Barriers for Smart Manufacturing Implementation in SMEs: A Comprehensive Exploration and Practical Insights

Abstract

1. Introduction

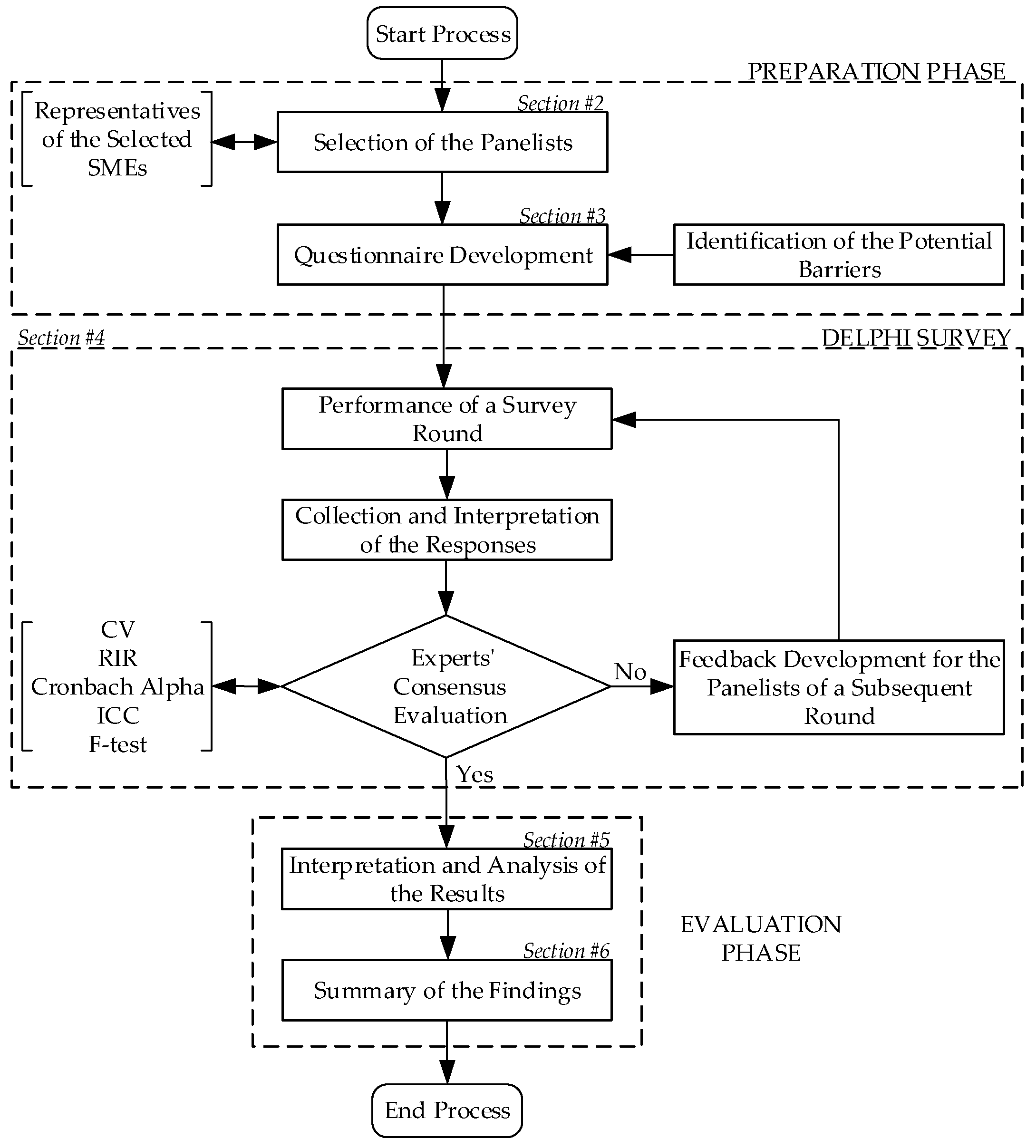

2. Methodological Framework

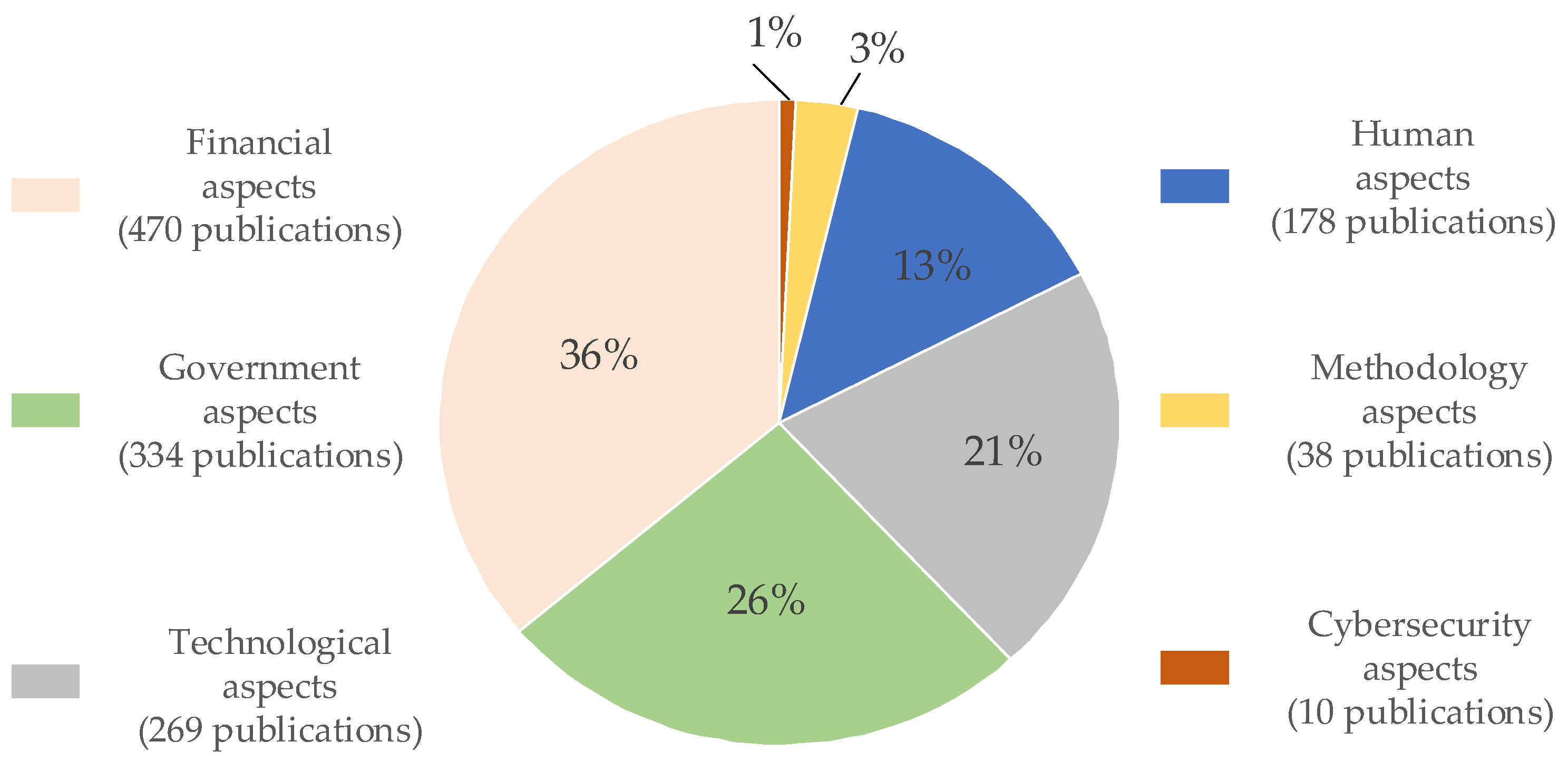

3. Identification of Potential Barriers for SM Implementation

4. Description of the Delphi Survey

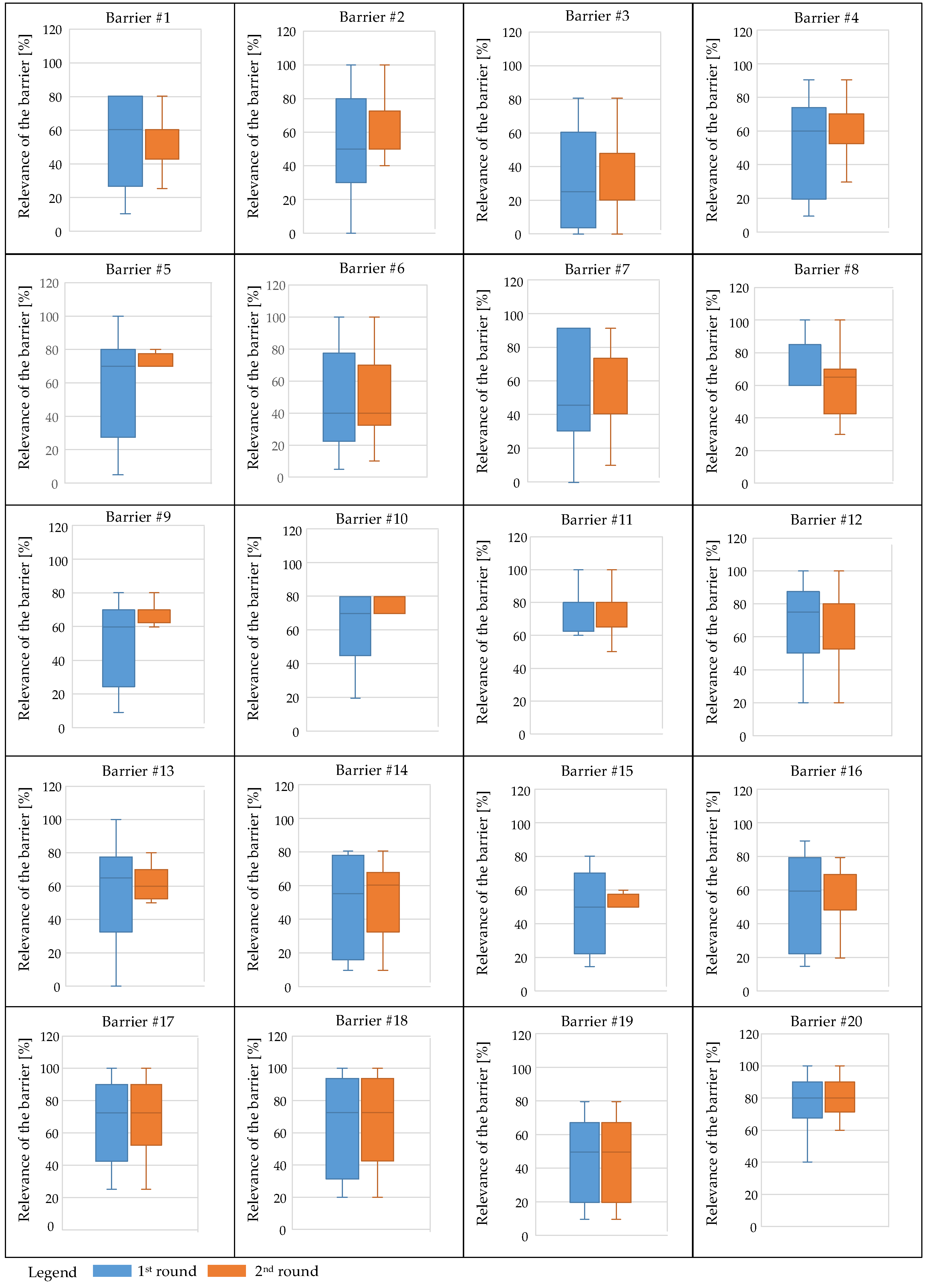

4.1. Performance of the Survey Rounds

4.2. Assessment of Responses’ Reliability

4.2.1. Evaluation of Internal Consistency After the First Round

- 0 ≤ CV ≤ 0.5—good degree of consensus, no additional round necessary,

- 0.5 < CV ≤ 0.8—less than satisfactory consensus, possible need for another round,

- 0.8 ≤ CV—poor degree of consensus, need for additional round.

- If 0 ≤ RIR ≤ 0.25, it means a very strong consensus, no additional round necessary,

- If 0.25 < RIR ≤ 0.50, it indicates less consensus—possible need for another round,

- 0.50 ≤ RIR, then there is a need for an additional round, due to a low consensus.

| α ≥ 0.9 | Excellent |

| 0.8 ≤ α < 0.9 | Good |

| 0.7 ≤ α < 0.8 | Acceptable |

| 0.6 ≤ α < 0.7 | Questionable |

| 0.5 ≤ α < 0.6 | Poor |

| α < 0.5 | Unacceptable |

| ICC ≥ 0.9 | Excellent reliability |

| 0.75 ≤ ICC < 0.9 | Good reliability |

| 0.5 ≤ ICC < 0.75 | Moderate reliability |

| ICC < 0.5 | Poor reliability |

4.2.2. Evaluation of Respondents’ Consensus After the Second Round

- -

- When analyzing the CV values of the 2nd round, a total of 75% of the items (15 of 20) achieved a good degree of consensus. The remaining items fell within the moderate range, suggesting a lower, but still acceptable level of agreement. Importantly, no item exceeded the threshold of CV > 0.8.

- -

- As regards the RIR values, 55% of the items (11 of 20) showed very strong consensus. Another 35% (7 items) were in the intermediate range, and only 4 items (20%) exceeded the threshold of 0.5.

- -

- In addition, the Cronbach’s alpha value was quantified as 0.816, indicating a good level of internal consistency and reliability of the questionnaire in this round. One can see that the level of respondents’ agreement in the second round increased by one level (from acceptable to good) compared to the first round.

- -

- When evaluating ICC values of the second round, ICC (2,1) equals 0.19 (poor agreement between individual experts), and in contrast, ICC (2,k) is 0.74, providing that the reliability of the panel’s mean rating is moderate, close to good. Based on that, it is demonstrated that the second round of the Delphi method effectively increased consensus within the expert panel.

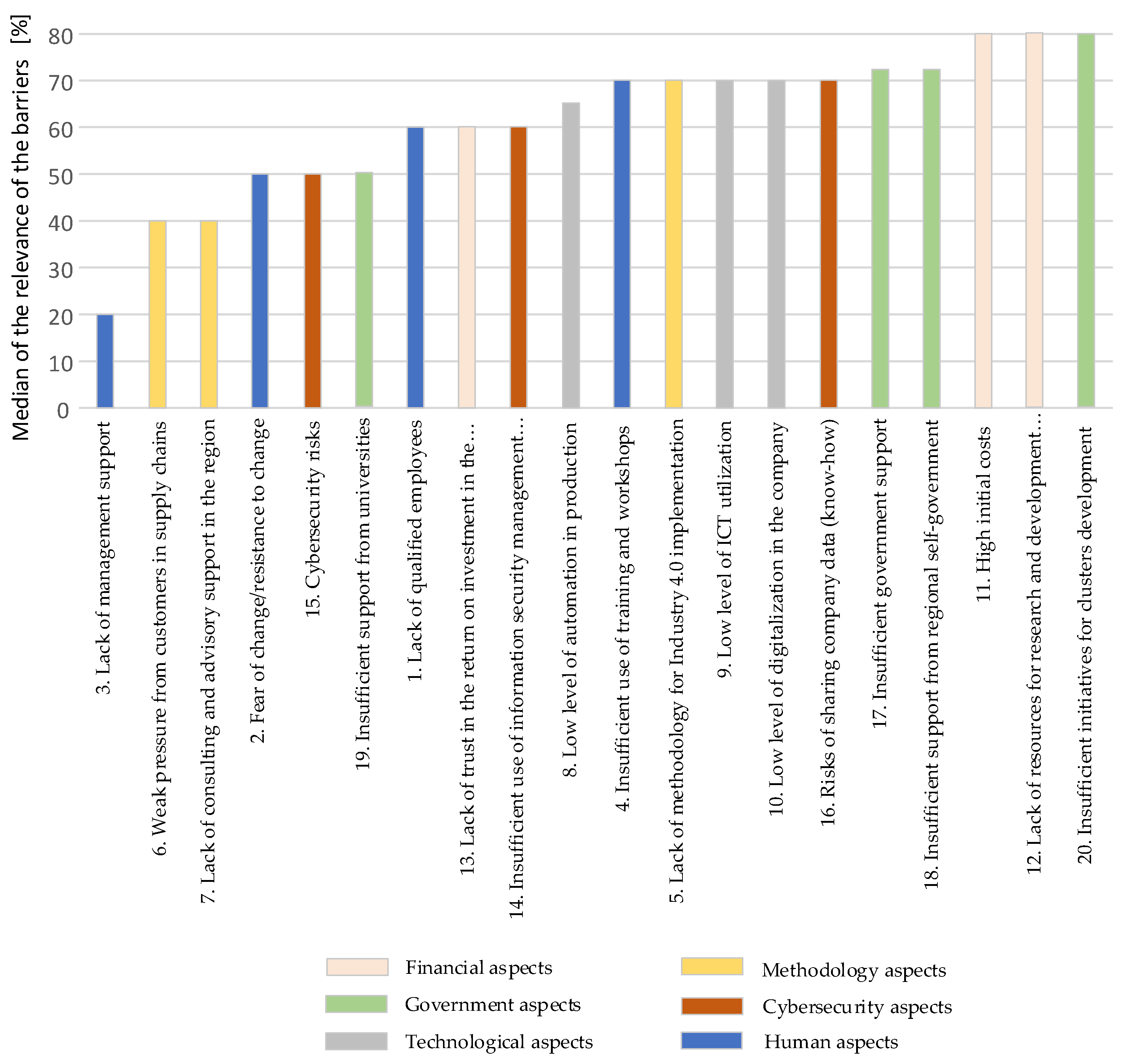

5. Discussion and Analyses of the Results

6. Conclusions and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart manufacturing and intelligent manufacturing: A comparative review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Modrak, V.; Sudhakarapandian, R.; Balamurugan, A.; Soltysova, Z. A review on reinforcement learning in production scheduling: An inferential perspective. Algorithms 2024, 17, 343. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Okkonen, H.; Mazhelis, O.; Ahokangas, P.; Pussinen, P.; Rajahonka, M.; Siuruainen, R.; Leminen, S.; Shveykovskiy, A.; Myllykoski, J.; Warma, H. Internet-of-Things Market, Value Networks, and Business Models: State of the Art Report. Computer Science and Information Systems Reports. TR-39. Technical Reports. 2013. Available online: https://jyx.jyu.fi/bitstreams/37eb8c0b-7d2d-4d8b-aa46-88d38f66f79e/download (accessed on 20 September 2025).

- Dai, G.; Huang, R.; Yuan, J.; Hu, Z.; Chen, L.; Lu, J.; Ji, F. Towards Flawless Designs: Recent Progresses in Non-Orthogonal Multiple Access Technology. Electronics 2023, 12, 4577. [Google Scholar] [CrossRef]

- Sammons, J.; Cross, M. The Basics of Cyber Safety: Computer and Mobile Device Safety Made Easy; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Munasser, H. Understanding the Adoption Challenges of IoT Among Small to Medium-Size Enterprises (SMEs): Study in Sweden, Dissertation, 2024. Available online: https://www.diva-portal.org/smash/get/diva2:1918587/FULLTEXT01.pdf (accessed on 20 May 2025).

- Mintzberg, H. Structure et Dynamique des Organisations; d’Organisation, V., Ed.; Eyrolles: Paris, France, 1982; p. 434. ISBN 978-2708119710. [Google Scholar]

- Moeuf, A.; Tamayo, S.; Lamouri, S.; Pellerin, R.; Lelievre, A. Strengths and Weaknesses of Small and Medium Sized Enterprises Regarding the Implementation of Lean Manufacturing. IFAC-PapersOnLine 2016, 49, 71–76. [Google Scholar] [CrossRef]

- Cullinan, C.; Sutton, S.G.; Arnold, V. Technology Monoculture: ERP Systems, ‘Techno-Process Diversity’ and the Threat to the Information Technology Ecosystem. In Advances in Accounting Behavioral Research; Arnold, V., Ed.; Emerald Group Publishing Limited: Bingley, UK, 2010; pp. 13–30. [Google Scholar] [CrossRef]

- Jeon, B.W.; Um, J.; Yoon, S.C.; Suk-Hwan, S. An architecture design for smart manufacturing execution system. Comput.-Aided Des. Appl. 2017, 14, 472–485. [Google Scholar] [CrossRef]

- Modrak, V.; Mandulak, J. Mapping Development of MES Functionalities. In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2009), Milan, Italy, 2–5 July 2009; pp. 244–247. [Google Scholar]

- Khairudin, S.M.H.H.S.; Amin, M. Towards Economic Growth—The Impact of Information Technology on Performance of SMEs. J. Secur. Sustain. Issues 2019, 9, 241–255. [Google Scholar] [CrossRef]

- Li, W.; Liu, K.; Belitski, M.; Ghobadian, A.; O’Regan, N. E-Leadership Through Strategic Alignment: An Empirical Study of Small- and Medium-Sized Enterprises in the Digital Age. J. Inf. Technol. 2016, 31, 185–206. [Google Scholar] [CrossRef]

- Robu, M. The dynamic and importance of SMEs in economy. USV Ann. Econ. Public Adm. 2013, 13, 84–89. [Google Scholar]

- Soltysova, Z.; Modrak, V. Challenges of the sharing economy for SMEs: A literature review. Sustainability 2020, 12, 6504. [Google Scholar] [CrossRef]

- Dalkey, N.; Helmer, O. An experimental application of the Delphi method to the use of experts. Manag. Sci. 1963, 9, 458–467. [Google Scholar] [CrossRef]

- Dalkey, N. Studies in the Quality of Life; Lexington Books: Lexington, MA, USA, 1972. [Google Scholar]

- Stone Fish, L.; Busby, D.M. The delphi technique. In Research Methods in Family Therapy, 2nd ed.; Sprenkle, D.H., Piercy, F.P., Eds.; Guilford: New York, NY, USA, 2005. [Google Scholar]

- Hasson, F.; Keeney, S. Enhancing rigour in the Delphi technique research. Technol. Forecast. Soc. Change 2011, 78, 695–1704. [Google Scholar] [CrossRef]

- Gossler, T.; Falagara Sigala, I.; Wakolbinger, T.; Buber, R. Applying the Delphi method to determine best practices for outsourcing logistics in disaster relief. J. Humanit. Logist. Supply Chain. Manag. 2019, 9, 438–474. [Google Scholar] [CrossRef]

- Nelson, A.J. Using a modified Delphi methodology to develop a competency model for vet practitioners. Partial Fulfillment of the Requirements of RM502E-Advanced Study in Research Methods, 2002. Available online: https://www.researchgate.net/publication/228918594_Using_a_modified_Delphi_methodology_to_develop_a_competency_model_for_VET_practitioners (accessed on 20 September 2025).

- Memon, M.A.; Ting, H.; Cheah, J.H.; Thurasamy, R.; Chuah, F.; Cham, T.H. Sample size for survey research: Review and recommendations. J. Appl. Struct. Equ. Model. 2020, 4, i–xx. [Google Scholar] [CrossRef]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular economy in Spanish SMEs: Challenges and opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.; Dwivedi, Y.K. Application of industry 4.0 technologies in SMEs for ethical and sustainable operations: Analysis of challenges. J. Clean. Prod. 2020, 275, 124063. [Google Scholar] [CrossRef]

- Bocken, N.M. Sustainable venture capital–catalyst for sustainable start-up success? J. Clean. Prod. 2015, 108, 647–658. [Google Scholar] [CrossRef]

- Gandhi, N.S.; Thanki, S.J.; Thakkar, J.J. Ranking of drivers for integrated lean-green manufacturing for Indian manufacturing SMEs. J. Clean. Prod. 2018, 171, 675–689. [Google Scholar] [CrossRef]

- Soluk, J.; Kammerlander, N. Digital transformation in family-owned Mittelstand firms: A dynamic capabilities perspective. Eur. J. Inf. Syst. 2021, 30, 676–711. [Google Scholar] [CrossRef]

- Ghazilla, R.A.R.; Sakundarini, N.; Abdul-Rashid, S.H.; Ayub, N.S.; Olugu, E.U.; Musa, S.N. Drivers and barriers analysis for green manufacturing practices in Malaysian SMEs: Preliminary findings. Procedia CIRP 2015, 26, 658–663. [Google Scholar] [CrossRef]

- Pizzi, S.; Corbo, L.; Caputo, A. Fintech and SMEs sustainable business models: Reflections and considerations for a circular economy. J. Clean. Prod. 2021, 281, 125217. [Google Scholar] [CrossRef]

- Paletta, A.; Leal Filho, W.; Balogun, A.L.; Foschi, E.; Bonoli, A. Barriers and challenges to plastics valorisation in the context of a circular economy: Case studies from Italy. J. Clean. Prod. 2019, 241, 118149. [Google Scholar] [CrossRef]

- Kurnia, S.; Choudrie, J.; Mahbubur, R.M.; Alzougool, B. E-commerce technology adoption: A Malaysian grocery SME retail sector study. J. Bus. Res. 2015, 68, 1906–1918. [Google Scholar] [CrossRef]

- Ilyas, S.; Hu, Z.; Wiwattanakornwong, K. Unleashing the role of top management and government support in green supply chain management and sustainable development goals. Environ. Sci. Pollut. Res. 2020, 27, 8210–8223. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, M.; Banihashemi, S.; Chileshe, N.; Namzadi, M.O.; Udaeja, C.; Rameezdeen, R.; McCuen, T. BIM adoption within Australian Small and Medium-sized Enterprises (SMEs): An innovation diffusion model. Constr. Econ. Build. 2016, 16, 71–86. [Google Scholar] [CrossRef]

- Türkeș, M.C.; Oncioiu, I.; Aslam, H.D.; Marin-Pantelescu, A.; Topor, D.I.; Căpușneanu, S. Drivers and barriers in using industry 4.0: A perspective of SMEs in Romania. Processes 2019, 7, 153. [Google Scholar] [CrossRef]

- Li, Y.; Mathiyazhagan, K. Application of DEMATEL approach to identify the influential indicators towards sustainable supply chain adoption in the auto components manufacturing sector. J. Clean. Prod. 2018, 172, 2931–2941. [Google Scholar] [CrossRef]

- Verma, S.; Bhattacharyya, S.S. Perceived strategic value-based adoption of Big Data Analytics in emerging economy: A qualitative approach for Indian firms. J. Enterp. Inf. Manag. 2017, 30, 354–382. [Google Scholar] [CrossRef]

- Khanzode, A.G.; Sarma, P.R.S.; Mangla, S.K.; Yuan, H. Modeling the Industry 4.0 adoption for sustainable production in Micro, Small & Medium Enterprises. J. Clean. Prod. 2021, 279, 123489. [Google Scholar] [CrossRef]

- ISO/IEC 27001:2013; Information technology—Security techniques—Information security management systems—Requirements. International Organization for Standardization; International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Agolla, J.E. Human capital in the smart manufacturing and industry 4.0 revolution. In Digital Transformation in Smart Manufacturing; IntechOpen: London, UK, 2018; Volume 2, pp. 41–58. [Google Scholar] [CrossRef]

- Restrepo-Morales, J.A.; Ararat-Herrera, J.A.; López-Cadavid, D.A.; Camacho-Vargas, A. Breaking the digitalization barrier for SMEs: A fuzzy logic approach to overcoming challenges in business transformation. J. Innov. Entrep. 2024, 13, 84. [Google Scholar] [CrossRef]

- Agostini, L.; Nosella, A. The adoption of Industry 4.0 technologies in SMEs: Results of an international study. Manag. Decis. 2020, 58, 625–643. [Google Scholar] [CrossRef]

- Wamba, S.F.; Carter, L. Social media tools adoption and use by SMEs: An empirical study. In Social Media and Networking: Concepts, Methodologies, Tools, and Applications; IGI Global: Hershey, PA, USA, 2016; pp. 791–806. [Google Scholar]

- Sufian, A.T.; Abdullah, B.M.; Ateeq, M.; Wah, R.; Clements, D. Six-gear roadmap towards the smart factory. Appl. Sci. 2021, 11, 3568. [Google Scholar] [CrossRef]

- Kumar, P.; Bhamu, J.; Sangwan, K.S. Analysis of barriers to Industry 4.0 adoption in manufacturing organizations: An ISM approach. Procedia CIRP 2021, 98, 85–90. [Google Scholar] [CrossRef]

- Majumdar, A.; Garg, H.; Jain, R. Managing the barriers of Industry 4.0 adoption and implementation in textile and clothing industry: Interpretive structural model and triple helix framework. Comput. Ind. 2021, 125, 103372. [Google Scholar] [CrossRef]

- Valipour Parkouhi, S.; Safaei Ghadikolaei, A.; Fallah Lajimi, H.; Salimi, N. Smart manufacturing implementation: Identifying barriers and their related stakeholders and components of technology. J. Sci. Technol. Policy Manag. 2024; ahead-of-print. [Google Scholar]

- Elhusseiny, H.M.; Crispim, J. SMEs, Barriers and Opportunities on adopting Industry 4.0: A Review. Procedia Comput. Sci. 2022, 196, 864–871. [Google Scholar] [CrossRef]

- Müller, J.M.; Islam, N.; Kazantsev, N.; Romanello, R.; Olivera, G.; Das, D.; Hamzeh, R. Barriers and Enablers for Industry 4.0 in SMEs: A Combined Integration Framework. IEEE Trans. Eng. Manag. 2024; early access. [Google Scholar]

- Mittal, S.; Khan, M.A.; Purohit, J.K.; Menon, K.; Romero, D.; Wuest, T. A smart manufacturing adoption framework for SMEs. Int. J. Prod. Res. 2020, 58, 1555–1573. [Google Scholar] [CrossRef]

- Modrak, V.; Soltysova, Z.; Poklemba, R. Mapping requirements and roadmap definition for introducing I 4.0 in SME environment. In Advances in Manufacturing Engineering and Materials: Proceedings of the International Conference on Manufacturing Engineering and Materials (ICMEM 2018), Nový Smokovec, Slovakia, 18–22 June 2018; Springer International Publishing: Cham, Switzerland, 2018; pp. 183–194. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 211–228. [Google Scholar] [CrossRef]

- Anderson, G.; Anderson, G. The Economic Impact of Technology Infrastructure for Smart Manufacturing; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016.

- Ghafari, F.; Shourangiz, E.; Wang, C. Cost Effectiveness of the Industrial Internet of Things Adoption in the US Manufacturing SMEs. Intell. Sustain. Manuf. 2024, 1, 10008. [Google Scholar] [CrossRef]

- Orzes, G.; Poklemba, R.; Towner, W.T. Implementing Industry 4.0 in SMEs: A focus group study on organizational requirements. In Industry 4.0 for SMEs: Challenges, Opportunities and Requirements; Springer: Cham, Switzerland, 2020; pp. 251–277. [Google Scholar]

- Häring, K.; Pimentel, C.; Teixeira, L. Industry 4.0 Implementation in Small-and Medium-Sized Enterprises: Recommendations Extracted from a Systematic Literature Review with a Focus on Maturity Models. Logistics 2023, 7, 99. [Google Scholar] [CrossRef]

- Matt, D.T.; Modrak, V.; Zsifkovits, H. Industry 4.0 for SMEs: Challenges, Opportunities and Requirements; Springer: Cham, Switzerland, 2020. [Google Scholar]

- de Mattos, C.S.; Pellegrini, G.; Hagelaar, G.; Dolfsma, W. Systematic literature review on technological transformation in SMEs: A transformation encompassing technology assimilation and business model innovation. Manag. Rev. Q. 2024, 74, 1057–1095. [Google Scholar] [CrossRef]

- Dzyubanenko, A.A.; Korshunov, G.I. Quality control in cyber-physical systems of smart electronics manufacturing. J. Phys. Conf. Ser. 2021, 2094, 042066. [Google Scholar] [CrossRef]

- Ho, J.Y.; O’Sullivan, E. Addressing the evolving standardisation challenges of ‘smart systems’ innovation: Emerging roles for government? Sci. Public Policy 2019, 46, 552–569. [Google Scholar] [CrossRef]

- Kedia, M.; Sekhani, R.; Katiyar, T. The Role of Standards in Diffusion of Emerging Technologies Internet of Things (IoT) (No. 20-r-04); Indian Council for Research on International Economic Relations (ICRIER): New Delhi, India, 2020. [Google Scholar]

- Bianchini, M.; Michalkova, V. Data analytics in SMEs: Trends and policies. Technol. Forecast. Soc. Change 2019, 140, 120–130. [Google Scholar]

- Mohamed, M.; Weber, P. Trends of digitalization and adoption of big data & analytics among UK SMEs: Analysis and lessons drawn from a case study of 53 SMEs. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–19 June 2020; pp. 1–6. [Google Scholar]

- Zhu, J.; Baker, J.S.; Song, Z.; Yue, X.G.; Li, W. Government regulatory policies for digital transformation in small and medium-sized manufacturing enterprises: An evolutionary game analysis. Humanit. Soc. Sci. Commun. 2023, 10, 751. [Google Scholar] [CrossRef]

- Siddique, H.; Dominic, D.D.; Bhushan, S. The Role of Government Regulations on Manufacturing SME’s Readiness for Industry4. 0 in Malaysia. In International Conference on Machine Learning, Advances in Computing, Renewable Energy and Communication; Springer: Singapore, 2024; pp. 391–401. [Google Scholar]

- Horvath, D.; Szabo, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Change 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Halili, S.H.; Sulaiman, S.; Sulaiman, H.; Razak, R. Embracing industrial revolution 4.0 in universities. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1088, 012111. [Google Scholar] [CrossRef]

- Haron, H. Education in the Era of IR 4.0. In Proceedings of the 2018 International Conference on Information Management and Technology 2018 (ICIMTech 2018), Jakarta, Indonesia, 3–5 September 2018; pp. 1–38. [Google Scholar]

- Von der Gracht, H.A. Consensus measurement in delphi studies: Review and implications for future quality assurance. Technol. Forecast. Soc. Change 2012, 79, 1525–1536. [Google Scholar] [CrossRef]

- Buck, A.J.; Gross, M.; Hakim, S.; Weinblatt, J. Using the delphi process to analyze social policy implementation: A post hoc case from vocational rehabilitation. Policy Sci. 1993, 26, 271–288. [Google Scholar] [CrossRef]

- Zinn, J.; Zalokowski, A.; Hunter, L. Identifying indicators of laboratory management performance: A multiple constituency approach. Health Care Manag. Rev. 2001, 26, 40–53. [Google Scholar] [CrossRef]

- Martínez-León, I.M.; Olmedo-Cifuentes, I.; Soria-García, J. Could you love your job again? Organisational factors to recover teacher enchantment. Teach. Teach. Educ. 2024, 144, 104580. [Google Scholar] [CrossRef]

- Rebollar, R.E.; Palacios, M.G.; Mangas, M.F.; Fernández, F.A.; Rodríguez, C.M.; Martín, A.C.; Morera, L.T. «safety first»: Design of an anesthetic checklist in pediatrics. Rev. Española De Anestesiol. Y Reanim. (Engl. Ed.) 2019, 66, 459–466. [Google Scholar] [CrossRef] [PubMed]

- Mengual-Andrés, S.; Roig-Vila, R.; Mira, J.B. Delphi study for the design and validation of a questionnaire about digital competences in higher education. Int. J. Educ. Technol. High. Educ. 2016, 13, 12. [Google Scholar] [CrossRef]

- Cronbach, L.J. Coefficient alpha and the internal structure of tests. Psychometrika 1951, 16, 297–334. [Google Scholar] [CrossRef]

- George, D.; Mallery, P. SPSS for Windows Step by Step: A Simple Guide and Reference, 4th ed.; 11.0 update; Allyn & Bacon: Boston, MA, USA, 2003. [Google Scholar]

- Koo, T.K.; Li, M.Y. A guideline of selecting and reporting intraclass correlation coefficients for reliability research. J. Chiropr. Med. 2016, 15, 155–163. [Google Scholar] [CrossRef]

- Kalaian, S.A.; Kasim, R.M. Terminating sequential Delphi survey data collection. Pract. Assess. Res. Eval. 2012, 17, n5. [Google Scholar]

- Shah, H.A.; Kalaian, S.A. Which is the best parametric statistical method for analyzing Delphi data? J. Mod. Appl. Stat. Methods 2009, 8, 20. [Google Scholar] [CrossRef]

- Salotti, J.M.; Suhir, E. Collaborative Robotics: Application of Delphi Method. J. Field Robot. 2025, 42, 1799–1807. [Google Scholar] [CrossRef]

- Shafer, D.S.; Zhang, Z. Introductory Statistics; Saylor Foundation: Washington, DC, USA, 2012. [Google Scholar]

- Müller, J.M.; Buliga, O.; Voigt, K.I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Change 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT driven service-oriented smart manufacturing: Framework and characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 81–91. [Google Scholar] [CrossRef]

- Hecklau, F.; Galeitzke, M.; Flachs, S.; Kohl, H. Holistic approach for human resource management in Industry 4.0. Procedia Cirp 2016, 54, 1–6. [Google Scholar] [CrossRef]

- Tretiakov, A.; Jurado, T.; Bensemann, J. Employee empowerment and HR flexibility in information technology SMEs. J. Comput. Inf. Syst. 2023, 63, 1394–1407. [Google Scholar] [CrossRef]

- Pahi, M.H.; Ahmed, U.; Imroz, S.M.; Shah, S.M.M.; Yong, I.S.C. The flexible HRM and firm performance nexus: Can empowering leadership play any contingent role? Int. J. Product. Perform. Manag. 2024, 73, 629–647. [Google Scholar] [CrossRef]

- Tan, H.S.; Oktarina, R.; Reynaldo, V.; Sharina, C. Conceptual development of learning factory for industrial engineering education in Indonesia context as an enabler of students’ competencies in industry 4.0 era. IOP Conf. Ser. Earth Environ. Sci. 2020, 426, 012123. [Google Scholar] [CrossRef]

- Tri, N.M.; Hoang, P.D.; Dung, N.T. Impact of the industrial revolution 4.0 on higher education in Vietnam: Challenges and opportunities. Linguist. Cult. Rev. 2021, 5 (Suppl. S3), 1–15. [Google Scholar] [CrossRef]

- Thong, J.Y. An integrated model of information systems adoption in small businesses. J. Manag. Inf. Syst. 1999, 15, 187–214. [Google Scholar] [CrossRef]

- Buonanno, G.; Faverio, P.; Pigni, F.; Ravarini, A.; Sciuto, D.; Tagliavini, M. Factors affecting ERP system adoption: A comparative analysis between SMEs and large companies. J. Enterp. Inf. Manag. 2005, 18, 384–426. [Google Scholar] [CrossRef]

- Abe, M.; Kim, J.; Jahan, S.M. Global value chain-oriented industrialization: Policies revisited. Int. J. Bus. Manag. Res. 2023, 11, 71–80. [Google Scholar] [CrossRef]

- Travaglioni, M.; Ferazzoli, A.; Petrillo, A.; Cioffi, R.; De Felice, F.; Piscitelli, G. Digital manufacturing challenges through open innovation perspective. Procedia Manuf. 2020, 42, 165–172. [Google Scholar] [CrossRef]

- Shirasawa, N.; Seo, Y. The Role of Institutional and Geographic Proximity in Enhancing Creating Shared Value (CSV) Initiatives Within Local Industrial Clusters: A Study of Japanese SMEs. Sustainability 2025, 17, 2410. [Google Scholar] [CrossRef]

- Evangelos, S.; Konstantia, D. Analytical support for identification trends and problems in the development of interaction between stakeholders of education, science and business. Екoнoміка Рoзвитку 2023, 4, 8–22. [Google Scholar]

- European Union. Digital Innovation Clusters Development in the EaP: EU Best Practices in Cluster Management. 2024. Available online: https://eufordigital.eu/wp-content/uploads/2024/07/EU4Digital-II_Report_EU-Best-Practices-in-Cluster-Management.pdf (accessed on 7 July 2025).

- Dutta, G.; Kumar, R.; Sindhwani, R.; Singh, R.K. Overcoming the barriers of effective implementation of manufacturing execution system in pursuit of smart manufacturing in SMEs. Procedia Comput. Sci. 2022, 200, 820–832. [Google Scholar] [CrossRef]

| No. | Author | The Number of Citations | Main Barriers/Limitations/Shortages | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. High Initial Costs | 2. Low Level of Automation | 3. Lack of Qualified Employees | 4. Fear of Change | 5. Insufficient Trainings | 6. Lack of Management Support | 7. Lack of I 4.0 Methodology | 8. Cybersecurity Risks | 9. Information Security Management System | 10. Risks of Sharing Company Data | 11. Weak Pressure from Customers | 12. Lack of Government Support | 13. Lack of Region Consulting Support | 14. Short Term Planning | 15. Organizational Barriers | 16. Trust in the Return of Investment | 17. Low Level of Digitalization | 18. Complexity Factors | 19. Cultural Barriers | 20. Lack of Suitable Investors | 21. Regulatory Challenges | 22. Lack of Consumer Interest | 23. Market Understanding | 24. Understanding of Suitable Practices | 25. Short-Term Investor Mind-Set | 26. Interrelationship Complexity | 27. Paternalism-Related Barriers | 28. Inadequate Research and Development | 29. Lack of Standards | 30. Lack of Demand | |||

| 1 | Ormazabal, M. et al. [25] | 327 | • | • | • | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | • | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 2 | Kumar, R. et al. [26] | 272 | • | ○ | • | • | ○ | ○ | • | ○ | ○ | ○ | • | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 3 | Bocken, N.M. [27] | 225 | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | • | ○ | ○ | • | ○ | • | ○ | ○ | ○ | ○ | ○ |

| 4 | Gandhi, N.S. et al. [28] | 214 | • | ○ | ○ | • | • | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ |

| 5 | Soluk, J. and Kammerlander, N. [29] | 185 | • | ○ | ○ | • | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ |

| 6 | Ghazilla, R.A.R. et al. [30] | 178 | • | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ |

| 7 | Pizzi, S. et al. [31] | 161 | • | • | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | • | • | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 8 | Paletta, A. et al. [32] | 158 | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 9 | Kurnia, S. et al. [33] | 145 | • | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 10 | Ilyas, S. et al. [34] | 145 | • | ○ | • | • | ○ | ○ | ○ | ○ | ○ | • | ○ | • | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 11 | Hosseini, M. et al. [35] | 124 | • | • | • | • | • | ○ | • | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • |

| 12 | Türkeș, M. C. et al. [36] | 122 | • | ○ | • | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ |

| 13 | Li, Y., and Mathiyazhagan, K. [37] | 120 | • | ○ | • | ○ | ○ | • | • | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ |

| 14 | Verma, S., and Bhattacharyya, S. S. [38] | 120 | • | • | • | ○ | ○ | ○ | ○ | ○ | • | ○ | • | ○ | ○ | ○ | • | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 15 | Khanzode, A.G. et al. [39] | 111 | • | • | • | ○ | ○ | ○ | • | • | ○ | • | ○ | • | ○ | ○ | ○ | ○ | • | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| No. | Preliminary Domain of Barriers | Identified Barriers Listed in Table 1 |

|---|---|---|

| 1 | Human aspects | 3, 4, 5, 6, 24 |

| 2 | Methodological aspects | 7, 11, 13, 14, 15, 18, 19, 26, 28, 29 |

| 3 | Technological aspects | 2, 17 |

| 4 | Financial aspects | 1, 16 |

| 5 | Information and cybersecurity aspects | 8, 9, 10 |

| 6 | Other (not-categorized) aspects | 12, 20, 21, 22, 23, 25, 27, 30 |

| No. | Areas | Barriers/Limitations/Shortages | Relevance in [%] |

|---|---|---|---|

| 1 | Human aspects | Lack of qualified employees | Respondents quantify the extent to which the barrier/constraint or deficiency is relevant, related or applicable to the given goal. |

| 2 | Fear of change/resistance to change | ||

| 3 | Lack of management support | ||

| 4 | Insufficient use of training and workshops | ||

| 5 | Methodology aspects | Lack of methodology for Industry 4.0 implementation | |

| 6 | Weak pressure from customers in supply chains | ||

| 7 | Lack of consulting and advisory support in the region | ||

| 8 | Technological aspects | Low level of automation in production | |

| 9 | Low level of ICT utilization | ||

| 10 | Low level of digitalization in the company | ||

| 11 | Financial aspects | High initial costs | |

| 12 | Lack of resources for research and development activities | ||

| 13 | Lack of trust in the return on investment in the Industry 4.0 strategy | ||

| 14 | Information and cybersecurity aspects | Insufficient use of information security management systems (ISO 27001 [40]) | |

| 15 | Cybersecurity risks | ||

| 16 | Risks of sharing company data (know-how) | ||

| 17 | Other aspects | Insufficient government support | |

| 18 | Insufficient support from regional self-government | ||

| 19 | Insufficient support from universities | ||

| 20 | Lack of initiatives for establishing business clusters |

| No. of Barrier | 1st Round | 2nd Round | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 | E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | E11 | E12 | |

| 1 | 80 | 80 | 30 | 60 | 80 | 10 | 80 | 20 | 70 | 25 | 60 | 50 | 80 | 70 | 60 | 60 | 60 | 25 | 60 | 40 | 60 | 25 | 60 | 50 |

| 2 | 90 | 80 | 45 | 30 | 70 | 30 | 50 | 10 | 80 | 0 | 50 | 100 | 90 | 80 | 50 | 50 | 50 | 40 | 50 | 50 | 50 | 0 | 50 | 100 |

| 3 | 70 | 60 | 20 | 0 | 30 | 15 | 20 | 0 | 50 | 0 | 60 | 80 | 70 | 50 | 20 | 20 | 20 | 15 | 20 | 30 | 20 | 0 | 40 | 80 |

| 4 | 90 | 70 | 20 | 10 | 70 | 10 | 40 | 20 | 80 | 75 | 70 | 50 | 90 | 60 | 70 | 70 | 70 | 30 | 70 | 30 | 70 | 75 | 70 | 50 |

| 5 | 90 | 80 | 50 | 20 | 70 | 5 | 50 | 20 | 80 | 80 | 70 | 100 | 90 | 70 | 70 | 70 | 70 | 20 | 70 | 40 | 70 | 80 | 70 | 100 |

| 6 | 80 | 80 | 30 | 60 | 40 | 5 | 30 | 40 | 70 | 100 | 20 | 10 | 80 | 70 | 40 | 40 | 40 | 10 | 70 | 40 | 40 | 100 | 30 | 10 |

| 7 | 90 | 90 | 30 | 20 | 90 | 0 | 40 | 30 | 90 | 80 | 40 | 50 | 90 | 80 | 40 | 40 | 40 | 10 | 40 | 30 | 40 | 80 | 40 | 50 |

| 8 | 60 | 90 | 60 | 60 | 70 | 15 | 70 | 0 | 90 | 60 | 60 | 100 | 60 | 80 | 70 | 70 | 50 | 30 | 40 | 40 | 70 | 60 | 70 | 100 |

| 9 | 70 | 80 | 40 | 20 | 60 | 10 | 60 | 20 | 70 | 70 | 70 | 60 | 70 | 80 | 70 | 70 | 70 | 30 | 70 | 30 | 70 | 70 | 70 | 60 |

| 10 | 80 | 80 | 60 | 20 | 60 | 20 | 70 | 40 | 70 | 80 | 80 | 80 | 80 | 80 | 70 | 70 | 70 | 25 | 70 | 40 | 70 | 80 | 75 | 80 |

| 11 | 80 | 90 | 75 | 80 | 80 | 20 | 80 | 60 | 80 | 100 | 70 | 30 | 80 | 90 | 80 | 80 | 80 | 50 | 80 | 60 | 80 | 100 | 80 | 30 |

| 12 | 90 | 80 | 80 | 20 | 70 | 25 | 90 | 50 | 80 | 100 | 70 | 50 | 90 | 80 | 80 | 20 | 80 | 50 | 80 | 60 | 80 | 100 | 70 | 50 |

| 13 | 60 | 70 | 40 | 0 | 60 | 30 | 70 | 20 | 80 | 80 | 70 | 100 | 60 | 70 | 60 | 0 | 60 | 50 | 60 | 50 | 60 | 80 | 70 | 100 |

| 14 | 70 | 80 | 30 | 20 | 80 | 15 | 60 | 10 | 70 | 80 | 50 | 10 | 70 | 80 | 60 | 20 | 60 | 30 | 60 | 40 | 60 | 80 | 60 | 10 |

| 15 | 70 | 80 | 30 | 60 | 70 | 15 | 50 | 20 | 70 | 50 | 50 | 20 | 70 | 80 | 50 | 60 | 50 | 25 | 50 | 50 | 50 | 50 | 50 | 20 |

| 16 | 70 | 80 | 30 | 20 | 90 | 15 | 80 | 30 | 70 | 80 | 50 | 20 | 70 | 80 | 70 | 20 | 70 | 45 | 70 | 60 | 70 | 80 | 60 | 20 |

| 17 | 90 | 80 | 75 | 70 | 90 | 25 | 40 | 30 | 90 | 100 | 70 | 50 | 90 | 80 | 75 | 70 | 90 | 25 | 40 | 60 | 90 | 100 | 70 | 50 |

| 18 | 95 | 80 | 75 | 20 | 100 | 25 | 60 | 20 | 90 | 50 | 70 | 100 | 95 | 80 | 75 | 20 | 100 | 25 | 60 | 40 | 90 | 50 | 70 | 100 |

| 19 | 80 | 70 | 20 | 10 | 60 | 20 | 20 | 20 | 80 | 50 | 50 | 50 | 80 | 70 | 20 | 10 | 60 | 20 | 20 | 20 | 80 | 50 | 50 | 50 |

| 20 | 80 | 65 | 40 | 40 | 95 | 90 | 80 | 75 | 90 | 100 | 80 | 80 | 80 | 80 | 60 | 80 | 95 | 90 | 70 | 75 | 90 | 100 | 80 | 70 |

| No. | SD | CV | Q1 | Q2 (Median) | Q3 | RIR | |

|---|---|---|---|---|---|---|---|

| 1 | 26.21 | 53.75 | 0.49 | 28.75 | 60 | 80 | 0.85 |

| 2 | 31.8 | 52.92 | 0.60 | 30 | 50 | 80 | 1.00 |

| 3 | 29.01 | 33.75 | 0.86 | 11.25 | 25 | 60 | 1.95 |

| 4 | 29.27 | 50.42 | 0.58 | 20 | 60 | 71.25 | 0.85 |

| 5 | 30.63 | 59.58 | 0.51 | 42.5 | 70 | 80 | 0.54 |

| 6 | 30.49 | 47.08 | 0.65 | 27.5 | 40 | 72.5 | 1.13 |

| 7 | 32.32 | 54.17 | 0.60 | 30 | 45 | 90 | 1.33 |

| 8 | 28.93 | 61.25 | 0.47 | 60 | 60 | 75 | 0.25 |

| 9 | 23.79 | 52.5 | 0.45 | 35 | 60 | 70 | 0.58 |

| 10 | 22.9 | 61.67 | 0.37 | 55 | 70 | 80 | 0.36 |

| 11 | 23.4 | 70.42 | 0.33 | 67.5 | 80 | 80 | 0.16 |

| 12 | 25.63 | 67.08 | 0.38 | 50 | 75 | 82.5 | 0.43 |

| 13 | 28.71 | 56.67 | 0.51 | 37.5 | 65 | 72.5 | 0.54 |

| 14 | 29.03 | 47.92 | 0.61 | 18.75 | 55 | 72.5 | 0.98 |

| 15 | 22.58 | 48.75 | 0.46 | 27.5 | 50 | 70 | 0.85 |

| 16 | 28.32 | 52.92 | 0.54 | 27.5 | 60 | 80 | 0.88 |

| 17 | 25.36 | 67.5 | 0.38 | 47.5 | 72.5 | 90 | 0.59 |

| 18 | 30.49 | 65.42 | 0.47 | 43.75 | 72.5 | 91.25 | 0.66 |

| 19 | 25.39 | 44.17 | 0.58 | 20 | 50 | 62.5 | 0.85 |

| 20 | 19.32 | 76.25 | 0.25 | 72.5 | 80 | 90 | 0.22 |

| No. | SD | CV | Q1 | Q2 (Median) | Q3 | RIR | |

|---|---|---|---|---|---|---|---|

| 1 | 16.63 | 54.2 | 0.31 | 47.5 | 60 | 60 | 0.21 |

| 2 | 25.76 | 55 | 0.47 | 50 | 50 | 57.5 | 0.15 |

| 3 | 23.69 | 32.1 | 0.74 | 20 | 20 | 42.5 | 1.13 |

| 4 | 17.9 | 62.92 | 0.28 | 57.5 | 70 | 70 | 0.18 |

| 5 | 20.82 | 68.3 | 0.31 | 70 | 70 | 72.5 | 0.04 |

| 6 | 27.35 | 47.5 | 0.58 | 37.5 | 40 | 70 | 0.81 |

| 7 | 23.29 | 48.3 | 0.48 | 40 | 40 | 57.5 | 0.44 |

| 8 | 19.46 | 61.7 | 0.32 | 47.5 | 65 | 70 | 0.35 |

| 9 | 16.14 | 63.3 | 0.26 | 67.5 | 70 | 70 | 0.04 |

| 10 | 17.26 | 67.5 | 0.26 | 70 | 70 | 80 | 0.14 |

| 11 | 18.81 | 74.2 | 0.25 | 75 | 80 | 80 | 0.06 |

| 12 | 21.74 | 70 | 0.31 | 57.5 | 80 | 80 | 0.28 |

| 13 | 23.36 | 60 | 0.39 | 57.5 | 60 | 70 | 0.21 |

| 14 | 22.61 | 52.5 | 0.43 | 37.5 | 60 | 62.5 | 0.42 |

| 15 | 16.3 | 50.42 | 0.32 | 50 | 50 | 52.5 | 0.05 |

| 16 | 20.72 | 59.6 | 0.35 | 56.25 | 70 | 70 | 0.20 |

| 17 | 22.66 | 70 | 0.32 | 57.5 | 72.5 | 90 | 0.45 |

| 18 | 28.24 | 67.1 | 0.42 | 47.5 | 72.5 | 91.25 | 0.60 |

| 19 | 25.39 | 44.17 | 0.58 | 20 | 50 | 62.5 | 0.85 |

| 20 | 11.45 | 80.83 | 0.14 | 73.75 | 80 | 90 | 0.20 |

| No. | SD of 1st Round | SD of 2nd Round | F-Test | Result |

|---|---|---|---|---|

| 1 | 26.21 | 16.63 | 2.4841 | Based on the F-test, the variance ratio between Round 1 and Round 2 is not large enough to be considered statistically significant, as the values fall within the interval [0.2879; 3.4737] |

| 2 | 31.8 | 25.76 | 1.5237 | |

| 3 | 29.01 | 23.69 | 1.4995 | |

| 4 | 29.27 | 17.9 | 2.6747 | |

| 5 | 30.63 | 20.82 | 2.1656 | |

| 6 | 30.49 | 27.35 | 1.2428 | |

| 7 | 32.32 | 23.29 | 1.926 | |

| 8 | 28.93 | 19.46 | 2.2096 | |

| 9 | 23.79 | 16.14 | 2.1716 | |

| 10 | 22.9 | 17.26 | 1.7607 | |

| 11 | 23.4 | 18.81 | 1.5477 | |

| 12 | 25.63 | 21.74 | 1.3891 | |

| 13 | 28.71 | 23.36 | 1.5111 | |

| 14 | 29.03 | 22.61 | 1.6485 | |

| 15 | 22.58 | 16.3 | 1.9181 | |

| 16 | 28.32 | 20.72 | 1.8681 | |

| 17 | 25.36 | 22.66 | 1.2522 | |

| 18 | 30.49 | 28.24 | 1.1652 | |

| 19 | 25.39 | 25.39 | 1 | |

| 20 | 19.32 | 11.45 | 2.8471 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Modrak, V.; Soltysova, Z. Barriers for Smart Manufacturing Implementation in SMEs: A Comprehensive Exploration and Practical Insights. Appl. Sci. 2025, 15, 10552. https://doi.org/10.3390/app151910552

Modrak V, Soltysova Z. Barriers for Smart Manufacturing Implementation in SMEs: A Comprehensive Exploration and Practical Insights. Applied Sciences. 2025; 15(19):10552. https://doi.org/10.3390/app151910552

Chicago/Turabian StyleModrak, Vladimir, and Zuzana Soltysova. 2025. "Barriers for Smart Manufacturing Implementation in SMEs: A Comprehensive Exploration and Practical Insights" Applied Sciences 15, no. 19: 10552. https://doi.org/10.3390/app151910552

APA StyleModrak, V., & Soltysova, Z. (2025). Barriers for Smart Manufacturing Implementation in SMEs: A Comprehensive Exploration and Practical Insights. Applied Sciences, 15(19), 10552. https://doi.org/10.3390/app151910552