The environmental impact of both types of natural aggregates produced in the dolomite quarry is relatively low compared to the data in the Environmental Product Declarations (EPDs) for natural aggregates extracted from carbonate bedrock and produced using similar technological processes, including rock blasting, crushing, and screening, without washing or drying. For example, the GWP of 1 tonne of natural aggregates from the dolomite quarry is 1.13 kg CO

2 equiv. (the aggregates intended for concrete production) and 0.97 kg CO

2 equiv. (the aggregates intended for road construction), while the GWP of limestone aggregates from other quarries is between 0.85 and 4.60 kg CO

2 equiv., depending on the type (fraction) of aggregate [

40,

41]. The GWP and environmental footprint of natural aggregates are directly related to the number of crushing and screening processes (e.g., primary crushing and secondary crushing). The relatively low impact of the natural aggregates produced in the Slovenian quarry is attributed to (i) the properties of the bedrock, which consists of tectonically fractured dolomite and, as such, does not require very intensive extraction (a relatively small amount of explosive for blasting) or processing (only screening is required; there is no additional crushing of excavated rock), and (ii) optimized use of non-road mobile machinery (the duty cycles of non-road mobile machinery are maximized to minimize idle time and reduce unnecessary emissions). It is also worth noting that natural aggregates do not need to be washed and dried, as the dolomite rock has a very high purity (the dolomite is chemically homogeneous) (cf. [

42]) and as such meets all market requirements.

Taking into account the data from [

28], the GWP of natural aggregates from different quarries in Quebec (Canada) is between 2.28 and 3.59 kg CO

2 equiv. Lower GWP values refer to the extraction of carbonate rock and higher values to the extraction of hard (volcanic) rock. Reference [

28] emphasized that the environmental footprint of aggregates in quarries is directly related to rock properties (e.g., hardness). Harder rocks require more explosives, which increases the impact. Blasting carbonate rock requires 0.17–0.26 kg of explosives per tonne of rock and 0.37 kg of explosives for blasting one tonne of hard rock (volcanic rock and sandstone) [

28]. In a given quarry, only 0.045 kg of explosives are needed to blast tectonically fractured dolomite rock (

Table 1), which is roughly 4 to 8 times less than the values reported in [

28]. This lower explosive consumption translates to a potential reduction in GWP of approximately 0.6–1.5 kg CO

2 equiv. per tonne of natural aggregates, compared to extraction from massive, unfractured rock. The quantity of explosives required depends not only on the general type and hardness of the rock, but also on local geological properties, such as strength, density, and the structure of the rock mass, including the presence of discontinuities such as joints, faults, and bedding planes [

43,

44]. Additionally, rocks extracted from massive geological formations require crushing, which is not necessary for tectonically fractured formations, as examined in this study. Crushing harder rock involves multiple stages and consumes significantly more electrical energy, further increasing the environmental impact.

Core environmental impacts of natural aggregates intended for concrete and road construction are presented in

Table 3. Particulate matter formation was additionally estimated based on secondary data [

36]. The processing of natural aggregates, such as drilling, blasting, screening, loading, and internal transport, is the primary contributor to particulate matter formation. Due to limitations in the secondary data, it was not possible to estimate the reduction in dust emissions resulting from fewer screening cycles, as is typical for natural aggregates intended for road construction. The estimated particulate matter formation is 0.000001 disease incidences per tonne of natural aggregates produced.

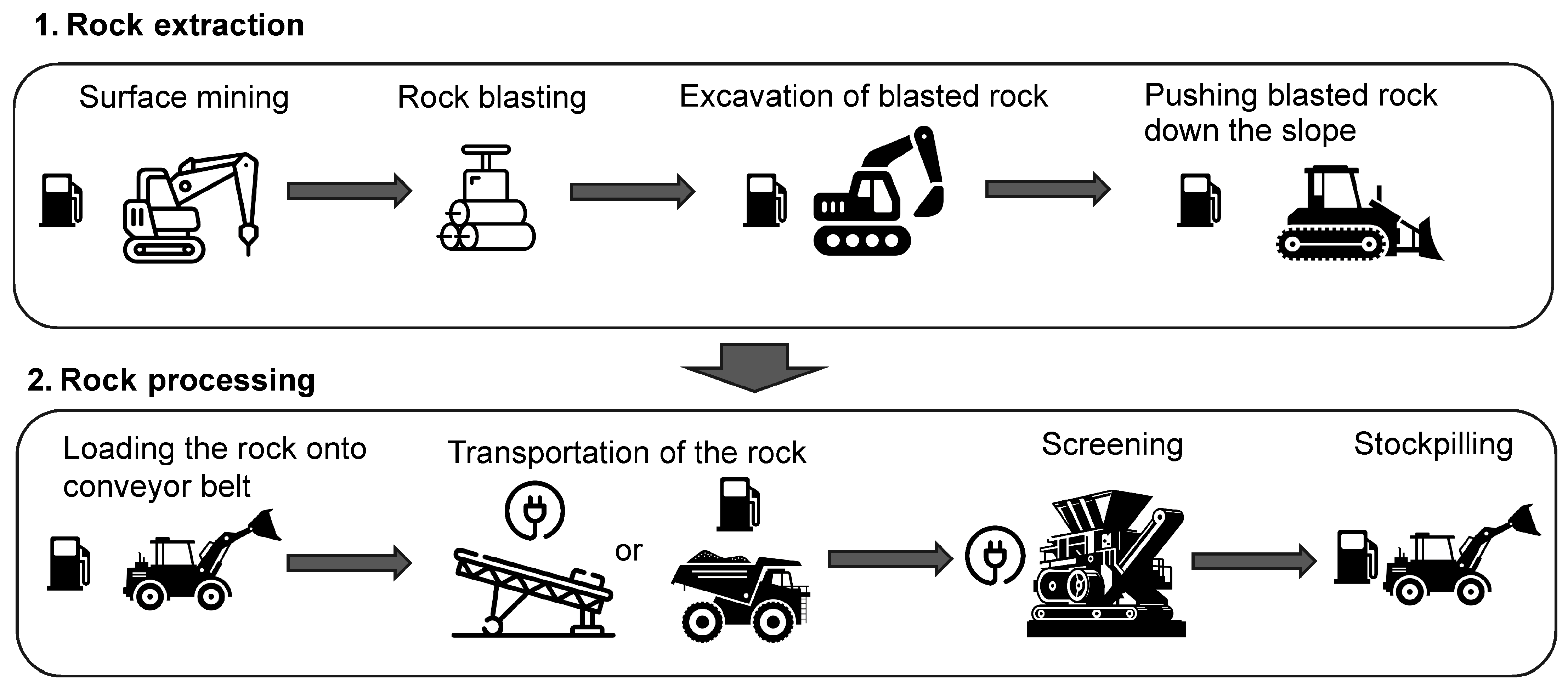

3.1. Contribution Analysis

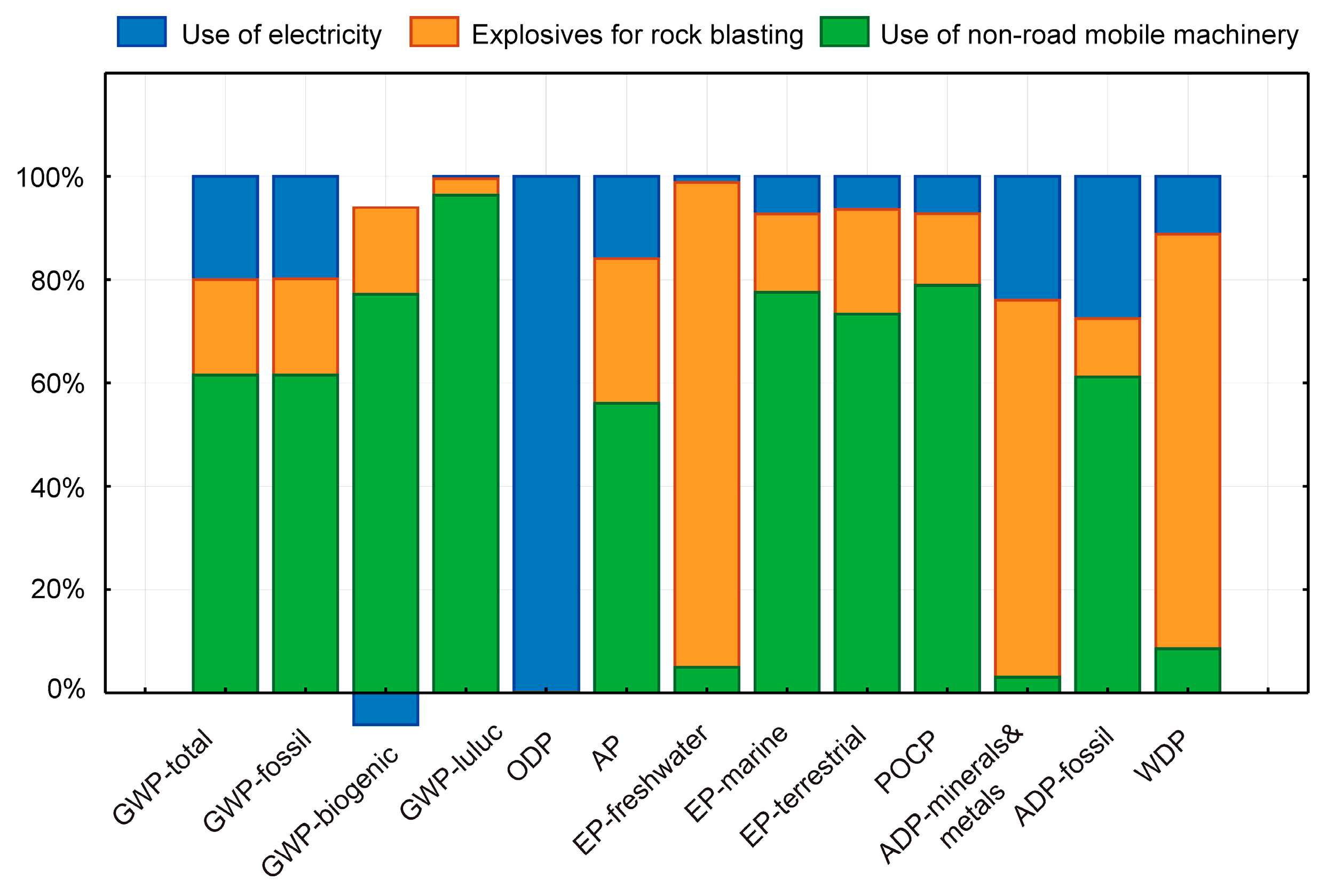

The contribution analysis shows which processes in the production chain have the greatest influence on the environmental footprint of natural aggregates. The use of non-road mobile machinery represents an environmental hotspot in the production process of natural aggregates. For example, it contributes to approximately 61% (in the case of natural aggregates for concrete production) or 71% (in the case of aggregates for road construction) of the total GWP impact. Non-road mobile machinery is involved in the processes of drilling (use of a drilling machine), excavation of blasted rock (use of an excavator), pushing the rock down the slope to the base of the quarry (use of a bulldozer), loading the blasted rock fragments onto a conveyor belt (use of a loader), and depositing (use of a loader) after the rock has been screened into the final fractions. These processes are identical in the production of both types of natural aggregates. The use of explosives accounts for approximately 20% of the total GWP impact. The contribution of auxiliary materials (engine oil for the working machines) is minor—less than 1% (

Figure 2 and

Figure 3). The details have been given in

Appendix A (

Table A1 and

Table A2).

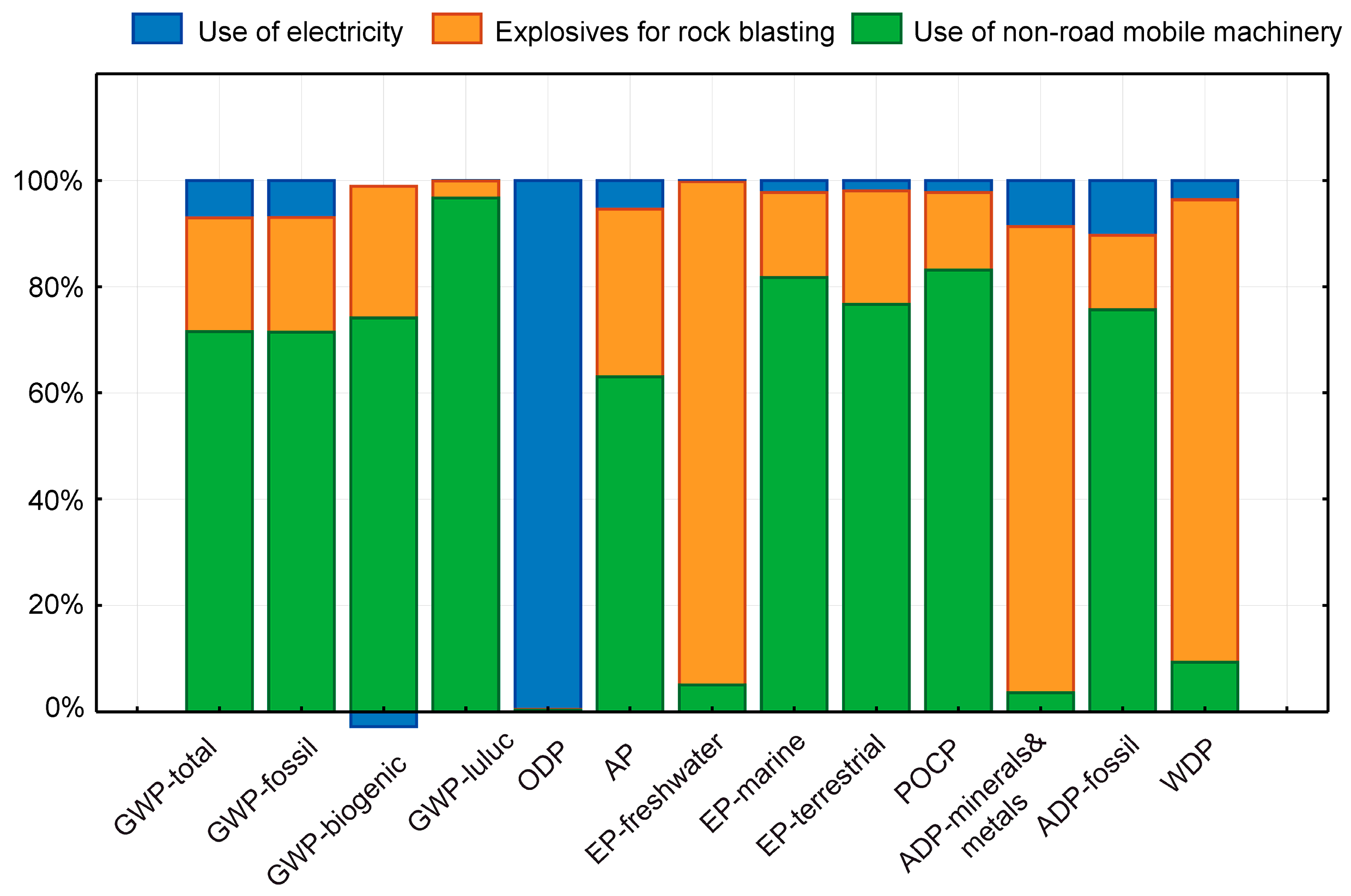

The contribution of the processes requiring electricity (e.g., conveying the blasted rock fragments via a conveyor belt and screening) to the total GWP value is 20% for natural aggregates used in concrete production (

Figure 2) and significantly less for aggregates used in road construction, e.g., 7% (

Figure 3). As shown in

Table 1, 1.31 kWh of electricity per tonne of aggregates produced is required for screening blasted rock fragments into fractions suitable for concrete production (fractions 0/2, 2/4, 0/4, 0/8, 4/8, 8/16, and 16/32). In contrast, the extraction and screening of blasted rock fragments into fractions for road construction (0/16, 0/32, 0/63, and 0/125) require significantly less electrical energy, e.g., 0.32 kWh per tonne of aggregates produced. The production of natural aggregates for road construction requires fewer screening processes. The difference in electricity consumption is 84%.

As shown in

Figure 2 and

Figure 3, the non-road mobile machinery contributes the most to the environmental footprint of natural aggregates in most impact categories. In terms of some impact categories, the environmental hotspot is related to the use of explosives to blast the bedrock (eutrophication of freshwater, water depletion potential, and abiotic depletion of minerals and metals). The effects on these environmental parameters arise upstream, during the production of explosives. The environmental impacts associated with electricity consumption significantly predominate in terms of their potential to deplete the ozone layer. Electricity generated by photovoltaic (PV) solar systems has a relatively high impact on ozone layer depletion potential, approximately 40 times greater than the electricity supplied by the Slovenian grid. This elevated impact primarily originates from the upstream manufacturing processes of PV systems, particularly the production of aluminum frames [

45].

In the production of natural aggregates for road construction, processes that require electricity contribute relatively little to other environmental parameters (

Figure 3). However, processes that require electrical energy have the greatest potential for environmental optimization of the production process.

3.2. Sensitivity Analysis

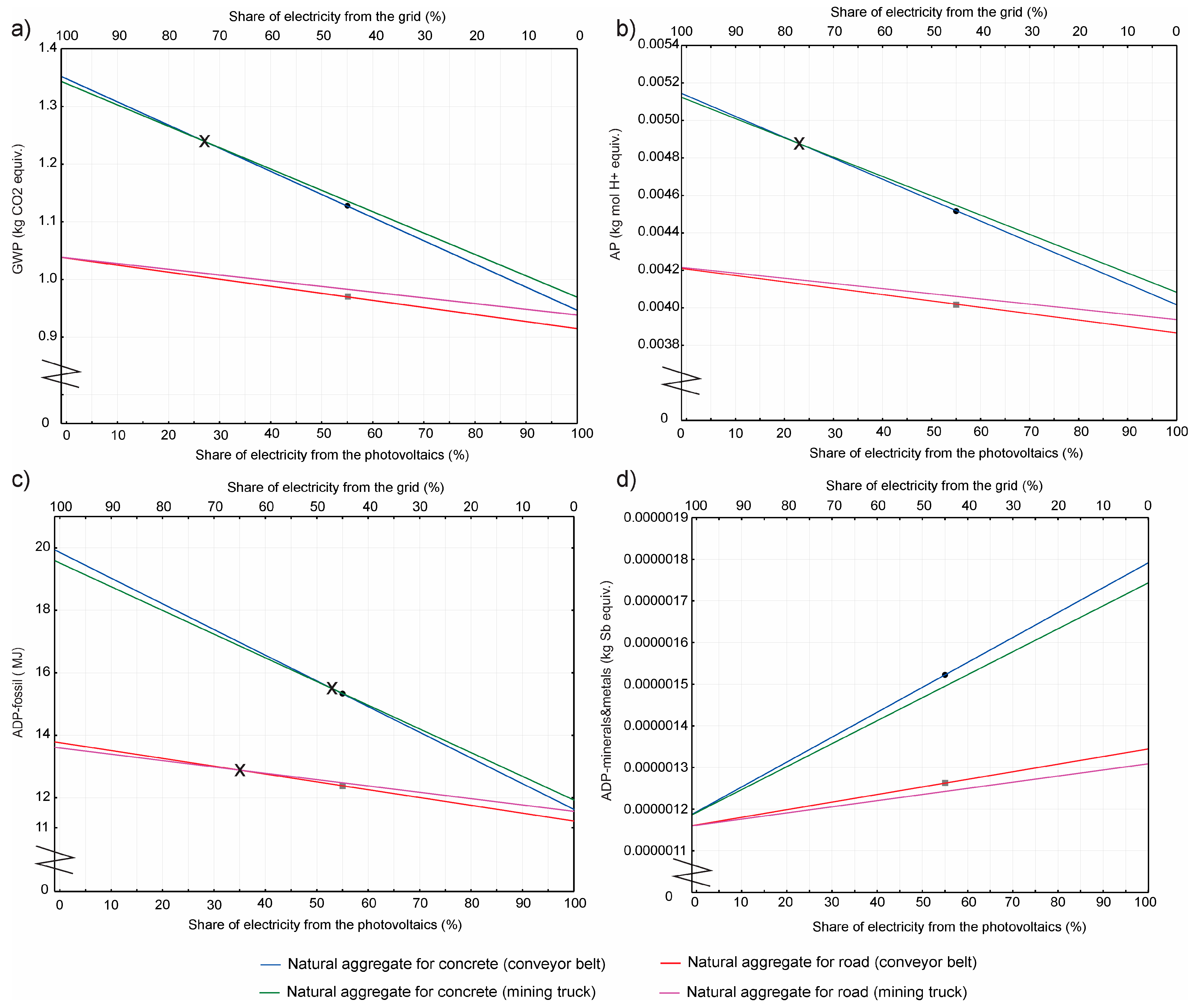

The impacts associated with conveying blasted rock fragments via a conveyor belt and the screening of the rock depend on the power source. In the quarry under consideration, 55% of electricity currently comes from solar energy (photovoltaic systems installed in the quarry), and the rest of the electricity (45%) is grid mix, considering the annual demand. A sensitivity analysis was carried out to show the relationship between the different proportions of electricity from the two sources and their environmental impact, which is significantly influenced by the processes powered by electrical energy. Such environmental impacts are the GWP, the acidification potential, the abiotic depletion of fossil resources, and the abiotic depletion of minerals and metals. These parameters were selected for the sensitivity analysis because they account for more than 15% of the total impact on the value of the parameters in the case of natural aggregate production for the concrete industry (

Figure 2). In the “best-case scenario”, it is assumed that all electricity is supplied by solar systems, whereas in the “worst-case scenario”, the entire electricity supply is derived from the grid mix. The GWP footprint of 1 tonne of natural aggregates for concrete production varies between 1.35 (“worst-case scenario”) and 0.95 CO

2 equiv. (“best-case scenario”). The GWP footprint of 1 tonne of natural aggregates for road construction varies between 1.04 (“worst-case scenario”) and 0.92 CO

2 equiv. (“best-case scenario”) (

Figure 4a).

The sensitivity analysis shows that the power source has a significant impact on the footprint of natural aggregates used in concrete production. Moving from the “worst-case scenario” to the “best-case scenario”, the abiotic depletion of fossil fuels is reduced by 42%, the GWP impact by 30%, and the acidification potential by 22% (

Figure 4). These reductions are less significant for natural aggregates for road construction (e.g., 18% in terms of the abiotic depletion of fossil resources, 12% in terms of the GWP, and 8% in terms of the acidification potential), as the demand for electrical energy in the screening processes is also lower.

This study looks at electricity from the Slovenian power grid. This electricity is primarily generated in nuclear power plants (approximately one-third) and hydropower plants (approximately one-third), followed by thermal power plants (approximately 23%) [

46]. The latter power plants are among the most polluting and therefore have a significantly high environmental impact, which is reflected in the footprint of the electricity in the grid.

However, electricity from photovoltaics has a greater impact on the abiotic depletion of minerals and metals compared to electricity sourced from a grid mix. For this reason, the so-called “best-case scenario”, which assumes a 100% supply of electricity from solar energy, has an adverse effect on the abiotic depletion of minerals and metals. Specifically, when considering the production of natural aggregates for the concrete industry, the abiotic depletion of minerals and metals increases by 48% compared to a scenario relying solely on grid mix electricity. For the production of natural aggregates used in road construction, the increase is 15% (

Figure 4d).

The reason the electricity generated in solar power plants has a significantly high impact on the depletion of minerals and metals is that photovoltaic panels usually contain metals (such as aluminum, copper, lead, and silicon) and rare elements (including indium, gallium, and tellurium). Metals and rare elements are important components of all three generations of photovoltaic panels currently in use [

47,

48].

A conveyor belt is operated exclusively with electricity, whereas a quarry dump truck is operated with diesel fuel. It is assumed that the dump truck (with a 40.6-tonne payload capacity and EURO VI emission standard) travels fully loaded in one direction and returns empty. For natural aggregates intended for concrete production, the LCA results indicate that the conveyor belt scenario has a slightly higher environmental impact when electricity is sourced entirely from the grid. However, this changes when a certain portion of the electricity is supplied by photovoltaics (a renewable energy source), as shown in

Figure 4. Considering the actual electricity mix (55% from photovoltaics and 45% from the grid), the conveyor belt becomes the environmentally preferable option compared to the quarry dump truck. The exception is the impact on the abiotic depletion of minerals and metals, where photovoltaic panels contribute significantly to this indicator (

Figure 4d).

For natural aggregates used in road construction, the conveyor belt scenario shows a comparable impact to that of the dump truck scenario, even when powered entirely by grid electricity. One exception is the impact on the abiotic depletion of fossil fuels; however, the difference remains slight (

Figure 4c). Electricity in Slovenia’s national grid is largely sourced from thermal power plants (23%), contributing to the relatively high environmental impact of grid electricity. As a result, the conveyor belt scenario (powered by 100% grid electricity) shows a higher impact on the abiotic depletion of fossil fuels than the quarry dump truck scenario.

Nevertheless, the change in transportation mode has had a relatively minor effect on the overall LCA results. For instance, when powered by grid electricity, the GWP of aggregates for concrete is only 0.62% higher in the conveyor belt scenario compared to the dump truck scenario. The GWP of both scenarios equalizes when approximately 27% of the conveyor belt’s electricity is sourced from solar energy. At higher photovoltaic shares, the conveyor belt scenario yields a lower GWP (

Figure 4a). When powered entirely by solar energy, the GWP difference between the two scenarios reaches 2.4%.

As mentioned, a generic dataset was used as a proxy for all types of non-road mobile machinery. The dataset “Excavator, 500 kW, mining (u-so)” was applied and linked to the dataset “Diesel mix at filling station (aggregated)” (

Table 1). The outputs represent combustion emissions from engine operation, including regulated emissions (NO

x, CO, hydrocarbons, and particulate matter), fuel-dependent emissions (CO

2, SO

2, benzene, toluene, and xylene), and other emissions such as CH

4 and N

2O. Emissions associated with machinery production, end-of-life processes, and the fuel supply chain (including exploration, refining, and transport) are excluded from this LCA [

49].

CO

2 emissions per liter of diesel are relatively consistent across machinery types, as CO

2 output is directly linked to the carbon content of the fuel [

50]. Therefore, fuel-dependent emissions are not expected to vary significantly among different types of non-road mobile machinery.

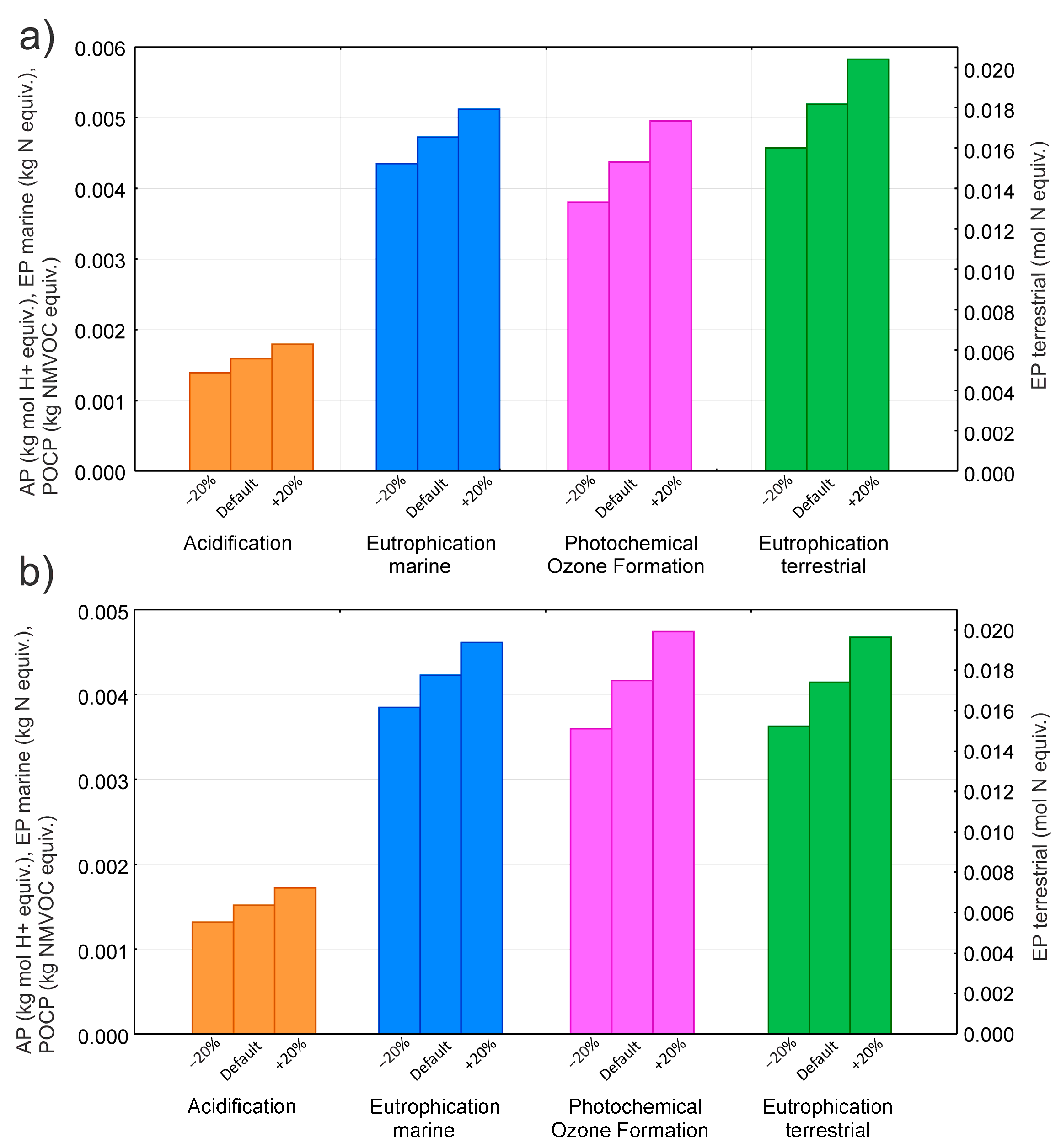

A sensitivity analysis was conducted for regulated emissions (NO

x, CO, hydrocarbons, and particulate matter) from non-road mobile machinery [

36], assuming a ±20% variation (

Figure 5). The results show that these emissions influence the following categories: acidification potential, marine eutrophication potential, terrestrial eutrophication potential, and photochemical ozone formation potential (

Figure 5). They do not affect the other nine core impact categories. The sensitivity analysis revealed that a ±20% change in regulated emissions affects acidification potential by ±8%, and marine eutrophication, terrestrial eutrophication, and photochemical ozone formation potentials by 12–13%, based on a cradle-to-gate LCA of natural aggregates for concrete. For natural aggregates used in road construction, environmental performance is slightly more sensitive to ±20% variations in regulated emissions, with acidification potential changing by ±9%, and eutrophication (marine and terrestrial) and photochemical ozone formation potentials by 13–14%. See also

Appendix A (

Table A3 and

Table A4).