to seasonal freezing and thawing. The evaluation of moisture susceptibility is based on the Indirect Tensile Strength Ratio (ITSR), which, according to national (Polish) specifications for wearing course mixtures, should not be lower than 90%. While the conventional testing approach involves non-aged specimens (NA), the present study also included specimens subjected to short-term ageing (STOA). The results, presented in Figure 4, indicate that only two mixtures—SMA 5 and BBTM 11—fulfilled the required performance threshold, whereas the remaining mixtures exhibited ITSR values ranging from 84.1% to 88.7%. The STOA-conditioned specimens demonstrated notable differences in performance. For four of the mixtures, ITSR values decreased, with the most pronounced reductions observed in SMA 5 and PA 11. Conversely, BBTM 11 exhibited an improvement in ITSR following ageing, increasing from 92% to 100%.

Figure 4.

Comparison of ITSR test results.

The analysis of ITSR results revealed, on the one hand, certain distinctions among the tested mixtures; yet, on the other hand, not all outcomes—particularly those obtained after ageing—align with expected trends. This discrepancy is primarily attributed to the nature of the ITSR parameter itself, which is a relative indicator; it does not directly reflect the mechanical strength of the asphalt mixtures but rather the degree of change resulting from conditioning processes. This phenomenon also explains the unexpected increase in the ITSR of the BBTM 11 mixture after the ageing process. In the authors’ opinion, a complete assessment should also include an analysis of the absolute values of indirect tensile strength. Consequently, the next stage of the analysis involved the evaluation of the indirect tensile strength of ‘dry’ (ITSd) and ‘wet’ (ITSw) specimens, as illustrated in Figure 5.

Figure 5.

Indirect tensile strength results of dry ITSd and wet ITSw specimens.

A key finding of this analysis is the superior performance of the SMA 5 mixture, which exhibited significantly higher tensile strength than the other mixtures, regardless of the specimen condition (dry or wet) or ageing state. Even under STOA conditions, ITSw values for SMA 5 remained the highest, despite the unexpectedly low ITSR.

Further examination of the results allows the mixtures to be categorised into two distinct groups based on mixture type: BBTM and PA. Notably, under non-aged (NA) conditions, the differences among those four mixtures ranged between 20% and 30%, with some falling near the statistical significance threshold. However, following short-term ageing (STOA), the disparities became more pronounced: the indirect tensile strength of BBTM mixtures was found to be two to three times greater than that of the PA mixtures.

Table 4 illustrates the effect of short-term ageing on moisture resistance and strength parameters by presenting the relative changes in each parameter. In general, short-term ageing exerts a negative influence on all the analysed properties. Although two instances of parameter increase were recorded, the differences were marginal—falling within the range of measurement uncertainty. Regarding the ITSR index, the most pronounced absolute reductions were observed for the SMA 5 mixture (–19%) and PA 11 (–32%). As for indirect tensile strength, more substantial changes were found in the ‘wet’ specimens, again for the SMA 5 and PA 11 mixtures, which evidently contributed to the overall decline in ITSR. For ‘dry’ specimens, the largest strength reductions were recorded for mixtures BBTM 11, PA 8, and PA 11.

Table 4.

Influence of short-term ageing on ITSR, ITSw, and ITSd characteristics (change).

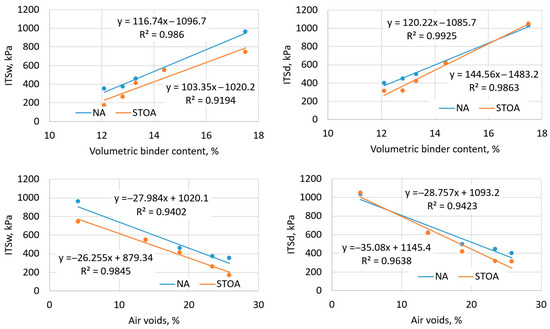

The next step in the analysis involved assessing the influence of mixture parameters—specifically air void content and asphalt content—on ITSR, ITSw, and ITSd values. In the case of the first indicator, the correlations are weaker; however, they suggest a favourable effect of higher binder content and lower mixture porosity. This relationship is evident only in the non-aged (NA) condition. After short-term oven ageing (STOA), the correlations become insignificant (Figure 6), which may indicate that the ageing process affects the properties of the mixture to such an extent that its physical characteristics lose relevance.

Figure 6.

Relationship between the ITSR index and asphalt content as well as air void content.

Significantly stronger correlations were obtained when evaluating the influence of mixture parameters on the strength of wet and dry specimens. The values of the coefficient of determination (R2) are very high—all exceeding 0.9. All derived relationships clearly indicate a directly proportional effect of asphalt content and an inversely proportional effect of air void content on the ITSw and ITSd strength indices (Figure 7).

Figure 7.

Relationship between ITSw/ITSd strength and asphalt content as well as air void content.

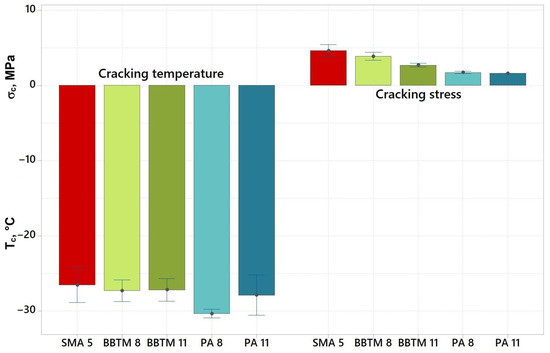

Another critical test influencing the durability of wearing courses is the evaluation of low-temperature cracking resistance. This test is conducted with consideration of short-term ageing (STOA). The results, presented in Figure 8, demonstrate clear variability depending on the type of asphalt mixture. In general, the Porous Asphalt mixture PA 8 exhibited the most favourable performance, with fracture temperatures around −29 to −30 °C, whereas the SMA 5 mixture showed the least favourable results, with a fracture temperature of approximately −26.5 °C.

Figure 8.

Comparison of TSRST results.

A statistical analysis of the fracture temperature data post-ageing indicates that only the PA 8 mixture differs significantly from the other mixtures. The temperature differences among the remaining mixtures do not exceed approximately 1.5 °C and are not statistically significant.

The second evaluated parameter is the fracture stress. In this case, the results exhibit greater variability, and the differences are statistically significant, with the exception of the PA 8 and PA 11 mixture pair, which showed no significant difference. Moreover, an inverse relationship was observed between low-temperature cracking resistance and fracture stress: mixtures with lower cracking resistance (i.e., higher fracture temperatures) exhibited higher fracture stress values.

The stress development trends, illustrated in Figure 9, further reveal that both the absolute values of fracture stress and the rate of stress increase with decreasing temperature serve to distinguish the analysed mixtures. The slowest rate of stress increase was observed in the Porous Asphalt mixtures PA 8 and PA 11, whereas the fastest increase was recorded for the SMA 5 and BBTM 8 mixtures.

Figure 9.

Development of thermal stress during TSRST test.

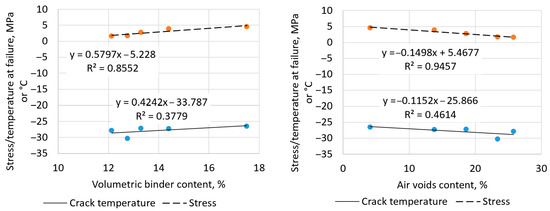

In the subsequent part of the study, Figure 10 presents an analysis of the relationship between low-temperature cracking resistance and both air void content and the volumetric asphalt content in the mixtures. The strongest linear correlation within the scope of air void content was observed in the relationship shown in Figure 10 (R2 = 0.94), indicating that the fracture stress is inversely proportional to the air void content in the asphalt mixture.

Figure 10.

Correlation between the volumetric properties of the mixture and the temperature or fracture stress.

The correlation between air void content and fracture temperature is slightly weaker (R2 = 0.46), yet it reveals a trend in which mixtures with higher air void content tend to exhibit more favourable (i.e., lower) fracture temperatures.

A similar conclusion can be drawn from the analysis of the asphalt binder content in the asphalt mixture. Here, a significant correlation with fracture stress was also found (R2 = 0.86). Although the correlation between asphalt content and fracture temperature is lower (R2 = 0.46), the results still suggest that an increase in asphalt content leads to an unfavourable increase in fracture temperature.

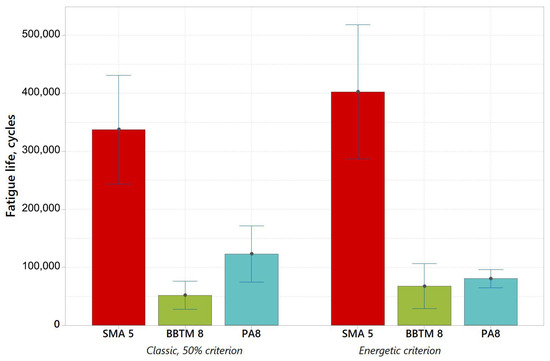

Although fatigue test is considered supplementary for surface course mixtures, it provides valuable insights by differentiating asphalt mixtures in terms of quality. It is also important to note that the mechanism of top-down fatigue cracking is well documented and relevant for surface layers.

The next two tests were conducted on a limited number of mixtures—three in total, one of each type: SMA 5, BBTM 8, and PA 8. The latter two mixtures were selected primarily due to their finer aggregate gradation, closer to that of the SMA 5 mixture. Additionally, the PA 8 mixture exhibited the best low-temperature cracking resistance.

The fatigue test was carried out under a relatively high strain amplitude (350 µm/m) to ensure a feasible test duration and to evaluate the performance of the mixtures under extreme conditions. The results are presented in Figure 11, incorporating two fatigue criteria: the conventional N criterion and the energy-based N1 criterion. For statistical evaluation, the results include 95% confidence intervals.

Figure 11.

Fatigue test results.

Data analysis indicates that, regardless of the fatigue criterion applied, the SMA 5 mixture exhibited the highest fatigue durability. In the next phase of the analysis, a one-way ANOVA test was performed to assess the equality of means. The results revealed no statistically significant differences between the PA 8 and BBTM 8 mixtures, as confirmed by p-values of 0.059 and 0.044, respectively. In contrast, the SMA 5 mixture demonstrated a significantly higher fatigue life.

This difference can be attributed to its favourable composition, particularly the higher asphalt binder content and lower air void content, which are known to enhance fatigue resistance. The influence of the fatigue criterion itself was found to be statistically insignificant, indicating that the energy-based approach does not yield meaningfully different results compared to the conventional 50% stiffness reduction method.

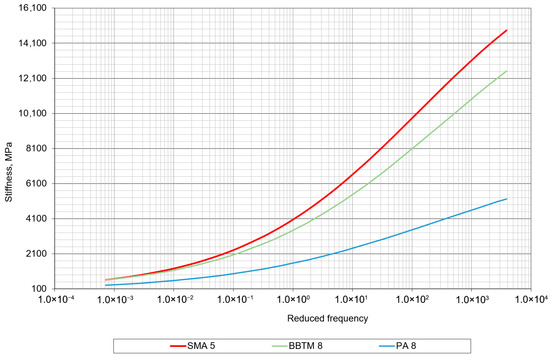

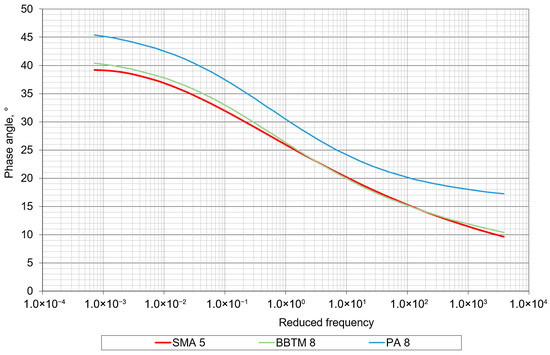

The final functional test conducted was the complex modulus analysis. The results are presented in the form of master curves for the complex modulus (Figure 12) and phase angle (Figure 13), as a function of reduced frequency. Both graphs reveal significantly different rheological properties among the tested asphalt mixtures.

Figure 12.

Master curves of stiffness modulus.

Figure 13.

Master curves of phase angle.

In terms of stiffness, the Porous Asphalt mixture PA 8 exhibited the lowest modulus values across the entire frequency spectrum. It is also worth noting that the rate of stiffness increase with rising frequency was lower for PA 8 compared to the other two mixtures. Overall, the SMA 5 mixture displayed the highest stiffness, with its difference relative to the BBTM 8 mixture becoming more pronounced at higher reduced frequencies. However, at low reduced frequencies (corresponding to higher temperatures), these two mixtures exhibited very similar stiffness values.

The phase angle analysis indicates that PA 8 had the highest values throughout the measured range, suggesting a greater contribution of the viscous phase in its complex modulus. The remaining two mixtures showed very similar phase angle characteristics, with BBTM 8 exhibiting slightly higher values.

Based on these findings, it can be observed that at low temperatures (i.e., high reduced frequencies), the PA 8 mixture is characterised by both the lowest stiffness and the greatest contribution of the viscous component. These findings are consistent with the results of low-temperature cracking resistance tests, where PA 8 demonstrated favourable performance by exhibiting lower fracture temperatures and reduced fracture stresses. Similar conclusions can be drawn when comparing the BBTM 8 mixture to the SMA 5 mixture.

Additionally, Figure 14 presents a Black diagram illustrating the relationship between stiffness and phase angle. This plot demonstrates how the mixture behaviour evolves with varying air void content—progressing from SMA (dense-graded) through BBTM to PA (open-graded). With increasing air void content, there is a noticeable shift towards lower stiffness and a greater contribution of the viscous phase.

Figure 14.

Black diagrams.

4.2. Water Permeability

Macrotexture and internal structure, which determine the air void content and access to active pores, are key factors influencing the water permeability of asphalt mixtures. Figure 15 presents the relationship between laboratory-measured water permeability and air void content (lab mixture).

Figure 15.

Water permeability results from laboratory measures in relationship to laboratory asphalt mixtures’ air voids.

It can be observed that as the air void content increases, water permeability—expressed in metres per second of water flow—rises exponentially. The SMA 5 mixture, characterised by a fine gradation and dense structure, exhibits virtually zero permeability; the small numerical values recorded are primarily due to minor leakages around the rubber cuff used to seal the specimen in the test column.

When analysing the results for open-graded mixtures shown in Figure 15, such as BBTM and porous asphalt (PA), it is evident that the horizontal permeability (Kh) is consistently higher than the vertical permeability (Kv). This reflects the likely water flow behaviour in real pavements with a single porous layer, where horizontal flow predominates in a wearing course. In such cases, the efficiency of water drainage will depend on both the pavement width and the cross slope. When comparing the horizontal water permeability (Kh) results of the mixtures, it is evident that mixtures with finer aggregate gradation, such as BBTM 8 and PA 8, exhibit lower horizontal permeability than their corresponding mixtures with coarser gradation, namely BBTM 11 and PA 11. The measured Kh values for BBTM 8 and BBTM 11 were 0.12 m/s and 0.90 m/s, respectively, while for PA 8 and PA 11, the values were 2.01 m/s and 4.15 m/s, respectively.

In situ testing using the Texas permeameter on trial road sections confirmed the trends observed in the laboratory investigations. In this field method, the water outflow time from the cylinder is measured and expressed in seconds. In addition to air void content, the macrotexture of the asphalt mixture plays a significant role in this test, as it affects water flow from the cylinder due to the flexible base seal’s adherence to the pavement surface.

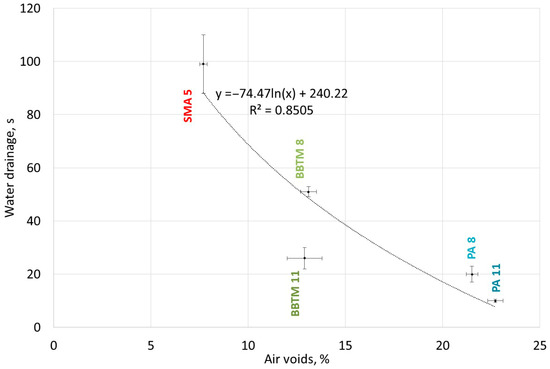

Figure 16 illustrates the relationship between water outflow time (determined in the field) and air void content (cores drilled from the pavement layers). Given the nature of the test, it can be observed that as the air void content increases, the outflow time decreases logarithmically. It is important to emphasise that the Texas method captures the real horizontal water flow behaviour of the pavement surface. Since the efficiency of water drainage may depend on pavement width and transverse slope, each measurement was taken at one metre from the pavement edge to ensure consistency.

Figure 16.

In situ water drainage in the field in relation to asphalt layers’ air voids.

As shown in Figure 16, the SMA 5 mixture, characterised by fine aggregate gradation and a dense structure, exhibited a very long water outflow time of 99 s. In this case, the water flow was surface-bound and occurred primarily through texture-induced pathways, governed by the macrotexture of the surface.

A comparison of the outflow times measured with the field device demonstrates that mixtures with a smaller maximum aggregate size (BBTM 8 and PA 8) have longer outflow times than coarser mixtures (BBTM 11 and PA 11). Specifically, water outflow times were 51 s for BBTM 8 and 26 s for BBTM 11; for PA 8 and PA 11, the times were significantly lower, with a value of 20 s and 10 s, respectively.

Analysis of the results for open-graded (BBTM) and porous (PA) mixtures reveals a trend consistent with the laboratory permeability tests: as the air void content increases, water drainage through the mixture improves, leading to shorter outflow times. These findings indicate that surface drainage performance can be effectively managed by selecting the appropriate mixture type, maximum aggregate size, and target air void content, depending on the functional requirements for macrotexture and pavement type.

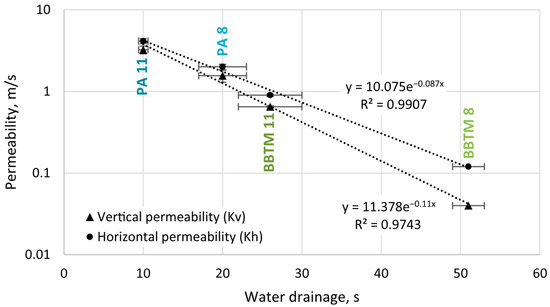

Figure 17 illustrates the relationship between laboratory-measured water permeability and field-measured drainage performance. The graph shows a strong correlation between field water drainage and both horizontal permeability (Kh) and vertical permeability (Kv). This correlation is significant, as it enables designers to predict in-service drainage performance during the laboratory mixture design stage by selecting appropriate mixture characteristics, thereby ensuring the required drainage capability of the surface layer.

Figure 17.

Correlation of the laboratory water permeability to the in situ water drainage in the field.

An analysis of the correlation trends shown in Figure 17 indicates that the PA 11 mixture demonstrates the most favourable drainage performance. It exhibits the highest water permeability and the shortest water outflow time. At the opposite end is the BBTM 8 mixture, which shows the lowest permeability and the longest outflow time, indicating a less effective drainage capacity. It should be noted that SMA 5 was excluded from this ranking comparison, as in its case, air void content does not influence water permeability. Instead, water outflow is governed solely by the surface macrotexture, with no contribution from interconnected porosity.

5. Conclusions

The study assessed asphalt mixtures intended for so-called quiet pavements in terms of selected properties that significantly impact the durability of the pavement surface course under traffic loads and climatic conditions. These mixtures included SMA 5, BBTM 8B, BBTM 11B, PA 8, and PA 11. The mixtures differed in component proportions, grain size, asphalt content, and void content. Based on the analyses conducted, the following conclusions have been drawn:

- In most cases, the analyses revealed significant differences resulting from the mixture type and its parameters.

- In terms of water and frost resistance, the SMA 5 mixture demonstrated slightly better parameters than the other mixtures, but the significantly higher tensile strength values were particularly observed, regardless of the ageing and conditioning of the samples. For mixtures with higher void content and lower asphalt content, meeting the ITSR requirement of at least 90% proved difficult. STOA technological ageing adversely affects water and frost resistance.

- The results of the low-temperature crack resistance test under limited deformation conditions yielded slightly different conclusions. In this case, the best results in terms of fracture temperature were achieved by the PA 8 and PA 11 Porous Asphalt mixtures, while the lowest results were achieved by the SMA 5 mixture. At the same time, the mixtures with the highest void content were characterised by significantly lower tensile stress at fracture and significantly lower stress increase. Despite the relatively positive assessment of PA mixtures based on TSRST test results, it should be noted that the method itself does not account for more unfavourable conditions that may occur during operation, such as freezing of a water-saturated porous layer, which can occur especially in the case of dirt or impeded drainage from the pavement.

- The third analysed characteristic was fatigue resistance. This phenomenon is primarily attributed to the lower structural layers, but the mechanism of fatigue crack initiation in the wearing course on roads with very heavy traffic is also known. In this case, the SMA 5 mixture is characterised by significantly higher fatigue life than the BBTM 8 and PA 8 mixtures. This is due to the beneficial effect of increased binder content and lower void content.

- According to the laboratory and in situ water permeability tests, it should be noticed that in the laboratory mixtures with finer aggregate gradation, such as BBTM 8 and PA 8, exhibit lower horizontal permeability than their corresponding mixtures with coarser gradation, namely, BBTM 11 and PA 11. In the field, the PA 11 mixture demonstrates the most favourable drainage performance. Moreover, as the air void content increases, water drainage improves.

In summary, the research indicates that mixtures with increased void content may exhibit lower durability parameters. In addition, the surface drainage performance can be effectively managed by selecting the appropriate mixture type, maximum aggregate size, and target air void content, depending on the functional requirements for macrotexture and pavement type. This should be considered both in the mix design process, by using the best possible materials and conducting additional testing, and also when selecting the mixture type to find an optimum between durability and acoustic parameters of the pavement layer. The conducted study demonstrates that, in terms of most durability-related properties, the use of BBTM-type mixtures is more advantageous, at the cost of lower water permeability and, as reported in other studies, reduced noise reduction.

The next stage of the work, currently planned and being carried out by the authors, involves a re-evaluation of the mixtures on the test section after several years of service. The study will focus on comparing the degree of ageing of the mixtures and the asphalt binder.

Author Contributions

W.B.: Writing—Review and Editing. J.B.K.: Writing, Investigation. K.J.K.: Writing, Conceptualization. R.H.: Methodology, Data Curation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Centre for Research and Development (NCBR) in Poland for technological development and demonstration under grant agreement [ZPB/22/64486/IT2/10].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| OGFC | Open-Graded Friction Course |

| RAP | Reclaimed Asphalt Pavement |

| SMA | Stone Mastic Asphalt |

| BBTM | Béton Bitumineux Très Mince (Very Thin Bituminous Concrete) |

| PA | Porous Asphalt |

| PMB | Polymer-Modified Bitumen |

| CT | Computed Tomography |

| NA | Non-Aged (unaged specimens) |

| STOA | Short Term Oven Ageing |

| ITS | Indirect Tensile Strength |

| ITSd | Indirect Tensile Strength (dry specimens) |

| ITSw | Indirect Tensile Strength (wet specimens) |

| ITSR | Indirect Tensile Strength Ratio |

| LTC | Low Temperature Cracking |

| TSRST | Thermal Stress Restrained Specimen Test |

| 4PB | Four-Point Bending |

| Kv | Vertical Permeability coefficient |

| Kh | Horizontal Permeability coefficient |

References

- McGhee, K.K.; Clark, T.M. Functionally optimized wearing course: Installation report. Transp. Res. Rec. 2010, 2180, 150–155. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Hasan, M.R.M.; van de Ven, M. Permeability loss in porous asphalt due to binder creep. Constr. Build. Mater. 2012, 30, 10–15. [Google Scholar] [CrossRef]

- Kowalski, K.J.; McDaniel, R.S.; Shah, A.; Olek, J. Long-Term Monitoring of Noise and Frictional Properties of Three Pavements: Dense-Graded Asphalt, Stone Matrix Asphalt, and Porous Friction Course. Transp. Res. Rec. (TRR) J. Transp. Res. Board (TRB) 2009, 2127, 12–19. [Google Scholar] [CrossRef]

- Ranieri, V.; Sansalone, J.J.; Shuler, S. Relationships among Gradation Curve, Clogging Resistance, and Pore-Based Indices of Porous Asphalt Mixes. Road Mater. Pavement Des. 2010, 11 (Suppl. S1), 507–525. [Google Scholar] [CrossRef]

- Fedele, V.; Berloco, N.; Colonna, P.; Hertrich, A.; Intini, P.; Ranieri, V.; Sansalone, J.J. Computational Fluid Dynamics as a Tool to Estimate Hydraulic Conductivity of Permeable Asphalts. Transp. Res. Rec. 2020, 2674, 370–383. [Google Scholar] [CrossRef]

- Chen, S.; You, Z.; Yang, S.-L.; Zhou, X. Prediction of the coefficient of permeability of asphalt mixtures using the lattice Boltzmann method. Constr. Build. Mater. 2020, 240, 117896. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Zhu, H. Investigation of permeability of open graded asphalt mixture considering effects of anisotropy and two-dimensional flow. Constr. Build. Mater. 2017, 145, 318–325. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, H.; Xie, K.; Jiang, L.; Ren, T.; Sun, Y. Meso-structural evolution characteristics of porous asphalt mixtures with stress-induced and their effects on environmental functions. Constr. Build. Mater. 2024, 432, 136687. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, J.; Wei, D.; Tan, Y. Research on the permanent deformation mechanism and dynamic meso-mechanical response of porous asphalt mixture composite structure using the discrete element method. Constr. Build. Mater. 2023, 407, 133531. [Google Scholar] [CrossRef]

- Maia, R.S.; Lu, Y.; Hajj, R. Porous asphalt mixture performance in cold regions: Case study of Chicago. Case Stud. Constr. Mater. 2024, 20, e03250. [Google Scholar] [CrossRef]

- Guo, M.; Yao, X.; Du, X. Low temperature cracking behavior of asphalt binders and mixtures: A review. J. Road Eng. 2023, 3, 350–369. [Google Scholar] [CrossRef]

- Pszczoła, M.; Ryś, D.; Jaskuła, P. Analysis of climatic zones in Poland with regard to asphalt performance grading. Roads Bridges–Drog. I Mosty 2017, 16, 245–264. [Google Scholar] [CrossRef]

- Zhou, Y.; Cheng, Z.; Zheng, X.; Wang, T.; Wu, X.; Yu, X.; Xie, S. A holistic exploration of porous asphalt mixtures: From durability and permeability to low-temperature and functional properties. Heliyon 2025, 11, e41437. [Google Scholar] [CrossRef]

- Ranieri, V.; Berloco, N.; Garofalo, F.; He, L.; Intini, P.; Kowalski, K.J. Effects of Reclaimed Asphalt, Wax Additive, and Compaction Temperature on Characteristics and Mechanical Properties of Porous Asphalt. Balt. J. Road Bridge Eng. 2022, 17, 187–213. [Google Scholar] [CrossRef]

- De Pascale, B.; Tataranni, P.; Lantieri, C.; Bonoli, A.; Vignali, V. Mechanical performance and environmental assessment of porous asphalt mixtures produced with EAF steel slags and RAP aggregates. Constr. Build. Mater. 2023, 400, 132889. [Google Scholar] [CrossRef]

- Ma, F.; Wang, Y.; Shi, K.; Fu, Z.; Huang, R.; Lou, B.; Barbieri, D.M.; Zhu, C.; Zhao, Z. Stiffness, fatigue and cracking performance of porous asphalt concrete under varying freeze-thaw cycles. Constr. Build. Mater. 2025, 483, 141709. [Google Scholar] [CrossRef]

- Sun, B.; Li, M.; Yang, L.; Li, D. Mitigation of freeze-thaw damage to open-graded friction courses in seasonal climate areas via a binary phase change system. Constr. Build. Mater. 2024, 412, 134764. [Google Scholar] [CrossRef]

- Liu, S.; Huang, R.; Wang, J.; Bie, J.; Hernandez, A.G. Shear strength parameters for porous asphalt mixtures: From macro to meso. Mater. Des. 2024, 238, 112670. [Google Scholar] [CrossRef]

- Arrieta, V.S.; Córdoba Maquilón, J.E. Resistance to Degradation or Cohesion Loss in Cantabro Test on Specimens of Porous Asphalt Friction Courses. Procedia—Soc. Behav. Sci. 2014, 162, 290–299. [Google Scholar] [CrossRef]

- Skaf, M.; Espinosa, A.; Ortega-López, V.; Revilla-Cuesta, V.; Manso, J.M. Field study evolution on a porous asphalt mixture pavement containing ladle furnace slag. Case Stud. Constr. Mater. 2025, 22, e04115. [Google Scholar] [CrossRef]

- Yuan, G.; Zhang, J.; Ren, Z.; Zhao, Z. Study on compaction characteristics and mechanical performance deterioration of large stone porous asphalt mixes. Constr. Build. Mater. 2023, 400, 132777. [Google Scholar] [CrossRef]

- Dehnad, M.H.; Akbari, A.; Hamedi, G.H. The effect of zirconium dioxide on the moisture sensitivity of porous asphalt mixtures under moisture situations with different degrees of acidity. Constr. Build. Mater. 2025, 492, 142899. [Google Scholar] [CrossRef]

- DeLaFuente-Navarro, C.; Lastra-González, P.; Indacoechea-Vega, I.; Castro-Fresno, D. Mechanical, rheological and functional consequences of healing of porous asphalt mixtures by magnetic induction. Constr. Build. Mater. 2024, 453, 139090. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).