Research on the Dynamic Response Characteristics of Soft Coal Under Impact Disturbance Based on Hamilton

Abstract

1. Introduction

2. Materials and Methods

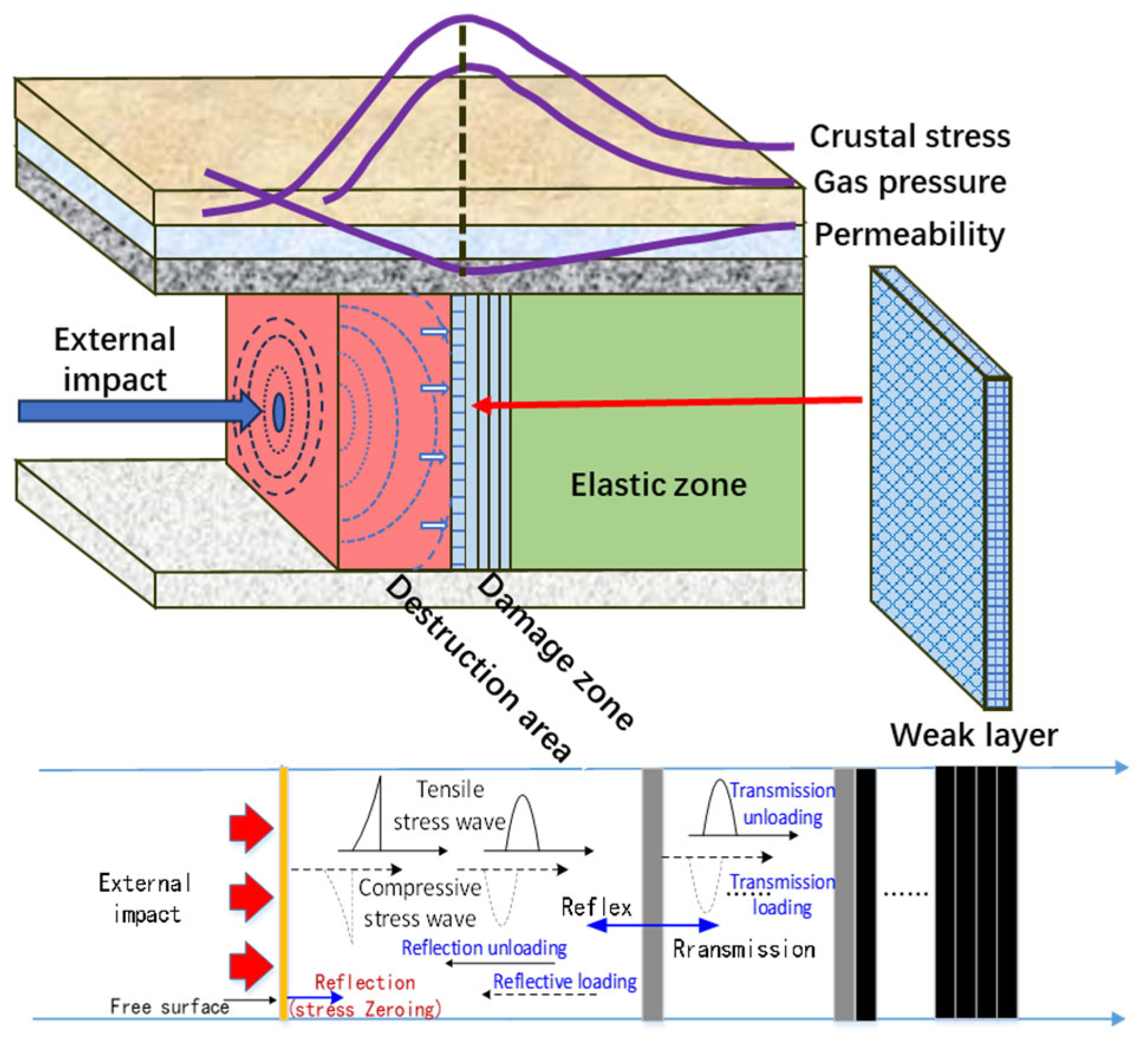

2.1. Determination of Coal and Gas High Outburst Risk Area in Front of Impact

2.2. Establishment of Hamilton Mechanics Model

2.3. Coal Plate Impact Vibration Control Theory Based on Hamilton

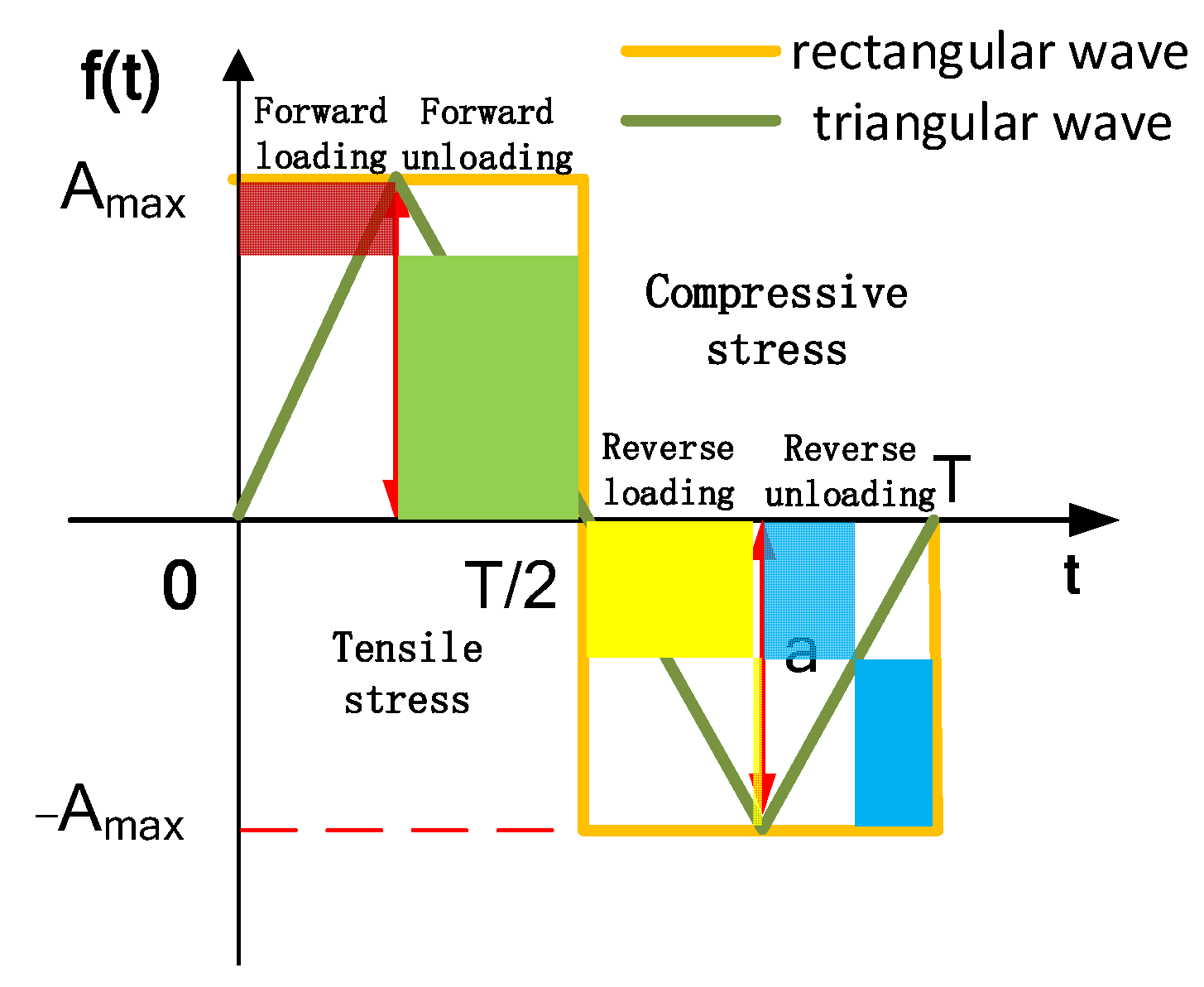

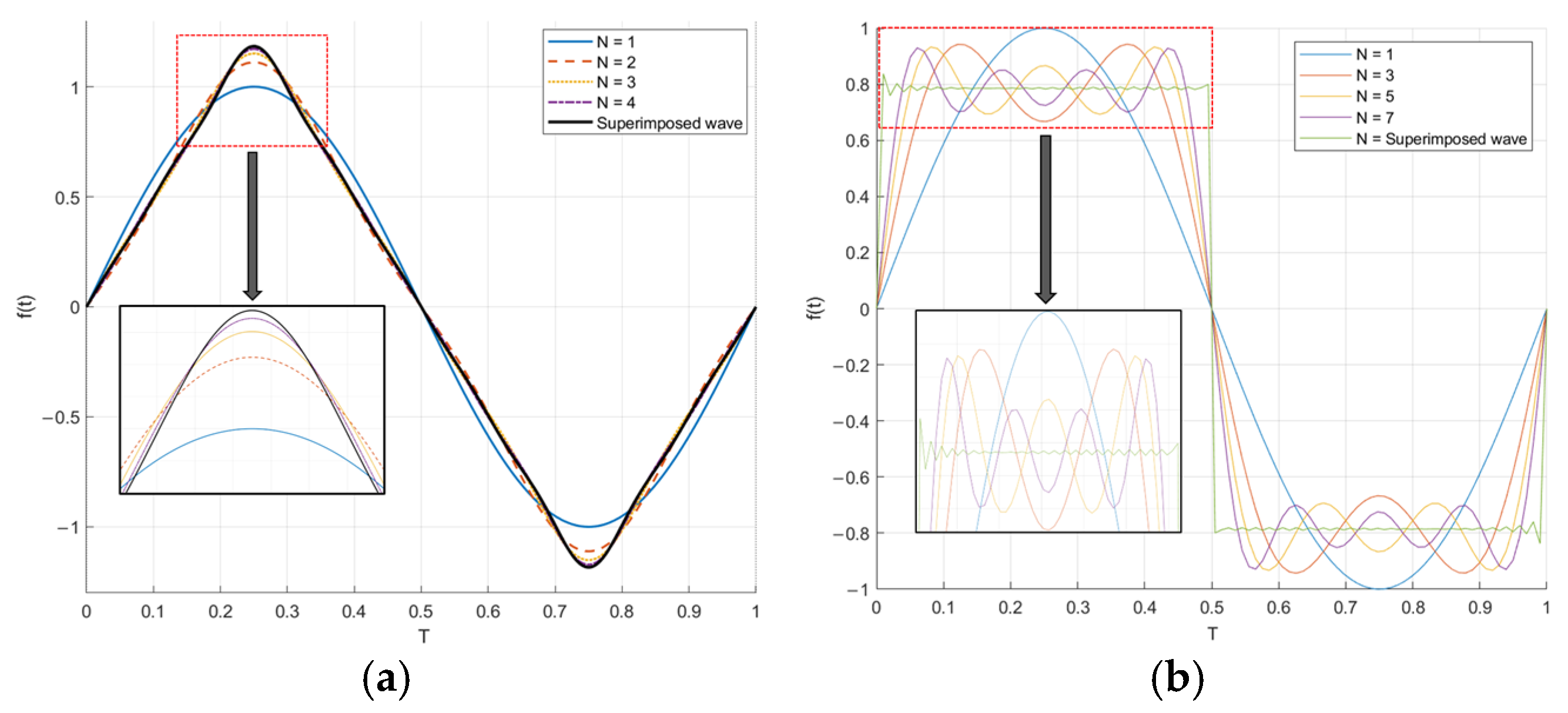

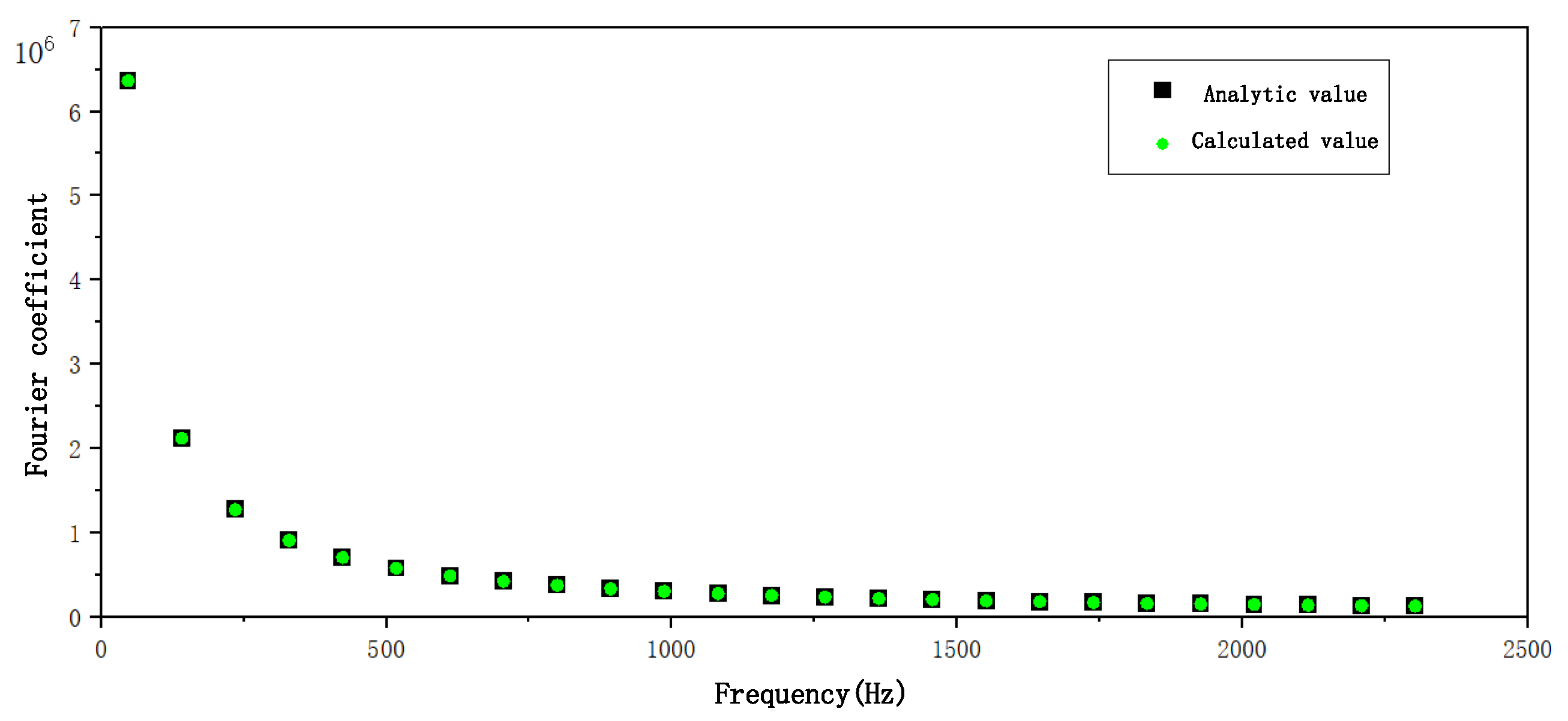

2.4. Pre-Conditioning of External Impact Waveforms for Hamiltonian Formulation

3. Results

3.1. Analysis of Dynamic Response Characteristics of Soft Coal Under Impact Loading

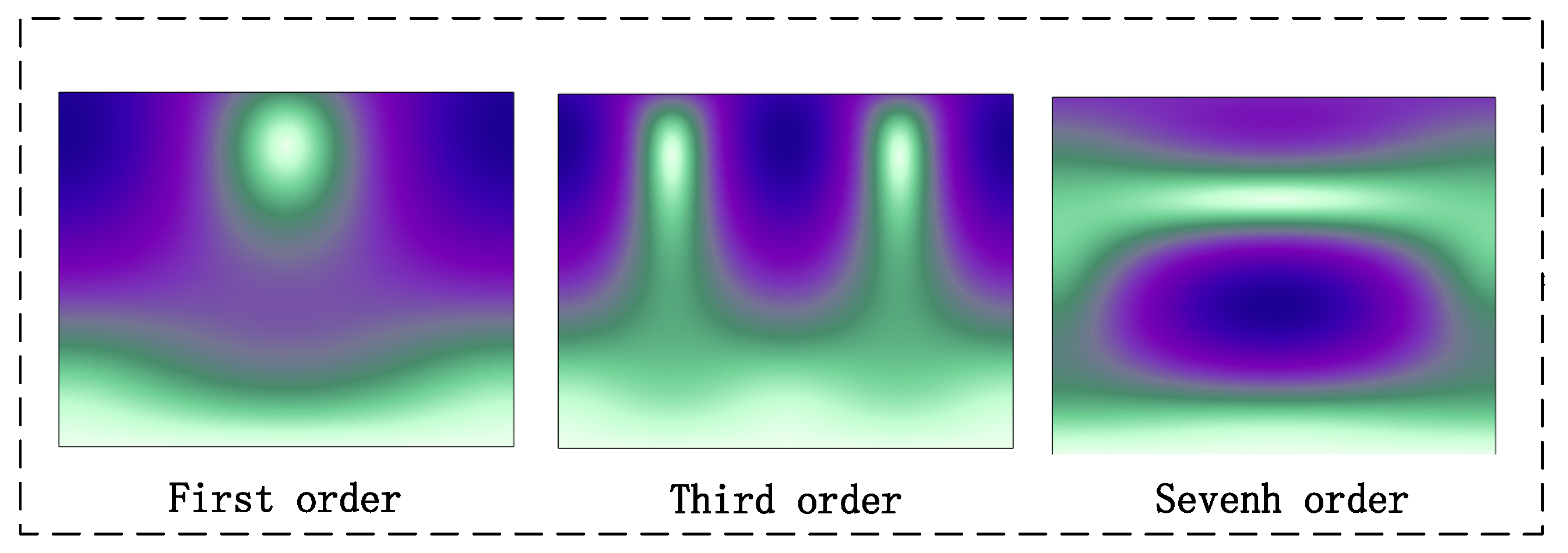

3.1.1. Dominant Vibration Modes and Frequency Calculation in the Dynamic Response of the Weak Layer

3.1.2. Analysis of Modal Variations in Dominant Modes of an Outburst-Prone Weak Layer Under Impact Disturbance

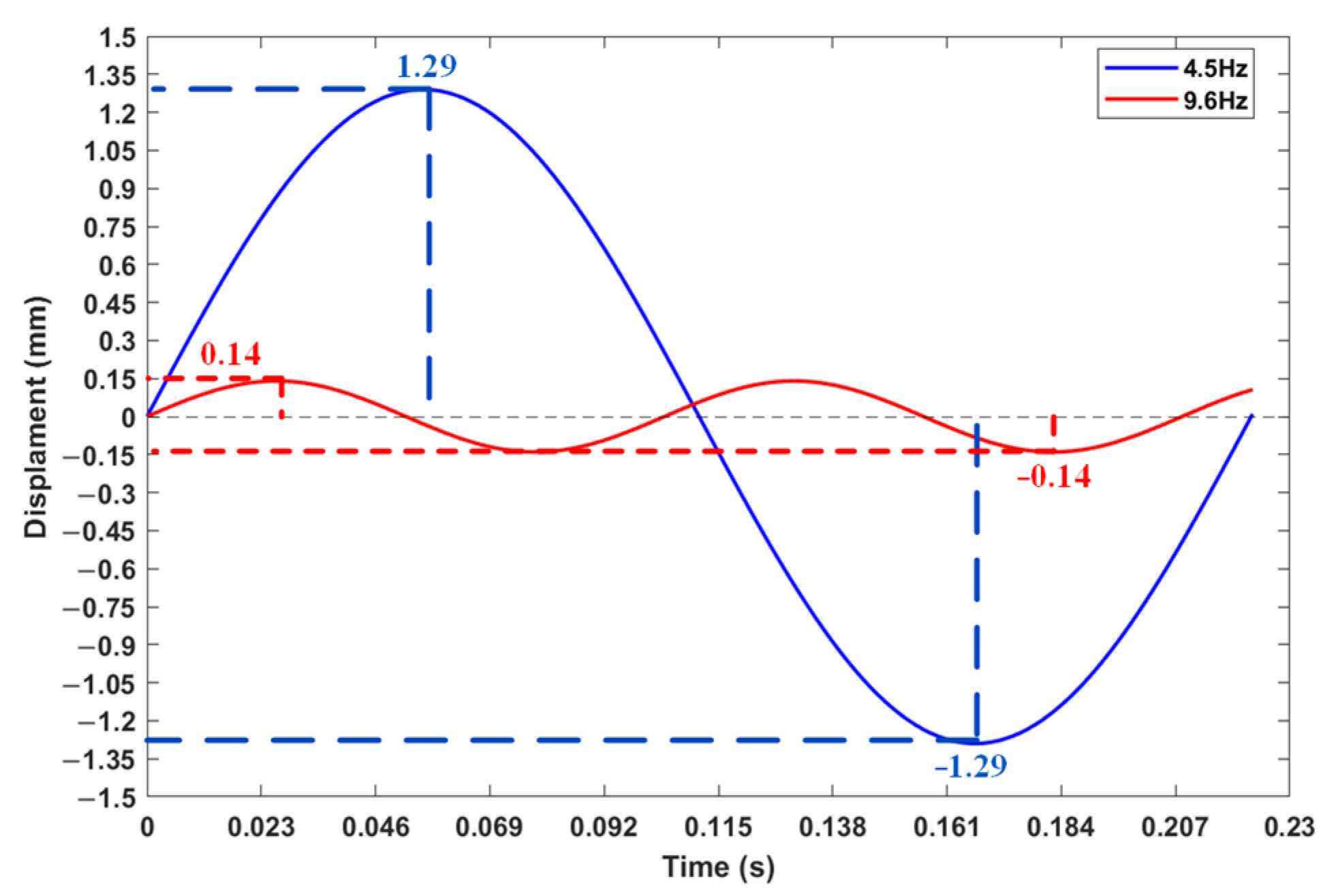

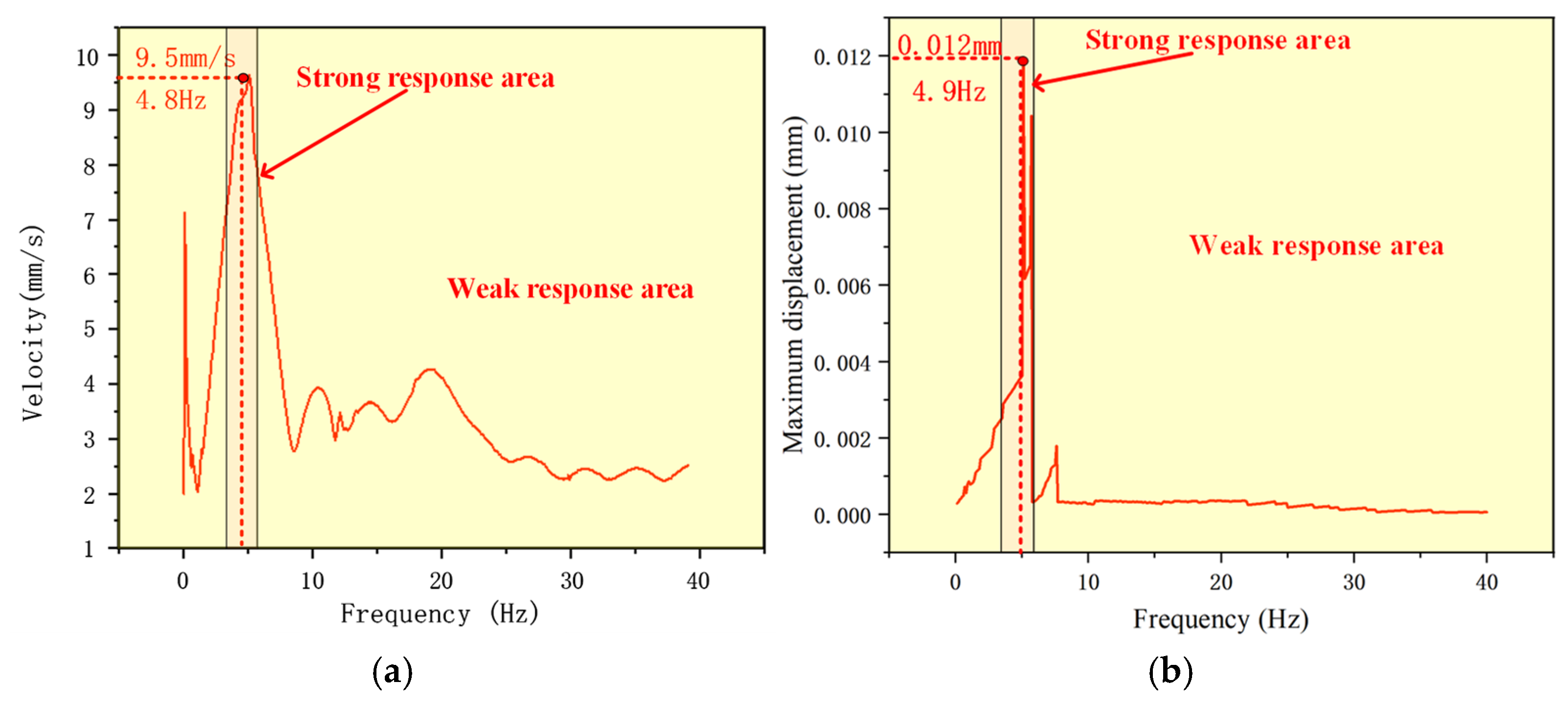

3.1.3. Analysis of Response Frequency in Soft Coal Under Impact Disturbance

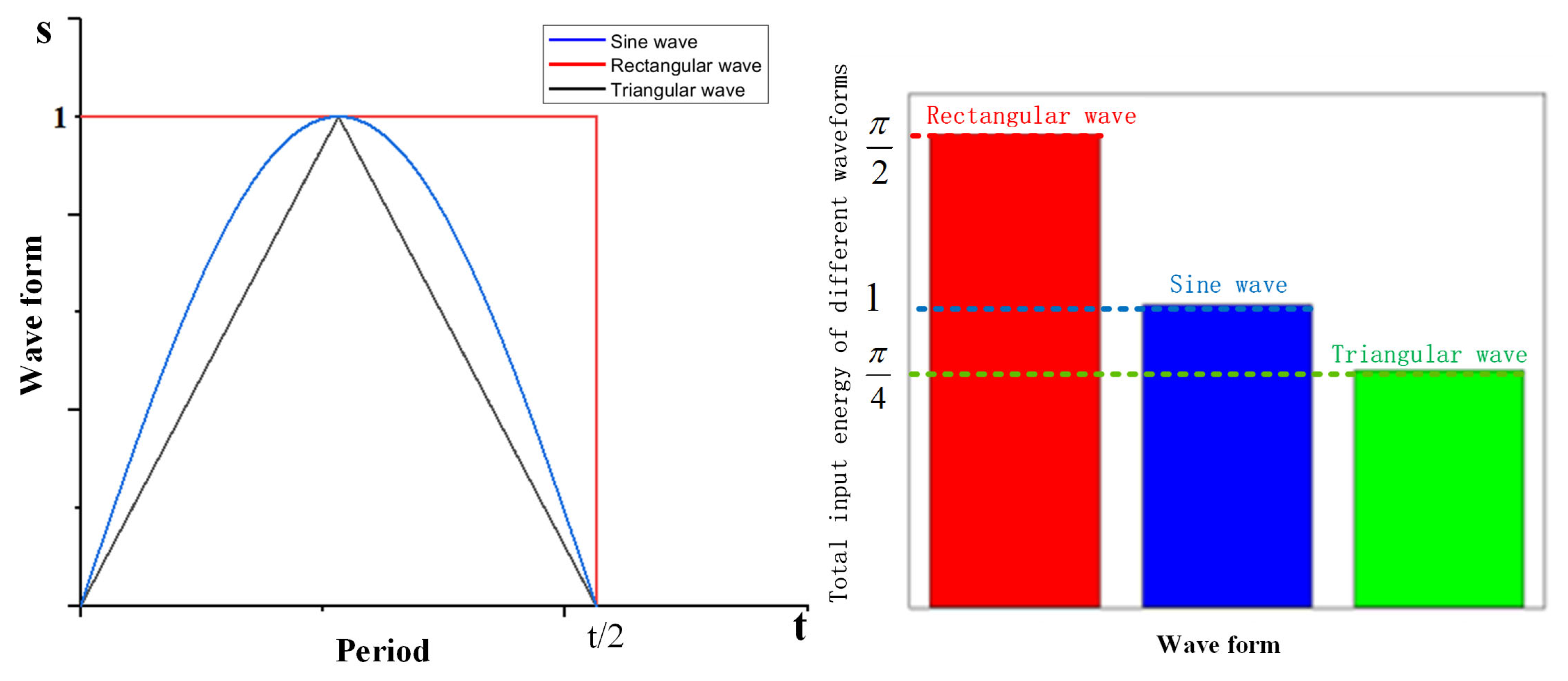

3.1.4. Response of the Outburst-Prone Weak Zone to Different Impact Waveforms

3.2. Numerical Simulation of the Dynamic Response of Friable Coal Under Impact Loading

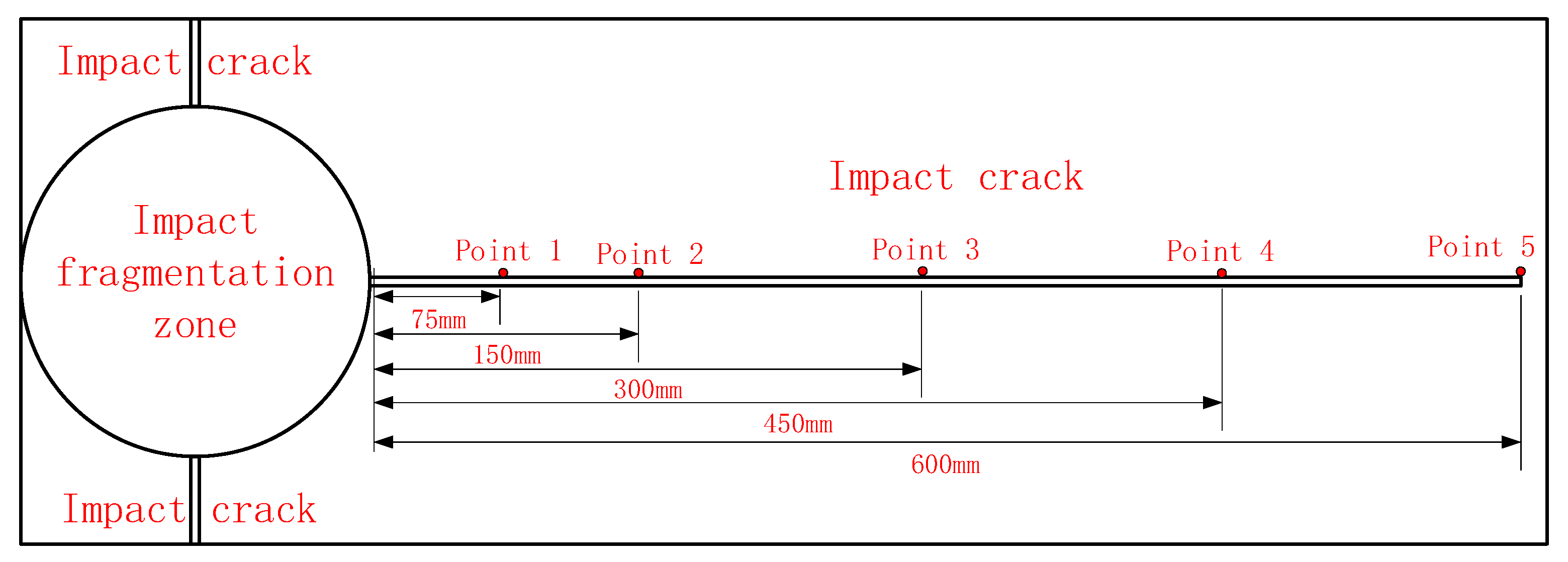

3.2.1. Design of a Similitude Simulation Test Rig for Impact Response in Soft Coal

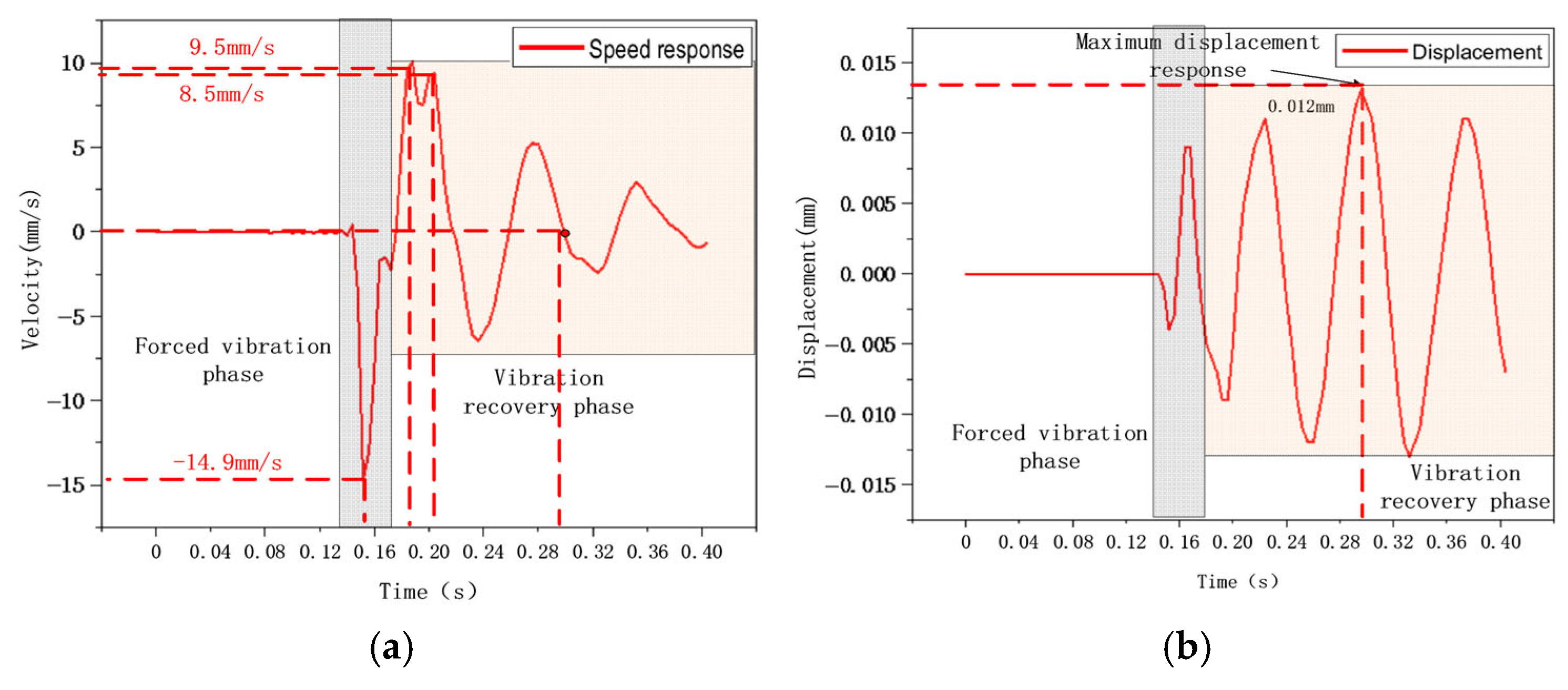

3.2.2. Analysis of Dynamic Response in Similitude Coal Under External Impact

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hodot, B.B. Coal and Gas Outburst; China Industry Press: Beijing, China, 1966; pp. 2–3. [Google Scholar]

- Jin, Y.; Tong, X.; Zheng, X.; Li, Y.; Dong, B. Risk assessment of coal and gas outbursts driven by the theory of three types of hazards coupled with 80 accident cases. Saf. Sci. 2025, 184, 106771. [Google Scholar] [CrossRef]

- Shen, B.H.; Lei, Y. Strategic considerations on unconventional energy development in China’s coal mining areas. Coal Sci. Technol. 2013, 41, 16–20. [Google Scholar] [CrossRef]

- Wei, J.; Chen, Y.; Wen, Z. Study on gas desorption law of tectonic coal. Coal Mine Saf. 2008, 8, 1–3. [Google Scholar]

- Yu, B. Enhanced Extraction Technology of High Pressure Jet in Soft and Low Permeability Coal Seam. Min. Saf. Environ. Prot. 2019, 46, 42–46. Available online: http://www.kyaqyhb.com/en/article/id/89309334-51ae-4b19-832f-71603ec91bc4 (accessed on 24 September 2025).

- Zhang, C.; Wang, P.; Liu, X.; Wang, E.; Jiang, Q.; Liu, M. Energy Evolution and Coal Crushing Mechanisms Involved in Coal and Gas Outburst. Nat. Resour. Res. 2023, 33, 455–470. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, H.; Song, D. Mechanics and Civil Engineering; China Water Resources and Hydropower Press: Beijing, China, 2012; Volume 8, p. 473. ISBN 9787517000662. [Google Scholar]

- Li, F.; Wang, C.; Sun, R.; Xiang, G.; Ren, B.; Zhang, Z. Frequency response characteristics and failure model of single-layered thin plate rock mass under dynamic loading. Sci. Rep. 2022, 12, 19047. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Wang, P.; Lv, F. Dynamic failure characteristics and acoustic emission response mechanism of coal mass with various coal burst liabilities. PLoS ONE 2025, 20, e0313910. [Google Scholar] [CrossRef]

- Cong, R.; Yang, R.; Gong, Y.; Li, H.; Huang, Z.; Zhang, B. Numerical investigation of mechanical responses and failure features of coal measure strata using combined finite-discrete element method. Comput. Geotech. 2024, 171, 106346. [Google Scholar] [CrossRef]

- Li, F.; Zhang, Y.; Liu, J.; Zhang, L.; Fang, S. The dynamical response characteristics of elastic–plastic coal under dynamic load. J. Nat. Gas Sci. Eng. 2016, 29, 497–505. [Google Scholar] [CrossRef]

- Ma, J.; Jin, Y.; Zhou, S.; Zhai, G. Experimental study on the effect of mechanical vibration on core permeability. J. Xi’an Pet. Inst. Nat. Sci. Ed. 1996, 5, 8–15. [Google Scholar]

- Ren, W.; Du, G.; Pan, Y. Effect of vibration on fracture distribution and mechanical properties of coal. J. Fuxin Inst. Min. Technol. Nat. Sci. Ed. 1997, 16, 687–690. [Google Scholar]

- Li, X.; Nie, B.; He, X. Mechanism of coal and gas outburst induced by vibration. J. Beijing Univ. Sci. Technol. 2011, 33, 149–152. [Google Scholar] [CrossRef]

- Li, C.; Sun, X.; Gao, T.; Sun, Y.; Xie, B.; Xu, X. Study on the variation characteristics of natural frequency in the process of coal rock vibration failure. J. Coal 2015, 40, 2422–2429. [Google Scholar] [CrossRef]

- Li, F.; Wang, C.; Xu, B.; Liang, D.; Li, Z.; Zhang, T.; Tian, B. Research on dynamic damage path of multi-layered combined coal mass under impact load. Phys. Chem. Earth 2025, 138, 103872. [Google Scholar] [CrossRef]

- Wang, C. Couple Stress Effect of Elastic Wave Propagation in Solids. Ph.D. Thesis, Beijing University of Science and Technology, Beijing, China, 2018. [Google Scholar]

- Li, H.; Zhu, X.; Wang, L.; Zhang, Z. Simplified theoretical model of overall motion of ship beam under spherical shock wave action. Explos. Shock 2010, 30, 85–90. [Google Scholar]

- Shen, Y.; Tang, P.; Wang, Y.; Yang, S. Dynamic response of rigid plastic circular plate under underwater explosion load. Explos. Impact 2005, 1, 90–96. [Google Scholar]

- Escalante, A.; González, P.A.J. The Hamilton–Jacobi analysis for higher-order modified gravity. Chin. J. Phys. 2024, 89, 973–979. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, L.; Xu, W.; Wang, X.; Gao, N. Analytical Solutions Based on Hamiltonian System for the Free Vibration of Polyline Thin Plates. Int. J. Struct. Stab. Dyn. 2024, 25, 2550184. [Google Scholar] [CrossRef]

- Emami, M.; Eskandari-Ghadi, M.; Amir, K. Ghorbani-Tanha Generalization of Duhamel’s integral to multi-degree-of-freedom systems. Proc. R. Soc. A 2022, 478, 20210576. [Google Scholar] [CrossRef]

- Li, S.; Guo, H.; Li, D. Overview of Vibration Signal Processing Methods. J. Instrum. 2013, 34, 1907–1915. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, P. Statistics and Analysis of Coal and Gas Outburst Accidents in China from 2020 to 2024. Min. Technol. 2025, 25, 259–262. [Google Scholar] [CrossRef]

- Li, Y. Numerical Simulation Study on the Influence of Dynamic Stress Waveform on Rock Crack Propagation. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2021. [Google Scholar]

- Hong, M.; Li, T. Spectral analysis of explosion waves. Geotech. Mech. 1987, 1, 51–57. [Google Scholar] [CrossRef]

- Cao, A. Research on Vibration Effects and Applications of Mining-Induced Coal Rock Impact Fracture. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2009. [Google Scholar]

- Jia, C.; Su, H.; Li, Y.; Gou, Y. Linearly Implicit Algorithm with Embedded Newton Iteration of Velocity and its Application in Nonlinear Dynamic Analysis of Structures. Int. J. Struct. Stab. Dyn. 2023, 24, 2450010. [Google Scholar] [CrossRef]

- Guo, J. Numerical Simulation and Testing of Vibration Modes of Wooden Plywood. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2013. [Google Scholar]

- Feng, L.; Hanwu, L.; Chenchen, W.; Sun, R.; Xiang, G.; Ren, B.; Wang, G. Stress Relief and Permeability Enhancement with Hydraulic Fracturing in Overlying Key Strata of Deep and Soft Coal Seams. ACS Omega 2023, 8, 12183–12193. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Wang, G.; Xiang, G.; Tang, J.; Ren, B.; Chen, Z. Vibration Response of the Interfaces in Multi-Layer Combined Coal and Rock Mass under Impact Load. Processes 2023, 11, 306. [Google Scholar] [CrossRef]

- Lu, C.; Dou, L.; Cao, A.; Wu, X.; Li, Z. Study on the regulation of mining tremors in deep high-stress concentration zones. Chin. J. Rock Mech. Eng. 2008, 11, 2302–2308. [Google Scholar]

- Zhang, L.; Liao, W.; Zeng, X.; Zhong, Y. Analysis of time-frequency characteristics of tectonic earthquakes and mining-induced seismicity in the Three Gorges key monitoring area. Seismol. Geol. 2009, 31, 699–706. [Google Scholar]

- Vadim, M. On uniform convergence of the inverse Fourier transform for differential equations and Hamiltonian systems with degenerating weight. Math. Nachrichten 2022, 295, 1755–1782. [Google Scholar] [CrossRef]

- Wang, W.; Hao, H.; Li, X.; Yan, Z.; Gong, F. Effects of a Single Open Joint on Energy Transmission Coefficients of Stress Waves with Different Waveforms. Rock Mech. Rock Eng. 2015, 48, 2157–2166. [Google Scholar] [CrossRef]

- Yang, Y.; Liao, H.; Xu, Y.; Niu, J.; Yang, L. Theoretical investigation of the energy transfer efficiency under percussive drilling loads. Arab. J. Geosci. 2019, 12, 175. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, L.; Sun, Z.; Liu, K.; Zhang, G.; Yu, X.; Song, X. Similar Material Simulation Test of Overlying Strata Characteristics of Isolated Working Face Mining with Thick-Hard Strata. Geotech. Geol. Eng. Int. J. 2020, 38, 1121–1132. [Google Scholar] [CrossRef]

| Parameter | 1st Order | 2nd Order | 3rd Order | 4th Order | 5th Order | 6th Order | 7th Order | 8th Order | 9th Order | 10th Order |

|---|---|---|---|---|---|---|---|---|---|---|

| β1 | 1.250 | 2.624 | 2.210 | 1.063 | 2.140 | 2.073 | 3.125 | 1.024 | 3.084 | 2.023 |

| β2 | 1.769 | 1.130 | 2.487 | 3.566 | 3.103 | 3.908 | 3.311 | 4.529 | 3.775 | 4.794 |

| α1 | 0.885 | 1.674 | 0.807 | 2.407 | 1.589 | 2.342 | 0.774 | 3.119 | 1.539 | 3.073 |

| α2 | 1.977 | 2.314 | 3.228 | 2.838 | 3.418 | 3.753 | 4.486 | 3.440 | 4.625 | 4.199 |

| k | 1.531 | 2.020 | 2.352 | 2.631 | 2.665 | 3.128 | 3.219 | 3.283 | 3.446 | 3.679 |

| 20.47 | 8.3 × 10−12 | 6.91 × 10−12 | 11.57 | 7.79 × 10−7 | 8.41 × 10−7 | 16.75 | 3.51 × 10−9 | 1.23 × 10−10 | 9.91 × 10−11 |

| Parameter | 1st Order | 4th Order | 7th Order |

|---|---|---|---|

| Oscillation/Rad·s−1 | 31.3372 | 70.2104 | 118.7548 |

| Order | 1 | 4 | 7 |

|---|---|---|---|

| Frequency (Hz/Rad·s−1) | 4.98/31.2744 | 11.15/70.022 | 18.92/118.8176 |

| Order | 1 | 4 | 7 |

|---|---|---|---|

| Frequency (Hz/Rad·s−1) | 4.85/30.45 | 10.12/63.5536 | 16.61/104.3108 |

| Material | Sand | Lime | Gypsum | Coal Powder | Water |

|---|---|---|---|---|---|

| Unit mass content/kg | 0.47 | 0.06 | 0.13 | 0.14 | 0.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Zhang, T.; Wang, C.; Tian, B. Research on the Dynamic Response Characteristics of Soft Coal Under Impact Disturbance Based on Hamilton. Appl. Sci. 2025, 15, 10443. https://doi.org/10.3390/app151910443

Li F, Zhang T, Wang C, Tian B. Research on the Dynamic Response Characteristics of Soft Coal Under Impact Disturbance Based on Hamilton. Applied Sciences. 2025; 15(19):10443. https://doi.org/10.3390/app151910443

Chicago/Turabian StyleLi, Feng, Tianyi Zhang, Chenchen Wang, and Binchan Tian. 2025. "Research on the Dynamic Response Characteristics of Soft Coal Under Impact Disturbance Based on Hamilton" Applied Sciences 15, no. 19: 10443. https://doi.org/10.3390/app151910443

APA StyleLi, F., Zhang, T., Wang, C., & Tian, B. (2025). Research on the Dynamic Response Characteristics of Soft Coal Under Impact Disturbance Based on Hamilton. Applied Sciences, 15(19), 10443. https://doi.org/10.3390/app151910443