1. Introduction

Rotary kilns are high-temperature devices widely used in industrial production, such as in the chemical, lime, and cement industries, primarily for processes such as solid decomposition, calcination, and heat treatment [

1,

2]. In the cement industry, rotary kilns account for the largest share of use and are a critical piece of equipment in cement production [

3], directly impacting cement quality, output, and production efficiency. They are primarily composed of a cylinder, a drive system, and a support system [

4]. Real-time monitoring of the operational status of rotary kilns to ensure their normal operation is an important means of improving industrial production efficiency.

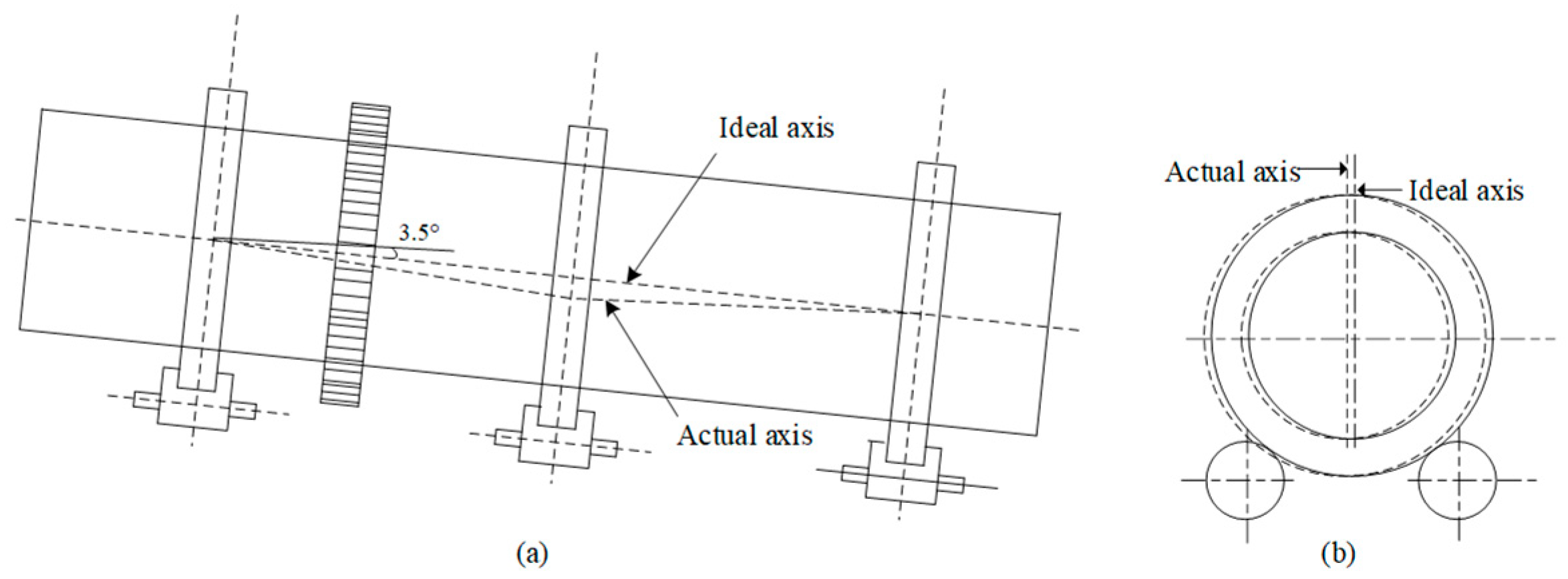

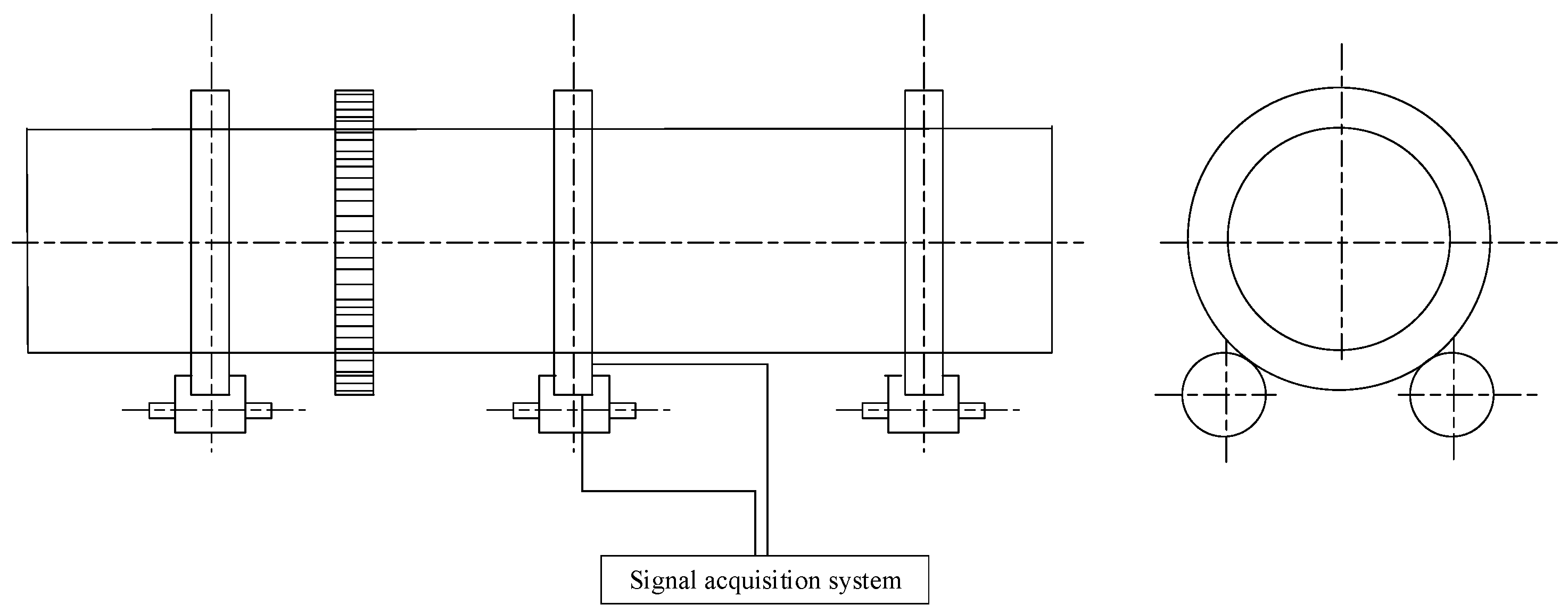

In actual operation, the centerline deviation fault of the rotary kiln, as shown in

Figure 1, primarily manifests as abnormal load on the support rollers, high temperatures in the bearing shells, and equipment damage. The main influencing factors include deformation of the kiln cylinder, uneven wear of the support rollers, and installation deviations. These issues require timely resolution through dynamic monitoring and process adjustments. The vibration signals of the rotary kiln contain operational characteristics, fault characteristics, and other operational status information. However, due to operational noise, it is challenging to extract fault characteristic signals. Researchers worldwide have conducted extensive studies on fault feature extraction. Commonly used techniques include Empirical Mode Decomposition (EMD) [

5], Integrated Empirical Mode Decomposition (EEMD) [

6], Wavelet Transform (WT) [

7], Empirical Wavelet Transform (EWT) [

8], and Local Mean Decomposition (LMD) [

9]. Meng et al. used EMD to process vibration signals and analyzed their characteristic signals to obtain fault patterns [

10]. Shah used EMD to extract modal components from nonlinear, non-stationary vibration signals [

11]. Shifat combined EEMD and similarity coefficients for fault diagnosis of motor vibration signals [

12]. Li combined EWT with soft threshold denoising methods to process vibration signals [

13]. Yan summarized the application of WT in fault diagnosis from the perspectives of intelligent fault diagnosis and traditional fault diagnosis [

14]. Han M proposed a new method for fault feature extraction by combining multi-scale symbol dynamic information entropy (MSDE) with LMD [

15]. Although the above methods can extract fault feature signals to some extent, the EMD method suffers from end-point effects and modal overlap issues. EEMD can address this issue, but it introduces white noise, requiring an increase in the number of averaging operations. WT is limited by the selection of the mother wavelet, resulting in insufficient applicability when processing non-stationary signals. EWT lacks adaptability and robustness in signal decomposition, and LMD still exhibits endpoint effects in signal decomposition.

Dragomiretskiy K and other scholars have proposed that the VMD method can effectively address modal overlap and end-point effects, and it is supported by theoretical foundations [

16,

17]. Currently, this method has been widely applied in the field of fault diagnosis. Liu used the VMD method to extract fault features from vibration signals in a high-noise environment [

18], so the VMD method was selected as the approach for processing rotary kiln vibration signals. However, the VMD method is influenced by the number of modal functions (IMFS) and the quadratic penalty term

. If the parameters are not appropriately set, modal overlap may still occur [

19]. To address this issue, many researchers have employed meta-heuristic algorithms to optimize VMD parameters.

Although existing PCA-based methods are widely applied in fluid leakage detection, they typically rely on fixed training data and parameter settings, which may lack the flexibility to adapt to varying operating conditions when applied to complex and dynamic rotary kiln systems [

20]. Heuristic algorithms are characterized by their fast computation speed, simple logic, and high flexibility, making them an increasingly popular choice for fault diagnosis and parameter optimization. Based on their principles, they can be categorized into four types: swarm-based, evolution-based, human-based, and physics-based. Swarm-based representatives include Ant Colony Optimization (ACO) [

21] and Whale Optimization Algorithm (WOA) [

22]. Evolution-based representatives include Evolutionary Strategy (ES) [

23] and Genetic Algorithm (GA) [

24]. Human-based representatives include Social Group Optimization (SGO) [

25] and Cognitive Behavioral Optimization Algorithm (COA) [

26]. Physically based representatives include Atomic Search Optimization (SVO) [

27] and Multiverse Evolver (MVO) [

28]. Given the flexibility of meta-heuristic algorithms, numerous scholars have proposed employing various optimization algorithms to search for VMD parameters, such as Sparrow Search Algorithm (SSA) [

29], Gray Wolf Optimization (GWO) [

16], Whale Optimization Algorithm (WOA) [

30], Grasshopper Optimization Algorithm (GOA) [

31], and others. Each possesses distinct advantages but also faces challenges such as susceptibility to local optima or excessive computational complexity. In contrast, the Secretary Bird Optimization Algorithm (SBOA) demonstrates superior global search capabilities and rapid convergence. It exhibits enhanced stability and robustness in solution accuracy, making it particularly well-suited for parameter optimization of nonlinear complex signals like those from cement rotary kiln vibration. Fu Y et al. compared SBOA with 15 other advanced algorithms and concluded that SBOA performs excellently in terms of convergence speed, solution quality, and stability [

32]. The essence of SBOA in parameter optimization is a mathematical model comprising two stages of intelligent optimization algorithms based on biomimetic mechanisms, which can precisely adapt to VMD parameter optimization problems. The algorithm has the advantages of being easy to implement, and having few parameters and a simple structure, but it still suffers from issues such as easily getting stuck in local optima and low convergence accuracy.

Therefore, this paper proposes an improved secretary bird parameter optimization algorithm (ISBOA) based on multiple strategies. By introducing a random inertia weight strategy, the randomness of the search is enhanced. The whale algorithm surrounder strategy is introduced to address the poor balance between global and local exploration capabilities of the algorithm. After improvement, the algorithm achieves higher convergence accuracy and speed, providing optimal parameter combinations for different operating states of cement rotary kilns.

2. Methodologies

2.1. The Principles of VMD

In Variational Modal Decomposition (VMD), modal components are defined as a finite set of amplitude-modulated frequency-modulated (AM-FM) signals with distinct center frequencies. Each modal component possesses unique center frequency and bandwidth characteristics. Consequently, in fault diagnosis applications, VMD can extract modal components distributed across different frequency ranges, providing an effective approach for identifying multiscale fault features within complex signals.

The VMD method decomposes the original signal

x(

t) into multiple modal components, each of which corresponds to a specific frequency band, as shown in Equation (1):

In the equation,

x(t) is the original signal, and is the

kth modal component. Each modal component can be regarded as an amplitude modulation-frequency modulation representation as shown in Equation (2):

In the equation, represents the time-varying amplitude of the modal component, represents the instantaneous phase, and represents time. Each modal component is considered to be a harmonic signal with a definite instantaneous frequency and amplitude within a finite time interval.

VMD converts different modal components

into their analytical signals via the Hilbert transform, thereby obtaining frequency domain information. Subsequently, the negative exponential mixture estimated at the center frequency is shifted to the baseband. Finally, the bandwidth of each component is determined by the square norm of the resolved signal

. This method reveals the frequency characteristics within the signal through frequency domain analysis. It effectively extracts relevant fault modes for diagnosing system states, particularly in complex nonlinear and non-stationary signals, constructing a fully non-recursive variational modal decomposition model as shown in Equation (3).

In the equation, is the analytical signal of the modal component , u(T) is the complex exponent of the center frequency estimate, and and represent the set of all modal components and center frequencies.

To find the optimal solution for

and

in Equation (3), introduce the Lagrange multiplier Y to replace the constraint conditions and quadratic penalty term M in the original model to ensure that the data is reconstructed without distortion, thereby converting the constrained problem into an unconstrained problem. Therefore, introduce the augmented Lagrange

expression as shown in Equation (4).

In the equation, is the Lagrange multiplier and is the quadratic penalty term.

VMD uses the alternating multiplier method to find the saddle point of

in Equation (4). To facilitate calculation, the optimal solution problem is optimized by equating the update of the modal component

to the minimization problem shown in Equation (5).

Solving Equation (5) in the frequency domain yields Equation (6).

The problem of minimizing the updated center frequency

is shown in Equation (7) below.

Optimize it to solve in the frequency domain as shown in Equation (8).

Based on the obtained and , the component can be reconstructed.

The PCA method is employed to reduce the dimensionality of rotary kiln fault diagnosis, transforming a large set of variables into a smaller one while retaining most of the information from the original set. The specific steps are as follows.

Standardize the raw data as shown in Equation (9).

Calculate the eigenvectors and eigenvalues of the correlation matrix

as shown in Equation (10).

The calculated eigenvectors of the correlation matrix are denoted as , and the eigenvalues are denoted as .

Calculate the variance contribution rate

of the characteristic parameters of the correlation matrix

as shown in Equation (11):

The number of principal components is selected based on the cumulative principal component percentage. Typically, when ≥ 95%, the first m principal components can represent most of the information.

Calculate the eigenvectors of each principal component in the feature parameters as shown in Equation (12):

The principal component matrix is shown in Equation (13):

This represents the principal component data after dimensionality reduction to dimensions.

2.2. The Principles of SBOA

SBOA is a population-based meta-heuristic optimization algorithm in which the positions of individuals in the population represent the corresponding decision variable values. When dealing with minimization problems, an initial solution set containing N individuals must be generated in the initial stage. The initial positions of each individual are generated using formula (14):

In the formula, and represent the lower and upper bounds of the decision variable search space, respectively. is a random number in the interval . The appropriate value corresponding to is used to evaluate the quality of the solution.

The VMD parameter optimization process for the secretary bird is divided into hunting strategies and escape strategies. In hunting strategies, the process can be divided into three time stages: searching for prey, consuming prey, and attacking prey.

2.2.1. Search for Prey

At this stage, the secretary bird quickly locates and discovers potential prey. According to formula (15), when time

satisfies

≤

, the secretary bird will update its position and search a wider area to find prey. The formula is as follows:

In the formula, represents the current iteration count, represents the maximum iteration count, is the new position of the secretary bird at this stage, and is the new position randomly generated in the second stage. is an array of dimension generated in the dimension interval.

2.2.2. Consuming Prey

At this stage, the secretary bird approaches the prey it is consuming. According to Equation (16), when

satisfies

, the secretary bird will update its position based on its current location to simulate the process of consuming the prey.

In the formula, represents the standardized dimension generation step, and represents the position of the optimal solution. This stage mainly optimizes the accuracy of the solution by gradually approaching the optimal position.

2.2.3. Attack Prey

When time exceeds

, the secretary bird attacks its prey, at which point the formula is as shown in Equations (17) and (18).

In the equation,

flight is a non-Gaussian random walk strategy that helps individuals make large jumps and avoid getting stuck in local optima. If the new

is better, accept the solution and update the position. Otherwise, keep the current solution and update the rules as shown in Equation (19).

Through continuous adjustment and optimization, the algorithm achieves a good balance between global search and local optimization.

2.2.4. The Secretary Bird’s Escape Strategy

When secretary birds encounter danger, they typically employ strategies such as camouflage or rapid escape to protect themselves. These two mechanisms occur with equal probability, as shown in Equations (20) and (21).

In the formula, is 0.5, represents a randomly generated array of dimension in the normal distribution, is a random candidate solution, and is a random integer 1 or 2.

2.3. Improved Secretary Bird Optimization Algorithm

2.3.1. Random Weighting Mechanism

During the dynamic optimization process of the secretary bird algorithm, the weight coefficients can be gradually adjusted to improve the balance between global search and local search, and updates can be performed using Equation (22) during the iteration process.

In the formula, is the inertial weight, is the randomly generated standard normal distribution value, is the minimum weight, and is the maximum weight.

The introduced random inertia weight mechanism achieves an adaptive balance between exploration and exploitation by combining iterative dynamic decay with normal random perturbations. During the early search phase, larger inertial weights endow individuals with robust global exploration capabilities, enabling extensive searches across complex signal spaces and preventing premature convergence to local optima. In the later search phase, as inertial weights gradually diminish, the search process converges, thereby enhancing the precision of approximating the global optimum solution. The introduction of random disturbance factors further increases the diversity of individual trajectories, reducing the population’s over-reliance on the current optimal solution. For non-stationary, nonlinear rotary kiln fault signals, this mechanism enhances the algorithm’s robustness and global optimization capability.

2.3.2. Improvements Incorporating WOA Strategies

Since the secretary bird algorithm relies too much on the offset of the current optimal solution for searching, it is easy to get stuck in a local area, which lowers the algorithm’s ability to get out of local optima. The whale optimization algorithm’s prey enclosure strategy effectively balances local and global searches. It also introduces a decreasing factor to gradually reduce the search range, achieving a dynamic balance between exploration and exploitation. Its position update is shown in Equation (23).

In the formula, is the convergence factor.

The Whale Optimization Algorithm’s Encirclement Strategy employs a decreasing factor to progressively narrow the search scope, enabling ISBOA to dynamically transition from global exploration to local exploitation during the search process. In early iterations, larger contraction factors guide individuals to disperse across the vast solution space, increasing the probability of escaping local optima. In later iterations, as contraction factors gradually decrease, the population converges near the global optimum, enabling refined searches that enhance convergence speed and accuracy. This mechanism effectively addresses the shortcomings of SBOA’s excessive reliance on the current optimal solution, ensuring that the algorithm can balance escaping local optima with convergence stability when processing complex multi-source interference in rotary kiln fault signals.

Envelope entropy effectively captures signal uncertainty and nonlinear characteristics by analyzing the dynamic changes in the signal’s envelope. In rotary kiln fault signal analysis, it demonstrates nonlinear processing capabilities, noise robustness, multiscale analysis advantages, and global feature capture ability. Compared to traditional metrics such as kurtosis, energy entropy, and correlation coefficients, envelope entropy can more comprehensively and accurately reveal the fault characteristics of complex rotary kiln signals. Therefore, envelope entropy is adopted as the fitness function. The analysis process is shown in

Figure 2.

3. Optimization Algorithm Verification Simulation Analysis

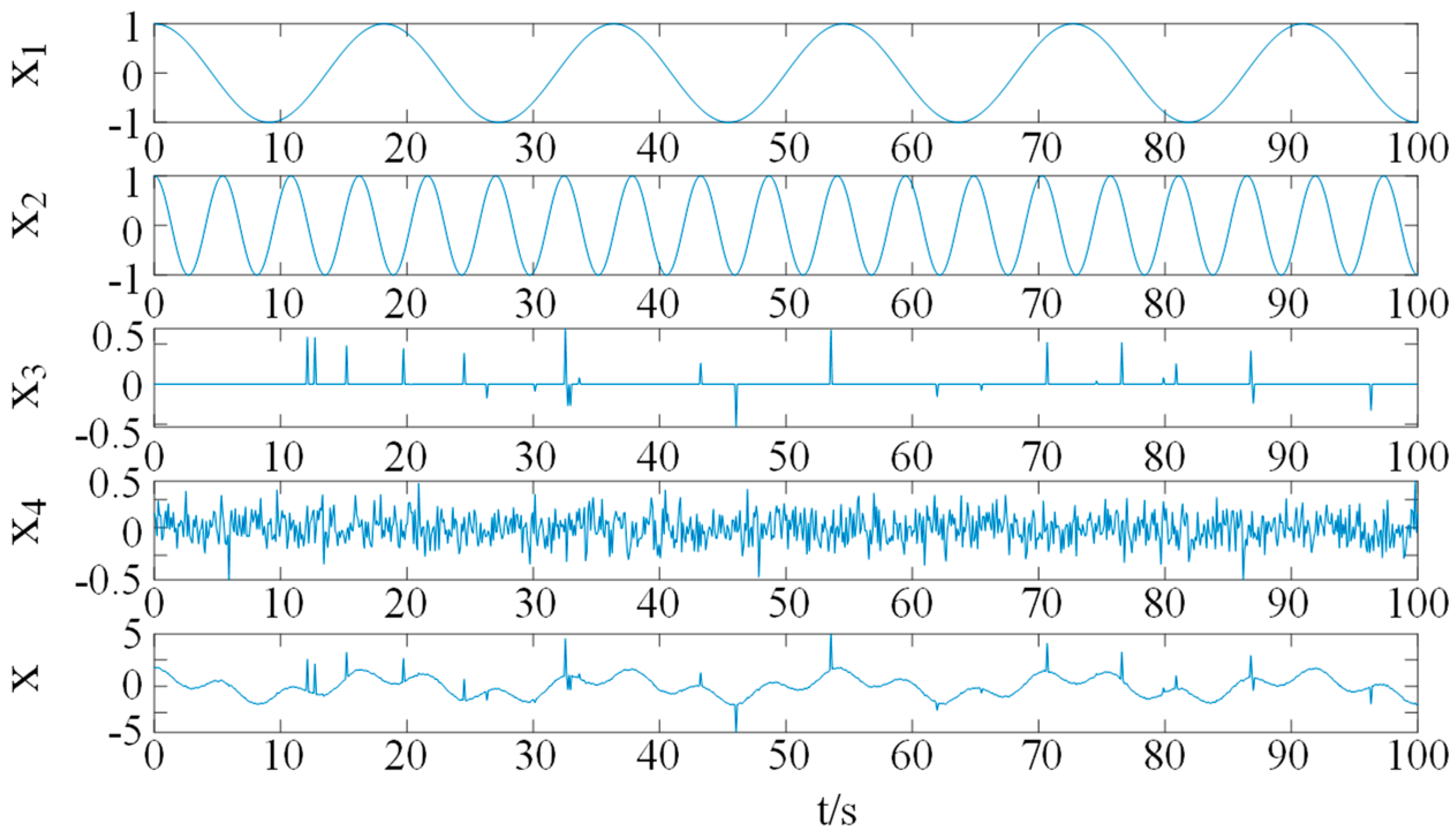

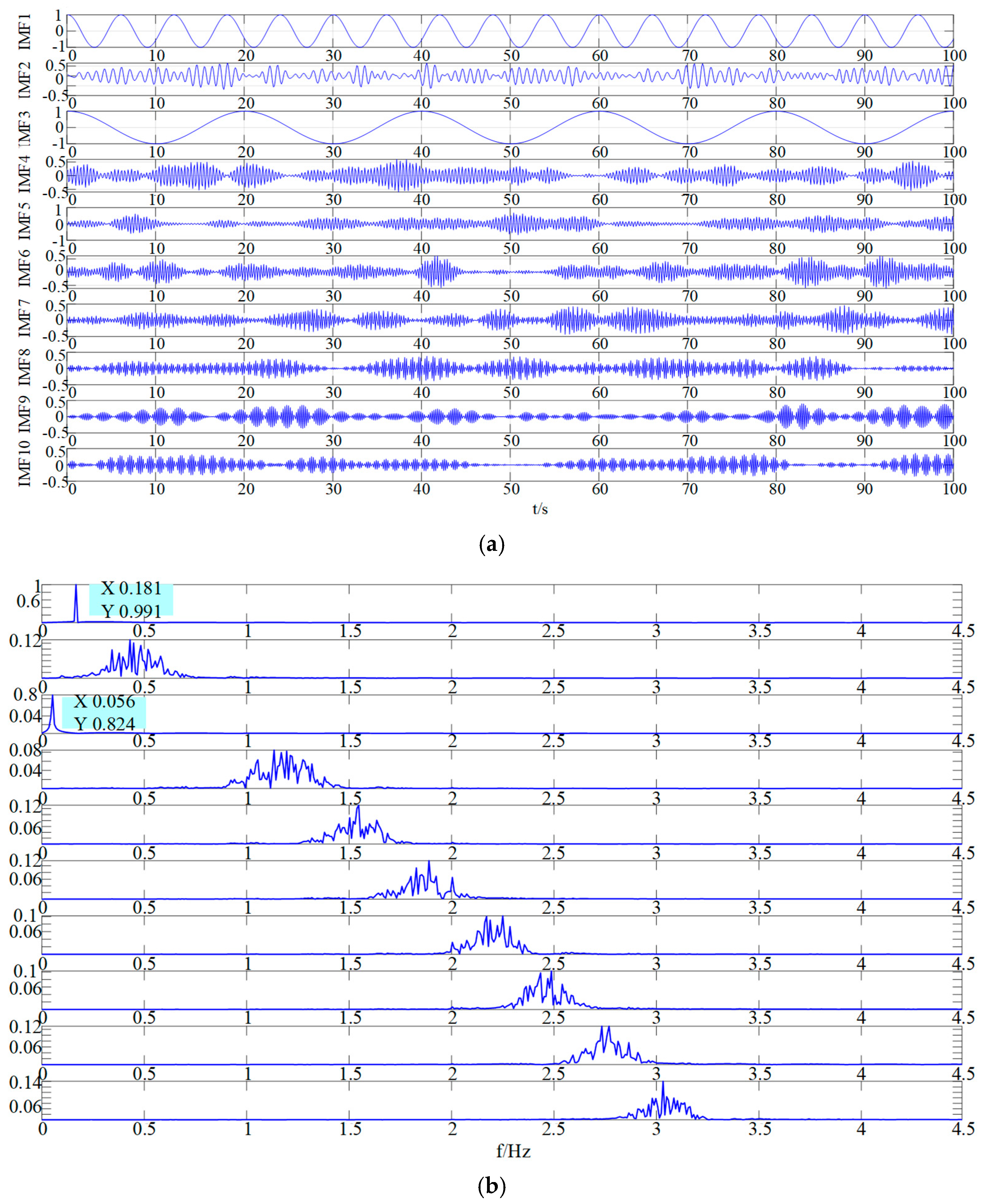

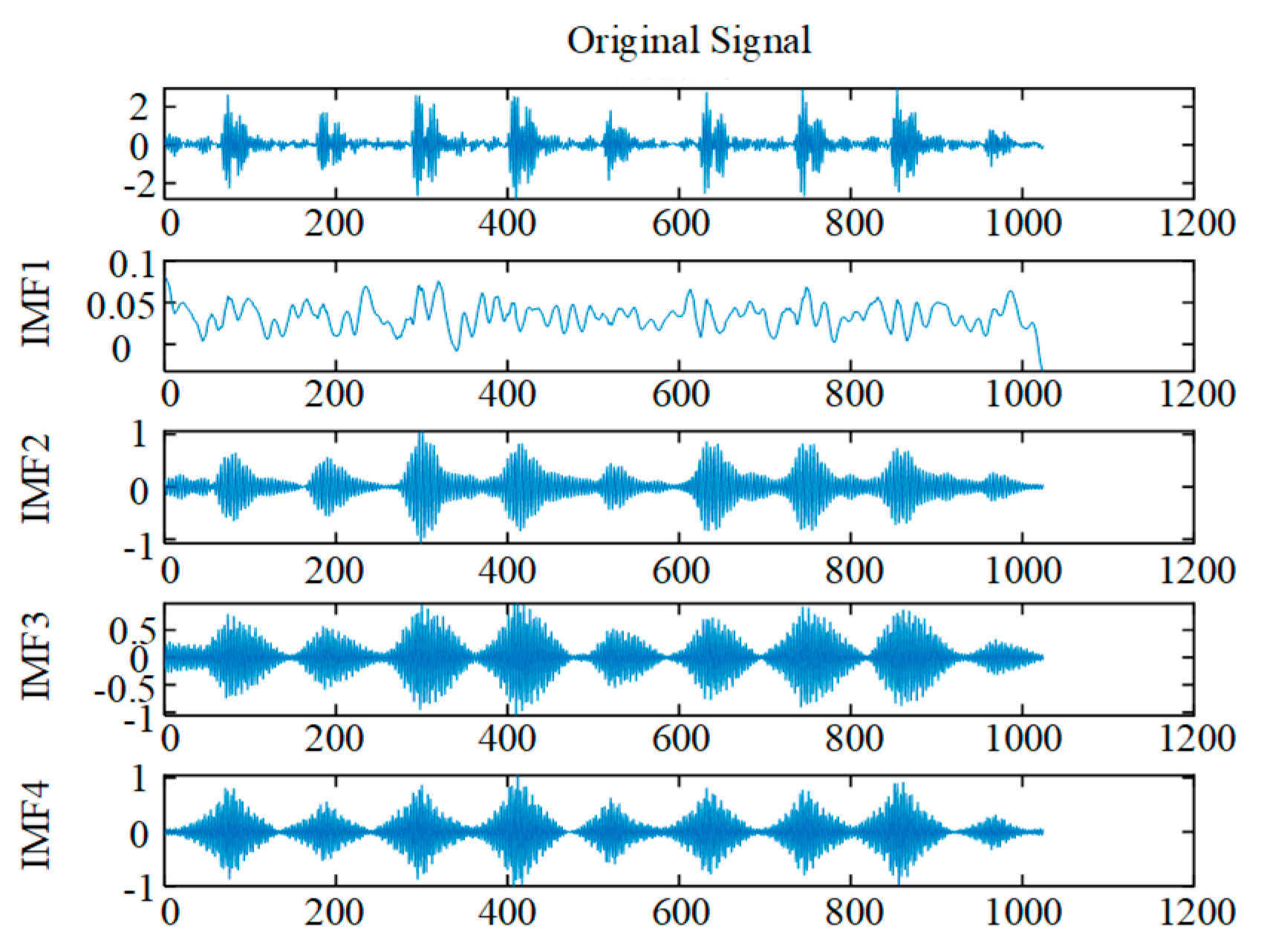

When operating a rotary kiln, the noise level at the site increases significantly, especially under heavy loads and high temperatures, which may cause pitting and spalling of the support rollers and wheel bands. All of the above situations can interfere with the accurate measurement of the rotary kiln displacement signal. Therefore, a multi-component superimposed signal model was constructed as shown in Equation (24), and the simulation signal is shown in

Figure 3.

In the equation, represents the pulse impact, denotes Gaussian white noise with a mean of 0 and variance , and signifies the filter impulse response.

Among these,

represents a characteristic signal simulating the rotational frequency of the cylinder body,

represents a characteristic signal simulating the rotational frequency of the support rollers,

represents a periodic Gaussian pulse signal simulating the impact of pitting and spalling, and

represents the residual noise interference in the signal after filtering.

and

are random processes implemented in numerical simulations by constructing Gaussian pulse sequences and filtered noise, thereby ensuring the input signals reasonably simulate the operating conditions of the rotary kiln. The number of sampling points is set to 1000. The input signal is shown in

Figure 3 above.

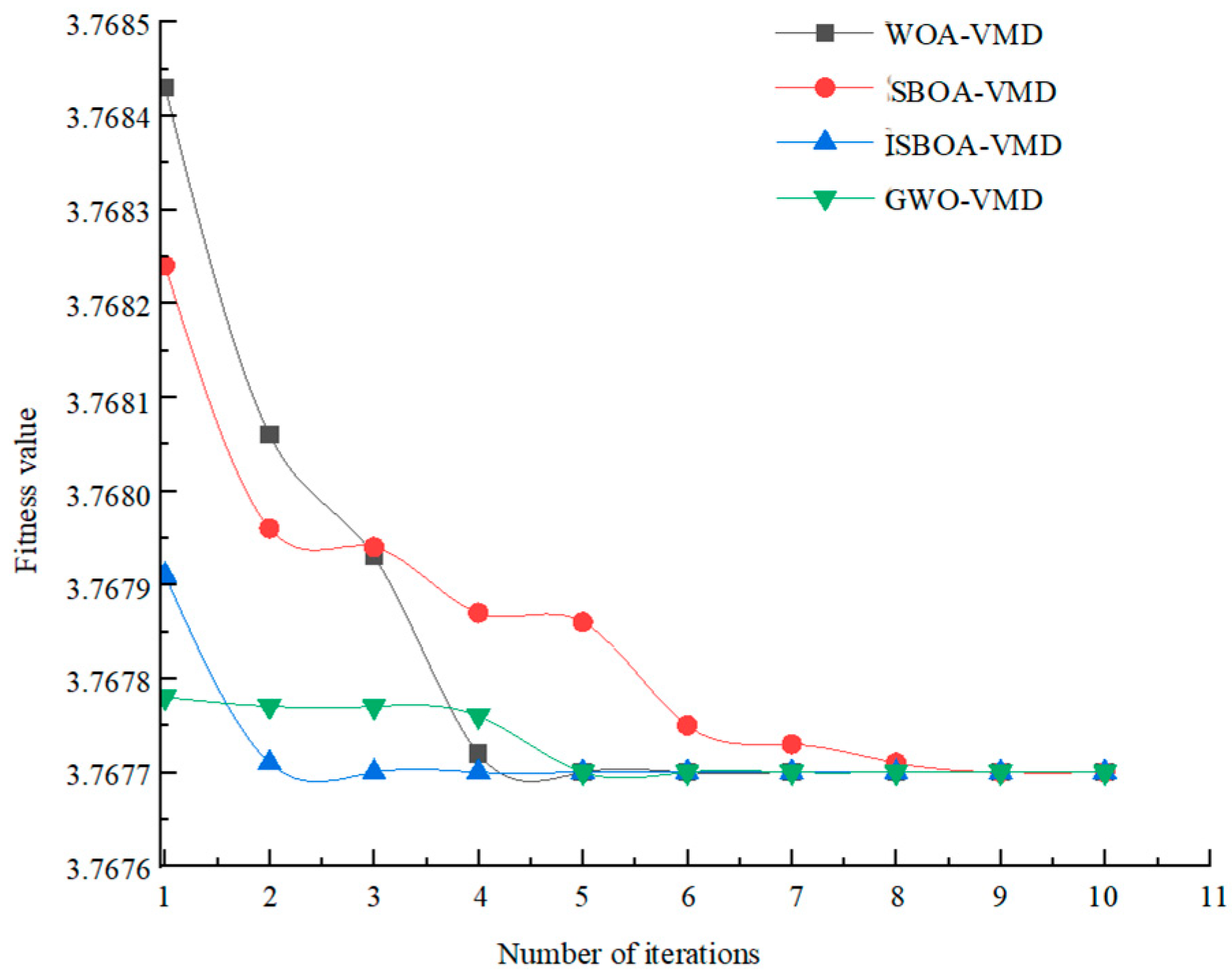

To evaluate the performance of the ISBOA in VMD parameter optimization, the optimization results of ISBOA were compared with those of the gray wolf optimization algorithm (GWO), whale optimization algorithm (WOA), and secretary bird optimization algorithm (SBOA).

Figure 4 shows the iterative convergence curves of different optimization algorithms in the VMD parameter optimization process.

As shown in

Figure 4, the ISBOA achieves the minimum adaptation value and converges by the second iteration. Compared with the other three algorithms, ISBOA not only exhibits faster convergence speed but also demonstrates better stability and robustness in terms of solution accuracy, effectively avoiding local optima. Therefore, ISBOA demonstrates superior performance to other intelligent optimization algorithms in VMD parameter selection, with a 75% improvement in convergence speed compared to before optimization.

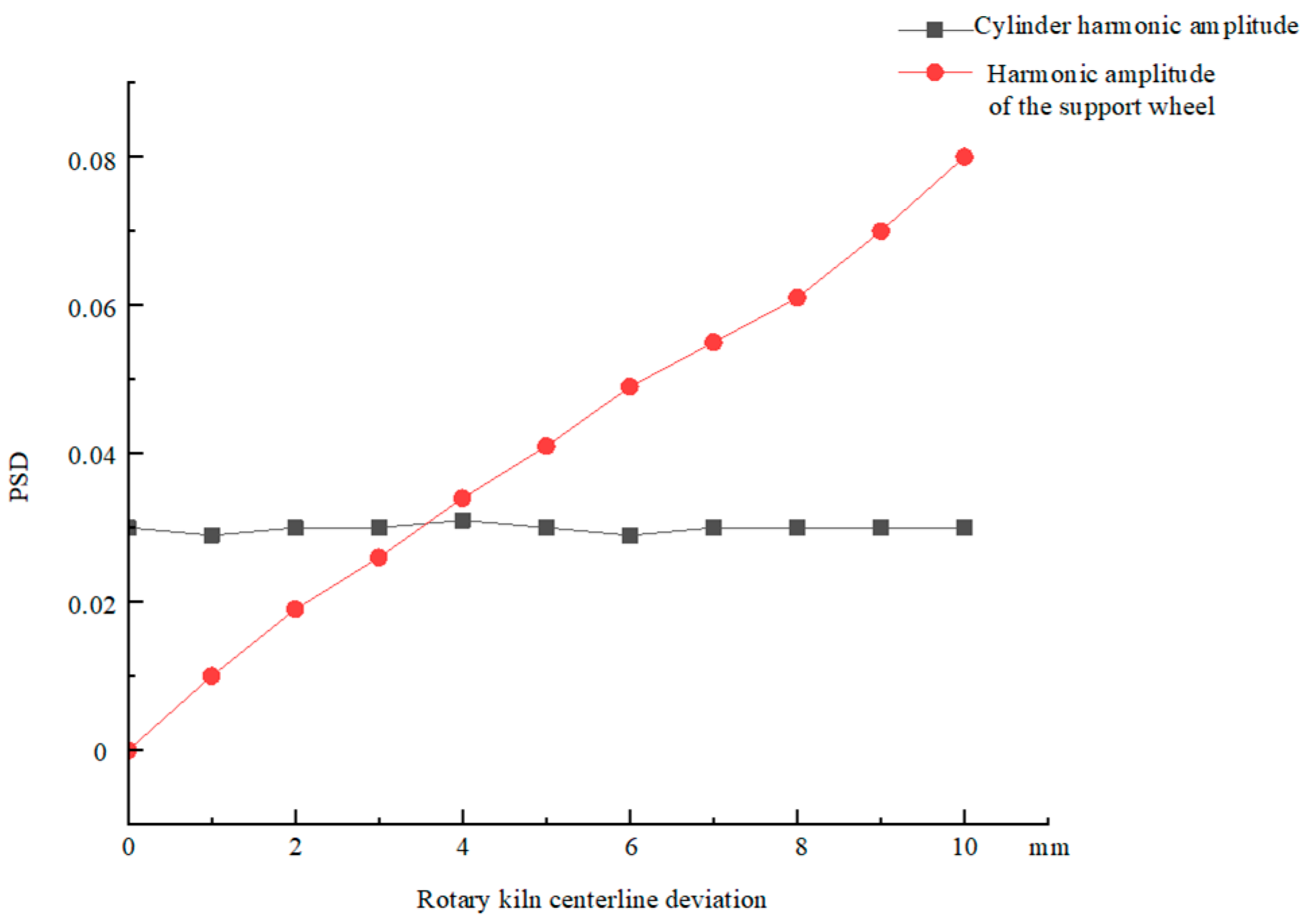

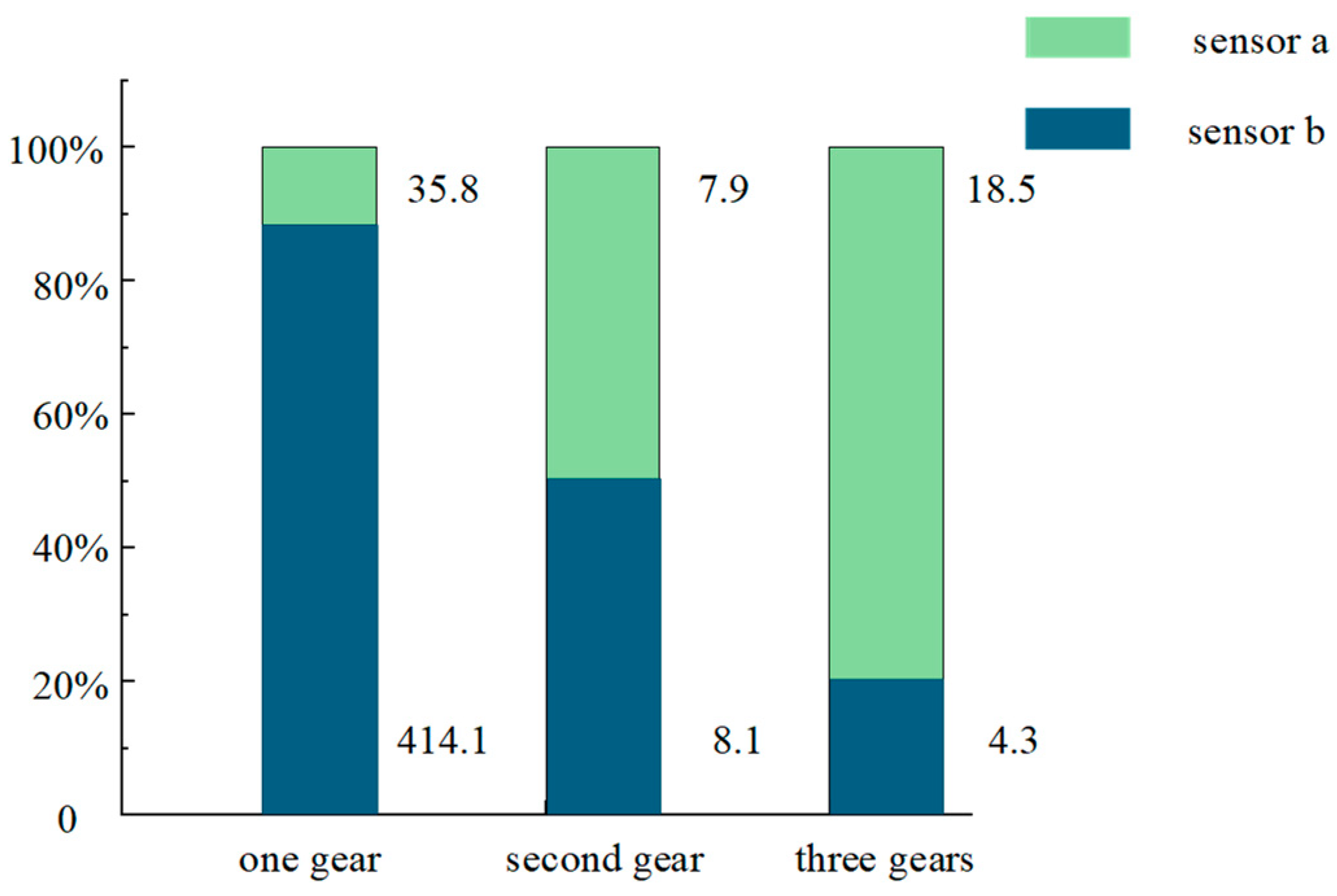

Further analysis of the relationship between rotary kiln faults and the harmonic amplitudes of the rotary kiln cylinder and support rollers is shown in

Figure 5 below. The PSD power spectral density is used as a parameter to measure the magnitude of harmonic amplitudes, as shown in Equation (25).

In the formula, is the PSD value at harmonic frequency , and is the frequency resolution.

As shown in

Figure 5, when the offset of the cylinder centerline increases, the amplitude of the rotary kiln cylinder harmonic (KH) remains unchanged, while the amplitude of the roller harmonic (RH) increases. When the rotary kiln undergoes thermal bending deformation, the amplitude of RH remains unchanged, while the amplitude of KH increases accordingly. Therefore, the operational status of the rotary kiln can be diagnosed by collecting displacement signals from the rotary kiln.

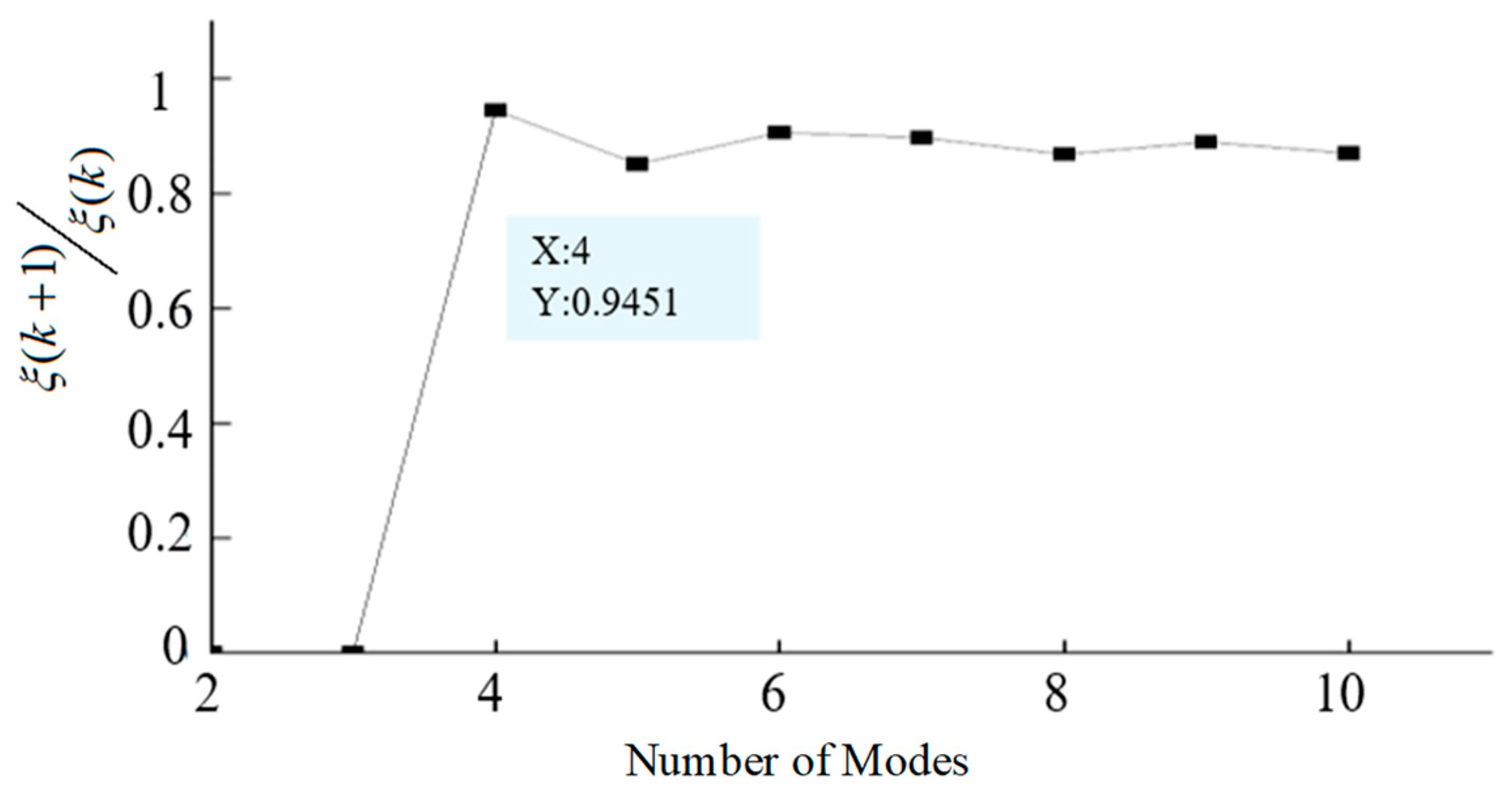

Optimization of VMD was performed using the ISBOA, yielding the optimal combination of decomposition parameters as α = 6 and K = 3000. To validate the effectiveness of the optimized VMD method, the decomposition results under different parameter conditions were extracted and compared. In the experiment, α = 3000 was selected, and K was set to 4, 5, 6, and 7, respectively, to perform feature frequency decomposition of the signal under different K values. The results are shown in

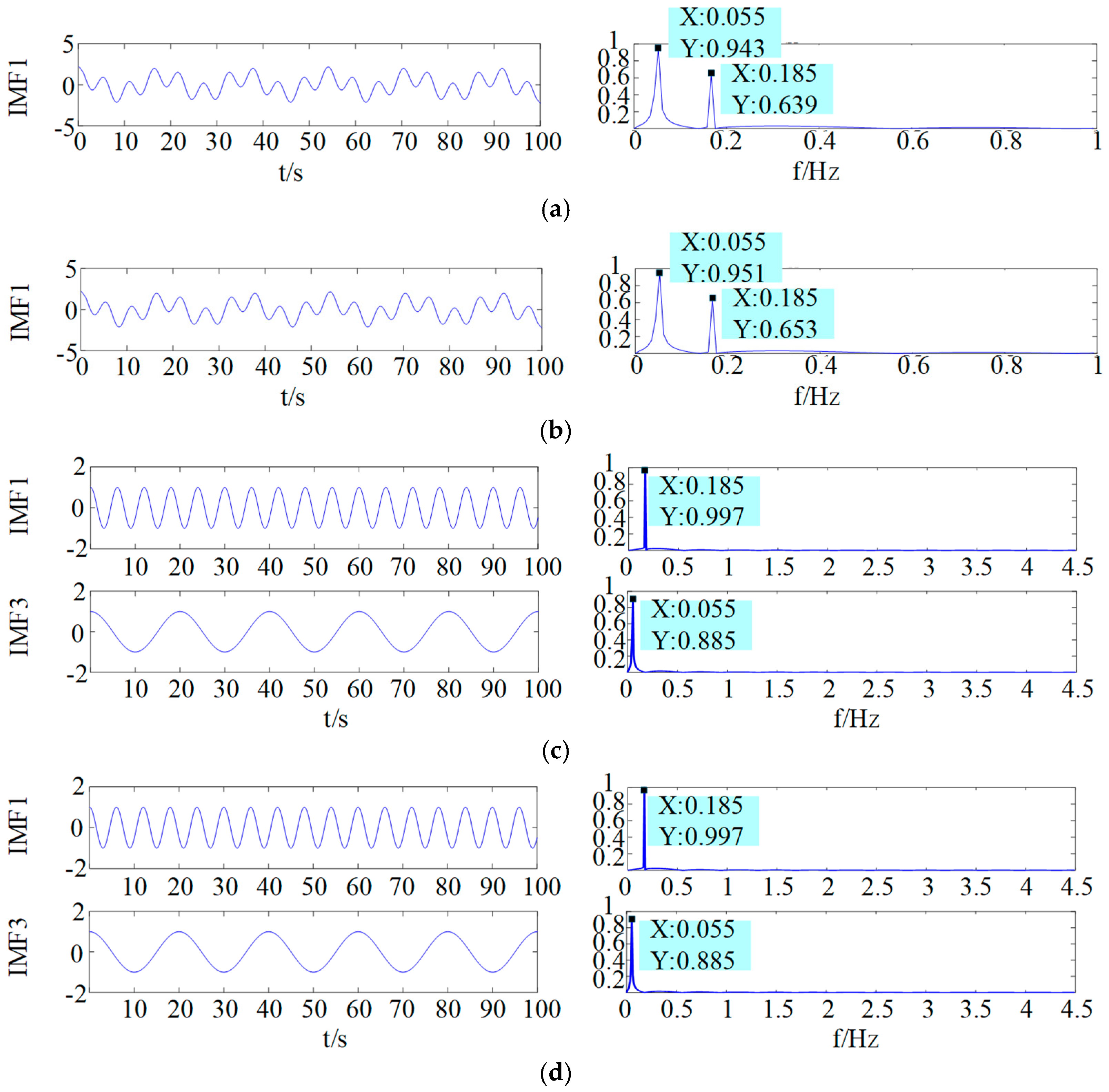

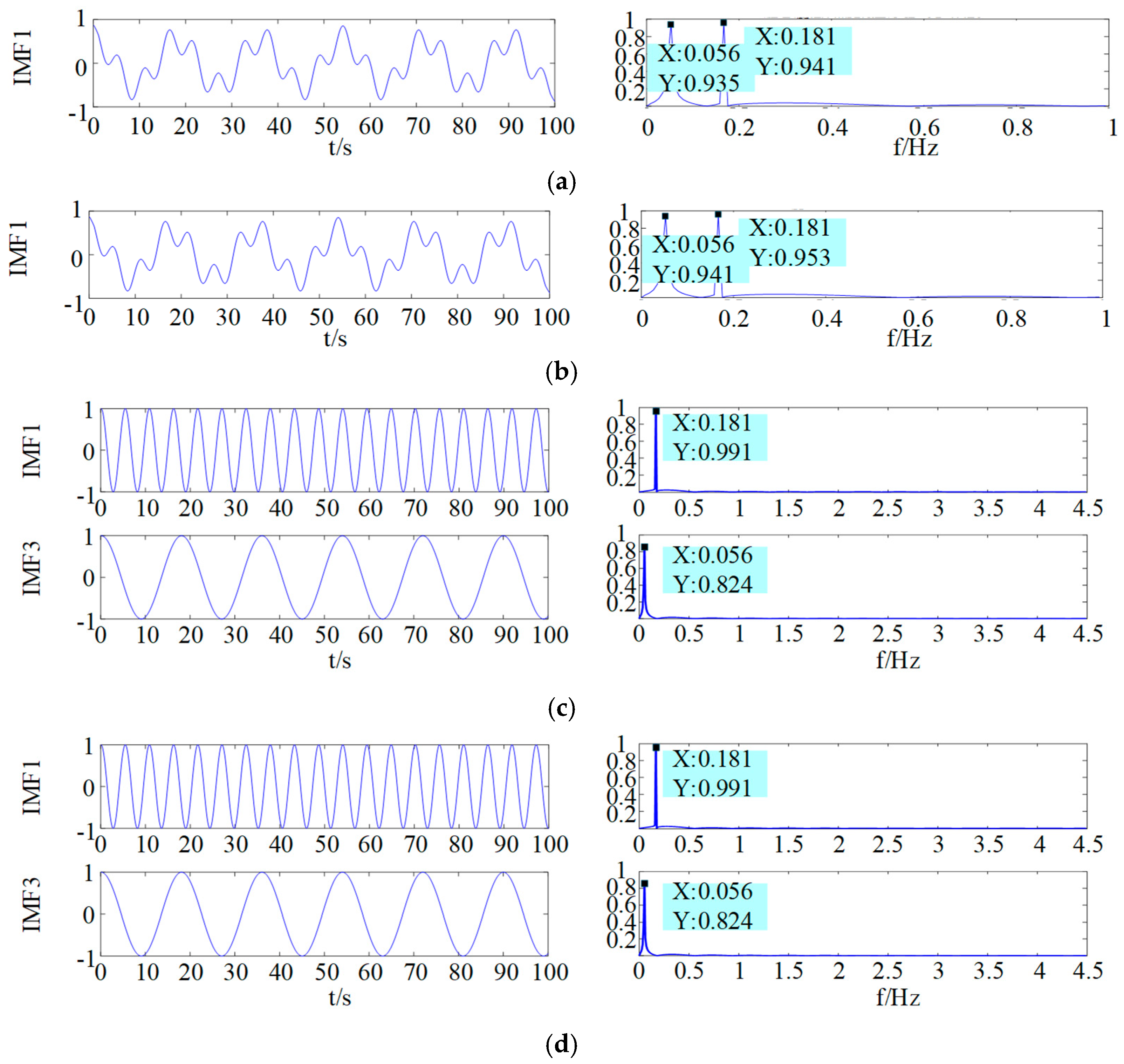

Figure 6.

In

Figure 6, insufficient decomposition occurs when K = 4 and K = 5, indicating that under these conditions, the signal fails to effectively decompose all signal components, resulting in insufficient decomposition. When K = 6 in

Figure 6, the input signal is completely decomposed. As the value of K increases, the decomposition of the signal remains virtually unchanged, indicating that the signal components have been sufficiently decomposed.

Therefore, ISBOA-VMD exhibits good signal retention characteristics during signal decomposition, effectively decomposing the rotary kiln displacement signal according to different frequency bands and retaining key information in the signal. Compared with other signal analysis methods, ISBOA-VMD has higher accuracy and can provide accurate and effective feature signals for the actual fault diagnosis of rotary kilns.

5. Conclusions

This paper proposes the ISBOA-VMD method, which combines the improved secretary bird optimization algorithm with VMD. It introduces random inertial weights and the whale algorithm to implement strategies for consuming and surrounding prey, effectively solving the problems of low convergence efficiency and getting stuck in local optima in the secretary bird algorithm.

To address the issue that the selection of modal numbers and quadratic penalty terms for VMD heavily relies on exhaustive search methods, the ISBOA was proposed and validated through simulation tests. The results demonstrated that ISBOA exhibited superior stability and convergence accuracy in the experiments. In experimental signal testing, the results showed that the improved algorithm achieved better convergence accuracy and stability, with a 75% improvement over previous methods, effectively enabling parameter selection for VMD and feature vector extraction for cement rotary kiln signals.

The VMD method, optimized with parameters, was used to decompose the rotary kiln signals and extract signals that reflect centerline deviation and thermal bending faults. Through energy mean comparison, it was found that the accuracy of the results was as high as 96.7% compared with the experimental results, indicating that the feature signals extracted by the VMD after parameter optimization can reflect the operating status of the rotary kiln, providing a strategic method for rotary kiln fault diagnosis.