Open-Source Smart Wireless IoT Solar Sensor

Abstract

Featured Application

Abstract

1. Introduction

1.1. Problem Description

1.2. Proposed Solution

2. Related Work and Literature Review

2.1. Integrating Solar Irradiance Meters in the Industrial IoT Context

2.2. Machine Learning in Corroboration with IoT

3. Methodology and Research Questions

3.1. Research Questions

- How can solar irradiance be reliably measured using a PV device that simultaneously serves as an energy harvester while maintaining accuracy comparable to industrial pyranometers?

- What architectural principles enable the design of an autonomous, energy-independent IoT irradiance meter that balances low power consumption, scalability, and reliable cloud connectivity?

- To what extent does the proposed temperature-compensation polynomial improve the accuracy of PV-based irradiance measurements under varying environmental conditions?

- How does the error profile of the developed device compare against that of reference industrial irradiance meters across different irradiance and temperature ranges?

- What are the advantages and limitations of integrating sensing and energy harvesting into the same PV panel, compared with conventional sensor-based IoT monitoring solutions?

- How can IoT-enabled irradiance meters contribute to data-driven applications such as short-term solar forecasting, anomaly detection, and predictive maintenance when coupled with machine learning methods?

- What implications does the proposed system have for large-scale deployment in distributed PV monitoring, particularly regarding cost reduction, calibration requirements, and long-term reliability?

3.2. Research Hypotheses

3.3. Methodology

- Literature Review and State-of-the-Art Analysis

- Conducted a comprehensive survey of research publications and commercial solutions.

- Identified gaps in solar irradiance measurement and IoT integration.

- Defined the motivation for a low-cost, autonomous, IoT-enabled irradiance sensor.

- System Architecture Definition

- Proposed a modular architecture with three key components:

- -

- Energy harvesting from a PV panel.

- -

- Irradiance measurement using the same PV panel.

- -

- IoT-based data transmission to the cloud.

- Designed for scalability, low energy consumption, and interoperability.

- Circuit Simulation

- Simulated the energy harvesting subsystem for efficiency under variable irradiance.

- Simulated the irradiance measurement circuitry for linearity and stability.

- Established baselines for prototype development.

- Prototyping and Validation of Simulations

- Built laboratory prototypes of the simulated circuits.

- Performed measurements to validate simulation results.

- Refined design based on component tolerances and real-world noise.

- Final Product Design and Implementation

- Integrated validated subsystems into a compact prototype.

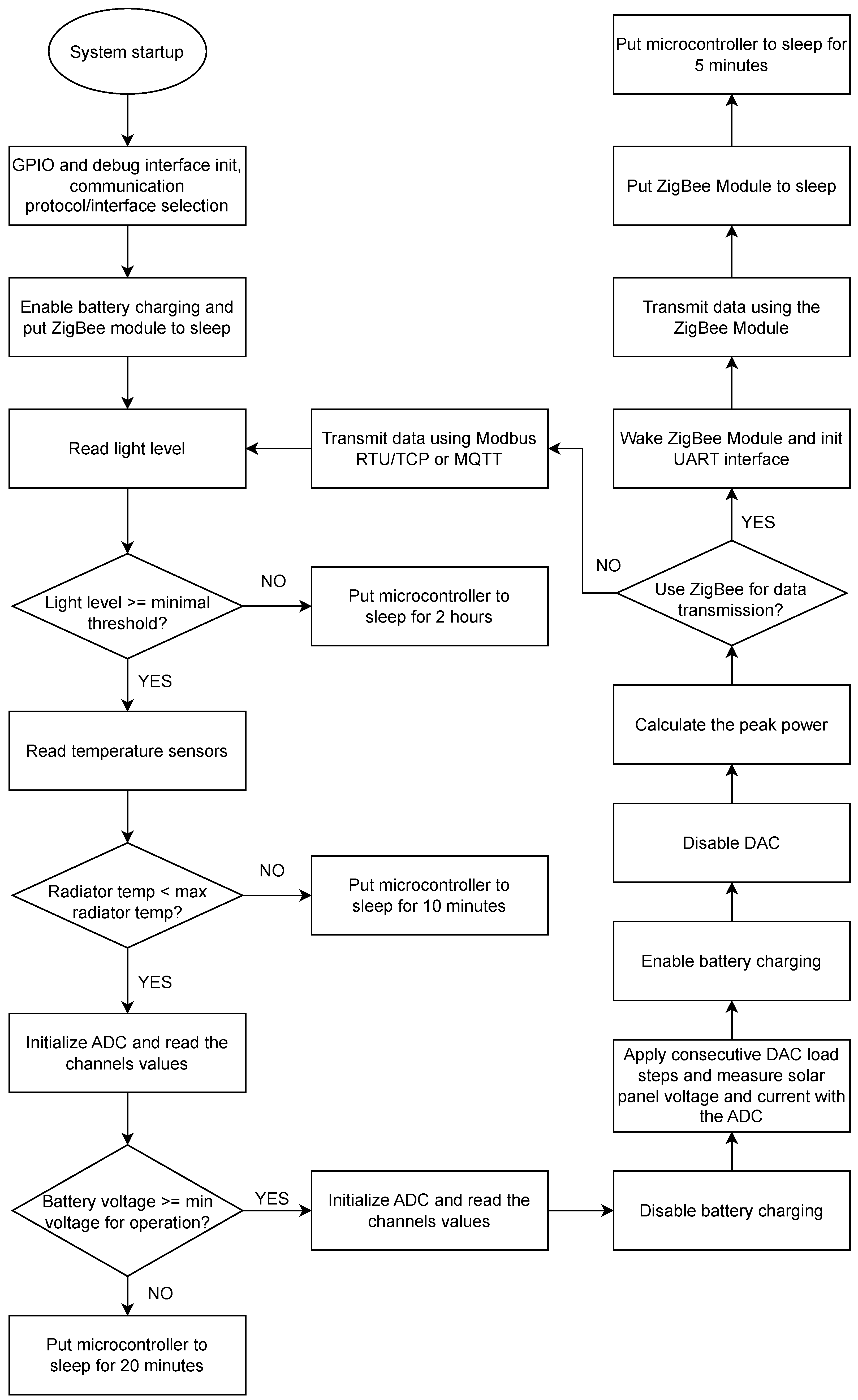

- Developed firmware for data acquisition, wireless communication, and power management.

- Ensured robustness and low-power operation for autonomous deployment.

- Functional Validation

- Verified energy harvesting, irradiance measurement, and IoT connectivity.

- Confirmed reliable operation under outdoor conditions.

- Data Collection and Temperature Compensation

- Deployed the device for continuous data acquisition.

- Collected reference data using an industrial irradiance meter.

- Developed a temperature-compensation polynomial to correct PV sensor deviations.

- Implementation of Temperature Compensation

- Embedded the polynomial correction model in the device firmware.

- Enabled real-time compensation of irradiance measurements.

- Calibration and Error Characterization

- Calibrated the device against the reference industrial irradiance meter.

- Analyzed residual errors to evaluate accuracy.

- Confirmed the suitability of the device for monitoring and research use.

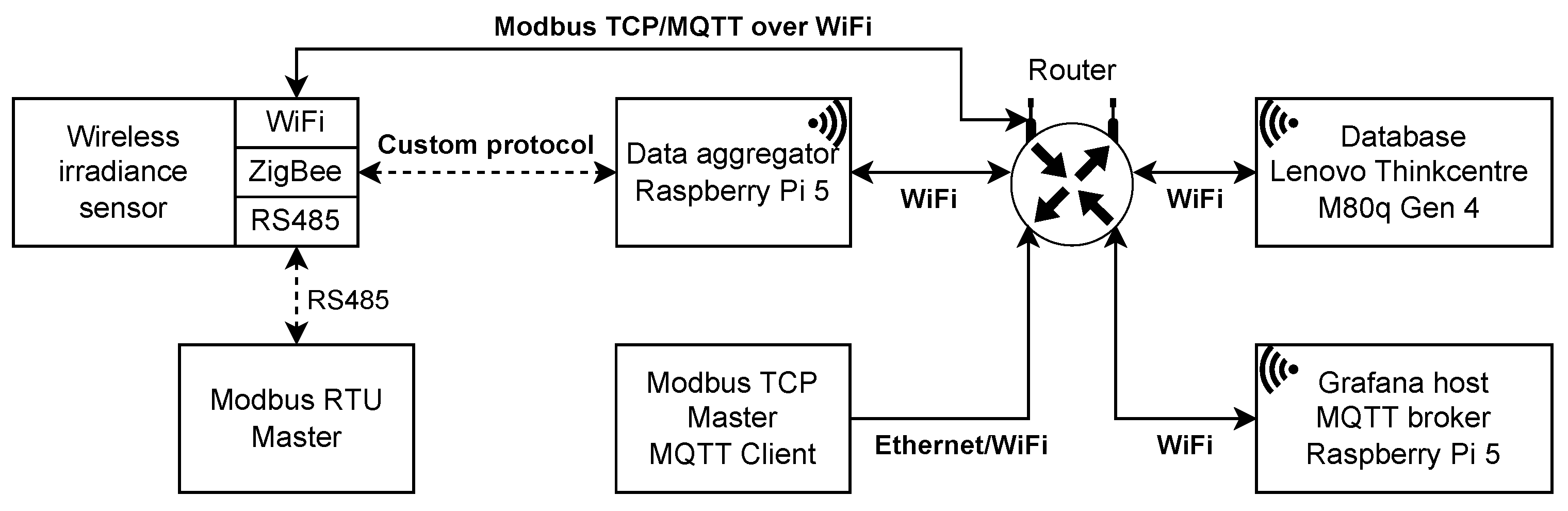

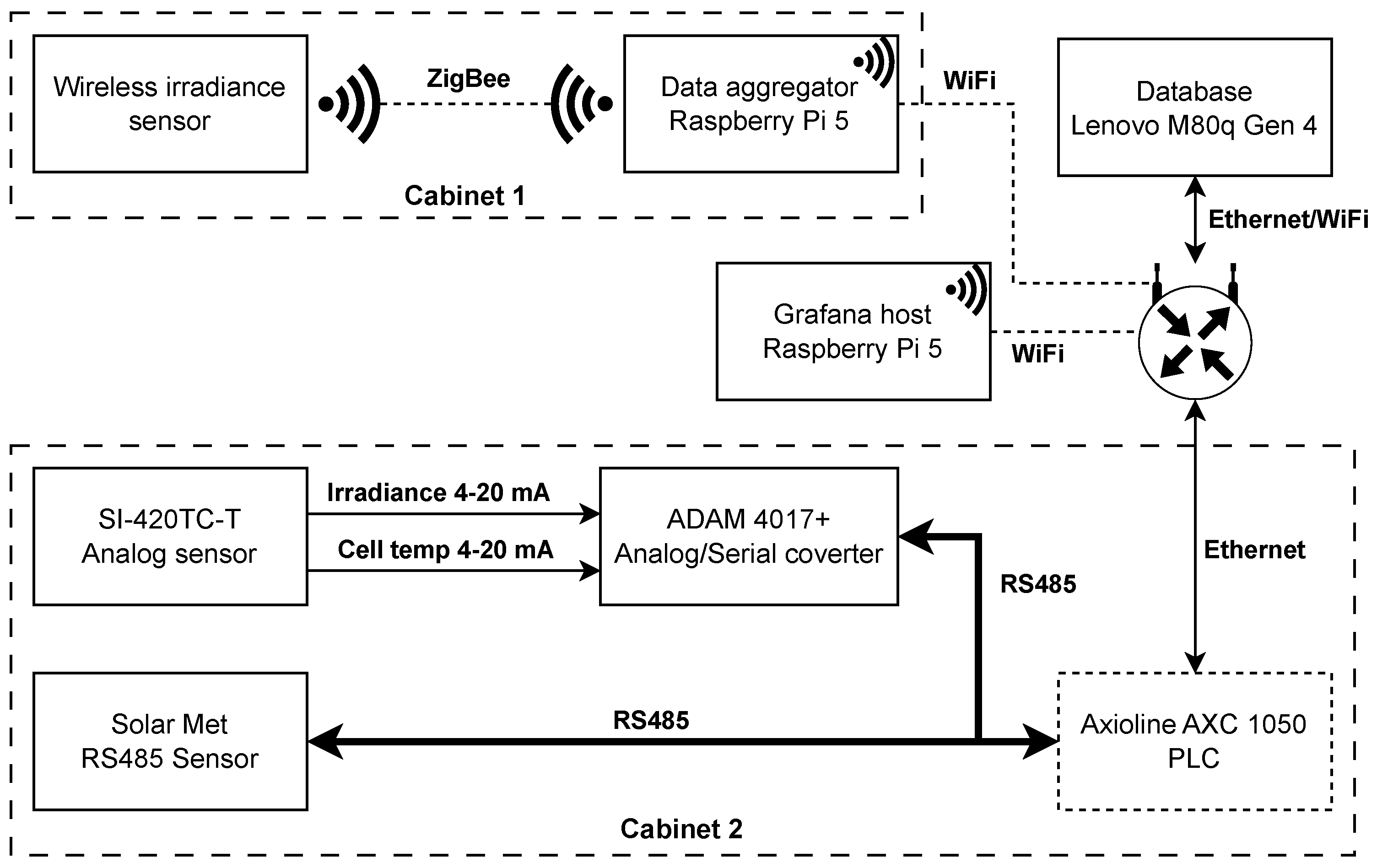

4. Solution Architecture

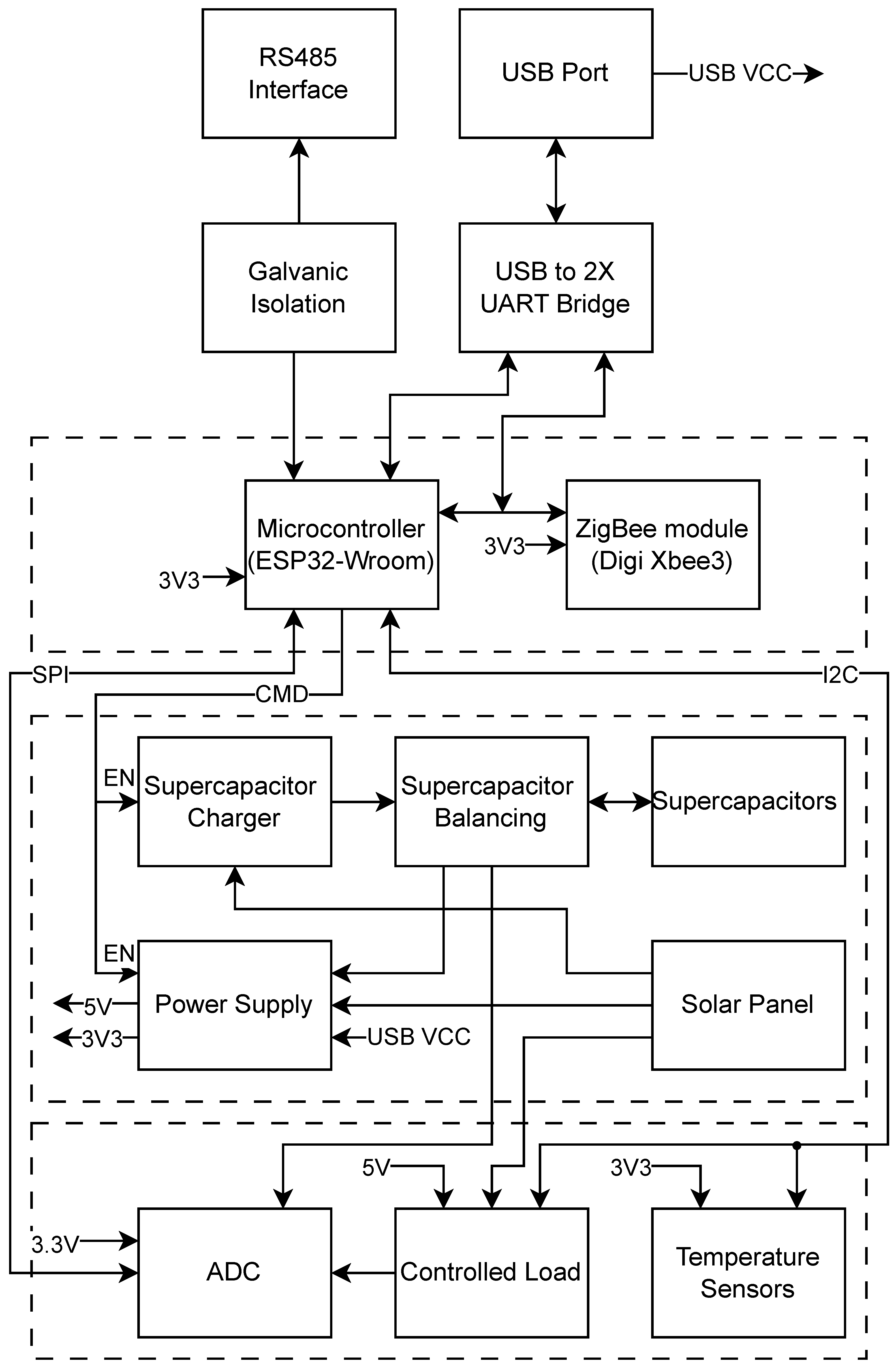

4.1. Hardware Architecture

- Communication interfaces;

- Processing;

- Power management;

- Solar irradiance measurement block.

4.1.1. Microcontroller

4.1.2. Power Supply

4.1.3. Analog-to-Digital Converter (ADC)

4.1.4. Communication Interfaces

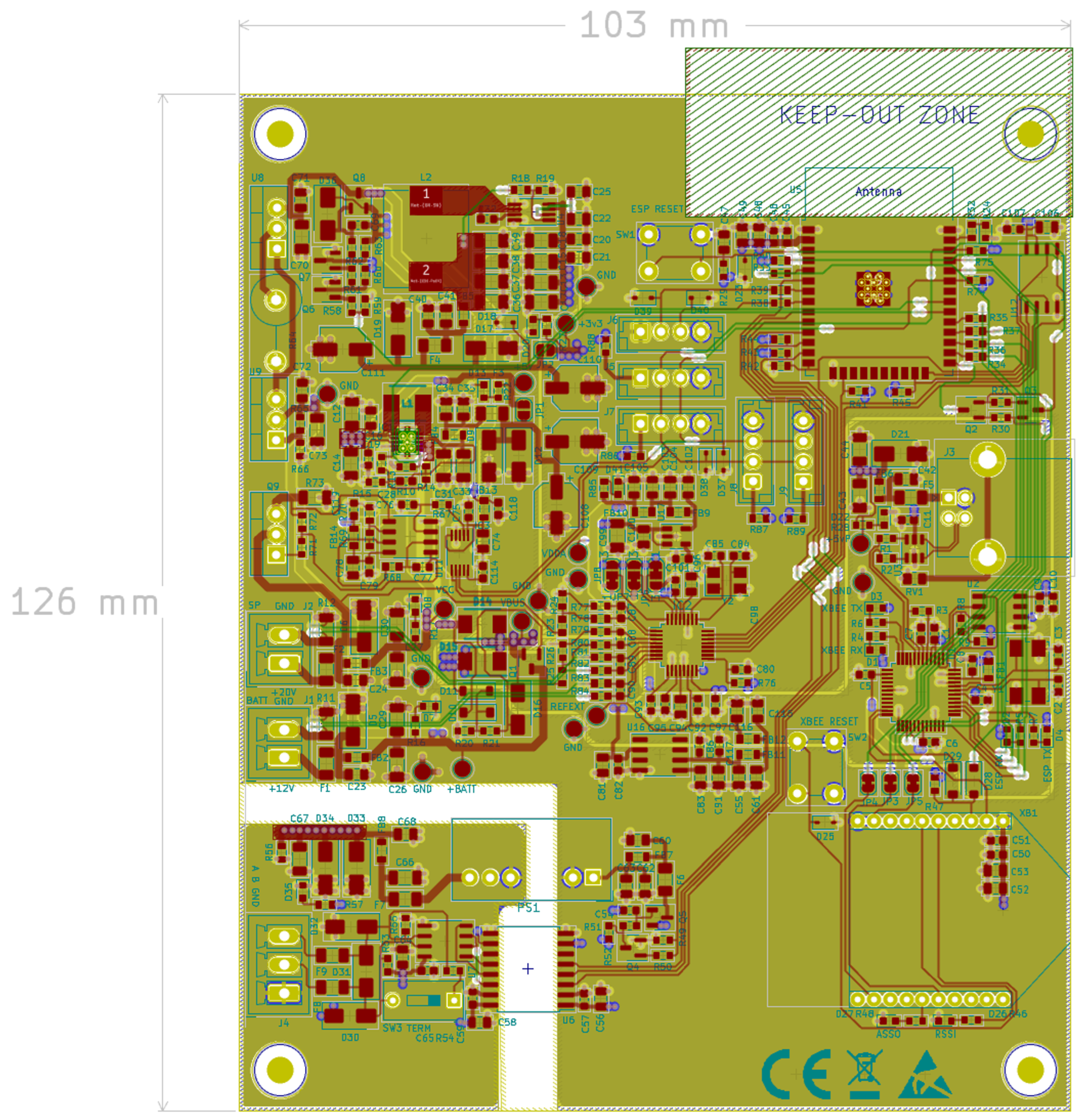

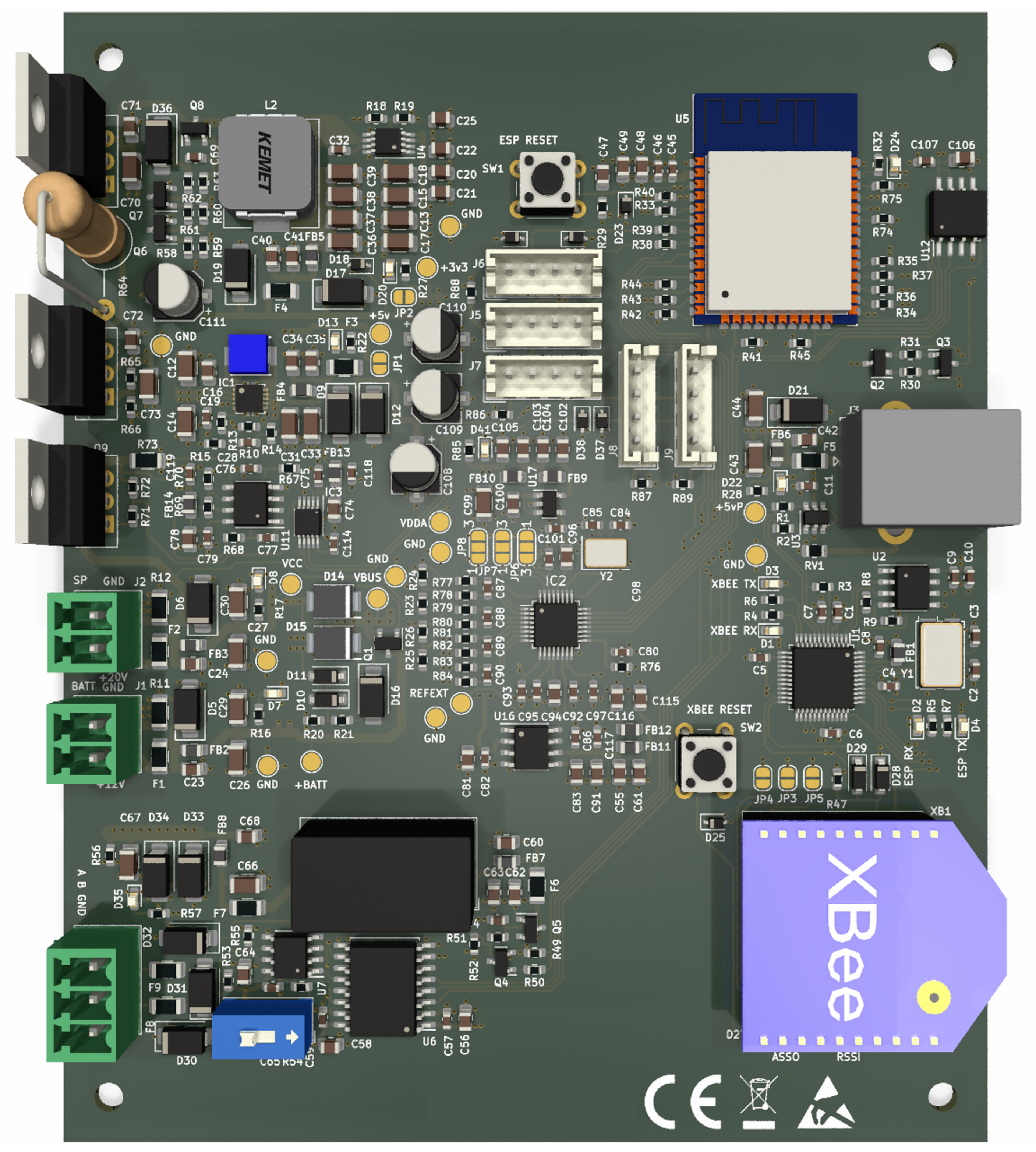

4.1.5. Device Assembly and PCBs

4.2. Software Architecture

4.2.1. Calibration Procedure and Measured Values Calculation

4.2.2. Measurement Data Acquisition Architecture

- Modbus RTU, via the RS-485 serial interface, is implemented with the device operating as a slave within the Modbus communication topology, allowing it to be interrogated by a master device. All measured values are continuously updated in the internal memory of the device and made available in the form of holding registers or input registers;

- Modbus TCP, through the Wi-Fi interface of the ESP32 microcontroller, is also supported, with the device operating as a slave within the Modbus communication topology and being interrogated by a Modbus TCP master device. The same memory map containing the measured values available for Modbus RTU is employed for the Modbus TCP protocol as well;

- MQTT, via the Wi-Fi interface of the microcontroller, is implemented with the device operating as a client that can connect to an MQTT broker, subscribe to a topic, and publish the measured values. Another client subscribing to the same MQTT topic can then receive the values transmitted by the sensor;

- A custom binary serial protocol, implemented within the microcontroller’s algorithm, utilizing the ZigBee interface to send data to an aggregator (further described below).

5. Experimental Setup and Testing Procedure

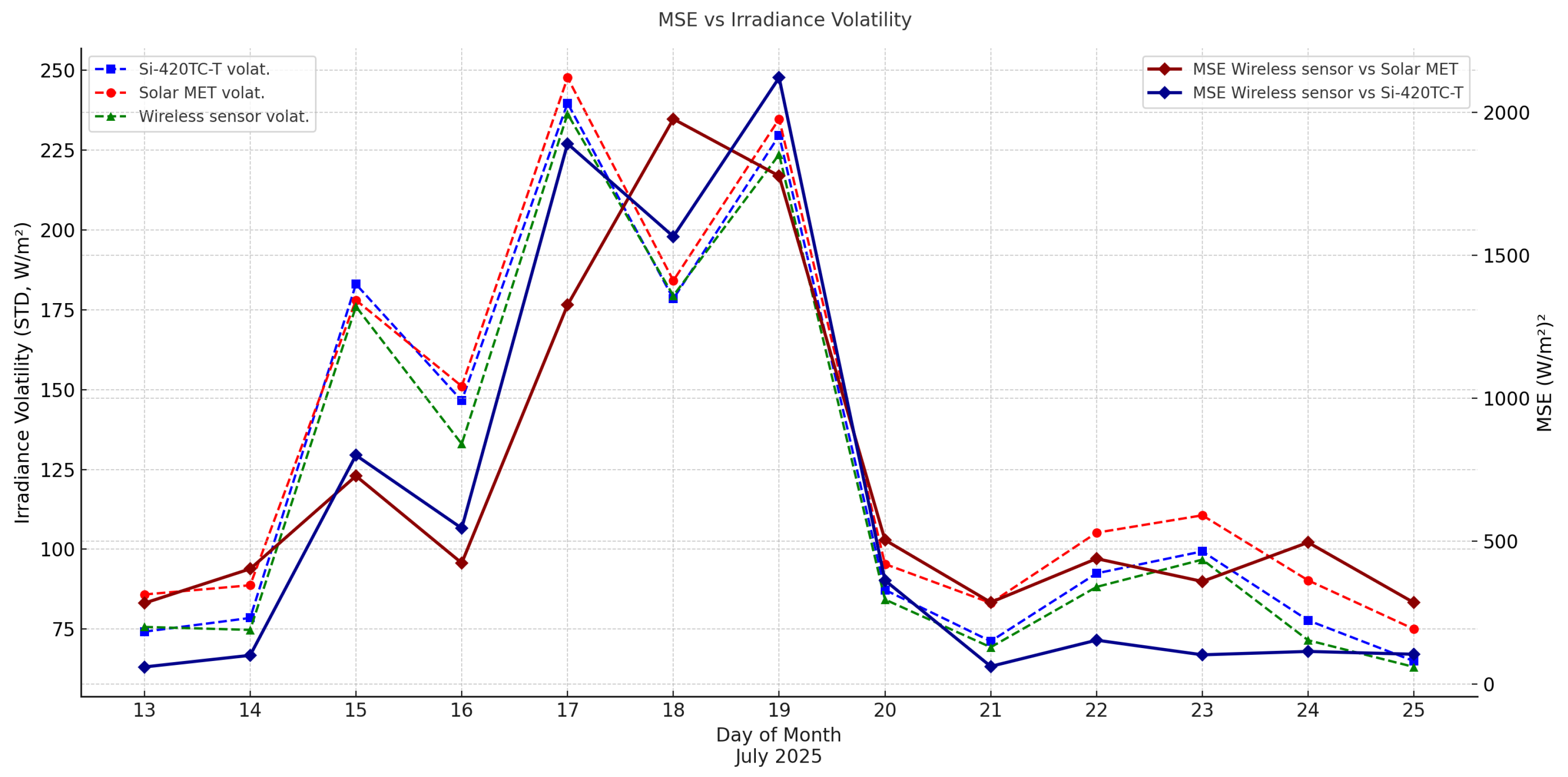

6. Results

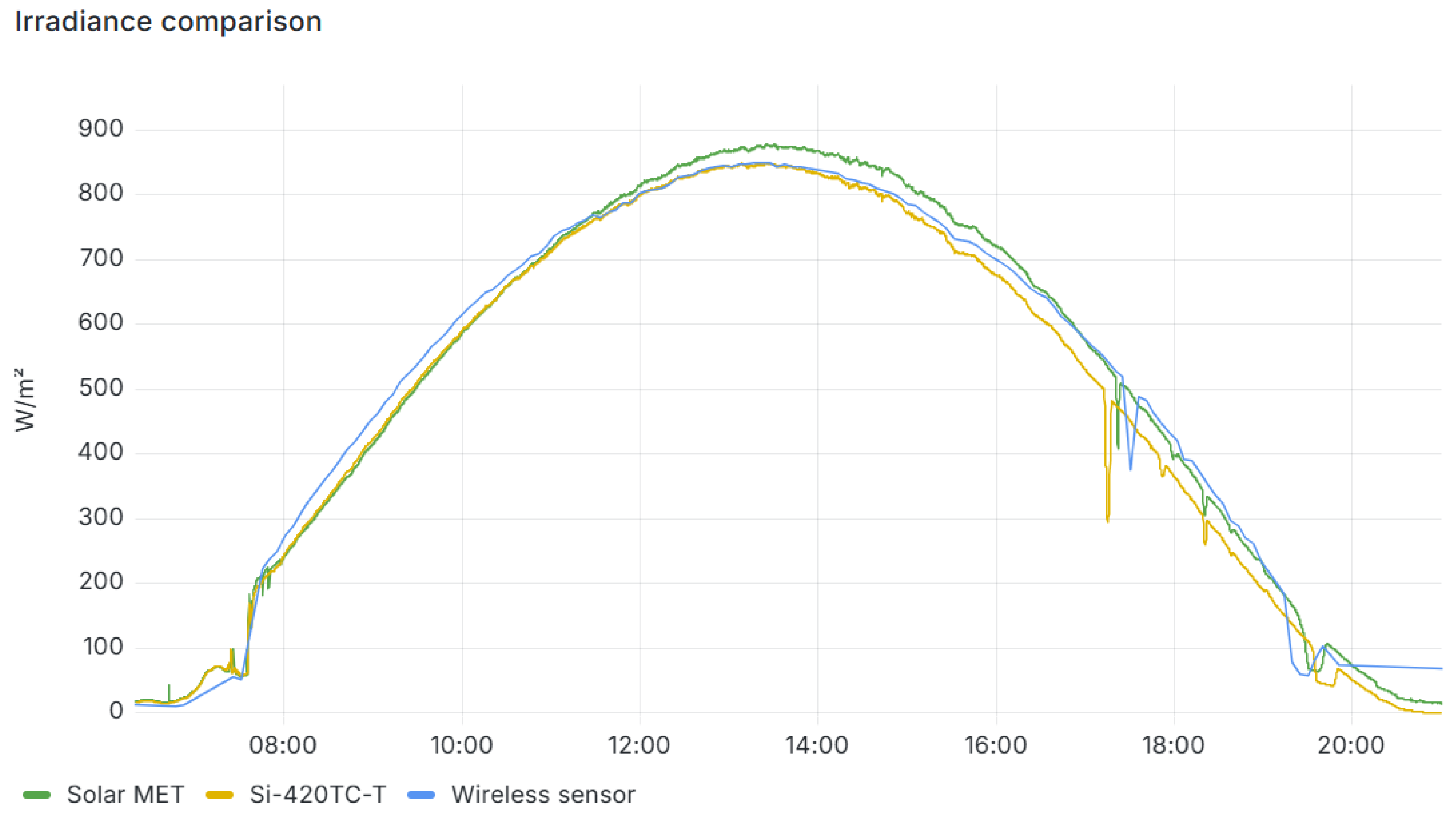

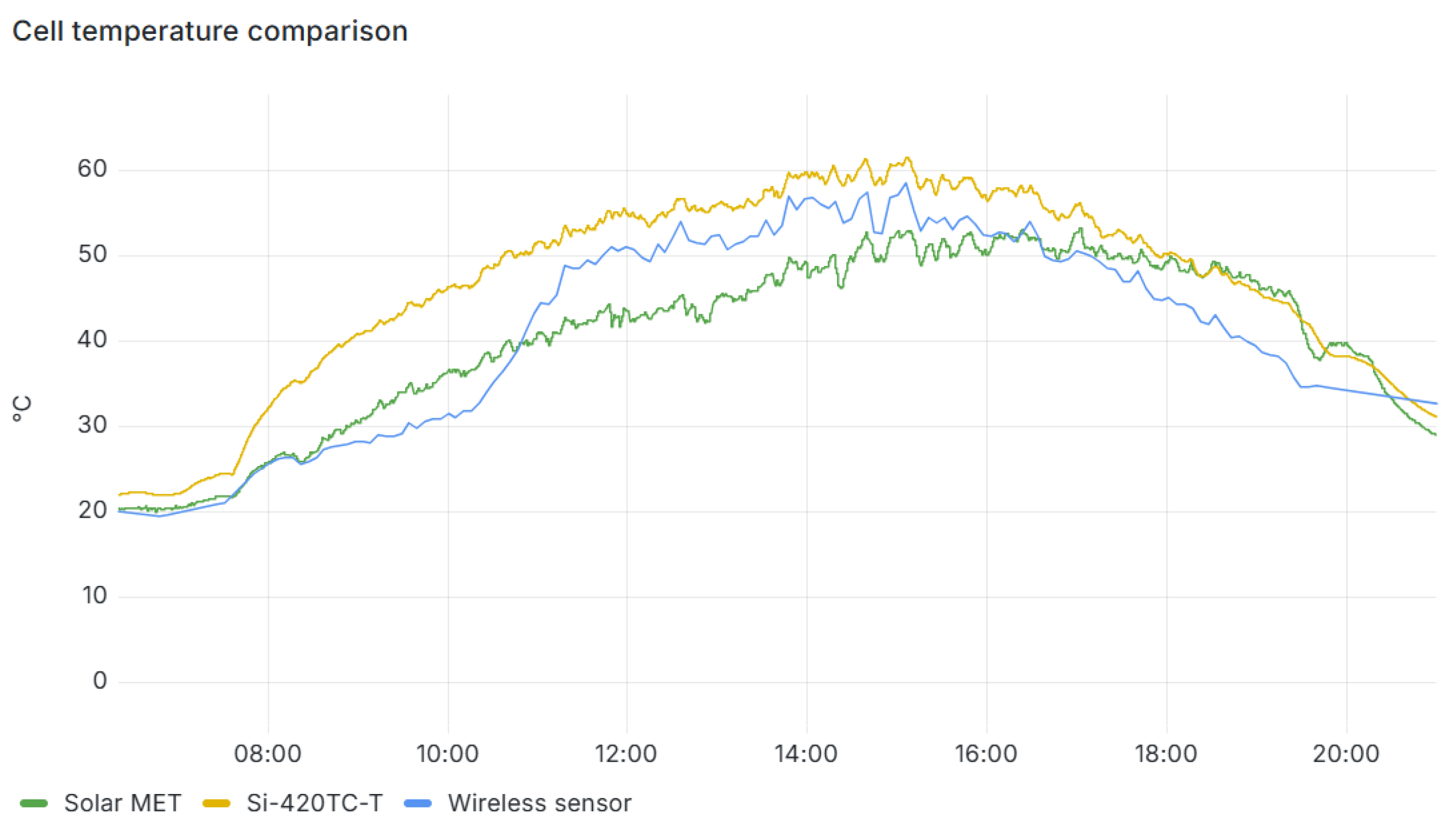

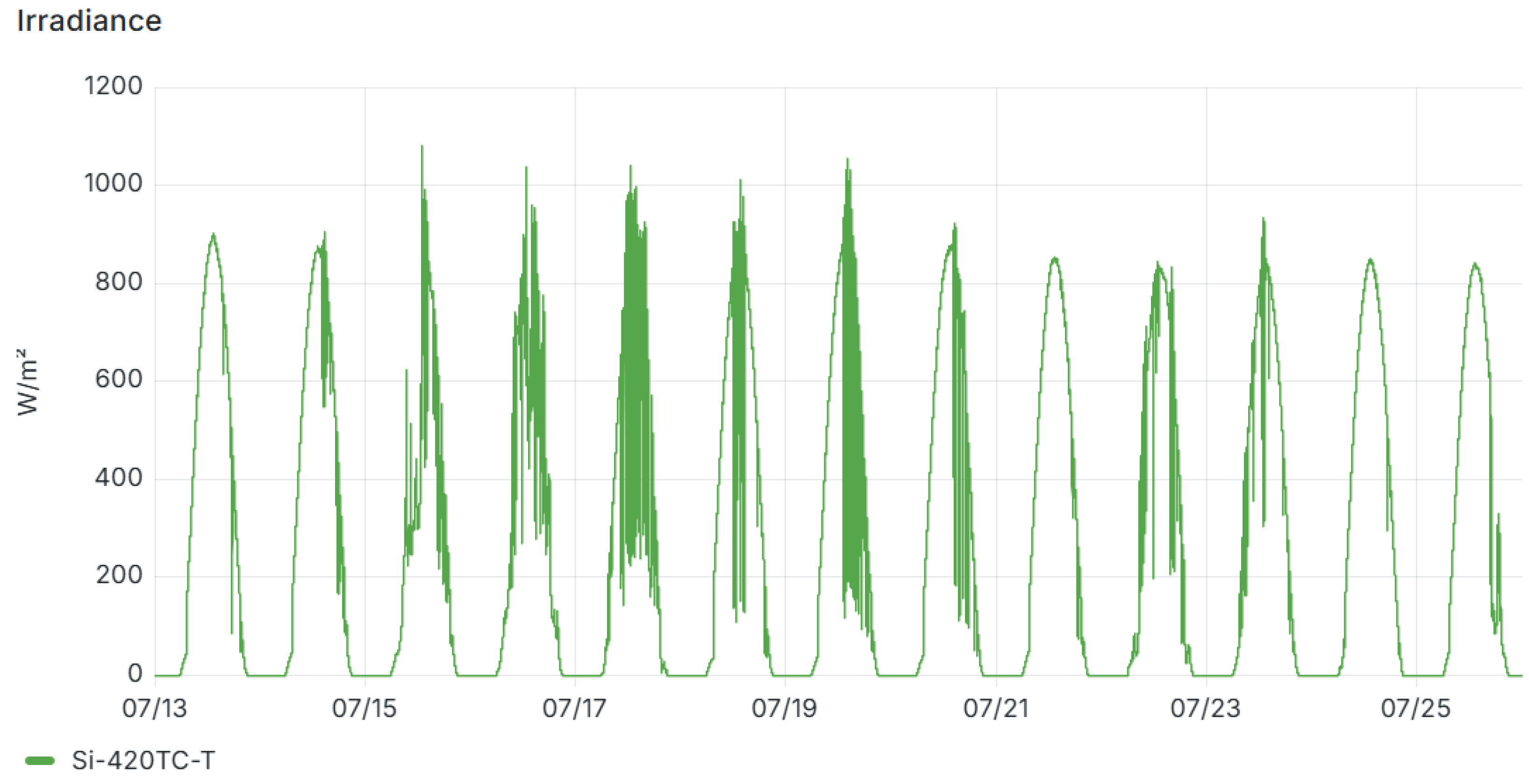

6.1. Irradiance and Cell Temperature Measurement

- Until 8:00, the wireless sensor alternated between waking for short measurements and re-entering sleep, due to low energy availability. Values recorded around 6:20 closely matched the industrial sensors, but gaps appeared when the wireless unit slept. Once energy stabilized, alignment improved;

- Between 8:00 and 11:30, the wireless sensor reported slightly higher values than the industrial references, though within a narrow margin;

- From 11:30 to 15:00, correlation was strongest with the Si-420TC-T, the sensor used for calibration;

- Between 15:00 and 19:30, the wireless unit tracked Solar MET more closely;

- From 17:30 until 20:00, all three sensors detected transient drops and rises in irradiance, likely due to passing clouds. These fluctuations appeared phase-shifted between sensors, suggesting localized partial shading as the sun descended. Around 20:00, the wireless sensor made its final transmission before nightfall, when it entered 2 h night sleep mode due to supercapacitor discharge.

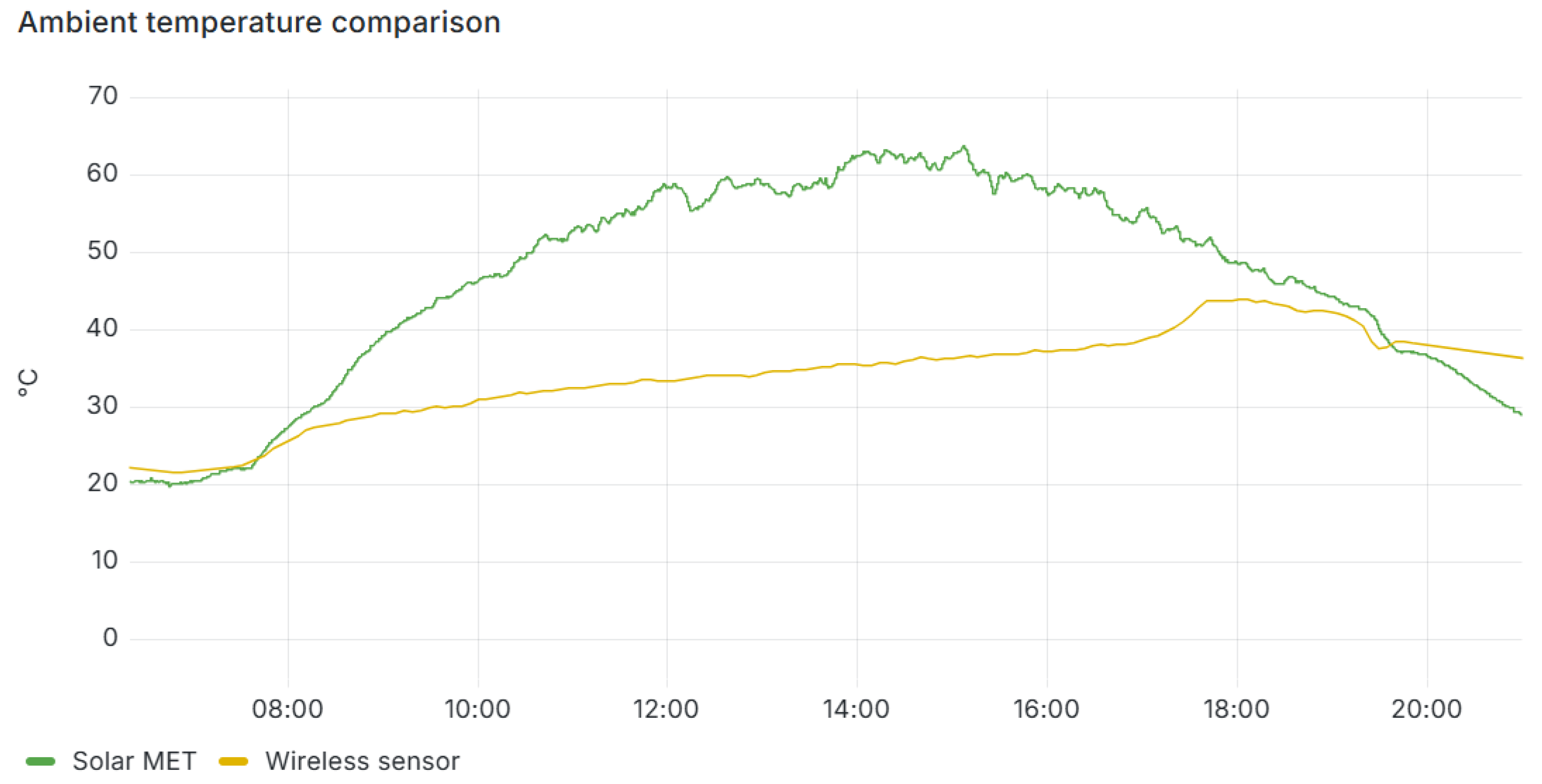

- In the wireless sensor, the temperature sensor is mounted on the back of the solar panel, with thermal paste ensuring direct thermal contact. The back of the panel is open, exposed to the ambient environment;

- In the Solar MET sensor, the temperature sensor is integrated into the electronic circuit board on the back of the solar cell. Heating of nearby circuits may influence the measured temperature;

- In the Si-420TC-T sensor, the cell temperature sensor is enclosed in a small aluminum case. Exposure to solar radiation heats the case significantly, which in turn raises the measured cell temperature. This explains why the Si-420TC-T reports the highest values.

| Time Period | Irradiance Measurement Error [%] | ||

|---|---|---|---|

| Error vs. Solar MET | Error vs. Si-420TC-T | Average | |

| Sunny day | 1.89 | 2.00 | 1.95 |

| Cloudy day | 1.97 | 2.26 | 2.11 |

| Two weeks | 1.21 | 1.33 | 1.27 |

| One month | 2.22 | 2.28 | 2.25 |

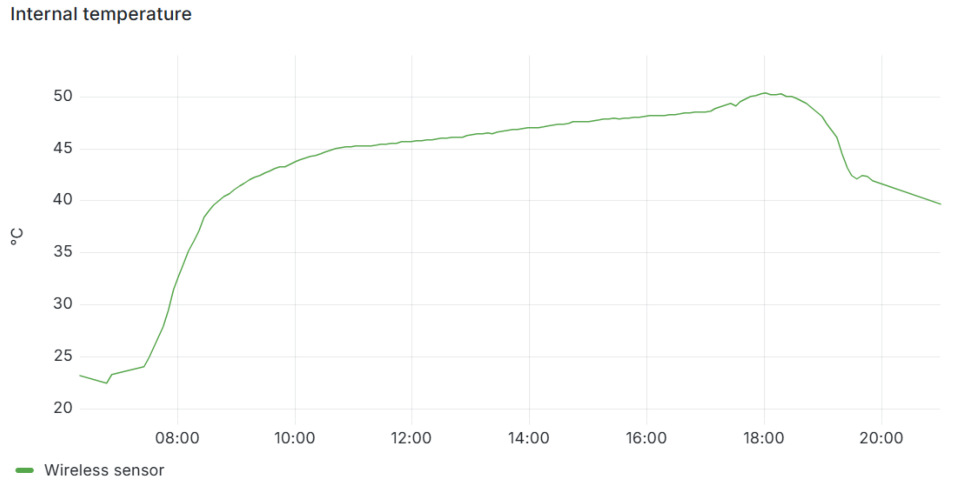

6.2. Ambient and Internal Temperature Measurement

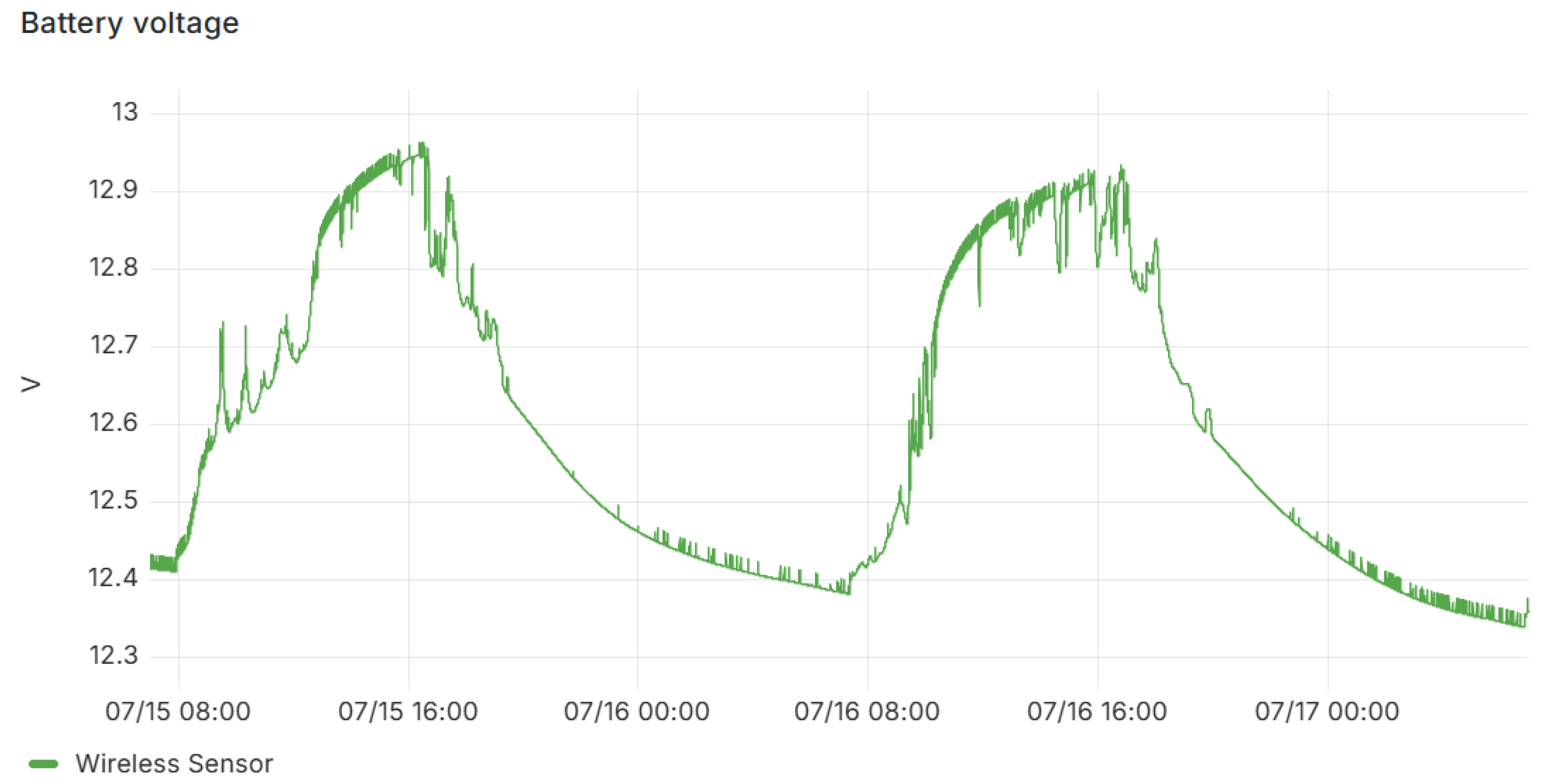

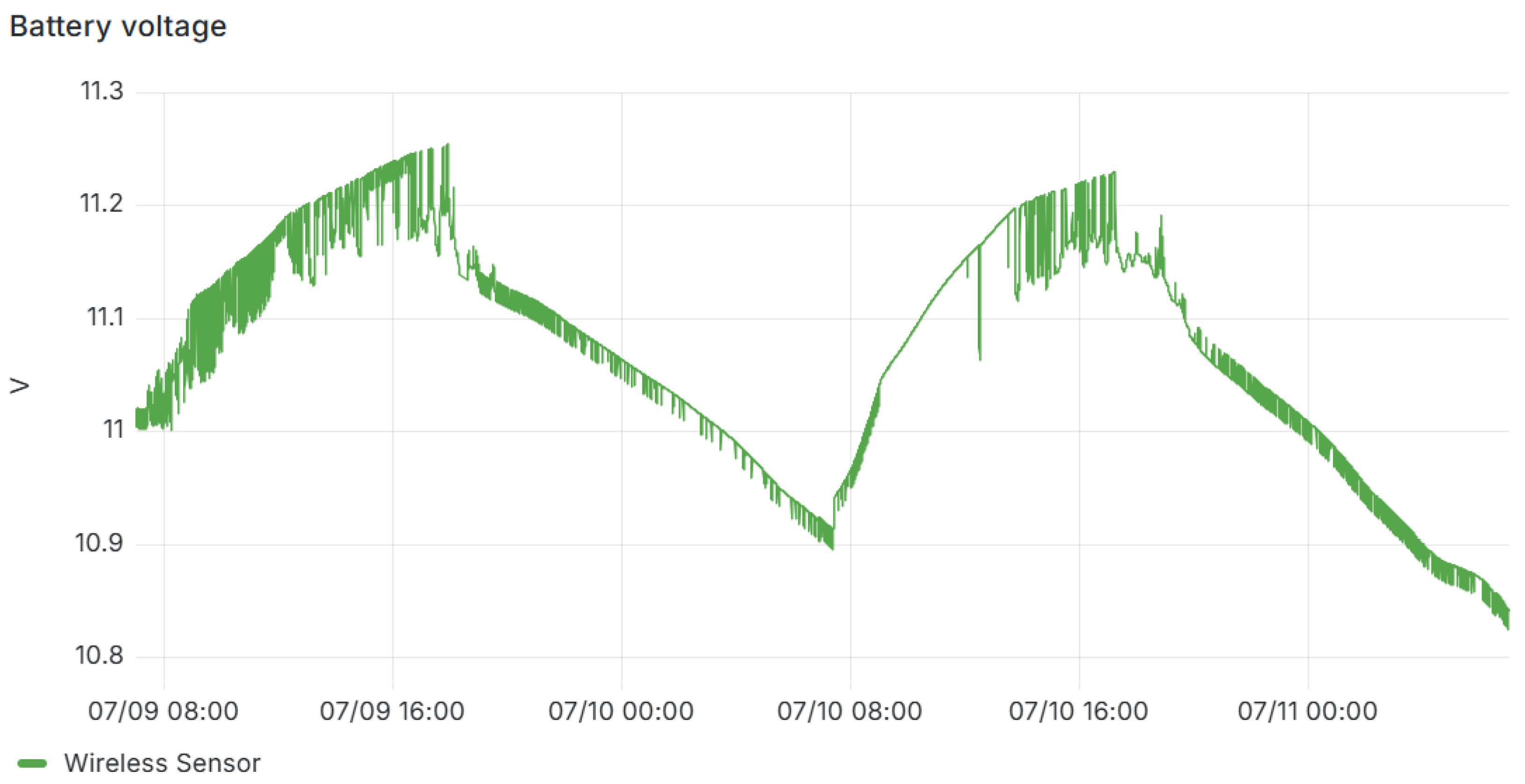

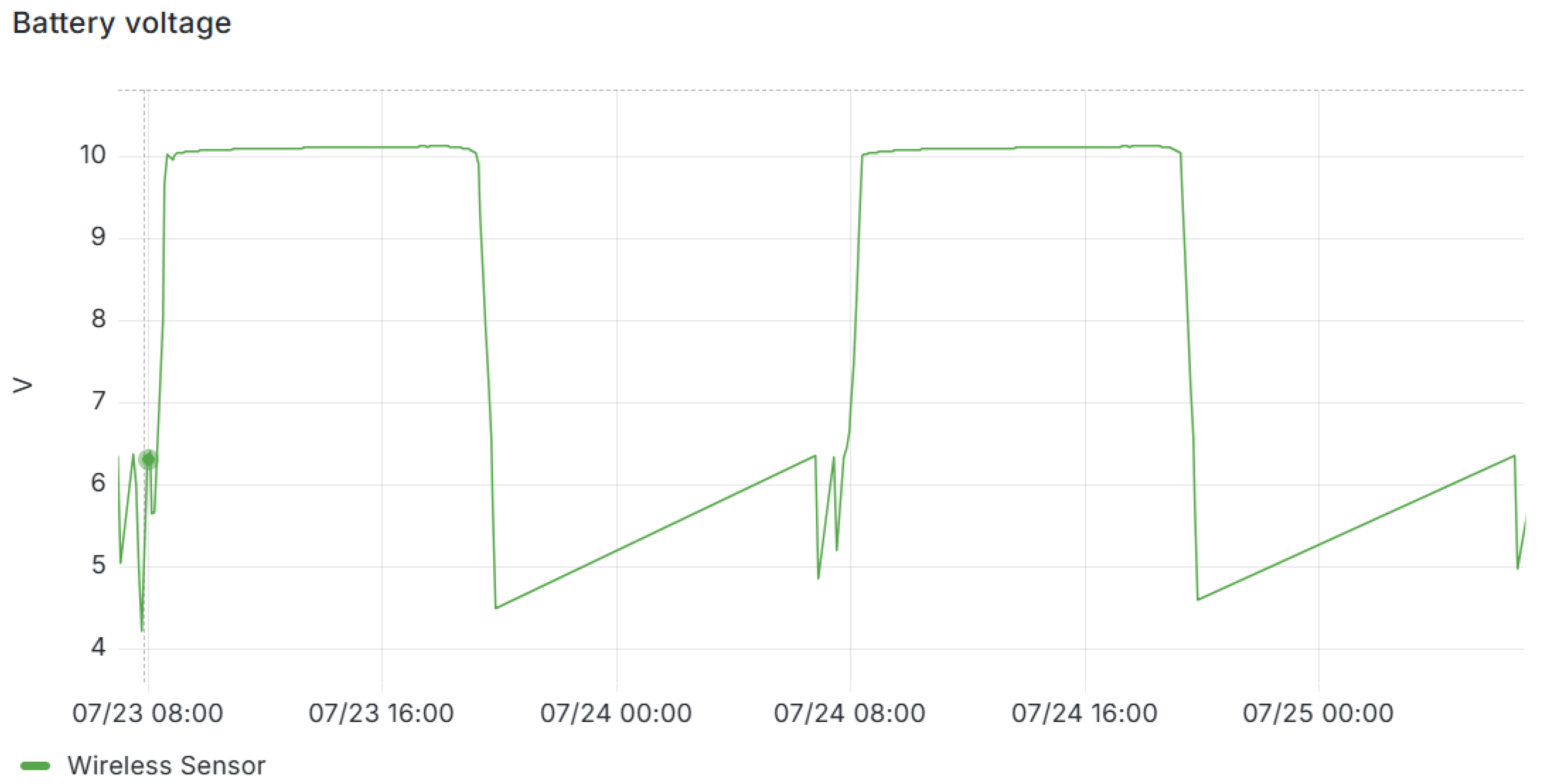

6.3. Battery and Solar Panel Voltage Measurement

6.4. Power Considerations for the Communication Interfaces

7. Conclusions, Contributions and Future Work

7.1. Conclusions and Contributions

7.2. Future Work

- Power optimization and circuit refinement: The electronic design, particularly the voltage regulation and power distribution stages, will be revisited to minimize quiescent and leakage currents during deep-sleep operation. Reducing the standby consumption will enable prolonged autonomous functioning when powered exclusively by supercapacitors, further reinforcing the device’s suitability for maintenance-free deployments in remote environments.

- Controlled calibration facility: A dedicated calibration chamber will be developed to allow the independent control of irradiance and temperature levels. Such an environment will facilitate systematic calibration and characterization campaigns, ensuring higher accuracy of the irradiance–temperature compensation models and enabling the study of sensor behavior under reproducible laboratory conditions.

- Outdoor tracking and test platform: For extended field evaluation, a mobile, sun-tracking frame will be designed to maintain optimal panel orientation throughout the day. This setup will maximize the received irradiance during outdoor experiments, allowing consistent exposure conditions for comparative testing between multiple devices and reference sensors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADC | Analog-to-Digital Converter |

| API | Application Programming Interface |

| BOM | Bill of Materials |

| DAC | Digital-to-Analog Converter |

| ESP32 | Espressif Systems 32-bit Microcontroller |

| FBD | Function Block Diagram |

| GPIO | General-Purpose Input/Output |

| GUI | Graphical User Interface |

| IIoT | Industrial Internet of Things |

| IoT | Internet of Things |

| I–V | Current–Voltage |

| ISO | International Organization for Standardization |

| kWh | Kilowatt-hour |

| LCOE | Levelized Cost of Electricity |

| Li-Po | Lithium-Polymer |

| LoRaWAN | Long Range Wide Area Network |

| LPWAN | Low-Power Wide Area Network |

| LSTM | Long Short-Term Memory |

| MSE | Mean Squared Error |

| MPPT | Maximum Power Point Tracking |

| MQTT | Message Queuing Telemetry Transport |

| NREL | National Renewable Energy Laboratory |

| O&M | Operations and Maintenance |

| OS | Operating System |

| PAN | Personal Area Network |

| PCB | Printed Circuit Board |

| PC | Personal Computer |

| PLC | Programmable Logic Controller |

| POA | Plane of Array |

| PR | Performance Ratio |

| PV | Photovoltaic |

| PVPS | Photovoltaic Power Systems Programme |

| RS-485 | Recommended Standard 485 (serial communication) |

| SCADA | Supervisory Control and Data Acquisition |

| SMA | SubMiniature version A (connector) |

| SPI | Serial Peripheral Interface |

| SSD | Solid State Drive |

| TCP | Transmission Control Protocol |

| UART | Universal Asynchronous Receiver–Transmitter |

| UFL | Ultra Miniature Coaxial Connector |

| USB | Universal Serial Bus |

| Wi-Fi | Wireless Fidelity |

References

- International Renewable Energy Agency (IRENA). World Energy Transitions Outlook 2023: 1.5 °C Pathway; Technical Report; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Fraunhofer Institute for Solar Energy Systems ISE. Photovoltaics Report; Technical Report; Fraunhofer Institute for Solar Energy Systems ISE: Freiburg, Germany, 2023. [Google Scholar]

- International Energy Agency (IEA). World Energy Outlook 2022; Technical Report; International Energy Agency: Paris, France, 2022.

- IEC 61724-1:2017; Photovoltaic System Performance—Part 1: Monitoring. International Electrotechnical Commission: Geneva, Switzerland, 2017; Technical Report.

- Huld, T.; Gracia Amillo, A. Estimating PV Module Performance over Large Geographical Regions: The Role of Irradiance, Air Temperature, Wind Speed and Solar Spectrum. Energies 2015, 8, 5159–5181. [Google Scholar] [CrossRef]

- Kratochvil, J.A.; Boyson, W.E.; King, D.L. Photovoltaic Array Performance Model; Technical Report; Sandia National Laboratories: Albuquerque, NM, USA, 2004. [CrossRef]

- Standard ISO 9060; Solar Energy, Specification and Classification of Instruments for Measuring Hemispherical Solar and Direct Solar Radiation. International Organization for Standardization: Geneva, Switzerland, 2018.

- IEC 61724-1:2021; Photovoltaic System Performance—Part 1: Monitoring. International Electrotechnical Commission: Geneva, Switzerland, 2021; Technical Report.

- Sengupta, M.; Habte, A.; Wilbert, S.; Gueymard, C.; Remund, J. Best Practices Handbook for the Collection and Use of Solar Resource Data for Solar Energy Applications: Third Edition; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2021.

- Driesse, A.; Gotseff, P.; Sengupta, M. PV Reference Cells for Outdoor Use: Comparison of First-Year Field Measurements; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2022.

- Vignola, F.; Peterson, J.; Kessler, R.; Sandhu, V.; Snider, S.; Habte, A.; Gotseff, P.; Andreas, A.; Sengupta, M.; Mavromatakis, F. Improved field evaluation of reference cells using spectral measurements. Sol. Energy 2021, 215, 482–491. [Google Scholar] [CrossRef]

- Chouay, Y.; Ouassaid, M. An accurate real time neural network based irradiance and temperature sensor for photovoltaic applications. Results Eng. 2024, 21, 101766. [Google Scholar] [CrossRef]

- Khalid, W.; Jamil, M.; Khan, A.A.; Awais, Q. Open-source internet of things-based supervisory control and data acquisition system for photovoltaic monitoring and control using HTTP and TCP/IP protocols. Energies 2024, 17, 4083. [Google Scholar] [CrossRef]

- El-Khozondar, H.J.; Mtair, S.Y.; Qoffa, K.O.; Qasem, O.I.; Munyarawi, A.H.; Nassar, Y.F.; Bayoumi, E.H.; Abd El, A.A.E.B. A smart energy monitoring system using ESP32 microcontroller. E-Prime Electr. Eng. Electron. Energy 2024, 9, 100666. [Google Scholar] [CrossRef]

- Witczak, D.; Szymoniak, S. Review of monitoring and control systems based on Internet of Things. Appl. Sci. 2024, 14, 8943. [Google Scholar] [CrossRef]

- Mirani, A.A.; Awasthi, A.; O’Mahony, N.; Walsh, J. Industrial IoT-Based Energy Monitoring System: Using Data Processing at Edge. IoT 2024, 5, 608–633. [Google Scholar] [CrossRef]

- Rojek, L.; Islam, S.; Hartmann, M.; Creutzburg, R. IoT-based real-time monitoring system for a smart energy house. Electron. Imaging 2021, 33, 38-1–38-10. [Google Scholar] [CrossRef]

- Ramadhan, J.M.; Mardiati, R.; Haq, I.N. Iot monitoring system for solar power plant based on mqtt publisher/subscriber protocol. In Proceedings of the 2021 7th International Conference on Wireless and Telematics (ICWT), Bandung, Indonesia, 19–20 August 2021; pp. 1–6. [Google Scholar]

- Rouibah, N.; Elhammoumi, A.; Bouttout, A.; Haddad, S.; Oukaci, S.; Limam, A.; Benghanem, M. Smart Monitoring of Photovoltaic Energy Systems: An IoT-Based Prototype Approach. Sci. Afr. 2025, 30, e02973. [Google Scholar] [CrossRef]

- Calderón, D.; Folgado, F.J.; González, I.; Calderón, A.J. Implementation and experimental application of industrial IoT architecture using automation and IoT Hardware/Software. Sensors 2024, 24, 8074. [Google Scholar] [CrossRef]

- Dobrea, M.A.; Vasluianu, M.; Neculoiu, G.; Arghira, N. Modeling and simulation of a 3 kw photovoltaic system for an autonomous consumer. UPB Sci. Bull. Ser. C 2021, 83, 35–46. [Google Scholar]

- Demir, B.E. A New Low-Cost IoT Based Monitoring System Design for Stand-Alone Solar Photovoltaic Plant and Power Estimation. Appl. Sci. 2023, 13, 13072. [Google Scholar] [CrossRef]

- Hamied, A.; Mellit, A.; Benghanem, M.; Boubaker, S. IoT-Based Low-Cost Photovoltaic Monitoring for a Greenhouse Farm in an Arid Region. Energies 2023, 16, 3860. [Google Scholar] [CrossRef]

- Botero-Valencia, J.; Valencia-Aguirre, J.; Gonzalez Montoya, D.; Ramos-Paja, C. A low-cost system for real-time measuring of the sunlight incident angle using IoT. HardwareX 2022, 11, e00272. [Google Scholar] [CrossRef] [PubMed]

- Nava-Pintor, J.A.; Alcalá-Rodríguez, U.E.; Guerrero-Osuna, H.A.; Mata-Romero, M.E.; Lopez-Neri, E.; García-Vázquez, F.; Solís-Sánchez, L.O.; Carrasco-Navarro, R.; Luque-Vega, L.F. Development and Evaluation of Solar Radiation Sensor Using Cost-Effective Light Sensors and Machine Learning Techniques. Technologies 2025, 13, 182. [Google Scholar] [CrossRef]

- Abe, C.F.; Dias, J.B.; Notton, G.; Faggianelli, G.A. Experimental Application of Methods to Compute Solar Irradiance and Cell Temperature of Photovoltaic Modules. Sensors 2020, 20, 2490. [Google Scholar] [CrossRef]

- Laudani, A.; Lozito, G.M.; Riganti Fulginei, F. Irradiance Sensing through PV Devices: A Sensitivity Analysis. Sensors 2021, 21, 4264. [Google Scholar] [CrossRef]

- Kyi, S.; Taparugssanagorn, A. IoT and machine learning models for multivariate very short-term time series solar power forecasting. IET Wirel. Sens. Syst. 2024, 14, 381–395. [Google Scholar] [CrossRef]

- Rogier, J.K.; Mohamudally, N. Forecasting Photovoltaic Power Generation via an IoT Network Using Nonlinear Autoregressive Neural Network. Procedia Comput. Sci. 2019, 151, 643–650, The 10th International Conference on Ambient Systems, Networks and Technologies (ANT 2019)/The 2nd International Conference on Emerging Data and Industry 4.0 (EDI40 2019)/Affiliated Workshops. [Google Scholar] [CrossRef]

- Hameed, B.H.; Kurnaz, S. Secure low-cost photovoltaic monitoring system based on LoRaWAN network and artificial intelligence. Discov. Comput. 2024, 27, 36. [Google Scholar] [CrossRef]

- Bueso, M.C.; Paredes-Parra, J.M.; Mateo-Aroca, A.; Molina-García, A. Sensitive Parameter Analysis for Solar Irradiance Short-Term Forecasting: Application to LoRa-Based Monitoring Technology. Sensors 2022, 22, 1499. [Google Scholar] [CrossRef]

- Ansong, M.; Huang, G.; Nyang’onda, T.N.; Musembi, R.J.; Richards, B.S. Very short-term solar irradiance forecasting based on open-source low-cost sky imager and hybrid deep-learning techniques. Sol. Energy 2025, 294, 113516. [Google Scholar] [CrossRef]

- Alzahrani, A. Short-Term Solar Irradiance Prediction Based on Adaptive Extreme Learning Machine and Weather Data. Sensors 2022, 22, 8218. [Google Scholar] [CrossRef]

- Macias, J.E.Z.; Trilles, S. Machine learning-based prediction model for battery levels in IoT devices using meteorological variables. Internet Things 2024, 25, 101109. [Google Scholar] [CrossRef]

- Digi. Digi XBee® 3 RF Module Hardware Reference Manual. Available online: https://docs.digi.com/resources/documentation/digidocs/pdfs/90001543.pdf (accessed on 14 August 2025).

- Espressif. ESP32-WROOM-32 Datasheet. Available online: https://www.espressif.com/sites/default/files/documentation/esp32-wroom-32_datasheet_en.pdf (accessed on 14 August 2025).

- Instruments, T. ADS131A0x Datasheet. Available online: https://www.ti.com/lit/ds/symlink/ads131a04.pdf (accessed on 14 August 2025).

- Instruments, T. TPS732xx-EP Datasheet. Available online: https://www.ti.com/lit/ds/symlink/tps73230-ep.pdf?ts=1755120122873 (accessed on 14 August 2025).

- Instruments, T. REF50xxA-Q1 Datasheet. Available online: https://www.ti.com/lit/ds/symlink/ref5020a-q1.pdf?ts=1755156346294&ref_url=https%253A%252F%252Fwww.ti.com%252Fproduct%252FREF5020A-Q1%252Fpart-details%252FREF5020AQDRQ1 (accessed on 14 August 2025).

- Instruments, T. TMP11 Datasheet. Available online: https://www.ti.com/lit/ds/symlink/tmp117.pdf?ts=1755096141116&ref_url=https%253A%252F%252Fwww.google.com%252F (accessed on 14 August 2025).

- Emelianov, A. Modbus Library for Arduino. Available online: https://github.com/emelianov/modbus-esp8266 (accessed on 11 September 2025).

- Software, W. Modbus Poll. Available online: https://www.modbustools.com/modbus_poll.html (accessed on 11 September 2025).

- O’Leary, N. Arduino Client for MQTT. Available online: https://github.com/knolleary/pubsubclient (accessed on 11 September 2025).

- Foundation, E. Mosquitto. Available online: https://mosquitto.org/ (accessed on 11 September 2025).

- Nordquist, T. MQTT-Explorer. Available online: https://mqtt-explorer.com/ (accessed on 11 September 2025).

- Instruments, N. USB-6009 Specifications. Available online: https://www.ni.com/docs/en-US/bundle/usb-6009-specs/page/specs.html?srsltid=AfmBOopROhAH3XUCnhV82tD60qahwT0j1oaWNLLHjanlPI_FiqTpipRM (accessed on 26 August 2025).

- Solar, I. SI-I-420TC-T Datasheet. Available online: https://imtsolar.com/wp-content/uploads/2012/10/IMT-Sensor-Cut-Sheet-2015.pdf (accessed on 1 September 2025).

- DATASOL MET. Radiation Acquisition Manual. Available online: https://atersa.shop/app/uploads/2018/03/MU-38-T-Manual-MET.pdf?srsltid=AfmBOooTximbvR7Z6M-EUEzZNEgr5saN4p9rwAKClMC6QKldL2S7K6H_ (accessed on 1 September 2025).

- Phoenix Contact. Axioline F: System and Installation User Manual. Available online: https://www.manualslib.com/manual/1536738/Phoenix-Contact-Axioline-F.html (accessed on 26 August 2025).

- Avantech. ADAM-4017 Datasheet. Available online: https://advdownload.advantech.com/productfile/PIS/ADAM-4017+/file/ADAM-4017_4018_4019_DS(092223)20230928142137.pdf (accessed on 26 August 2025).

- Energy, J. SOLAR IRRADIANCE SENSOR SI-I-420TC-T. Available online: https://www.jedsenergy.com/products/solar-irradiance-sensor-si-i-420tc-t (accessed on 8 September 2025).

- ATERSA. Calibrated Cell 65mV Compensated (ATERSA). Available online: https://atersa.shop/celula-calibrada-0-65-mv-compensada-atersa/ (accessed on 8 September 2025).

- Fondriest Environmental, I. Kipp & Zonen SMP Series Smart Pyranometers. Available online: https://www.fondriest.com/kipp-zonen-smp-series-smart-pyranometers.htm (accessed on 8 September 2025).

- Computer Science Department @ UPB. Smart Solar Irradiance Sensor-Source Code & Schematics. Available online: https://github.com/cs-pub-ro/smart-solar-irradiance-sensor (accessed on 24 September 2025).

| Time Period | Irradiance Measurement Error [%] | ||

|---|---|---|---|

| Error vs. Solar MET | Error vs. Si-420TC-T | Average | |

| Sunrise to 9:59 | 2.88 | 2.45 | 2.67 |

| 10:00 to 15:59 | 1.74 | 0.83 | 1.29 |

| 16:00 to 18:59 | 1.16 | 3.62 | 2.39 |

| 19:00 to sunset | 2.80 | 3.77 | 3.29 |

| Time Period | Irradiance Measurement Error [%] | ||

|---|---|---|---|

| Error vs. Solar MET | Error vs. Si-420TC-T | Average | |

| Sunrise to 9:59 | 2.18 | 1.36 | 1.77 |

| 10:00 to 15:59 | 1.79 | 2.19 | 1.99 |

| 16:00 to 18:59 | 2.04 | 3.83 | 2.94 |

| 19:00 to sunset | 1.90 | 2.07 | 1.99 |

| Parameter | Sensor | |||

|---|---|---|---|---|

| IMT Solar Si Series | Atersa Solar MET | Kipp Zonen SMP Series | Our Solution | |

| Irradiance | 0–1200 W/m2 | 0–1400 W/m2 | 0–1500 W/m2 | 0–1200 W/m2 (can be extended) |

| Cell temperature sensor | Yes | Yes | Yes | Yes |

| Ambient temperature sensor | Optional | Yes | Optional | Yes |

| Output type | Analog/RS-485 | RS-485 | Analog/RS-485 | Wireless/RS-485 |

| (different versions) | (different versions) | |||

| Protocols | Modbus RTU | Modbus RTU | Modbus RTU | Wi-Fi/ZigBee/MQTT, Modbus TCP, |

| Modbus RTU (can be extended) | ||||

| Power supply | Wired | Wired | Wired | Battery/Wired |

| Price | ≥400 € [51] | ≥450 € [52] | ≥1000 € [53] | 165 € (BOM) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoica, V.-V.; Pălăcean, A.-V.; Trancă, D.-C.; Stancu, F.-A. Open-Source Smart Wireless IoT Solar Sensor. Appl. Sci. 2025, 15, 11059. https://doi.org/10.3390/app152011059

Stoica V-V, Pălăcean A-V, Trancă D-C, Stancu F-A. Open-Source Smart Wireless IoT Solar Sensor. Applied Sciences. 2025; 15(20):11059. https://doi.org/10.3390/app152011059

Chicago/Turabian StyleStoica, Victor-Valentin, Alexandru-Viorel Pălăcean, Dumitru-Cristian Trancă, and Florin-Alexandru Stancu. 2025. "Open-Source Smart Wireless IoT Solar Sensor" Applied Sciences 15, no. 20: 11059. https://doi.org/10.3390/app152011059

APA StyleStoica, V.-V., Pălăcean, A.-V., Trancă, D.-C., & Stancu, F.-A. (2025). Open-Source Smart Wireless IoT Solar Sensor. Applied Sciences, 15(20), 11059. https://doi.org/10.3390/app152011059