1. Introduction

Leymus chinensis (Trin.) Tzvel. is a perennial gramineous forage species extensively distributed in the northern grasslands and agro-pastoral ecotones of China. It serves as a dominant and constructive species in the steppe ecosystems of eastern Eurasia [

1,

2]. This species demonstrates strong resistance to environmental stressors such as drought, salinity, and low temperatures, making it both a key species for restoring degraded grasslands and a high-quality forage resource [

3,

4]. With the rapid advancement of grassland agricultural mechanization in recent years, the lack of efficient seed cleaning technology for

L. chinensis has become a major bottleneck hindering large-scale cultivation. Traditional cleaning methods are characterized by low separation precision and considerable mechanical damage to seeds, which fail to meet the quality and efficiency demands of mechanized seeding [

5].

Due to the similar physical properties of

L. chinensis seeds and straw, mechanical cleaning processes often experience clogging, low separation efficiency, and seed damage caused by material intermixing. These issues directly affect the quality of seed cleaning and reduce overall economic efficiency [

6,

7,

8]. In the development of

L. chinensis seed cleaning equipment, traditional approaches depend heavily on empirical, trial-and-error methods, leading to prolonged development cycles and elevated costs [

9,

10]. There is an urgent need for simulation-based design optimization. Purely experimental methods fail to capture the micro-mechanical interactions between seeds and straw, thus restricting theoretical advancements in

L. chinensis cleaning technology.

Recently, the discrete element method (DEM) has found wide application in agricultural machinery research [

11,

12,

13]. In the field of discrete element method (DEM) research related to crop seeds, numerous scholars have conducted calibration of DEM simulation parameters for mainstream crop seeds such as maize [

14,

15,

16], rice [

17], wheat [

18,

19], and

Panax notoginseng [

20]. Zhao Xuan et al. [

21,

22] combined response surface methodology (RSM) with feedforward neural networks (FNN) to optimize key variables in DEM parameter calibration for sunflower seeds. Hou Zhanfeng et al. [

23] calibrated parameters for

Elymus sibiricus seeds to ensure that simulated repose angles closely matched empirical values during coating simulations. In crop straw studies, Zhang Xirui et al. [

24] developed a bonding discrete element model for banana straw using the Hertz–Mindlin with bonding contact model and conducted parameter calibration. Xia Junfang [

25] constructed a flexible DEM model of rice straw via particle replacement, followed by parameter calibration and multi-condition validation. Du Zhe [

26] proposed a three-layer DEM model for tea stems based on an enhanced bonding approach and conducted relevant simulations and experiments.

These studies suggest that most existing DEM research has concentrated on either crop seeds or straw as single materials. However, no DEM model has yet been developed for mixtures of L. chinensis seeds and straw. This study systematically determines the physical properties, calibrates the contact parameters, and develops a DEM model for this mixed-material system. The results aim to support the simulation-based design of L. chinensis cleaning equipment, offer insights into contact–collision behaviors in mixed materials, reduce field testing costs, and enhance research and development efficiency.

3. Results

3.1. Results of the Plackett–Burman Screening Experiment

The experimental design and results of the Plackett–Burman screening test are summarized in

Table 9. The data were analyzed using Design-Expert 13 software to evaluate the significance of each parameter on the repose angle. The significance analysis results are presented in

Table 10.

As shown in

Table 10, the influence of contact parameters on the repose angle, ranked in descending order of significance, was as follows: seed–straw dynamic friction coefficient, seed–seed static friction coefficient, seed–straw static friction coefficient, seed–seed coefficient of restitution, seed–seed dynamic friction coefficient, seed–straw coefficient of restitution, straw–straw static friction coefficient, straw–straw coefficient of restitution, and straw–straw dynamic friction coefficient.

Among these, three parameters—the seed–straw dynamic friction coefficient, seed–seed static friction coefficient, and seed–straw static friction coefficient—exhibited statistically significant effects, with p-values less than 0.01. The remaining six parameters did not exhibit statistically significant effects. Therefore, these three significant parameters were selected for further investigation using the steepest ascent experimental design.

3.2. Results of the Steepest Ascent Experiment

The design and results of the steepest ascent experiment are summarized in

Table 11. The minimum relative error of the repose angle occurred in Run 3, indicating that the optimal parameter region lies near the values used in that run. Accordingly, the parameter set from Run 3 was chosen as the center point, while those from Runs 2 and 4 were used as the low and high levels, respectively, in the subsequent Box–Behnken design.

3.3. Results of the Box–Behnken Experimental Design

A three-factor, three-level response surface experiment was conducted based on the results of the steepest ascent test to optimize the seed–straw dynamic friction coefficient, seed–seed static friction coefficient, and seed–straw static friction coefficient in the simulation. The repose angle was selected as the evaluation index. The experimental design and results are summarized in

Table 12.

A regression analysis of the experimental results was conducted using Design-Expert 13 software to evaluate the significance of each factor, as summarized in

Table 13. The resulting regression equation for the repose angle response variable (

Y) is as follows:

The significance analysis results indicate that the seed–seed static friction coefficient L, seed–straw static friction coefficient M, and seed–straw dynamic friction coefficient N all have highly significant effects on the repose angle. Moreover, significant pairwise interactions were observed among certain factors. In particular, the interaction between L and M was highly significant, whereas the interaction between L and N was not statistically significant.

The regression model for the response variable (repose angle) demonstrated a highly significant overall fit. A p-value greater than 0.05 from the lack-of-fit test suggests that no significant terms were omitted from the model. The results of this study indicate that the seed-seed static friction coefficient and the seed-straw static friction coefficient are the two key factors influencing the seed cleaning performance of Leymus chinensis. Therefore, in constructing the discrete element model for Leymus chinensis straw and seeds, it is crucial to accurately calibrate the interactions between the two to accurately predict the actual cleaning performance.

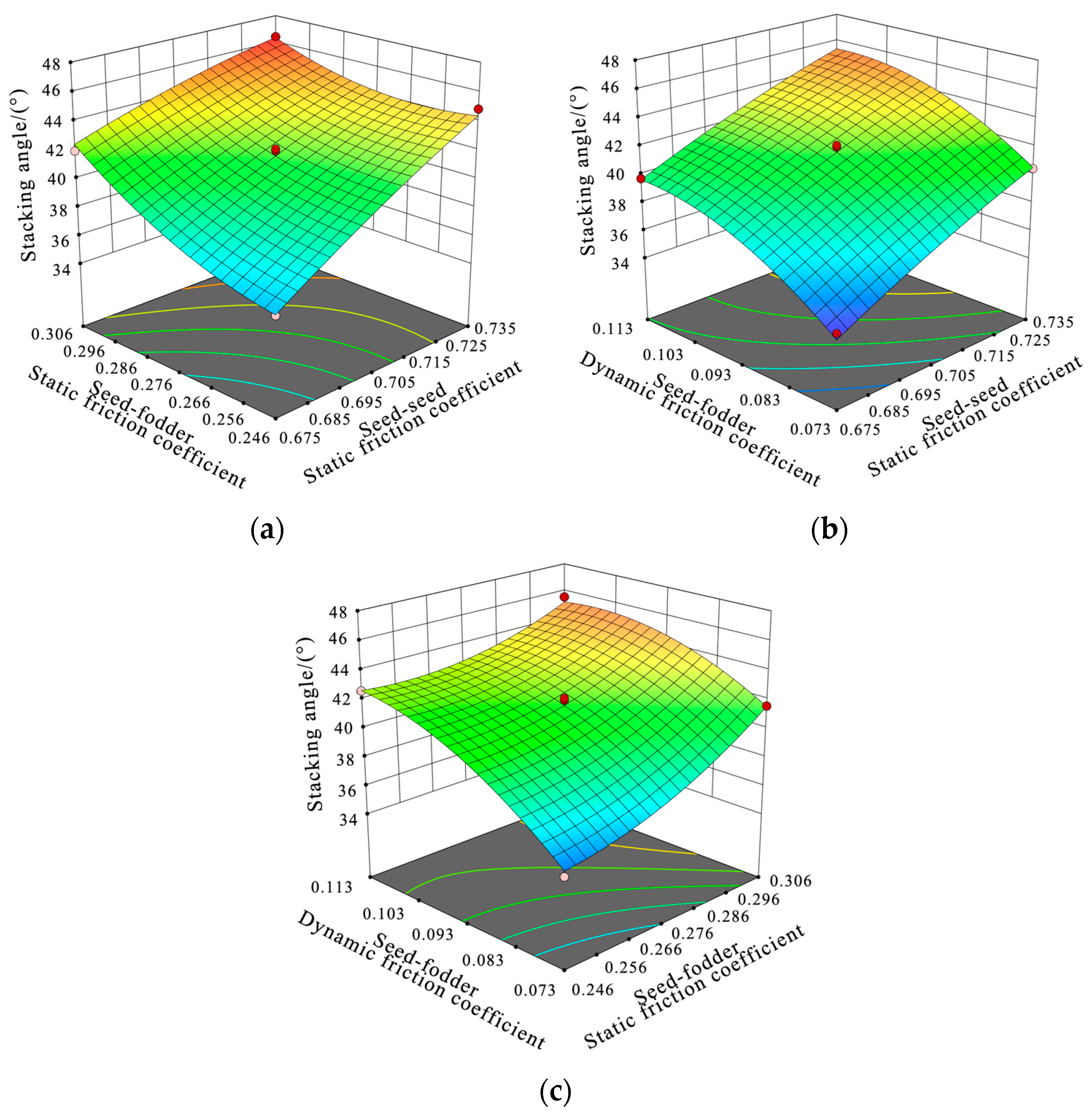

Based on the regression equation given in Equation (5), response surface plots were generated to visualize the effects of significant factor interactions on the repose angle, as shown in

Figure 7. As shown in

Figure 7a, the response surface is steeper along the seed–seed static friction coefficient

L axis than along the seed–straw static friction coefficient

M axis, indicating that

L has a stronger effect on the repose angle.

Figure 7b and

Table 11 confirm that the interaction between

L and seed–straw dynamic friction coefficient

N is not significant. As shown in

Figure 7c, the response surface is steeper along the

M axis than the

N axis, further confirming that

M has a greater effect on the repose angle than

N.

3.4. Parameter Optimization and Simulation Validation

A repose angle test was conducted using the L. chinensis seed–straw mixture, and the measured repose angle was 41.14°. Taking the experimentally measured repose angle as the target response, multi-objective parameter optimization was performed with Design-Expert 13 software using the established quadratic regression model. The optimal values of the seed–seed static friction coefficient L, seed–straw static friction coefficient M, and seed–straw dynamic friction coefficient N were determined to be 0.709, 0.281, and 0.085, respectively.

The repose angle was simulated three times using the discrete element method (DEM), yielding values of 42.534°, 41.921°, and 41.669°. The average simulated repose angle was 42.041°, with a relative error of 2.14% compared to the measured value.

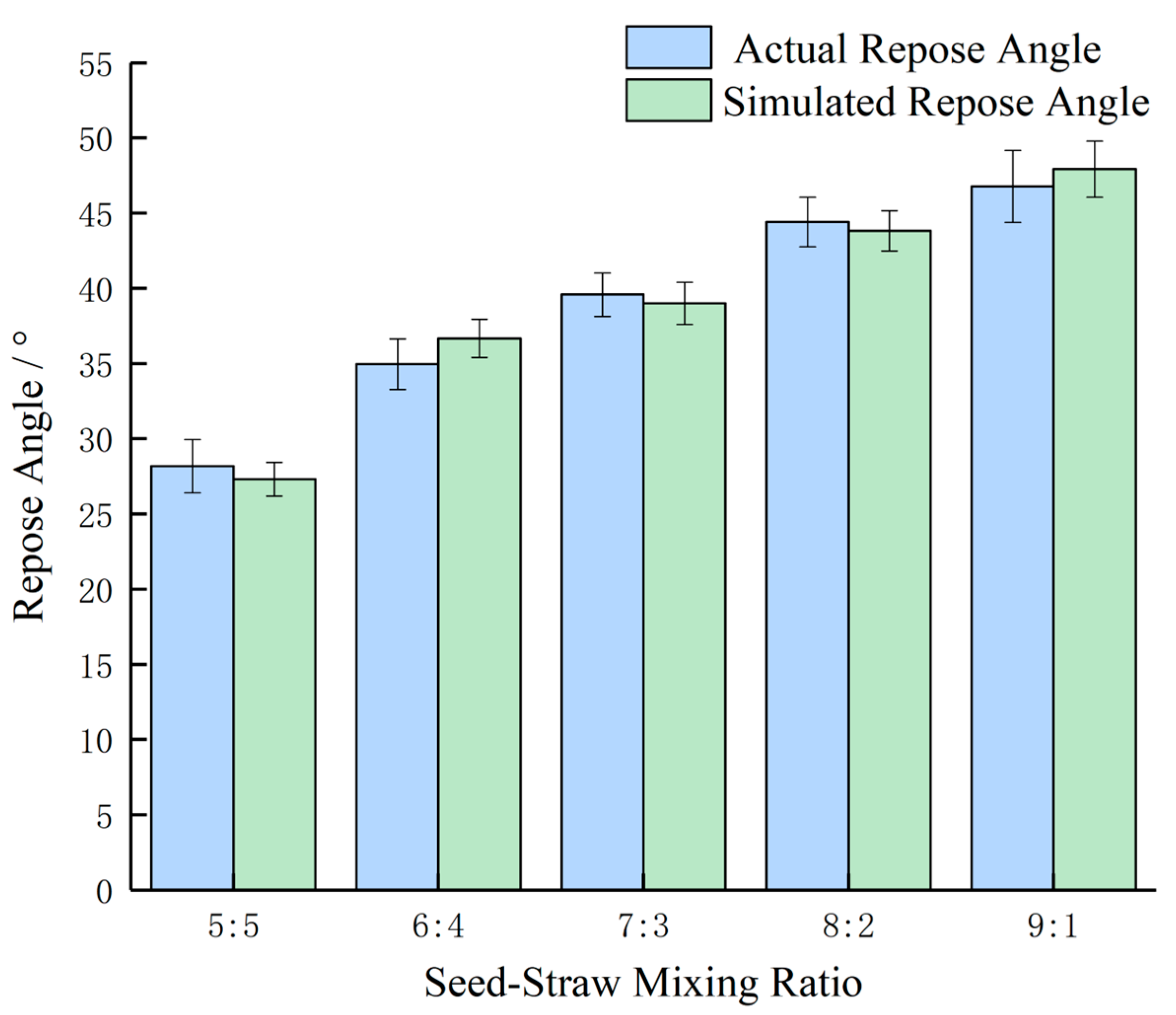

To verify the accuracy of the parameters, the seed-straw mixing ratio of

L. chinensis seeds and straw was divided by weight into 5:5, 6:4, 7:3, 8:2, and 9:1, as shown in

Figure 8. Five groups of physical- and simulation-combined validation experiments were then conducted, with experimental errors of 3.05%, 4.86%, 1.44%, 1.31%, and 2.46%, respectively. The small errors demonstrate the accuracy of the calibrated parameters.

4. Conclusions

This study conducted a comprehensive investigation into the mechanical characteristics and interaction mechanisms of L. chinensis seed–straw mixtures by measuring physical properties, calibrating contact parameters, and constructing a discrete element model. The findings provide key parameters and theoretical support for the simulation-based optimization of seed cleaning equipment, with the main conclusions outlined below:

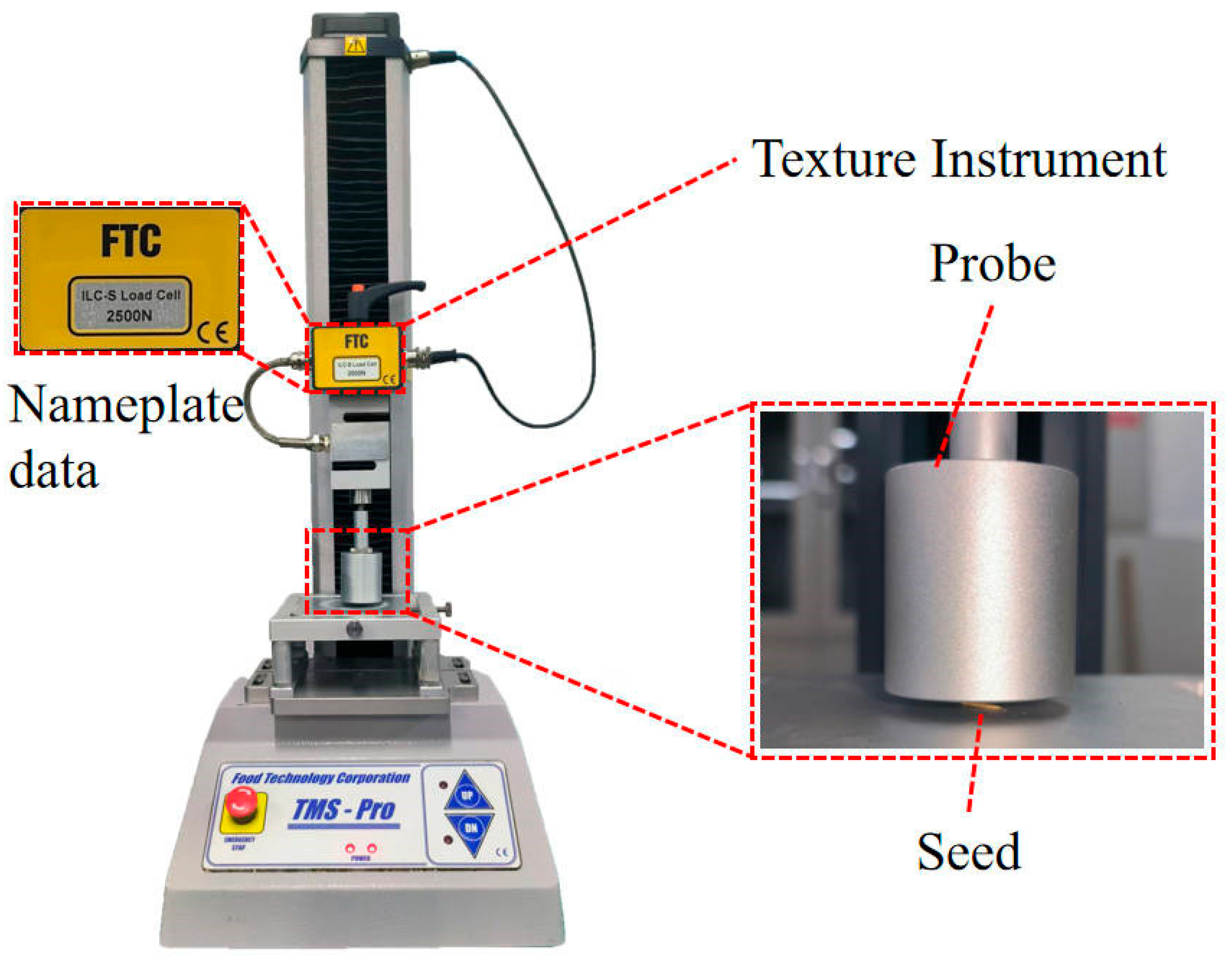

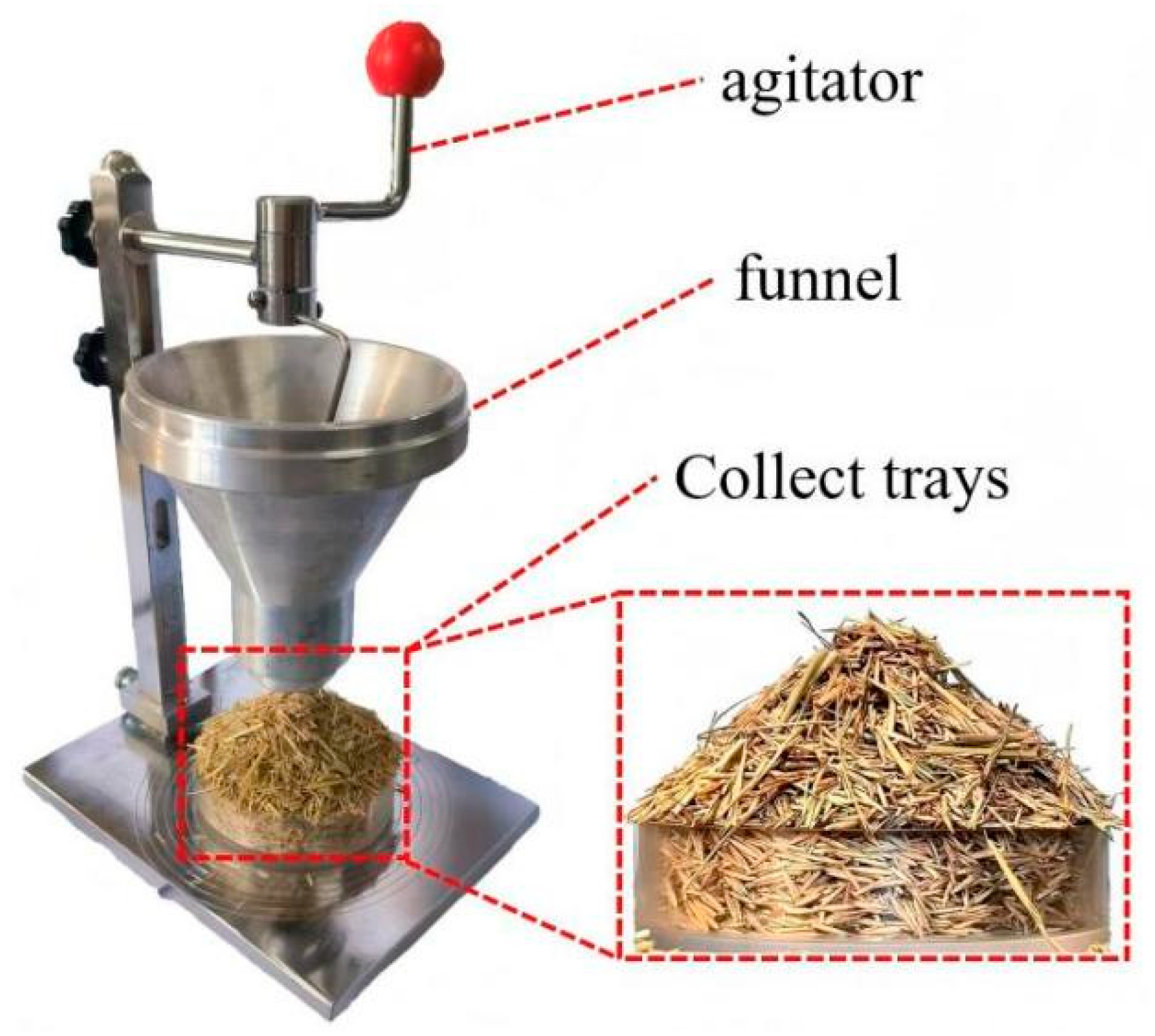

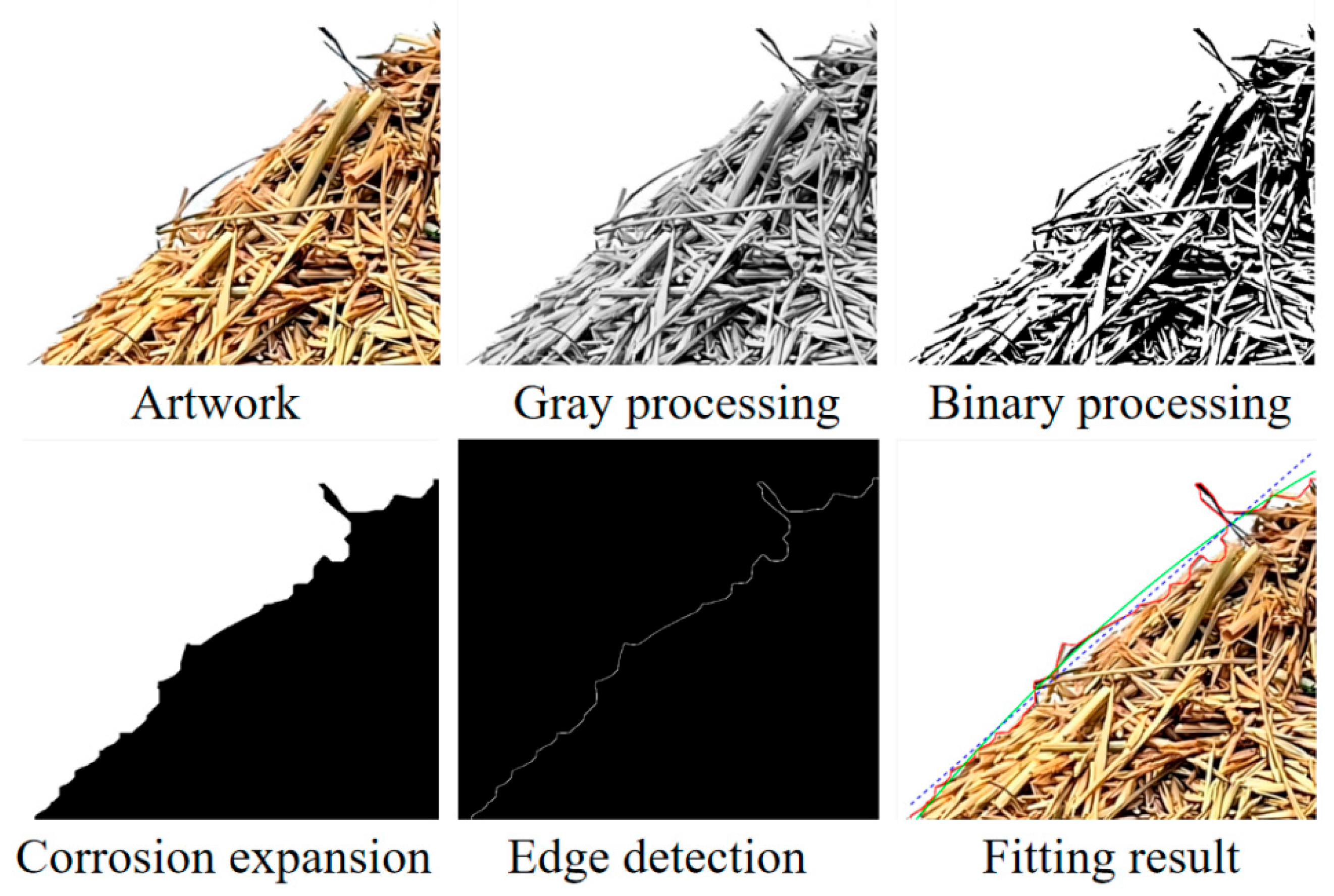

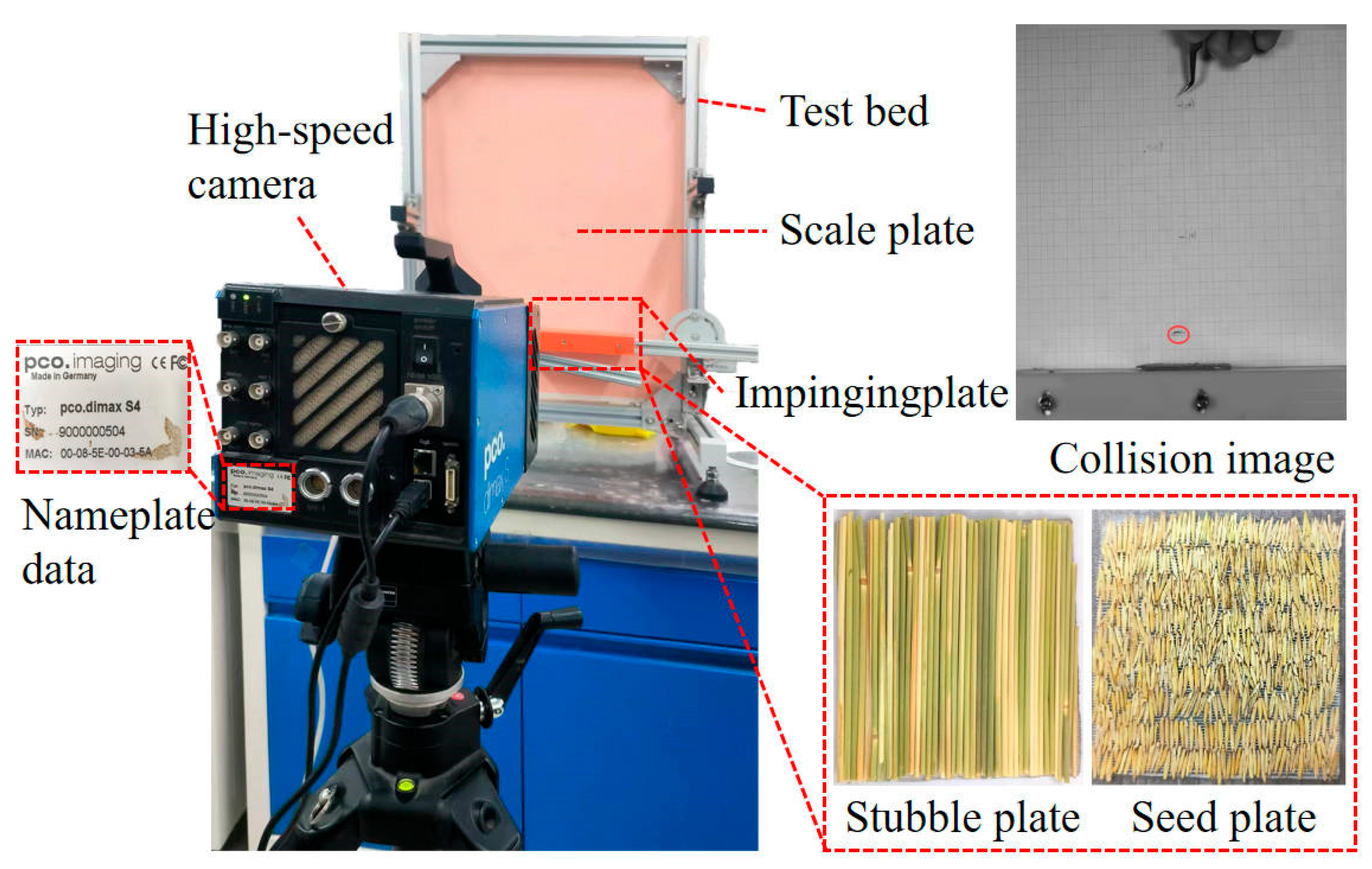

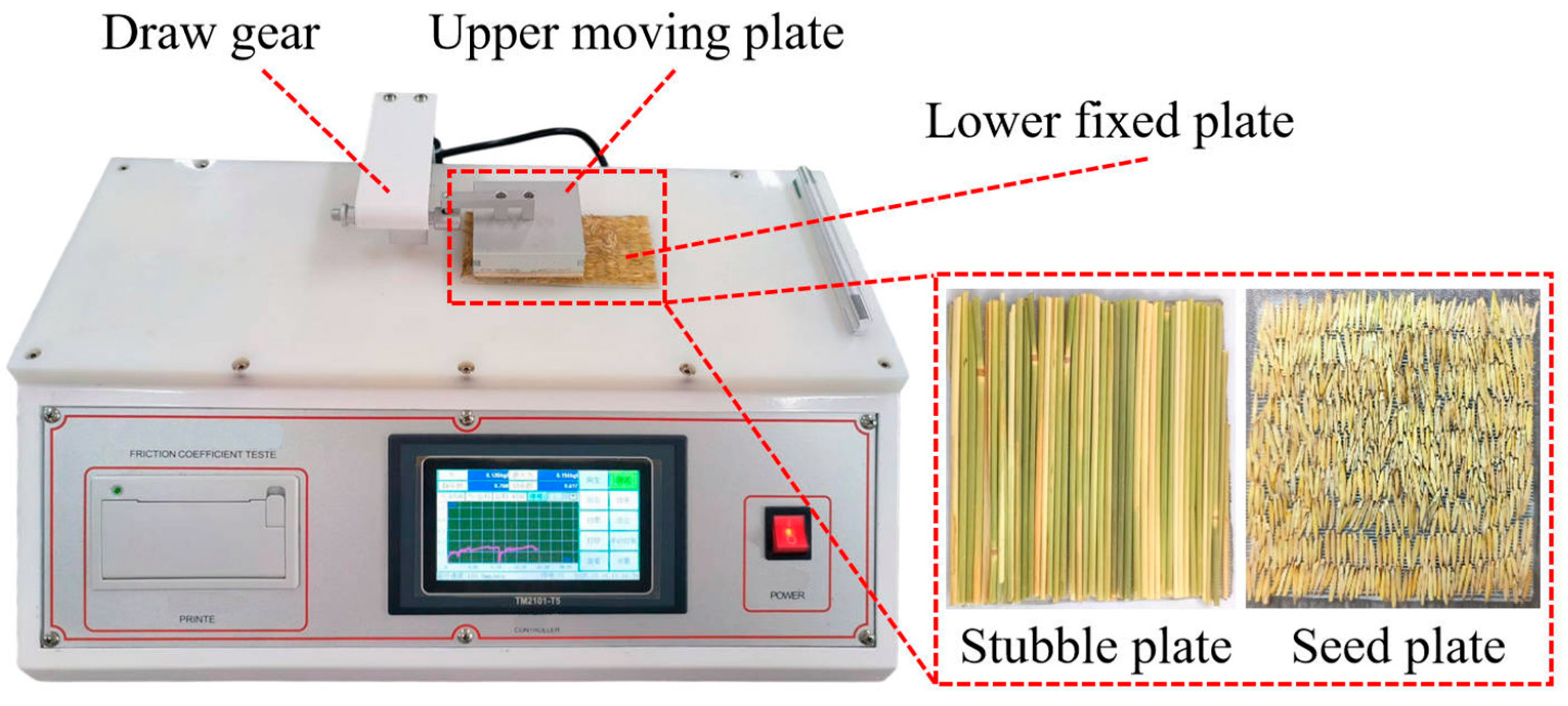

1. The basic physical properties of L. chinensis seeds and straw—including triaxial dimensions, thousand-seed weight, density, moisture content, Poisson’s ratio, elastic modulus, and shear modulus—were obtained through physical experiments. The average repose angle was measured to be 41.14° using a SC-104B repose angle tester in combination with MATLAB-based image processing. The restitution coefficients for seed–seed, seed–straw, and straw–straw contacts were 0.349, 0.378, and 0.241, respectively, based on high-speed camera analysis. The static and dynamic friction coefficients were measured to be 0.72 and 0.46 (seed–seed), 0.30 and 0.10 (seed–straw), and 0.26 and 0.09 (straw–straw), respectively.

Through the determination of physical properties, the density and moisture content of L. chinensis seeds and straw are nearly identical, which is a significant challenge in the cleaning of L. chinensis materials. However, in the contact parameters, the friction coefficient and restitution coefficient of L. chinensis straw relative to the seeds are smaller, indicating that the straw has better sliding properties and poorer elasticity. This aspect can be considered for optimizing the structure in subsequent cleaning processes.

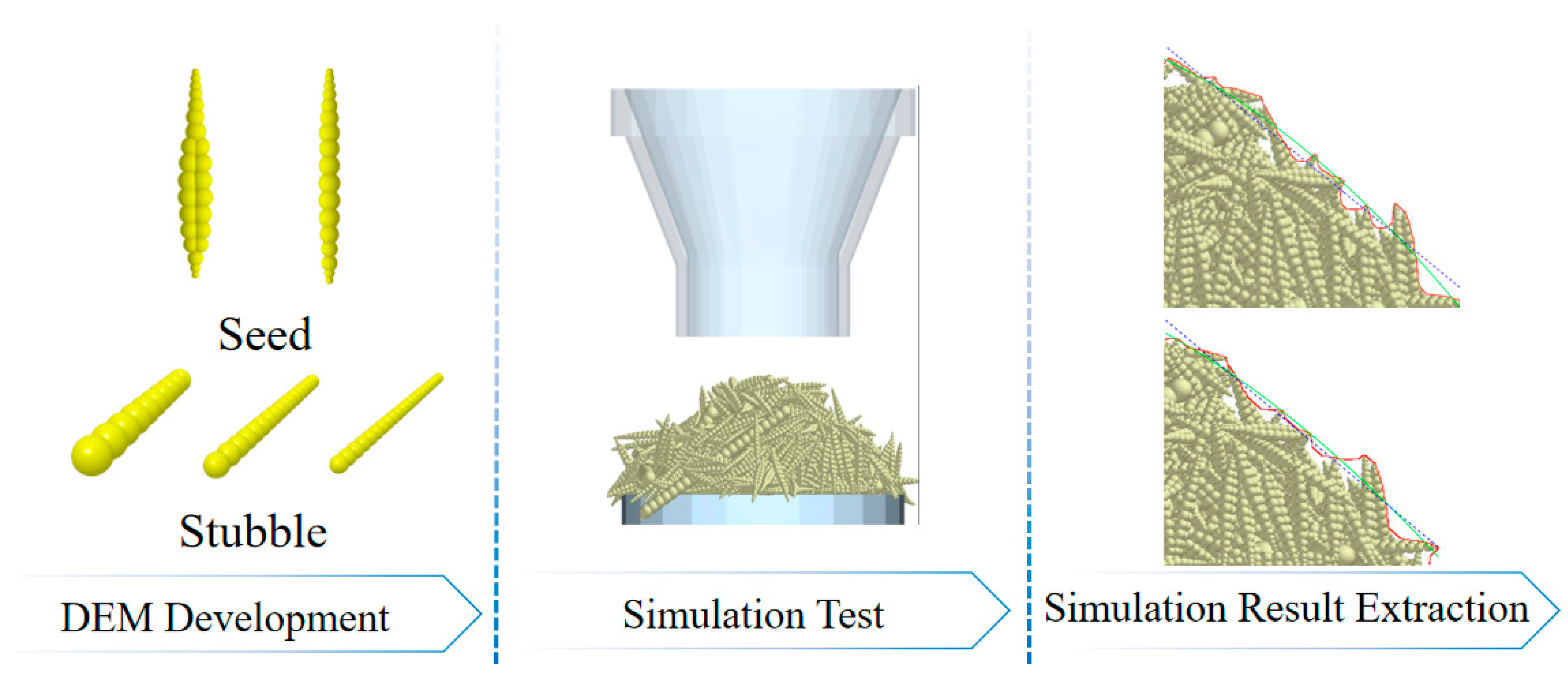

2. A discrete element simulation model of the L. chinensis seed–straw mixture was developed using the Hertz–Mindlin (no slip) contact model. The seed mass proportion was 73.2%, and each seed was represented by a cluster of 24 particles to capture its elongated, flattened geometry. Straw particles were categorized into three length-based groups—long, medium, and short—with mass proportions of 21%, 36%, and 43%, respectively. This modeling strategy greatly improved the realism of the simulation. However, potential issues may arise when applied to more complex or industrial-scale flows, and further optimization will be conducted thereafter.

3. Key parameters affecting the repose angle of the mixture were identified and optimized. The Plackett–Burman experiment revealed that the seed–straw dynamic friction coefficient, seed–seed static friction coefficient, and seed–straw static friction coefficient had significant effects (p < 0.01). These parameters were further optimized using steepest ascent and Box–Behnken experimental designs. The optimized values for the seed–seed static friction coefficient, seed–straw static friction coefficient, and seed–straw dynamic friction coefficient were 0.709, 0.281, and 0.085, respectively. Validation tests using the parameter set derived from the experimental results yielded a relative error of 2.14% compared to the measured repose angle. Additionally, five sets of validation tests combining physical and simulation results were conducted, with experimental errors of 3.05%, 4.86%, 1.44%, 1.31%, and 2.46%, respectively. The small errors indicate the reliability of the model.

This study presents the first discrete element model for L. chinensis seed–straw mixtures. The findings offer essential parameters and theoretical insights for the simulation-based design of seed cleaning equipment and provide a valuable reference for discrete element modeling of other forage seed–straw systems.