Sustainable Aviation Fuels: Addressing Barriers to Global Adoption

Abstract

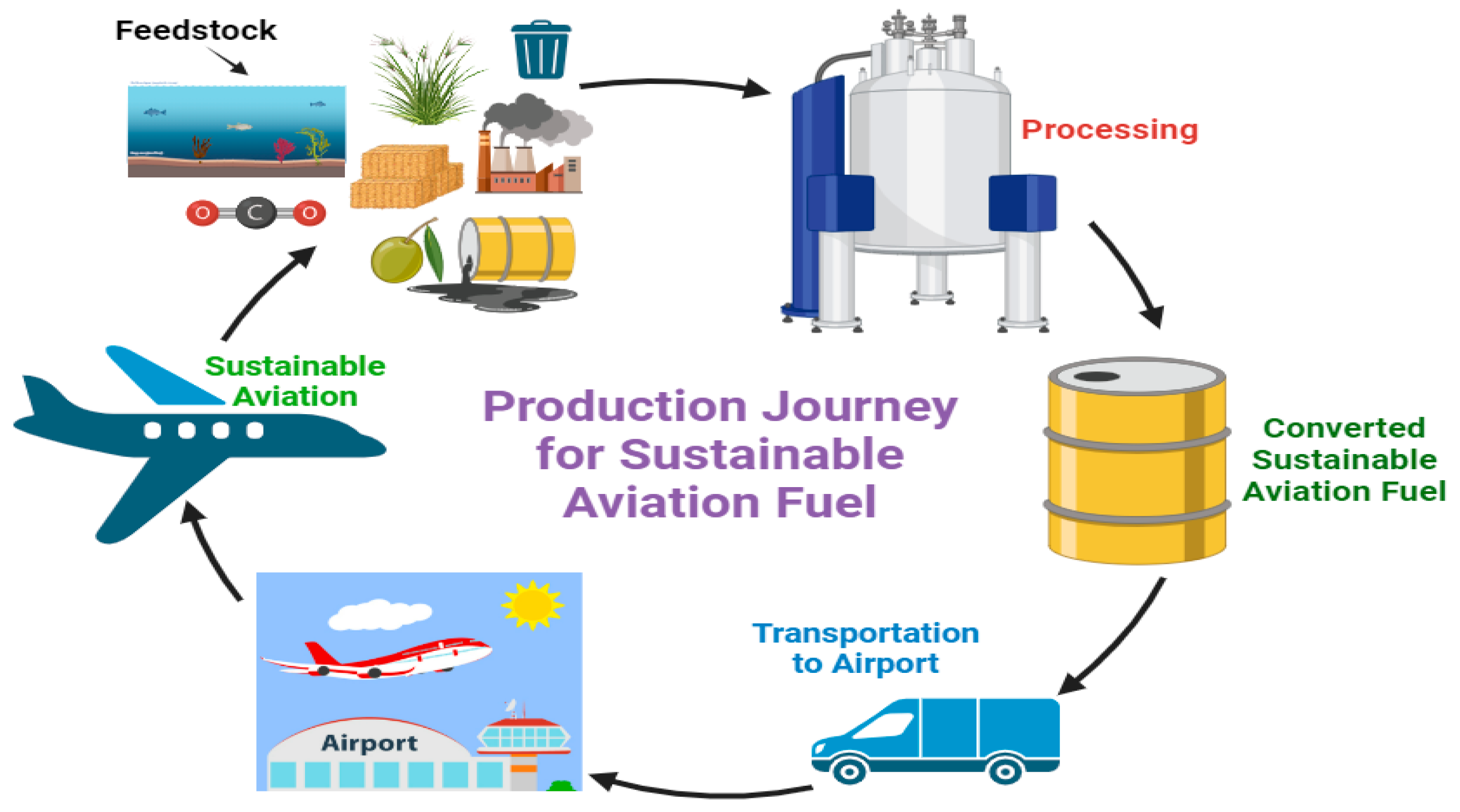

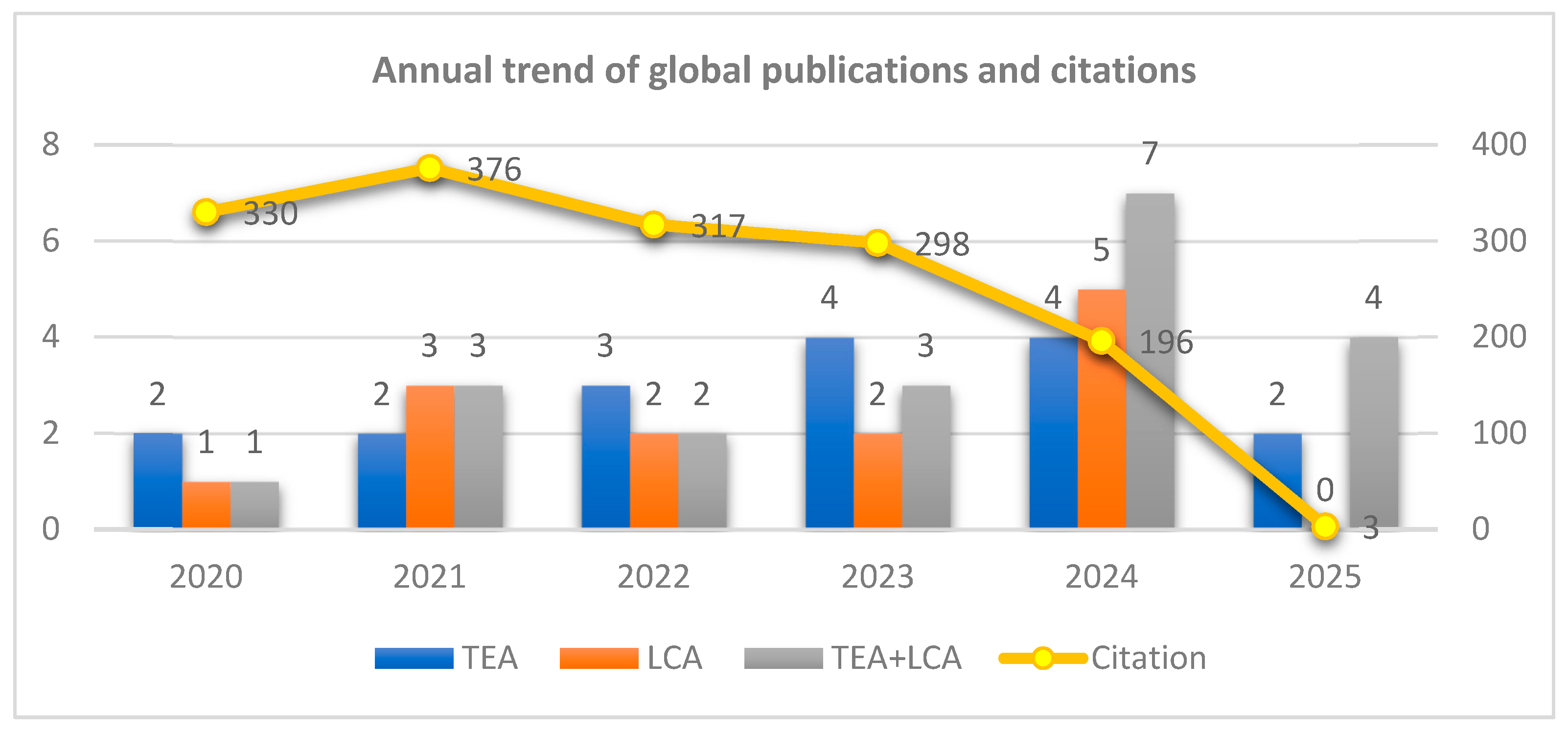

1. Introduction

2. Major Types of Sustainable Aviation Fuel

3. Challenges of Sustainable Aviation Fuel

3.1. Technical Challenges of Sustainable Aviation Fuel

3.2. Economic Challenges Sustainable Aviation Fuel

3.3. Environmental Challenges Sustainable Aviation Fuel

3.4. Regulatory Challenges of Sustainable Aviation Fuel

4. Future Perspective of Sustainable Aviation Fuel

4.1. Potential Advancements in SAF Technology

4.2. Collaborative Efforts Between Industry and Academia

4.3. Commercialization Prospects and Market Growth

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| A | Acidification |

| ARENA | Australian Renewable Energy Agency |

| ASEAN | Association of Southeast Asian Nations |

| BNG | Bio-natural gas |

| C6H12O5 | Cellulose |

| CA | Cellulose acetate |

| CE | Contemporary era |

| CH3COOH | Acetic acid |

| CH4 | Methane |

| CSIRO | Commonwealth Scientific and Industrial Research Organisation |

| CNG | Compressed natural gas |

| E | Eutrophication |

| EPA | Environmental Protection Agency Victoria |

| FT | Fischer Tropsc |

| GIE | Gas Infrastructure Europe |

| GWh | Gigawatt hours |

| H2 | Hydrogen |

| HT | Human toxicity |

| LCA | Life-cycle assessment |

| LNG | Liquified natural gas |

| MW | Megawatt |

| N2 | Nitrogen |

| NH3 | Ammonia |

| O2 | Oxygen |

| PTL | Power to Liquid |

| RGF | Renewable “Green” Fuels |

| WE | Waste Energy |

| TEA | Techno-economic analysis/assessment |

| TJ | Terajoule |

| AbD | Abiotic depletion |

| AS | Amine scrubbing |

| bcm | Billion cubic meters |

| C&SAmerica | Central and South America |

| C6H12O6 | Glucose |

| CAGR | Compound annual growth rate |

| CH3CH2OH | Ethanol |

| CH3OH | Methanol |

| CHP | Combined heat and power |

| SUPRA | Swinburne University Postgraduate Research Award |

| CO2 | Carbon dioxide |

| EBA | European Biogas Association |

| EU | European Union |

| GHG | Greenhouse gases |

| GJ | Gigajoule |

| GWP | Global warming potential |

| H2O | Water |

| IEA | International Energy Agency |

| LCC | Lifecycle costing |

| WWTP | Waste Water treatment plant |

| MWh | Megawatt hours |

| NCf | Net cash flow |

| NPV | Net present value |

| CO | Carbon monoxide |

| RES | Renewable energy source(s) |

| SO2 | Sulfur dioxide |

| STP | Standard temperature and pressure |

| TE | Thermal energy |

| TRL | Technological readiness level |

References

- Kwilinski, A.; Lyulyov, O.; Pimonenko, T. Environmental Sustainability within Attaining Sustainable Development Goals: The Role of Digitalization and the Transport Sector. Sustainability 2023, 15, 11282. [Google Scholar] [CrossRef]

- Miao, Q.; Nduneseokwu, C. Global environmental leadership: Addressing the triple planetary crisis. In Environmental Leadership in a VUCA Era: An Interdisciplinary Handbook; Springer Nature: Singapore, 2025; pp. 37–119. [Google Scholar]

- Uddin, M.; Rashid, M.; Mostafa, M.; Belayet, H.; Salam, S.; Nithe, N. Global energy: Need, present status, future trend and key issues. Glob. J. Res. Eng. Electr. Electron. Eng. 2016, 16, 36–50. [Google Scholar]

- Cabrera, E.; de Sousa, J.M.M. Use of sustainable fuels in aviation—A review. Energies 2022, 15, 2440. [Google Scholar] [CrossRef]

- Bauen, A.; Bitossi, N.; German, L.; Harris, A.; Leow, K. Sustainable Aviation Fuels: Status, challenges and prospects of drop-in liquid fuels, hydrogen and electrification in aviation. Johns. Matthey Technol. Rev. 2020, 64, 263–278. [Google Scholar] [CrossRef]

- Pintos, P.B.; Sande, C.U.; Álvarez, Ó.C. Sustainable propulsion alternatives in regional aviation: The case of the Canary Islands. Transp. Res. Part D Transp. Environ. 2023, 120, 103779. [Google Scholar] [CrossRef]

- Pearson, R.; Coe, A.; Paterson, J. Innovation in Fischer-Tropsch: A Sustainable Approach to Fuels Production: A cost-effective method of converting any carbon source into high-quality liquid hydrocarbon fuels. Johns. Matthey Technol. Rev. 2021, 65, 395–403. [Google Scholar] [CrossRef]

- Chong, J.W.; Chemmangattuvalappil, N.G.; Thangalazhy-Gopakumar, S. Aviation biofuels: Conversion routes and challenges. In Sustainable Technologies for the Oil Palm Industry: Latest Advances and Case Studies; Springer: Singapore, 2022; pp. 33–85. [Google Scholar]

- Okolie, J.A.; Awotoye, D.; Tabat, M.E.; Okoye, P.U.; Epelle, E.I.; Ogbaga, C.C.; Güleç, F.; Oboirien, B. Multi criteria decision analysis for the evaluation and screening of sustainable aviation fuel production pathways. iScience 2023, 26, 106944. [Google Scholar] [CrossRef] [PubMed]

- Lewis, K.C.; Brown, N.L.; Goldner, W.R.; Haq, Z.; Hoard, S.; Holladay, J.E.; Wolcott, M.P. The motivations for and the value proposition of sustainable aviation fuels. Front. Energy Res. 2022, 10, 1005493. [Google Scholar] [CrossRef]

- Detsios, N.; Theodoraki, S.; Maragoudaki, L.; Atsonios, K.; Grammelis, P.; Orfanoudakis, N.G. Recent advances on alternative aviation fuels/pathways: A critical review. Energies 2023, 16, 1904. [Google Scholar] [CrossRef]

- Emmanouilidou, E.; Mitkidou, S.; Agapiou, A.; Kokkinos, N.C. Solid waste biomass as a potential feedstock for producing sustainable aviation fuel: A systematic review. Renew. Energy 2023, 206, 897–907. [Google Scholar] [CrossRef]

- Wandelt, S.; Zhang, Y.; Sun, X. Sustainable aviation fuels: A meta-review of surveys and key challenges. J. Air Transp. Res. Soc. 2025, 4, 100056. [Google Scholar] [CrossRef]

- Ansell, P.J. Hydrogen-Electric Aircraft Technologies and Integration: Enabling an environmentally sustainable aviation future. IEEE Electrif. Mag. 2022, 10, 6–16. [Google Scholar] [CrossRef]

- Santos, K.; Delina, L. Soaring sustainably: Promoting the uptake of sustainable aviation fuels during and post-pandemic. Energy Res. Soc. Sci. 2021, 77, 102074. [Google Scholar] [CrossRef]

- Tiwari, R.; Mishra, R.; Choubey, A.; Kumar, S.; Atabani, A.; Badruddin, I.A.; Khan, T.Y. Environmental and economic issues for renewable production of bio-jet fuel: A global prospective. Fuel 2023, 332, 125978. [Google Scholar] [CrossRef]

- Undavalli, V.; Olatunde, O.B.G.; Boylu, R.; Wei, C.; Haeker, J.; Hamilton, J.; Khandelwal, B. Recent advancements in sustainable aviation fuels. Prog. Aerosp. Sci. 2023, 136, 100876. [Google Scholar] [CrossRef]

- Thanigaivel, S.; Priya, A.; Balakrishnan, D.; Dutta, K.; Rajendran, S.; Soto-Moscoso, M. Insight on recent development in metallic biomaterials: Strategies involving synthesis, types and surface modification for advanced therapeutic and biomedical applications. Biochem. Eng. J. 2022, 187, 108522. [Google Scholar] [CrossRef]

- Culaba, A.B.; Mayol, A.P.; San Juan, J.L.G.; Ubando, A.T.; Bandala, A.A.; Concepcion II, R.S.; Alipio, M.; Chen, W.-H.; Show, P.L.; Chang, J.-S. Design of biorefineries towards carbon neutrality: A critical review. Bioresour. Technol. 2022, 369, 128256. [Google Scholar] [CrossRef]

- Rony, Z.I.; Mofijur, M.; Hasan, M.; Ahmed, S.; Almomani, F.; Rasul, M.; Jahirul, M.; Show, P.L.; Kalam, M.; Mahlia, T. Unanswered issues on decarbonizing the aviation industry through the development of sustainable aviation fuel from microalgae. Fuel 2023, 334, 126553. [Google Scholar] [CrossRef]

- Molewijk, M.R. Startups and Their Contribution to the Future of Sustainable Aviation—A Qualitative Study on the Role of Startups in the Transition of the Aviation Industry Toward Sustainable Air Mobility. Master’s Thesis, Gothenburg University Publications, Gothenburg, Sweden, 2023. [Google Scholar]

- Bole, D.K. Wine Packaging, Distribution, and Greenhouse Gas Emissions: Challenges to Achieve Zero Emissions in the Packaging and Logistics Industries. In Handbook of Research on Sustainability Challenges in the Wine Industry; IGI Global: Hershey, PA, USA, 2023; pp. 261–282. [Google Scholar]

- Ngo, T.; Le, T.; Ullah, S.; Trinh, H.H. Climate risk disclosures and global sustainability initiatives: A conceptual analysis and agenda for future research. Bus. Strategy Environ. 2023, 32, 3705–3720. [Google Scholar] [CrossRef]

- Seber, G.; Escobar, N.; Valin, H.; Malina, R. Uncertainty in life cycle greenhouse gas emissions of sustainable aviation fuels from vegetable oils. Renew. Sustain. Energy Rev. 2022, 170, 112945. [Google Scholar] [CrossRef]

- Kito, M.; Takayabu, H.; Nansai, K. Carbon-neutral pathways to 2050 for Japan’s aviation industry in the absence of a mass supply of sustainable aviation fuels. J. Ind. Ecol. 2023, 27, 1579–1592. [Google Scholar] [CrossRef]

- Pavlenko, N. An Assessment of the Policy Options for Driving Sustainable Aviation Fuels in the European Union; ICCT: Washington, DC, USA, 2021. [Google Scholar]

- Oginni, O.A.R. The Unique Challenges of the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA). Master’s Thesis, University of Windsor, Windsor, ON, Canada, 2023. [Google Scholar]

- Prussi, M.; Lee, U.; Wang, M.; Malina, R.; Valin, H.; Taheripour, F.; Velarde, C.; Staples, M.D.; Lonza, L.; Hileman, J.I. CORSIA: The first internationally adopted approach to calculate life-cycle GHG emissions for aviation fuels. Renew. Sustain. Energy Rev. 2021, 150, 111398. [Google Scholar] [CrossRef]

- Budsberg, E.; Crawford, J.T.; Morgan, H.; Chin, W.S.; Bura, R.; Gustafson, R. Hydrocarbon bio-jet fuel from bioconversion of poplar biomass: Life cycle assessment. Biotechnol. Biofuels 2016, 9, 170. [Google Scholar] [CrossRef] [PubMed]

- Ukaew, S.; Shi, R.; Lee, J.H.; Archer, D.W.; Pearlson, M.; Lewis, K.C.; Bregni, L.; Shonnard, D.R. Full Chain Life Cycle Assessment of Greenhouse Gases and Energy Demand for Canola-Derived Jet Fuel in North Dakota, United States. ACS Sustain. Chem. Eng. 2016, 4, 2771–2779. [Google Scholar] [CrossRef]

- Watson, M.J.; Machado, P.G.; Da Silva, A.; Saltar, Y.; Ribeiro, C.; Nascimento, C.A.O.; Dowling, A.W. Sustainable aviation fuel technologies, costs, emissions, policies, and markets: A critical review. J. Clean. Prod. 2024, 449, 141472. [Google Scholar] [CrossRef]

- Braun, M.; Grimme, W.; Oesingmann, K. Pathway to net zero: Reviewing sustainable aviation fuels, environmental impacts and pricing. J. Air Transp. Manag. 2024, 117, 102580. [Google Scholar] [CrossRef]

- Klimczyk, W.; Jasiński, R.; Niklas, J.; Siedlecki, M.; Ziółkowski, A. Sustainable Aviation Fuels: A Comprehensive Review of Production Pathways, Environmental Impacts, Lifecycle Assessment, and Certification Frameworks. Energies 2025, 18, 3705. [Google Scholar] [CrossRef]

- Kurzawska-Pietrowicz, P.; Jasiński, R. A Review of Alternative Aviation Fuels. Energies 2024, 17, 3890. [Google Scholar] [CrossRef]

- Jagtap, S.S.; Childs, P.R.; Stettler, M.E. Comparative life cycle evaluation of alternative fuels for a futuristic subsonic long-range aircraft. Sustain. Prod. Consum. 2025, 56, 431–446. [Google Scholar] [CrossRef]

- Yun, S.; Choe, B.; Na, H.; Ahn, B.; Cho, H.; Kim, Y.J.; Won, W. Improving the Economics of Sustainable Aviation Fuels: System-Level Analyses and Perspective. ChemSusChem 2025, 18, 2500878. [Google Scholar] [CrossRef]

- Sharma, A.; Arief, M.M. Hydrogen in Aviation: Evaluating the Feasibility and Benefits of a Green Fuel Alternative. arXiv 2024, arXiv:2412.15137. [Google Scholar] [CrossRef]

- Ahrens, D.; Gebel, G.; Pathania, R.S.; Armit, C.; Löhnert, K.; Clemen, C. Experimental Combustor Research in Sustainable Aviation Fuel at Rolls-Royce: Strategy, Achievements, and Outlook. In Proceedings of the ASME Turbo Expo 2025: Turbomachinery Technical Conference and Exposition, Milan, Italy, 15–19 June 2026. [Google Scholar]

- Challoumis, C.; Eriotis, N.; Vasiliou, D. Social Movements’ Impact on the Greek Economy During the Financial Crisis. Economies 2025, 13, 269. [Google Scholar] [CrossRef]

- Pominville-Racette, M.; Overend, R.; Achouri, I.E.; Abatzoglou, N. Hydroprocessed Ester and Fatty Acids to Jet: Are We Heading in the Right Direction for Sustainable Aviation Fuel Production? Energies 2025, 18, 4156. [Google Scholar] [CrossRef]

- Szyc, R.; Lenort, R. Sustainable Aviation Fuels as the Path to Carbon Neutrality in Air Transport. Rocz. Ochr. Sr. 2024, 26, 707–715. [Google Scholar] [CrossRef]

- Rosales Calderon, O.; Tao, L.; Abdullah, Z.; Moriarty, K.; Smolinski, S.; Milbrandt, A.; Talmadge, M.; Bhatt, A.; Zhang, Y.; Ravi, V. Sustainable Aviation Fuel (SAF) State-of-Industry Report: State of SAF Production Process; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2024.

- Tiwari, H.; Samal, K.; Geed, S.R. Origin and Historical Perspectives of Green Gasoline. In Green Gasoline: A Green Spark Transportation Fuel; Royal Society of Chemistry: Cambridge, UK, 2023; Volume 77, pp. 1–22. [Google Scholar]

- Aksoy, T.; Yüksel, S.; Dınçer, H.; Hacioglu, U.; Maialeh, R. Complex fuzzy assessment of green flight activity investments for sustainable aviation industry. IEEE Access 2022, 10, 127297–127312. [Google Scholar] [CrossRef]

- Panzone, C.; Philippe, R.; Chappaz, A.; Fongarland, P.; Bengaouer, A. Power-to-Liquid catalytic CO2 valorization into fuels and chemicals: Focus on the Fischer-Tropsch route. J. CO2 Util. 2020, 38, 314–347. [Google Scholar] [CrossRef]

- Kramer, S.; Andac, G.; Heyne, J.; Ellsworth, J.; Herzig, P.; Lewis, K.C. Perspectives on fully synthesized sustainable aviation fuels: Direction and opportunities. Front. Energy Res. 2022, 9, 782823. [Google Scholar] [CrossRef]

- Oliveira, P.R.; May, M.; Panzera, T.H.; Hiermaier, S. Bio-based/green sandwich structures: A review. Thin-Walled Struct. 2022, 177, 109426. [Google Scholar] [CrossRef]

- Hashem, A.H.; El-Naggar, M.E.; Abdelaziz, A.M.; Abdelbary, S.; Hassan, Y.R.; Hasanin, M.S. Bio-based antimicrobial food packaging films based on hydroxypropyl starch/polyvinyl alcohol loaded with the biosynthesized zinc oxide nanoparticles. Int. J. Biol. Macromol. 2023, 249, 126011. [Google Scholar] [CrossRef]

- Zhang, L.; Butler, T.L.; Yang, B. Recent trends, opportunities and challenges of sustainable aviation fuel. In Green Energy to Sustainability: Strategies for Global Industries; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2020; pp. 85–110. [Google Scholar]

- Uddin, M.N.; Rashid, M.; Mostafa, M.; Belayet, H.; Salam, S.; Nithe, N. New Energy Sources: Technological Status and Economic Potentialities. Glob. J. Sci. Front. Res. 2016, 16, 24–37. [Google Scholar]

- Rahman, M.M.; Mahlia, T.; Uddin, M.N. Energy efficiency analysis in building walls in tropical climate using thermal insulation system. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Task, I.B. Progress in Commercialization of Biojet/Sustainable Aviation Fuels (SAF): Technologies, Potential and Challenges; IEA Bioenergy: Paris, France, 2021. [Google Scholar]

- Quante, G.; Bullerdiek, N.; Bube, S.; Neuling, U.; Kaltschmitt, M. Renewable fuel options for aviation–a System-Wide comparison of Drop-In and non Drop-In fuel options. Fuel 2023, 333, 126269. [Google Scholar] [CrossRef]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef]

- Rony, M.A.; Rangon, M.T.; Uddin, M.N. A Review on the Production of Sustainable Aviation Fuels from Biomass and Wastes using Pyrolysis Technologies: Part II. Johns. Matthey Technol. Rev. 2025, 69, 546–556. [Google Scholar] [CrossRef]

- Huerta-Rosas, B.; Juarez-García, M.; Núñez-López, J.M.; Alcocer-García, H.; Segovia-Hernández, J.G.; Sánchez-Ramírez, E. Power-to-X Technologies for Net-Zero: Bridging Process Innovation, System Integration, and Policy. Process Integr. Optim. Sustain. 2025. [Google Scholar] [CrossRef]

- Uddin, M.; Rahman, M.; Mofijur, M.; Taweekun, J.; Techato, K.; Rasul, M. Renewable energy in Bangladesh: Status and prospects. Energy Procedia 2019, 160, 655–661. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Prussi, M.; Buffi, M.; Tacconi, D. Sustainable bio kerosene: Process routes and industrial demonstration activities in aviation biofuels. Appl. Energy 2014, 136, 767–774. [Google Scholar] [CrossRef]

- de Klerk, A.; Chauhan, G.; Halmenschlager, C.; Link, F.; Montoya Sánchez, N.; Gartley, B.; El-Sayed, H.E.; Sehdev, R.; Lehoux, R. Sustainable aviation fuel: Pathways to fully formulated synthetic jet fuel via Fischer–Tropsch synthesis. Energy Sci. Eng. 2023, 12, 394–409. [Google Scholar] [CrossRef]

- Blakey, S.; Rye, L.; Wilson, C.W. Aviation gas turbine alternative fuels: A review. Proc. Combust. Inst. 2011, 33, 2863–2885. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental sustainability of biofuels: A review. Proc. Math. Phys. Eng. Sci. 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Uddin, M.; Techato, K.; Rasul, M.; Hassan, N.; Mofijur, M. Waste coffee oil: A promising source for biodiesel production. Energy Procedia 2019, 160, 677–682. [Google Scholar] [CrossRef]

- Uddin, M.; Rahman, M.; Taweekun, J.; Techato, K.; Mofijur, M.; Rasul, M. Enhancement of biogas generation in up-flow sludge blanket (UASB) bioreactor from palm oil mill effluent (POME). Energy Procedia 2019, 160, 670–676. [Google Scholar] [CrossRef]

- Rahman, M.M.; Rasul, M.; Hassan, N.; Uddin, M. Investigation of exhaust emissions from a stationary diesel engine fuelled with biodiesel. Energy Procedia 2019, 160, 791–797. [Google Scholar] [CrossRef]

- Han, G.B.; Jang, J.H.; Ahn, M.H.; Jung, B.H. Recent Application of Bio-Alcohol: Bio-Jet Fuel; IntechOpen: London, UK, 2019; Volume 1. [Google Scholar]

- Romero-Izquierdo, A.G.; Gómez-Castro, F.I.; Gutierrez-Antonio, C.; Hernández, S.; Errico, M. Intensification of the alcohol-to-jet process to produce renewable aviation fuel. Chem. Eng. Process.-Process Intensif. 2021, 160, 108270. [Google Scholar] [CrossRef]

- Corporan, E.; Edwards, J.T.; Stouffer, S.; DeWitt, M.; West, Z.; Klingshirn, C.; Bruening, C. Impacts of fuel properties on combustor performance, operability and emissions characteristics. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Rahman, M.M.; Rasul, M.G.; Hassan, N.M.S.; Azad, A.K.; Uddin, M.N. Effect of small proportion of butanol additive on the performance, emission, and combustion of Australian native first-and second-generation biodiesel in a diesel engine. Environ. Sci. Pollut. Res. 2017, 24, 22402–22413. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2022, 250, 110463. [Google Scholar] [CrossRef]

- Uddin, M.; Taweekun, J.; Techato, K.; Rahman, M.; Mofijur, M.; Rasul, M. Sustainable biomass as an alternative energy source: Bangladesh perspective. Energy Procedia 2019, 160, 648–654. [Google Scholar] [CrossRef]

- Habermeyer, F.; Weyand, J.; Maier, S.; Kurkela, E.; Dietrich, R.-U. Power Biomass to Liquid—An option for Europe’s sustainable and independent aviation fuel production. Biomass Convers. Biorefinery 2023, 14, 16199–16217. [Google Scholar] [CrossRef]

- Neves, R.C.; Klein, B.C.; da Silva, R.J.; Rezende, M.C.A.F.; Funke, A.; Olivarez-Gómez, E.; Bonomi, A.; Maciel-Filho, R. A vision on biomass-to-liquids (BTL) thermochemical routes in integrated sugarcane biorefineries for biojet fuel production. Renew. Sustain. Energy Rev. 2020, 119, 109607. [Google Scholar] [CrossRef]

- Boter, T. Bio-SAF vs. e-SAF: Land-Use Efficiency of Conversion Routes for Sustainable Aviation Fuel Production in the EU. Master’s Thesis, Utrecht University, Utrecht, The Netherlands, 2023. [Google Scholar]

- Uddin, M.; Techato, K.; Taweekun, J.; Rahman, M.M.; Rasul, M.; Mahlia, T.; Ashrafur, S. An overview of recent developments in biomass pyrolysis technologies. Energies 2018, 11, 3115. [Google Scholar] [CrossRef]

- Fernanda Rojas Michaga, M.; Michailos, S.; Akram, M.; Cardozo, E.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. Bioenergy with carbon capture and storage (BECCS) potential in jet fuel production from forestry residues: A combined Techno-Economic and Life Cycle Assessment approach. Energy Convers. Manag. 2022, 255, 115346. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Uddin, M.N.; Chowdhury, J.; Ahmed, S.; Uddin, M.; Mofijur, M.; Uddin, M. A review of the recent development, challenges, and opportunities of electronic waste (e-waste). Int. J. Environ. Sci. Technol. 2023, 20, 4513–4520. [Google Scholar] [CrossRef]

- Rojas-Michaga, M.F.; Michailos, S.; Cardozo, E.; Akram, M.; Hughes, K.J.; Ingham, D.; Pourkashanian, M. Sustainable aviation fuel (SAF) production through power-to-liquid (PtL): A combined techno-economic and life cycle assessment. Energy Convers. Manag. 2023, 292, 117427. [Google Scholar] [CrossRef]

- Garcia-Perez, M.; Wolcott, M.P.; Barrett, S.R.; Allroggen, F. Project 080 Hydrogen and Power-to-Liquid Concepts for Sustainable Aviation Fuel Production. Washington State University. Available online: https://s3.wp.wsu.edu/uploads/sites/2479/2025/06/ASCENT-Project-080A-2024-Annual-Report.pdf (accessed on 1 October 2023).

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Barbosa, F.C. Power to Liquid (PtL) Synthetic Aviation Fuel-A Sustainable Pathway for Jet Fuel Production. In Proceedings of the SAE BRASIL 2021 Web Forum, São Paulo, Brazil, 7–9 December 2021. [Google Scholar]

- Wang, W.C.; Liu, Y.C.; Nugroho, R.A.A. Techno-economic analysis of renewable jet fuel production: The comparison between Fischer-Tropsch synthesis and pyrolysis. Energy 2022, 239, 121970. [Google Scholar] [CrossRef]

- Siddiki, S.Y.A.; Uddin, M.; Mofijur, M.; Fattah, I.; Ong, H.C.; Lam, S.S.; Kumar, P.S.; Ahmed, S. Theoretical calculation of biogas production and greenhouse gas emission reduction potential of livestock, poultry and slaughterhouse waste in Bangladesh. J. Environ. Chem. Eng. 2021, 9, 105204. [Google Scholar] [CrossRef]

- Winckelmann, D.; Bleeke, F.; Thomas, B.; Elle, C.; Klöck, G. Open pond cultures of indigenous algae grown on non-arable land in an arid desert using wastewater. Int. Aquat. Res. 2015, 7, 221–233. [Google Scholar] [CrossRef]

- Rony, M.A.; Rangon, M.T.; Uddin, M.N. A Review on the Production of Sustainable Aviation Fuels from Biomass and Wastes using Pyrolysis Technologies: Part I. Johns. Matthey Technol. Rev. 2025, 69, 536–545. [Google Scholar] [CrossRef]

- Singh, A.; Nigam, P.S.; Murphy, J.D. Renewable fuels from algae: An answer to debatable land based fuels. Bioresour. Technol. 2011, 102, 10–16. [Google Scholar] [CrossRef] [PubMed]

- Leite, G.B.; Abdelaziz, A.E.; Hallenbeck, P.C. Algal biofuels: Challenges and opportunities. Bioresour. Technol. 2013, 145, 134–141. [Google Scholar] [CrossRef]

- Tibesigwa, T.; Olupot, P.W.; Kirabira, J.B. The critical techno-economic aspects for production of B10 biodiesel from second generation feedstocks: A review. Int. J. Sustain. Energy 2022, 41, 751–771. [Google Scholar] [CrossRef]

- Resurreccion, E.P.; Roostaei, J.; Martin, M.J.; Maglinao, R.L.; Zhang, Y.; Kumar, S. The case for camelina-derived aviation biofuel: Sustainability underpinnings from a holistic assessment approach. Ind. Crops Prod. 2021, 170, 113777. [Google Scholar] [CrossRef]

- Mupondwa, E.; Li, X.; Tabil, L.; Falk, K.; Gugel, R. Technoeconomic analysis of camelina oil extraction as feedstock for biojet fuel in the Canadian Prairies. Biomass Bioenergy 2016, 95, 221–234. [Google Scholar] [CrossRef]

- Pasa, V.M.D.; Scaldadaferri, C.A.; dos Santos Oliveira, H. Main feedstock for sustainable alternative fuels for aviation. In Sustainable Alternatives for Aviation Fuels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 69–102. [Google Scholar]

- Velvizhi, G.; Goswami, C.; Shetti, N.P.; Ahmad, E.; Pant, K.K.; Aminabhavi, T.M. Valorisation of lignocellulosic biomass to value-added products: Paving the pathway towards low-carbon footprint. Fuel 2022, 313, 122678. [Google Scholar] [CrossRef]

- Susmozas, A.; Martín-Sampedro, R.; Ibarra, D.; Eugenio, M.E.; Iglesias, R.; Manzanares, P.; Moreno, A.D. Process strategies for the transition of 1G to advanced bioethanol production. Processes 2020, 8, 1310. [Google Scholar] [CrossRef]

- Mondal, A.S.; Sharma, R.; Trivedi, N. Cutting-edge approaches for overcoming challenges in microalgal biodiesel production. In Microalgal Biomass for Bioenergy Applications; Elsevier: Amsterdam, The Netherlands, 2024; pp. 355–394. [Google Scholar]

- Wang, X.; Guo, L.; Lv, J.; Li, M.; Huang, S.; Wang, Y.; Ma, X. Process design, modeling and life cycle analysis of energy consumption and GHG emission for jet fuel production from bioethanol in China. J. Clean. Prod. 2023, 389, 136027. [Google Scholar] [CrossRef]

- Colelli, L.; Dell’Aversano, S.; Bassano, C.; Vanga, G.; Gallucci, K.; Vilardi, G. Liquid e-fuels for a sustainable future: A comprehensive review of production, regulation, and technological innovation. Energy Convers. Manag. 2026, 347, 120529. [Google Scholar] [CrossRef]

- Li, H.; Zhao, H.; Jian, S.; Tao, B.; Gu, S.; Xu, G.; Wang, G.; Chang, H. Designing proton exchange membrane fuel cells with high specific power density. J. Mater. Chem. A 2023, 11, 17373–17391. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Talluri, G.; Vourliotakis, G.; Testa, L.; Prussi, M.; Scarlat, N. Can lower carbon aviation fuels (LCAF) really complement sustainable aviation fuel (SAF) towards EU aviation Decarbonization? Energies 2021, 14, 6430. [Google Scholar] [CrossRef]

- Aziz, M. Liquid hydrogen: A review on liquefaction, storage, transportation, and safety. Energies 2021, 14, 5917. [Google Scholar] [CrossRef]

- Rayner, T. Taking the slow route to decarbonisation? Developing climate governance for international transport. Earth Syst. Gov. 2021, 8, 100100. [Google Scholar] [CrossRef]

- Korkut, E.; Fowler, L.B. Regulatory and policy analysis of production, development and use of sustainable aviation fuels in the United States. Front. Energy Res. 2021, 9, 750514. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, Y.; Sadiq, M.; Hieu, V.M.; Ngo, T.Q. Testing green fiscal policies for green investment, innovation and green productivity amid the COVID-19 era. Econ. Change Restruct. 2021, 56, 2943–2964. [Google Scholar] [CrossRef]

- O’malley, J.; Pavlenko, N.; Searle, S. Estimating Sustainable Aviation Fuel Feedstock Availability to Meet Growing European Union Demand; International Council on Clean Transportation: Berlin, Germany, 2021. [Google Scholar]

- Ng, K.S.; Farooq, D.; Yang, A. Global biorenewable development strategies for sustainable aviation fuel production. Renew. Sustain. Energy Rev. 2021, 150, 111502. [Google Scholar] [CrossRef]

- Mäntyvaara, A. Economic Characteristics of Power Purchase Agreements. Master’s Thesis, Aalto University, Espoo, Finland, 2022. [Google Scholar]

- Wang, Z.J.; Staples, M.D.; Tyner, W.E.; Zhao, X.; Malina, R.; Olcay, H.; Allroggen, F.; Barrett, S.R. Quantitative policy analysis for sustainable aviation fuel production technologies. Front. Energy Res. 2021, 9, 751722. [Google Scholar] [CrossRef]

- Phadke, A.; Bennett, J.L.D.; Popovich, N.; Paliwal, U. Inflation Reduction Act Incentives Increase Cost-Competitiveness of Lower-Footprint Clean Hydrogen-Based Sustainable Aviation Fuel; Springer Science and Business Media LLC: New York, NY, USA, 2024. [Google Scholar]

- Scheelhaase, J.; Grimme, W.; Maertens, S. EU trilogue results for the aviation sector–key issues and expected impacts. Transp. Res. Procedia 2024, 78, 206–214. [Google Scholar] [CrossRef]

- Proost, S. Looking for winning policies to address the climate issue in EU-aviation. J. Air Transp. Manag. 2024, 115, 102534. [Google Scholar] [CrossRef]

- Brandt, K.L.; Martinez-Valencia, L.; Wolcott, M.P. Cumulative impact of federal and state policy on minimum selling Price of sustainable aviation fuel. Front. Energy Res. 2022, 10, 828789. [Google Scholar] [CrossRef]

- Why, E.S.K.; Ong, H.C.; Lee, H.V.; Gan, Y.Y.; Chen, W.-H.; Chong, C.T. Renewable aviation fuel by advanced hydroprocessing of biomass: Challenges and perspective. Energy Convers. Manag. 2019, 199, 112015. [Google Scholar] [CrossRef]

- Occhipinti, Z.; Verona, R. Kyoto Protocol (KP). In Climate Action; Springer International Publishing: Cham, Switzerland, 2020; pp. 605–617. [Google Scholar]

- Owen, B.; Anet, J.G.; Bertier, N.; Christie, S.; Cremaschi, M.; Dellaert, S.; Edebeli, J.; Janicke, U.; Kuenen, J.; Lim, L. Particulate matter emissions from aircraft. Atmosphere 2022, 13, 1230. [Google Scholar] [CrossRef]

- Hille, E. Europe’s energy crisis: Are geopolitical risks in source countries of fossil fuels accelerating the transition to renewable energy? Energy Econ. 2023, 127, 107061. [Google Scholar] [CrossRef]

- Peters, M.A.; Alves, C.T.; Onwudili, J.A. A Review of Current and Emerging Production Technologies for Biomass-Derived Sustainable Aviation Fuels. Energies 2023, 16, 6100. [Google Scholar] [CrossRef]

- Brodzik, Ł.; Prokopowicz, W.; Ciupek, B.; Frąckowiak, A. Minimizing the Environmental Impact of Aircraft Engines with the Use of Sustainable Aviation Fuel (SAF) and Hydrogen. Energies 2025, 18, 472. [Google Scholar] [CrossRef]

- Kumar, T.; Basakran, G.K.; Marsuki, M.Z.; Wash, A.M.; Mohsin, R.; Majid, Z.A.; Ghafir, M.F.A. Exploring socioeconomic and political feasibility of aviation biofuel production and usage in Malaysia: A thematic analysis approach using expert opinion from aviation industry. Green Energy Intell. Transp. 2023, 2, 100111. [Google Scholar] [CrossRef]

- Fernandez Rivas, D.; Boffito, D.C.; Faria-Albanese, J.; Glassey, J.; Afraz, N.; Akse, H.; Boodhoo, K.V.; Bos, R.; Cantin, J.; Chiang, Y.W.E. Process intensification education contributes to sustainable development goals. Part 1. Educ. Chem. Eng. 2020, 32, 1–14. [Google Scholar] [CrossRef]

- Koščáková, M.; Korba, P.; Sekelová, I.; Koščák, P.; Pastír, D. Analysis of Sustainable Aviation Fuels Market. In Proceedings of the 2022 New Trends in Aviation Development (NTAD), Novy Smokovec, Slovakia, 24–25 November 2022. [Google Scholar]

- Korba, P.; Sekelová, I.; Koščáková, M.; Behúnová, A. Passengers’ Knowledge and Attitudes toward Green Initiatives in Aviation. Sustainability 2023, 15, 6187. [Google Scholar] [CrossRef]

- Wong, M.H.; Purchase, D.; Dickinson, N. Impacts, Management, and Recycling of Food Waste: Global Emerging Issues. In Food Waste Valorisation: Food, Feed, Fertiliser, Fuel and Value-Added Products; World Scientific: Singapore, 2023; pp. 3–31. [Google Scholar]

- Sieger, M.; Turner, J.; Allu, S.; Ameen, M.; Chaudhuri, S.; Chen, J.; Chen, Y.; Dal Forno Chuahy, F.; Finney, C.; Gururajan, V. Computational Requirements in Clean Energy and Manufacturing: Summary Report of the Virtual Workshop Held on 28–29 June 2021; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2023.

- Watson, M.J.; da Silva, A.V.; Machado, P.G.; Ribeiro, C.O.; Nascimento, C.A.; Dowling, A.W. The case for biojet fuel from bioethanol in Brazil: An optimization-based analysis using historical market data. Ind. Eng. Chem. Res. 2025, 64, 4410–4424. [Google Scholar] [CrossRef]

- Tanzil, A.H.; Brandt, K.; Zhang, X.; Wolcott, M.; Stockle, C.; Garcia-Perez, M. Production of sustainable aviation fuels in petroleum refineries: Evaluation of new bio-refinery concepts. Front. Energy Res. 2021, 9, 735661. [Google Scholar] [CrossRef]

- Münch, M.; Teichmann, F. Australian e-SAF for the German Aviation Sector; Adelphi Consult GmbH: Berlin, Germany, 2025. [Google Scholar]

- Greene, J.M.; Quiroz, D.; Limb, B.J.; Quinn, J.C. Geographically-resolved techno-economic and life cycle assessment comparing microalgae-based renewable diesel and sustainable aviation fuel in the United States. Environ. Sci. Technol. 2025, 59, 3472–3483. [Google Scholar] [CrossRef]

- Quiroz, D.; Greene, J.M.; Limb, B.J.; Quinn, J.C. Prospective Life Cycle Assessment of Sustainable Aviation Fuel Systems. Environ. Sci. Technol. 2025, 56, 19269–19282. [Google Scholar] [CrossRef]

- Marchesan, A.N.; de Mesquita Sampaio, I.L.; Chagas, M.F.; Generoso, W.C.; Hernandes, T.A.D.; Morais, E.R.; Junqueira, T.L. Alternative feedstocks for sustainable aviation fuels: Assessment of sugarcane-derived microbial oil. Bioresour. Technol. 2025, 416, 131772. [Google Scholar] [CrossRef] [PubMed]

- Cid Gomes, L.; Vajravel, S.; Siljebo, W.; Rana, A.; Gustafsson, T.; Bairaktari, A.; Thomsen, M.; Ottosson, H. Multiliter-Scale Photosensitized Dimerization of Isoprene to Sustainable Aviation Fuel Precursors. ACS Sustain. Chem. Eng. 2025, 13, 2467–2476. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Y.; Deng, X.; Lee, S.-Y.; Wang, K. Developing sustainable aviation fuel to deepen south Australia’s green economy: A BERTopic-enhanced SWOT analysis. Case Stud. Transp. Policy 2025, 21, 101562. [Google Scholar] [CrossRef]

- Abdin, Z.; Zafaranloo, A.; Rafiee, A.; Mérida, W.; Lipiński, W.; Khalilpour, K.R. Hydrogen as an energy vector. Renew. Sustain. Energy Rev. 2020, 120, 109620. [Google Scholar] [CrossRef]

- Petersen, A.M.; Chireshe, F.; Okoro, O.; Gorgens, J.; Van Dyk, J. Evaluating refinery configurations for deriving sustainable aviation fuel from ethanol or syncrude. Fuel Process. Technol. 2021, 219, 106879. [Google Scholar] [CrossRef]

- Dodd, T.; Yengin, D. Deadlock in sustainable aviation fuels: A multi-case analysis of agency. Transp. Res. Part D Transp. Environ. 2021, 94, 102799. [Google Scholar] [CrossRef]

- Wang, W.C. Techno-economic analysis for evaluating the potential feedstocks for producing hydro-processed renewable jet fuel in Taiwan. Energy 2019, 179, 771–783. [Google Scholar] [CrossRef]

- Uddin, N.M.; Nithe, N.A. A comprehensive exploration of biomass gasification technologies advancing United Nations sustainable development goals: Part II: Reactor types, power generation, current status and future challenges. Johns. Matthey Technol. Rev. 2025, 69, 13–23. [Google Scholar] [CrossRef]

- Barbera, E.; Naurzaliyev, R.; Asiedu, A.; Bertucco, A.; Resurreccion, E.P.; Kumar, S. Techno-economic analysis and life-cycle assessment of jet fuels production from waste cooking oil via in situ catalytic transfer hydrogenation. Renew. Energy 2020, 160, 428–449. [Google Scholar] [CrossRef]

- Uddin, M.; Wang, F. Fuelling a clean future: A systematic review of Techno-Economic and Life Cycle assessments in E-Fuel Development. Appl. Sci. 2024, 14, 7321. [Google Scholar] [CrossRef]

| Property | Conventional Jet Fuel (Jet A/Jet A-1) | Sustainable Aviation Fuels (SAFs) | Critical Sustainability Perspective |

|---|---|---|---|

| Lifecycle GHG Emissions | 89 kg CO2-eq/GJ (well-to-wake) | 20–30 kg CO2-eq/GJ (70–80% reduction) | Aviation contributes 2–3% of global CO2 emissions; SAFs offer the only viable near-term pathway to achieve ICAO’s net-zero 2050 targets while maintaining existing infrastructure [35,36]. |

| Energy Density | ~43 MJ/kg (Higher Heating Value) | 42–44 MJ/kg (comparable performance) | SAFs maintain operational performance while delivering environmental benefits—no trade-off between efficiency and sustainability [37,38]. |

| Production Cost | $0.50–0.80/L | $1.20–2.00/L (1.5–2.5 × higher) | High costs currently limit adoption, but carbon pricing and policy incentives are narrowing the gap; projected cost parity by 2030–2035 with scale-up [39,40,41]. |

| Feedstock Sources | Crude oil (finite fossil resource) | Biomass waste, algae, municipal solid waste, CO2 + renewable electricity (PtL) [11] | Diversified renewable feedstocks reduce dependence on volatile fossil fuel markets and geopolitically sensitive regions [11,12] |

| Infrastructure Compatibility | Standard (baseline compatibility) | 100% compatible as drop-in fuel (ASTM D7566) [13] | No infrastructure modification required enables immediate implementation across existing fleet and fuel systems [13] |

| Certification Requirements | ASTM D1655, DEF STAN 91-91 [13,14,16] | ASTM D7566 (blend components), ongoing 100% SAF certification [13,14] | Rigorous standards ensure safety while enabling sustainable transition; 100% SAF approval expected by 2030 [14] |

| Policy & Regulation | Long-established global standards; low regulatory risk | ASTM D7566-certified for seven pathways; supported by CORSIA, EU Fit-for-55, US SAF Grand Challenge | Policy support is accelerating SAF adoption; however, regulatory heterogeneity and lack of harmonized LCA criteria hinder global deployment [27,31,33]. |

| Supply Chain Resilience | Centralized, geographically concentrated | Distributed, regionally producible from local feedstocks [18] | Local production enhances energy security and reduces transportation-related emissions [18] |

| Job Potential | Limited (mature industry) | High (emerging sector): 1 million jobs projected by 2030 [19] | SAF industry development stimulates rural economies and creates high-skilled green jobs [19,20] |

| Pollutant Emissions | Higher particulate matter (PM) and SOx/NOx emissions | Lower PM, sulfur, and aromatic compounds → improved air quality and reduced contrail formation | Demonstrated air-quality benefits; however, real-world emission reductions vary depending on production pathway and blending ratio [13,16,17]. |

| Type of SAF | Feedstock | Details | TRL/FRL | Blend Limit | Merits | Drawbacks |

|---|---|---|---|---|---|---|

| Hydroprocessed Esters and Fatty Acids (HEFA) [54] | Vegetable oils, animal fats, used cooking oil, and tallow | Hydroprocessing technology to convert fats and oils into LCHs. | 9/9 | Up to 50% |

| |

| Fischer–Tropsch (FT) Synthetic Kerosene [58,59] | Biomass, coal, natural gas | Via FT, converting CO and H2 into LCHs. | 6–8/6–7 | Up to 50% | ||

| Alcohol-to-Jet (ATJ) [65,66] | Alcohols like ethanol or isobutanol | Converts alcohols to LCHs through dehydration, oligomerization, hydrogenation. | 7–8/7–8 | Up to 50% | ||

| Biomass-to-Liquid (BtL) [71,72] | Biomass (e.g., waste, sugarcane, corn, etc.) | Produced through biological fermentation into LCHs | 4–7/5–8 | Up to 50% | ||

| Power-to-Liquid (PtL) [77,78] | Water, CO2 | electrolysis, CO2 | 6–8/6–7 | Up to 50% | ||

| Algal Biofuels [83,84] | Biomass (e.g., oilseeds, algae, microalgae, macroalgae, etc.) | Converts lipids di-rectly into SAF through catalytic hydrother-molysis | 3–5/4–6 | Up to 50% | ||

| Co-processing [87] | Bio-feedstocks | Blending bio-feedstocks with conventional crude oil in refineries | 6–7/6–7 | ≤5–10% |

|

|

| Challenges | Key Areas | Descriptions | Possible Solutions |

|---|---|---|---|

| Technical |

|

|

|

| Economic |

|

|

|

| Environmental |

|

|

|

| Regulatory |

|

|

|

| Aviation-Sectoral (Broader Context) |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uddin, M.N.; Wang, F. Sustainable Aviation Fuels: Addressing Barriers to Global Adoption. Appl. Sci. 2025, 15, 10925. https://doi.org/10.3390/app152010925

Uddin MN, Wang F. Sustainable Aviation Fuels: Addressing Barriers to Global Adoption. Applied Sciences. 2025; 15(20):10925. https://doi.org/10.3390/app152010925

Chicago/Turabian StyleUddin, Md. Nasir, and Feng Wang. 2025. "Sustainable Aviation Fuels: Addressing Barriers to Global Adoption" Applied Sciences 15, no. 20: 10925. https://doi.org/10.3390/app152010925

APA StyleUddin, M. N., & Wang, F. (2025). Sustainable Aviation Fuels: Addressing Barriers to Global Adoption. Applied Sciences, 15(20), 10925. https://doi.org/10.3390/app152010925