Physical Support of Soldiers During CBRN Scenarios with Exoskeletons

Abstract

1. Introduction

2. Concept and Design

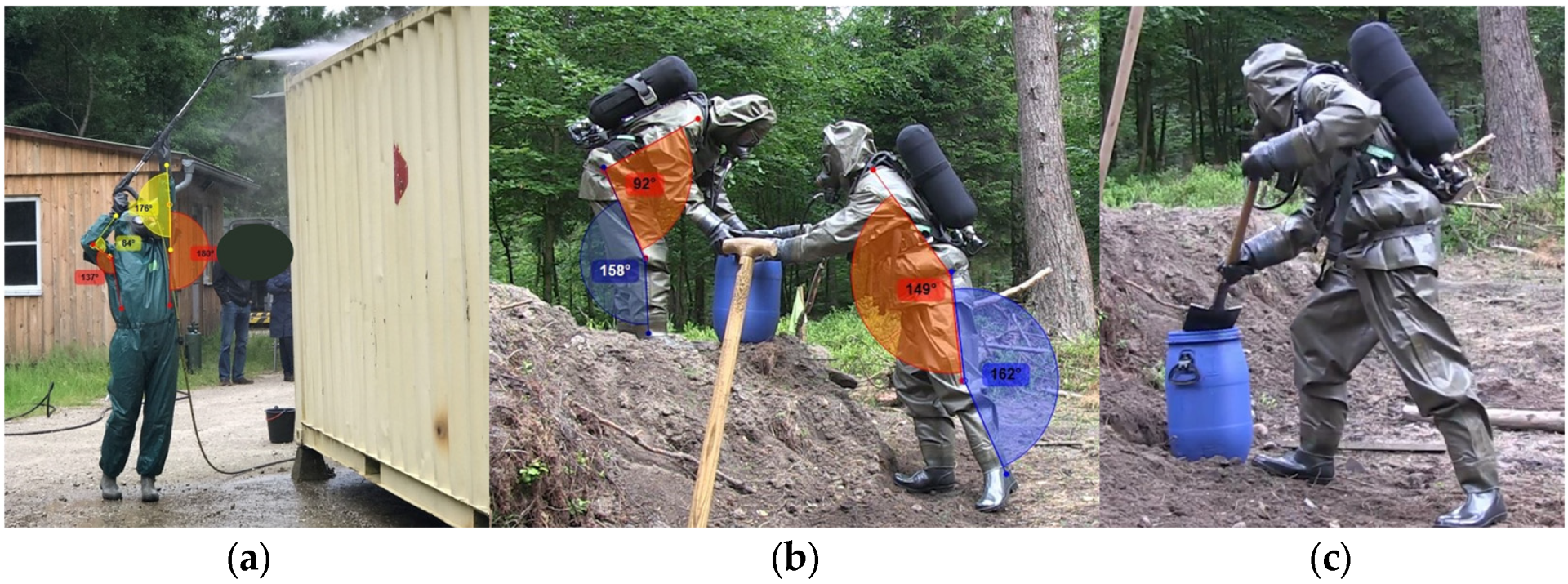

2.1. Requirements

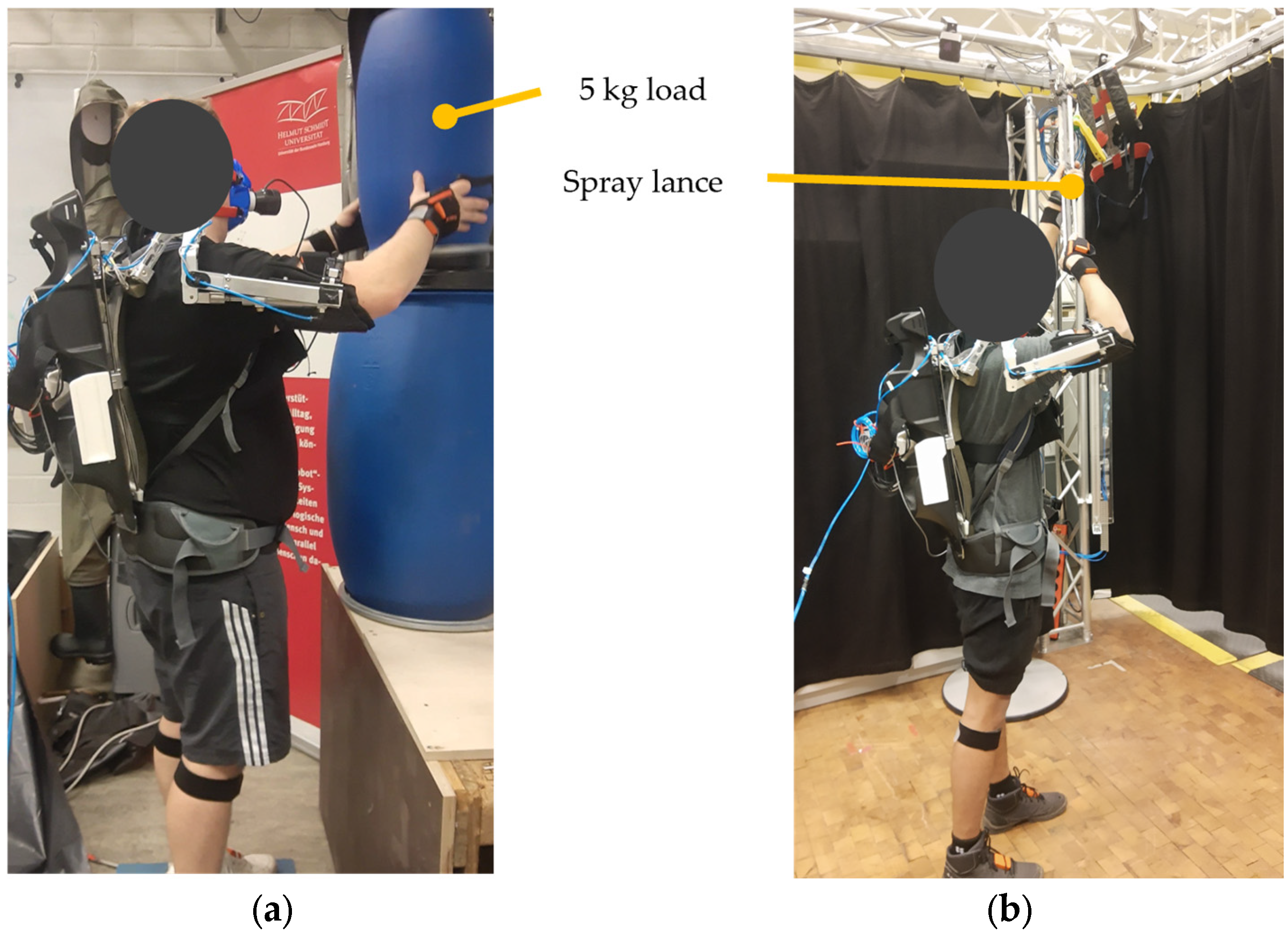

2.2. Design of Exoskeleton for Shoulder Support

- (1)

- Actuation and Sensing—The actuation of the shoulder–neck exoskeleton is based on a proven pneumatic concept derived from the “Lucy” support system [23]. A pneumatic cylinder induces a linear stroke that generates torque (TExo) in the sagittal plane at the shoulder joint, depending on the shoulder flexion angle. The shoulder angle is measured using a rotary potentiometer integrated into the joint mechanism of the exoskeleton. The exoskeleton provides a peak assistance of approximately 8 Nm per shoulder joint at a system pressure of 5 bar, corresponding to an actuator force of 45 N.

- (2)

- Control Module—The control module is integrated as a compact and protected unit mounted laterally on the bracket for the compressed air cylinder. It includes three 9-volt batteries, a microcontroller (Arduino-based), solenoid valves, and an inertial measurement unit (IMU). All electrical and pneumatic connections are sealed to IP68 standard. The microcontroller processes input from the user interface and sensor data, including arm position from a potentiometer, torso inclination from the IMU, and internal system pressure from pressure sensors. A predefined force profile, modeled as a parabolic curve based on the biomechanical loading of the shoulder joint relative to arm angle [24], determines the level of support. Assistance begins at approximately 35° of arm elevation, increases to a peak at 90°, and then tapers off. The user can adjust the overall level of support via the potentiometer to tailor the assistance to task demands or personal preference. The overall control structure including the calculation of the reference pressure and the characteristics of the actuator are already described in detail by Otten et al. [23].

- (3)

- Back Structure—The back structure is designed to be as lightweight as possible while maintaining mechanical stability. A thin metal plate spans from the shoulder mechanism to the pelvic region, forming the main load path that transmits forces from the shoulders to the pelvis. The two-piece plate can be adjusted in length via an overlap and clamp mechanism, allowing for user-specific sizing. The upper segment is slightly thicker to enhance stiffness. Two fiberglass rods run parallel to the plate from the hip belt to the coupling interface, transferring the weight of respiratory gear, the compressed air tank, and control module into the pelvic region. The metal plate mimics the double-S shape of the human spine, providing a low-profile fit and facilitating upper-body mobility, including torso rotation. The structural design of the exoskeleton follows a backpack-like principle, allowing for intuitive and secure donning. A padded shoulder strap at the upper end of the metal backplate and a pelvic belt at the lower end ensure that the system’s weight is evenly distributed across the shoulders and hips.

- (4)

- Shoulder Mechanism and Degrees of Freedom—The shoulder mechanism offers two passive degrees of freedom (frontal and transversal rotation) and one actively actuated degree (sagittal rotation), allowing for high motion fidelity. To accommodate different users and enabling anthropometric fitting, the shoulder unit is fully adjustable in width and height.

- (5)

- Arm Interface—Assistance is transmitted to the user via a semi-open arm shell, 3D-printed from PLA, which distributes force broadly over the upper arm. The modular design allows complete replacement for different arm sizes. The shell is secured with a fastening strap and reinforced on both sides by durable textile bands with magnetic FIDLOCK® closures (www.fidlock.com), ensuring a stable fit during use. The inner lining consists of 2 cm thick PPI 10 polyurethane soft foam, selected for its pollutant-free, antibacterial, anti-allergenic, elastic, and moisture-resistant properties.

- (6)

- Coupling Interface—The coupling element enables quick attachment of the respiratory equipment to the exoskeleton. The breathing gas cylinder is mounted directly to the back frame. Pneumatic lines delivering compressed air to the actuator pass through sealed ports in the protective suit. A clamping nut secures the interface by clamping the suit material between the exoskeleton and the external coupling unit, maintaining airtight integrity in contaminated environments.

3. Evaluation

- Localized muscular unloading in target areas addressed by the exoskeleton (electromyography),

- Global physiological load or relief (spiroergometry),

- Alterations in movement patterns during task execution (motion capture) as well as

- Subjective perception of exertion or system-induced relief (questionnaire).

3.1. Participants

3.2. Biomechanical Measurement Instruments

3.3. Measures

- Control—Condition without any exoskeleton as well as

- Intervention—Condition while using the shoulder-support exoskeleton (set to 100% assistance).

3.4. Data Analysis

3.5. Statistical Analysis

4. Results

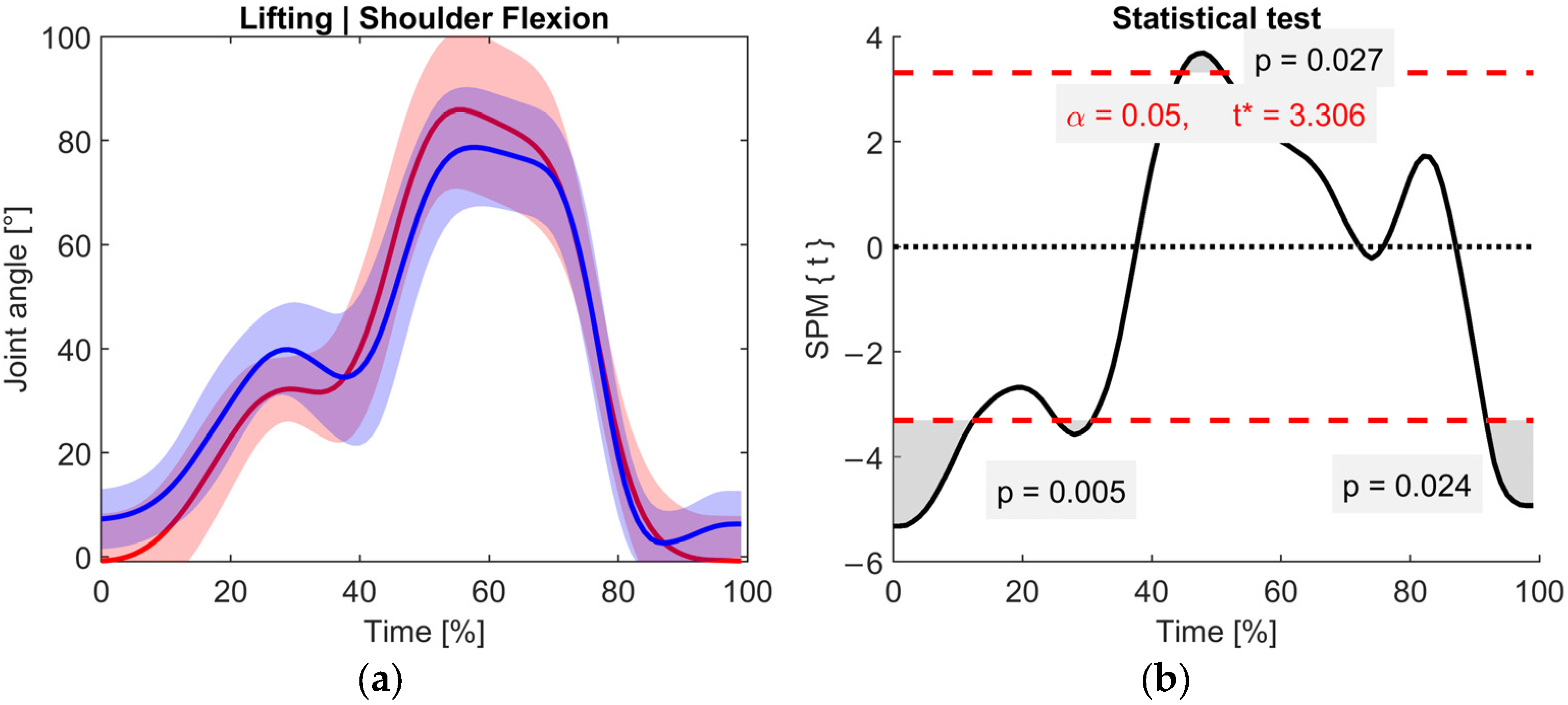

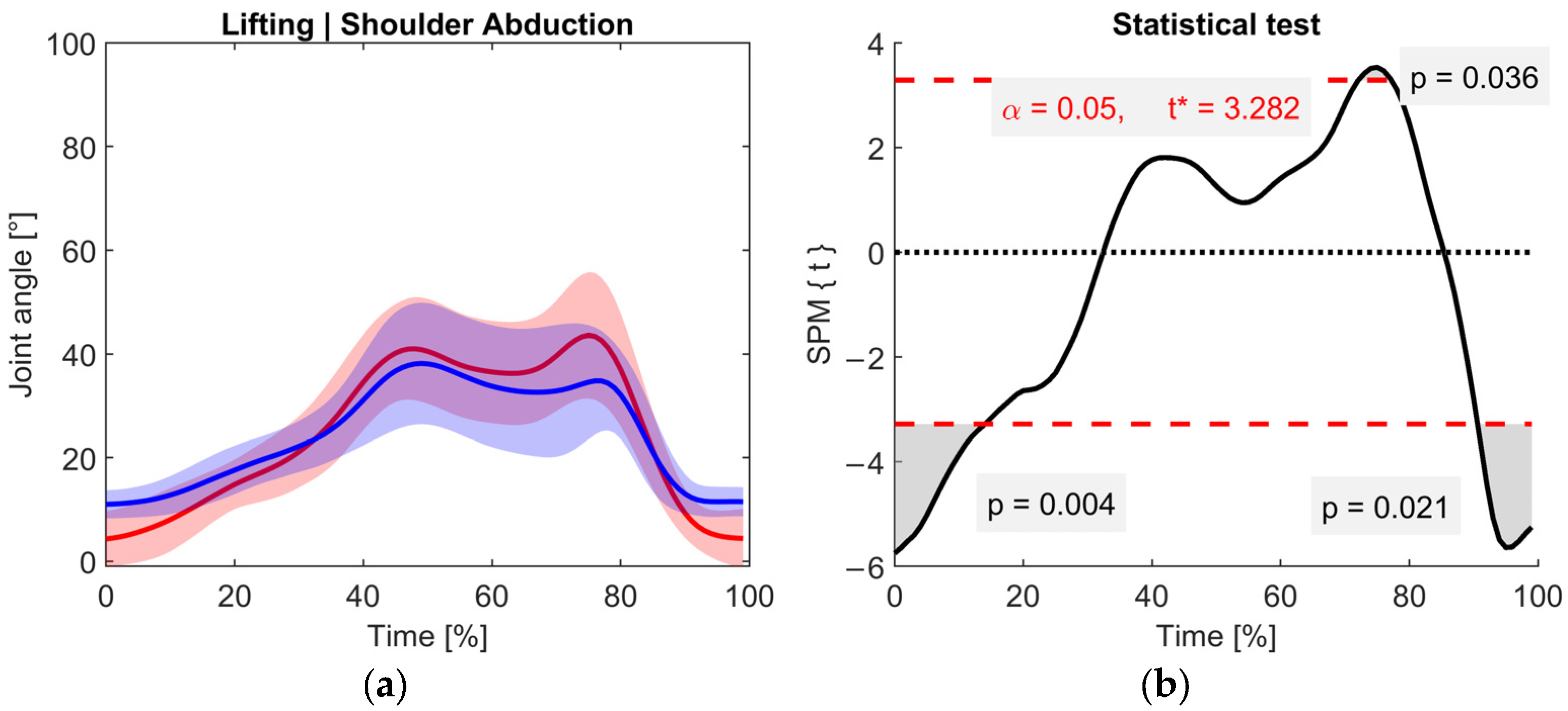

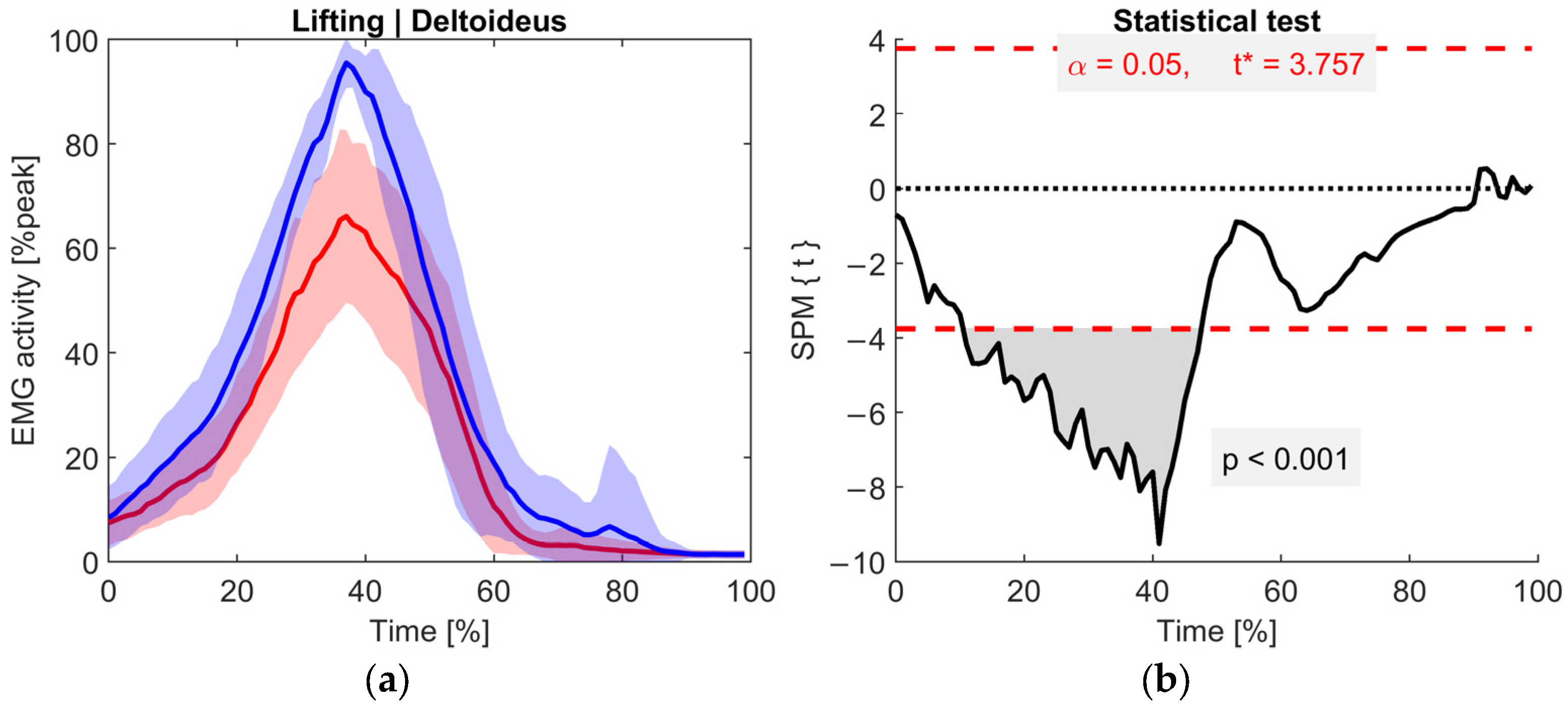

4.1. Lifting Task with Shoulder Exoskeleton

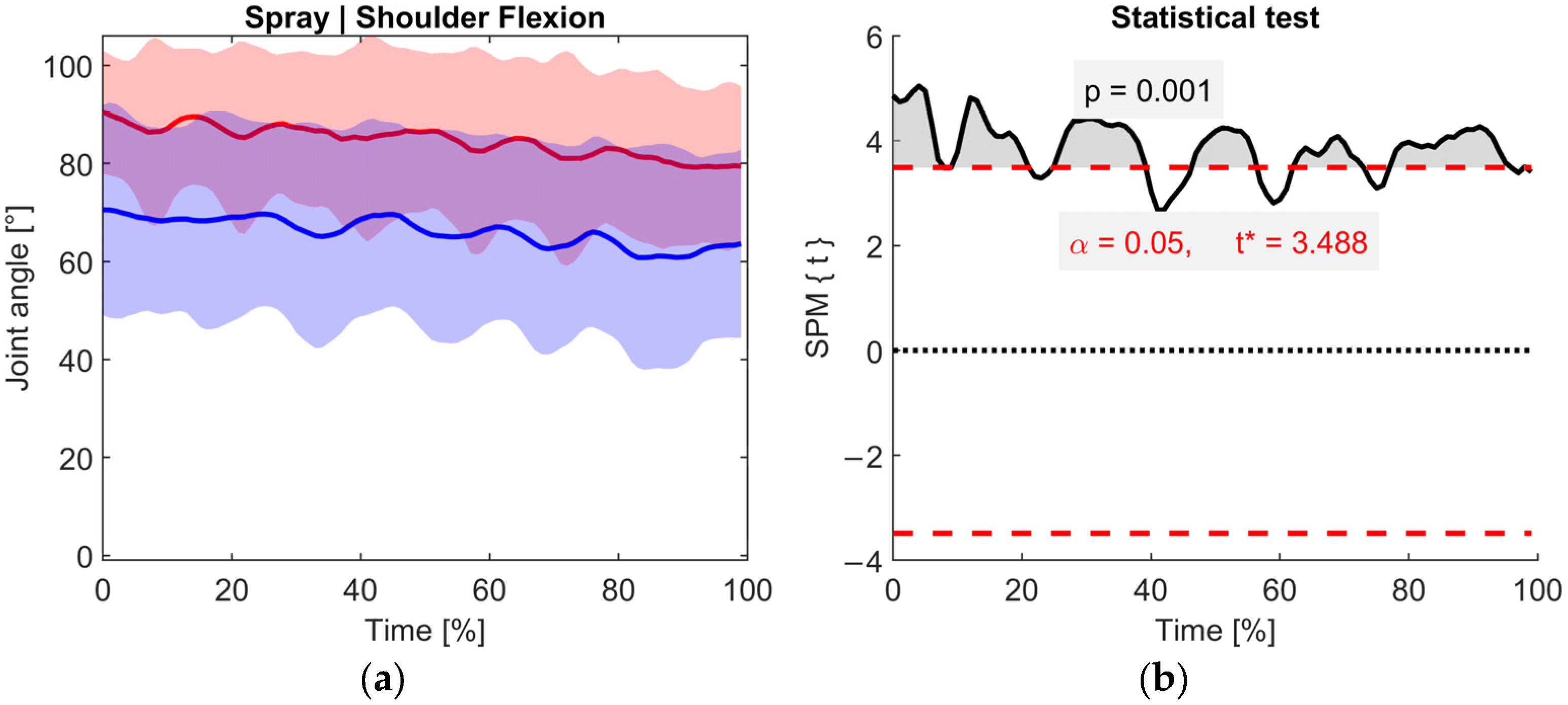

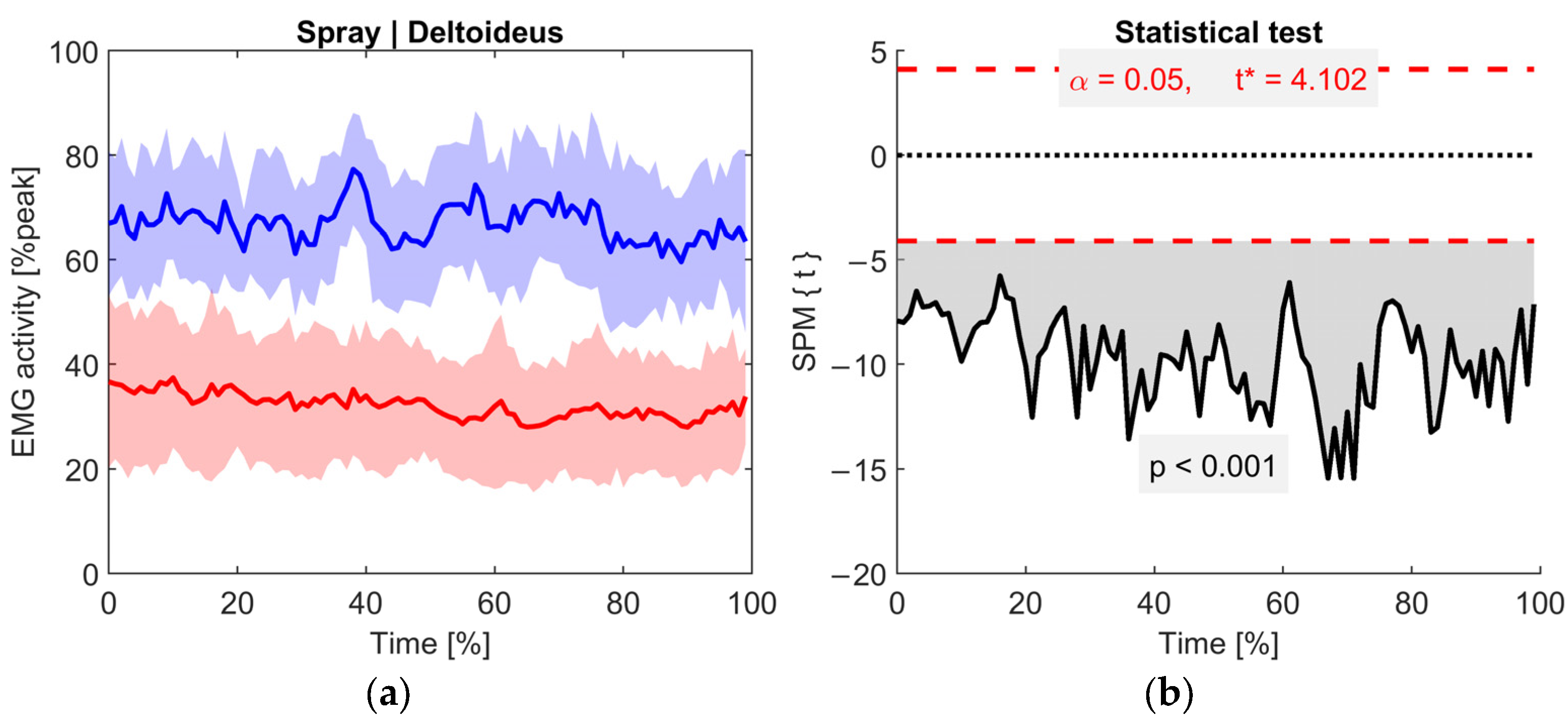

4.2. Horizontal Spraying Task with Shoulder Exoskeleton

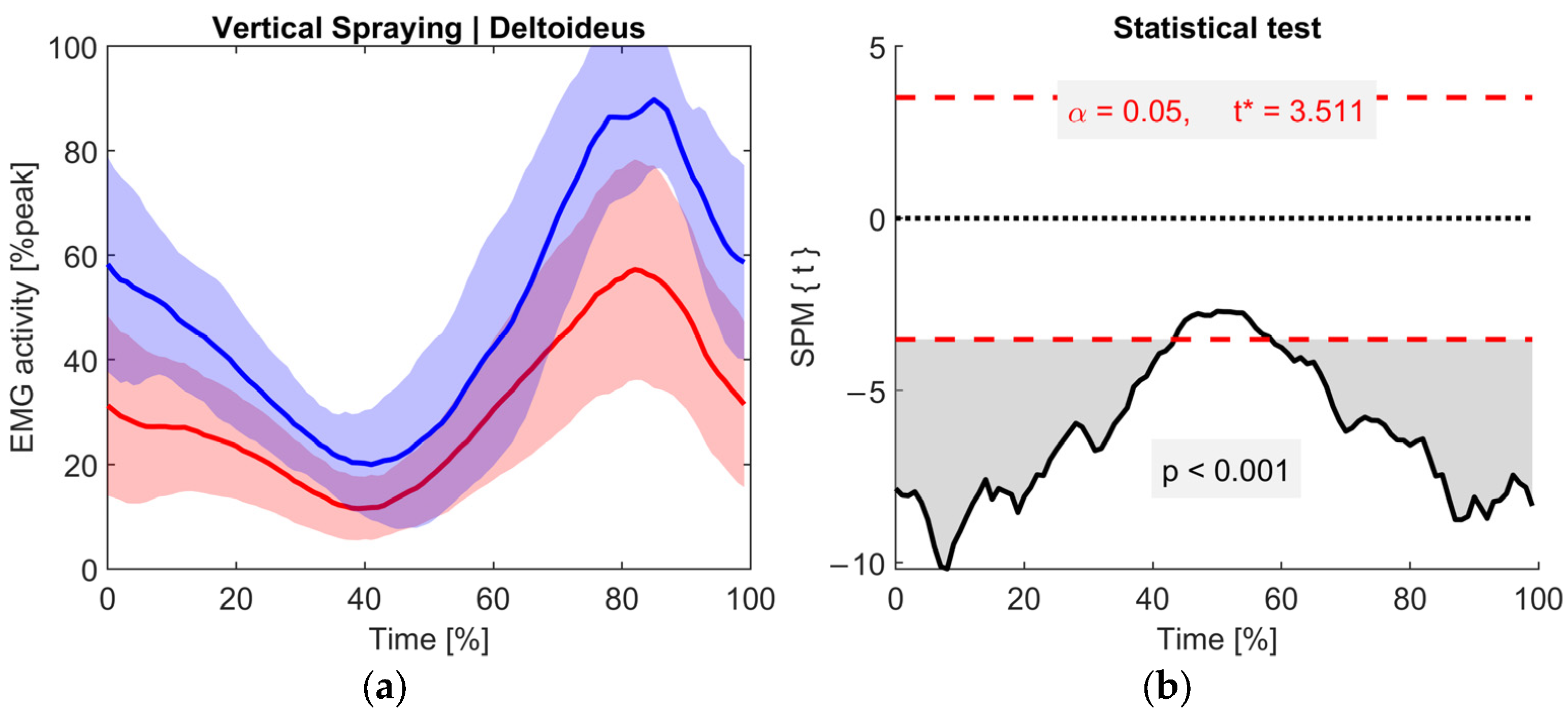

4.3. Vertical Spraying Task with Shoulder Exoskeleton

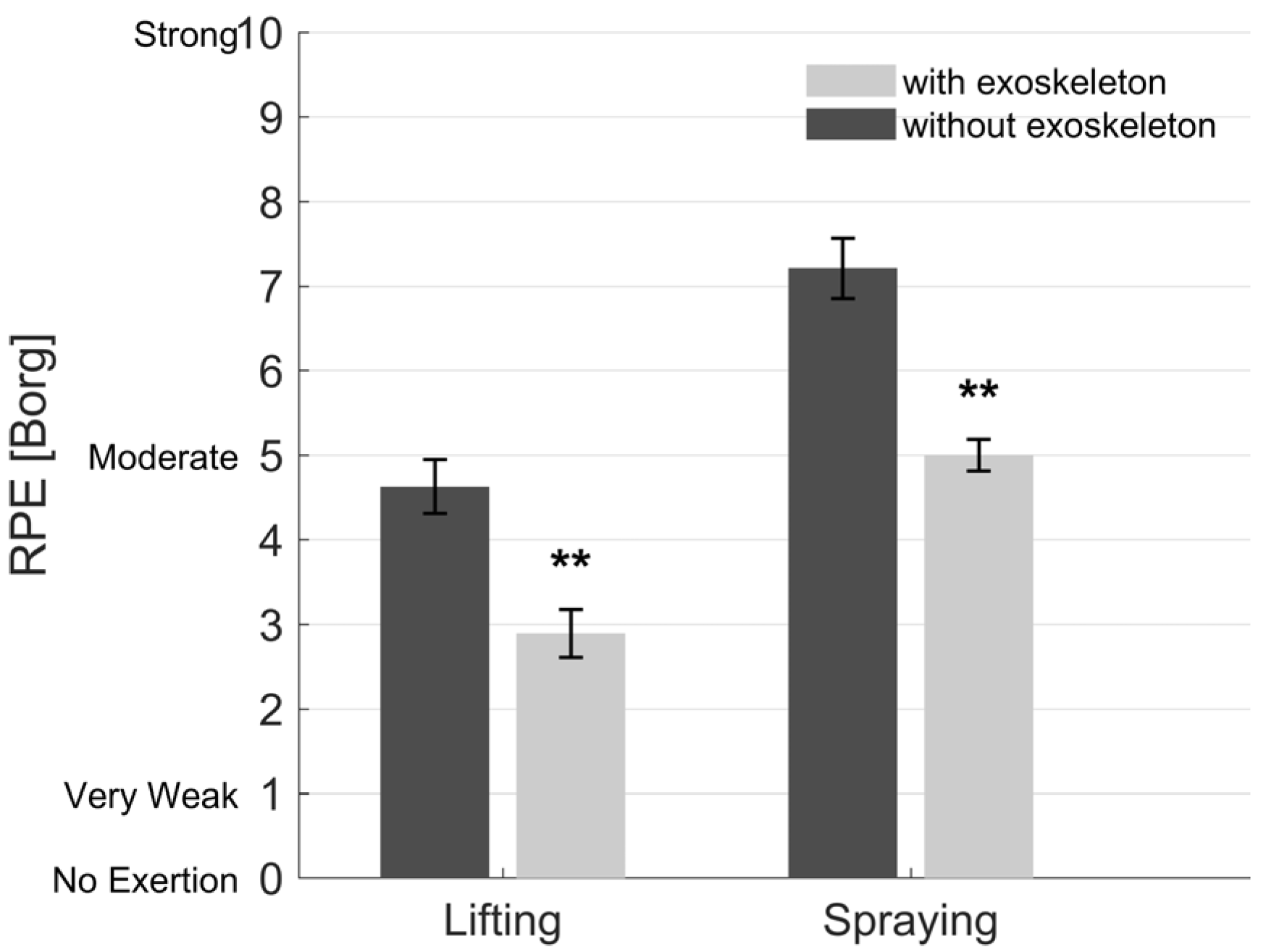

4.4. Subjective Strain Perception

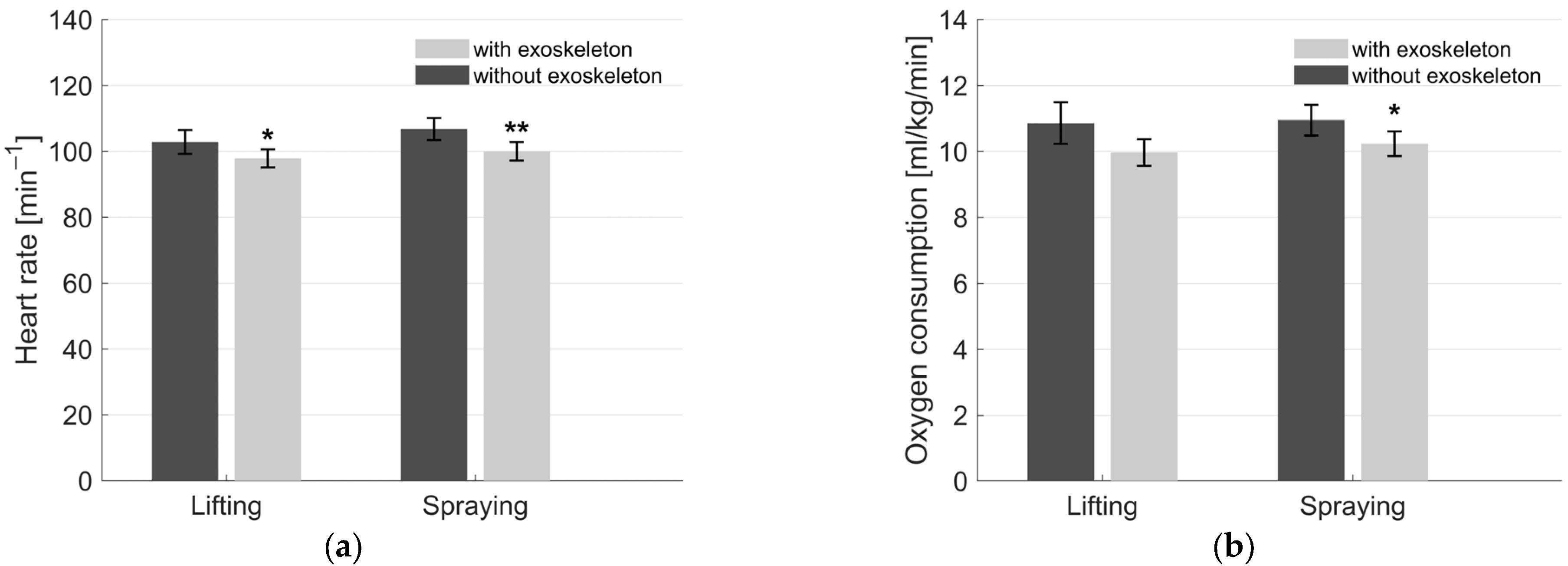

4.5. Workload Analysis

5. Discussion

5.1. Biomechanical Parameters

5.2. Metabolic Parameters

5.3. Subjective Perceived Exertion

5.4. Limitations of the Study

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Orr, R.; Pope, R.; Lopes, T.J.A.; Leyk, D.; Blacker, S.; Bustillo-Aguirre, B.S.; Knapik, J.J. Soldier Load Carriage, Injuries, Rehabilitation and Physical Conditioning: An International Approach. Int. J. Environ. Res. Public Health 2021, 18, 4010. [Google Scholar] [CrossRef] [PubMed]

- Farris, D.J.; Harris, D.J.; Rice, H.M.; Campbell, J.; Weare, A.; Risius, D.; Armstrong, N.; Rayson, M.P. A systematic literature review of evidence for the use of assistive exoskeletons in defence and security use cases. Ergonomics 2023, 66, 61–87. [Google Scholar] [CrossRef]

- Sammito, S.; Hadzic, V.; Karakolis, T.; Kelly, K.R.; Proctor, S.P.; Stepens, A.; White, G.; Zimmermann, W.O. Risk factors for musculoskeletal injuries in the military: A qualitative systematic review of the literature from the past two decades and a new prioritizing injury model. Mil. Med. Res. 2021, 8, 66. [Google Scholar] [CrossRef] [PubMed]

- Linnenberg, C.; Klabunde, J.; Hagner, K.; Weidner, R. Exoskeletons for Unarmed Military Use: Requirements and Approaches to Support Human Movements Using an Example of Protection Against Unknown CBRN Dangers. In Wearable Robotics, Proceedings of the 5th International Symposium on Wearable Robotics, WeRob2020, and of WearRAcon Europe 2020, Online, 13–16 October 2020; International Symposium on Wearable, Robotics; Moreno, J.C., Ed.; Springer International Publishing AG: Cham, Switzerland, 2022; pp. 535–539. ISBN 978-3-030-69547-7. [Google Scholar]

- Weidner, R.; Linnenberg, C.; Hoffmann, N.; Prokop, G.; Edwards, V. Exoskelette für den industriellen Kontext: Systematisches Review und Klassifikation. In Digitale Arbeit, Digitaler Wandel, Digitaler Mensch? 66. Kongress der Gesellschaft für Arbeitswissenschaft, Berlin; Gesellschaft für Arbeitswissenschaft e.V., Ed.; GfA-Press: Berlin, Germany, 2020. [Google Scholar]

- Cooper, R.A.; Smolinski, G.; Candiotti, J.L.; Satpute, S.; Grindle, G.G.; Sparling, T.L.; Nordstrom, M.J.; Yuan, X.; Symsack, A.; Dae Lee, C.; et al. Current State, Needs, and Opportunities for Wearable Robots in Military Medical Rehabilitation and Force Protection. Actuators 2024, 13, 236. [Google Scholar] [CrossRef] [PubMed]

- Proud, J.K.; Lai, D.T.H.; Mudie, K.L.; Carstairs, G.L.; Billing, D.C.; Garofolini, A.; Begg, R.K. Exoskeleton Application to Military Manual Handling Tasks. Hum. Factors 2022, 64, 527–554. [Google Scholar] [CrossRef]

- Leova, L.; Cubanova, S.; Kutilek, P.; Volf, P.; Hejda, J.; Hybl, J.; Stastny, P.; Vagner, M.; Krivanek, V. Current State and Design Recommendations of Exoskeletons of Lower Limbs in Military Applications. In Modelling and Simulation for Autonomous Systems: 8th International Conference, MESAS 2021, Virtual Event, 13–14 October 2021, Revised Selected Papers, 1st ed.; Mazal, J., Fagiolini, A., Vasik, P., Turi, M., Bruzzone, A., Pickl, S., Neumann, V., Stodola, P., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 452–463. ISBN 978-3-030-98259-1. [Google Scholar]

- Jia-Yong, Z.; Ye, L.I.; Xin-Min, M.O.; Chong-Wei, H.A.; Xiao-Jing, M.; Qiang, L.I.; Yue-Jin, W.; Ang, Z. A preliminary study of the military applications and future of individual exoskeletons. J. Phys. Conf. Ser. 2020, 1507, 102044. [Google Scholar] [CrossRef]

- Tian, J.; Wei, B.; Luo, S.; Yang, C.; Chen, C.; Liu, Y.; Feng, J.; Li, P.; Zhu, H.; Yi, C. A Systematic Review of Occupational Shoulder Exoskeletons for Industrial Use: Mechanism Design, Actuators, Control, and Evaluation Aspects. Actuators 2024, 13, 501. [Google Scholar] [CrossRef]

- Carnazzo, C.; Spada, S.; Ghibaudo, L.; Eaton, L.; Fajardo, I.; Zhu, S.; Cavatorta, M.P. Exoskeletons in Automotive Industry: Investigation into the Applicability Across Regions. In Proceedings of the 21st Congress of the International Ergonomics Association (IEA 2021), Online, 13–18 June 2021, Volume III: Sector Based Ergonomics; Congress of the International Ergonomics Association; Black, N.L., Neumann, W.P., Noy, I., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 398–406, ISBN 978-3-030-74608-7. [Google Scholar]

- Reyes, F.A.; Shuo, D.; Yu, H. Shoulder-Support Exoskeletons for Overhead Work: Current State, Challenges and Future Directions. IEEE Trans. Med. Robot. Bionics 2023, 5, 516–527. [Google Scholar] [CrossRef]

- Maurice, P.; Camernik, J.; Gorjan, D.; Schirrmeister, B.; Bornmann, J.; Tagliapietra, L.; Latella, C.; Pucci, D.; Fritzsche, L.; Ivaldi, S.; et al. Objective and Subjective Effects of a Passive Exoskeleton on Overhead Work. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 152–164. [Google Scholar] [CrossRef]

- Fritzsche, L.; Galibarov, P.E.; Gärtner, C.; Bornmann, J.; Damsgaard, M.; Wall, R.; Schirrmeister, B.; Gonzalez-Vargas, J.; Pucci, D.; Maurice, P.; et al. Assessing the efficiency of exoskeletons in physical strain reduction by biomechanical simulation with AnyBody Modeling System. Wearable Technol. 2021, 2, e6. [Google Scholar] [CrossRef]

- Mänttäri, S.; Rauttola, A.-P.; Halonen, J.; Karkulehto, J.; Säynäjäkangas, P.; Oksa, J. Effects of an exoskeleton on muscle activity in tasks requiring arm elevation: Part I—Experiments in a controlled laboratory setting. Work 2024, 77, 1179–1188. [Google Scholar] [CrossRef]

- Rafique, S.; Rana, S.M.; Bjorsell, N.; Isaksson, M. Evaluating the advantages of passive exoskeletons and recommendations for design improvements. J. Rehabil. Assist. Technol. Eng. 2024, 11, 20556683241239875. [Google Scholar] [CrossRef]

- Gillette, J.C.; Saadat, S.; Butler, T. Electromyography-based fatigue assessment of an upper body exoskeleton during automotive assembly. Wearable Technol. 2022, 3, e23. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, A. Stuttgart Exo-Jacket: An exoskeleton for industrial upper body applications. In Proceedings of the 2017 10th International Conference on Human System Interactions (HSI), Proceedings: International Hall, University of Ulsan, Ulsan, Republic of Korea, 17–19 July 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 258–263, ISBN 978-1-5090-4688-1. [Google Scholar]

- Nagwekar, R.; Sonnenschein, J.; Latifi, S.M.M.; Gökay, R.; Weidner, R. Biomechanical Study of Passive and Active Exoskeletons for Analyzing the Dependent Parameters for an Intelligent Control System. In Proceedings of the 11th International Conference on Control, Automation and Robotics (ICCAR), Kyoto, Japan, 18–20 April 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 252–257, ISBN 979-8-3315-2026-7. [Google Scholar]

- Shuvo, I.I.; Dolez, P.I. Design of a military protective suit against biological agents. In Functional and Technical Textiles; Maity, S., Singha, K., Pandit, P., Eds.; Woodhead Publishing: Cambridge, UK, 2023; pp. 141–176. ISBN 978-0-323-91593-9. [Google Scholar]

- Harmata, W.; Wachna, P. Soldier protection in the defence system against weapons of mass destruction. Bull. Mil. Univ. Technol. 2024, 73, 21–38. [Google Scholar] [CrossRef]

- Preethichandra, D.M.G.; Piyathilaka, L.; Sul, J.-H.; Izhar, U.; Samarasinghe, R.; Arachchige, S.D.; de Silva, L.C. Passive and Active Exoskeleton Solutions: Sensors, Actuators, Applications, and Recent Trends. Sensors 2024, 24, 7095. [Google Scholar] [CrossRef]

- Otten, B.; Weidner, R.; Argubi-Wollesen, A. Evaluation of a Novel Active Exoskeleton for Tasks at or Above Head Level. IEEE Robot. Autom. Lett. 2018, 3, 2408–2415. [Google Scholar] [CrossRef]

- Wollesen, A.A.; Schubert, T.; Mattes, K.; Weidner, R. Assessment of shoulder asymmetry for the design of an exoskeleton. In Proceedings of the Congress of the European College of Sport Science (ECSS), Dublin, Ireland, 4–7 July 2018. [Google Scholar]

- Foster, C.; Florhaug, J.A.; Franklin, J.; Gottschall, L.; Hrovatin, L.A.; Parker, S.; Doleshal, P.; Dodge, C. A new approach to monitoring exercise training. J. Strength Cond. Res. 2001, 15, 109–115. [Google Scholar]

- Herman, L.; Foster, C.; Maher, M.A.; Mikat, R.P.; Porcari, J.P. Validity and reliability of the session RPE method for monitoring exercise training intensity. S. Afr. J. Sports Med. 2006, 18, 14. [Google Scholar] [CrossRef]

- Haddad, M.; Stylianides, G.; Djaoui, L.; Dellal, A.; Chamari, K. Session-RPE Method for Training Load Monitoring: Validity, Ecological Usefulness, and Influencing Factors. Front. Neurosci. 2017, 11, 612. [Google Scholar] [CrossRef]

- Pataky, T.C. One-dimensional statistical parametric mapping in Python. Comput. Methods Biomech. Biomed. Eng. 2012, 15, 295–301. [Google Scholar] [CrossRef]

- Garby, L.; Astrup, A. The relationship between the respiratory quotient and the energy equivalent of oxygen during simultaneous glucose and lipid oxidation and lipogenesis. Acta Physiol. Scand. 1987, 129, 443–444. [Google Scholar] [CrossRef] [PubMed]

- Kipp, S.; Byrnes, W.C.; Kram, R. Calculating metabolic energy expenditure across a wide range of exercise intensities: The equation matters. Appl. Physiol. Nutr. Metab. 2018, 43, 639–642. [Google Scholar] [CrossRef] [PubMed]

- De Bock, S.; Rossini, M.; Lefeber, D.; Rodriguez-Guerrero, C.; Geeroms, J.; Meeusen, R.; De Pauw, K. An Occupational Shoulder Exoskeleton Reduces Muscle Activity and Fatigue During Overhead Work. IEEE Trans. Biomed. Eng. 2022, 69, 3008–3020. [Google Scholar] [CrossRef]

- Park, S.; Jung, M.K.; Kim, K.; Lim, H.; Yoon, J.; Hyun, D.J. Correlations Between Biomechanical Variables and Subjective Measures of Satisfaction While Using a Passive Upper-Limb Exoskeleton for Overhead Tasks in the Field. IEEE Trans. Human-Mach. Syst. 2025, 55, 176–184. [Google Scholar] [CrossRef]

- McFarland, T.C.; McDonald, A.C.; Whittaker, R.L.; Callaghan, J.P.; Dickerson, C.R. Level of exoskeleton support influences shoulder elevation, external rotation and forearm pronation during simulated work tasks in females. Appl. Ergon. 2022, 98, 103591. [Google Scholar] [CrossRef]

- Mashud, G.; Hasan, S.K.; Alam, N. Advances in Control Techniques for Rehabilitation Exoskeleton Robots: A Systematic Review. Actuators 2025, 14, 108. [Google Scholar] [CrossRef]

- Pinho, J.P.; Forner-Cordero, A. Shoulder muscle activity and perceived comfort of industry workers using a commercial upper limb exoskeleton for simulated tasks. Appl. Ergon. 2022, 101, 103718. [Google Scholar] [CrossRef]

- Ding, S.; Reyes Francisco, A.; Li, T.; Yu, H. A novel passive shoulder exoskeleton for assisting overhead work. Wearable Technol. 2023, 4, e7. [Google Scholar] [CrossRef]

- Mänttäri, S.; Rauttola, A.-P.; Halonen, J.; Karkulehto, J.; Säynäjäkangas, P.; Oksa, J. Effects of upper-limb exoskeleton on muscle activity in tasks requiring arm elevation: Part II—In-field experiments in construction industry settings. Work 2024, 79, 753–763. [Google Scholar] [CrossRef] [PubMed]

- van Engelhoven, L.; Poon, N.; Kazerooni, H.; Rempel, D.; Barr, A.; Harris-Adamson, C. Experimental Evaluation of a Shoulder-Support Exoskeleton for Overhead Work: Influences of Peak Torque Amplitude, Task, and Tool Mass. IISE Trans. Occup. Ergon. Hum. Factors 2019, 7, 250–263. [Google Scholar] [CrossRef]

- Schmalz, T.; Schändlinger, J.; Schuler, M.; Bornmann, J.; Schirrmeister, B.; Kannenberg, A.; Ernst, M. Biomechanical and Metabolic Effectiveness of an Industrial Exoskeleton for Overhead Work. Int. J. Environ. Res. Public Health 2019, 16, 4792. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schubert, T.; Weidner, R. Physical Support of Soldiers During CBRN Scenarios with Exoskeletons. Appl. Sci. 2025, 15, 10763. https://doi.org/10.3390/app151910763

Schubert T, Weidner R. Physical Support of Soldiers During CBRN Scenarios with Exoskeletons. Applied Sciences. 2025; 15(19):10763. https://doi.org/10.3390/app151910763

Chicago/Turabian StyleSchubert, Tim, and Robert Weidner. 2025. "Physical Support of Soldiers During CBRN Scenarios with Exoskeletons" Applied Sciences 15, no. 19: 10763. https://doi.org/10.3390/app151910763

APA StyleSchubert, T., & Weidner, R. (2025). Physical Support of Soldiers During CBRN Scenarios with Exoskeletons. Applied Sciences, 15(19), 10763. https://doi.org/10.3390/app151910763