Transient Vibration Loads Characteristics Analysis of Variable Speed Rotor

Abstract

1. Introduction

2. Methods

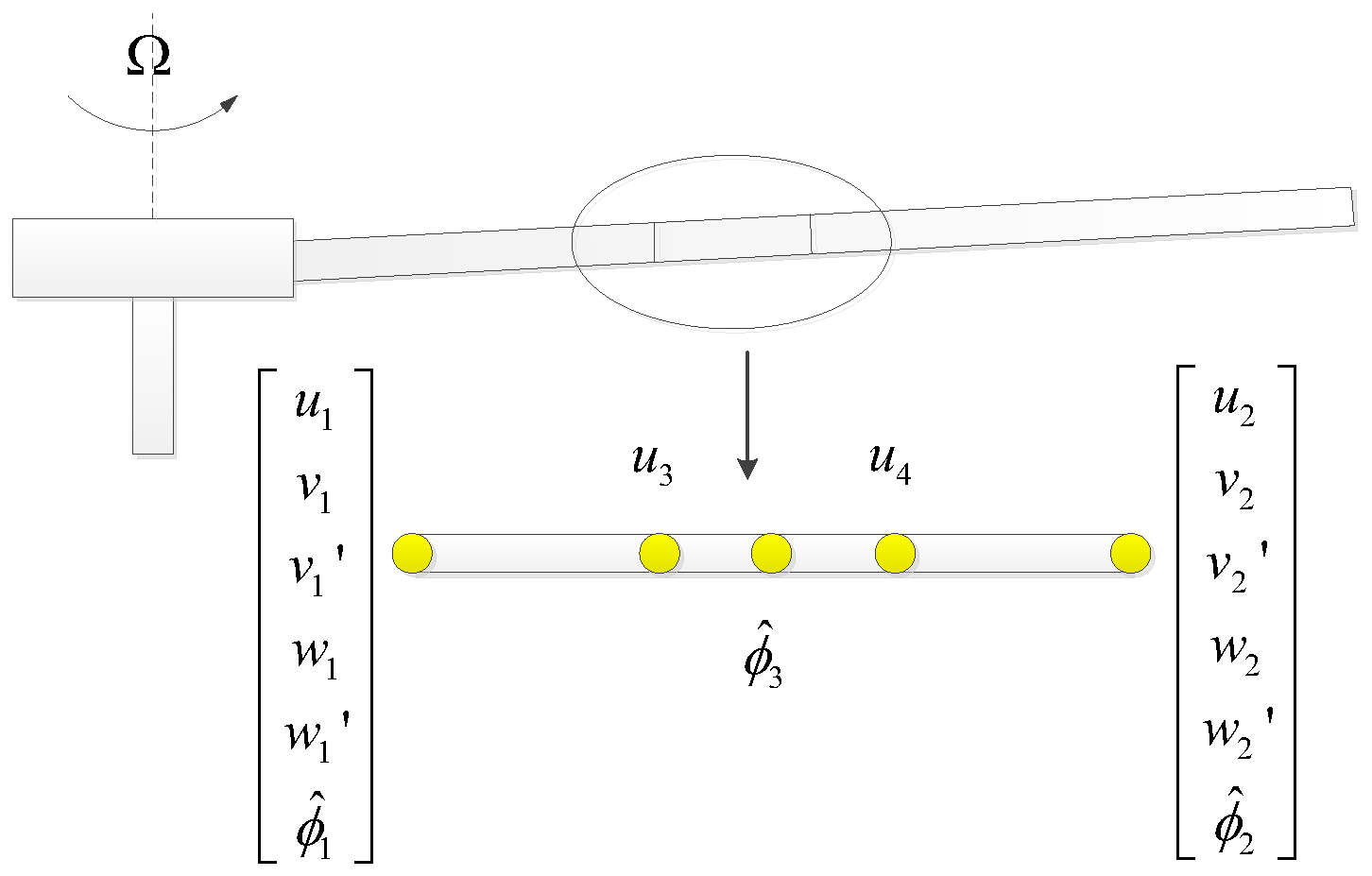

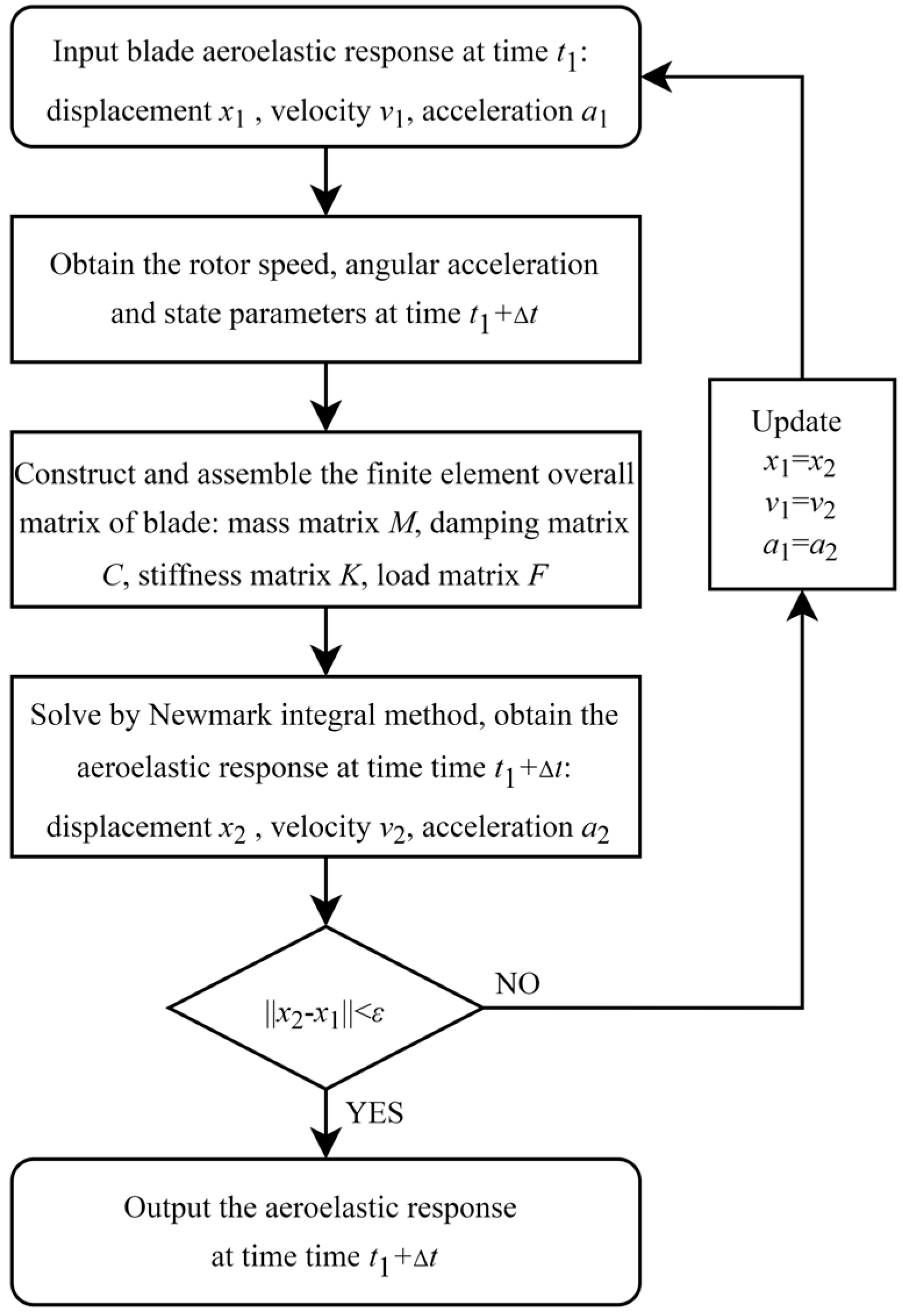

2.1. Transient Rotor Dynamic Method

2.2. Transient Rotor Loads Method

2.3. Rotor Trim Model

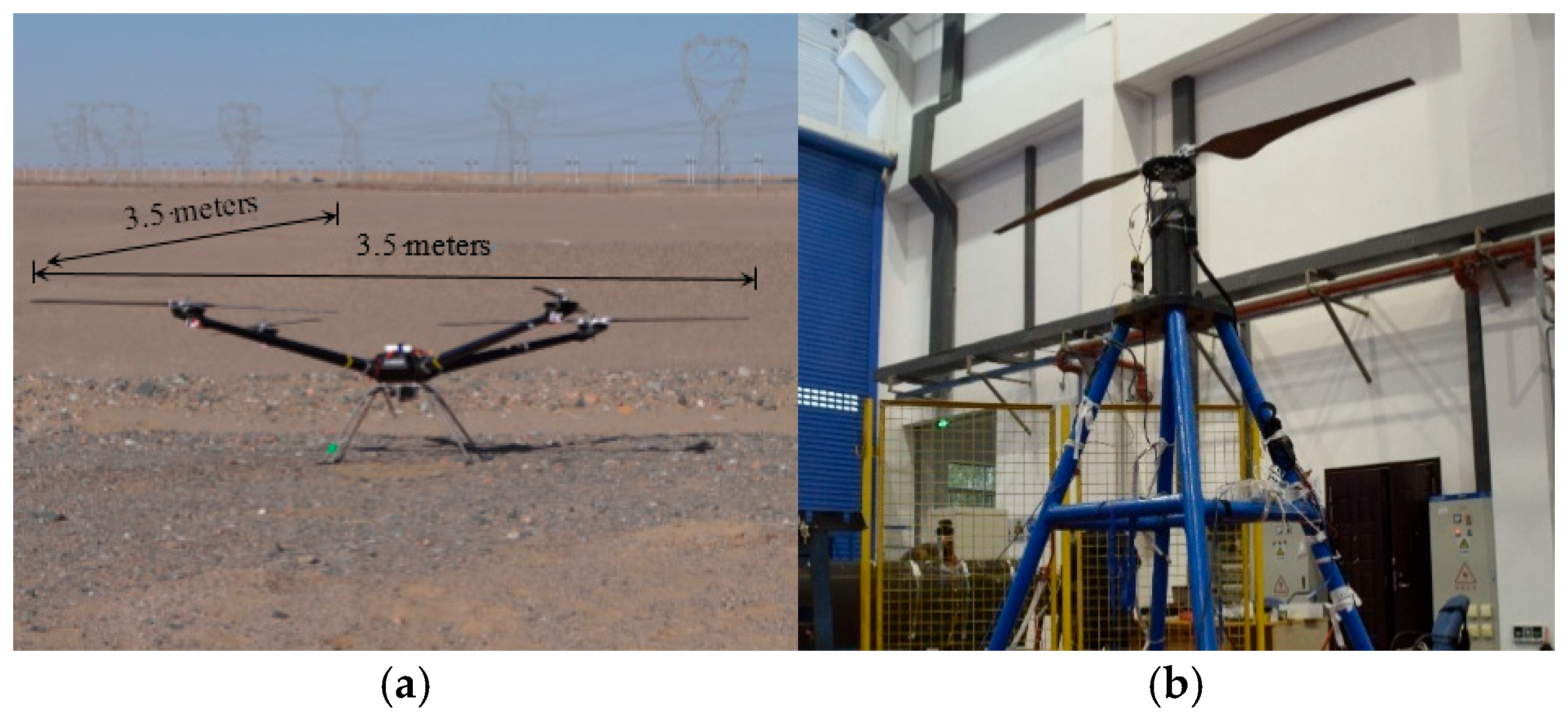

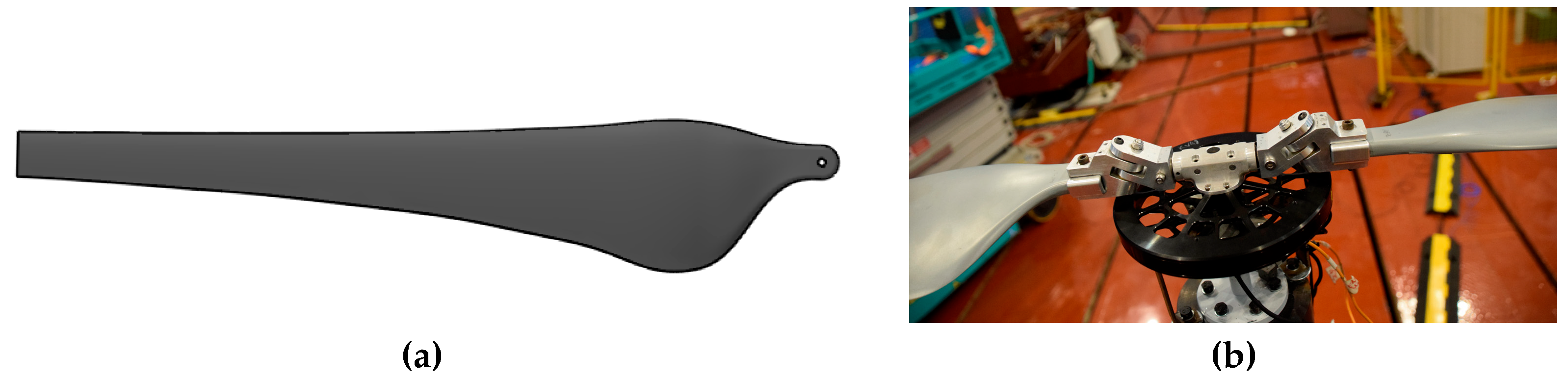

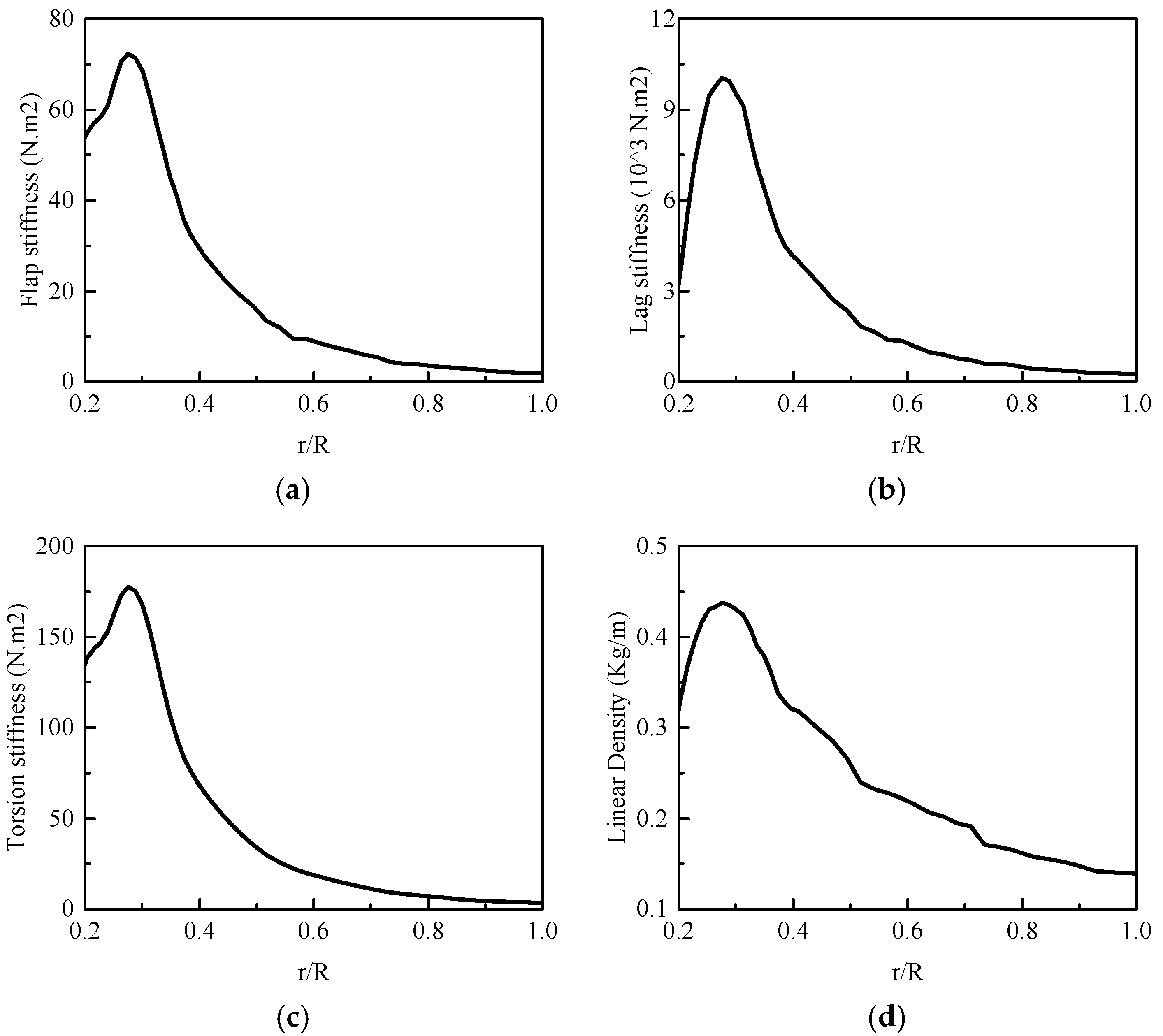

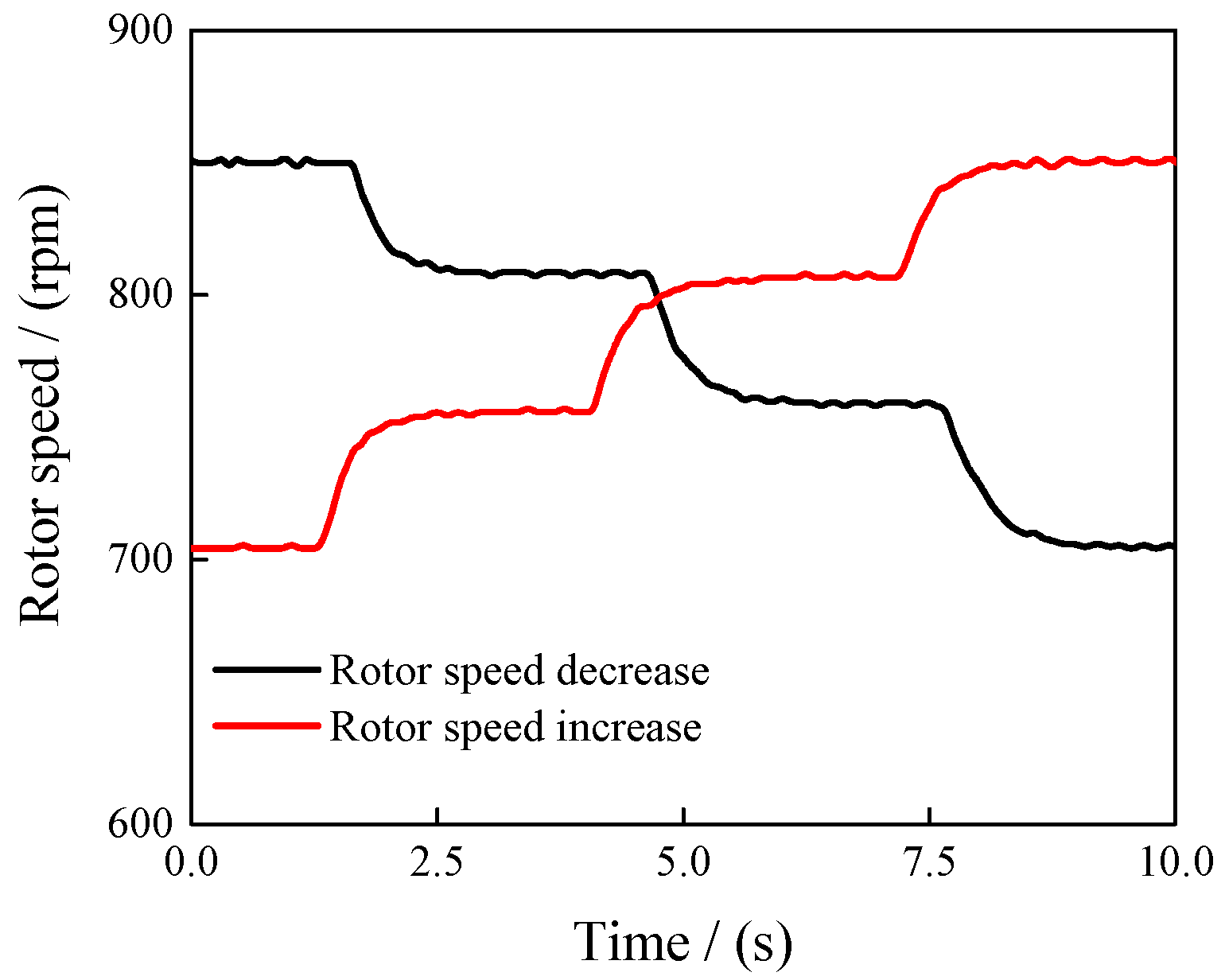

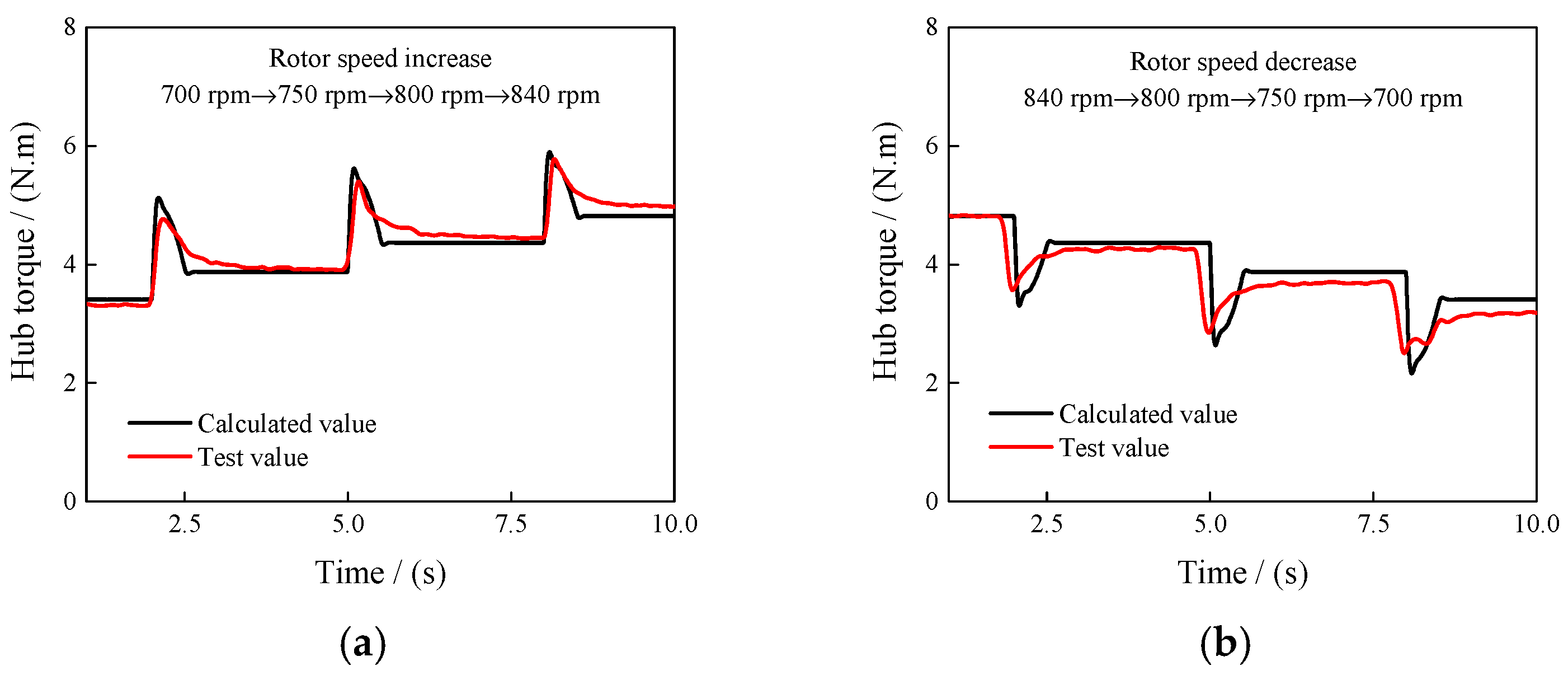

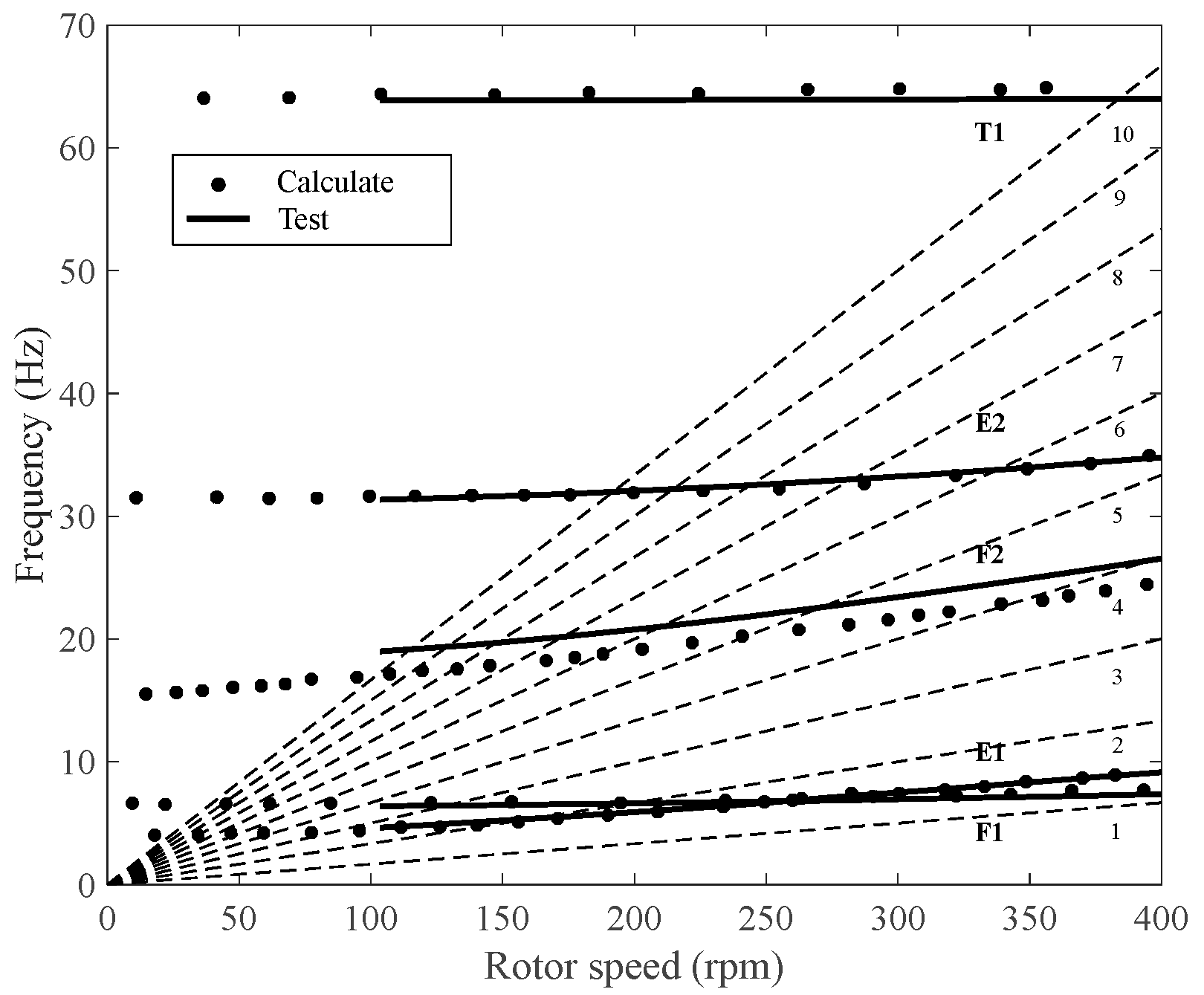

2.4. Validation of the Numerical Method

3. Analysis

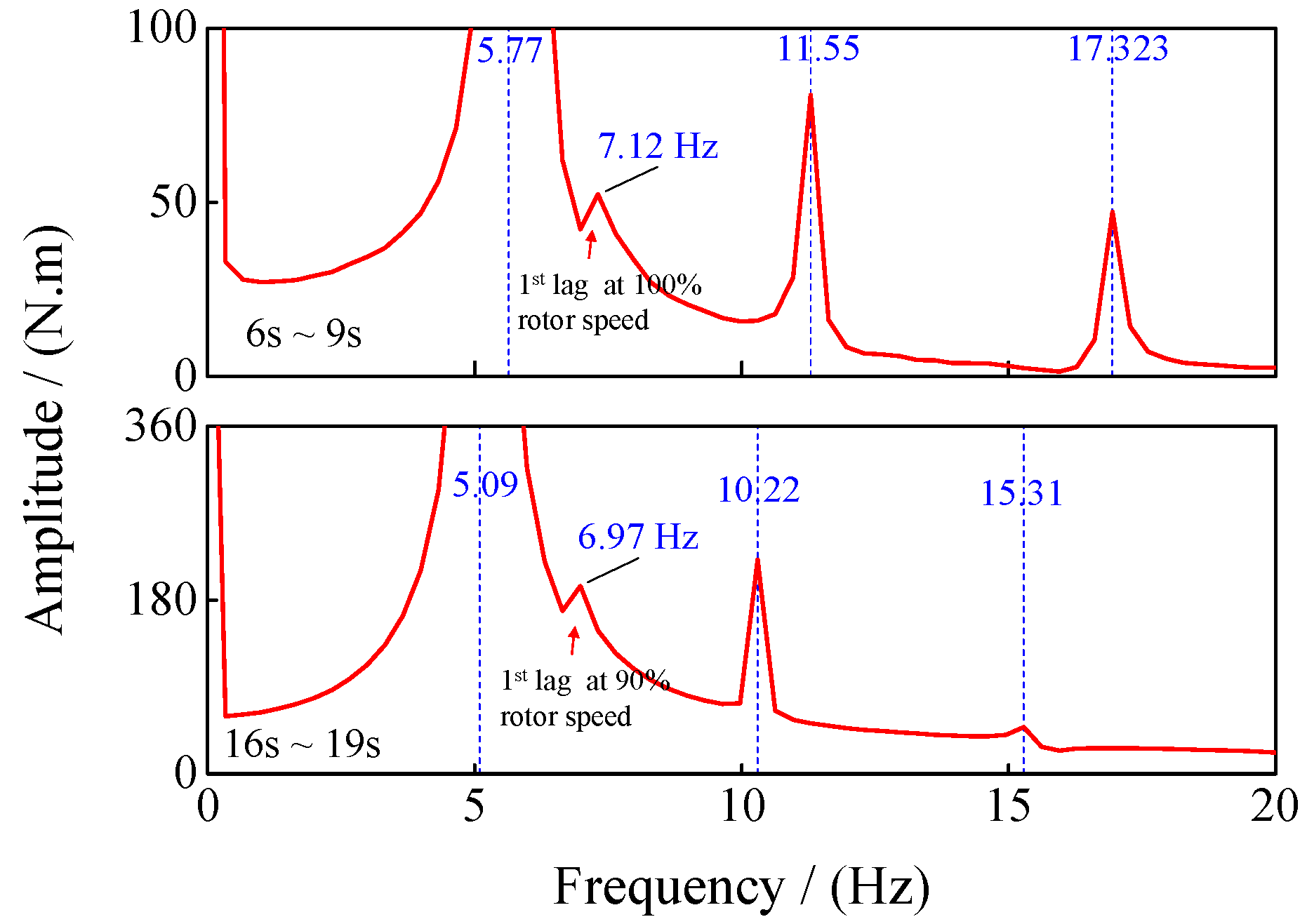

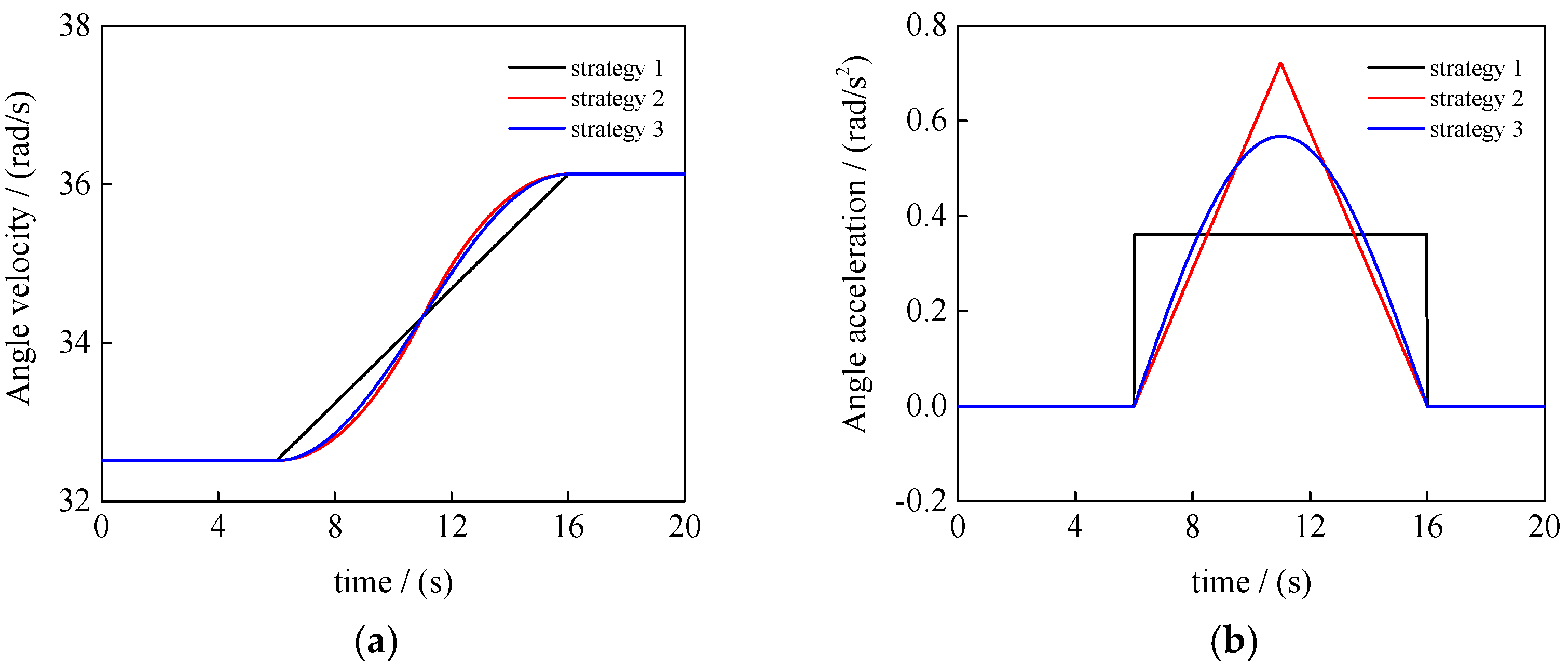

3.1. Hub Torque Overshoot

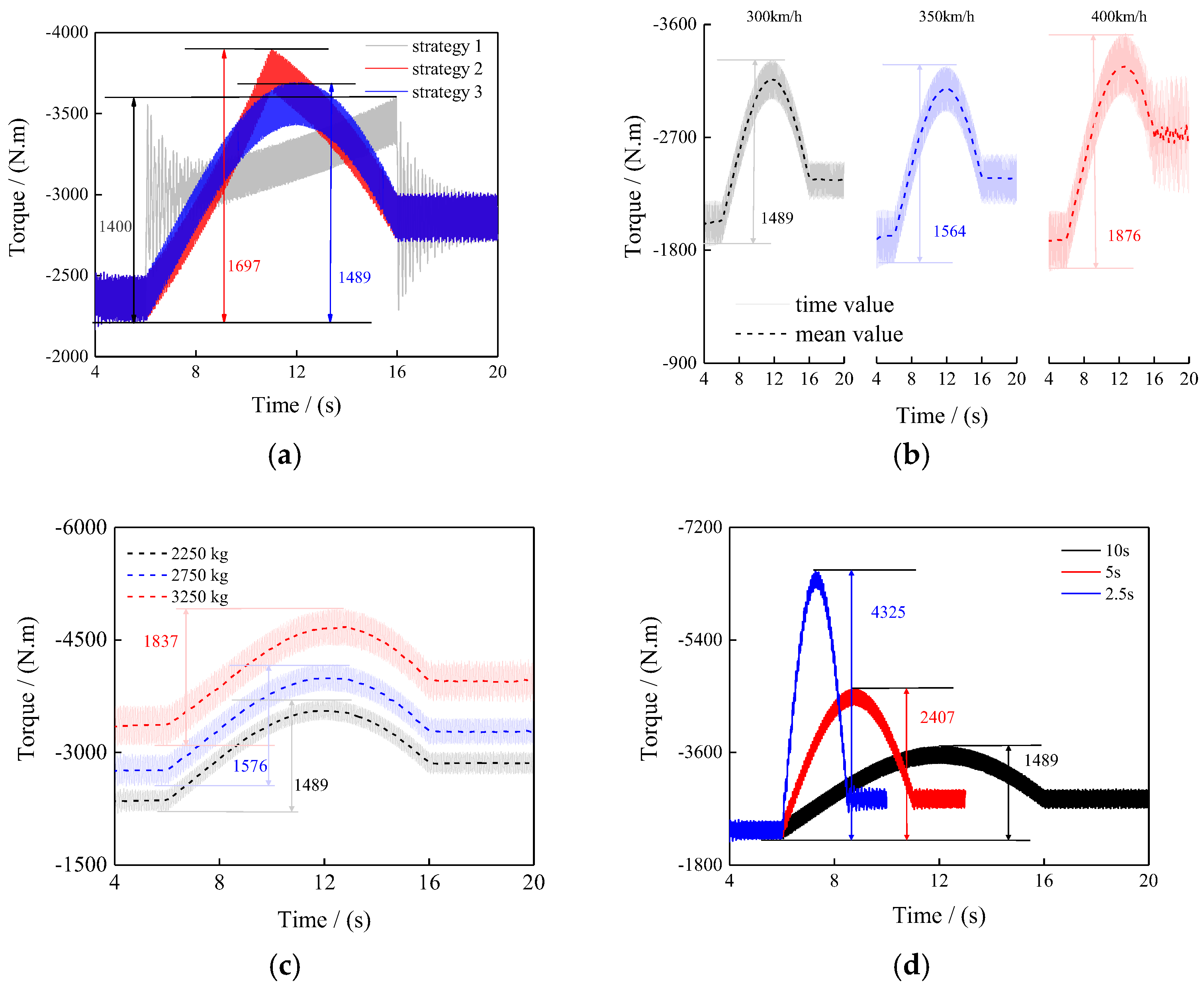

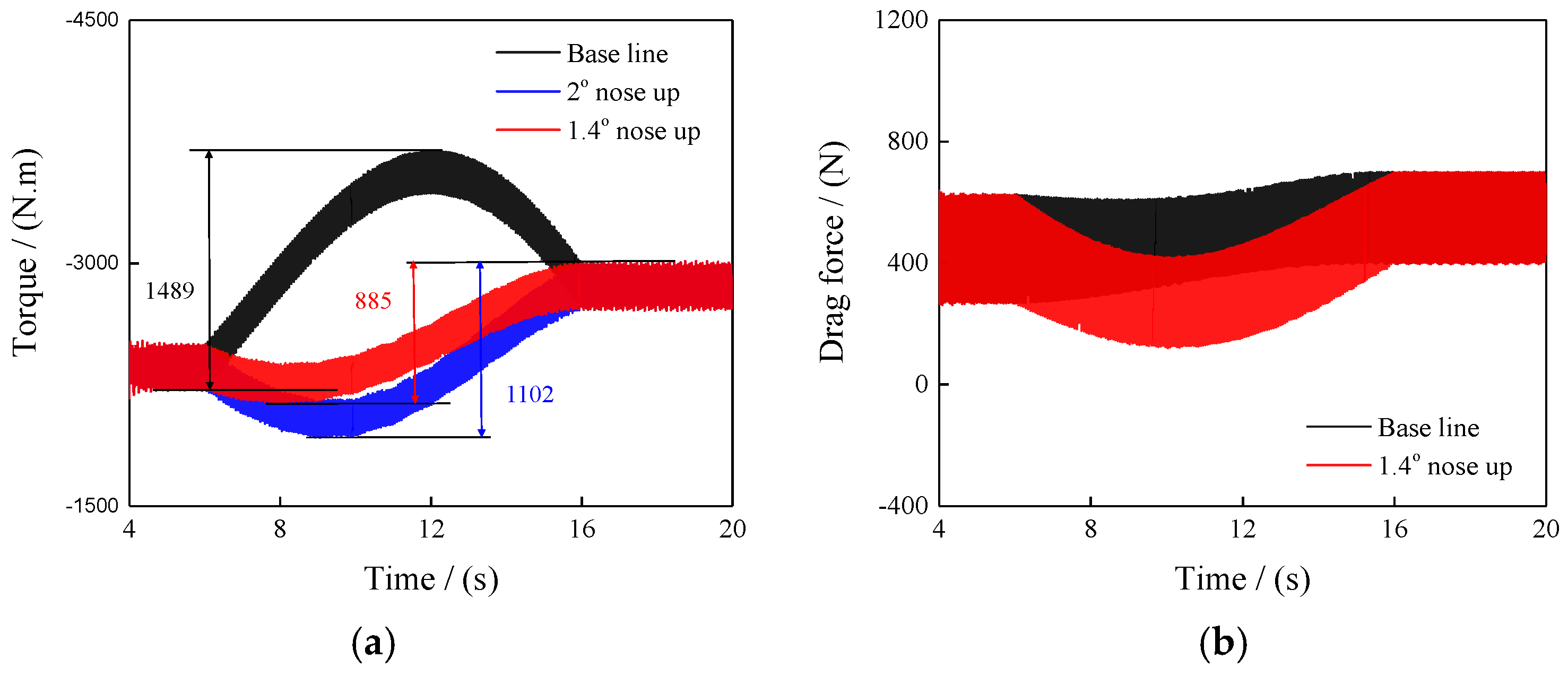

3.2. Parameter Influence

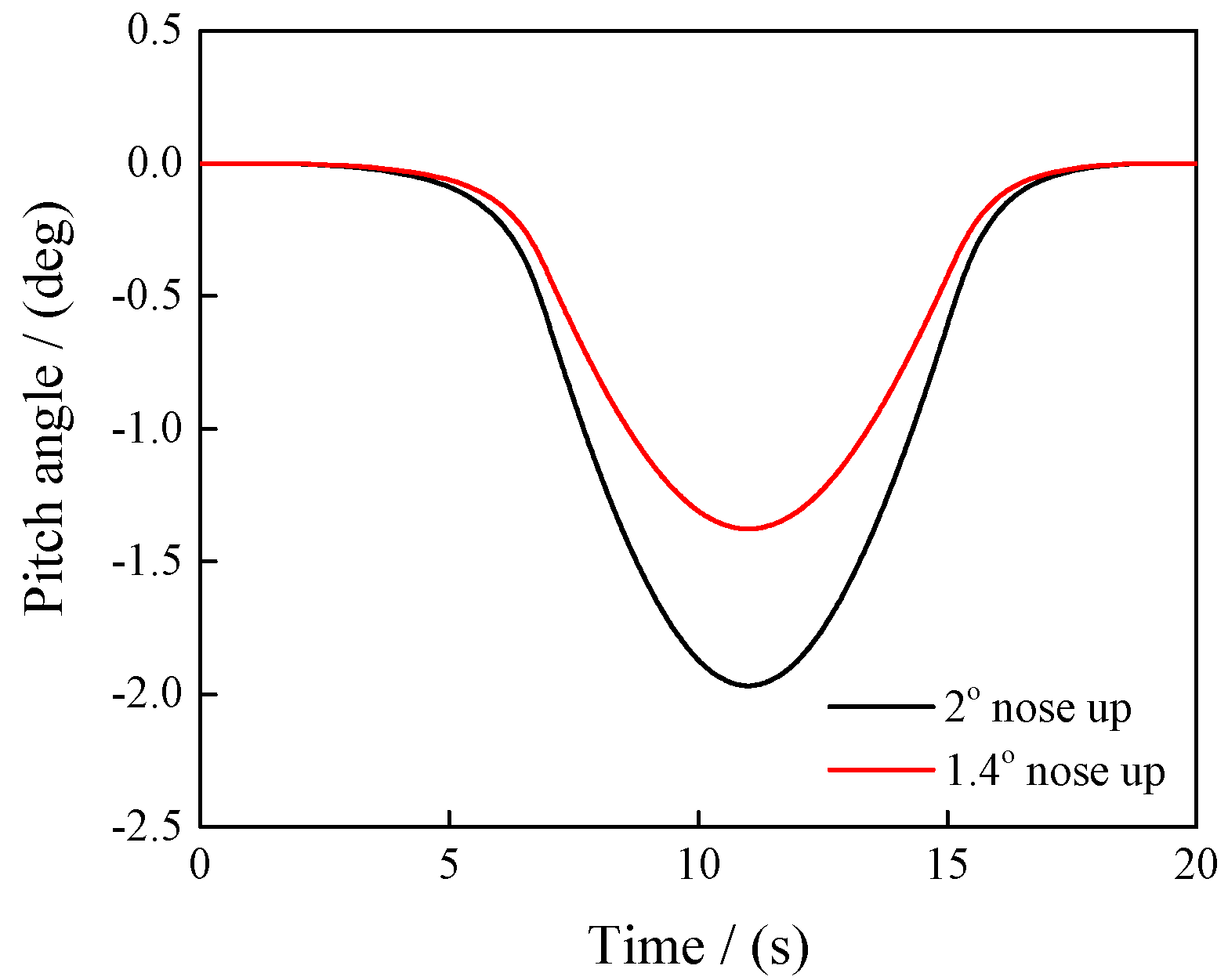

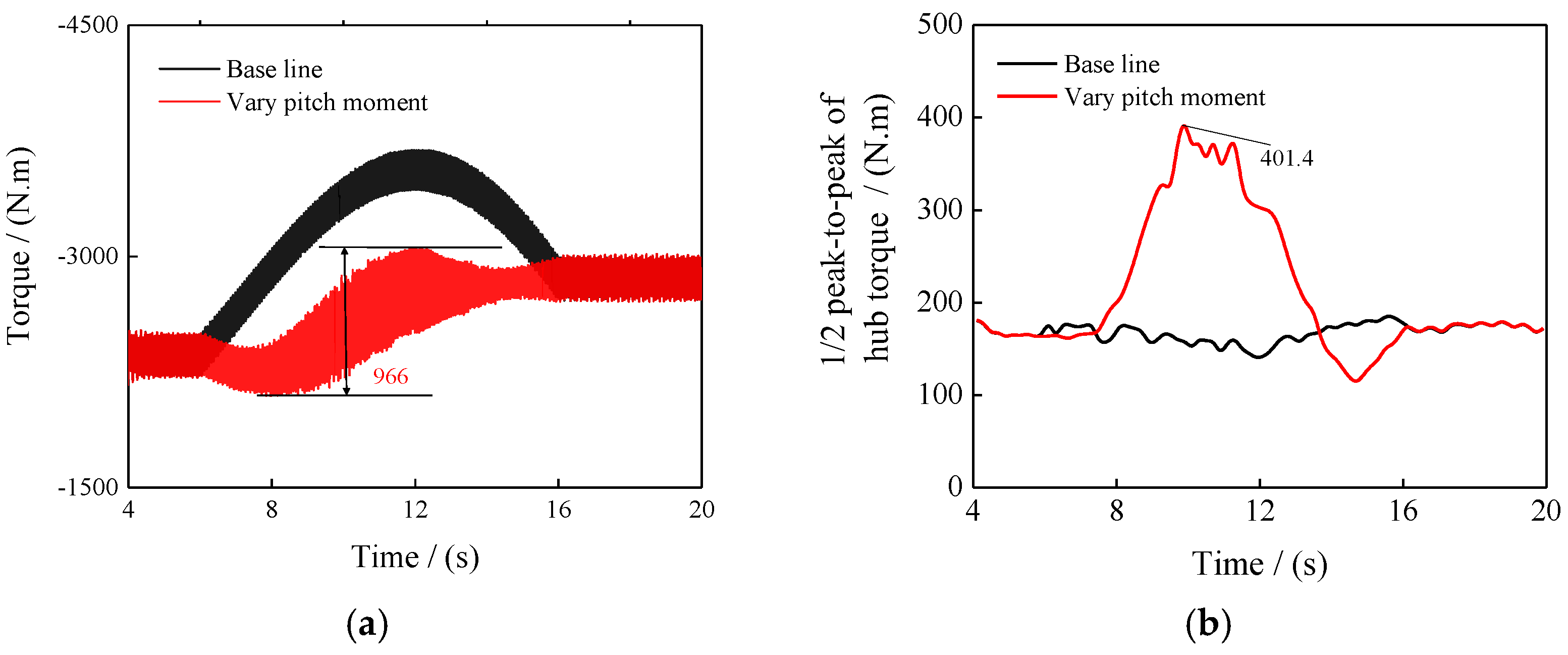

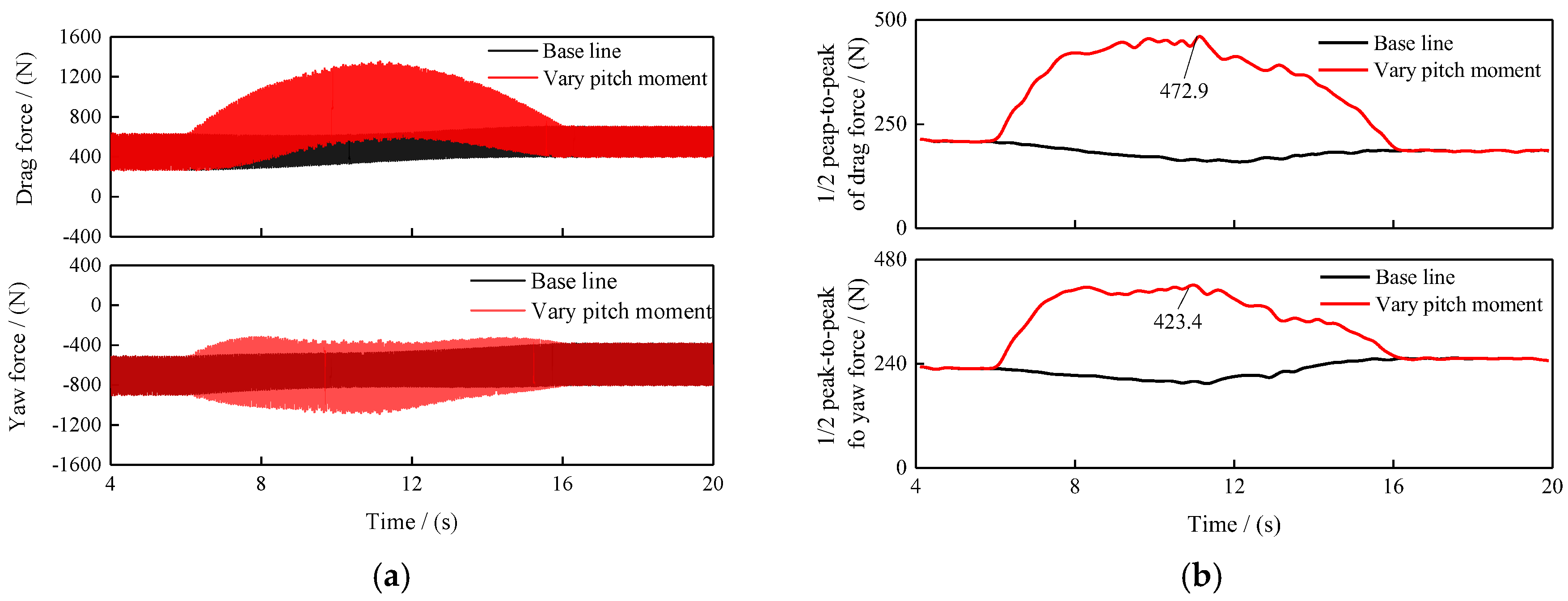

3.3. Torque Reduction

4. Conclusions

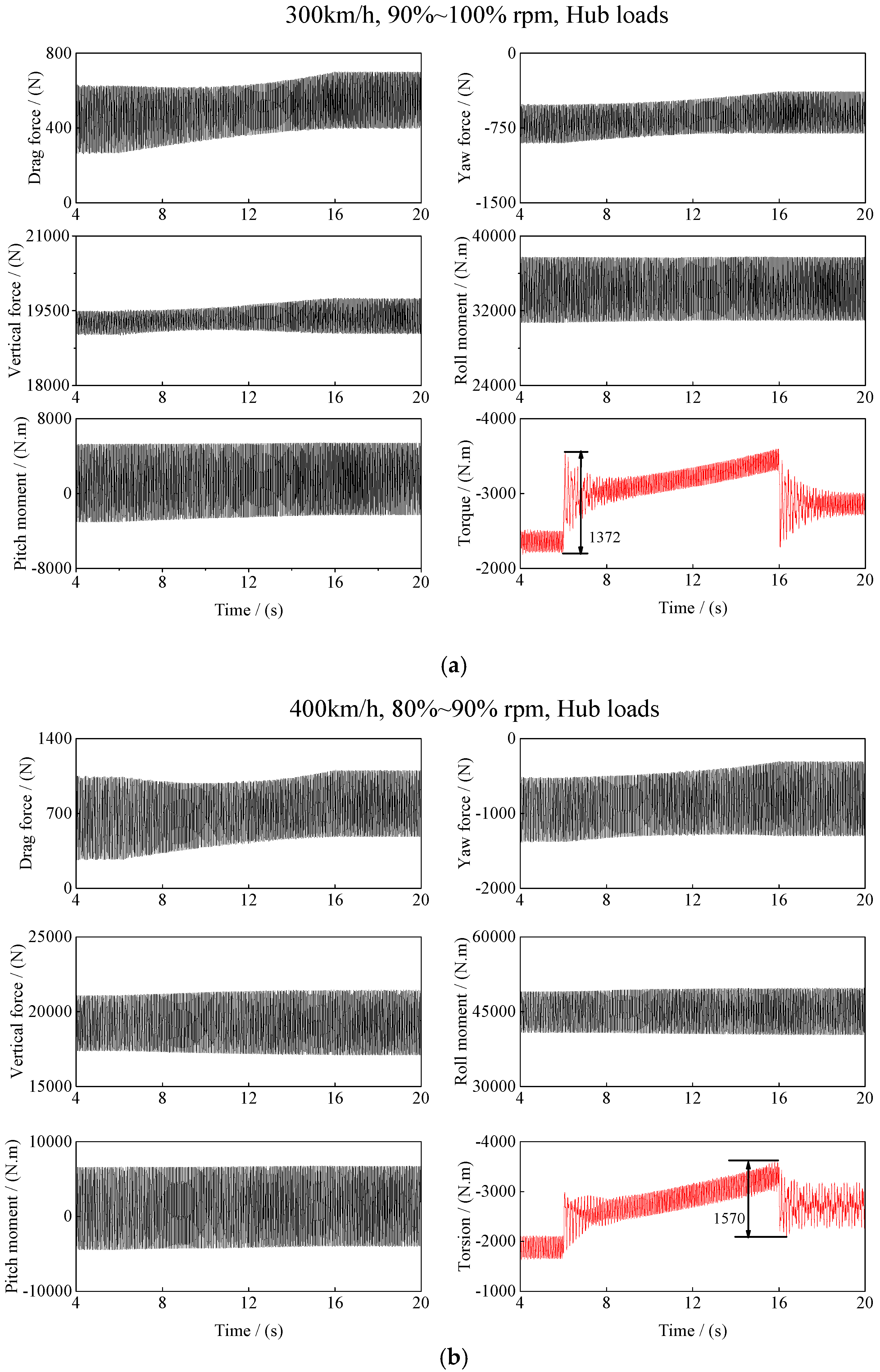

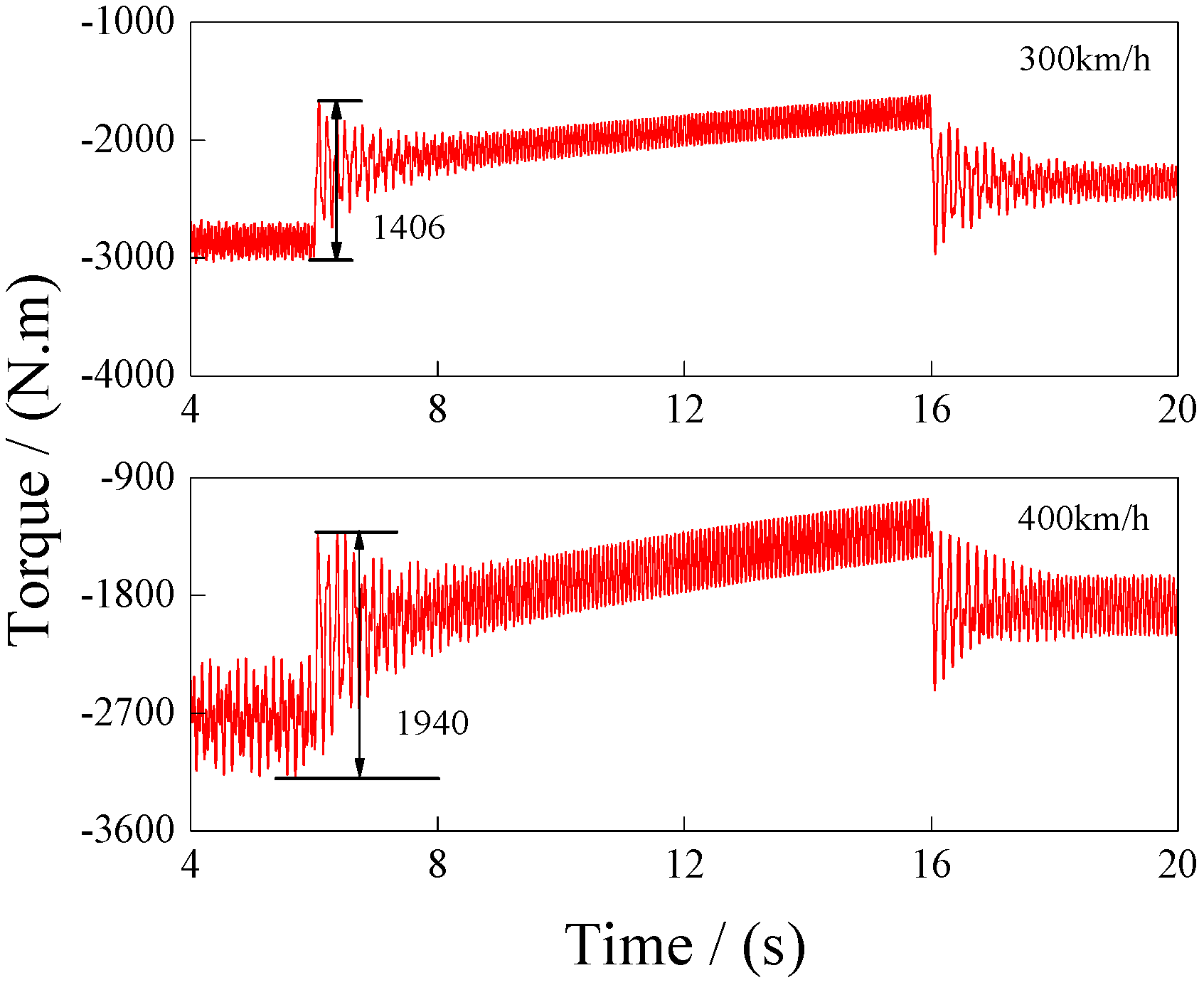

- (1)

- During transient processes, the rotor hub torque is significantly affected, whereas other hub forces and moments remain largely unchanged. Notably, there is a pronounced overshoot in rotor hub torque at both the start and end of the rotor speed change, whether the rotor speed is accelerated or decelerated. The maximum total overshoot is 1940 N·m within 0.2 s at 400 km/h rotor speed decrease transient process. Special attention should be given to the dynamic behavior of the rotor and transmission system.

- (2)

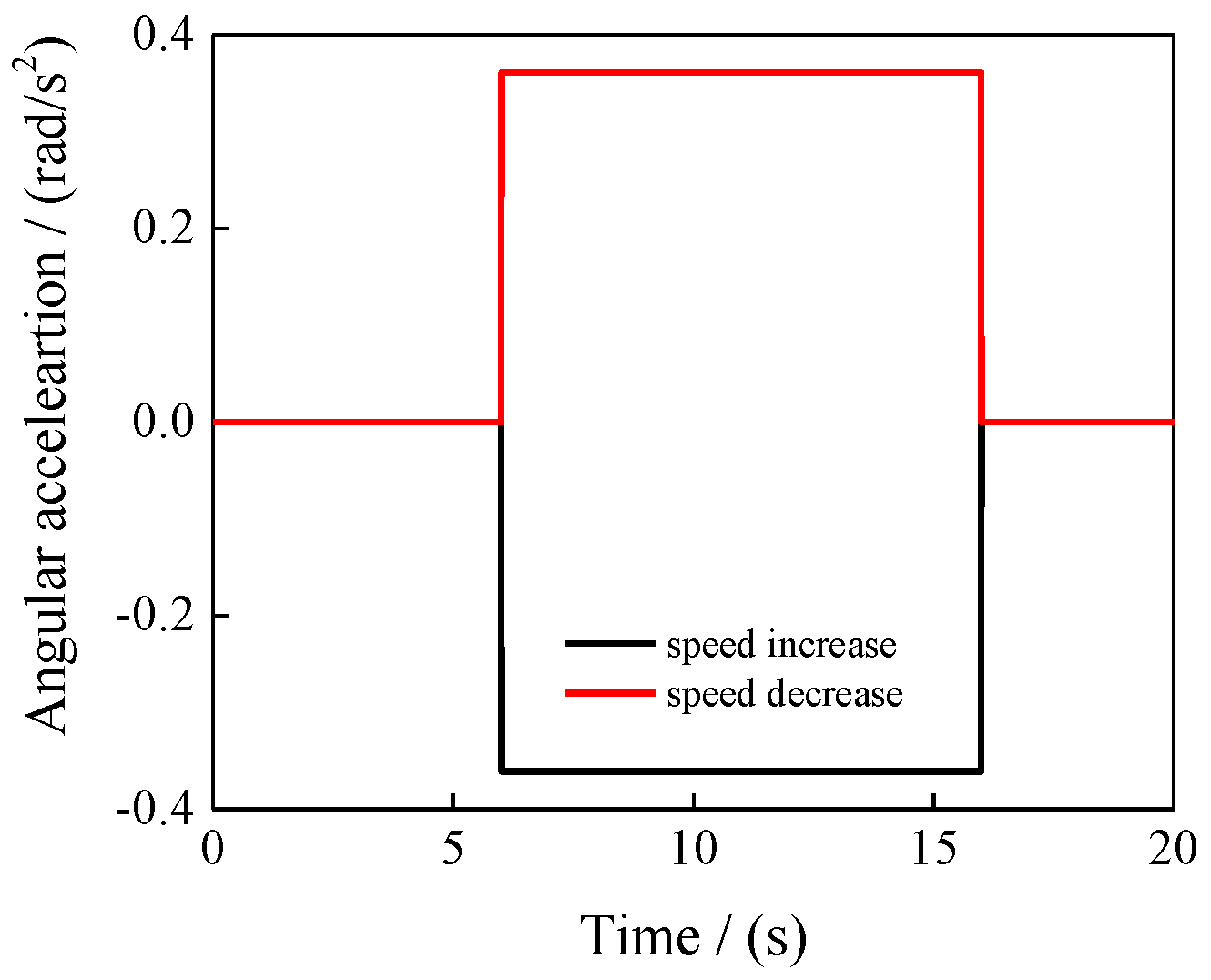

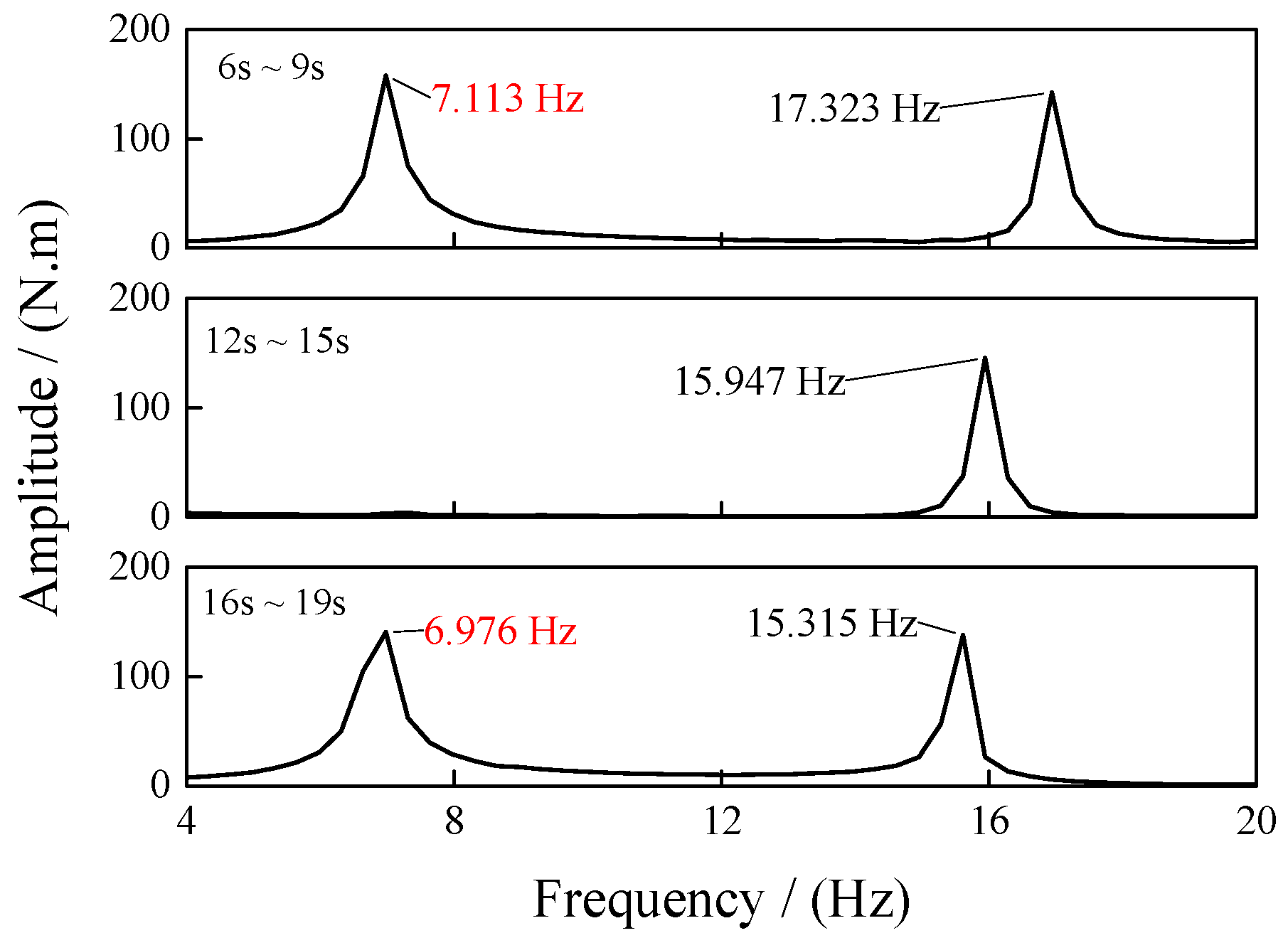

- The characteristics of rotor hub torque are closely associated with the transient process of rotor angular acceleration. A linear transient process of angular acceleration results in significant impulsive effects at the start and end of the rotor speed change. The maximum value of overshoot/time is 17,500 N·m·s−1. To minimize these effects, it is essential to ensure that the rotor angular acceleration is as smooth as possible, thereby achieving a smoother variation in rotor hub torque.

- (3)

- The overshoot of rotor hub torque during the transient process is primarily influenced by angular acceleration, whereas flight speed and rotor thrust have minimal impact. The value of overshoot/time can be reduced by 98.6% at most in three angular acceleration strategies, and it can be reduced by 92.7% at most in three transient times.

- (4)

- Adjusting the rotor pitch attitude and control mechanisms can effectively mitigate hub torque overshoot. Adjusting the rotor pitch attitude during the transient state appears to be an effective strategy for reducing hub torque. Altering the hub pitch moment during transient states incurs additional costs and does not appear to be an effective torque reduction strategy; the 1/2 peak-to-peak of hub torque, drag force, and yaw force would increase by around 2 times. Future research should focus on analyzing load reduction techniques during maneuvering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, J.H. Key technologies and development for high-speed helicopters. Acta Aeronaut. Et Astronsutica Sin. 2024, 45, 1–20. [Google Scholar]

- Deng, J.H. Technical status and development of electric vertical take-off and landing aircraft. Acta Aeronaut. Et Astronsutica Sin. 2024, 45, 47–69. [Google Scholar]

- Schuster, D. S-97 Raider Propulsor Flight Loads and Validation. In Proceedings of the 79th Annual Vertical Flight Society Forum and Technology Display, West Palm Beach, FL, USA, 16–18 May 2023. [Google Scholar]

- Muscarello, V.; Quaranta, G. Optimal Tiltrotor Blade Twist to Extend Whirl-Flutter Stability Boundaries. In Proceedings of the 62nd American Institute of Aeronautics and Astronautics Science and Technology Forum and Exposition, Harbor, MD, USA, 23–27 January 2023. [Google Scholar]

- Lu, Y.L.; Cao, D.; Qu, Q.; Zu, J.K. Active Disturbance Rejection Control for a Compound Helicopter during Transitional Period. In Proceedings of the 2023 China Automation Congress(CAC), Chongqing, China, 17–19 November 2023. [Google Scholar]

- Littell, J.; Putnam, J. A Summary of Test Results from a NASA Lift + Cruise eVTOL Crash Test. In Proceedings of the 79th Annual Vertical Flight Society Forum and Technology Display, West Palm Beach, FL, USA, 16–18 May 2023. [Google Scholar]

- Graham, M.B.D. Performance and Loads of Variable Tip Speed Rotorcraft at High Advance Ratios. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2015. [Google Scholar]

- Weiss, F.; Kessler, C. Drivetrain Influence on the Blade Loads of Hingeless Helicopter Rotors. In Proceedings of the 79th Annual Vertical Flight Society Forum and Technology Display, Philadelphia, PA, USA, 13–16 May 2019. [Google Scholar]

- Wang, X.; Bauknech, A.; Maurya, S.; Chopra, I. Slowed Hingeless Rotor Wind Tunnel Tests and Validation at High Advance Ratios. J. Aircr. 2020, 58, 1–14. [Google Scholar] [CrossRef]

- Han, D.; Wang, H.W.; Gao, Z. Aeroelastic analysis of a shipboard helicopter rotor with ship motions during engagement and disengagement operations. Aerosp. Sci. Technol. 2012, 16, 1–9. [Google Scholar] [CrossRef]

- Yu, Z.; Zhuo, Y.; Song, B. Aeroelastic modeling and load analysis of a variable speed rotor in high advance ratio. J. Vib. Shock 2021, 40, 17–22. [Google Scholar]

- Huang, J.; Yu, Z.; Cheng, Y. Transient dynamic modeling and load characteristic analysis of variable speed rotor. China Sci. Technol. Inf. 2023, 22, 41–45. [Google Scholar]

- Jinggen, Z.; Lorber, P.F.; Brigley, M. S-97 RAIDER Empennage Loads and Vibrations: Analysis, Correlation and Understanding. In Proceedings of the 61st American Institute of Aeronautics and Astronautics Science and Technology Forum and Exposition, San Diego, CA, USA, 3–7 January 2022. [Google Scholar]

- Öhrle, C.; Frey, F.; Thiemeier, J.; Keßler, M.; Krämer, E.; Embacher, M.; Cranga, P.; Eglin, P. Compound Helicopter X-3 in High-Speed Flight: Correlation of Simulation and Flight Test. In Proceedings of the 75th Annual Vertical Flight Society Forum and Technology Display, Philadelphia, PA, USA, 13–16 May 2019. [Google Scholar]

- Malpica, C.; Withrow-Maser, S. Handling Qualities Analysis of Blade Pitch and Rotor Speed Controlled eVTOL Quadrotor Concepts for Urban Air Mobility. In Proceedings of the VFS International Powered Lift Conference, San Jose, CA, USA, 21–23 January 2020. [Google Scholar]

- Brenner, F.; Foraste, G.L.; Goericke, J.; Hasbun, M. Comprehensive Simulation for eVTOL Air-craft-Diagnosing Coupled Airframe Propulsion Dynamic Instabilities. In Proceedings of the 78th Annual Vertical Flight Society Forum and Technology Display, Fort Worth, TX, USA, 10–12 May 2022. [Google Scholar]

- Cho, C.; Rahn, C.D.; Smith, E.; Singh, P. Active Vibration Damping and Harmonic Vibration Reduction in an eVTOL Aircraft Model Using Electric Rotor Torque. In Proceedings of the 80th Annual Vertical Flight Society Forum and Technology Display, Montreal, QC, Canada, 7–9 May 2024. [Google Scholar]

- Yu, Z.; Huang, J.; Jiang, Q.; Fan, F.; Huang, S. Rotor Dynamic Loads Characteristic Analysis With Blade Tip Twist Distribution. In Proceedings of the 34th Congress of the International Council of the Aeronautical Sciences, Florence, Italy, 9–13 September 2024. [Google Scholar]

- Yu, D.; Sirohi, J.; Mortimer, P. Extraction of a Dynamic Inflow Model from Wake Measurements on a Hovering Rotor. In Proceedings of the 80th Annual Vertical Flight Society Forum and Technology Display, Montreal, QC, Canada, 7–9 May 2024. [Google Scholar]

- Felker, F.F. Performance and Loads Data form a wind Tunnel Test of a Full-Scale, Coaxial, Hingeless Rotor Helicopter; Report No. TM81329; NASA: Washington, DC, USA, 1981.

- Ferguson, K.M. Towards a Better Understanding of the Flight Mechanics of Compound Helicopter Configurations. Ph.D. Thesis, University of Glasgow, Glasgow, UK, 2015. [Google Scholar]

- Eller, E. X2TM Load Alleviating Controls. In Proceedings of the 68th American Helicopter Society International Annual Forum, Fort Worth, TX, USA, 1–4 May 2012; p. 1578. [Google Scholar]

| Parameter | Values |

|---|---|

| Rotor radius (m) | 0.829 |

| Number of blades | 2 |

| Extension of lag hinge (mm) | 100 |

| Mass (g) | 250 |

| Rotor solidity (σ) | 0.049 |

| Blade installation angle (o) | 6.5 |

| Blade twist angle (o) | −10.2 |

| Rotor Speed (rpm) | Test Value (N·m) | Calculated Value (N·m) | Error |

|---|---|---|---|

| 700 | 3.31 | 3.15 | −4.8% |

| 745 | 3.67 | 3.55 | −3.3% |

| 754 | 3.8 | 3.63 | −4.5% |

| 775 | 3.95 | 3.83 | −3.0% |

| 805 | 4.31 | 4.12 | −4.4% |

| 847 | 4.75 | 4.54 | −4.4% |

| Parameters | Values |

|---|---|

| Rotor radius (m) | 5.4864 |

| Number of blades | 2 × 3 |

| Taper ratio | 2:1 |

| Tip chord | 0.286 |

| Rotor space (m) | 0.762 |

| Pre-twist (deg) | 3 |

| Rotor solidity | 0.1267 |

| Rotor speed (rad/s) | 36.11 |

| Strategy | The Total Overshoot (N·m) | Time to Total Overshoot (s) | Overshoot/Time (N·m·s−1) | |

|---|---|---|---|---|

| Angular acceleration | Strategy 1 | 1400 | 0.08 | 17500 |

| Strategy 2 | 1697 | 5.02 | 338.04 | |

| Strategy 3 | 1489 | 6.21 | 239.77 | |

| Flight speed | 300 km/h | 1489 | 5.84 | 254.97 |

| 350 km/h | 1564 | 6.04 | 258.94 | |

| 400 km/h | 1876 | 6.65 | 282.10 | |

| Rotor thrust | 2250 kg | 1489 | 5.79 | 257.17 |

| 2750 kg | 1576 | 6.24 | 252.56 | |

| 3250 kg | 1837 | 6.51 | 282.18 | |

| Transient times | 10 s | 1489 | 6.09 | 244.50 |

| 5 s | 2407 | 2.77 | 868.95 | |

| 2.5 s | 4325 | 1.29 | 3352.71 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.; Li, C.; Huang, J.; Cheng, Y. Transient Vibration Loads Characteristics Analysis of Variable Speed Rotor. Appl. Sci. 2025, 15, 10493. https://doi.org/10.3390/app151910493

Yu Z, Li C, Huang J, Cheng Y. Transient Vibration Loads Characteristics Analysis of Variable Speed Rotor. Applied Sciences. 2025; 15(19):10493. https://doi.org/10.3390/app151910493

Chicago/Turabian StyleYu, Zhihao, Chunhua Li, Jian Huang, and Yi Cheng. 2025. "Transient Vibration Loads Characteristics Analysis of Variable Speed Rotor" Applied Sciences 15, no. 19: 10493. https://doi.org/10.3390/app151910493

APA StyleYu, Z., Li, C., Huang, J., & Cheng, Y. (2025). Transient Vibration Loads Characteristics Analysis of Variable Speed Rotor. Applied Sciences, 15(19), 10493. https://doi.org/10.3390/app151910493