Influences of Different Factors and Sensitivity Analysis of Permeability of Gassy Coal

Abstract

1. Introduction

2. Test Equipment and Sample Preparation

2.1. Test Equipment

2.2. Preparation of Test Coal Samples

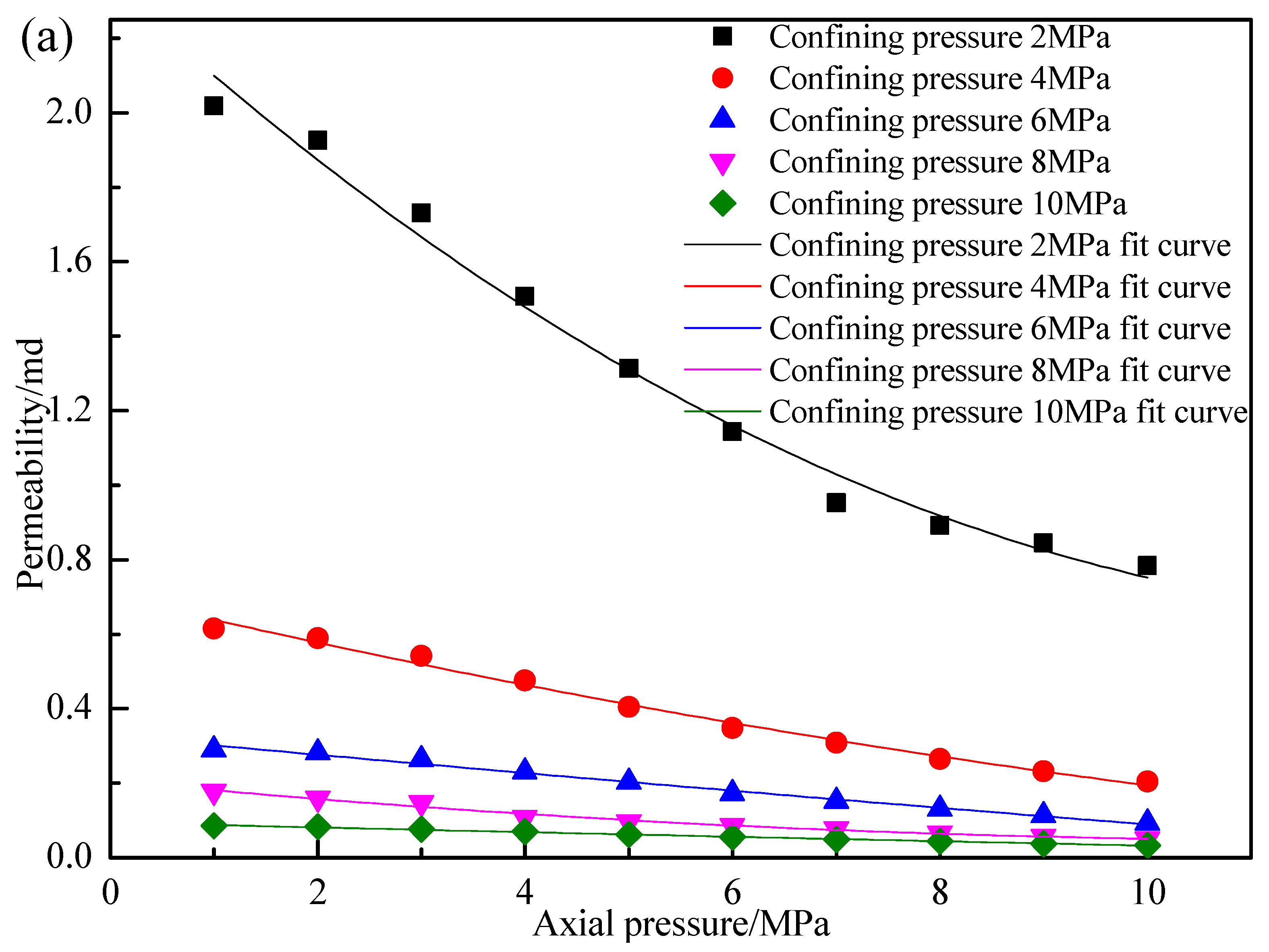

3. Influences of Axial Pressure and Confining Pressure on the Permeability of Gassy Coal

3.1. Test Schemes

3.2. Test Results and Discussion

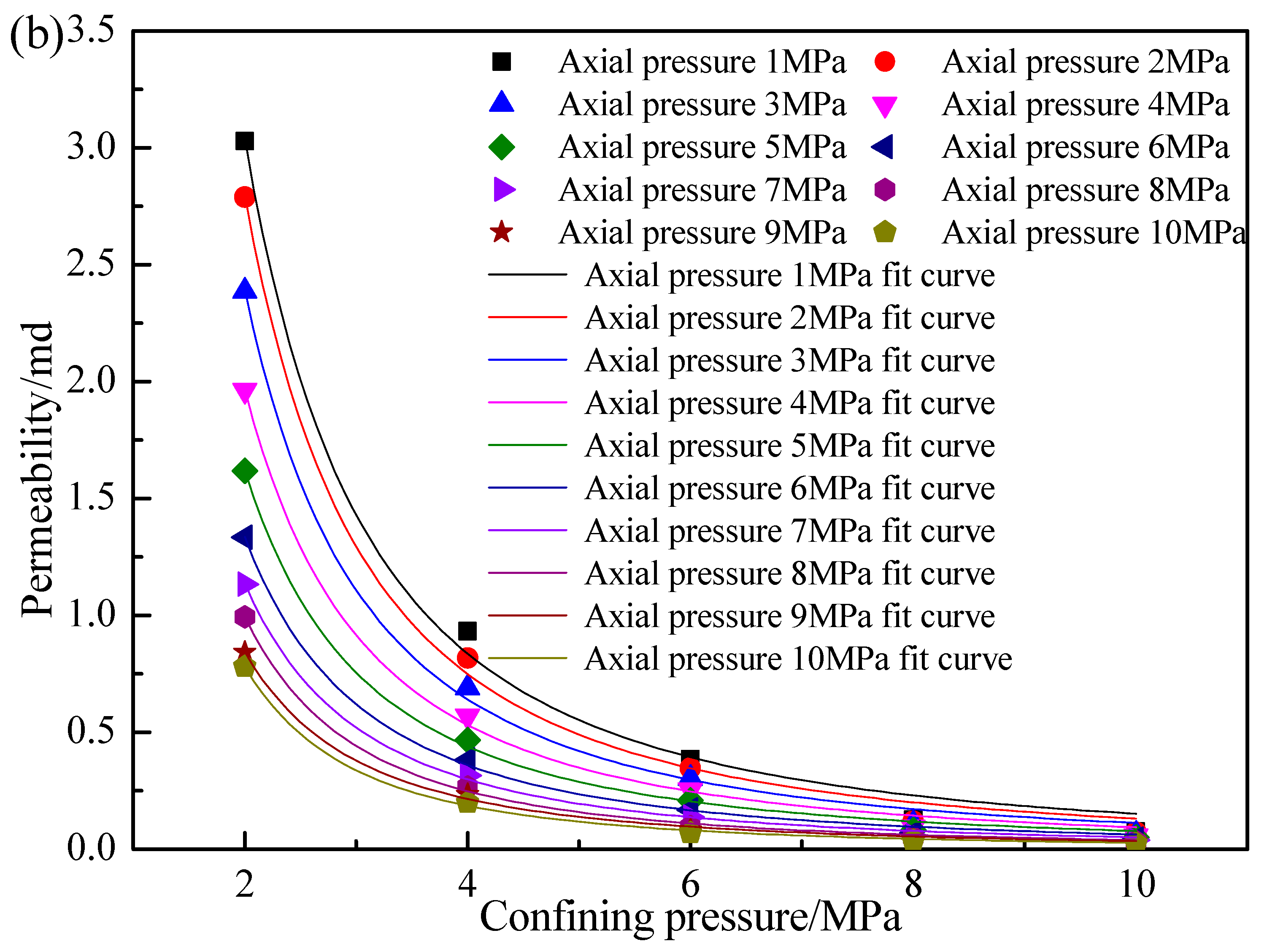

4. Influences of Gas Pressure on the Permeability of Gassy Coal

4.1. Test Schemes

4.2. Test Results and Discussion

5. Sensitivity Analysis of Permeability of Gassy Coal to Axial Pressure, Confining Pressure, and Gas Pressure

5.1. Experimental Schemes

5.2. Experimental Results and Discussion

6. Conclusions

- (1)

- The relationship between permeability and axial pressure in gassy coal follows a quadratic polynomial function under constant confining pressure, while the relationship between permeability and confining pressure is described by a power function under constant axial pressure. During axial seepage, gassy coal’s permeability is significantly more sensitive to confining pressure than axial pressure, with the sensitivity to confining pressure being approximately 8.5 times greater. Therefore, reducing vertical stress in the protected layer has a more pronounced pressure-relief and permeability-enhancing effect compared to decreasing horizontal stress in protective layer mining;

- (2)

- At constant axial and confining pressures (same stress), the permeability of gassy coal initially decreases and then increases, following a V-shaped pattern as gas pressure increases. There is a turning point in the seepage tests, that is, the critical gas pressure, which is the boundary between the slippage effect and effective stress. When the gas pressure is lower than the critical value, the slippage effect plays the leading role, and the lower the stress and gas pressure are, the more significant the influence of the slippage effect on the permeability; on the contrary, the effective stress plays a dominant role in the variation of permeability of coal when the gas pressure exceeds the critical value;

- (3)

- Under a non-isobaric deviatoric stress state, the permeability of gassy coal is primarily influenced by confining pressure, followed by gas pressure and axial pressure in decreasing order of sensitivity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, C.; Yang, Y.; Wei, W.; Duan, M.; Yu, T. A new stress-damage-flow coupling model and the damage characterization of raw coal under loading and unloading conditions. Int. J. Rock Mech. Min. Sci. 2021, 138, 104601. [Google Scholar] [CrossRef]

- Wei, J.; Su, E.; Xu, G.; Yang, Y.; Han, S.; Chen, X.; An, F. Comparative analysis of permeability rebound and recovery of tectonic and intact coal: Implications for coalbed methane recovery in tectonic coal reservoirs. Energy 2024, 301, 131702. [Google Scholar] [CrossRef]

- Salmachi, A.; Karacan, C.Ö. Cross-formational flow of water into coalbed methane reservoirs: Controls on relative permeability curve shape and production profile. Environ. Earth Sci. 2017, 76, 200. [Google Scholar] [CrossRef]

- Shevtsov, A.; Khyamyalyaynen, V. Geomechanical Estimation of the Influence of Horizontal Coalbed Methane Well Design on Coal Seam Permeability. E3S Web Conf. 2019, 105, 01014. [Google Scholar] [CrossRef]

- Li, B.; Zou, Q.; Liang, Y. Experimental Research into the Evolution of Permeability in a Broken Coal Mass under Cyclic Loading and Unloading Conditions. Appl. Sci. 2019, 9, 762. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; Wang, J.; Zhang, H.; Shen, W.; Jiang, H. Coupled Effects of Stress, Moisture Content and Gas Pressure on the Permeability Evolution of Coal Samples: A Case Study of the Coking Coal Resourced from Tunlan Coalmine. Water 2021, 13, 1653. [Google Scholar] [CrossRef]

- Su, E.; Wei, J.; Chen, H.; Chen, X.; Liang, Y.; Zou, Q.; Zhu, X. Effect of CO2 injection on Coalbed Permeability Based on a Thermal–Hydraulic–Mechanical Coupling Model. Energy Fuels 2024, 38, 11078–11092. [Google Scholar] [CrossRef]

- Bai, X.; Wang, Y.; He, G.; Zhou, Z.; Wang, D.; Zhang, D. Research on a permeability model of coal damaged under triaxial loading and unloading. Fuel 2023, 354, 129375. [Google Scholar] [CrossRef]

- Wang, F.; Liang, Y.; Li, X.; Li, L.; Li, J.; Chen, Y. Study on the change of permeability of gas-containing coal under many factors. Energy Sci. Eng. 2019, 7, 194–206. [Google Scholar] [CrossRef]

- Thararoop, P.; Karpyn, Z.T.; Ertekin, T. Development of a multi-mechanistic, dual-porosity, dual-permeability, numerical flow model for coalbed methane reservoirs. J. Nat. Gas Sci. Eng. 2012, 8, 121–131. [Google Scholar] [CrossRef]

- Zakharov, V.N.; Malinnikova, O.N.; Trofimov, V.A.; Filippov, Y.A. Effect of gas content and actual stresses on coalbed permeability. J. Min. Sci. 2016, 52, 218–225. [Google Scholar] [CrossRef]

- Zeng, S.; Zhang, L.; Luo, L.; Ye, Z.; Wang, C. Permeability Evolution of Anthracite Subjected to Liquid Nitrogen Treatment under Repeated Loading–Unloading Conditions. Nat. Resour. Res. 2023, 32, 2753–2767. [Google Scholar] [CrossRef]

- Zhang, C.; Tu, S.; Zhao, Y. Compaction characteristics of the caving zone in a longwall goaf: A review. Environ. Earth Sci. 2019, 78, 27. [Google Scholar] [CrossRef]

- Peng, K.; Shi, S.; Zou, Q.; Wang, G.; Jiang, Z. Disaster-Triggering Mechanisms Based on Interaction of Various Factors in Structured Gas Migration in Coal Seams Under Loading and Unloading Conditions. Nat. Resour. Res. 2021, 30, 1445–1465. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. Modelling permeability for coal reservoirs: A review of analytical models and testing data. Int. J. Coal Geol. 2012, 92, 1–44. [Google Scholar] [CrossRef]

- Lu, S.; Li, M.; Ma, Y.; Wang, S.; Zhao, W. Permeability changes in mining-damaged coal: A review of mathematical models. J. Nat. Gas Sci. Eng. 2022, 106, 104739. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, L.; Pan, J.; Li, M.; Tian, Y.; Wang, C.; Li, S. Evolution of Broken Coal’s Permeability Characteristics under Cyclic Loading–Unloading Conditions. Nat. Resour. Res. 2024, 33, 2279–2297. [Google Scholar] [CrossRef]

- Li, B.; Liang, Y.; Zhang, L.; Zou, Q. Experimental investigation on compaction characteristics and permeability evolution of broken coal. Int. J. Rock Mech. Min. Sci. 2019, 118, 63–76. [Google Scholar] [CrossRef]

- Ye, Z.W.; Zhang, L.; Hao, D.Y.; Zhang, C.; Wang, C. Experimental study on the response characteristics of coal permeability to pore pressure under loading and unloading conditions. J. Geophys. Eng. 2017, 14, 1020–1031. [Google Scholar] [CrossRef]

- Zhang, L.; Hao, D.; Ye, Z.; Zhang, C.; Chen, S. Experimental study of gas pressure and effective stress influencing on gas seepage characteristics of bituminous coal in both axial and radial directions. Int. J. Oil Gas Coal Technol. 2019, 22, 527–553. [Google Scholar] [CrossRef]

- Meng, Y.; Li, Z.; Lai, F. Experimental study on porosity and permeability of anthracite coal under different stresses. J. Pet. Sci. Eng. 2015, 133, 810–817. [Google Scholar] [CrossRef]

- Zou, J.; Chen, W.; Yang, D.; Yu, H.; Yuan, J. The impact of effective stress and gas slippage on coal permeability under cyclic loading. J. Nat. Gas Sci. Eng. 2016, 31, 236–248. [Google Scholar] [CrossRef]

- Li, B.; Ren, C.; Wang, Z.; Li, J.; Yang, K.; Xu, J. Experimental study on damage and the permeability evolution process of methane-containing coal under different temperature conditions. J. Pet. Sci. Eng. 2020, 184, 106509. [Google Scholar] [CrossRef]

- Ren, C.; Li, B.; Xu, J.; Zhang, Y.; Li, J.; Gao, Z.; Yu, J. A novel damage-based permeability model for coal in the compaction and fracturing process under different temperature conditions. Rock Mech. Rock Eng. 2020, 53, 5697–5713. [Google Scholar] [CrossRef]

- Wang, D.; Yao, B.; Gao, Y.; Li, W.; Lv, R. Effect of cyclic temperature impact on coal seam permeability. Therm. Sci. 2017, 21 (Suppl. S1), 351–357. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Pan, Z.; Yao, Y.; Li, J.; Qiu, Y. Petrophysical characterization of Chinese coal cores with heat treatment by nuclear magnetic resonance. Fuel 2013, 108, 292–302. [Google Scholar] [CrossRef]

- Li, J.; Li, B.; Pan, Z.; Wang, Z.; Yang, K.; Ren, C.; Xu, J. Coal permeability evolution under different water-bearing conditions. Nat. Resour. Res. 2020, 29, 2451–2465. [Google Scholar] [CrossRef]

- Chao, J.; Yu, M.; Chu, T.; Han, X.; Teng, F.; Li, P. Evolution of broken coal permeability under the condition of stress, temperature, moisture content, and pore pressure. Rock Mech. Rock Eng. 2019, 52, 2803–2814. [Google Scholar] [CrossRef]

- Braga, L.T.P.; Kudasik, M. Permeability measurements of raw and briquette coal of various porosities at different temperatures. Mater. Res. Express 2019, 6, 105609. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H.; Wang, L.; Zhang, D. Experimental Study on Mechanics and Permeability Properties of Water-Bearing Raw Coal Samples Under In-Situ Stress. Appl. Sci. 2019, 9, 2549. [Google Scholar] [CrossRef]

- Yin, G.; Jiang, C.; Xu, J.; Guo, L.; Peng, S.; Li, W. An experimental study on the effects of water content on coalbed gas permeability in ground stress fields. Transp. Porous Media 2012, 94, 87–99. [Google Scholar] [CrossRef]

- Zhao, T.; Xu, H.; Tang, D.; Zong, P. A new relative permeability model of coal reservoir considering interface effect. J. Pet. Sci. Eng. 2021, 207, 109082. [Google Scholar] [CrossRef]

- Zhou, H.W.; Zhang, L.; Wang, X.Y.; Rong, T.L.; Wang, L.J. Effects of matrix-fracture interaction and creep deformation on permeability evolution of deep coal. Int. J. Rock Mech. Min. Sci. 2020, 127, 104236. [Google Scholar] [CrossRef]

- Jia, H.; Zou, D. Study on the Permeability Evolution Model of Mining-Disturbed Coal. Geofluids 2021, 2021, 1810915. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Elsworth, D.; Miao, X.; Mao, X. Linking gas-sorption induced changes in coal permeability to directional strains through a modulus reduction ratio. Int. J. Coal Geol. 2010, 83, 21–30. [Google Scholar] [CrossRef]

- Wang, J.G.; Liu, J.; Kabir, A. Combined effects of directional compaction, non-Darcy flow and anisotropic swelling on coal seam gas extraction. Int. J. Coal Geol. 2013, 109, 1–14. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Elsworth, D.; Miao, X.; Mao, X. Development of anisotropic permeability during coalbed methane production. J. Nat. Gas Sci. Eng. 2010, 2, 197–210. [Google Scholar] [CrossRef]

- Xue, Y.; Gao, F.; Gao, Y.; Cheng, H.; Liu, Y.; Hou, P.; Teng, T. Quantitative evaluation of stress-relief and permeability-increasing effects of overlying coal seams for coal mine methane drainage in Wulan coal mine. J. Nat. Gas Sci. Eng. 2016, 32, 122–137. [Google Scholar] [CrossRef]

- Xiao, W.; Bernabé, Y.; Evans, B.; Mok, U.; Zhao, J.; Ren, X.; Chen, M. Klinkenberg effect and effective pressure for gas permeability of tight sandstones. J. Geophys. Res. Solid Earth 2019, 124, 1412–1429. [Google Scholar] [CrossRef]

- Lv, Q.; Chen, Z.; Wang, M. An improved elastic-tubes model for the correlation of permeability and stress with correction for the Klinkenberg effect. J. Nat. Gas Sci. Eng. 2017, 48, 24–35. [Google Scholar] [CrossRef]

| Coal Sample Number | Confining Pressure/MPa | Permeability–Axial Pressure Fitting Formula | Correlation Coefficient |

|---|---|---|---|

| Z1 | 2 | K = 0.0096σ12 − 0.2549σ1 + 2.3451 | R2 = 0.9882 |

| 4 | K = 0.0015σ12 − 0.0657σ1 + 0.7028 | R2 = 0.9911 | |

| 6 | K = 0.0002σ12 − 0.0257σ1 + 0.3268 | R2 = 0.991 | |

| 8 | K = 0.0011σ12 − 0.0267σ1 + 0.2064 | R2 = 0.9868 | |

| 10 | K = 3 × 10−5σ12 − 0.0065σ1 + 0.094 | R2 = 0.9959 | |

| Z2 | 2 | K = 0.0214σ12 − 0.4995σ1 + 3.6111 | R2 = 0.9949 |

| 4 | K = 0.0071σ12 − 0.1608σ1 + 1.0985 | R2 = 0.999 | |

| 6 | K = 0.002σ12 − 0.0586σ1 + 0.4521 | R2 = 0.9963 | |

| 8 | K = 0.0003σ12 − 0.0142σ1 + 0.1452 | R2 = 0.9952 | |

| 10 | K = 0.0002σ12 − 0.0083σ1 + 0.086 | R2 = 0.9975 |

| Coal Sample Number | Axial Pressure/MPa | Permeability–Confining Pressure Fitting Formula | Correlation Coefficient |

|---|---|---|---|

| Z1 | 1 | K = 8.0727σ2−1.896 | R2 = 0.9894 |

| 2 | K = 7.7766σ2−1.905 | R2 = 0.9918 | |

| 3 | K = 6.975σ2−1.891 | R2 = 0.9903 | |

| 4 | K = 6.1974σ2−1.915 | R2 = 0.9925 | |

| 5 | K = 5.2467σ2−1.893 | R2 = 0.9935 | |

| 6 | K = 4.4602σ2−1.878 | R2 = 0.9957 | |

| 7 | K = 3.6655σ2−1.84 | R2 = 0.9945 | |

| 8 | K = 3.4334σ2−1.879 | R2 = 0.9972 | |

| 9 | K = 3.3461σ2−1.939 | R2 = 0.9981 | |

| 10 | K = 3.0957σ2−1.968 | R2 = 0.9997 | |

| Z2 | 1 | K = 18.31σ2−2.312 | R2 = 0.9754 |

| 2 | K = 16.224σ2−2.292 | R2 = 0.98 | |

| 3 | K = 13.436σ2−2.26 | R2 = 0.9815 | |

| 4 | K = 10.582σ2−2.217 | R2 = 0.9833 | |

| 5 | K = 8.2168σ2−2.163 | R2 = 0.9875 | |

| 6 | K = 6.5522σ2−2.138 | R2 = 0.9905 | |

| 7 | K = 5.4545σ2−2.134 | R2 = 0.9928 | |

| 8 | K = 4.673σ2−2.152 | R2 = 0.9976 | |

| 9 | K = 4.0289σ2−2.159 | R2 = 0.9954 | |

| 10 | K = 3.6822σ2−2.185 | R2 = 0.9971 |

| Number | Gas Pressure/MPa | Initial Axial Pressure/MPa | Initial Confining Pressure/MPa | Ratio of Axial Unloading Rate to Confining Pressure Loading Rate |

|---|---|---|---|---|

| 1 | 0.5 | 10 | 2 | 1:1 |

| 2 | 0.5 | 10 | 2 | 1.5:1 |

| 3 | 0.5 | 10 | 2 | 2:1 |

| 4 | 0.5 | 10 | 2 | 2.5:1 |

| 5 | 0.5 | 10 | 2 | 3:1 |

| 6 | 0.5 | 10 | 2 | 3.5:1 |

| 7 | 0.5 | 10 | 2 | 4:1 |

| 8 | 0.5 | 10 | 2 | 4.5:1 |

| 9 | 0.5 | 10 | 2 | 5:1 |

| 10 | 0.5 | 10 | 2 | 5.5:1 |

| 11 | 0.5 | 10 | 2 | 6:1 |

| 12 | 0.5 | 10 | 2 | 6.5:1 |

| 13 | 0.5 | 10 | 2 | 7:1 |

| 14 | 0.5 | 10 | 2 | 7.5:1 |

| 15 | 0.5 | 10 | 2 | 8:1 |

| 16 | 0.5 | 10 | 2 | 8.5:1 |

| 17 | 0.5 | 10 | 2 | 9:1 |

| Coal Sample Number | Axial Pressure/MPa | Confining Pressure/MPa | Permeability–Gas Pressure Fitting Formula | Correlation Coefficient | Critical Gas Pressure/MPa |

|---|---|---|---|---|---|

| W1 | 4 | 4 | K = 0.0409P2 − 0.1003P + 0.1427 | R2 = 0.9247 | 1.226 |

| 5 | 5 | K = 0.0141P2 − 0.0440P + 0.0828 | R2 = 0.9094 | 1.560 | |

| 6 | 6 | K = 0.0072P2 − 0.0290P + 0.0644 | R2 = 0.9188 | 2.014 | |

| 7 | 7 | K = 0.0043P2 − 0.0231P + 0.0544 | R2 = 0.8898 | 2.686 | |

| W2 | 4 | 4 | K = 0.0193P2 − 0.0532P + 0.0609 | R2 = 0.8960 | 1.378 |

| 5 | 5 | K = 0.0086P2 − 0.0316P + 0.0407 | R2 = 0.8933 | 1.837 | |

| 6 | 6 | K = 0.0037P2 − 0.0169P + 0.0253 | R2 = 0.8298 | 2.284 | |

| 7 | 7 | K = 0.0021P2 − 0.0116P + 0.0181 | R2 = 0.8382 | 2.762 |

| Orthogonal Test Table Number | Level | Influencing Factor (A) Axial Pressure/MPa | Influencing Factor (B) Confining Pressure/MPa | Influencing Factor (C) Gas Pressure/MPa |

|---|---|---|---|---|

| 1 | 1 | 3 | 3 | 0.5 |

| 2 | 4 | 4 | 1 | |

| 3 | 5 | 5 | 1.5 | |

| 4 | 6 | 6 | 2 | |

| 2 | 1 | 6 | 6 | 3 |

| 2 | 7 | 7 | 3.5 | |

| 3 | 8 | 8 | 4 | |

| 4 | 9 | 9 | 4.5 |

| Influencing Factor (A) Axial Pressure/MPa | Influencing Factor (B) Confining Pressure/MPa | Influencing Factor (C) Gas Pressure/MPa | Permeability/md | |

|---|---|---|---|---|

| 1 | 3 | 3 | 0.5 | 0.7388 |

| 2 | 4 | 4 | 0.5 | 0.5873 |

| 3 | 5 | 5 | 0.5 | 0.2674 |

| 4 | 6 | 6 | 0.5 | 0.1917 |

| 5 | 3 | 4 | 1 | 0.343 |

| 6 | 4 | 3 | 1 | 0.4843 |

| 7 | 5 | 6 | 1 | 0.2264 |

| 8 | 6 | 5 | 1 | 0.255 |

| 9 | 3 | 5 | 1.5 | 0.2701 |

| 10 | 4 | 6 | 1.5 | 0.2204 |

| 11 | 5 | 3 | 1.5 | 0.3126 |

| 12 | 6 | 4 | 1.5 | 0.4803 |

| 13 | 3 | 6 | 2 | 0.2272 |

| 14 | 4 | 5 | 2 | 0.2696 |

| 15 | 5 | 4 | 2 | 0.366 |

| 16 | 6 | 3 | 2 | 0.6602 |

| k1 | 0.394775 | 0.548975 | 0.4463 | |

| k2 | 0.3904 | 0.44415 | 0.327175 | |

| k3 | 0.2931 | 0.265525 | 0.32085 | |

| k4 | 0.3968 | 0.216425 | 0.38075 | |

| Extreme value (R) | 0.1037 | 0.33255 | 0.12545 | |

| Ranking of influencing factors | Confining pressure > Gas pressure > Axial pressure | |||

| Influencing Factor (A) Axial Pressure/MPa | Influencing Factor (B) Confining Pressure/MPa | Influencing Factor (C) Gas Pressure/MPa | Permeability/md | |

|---|---|---|---|---|

| 1 | 6 | 6 | 3 | 0.2081 |

| 2 | 7 | 7 | 3 | 0.1766 |

| 3 | 8 | 8 | 3 | 0.1443 |

| 4 | 9 | 9 | 3 | 0.1093 |

| 5 | 6 | 7 | 3.5 | 0.1533 |

| 6 | 7 | 6 | 3.5 | 0.195 |

| 7 | 8 | 9 | 3.5 | 0.1135 |

| 8 | 9 | 8 | 3.5 | 0.1252 |

| 9 | 6 | 8 | 4 | 0.1346 |

| 10 | 7 | 9 | 4 | 0.1171 |

| 11 | 8 | 6 | 4 | 0.2013 |

| 12 | 9 | 7 | 4 | 0.1587 |

| 13 | 6 | 9 | 4.5 | 0.1206 |

| 14 | 7 | 8 | 4.5 | 0.1376 |

| 15 | 8 | 7 | 4.5 | 0.1651 |

| 16 | 9 | 6 | 4.5 | 0.2212 |

| k1 | 0.6166 | 0.8256 | 0.159575 | |

| k2 | 0.6263 | 0.6537 | 0.14675 | |

| k3 | 0.6242 | 0.5417 | 0.152925 | |

| k4 | 0.6144 | 0.4605 | 0.161125 | |

| Extreme value (R) | 0.0119 | 0.3651 | 0.014375 | |

| Ranking of influencing factors | Confining pressure > Gas pressure > Axial pressure | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Yuan, Y.; Liang, Y.; Qin, Z. Influences of Different Factors and Sensitivity Analysis of Permeability of Gassy Coal. Appl. Sci. 2025, 15, 808. https://doi.org/10.3390/app15020808

Li B, Yuan Y, Liang Y, Qin Z. Influences of Different Factors and Sensitivity Analysis of Permeability of Gassy Coal. Applied Sciences. 2025; 15(2):808. https://doi.org/10.3390/app15020808

Chicago/Turabian StyleLi, Bo, Yong Yuan, Yunpei Liang, and Zhenghan Qin. 2025. "Influences of Different Factors and Sensitivity Analysis of Permeability of Gassy Coal" Applied Sciences 15, no. 2: 808. https://doi.org/10.3390/app15020808

APA StyleLi, B., Yuan, Y., Liang, Y., & Qin, Z. (2025). Influences of Different Factors and Sensitivity Analysis of Permeability of Gassy Coal. Applied Sciences, 15(2), 808. https://doi.org/10.3390/app15020808