Development and Field Testing of a Suspended Mulberry Branch Harvesting and Stubble Cutting Machine

Abstract

1. Introduction

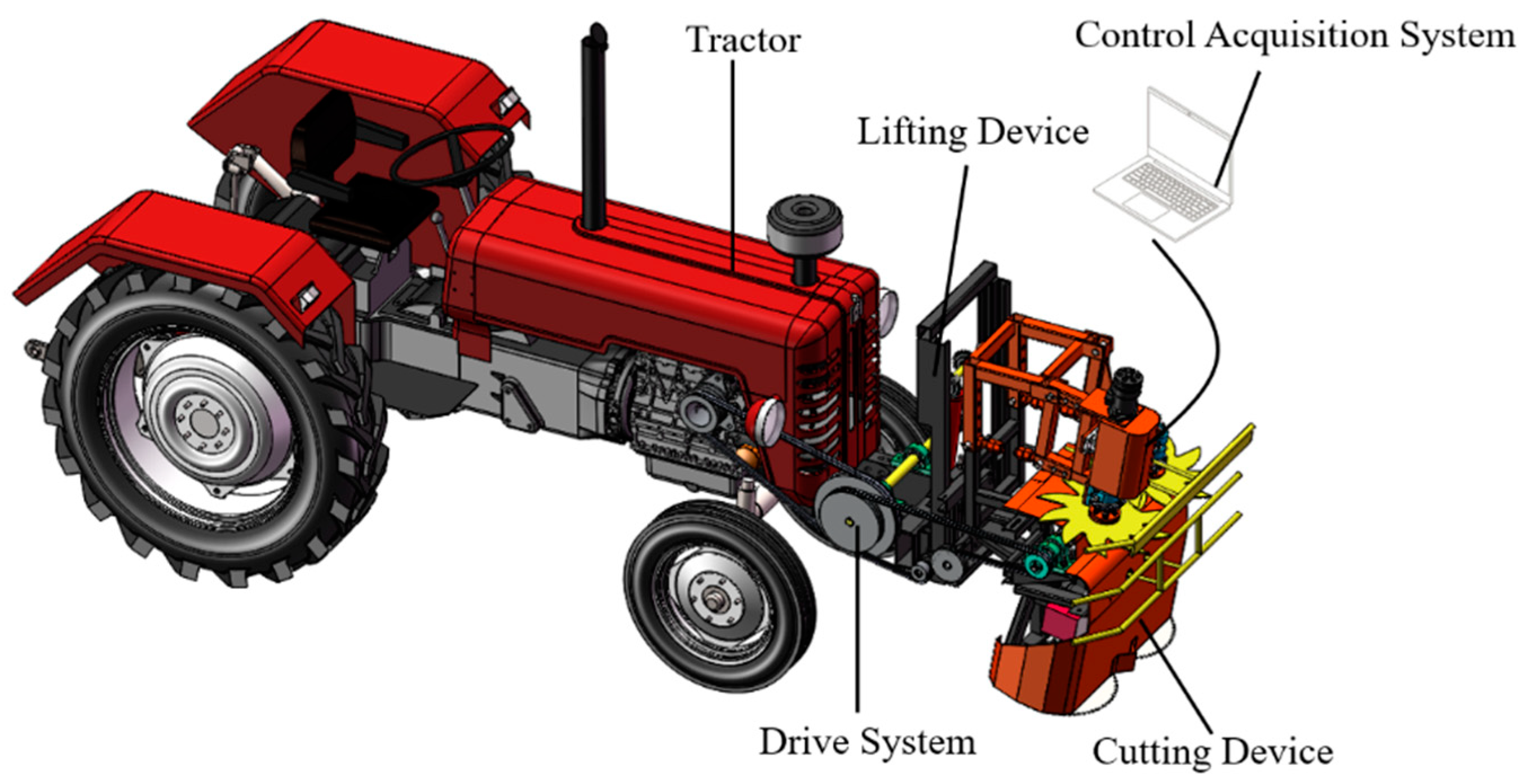

2. Mechanical Structure and Working Principles

2.1. Mechanical Structure

2.2. Working Principles

2.3. Main Technical Parameters

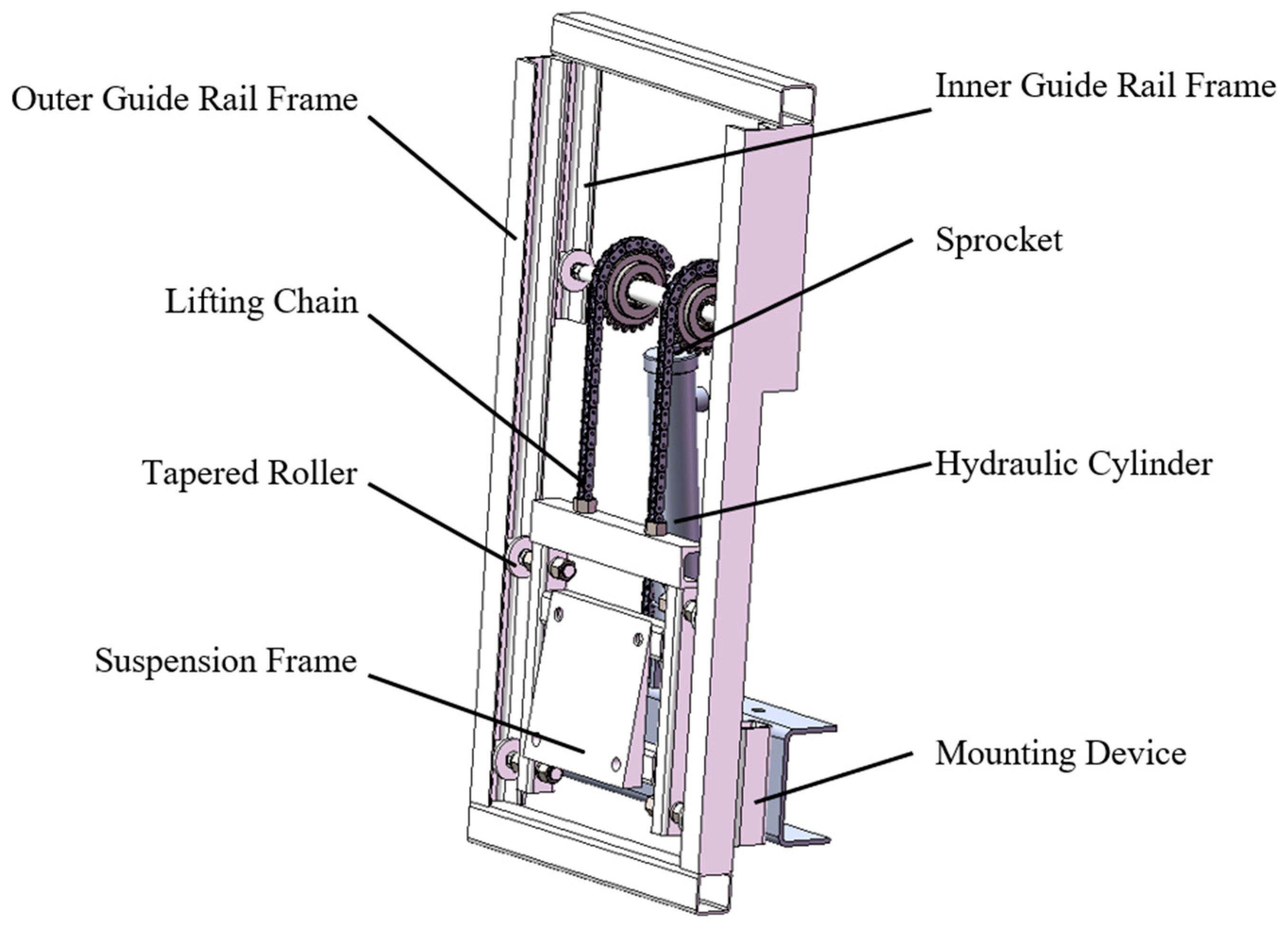

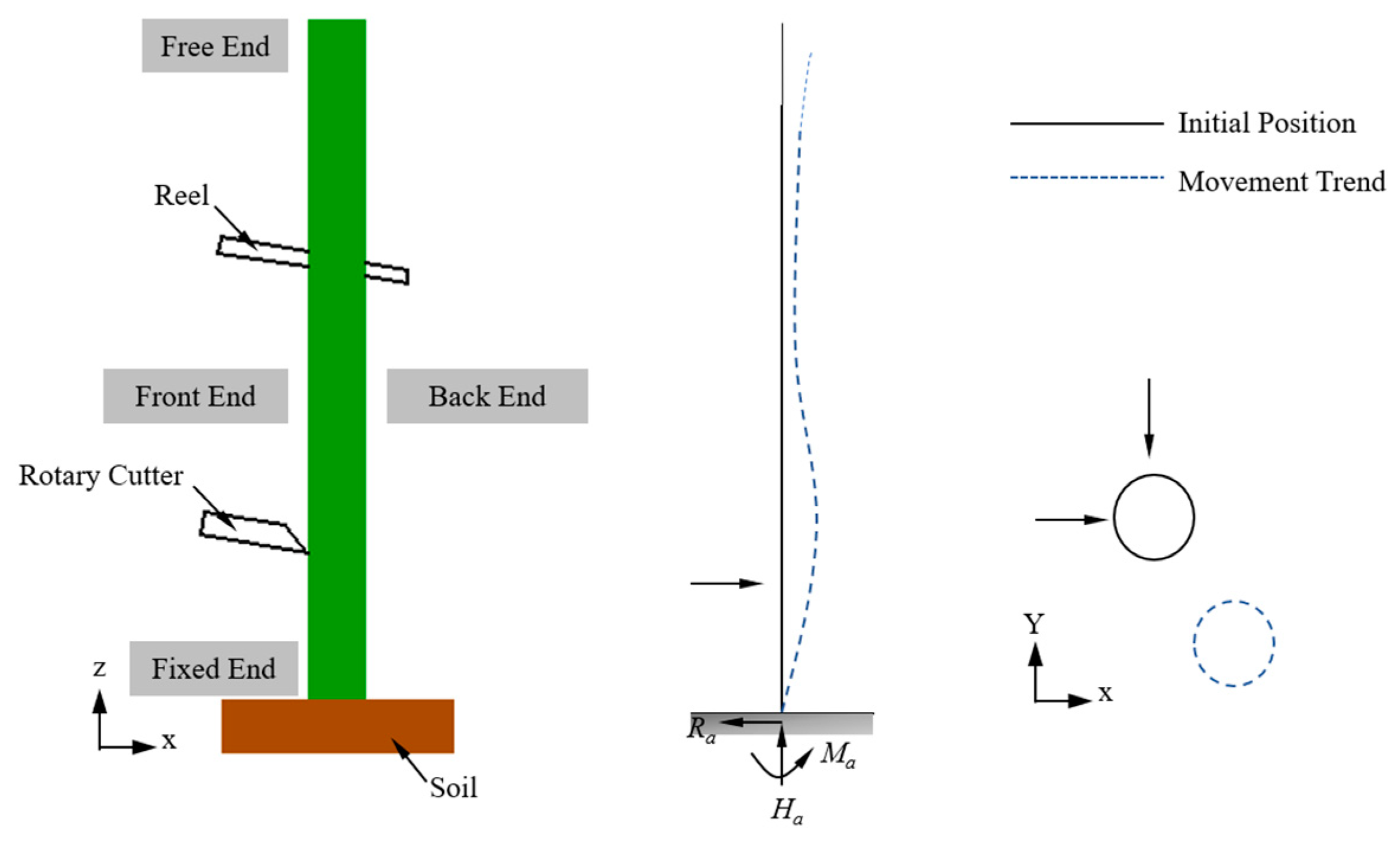

3. Key Component Design

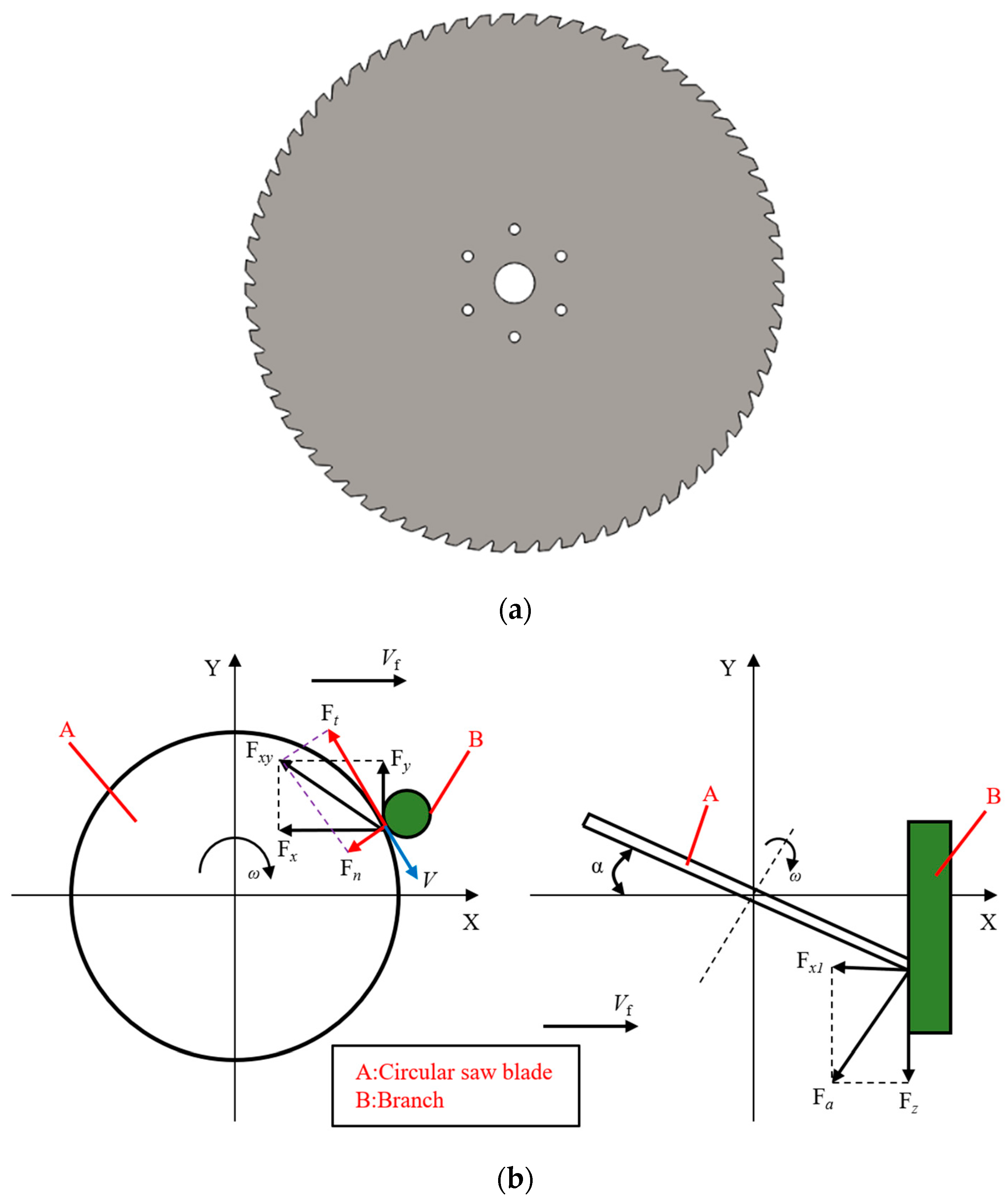

3.1. Cutter Design

3.1.1. Lifting Apparatus Design

3.1.2. Design of the Circular Saw-Type Cutter

3.1.3. Design of the Grain Separation Device

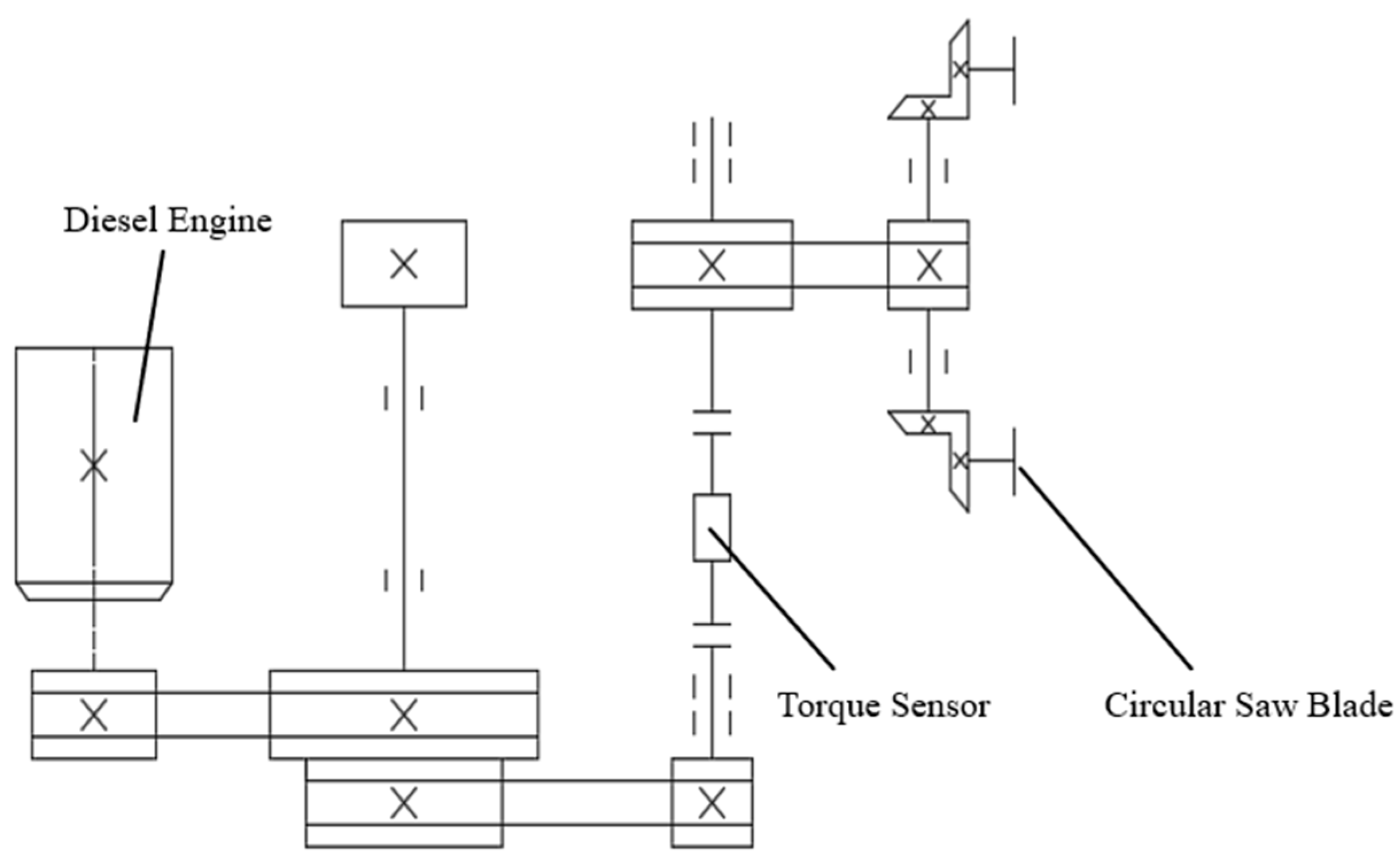

3.2. Transmission System Design

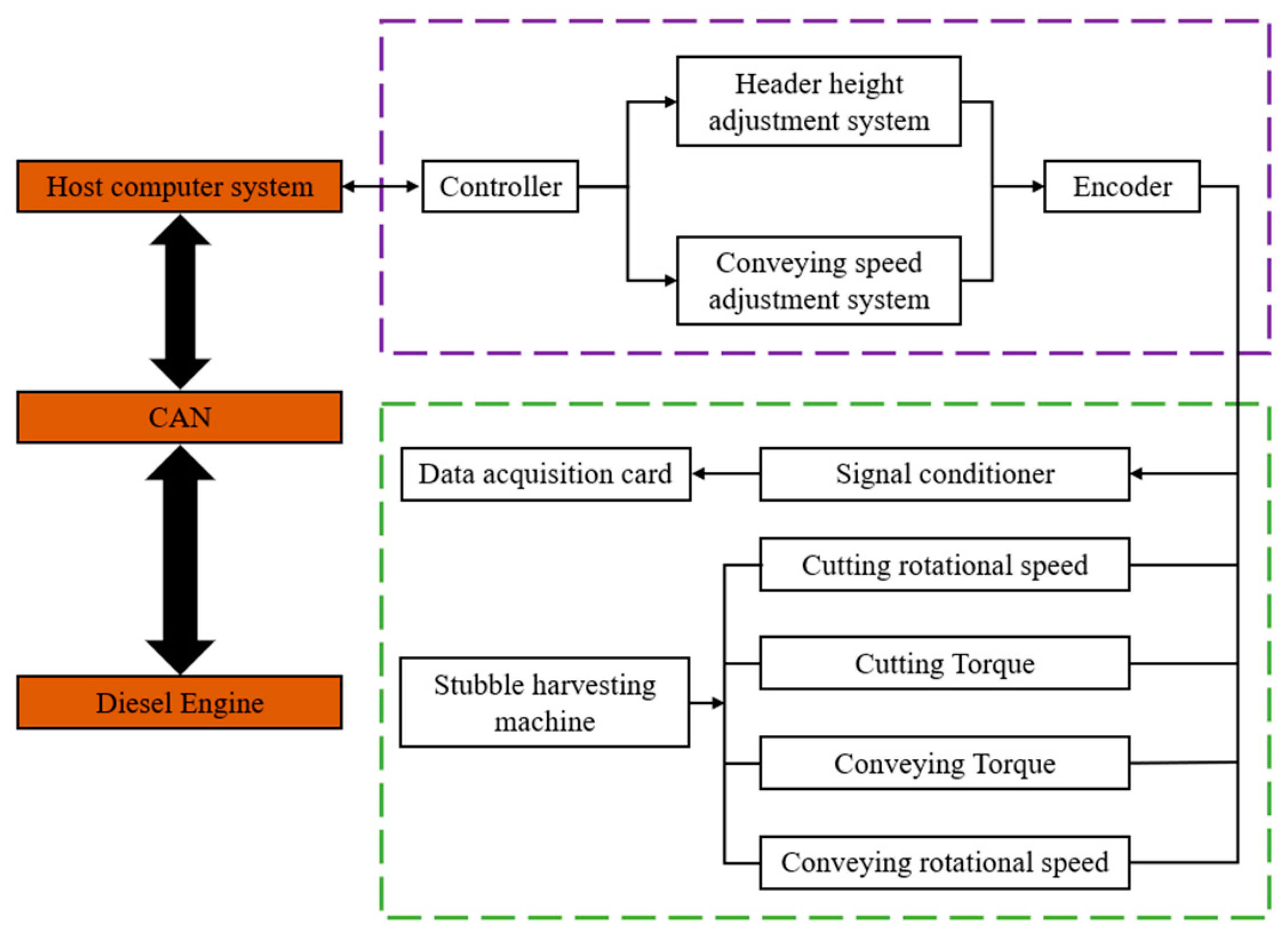

3.3. Control and Acquisition System Design

4. Prototype Field Test

4.1. Cutting Quality Evaluation Standards

- No damage to lateral buds (no occurrence of xylem splitting or phloem tearing) and the damage degree of a single mulberry branch within 5% is rated 10 points.

- The damage degree of a single mulberry branch within 5–10% is rated 9 points.

- The damage degree of a single mulberry branch within 11–15% is rated 8 points.

- The damage degree of a single mulberry branch within 16–20% is rated 7 points.

- The damage degree of a single mulberry branch within 21–30% is rated 6 points.

- Damage to lateral buds (occurrence of xylem splitting and phloem tearing) is rated 0 points, indicating severe damage.

4.2. Field Test

4.2.1. Test Methodology

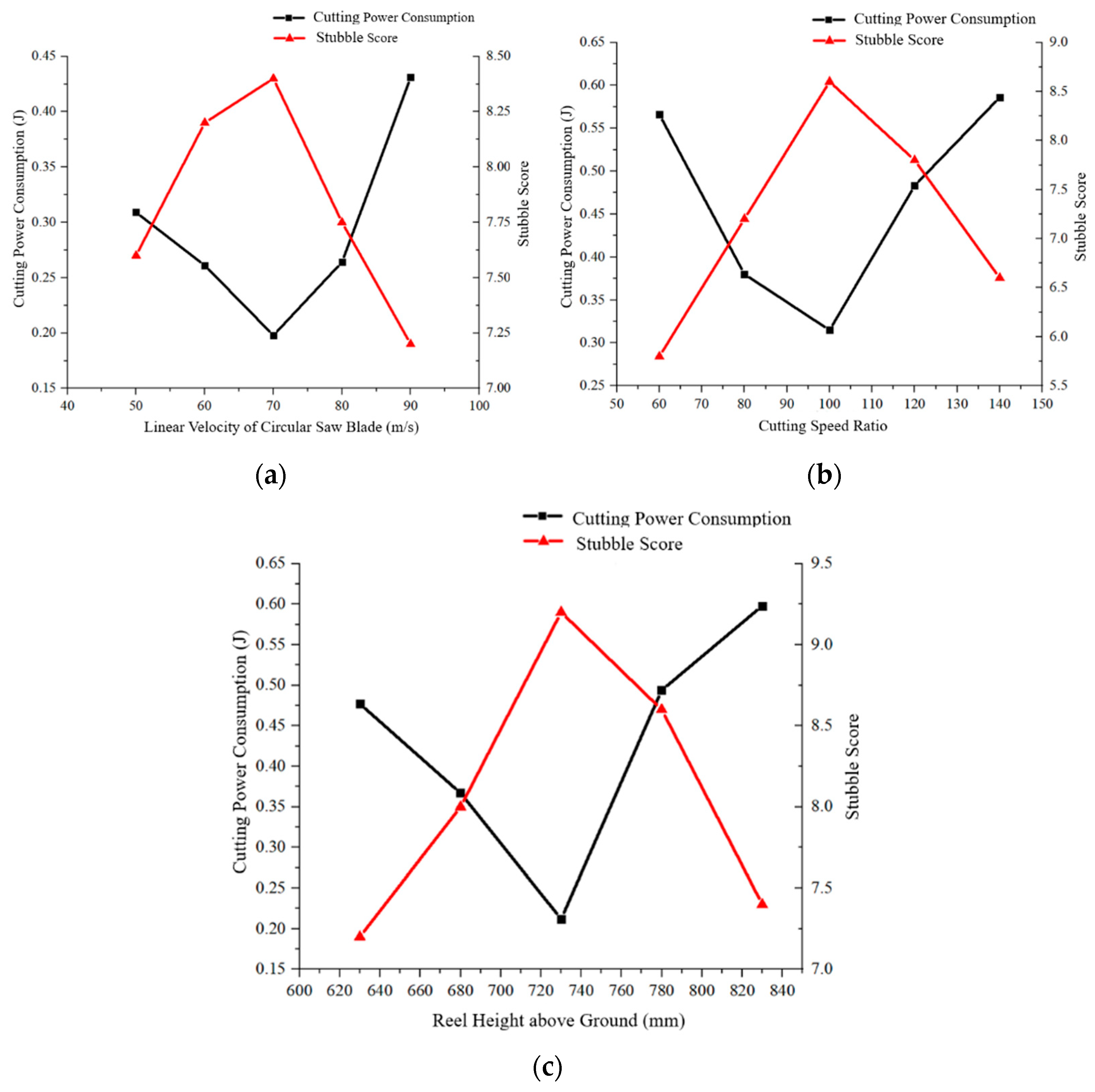

4.2.2. Single-Factor Experiment Results and Analysis

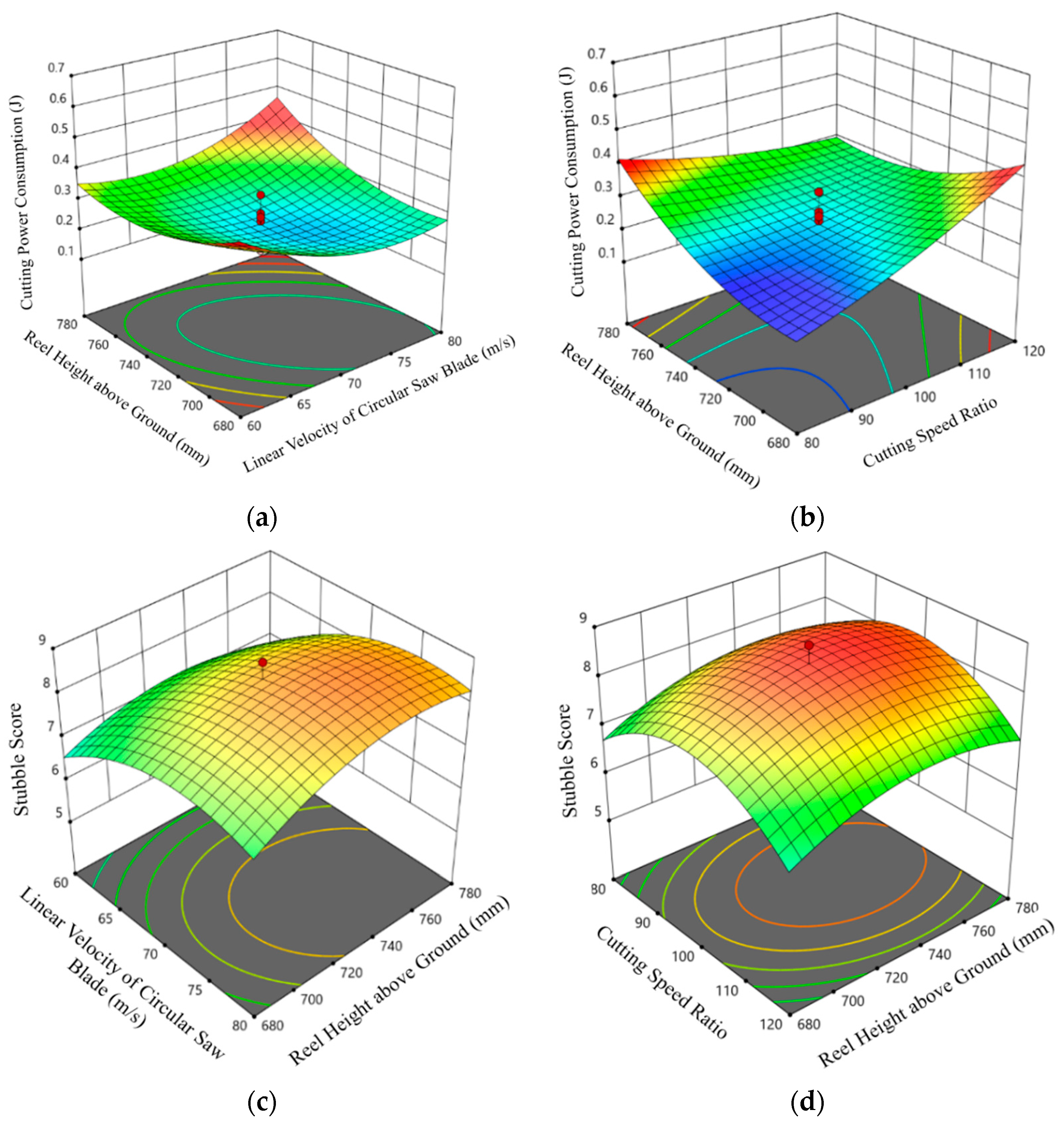

4.2.3. Central Composite Experiment Results and Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baciu, E.-D.; Baci, G.-M.; Moise, A.R.; Dezmirean, D.S. A status review on the importance of mulberry (Morus spp.) and prospects towards its cultivation in a controlled environment. Horticulturae 2023, 9, 444. [Google Scholar] [CrossRef]

- Rohela, G.K.; Shukla, P.; Kumar, R.; Chowdhury, S.R. Mulberry (Morus spp.): An ideal plant for sustainable development. Trees For. People 2020, 2, 100011. [Google Scholar] [CrossRef]

- Yan, C.; Chen, F.; Yang, Y.; Shen, L.; Xun, X.; Zhang, Z.; Zhan, Y.; You, S.; Wang, J. Biochemical and protein nutritional potential of mulberry (Morus alba L.) leaf: Partial substitution improves the nutrition of conventional protein. J. Sci. Food Agric. 2024, 104, 2204–2214. [Google Scholar] [CrossRef] [PubMed]

- Saini, P.; Rohela, G.K.; Kumar, J.S.; Shabnam, A.A.; Kumar, A. Cultivation, utilization, and economic benefits of Mulberry. In The Mulberry Genome; Springer: Berlin/Heidelberg, Germany, 2023; pp. 13–56. [Google Scholar]

- Liang, L.; Wu, X.; Zhu, M.; Zhao, W.; Li, F.; Zou, Y.; Yang, L. Chemical composition, nutritional value, and antioxidant activities of eight mulberry cultivars from China. Pharmacogn. Mag. 2012, 8, 215. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.; Gangopadhyay, D.; Chowdhury, T. Economical and environmental importance of mulberry: A review. Int. J. Plant Environ. 2017, 3, 51–58. [Google Scholar] [CrossRef]

- Sharma, S.; Zote, K. MULBERRY—A multi purpose tree species for varied climate. Range Manag. Agrofor. 2010, 31, 97–101. [Google Scholar]

- Yu, Y.; Li, H.; Zhang, B.; Wang, J.; Shi, X.; Huang, J.; Yang, J.; Zhang, Y.; Deng, Z. Nutritional and functional components of mulberry leaves from different varieties: Evaluation of their potential as food materials. Int. J. Food Prop. 2018, 21, 1495–1507. [Google Scholar] [CrossRef]

- Lu, L.; Tang, Y.; Xie, J.; Yuan, Y. The role of marginal agricultural land-based mulberry planting in biomass energy production. Renew. Energy 2009, 34, 1789–1794. [Google Scholar] [CrossRef]

- Sung, G.B.; Kim, Y.S.; Kim, K.Y.; Ji, S.D.; Kim, N.S. Studies on mulberry tree years and mulberry fruit yield and mulberry popcorn disease and sales price. J. Sericultural Entomol. Sci. 2015, 53, 19–28. [Google Scholar]

- Momin, M.A.; Wempe, P.A.; Grift, T.E.; Hansen, A.C. Effects of four base cutter blade designs on sugarcane stem cut quality. Trans. ASABE 2017, 60, 1551–1560. [Google Scholar] [CrossRef]

- Wang, Q.Q.; Zhou, G.A.; Huang, X.; Song, J.L.; Xie, D.B.; Chen, L.Q. Experimental research on the effect of sugarcane stalk lifting height on the cutting breakage mechanism based on the sugarcane lifting–cutting system (SLS). Agriculture 2022, 12, 2078. [Google Scholar] [CrossRef]

- Zhou, B.C.; Ma, S.C.; Li, W.Z.; Peng, C.; Li, W.Q. Study on sugarcane chopping and damage mechanism during harvesting of sugarcane chopper harvester. Biosyst. Eng. 2024, 243, 1–12. [Google Scholar] [CrossRef]

- Gao, Y.Y.; Wang, Y.T.; Kang, F.; Kan, J.M. Multi-objective optimization of cross-section integrity rate and sawing energy consumption in sawing Caragana korshinskii Kom. branches. Ind. Crops Prod. 2023, 193, 116244. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.Y.; Li, D.T.; Huang, W.; Liu, Z.Q. Research on Establishment the Quality Evaluation Indicator System for Cutting Stubble Surface of Caragana. J. Agric. Mech. Res. 2008, 11, 169–172. [Google Scholar]

- Meng, Y.M.; Wei, J.D.; Wei, J.; Chen, H.; Cui, Y.S. An ANSYS/LS-DYNA simulation and experimental study of circular saw blade cutting system of mulberry cutting machine. Comput. Electron. Agric. 2019, 157, 38–48. [Google Scholar] [CrossRef]

- Toledo, A.d.; Silva, R.P.d.; Furlani, C.E.A. Quality of cut and basecutter blade configuration for the mechanized harvest of green sugarcane. Sci. Agric. 2013, 70, 384–389. [Google Scholar] [CrossRef]

- Qiu, M.M.; Meng, Y.M.; Li, Y.Z.; Shen, X.B. Sugarcane stem cut quality investigated by finite element simulation and experiment. Biosyst. Eng. 2021, 206, 135–149. [Google Scholar] [CrossRef]

- Aravind, C.; Shivashankar, V.; Vikas, R.; Vikas, V. Design & Development of Mini Paddy Harvester. Int. J. Sci. Res. Dev. 2015, 3, 2321-0613. [Google Scholar]

- van Rest, D.J. Evaluation of a portable brush-cutter for harvesting sugar cane. J. Agric. Univ. PR 1969, 53, 338–347. [Google Scholar]

- Li, B.; Li, S.S. Research on security of improved design of knapsack brush cutter. Int. J. Simul. Syst. Sci. Technol. 2017, 36, 1473–8031. [Google Scholar]

- Deng, L.L.; Li, Y.M.; Xu, L.Z.; Qin, T.D.; Pang, J. The design and analysis of cutting process about the disc type corn stalk cutting test bed. J. Agric. Mech. Res. 2013, 35, 73–77. [Google Scholar]

- Shen, C.; Zhang, B.; Li, X.W.; Yin, G.D.; Chen, Q.M.; Xia, C.H. Bench cutting tests and analysis for harvesting hemp stalk. Int. J. Agric. Biol. Eng. 2017, 10, 56–67. [Google Scholar]

- Lu, Y.; Yang, J.; Liang, Z.X.; Mo, J.L.; Qiao, Y.H. Simulative kinematics analysis on the affecting factors of rate of broken biennial root of single base cutter of sugarcane harvester. Trans. Chin. Soc. Agric. Mach. 2008, 39, 50–55. [Google Scholar]

- Gao, Y.Y.; Kang, F.; Kan, J.M.; Wang, Y.T.; Tong, S.Y. Analysis and experiment of cutting mechanical parameters for Caragana korshinskii (CK) Branches. Forests 2021, 12, 1359. [Google Scholar] [CrossRef]

- Zhang, S.F.; Song, Z.H.; Yan, Y.F.; Li, Y.D.; Li, F.D. Development and experiment of measure and control system for stalk cutting test bench. Trans. Chin. Soc. Agric. Eng. 2013, 29, 10–17. [Google Scholar]

- Zhao, J.L.; Huang, D.Y.; Jia, H.L.; Zhuang, J.; Guo, M.Z. Analysis and experiment on cutting performances of high-stubble maize stalks. Int. J. Agric. Biol. Eng. 2017, 10, 40–52. [Google Scholar]

- Luo, H.F.; Tang, C.Z.; Zhou, D.S.; Li, S.C.; Wu, W.G.; Zhou, Y.M. Experimental study on reciprocating cutting of the stem of Euonymus japonicus. Trans. CSAE 2012, 28, 13–17. [Google Scholar]

- Kong, F.T.; Wang, D.F.; sHI, L.; Wu, T.; Chen, C.L.; Sun, Y.F.; Xie, Q. Design and Experiment of Disc Cutting Castor Picking Device. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–9. [Google Scholar]

- Bo, S.W.; Li, Y.X.; Wang, H.B. Design and Experiment of a Circular Saw Type Shrub Cutting Test Device. JAMR 2023, 45, 165–172. [Google Scholar] [CrossRef]

- Chinese Academy of Agricultural Mechanization Sciences. Agricultural Machinery Design Handbook (Volume I & II) (Hardcover); China Agricultural Science and Technology Press: Beijing, China, 2007. [Google Scholar]

- Zhang, X.H. Development of Herbal Mulberry Stubble Machine with Adjustable Stubble Height. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2020. [Google Scholar]

| Parameter | Value |

|---|---|

| Length × Width × Height of the header (mm × mm × mm) | 800 × 980 × 1260 |

| Harvesting width (mm) | 800 |

| Cutting stubble height (mm) | 0–300 |

| The linear velocity of the grain separation star wheel (m/s) | 0–3.5 |

| The linear velocity of the circular saw (m/s) | 0–90 |

| Forward speed (km/h) | 0–27.62 |

| Cutting inclination angle (°) | 10 |

| Star wheel height (mm) | 630–830 |

| Factor | Level | ||||

|---|---|---|---|---|---|

| The linear velocity of the circular saw (m/s) | 50 | 60 | 70 | 80 | 90 |

| Cutting speed ratio | 60 | 80 | 100 | 120 | 140 |

| The height of the star wheel above the ground (mm) | 630 | 680 | 730 | 780 | 830 |

| Number | Factor Level | ||

|---|---|---|---|

| The Linear Velocity of the Circular Saw (m/s) | Cutting Speed Ratio | The Height of the Star Wheel Above the Ground (mm) | |

| 1 | 80 | 120 | 780 |

| 2 | 70 | 100 | 730 |

| 3 | 80 | 120 | 680 |

| 4 | 80 | 80 | 780 |

| 5 | 70 | 100 | 814 |

| 6 | 70 | 100 | 730 |

| 7 | 70 | 100 | 730 |

| 8 | 70 | 100 | 646 |

| 9 | 53 | 100 | 730 |

| 10 | 80 | 80 | 680 |

| 11 | 70 | 134 | 730 |

| 12 | 87 | 100 | 730 |

| 13 | 60 | 120 | 680 |

| 14 | 70 | 66 | 730 |

| 15 | 60 | 80 | 780 |

| 16 | 70 | 100 | 730 |

| 17 | 70 | 100 | 730 |

| 18 | 60 | 80 | 680 |

| 19 | 70 | 100 | 730 |

| 20 | 60 | 120 | 780 |

| Number | Factor Level | Target Value | |||

|---|---|---|---|---|---|

| The Linear Velocity of the Circular Saw (m/s) | Cutting Speed Ratio | The Height of the Star Wheel Above the Ground (mm) | Cutting Energy Consumption/mJ | Stubble Cutting Score | |

| 1 | 80 | 120 | 780 | 498 | 6.6 |

| 2 | 70 | 100 | 730 | 155 | 8.8 |

| 3 | 80 | 120 | 680 | 628 | 5.8 |

| 4 | 80 | 80 | 780 | 537 | 7.8 |

| 5 | 70 | 100 | 814 | 296 | 7.6 |

| 6 | 70 | 100 | 730 | 171 | 7.8 |

| 7 | 70 | 100 | 730 | 266 | 8.4 |

| 8 | 70 | 100 | 646 | 268 | 6.4 |

| 9 | 53 | 100 | 730 | 548 | 5.6 |

| 10 | 80 | 80 | 680 | 155 | 7 |

| 11 | 70 | 134 | 730 | 410 | 5.6 |

| 12 | 87 | 100 | 730 | 317 | 7.6 |

| 13 | 60 | 120 | 680 | 377 | 6 |

| 14 | 70 | 66 | 730 | 396 | 5.8 |

| 15 | 60 | 80 | 780 | 551 | 5.4 |

| 16 | 70 | 100 | 730 | 253 | 8.4 |

| 17 | 70 | 100 | 730 | 279 | 8.8 |

| 18 | 60 | 80 | 680 | 286 | 5.2 |

| 19 | 70 | 100 | 730 | 340 | 8.4 |

| 20 | 60 | 120 | 780 | 359 | 6 |

| Source | Cutting Energy Consumption (mJ) | |

|---|---|---|

| F-Value | p-Value | |

| Model | 3.72 | 0.0264 * |

| A2 | 9.88 | 0.0104 * |

| BC | 9.42 | 0.0119 * |

| C2 | 7.35 | 0.0219 * |

| AC | 4.27 | 0.0658 |

| B | 2.60 | 0.1377 |

| C | 1.11 | 0.3169 |

| B2 | 0.8799 | 0.3703 |

| A | 0.1797 | 0.6806 |

| AB | 0.0004 | 0.9850 |

| Lack of fit | 2.46 | 0.173 |

| SNR | 6.6935 | |

| Source | Stubble Cutting Score | |

|---|---|---|

| F-Value | p-Value | |

| Model | 41.05 | <0.0001 ** |

| B2 | 180.19 | <0.0001 ** |

| A2 | 82.56 | <0.0001 ** |

| A | 59.88 | <0.0001 ** |

| C2 | 51.24 | <0.0001 ** |

| AB | 23.27 | 0.0007 ** |

| C | 13.76 | 0.0040 ** |

| AC | 3.16 | 0.1059 |

| B | 1.69 | 0.2233 |

| BC | 0.0645 | 0.8047 |

| Lack of fit | 0.1518 | 0.9705 |

| SNR | 16.5867 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Yan, Y.; Sui, H.; Tian, F.; Yan, Y.; Zhao, B.; Song, Z. Development and Field Testing of a Suspended Mulberry Branch Harvesting and Stubble Cutting Machine. Appl. Sci. 2025, 15, 940. https://doi.org/10.3390/app15020940

Liu T, Yan Y, Sui H, Tian F, Yan Y, Zhao B, Song Z. Development and Field Testing of a Suspended Mulberry Branch Harvesting and Stubble Cutting Machine. Applied Sciences. 2025; 15(2):940. https://doi.org/10.3390/app15020940

Chicago/Turabian StyleLiu, Tianhong, Yunpeng Yan, Haitao Sui, Fuyang Tian, Yinfa Yan, Bo Zhao, and Zhanhua Song. 2025. "Development and Field Testing of a Suspended Mulberry Branch Harvesting and Stubble Cutting Machine" Applied Sciences 15, no. 2: 940. https://doi.org/10.3390/app15020940

APA StyleLiu, T., Yan, Y., Sui, H., Tian, F., Yan, Y., Zhao, B., & Song, Z. (2025). Development and Field Testing of a Suspended Mulberry Branch Harvesting and Stubble Cutting Machine. Applied Sciences, 15(2), 940. https://doi.org/10.3390/app15020940