Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations

Abstract

1. Introduction

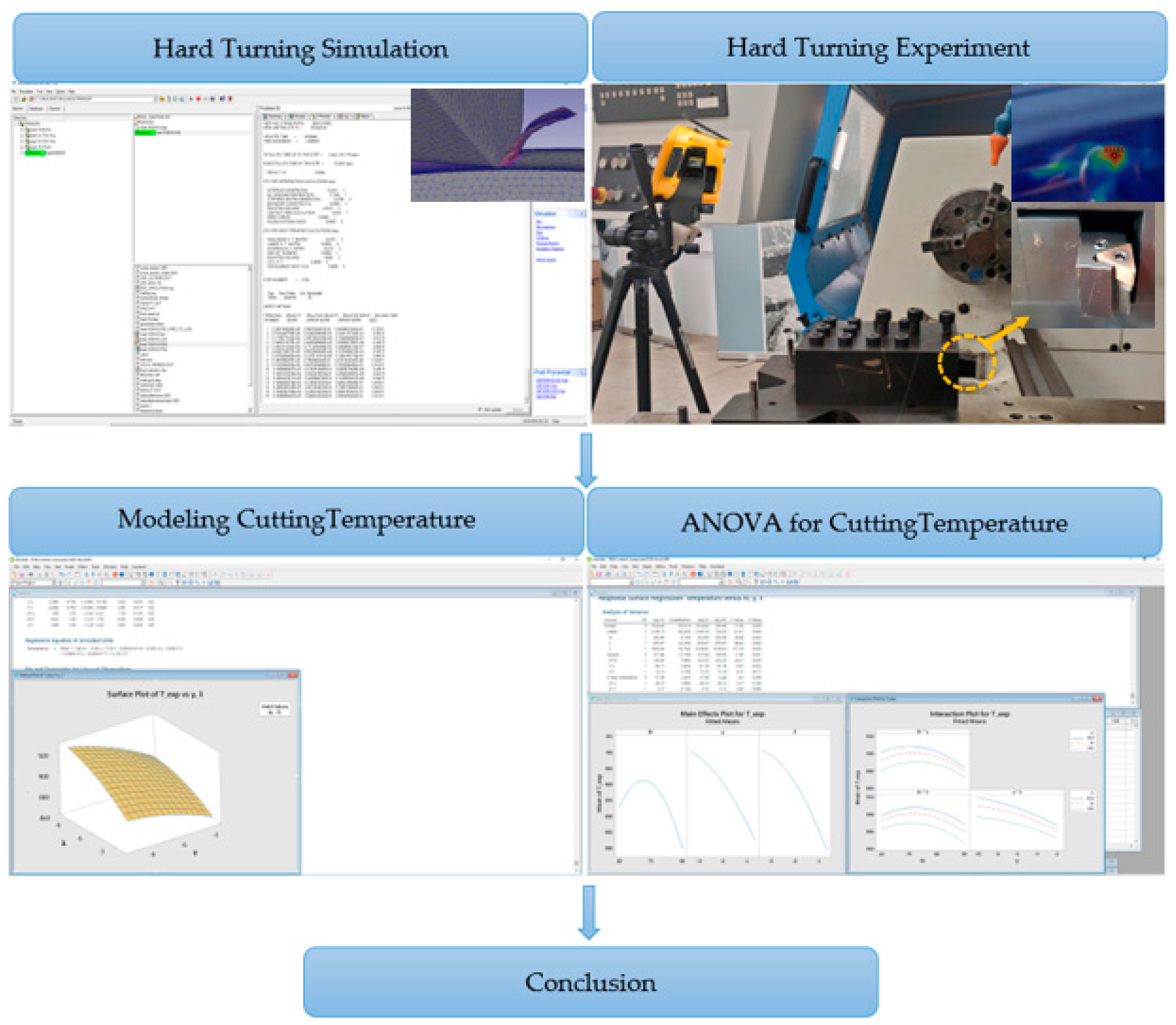

2. Materials and Methods

2.1. The CCD Experimental Design

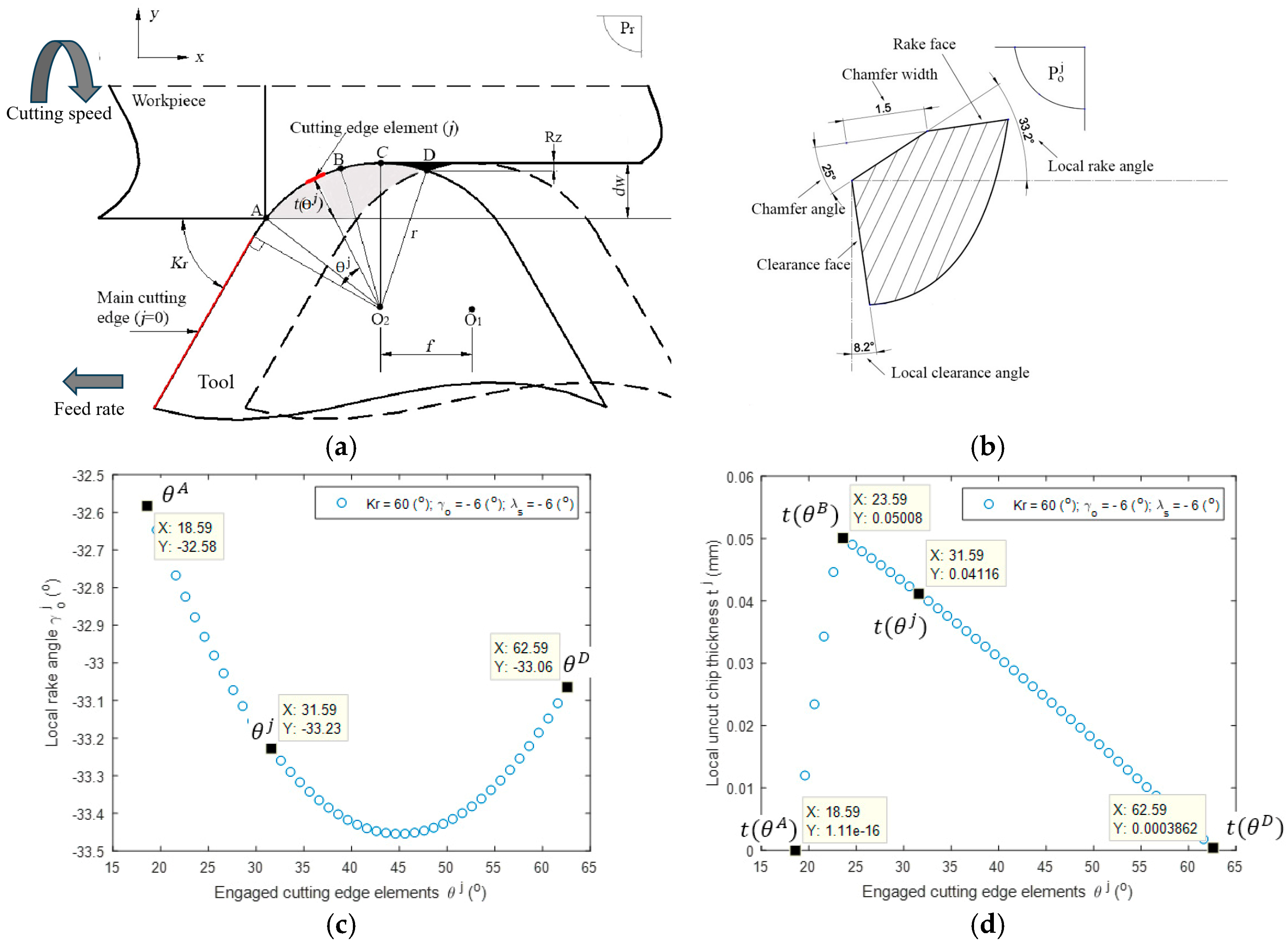

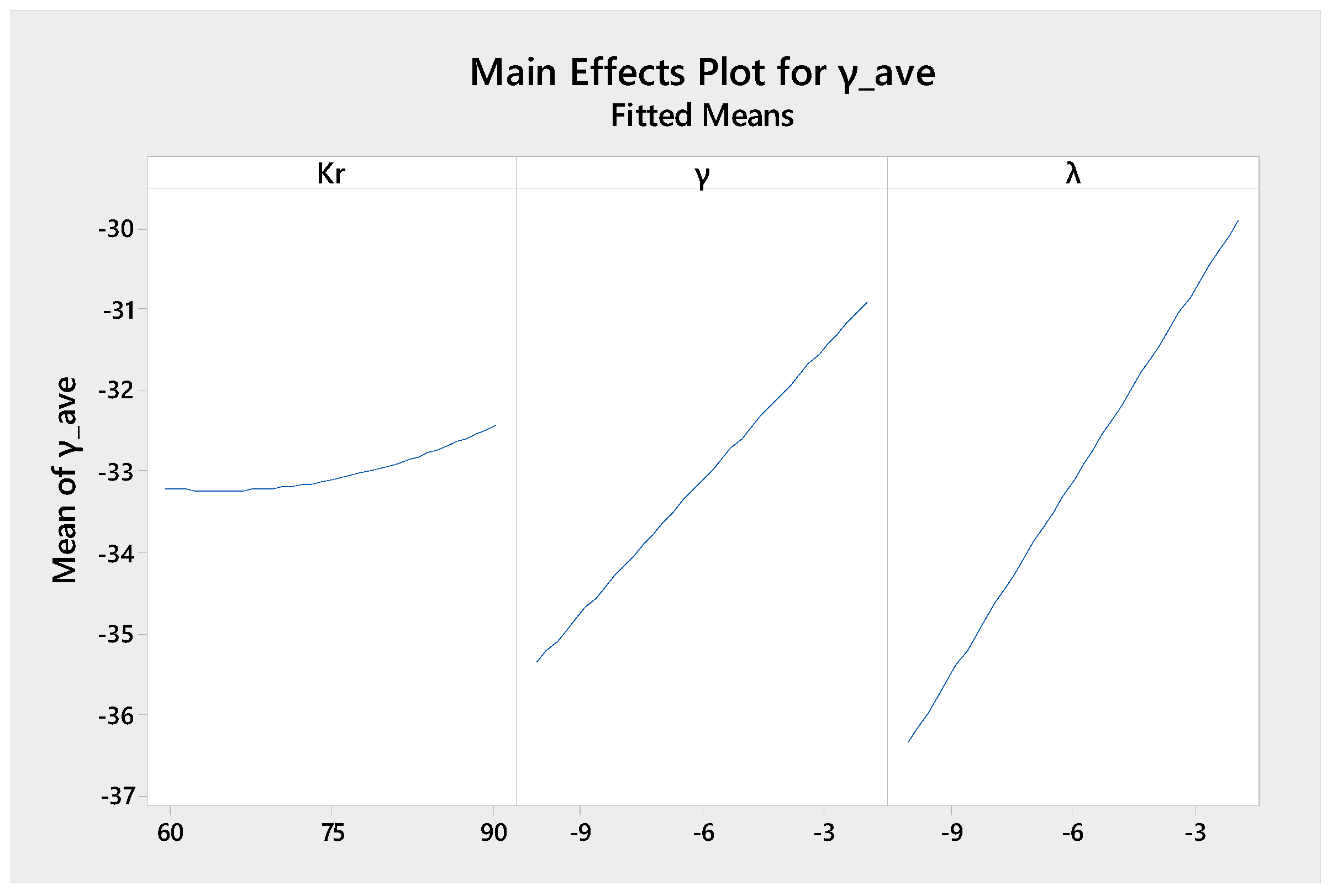

2.2. Analysis of Tool Geometry in Hard Turning

- -

- The portion of the nose radius involved in the cutting process:

- -

- Local rake angle:

- -

- Local undeformed chip thickness:

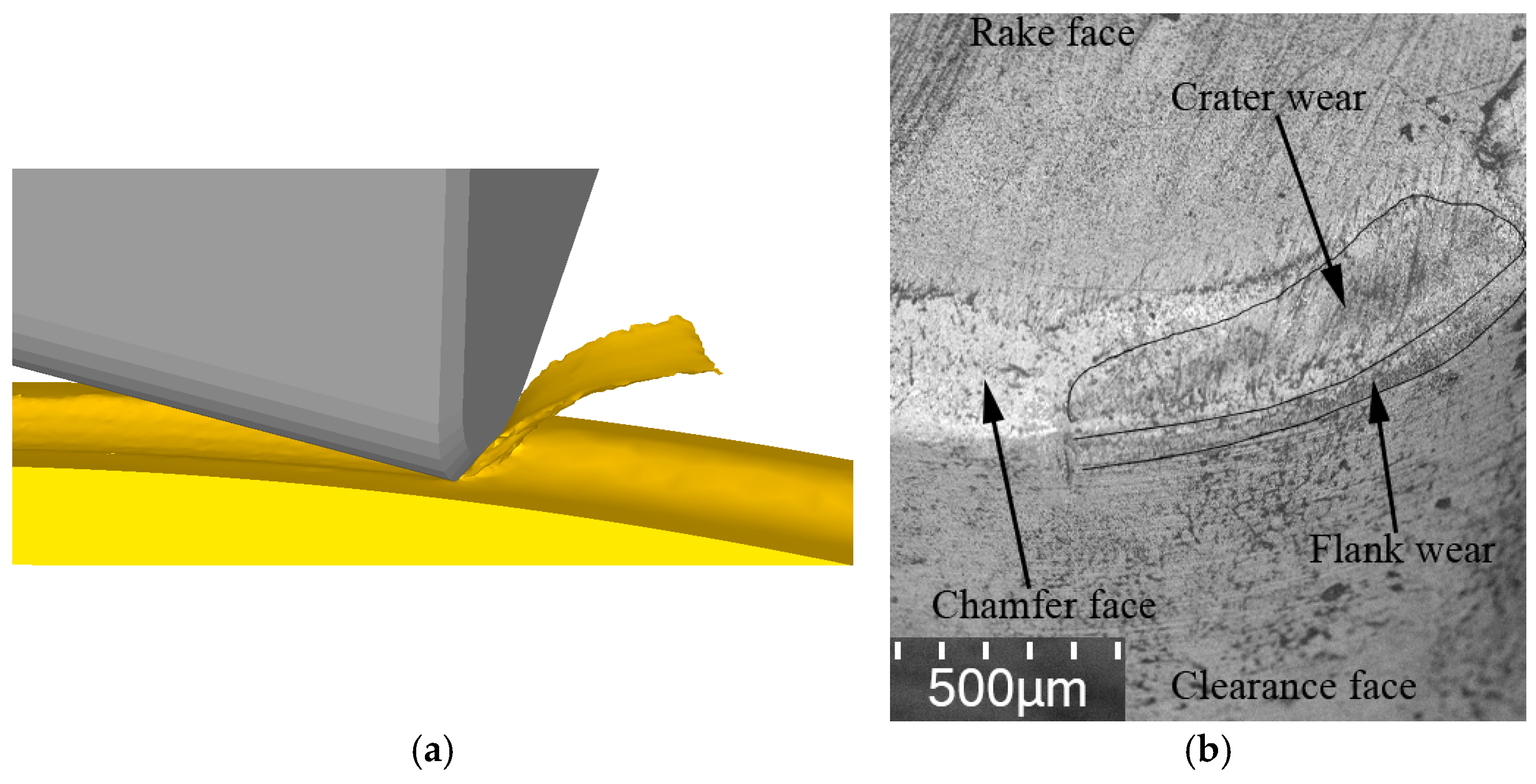

2.3. FEM Simulation

2.4. Experimental Procedure

3. Results and Discussion

4. Conclusions

- -

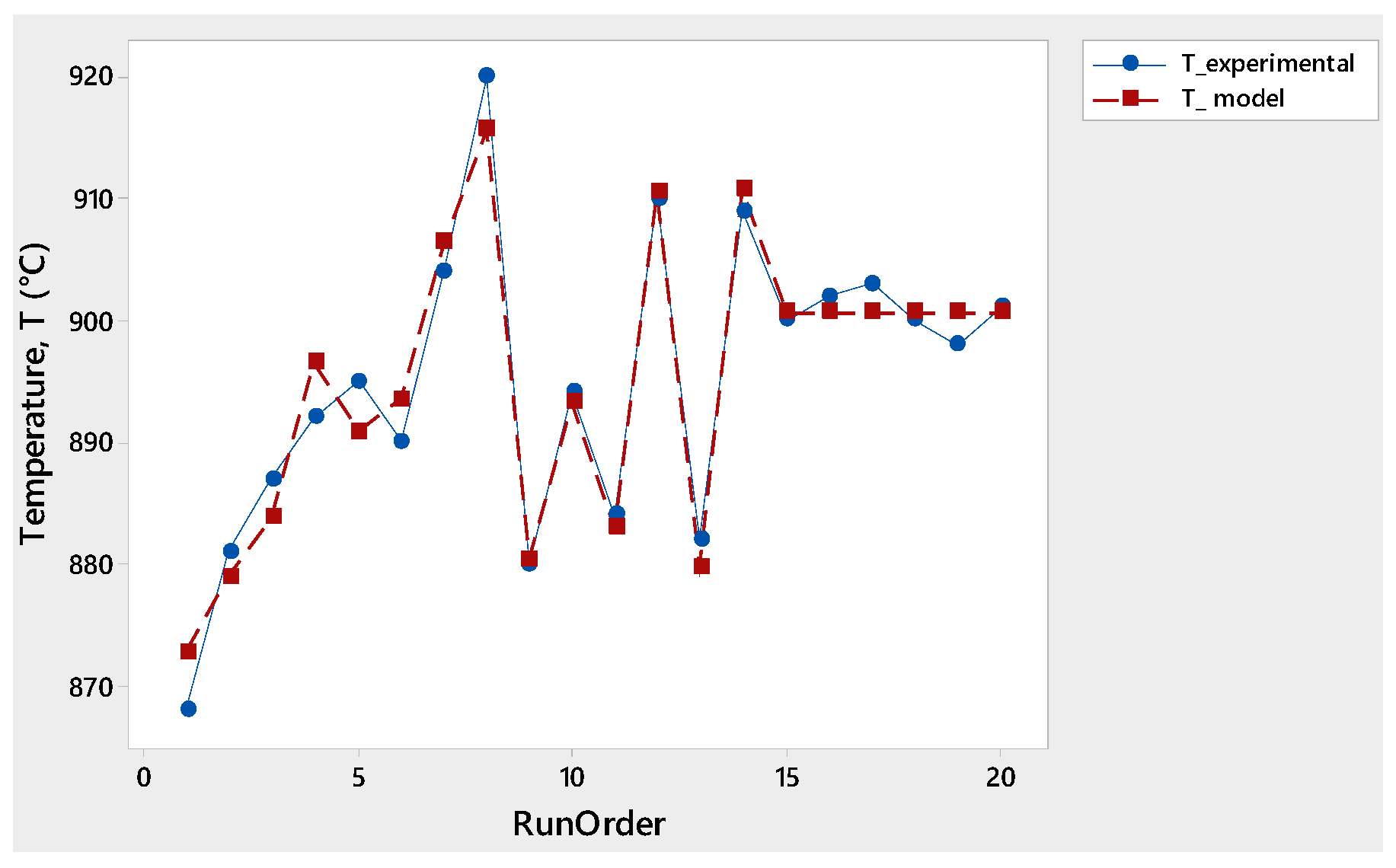

- The cutting temperature from the experiment and the simulation results have consistent values, reaching about 900 °C. The difference in the experiment and simulation results is small—approximately 2%.

- -

- Only the tool-nose radius cuts during the hard-turning operation, and the chip makes contact with the cutting edge’s chamfered face. At each cutting point, the local tool-geometry parameters and the thickness of the undeformed chip change, and the local rake angle becomes noticeably negative.

- -

- Increasing the negative rake angle and negative inclination angle improves the local negative rake angle of the cutting-edge elements at the tool-nose radius during the hard-turning process, accounting for 65.84% and 31.43%, respectively.

- -

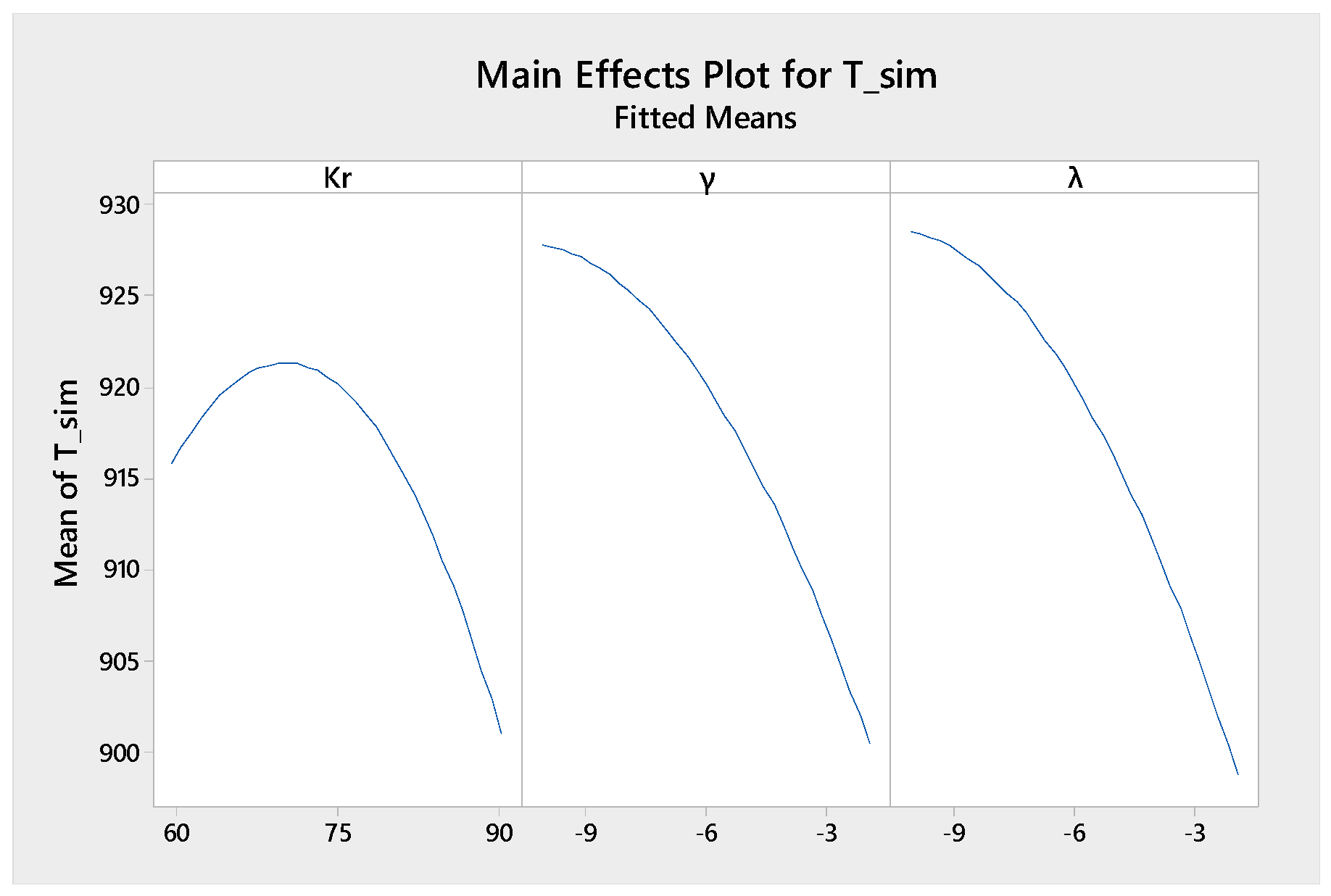

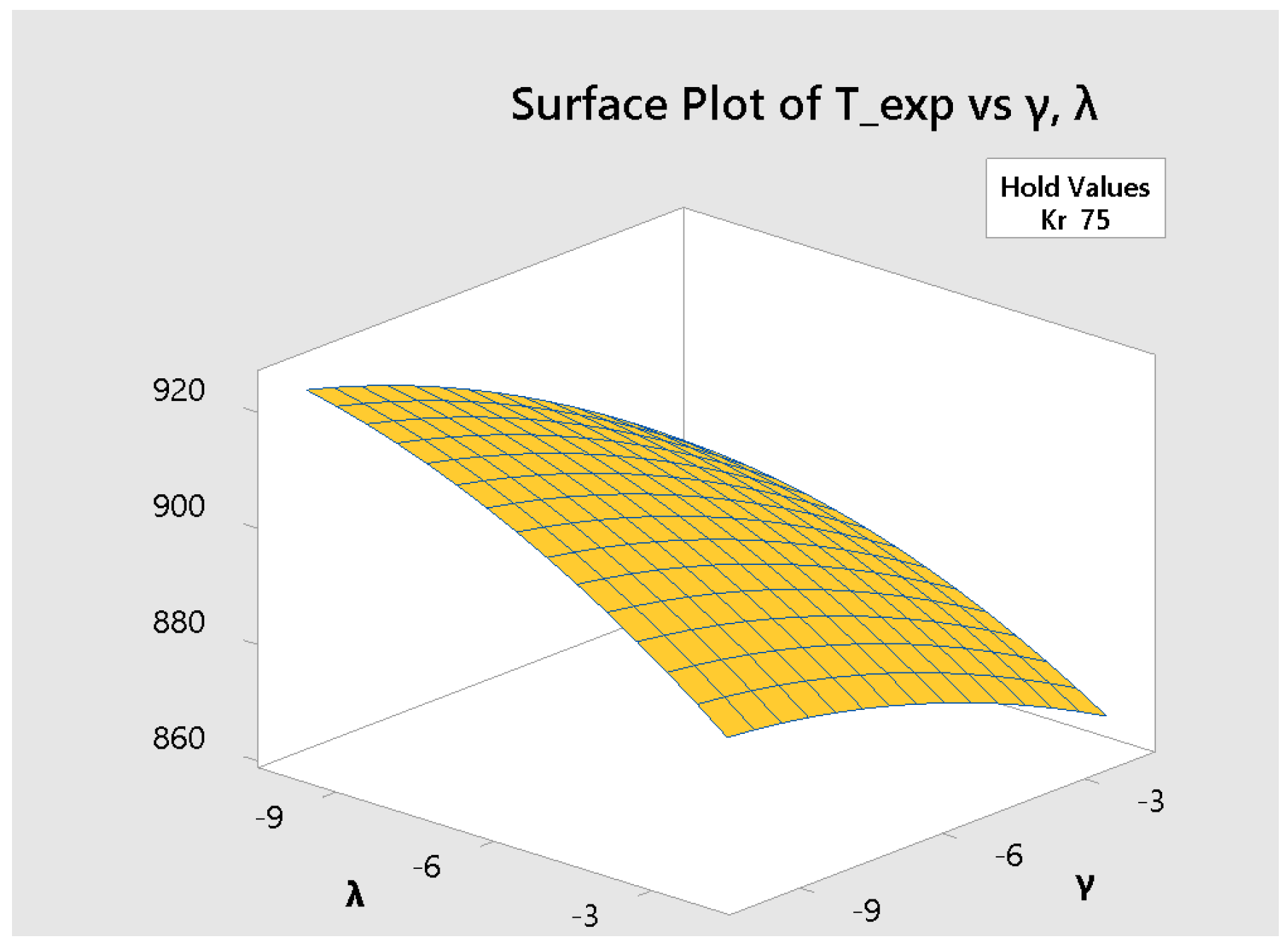

- The most significant factor influencing cutting temperature is the inclination angle, which accounts for 40.75% of the total variability. The rake angle has a smaller effect, accounting for 32.39% of the total variability, and the cutting-edge angle accounts for 7.03%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haq, A.N.; Tamizharasan, T. Investigation of the effects of cooling in hard turning operations. Int. J. Adv. Manuf. Technol. 2006, 30, 808–816. [Google Scholar]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat generation and temperature prediction in metal cutting: A review and implications for high-speed machining. Int. J. Mach. Tools Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Silva, M.B.; Wallbank, J. Cutting temperature: Prediction and measurement methods—A review. J. Mater. Process. Technol. 1999, 88, 195–202. [Google Scholar] [CrossRef]

- Hao, G.; Liu, Z. The heat partition into cutting tool at tool-chip contact interface during cutting process: A review. Int. J. Adv. Manuf. Technol. 2020, 108, 393–411. [Google Scholar] [CrossRef]

- Bhirud, N.L.; Gawande, R.R. Measurement and prediction of cutting temperatures during dry milling: Review and discussions. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 5135–5158. [Google Scholar] [CrossRef]

- Grzesik, W. Heat in metal cutting. In Advanced Machining Processes of Metallic Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 163–182. [Google Scholar]

- Trent, E.M.; Wright, P.K. Heat in metal cutting. In Metal Cutting; Butterworth-Heinemann: Oxford, UK, 2000; pp. 97–131. [Google Scholar]

- Wang, Y.; Wang, Z.; Ni, P.; Wang, D.; Lu, Y.; Lu, H.; Guo, S.; Chen, Z. Experimental and numerical study on regulation of cutting temperature during the circular sawing of 45 steel. Coatings 2023, 13, 758. [Google Scholar] [CrossRef]

- Puls, H.; Klocke, F.; Veselovac, D. FEM-based prediction of heat partition in dry metal cutting of AISI 1045. Int. J. Adv. Manuf. Technol. 2016, 86, 737–745. [Google Scholar] [CrossRef]

- Davim, J.P. Machining of Hard Materials; Springer: London, UK, 2011. [Google Scholar]

- Dessoly, V.; Melkote, S.N.; Lescalier, C. Modeling and verification of cutting tool temperature in rotary tool turning of hardened steels. Int. J. Mach. Tools Manuf. 2004, 44, 1463–1470. [Google Scholar] [CrossRef]

- Diniz, A.E.; Oliveira, A.J. Hard turning of interrupted surfaces using CBN tool. J. Mater. Process. Technol. 2008, 195, 275–281. [Google Scholar] [CrossRef]

- Grezesik, W. Influence of tool wear on surface roughness in HT using differently shaped ceramic tools. Wear 2008, 265, 327–335. [Google Scholar] [CrossRef]

- Bartarya, G.; Choudhury, S.K. State of the art in hard turning. Int. J. Mach. Tools Manuf. 2012, 53, 1–14. [Google Scholar] [CrossRef]

- Lazoglu, I.; Altintas, Y. Prediction of tool and chip temperature in continuous and interrupted machining. Int. J. Mach. Tools Manuf. 2002, 42, 1011–1022. [Google Scholar] [CrossRef]

- Mathivanan, A.; Sudeshkumar, M.P.; Ramadoss, R.; Ezilarasan, C.; Raju, G.; Jayaseelan, V. Finite element simulation and regression modeling of machining attributes on turning AISI 304 stainless steel. Manuf. Rev. 2021, 8, 24. [Google Scholar] [CrossRef]

- Liu, Z.; Yue, C.; Li, X.; Liu, X.; Liang, S.Y.; Wang, L. Research on tool wear based on 3D FEM simulation for milling process. J. Manuf. Mater. Process. 2020, 4, 121. [Google Scholar] [CrossRef]

- Elsadek, A.A.; Gaafer, A.M.; Mohamed, S.S. Prediction and optimization of cutting temperature on hard turning. SN Appl. Sci. 2020, 2, 540. [Google Scholar] [CrossRef]

- Abrão, A.M.; Aspinwall, D.K.; Wise, M.H.L. Tool Life and Workpiece Surface Integrity Evaluations when Machining Hardened AISI H13 and AISI E52100 Steels with Conventional Ceramic and PCBN Tool Materials; Society of Manufacturing Engineers: Southfield, MI, USA, 1995; pp. 1–7. [Google Scholar]

- Santhanakrishnan, M.; Sivasakthivel, P.S.; Sudhakaran, R. Modeling of geometrical and machining parameters on temperature rise while machining Al 6351 using response surface methodology and genetic algorithm. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 487–496. [Google Scholar] [CrossRef]

- Xu, D.; Ding, L.; Liu, Y.; Zhou, J.; Liao, Z. Investigation of the Influence of Tool Rake Angles on Machining of Inconel 718. J. Manuf. Mater. Process. 2021, 5, 100. [Google Scholar] [CrossRef]

- Saglam, H.; Unsacar, F.; Yaldiz, S. Investigation of the effect of rake angle and approaching angle on main cutting force and tool tip temperature. Int. J. Mach. Tools Manuf. 2006, 46, 132–141. [Google Scholar] [CrossRef]

- Shah, D.; Bhavsar, S. Effect of tool nose radius and machining parameters on cutting force, cutting temperature and surface roughness—An experimental study of Ti-6Al-4V (ELI). Mater. Today Proc. 2020, 22, 1977–1986. [Google Scholar] [CrossRef]

- Dutta, S.; Narala, S.K.R. Effect of tool nose radius in turning of novel Mg alloy. Mater. Today Proc. 2021, 38, 2675–2679. [Google Scholar] [CrossRef]

- Duc, P.M.; Dai, M.D.; Giang, L.H. Modeling and optimizing the effects of insert angles on hard turning performance. Math. Probl. Eng. 2021, 2021, 9924427. [Google Scholar] [CrossRef]

- Tzotzis, A.; Garcia-Hernandez, C.; Talón, J.L.H.; Kyratsis, P. Influence of the nose radius on the machining forces induced during AISI-4140 hard turning: A CAD-based and 3D FEM approach. Micromachines 2020, 11, 798. [Google Scholar] [CrossRef] [PubMed]

- Tzotzis, A.; Garcia-Hernandez, C.; Talón, J.L.H.; Kyratsis, P. 3D FE Modelling of machining forces during AISI 4140 hard turning. Strojniški Vestn. J. Mech. Eng. 2020, 66, 467–478. [Google Scholar] [CrossRef]

- Haglund, A.J.; Kishawy, H.A.; Rogers, R.J. An exploration of friction models for the chip-tool interface using an Arbitrary Lagrangian-Eulerian finite element model. Wear 2008, 265, 452–460. [Google Scholar] [CrossRef]

- Zhang, S.; Li, B.; Li, J.; Man, J. Effects of constitutive model parameters on finite element simulation process for hard milling of AISI H13 steel. MM Sci. J. 2021, 2021, 5234–5240. [Google Scholar] [CrossRef]

- Davies, M.; Ueda, T.; M’Saoubi, R.; Mullany, B.; Cooke, A. On the measurement of temperature in material removal processes. CIRP Ann. 2007, 56, 581–604. [Google Scholar] [CrossRef]

- Weng, J.; Saelzer, J.; Berger, S.; Zhuang, K.; Bagherzadeh, A.; Budak, E.; Biermann, D. Analytical and experimental investigations of rake face temperature considering temperature-dependent thermal properties. J. Mater. Process. Technol. 2023, 314, 117905. [Google Scholar] [CrossRef]

- Guimaraes, B.M.P.; Fernandes, C.M.D.S.; de Figueiredo, D.A.; da Silva, F.S.C.P.; Miranda, M.G.M. Cutting temperature measurement and prediction in machining processes: Comprehensive review and future perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 2849–2878. [Google Scholar] [CrossRef]

- Hao, G.; Tang, A.; Zhang, Z.; Xing, H.; Xu, N.; Duan, R. Finite element simulation of orthogonal cutting of H13-hardened steel to evaluate the influence of coatings on cutting temperature. Coatings 2024, 14, 293. [Google Scholar] [CrossRef]

| Tool-Geometry Parameter | Unit | Levels | ||||

|---|---|---|---|---|---|---|

| −α | −1 | 0 | +1 | +α | ||

| Kr | (°) | 60 | 66 | 75 | 84 | 90 |

| γ | (°) | −2 | −3.6 | −6 | −8.4 | −10 |

| λ | (°) | −2 | −3.6 | −6 | −8.4 | −10 |

| No. | Factors | No. | Factors | ||||

|---|---|---|---|---|---|---|---|

| Kr | γ | λ | Kr | γ | λ | ||

| 1 | +1 | −1 | −1 | 11 | 0 | −α | 0 |

| 2 | −1 | −1 | −1 | 12 | 0 | +α | 0 |

| 3 | +1 | +1 | −1 | 13 | 0 | 0 | −α |

| 4 | −1 | +1 | −1 | 14 | 0 | 0 | +α |

| 5 | +1 | −1 | +1 | 15 | 0 | 0 | 0 |

| 6 | −1 | −1 | +1 | 16 | 0 | 0 | 0 |

| 7 | +1 | +1 | +1 | 17 | 0 | 0 | 0 |

| 8 | −1 | +1 | +1 | 18 | 0 | 0 | 0 |

| 9 | +α | 0 | 0 | 19 | 0 | 0 | 0 |

| 10 | −α | 0 | 0 | 20 | 0 | 0 | 0 |

| Cutting Speed v (m/min) | Feed Rate f (mm/rev) | Depth of Cut dw (mm) |

|---|---|---|

| 150 | 0.08 | 0.2 |

| A (MPa) | B (MPa) | n | C | m | (1/s) | (°C) | (°C) |

|---|---|---|---|---|---|---|---|

| 908.54 | 321.39 | 0.278 | 0.028 | 1.18 | 1.0 | 27 | 1475 |

| Thermo-Mechanical Properties | AISI H13 | Ceramic Tool | TiN Coating |

|---|---|---|---|

| Young’s Modulus (GPa) | 211 | 145 | - |

| Poisson ratio | 0.28 | 0.22 | 0.25 |

| Density (kg/m3) | 7800 | 3500 | 4650 |

| Thermal conductivity (W/m·°C) | 37 | 24 | 23.5 |

| Hardness (HV) | 544 | - | 2300 |

| No. | Cutting-Edge Angle Kr (°) | Rake Angle γ (°) | Inclination Angle λ (°) | Average Local Rake Angle γ_ave (°) | Simulated Temperature T_sim (°C) | Experimental Temperature T_exp (°C) |

|---|---|---|---|---|---|---|

| 1 | 84 | −3.6 | −3.6 | −29.7 | 888 | 868 |

| 2 | 66 | −3.6 | −3.6 | −30 | 900 | 881 |

| 3 | 84 | −8.4 | −3.6 | −31.7 | 905 | 887 |

| 4 | 66 | −8.4 | −3.6 | −33.2 | 914 | 892 |

| 5 | 84 | −3.6 | −8.4 | −33.9 | 912 | 895 |

| 6 | 66 | −3.6 | −8.4 | −33.3 | 911 | 890 |

| 7 | 84 | −8.4 | −8.4 | −35.9 | 922 | 904 |

| 8 | 66 | −8.4 | −8.4 | −36.5 | 939 | 920 |

| 9 | 90 | −6.0 | −6.0 | −32.4 | 903 | 880 |

| 10 | 60 | −6.0 | −6.0 | −33.2 | 916 | 894 |

| 11 | 75 | −2.0 | −6.0 | −30.9 | 903 | 884 |

| 12 | 75 | −10.0 | −6.0 | −35.3 | 927 | 910 |

| 13 | 75 | −6.0 | −2.0 | −29.9 | 902 | 882 |

| 14 | 75 | −6.0 | −10.0 | −36.3 | 927 | 909 |

| 15 | 75 | −6.0 | −6.0 | −33.1 | 919 | 900 |

| 16 | 75 | −6.0 | −6.0 | −33.1 | 922 | 902 |

| 17 | 75 | −6.0 | −6.0 | −33.1 | 921 | 903 |

| 18 | 75 | −6.0 | −6.0 | −33.1 | 920 | 900 |

| 19 | 75 | −6.0 | −6.0 | −33.1 | 919 | 898 |

| 20 | 75 | −6.0 | −6.0 | −33.1 | 920 | 901 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Model | 9 | 73.7959 | 99.98% | 73.7959 | 8.1995 | 6783.94 | 0.000 |

| Linear | 3 | 72.5213 | 98.26% | 72.5213 | 24.1738 | 20,000.32 | 0.000 |

| Kr | 1 | 0.7243 | 0.98% | 0.7243 | 0.7243 | 599.22 | 0.000 |

| γ | 1 | 23.1987 | 31.43% | 23.1987 | 23.1987 | 19,193.58 | 0.000 |

| λ | 1 | 48.5984 | 65.84% | 48.5984 | 48.5984 | 40,208.15 | 0.000 |

| Square | 3 | 0.1496 | 0.20% | 0.1496 | 0.0499 | 41.26 | 0.000 |

| 1 | 0.1483 | 0.20% | 0.1426 | 0.1426 | 118.01 | 0.000 | |

| γ | 1 | 0.0006 | 0.00% | 0.0007 | 0.0007 | 0.60 | 0.458 |

| λ | 1 | 0.0007 | 0.00% | 0.0007 | 0.0007 | 0.60 | 0.458 |

| 2-Way Interaction | 3 | 1.1250 | 1.52% | 1.1250 | 0.3750 | 310.26 | 0.000 |

| γ | 1 | 0.7200 | 0.98% | 0.7200 | 0.7200 | 595.70 | 0.000 |

| λ | 1 | 0.4050 | 0.55% | 0.4050 | 0.4050 | 335.08 | 0.000 |

| λ | 1 | 0.0000 | 0.00% | 0.0000 | 0.0000 | 0.00 | 1.000 |

| Error | 10 | 0.0121 | 0.02% | 0.0121 | 0.0012 | ||

| Lack-of-Fit | 5 | 0.0121 | 0.02% | 0.0121 | 0.0024 | ||

| Pure Error | 5 | 0.0000 | 0.00% | 0.0000 | 0.0000 | ||

| Total | 19 | 73.8080 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Model | 9 | 2736.17 | 95.20% | 2736.17 | 304.02 | 22.06 | 0.000 |

| Linear | 3 | 2304.11 | 80.17% | 2304.11 | 768.04 | 55.72 | 0.000 |

| Kr | 1 | 202.04 | 7.03% | 202.04 | 202.04 | 14.66 | 0.003 |

| γ | 1 | 930.89 | 32.39% | 930.89 | 930.89 | 67.54 | 0.000 |

| λ | 1 | 1171.18 | 40.75% | 1171.18 | 1171.18 | 84.97 | 0.000 |

| Square | 3 | 394.68 | 13.73% | 394.68 | 131.56 | 9.55 | 0.003 |

| 1 | 319.34 | 11.11% | 352.95 | 352.95 | 25.61 | 0.000 | |

| γ | 1 | 21.68 | 0.75% | 28.12 | 28.12 | 2.04 | 0.184 |

| λ | 1 | 53.67 | 1.87% | 53.67 | 53.67 | 3.89 | 0.077 |

| 2-Way Interaction | 3 | 37.38 | 1.30% | 37.38 | 12.46 | 0.90 | 0.473 |

| γ | 1 | 21.13 | 0.74% | 21.12 | 21.12 | 1.53 | 0.244 |

| λ | 1 | 6.12 | 0.21% | 6.12 | 6.12 | 0.44 | 0.520 |

| λ | 1 | 10.13 | 0.35% | 10.13 | 10.13 | 0.73 | 0.411 |

| Error | 10 | 137.83 | 4.80% | 137.83 | 13.78 | ||

| Lack-of-Fit | 5 | 122.49 | 4.26% | 122.49 | 24.50 | 7.99 | 0.020 |

| Pure Error | 5 | 15.33 | 0.53% | 15.33 | 3.07 | ||

| Total | 19 | 2874.00 | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minh Duc, P.; Hieu Giang, L.; Nguyen, V.T. Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations. Appl. Sci. 2025, 15, 983. https://doi.org/10.3390/app15020983

Minh Duc P, Hieu Giang L, Nguyen VT. Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations. Applied Sciences. 2025; 15(2):983. https://doi.org/10.3390/app15020983

Chicago/Turabian StyleMinh Duc, Pham, Le Hieu Giang, and Van Thuc Nguyen. 2025. "Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations" Applied Sciences 15, no. 2: 983. https://doi.org/10.3390/app15020983

APA StyleMinh Duc, P., Hieu Giang, L., & Nguyen, V. T. (2025). Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations. Applied Sciences, 15(2), 983. https://doi.org/10.3390/app15020983