Microstructural Evolution and Mechanical Properties of Hybrid Al6060/TiB2–MWCNT Composites Fabricated by Ultrasonically Assisted Stir Casting and Radial-Shear Rolling

Abstract

1. Introduction

2. Materials and Methods

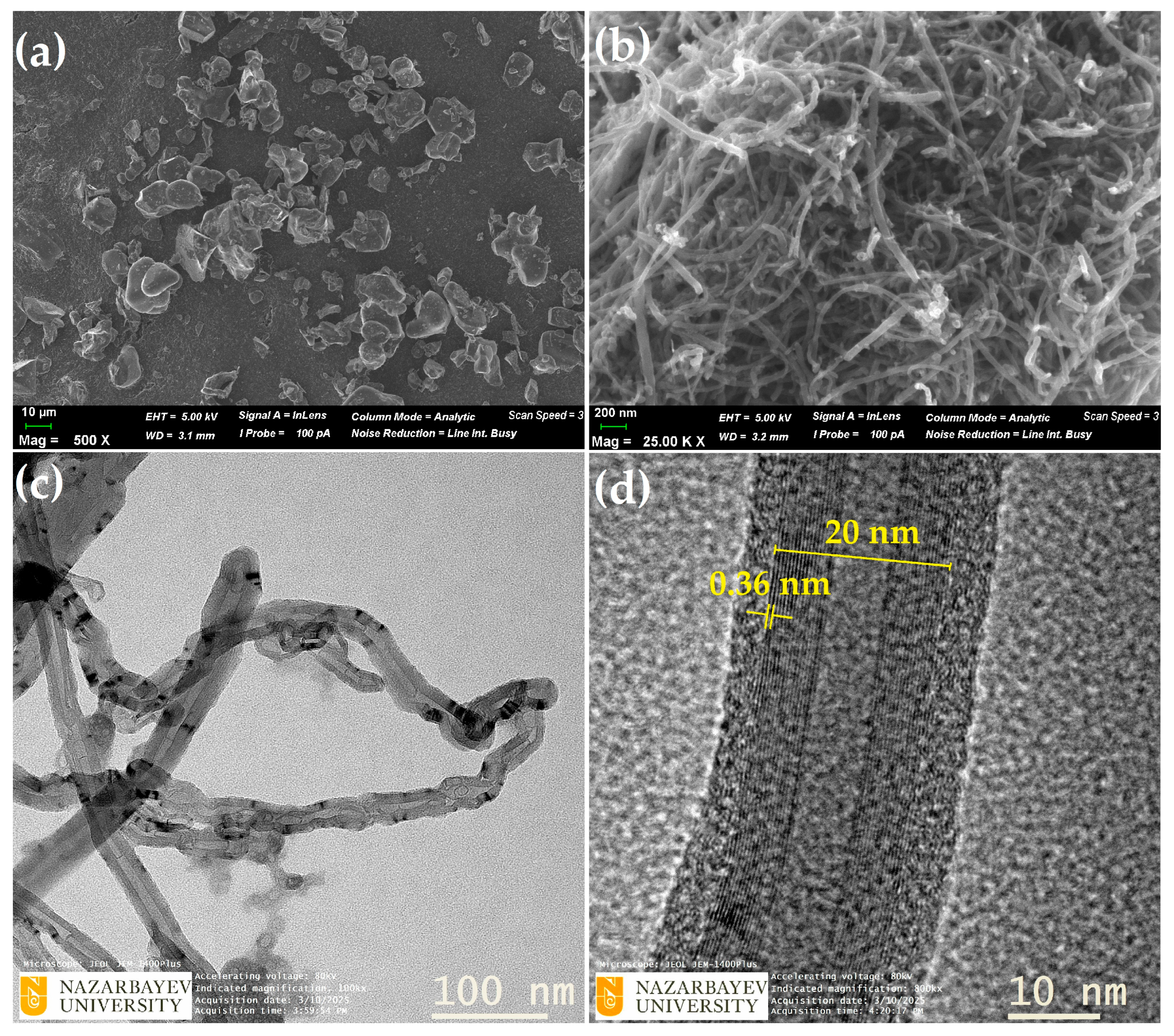

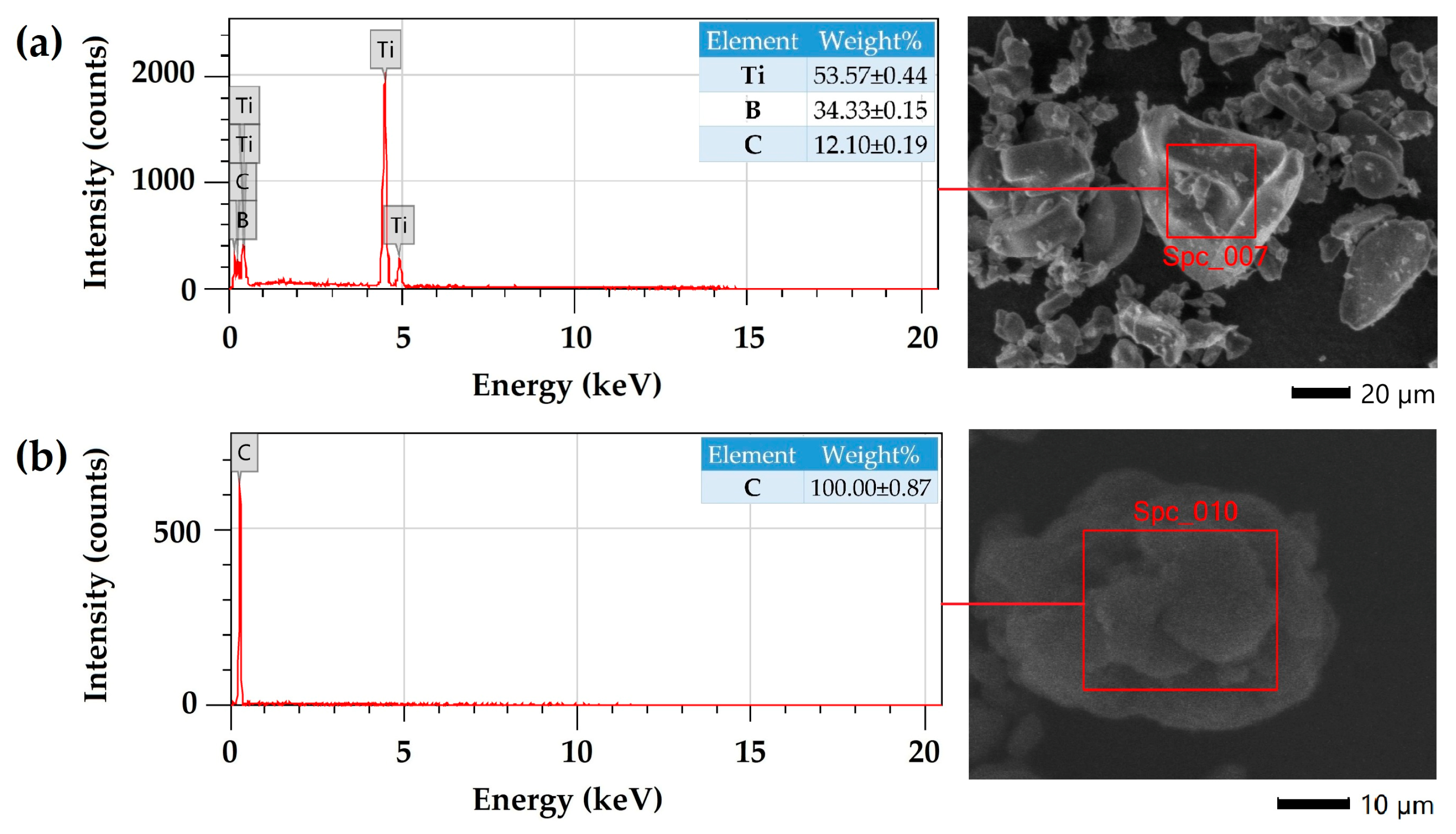

2.1. Raw Materials

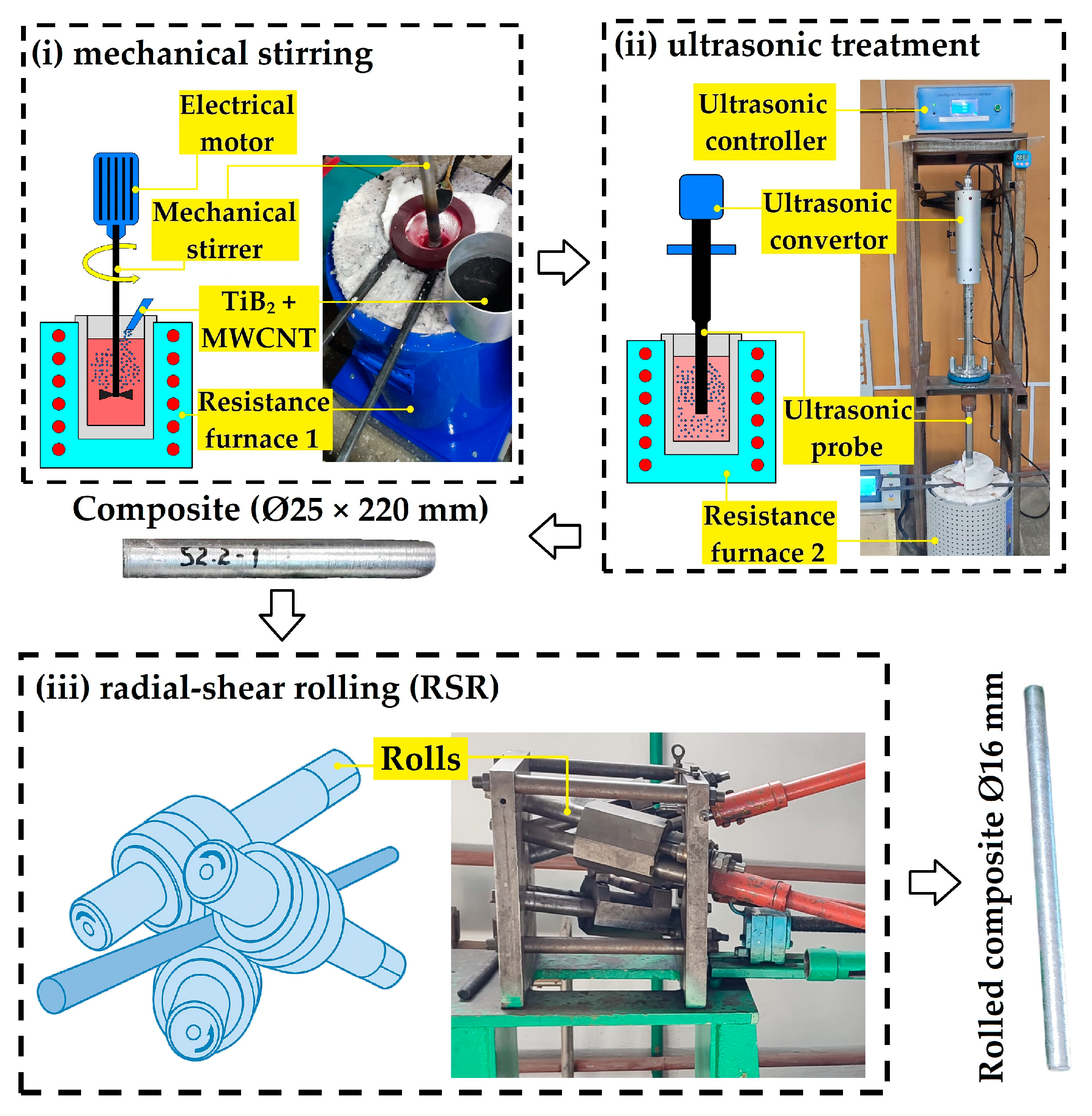

2.2. Composite Fabrication Procedure

2.3. Material Characterization

3. Results and Discussion

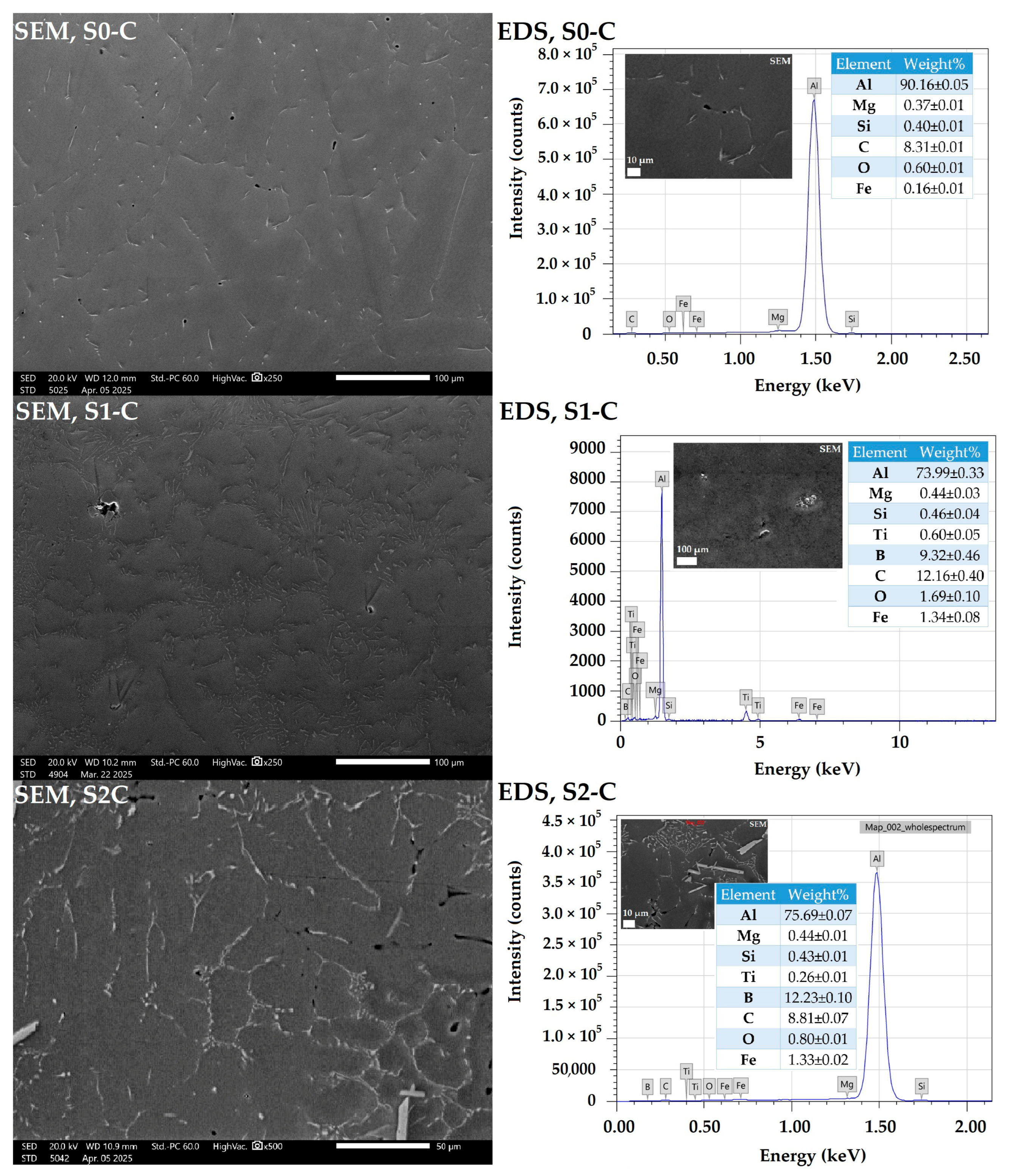

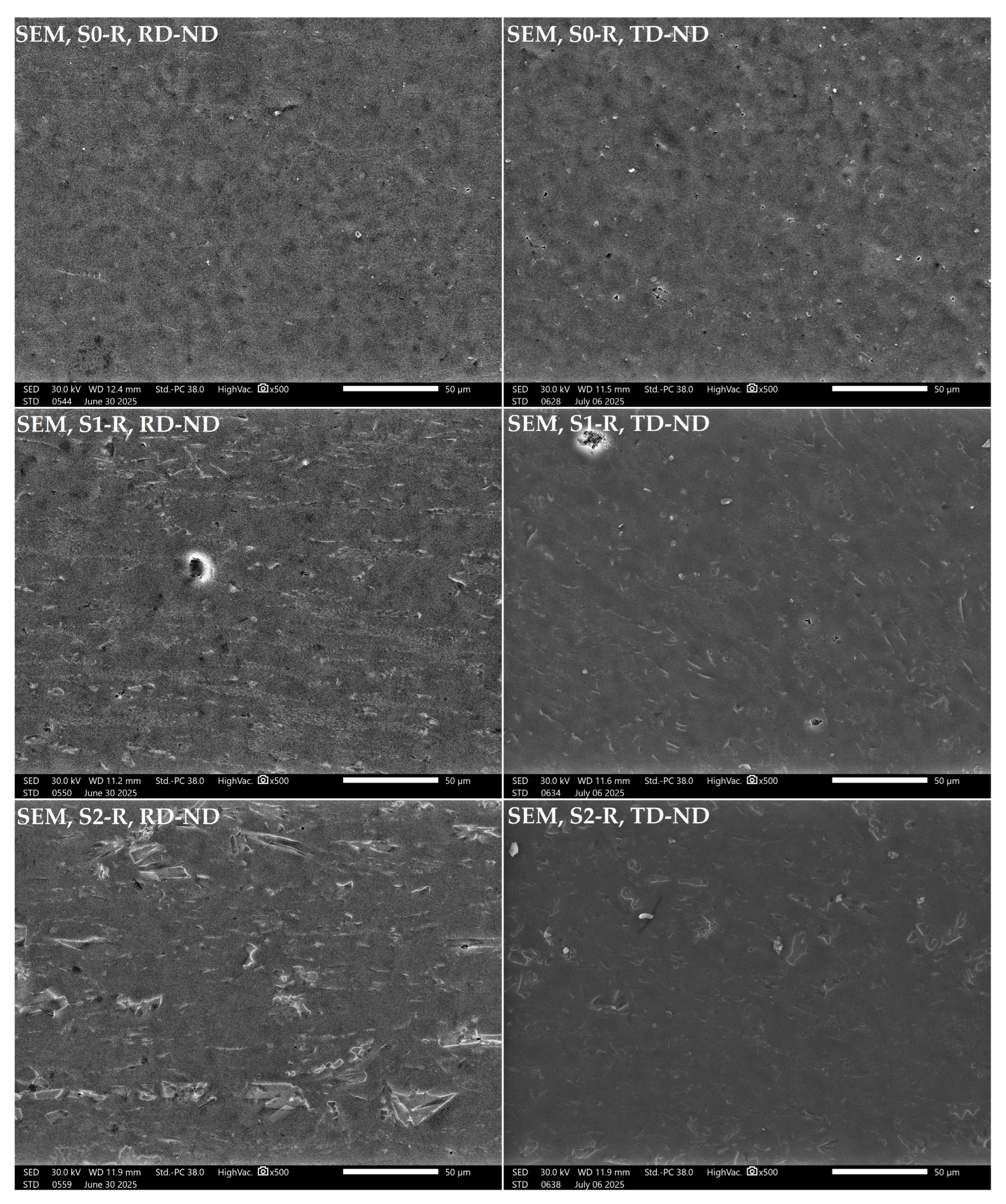

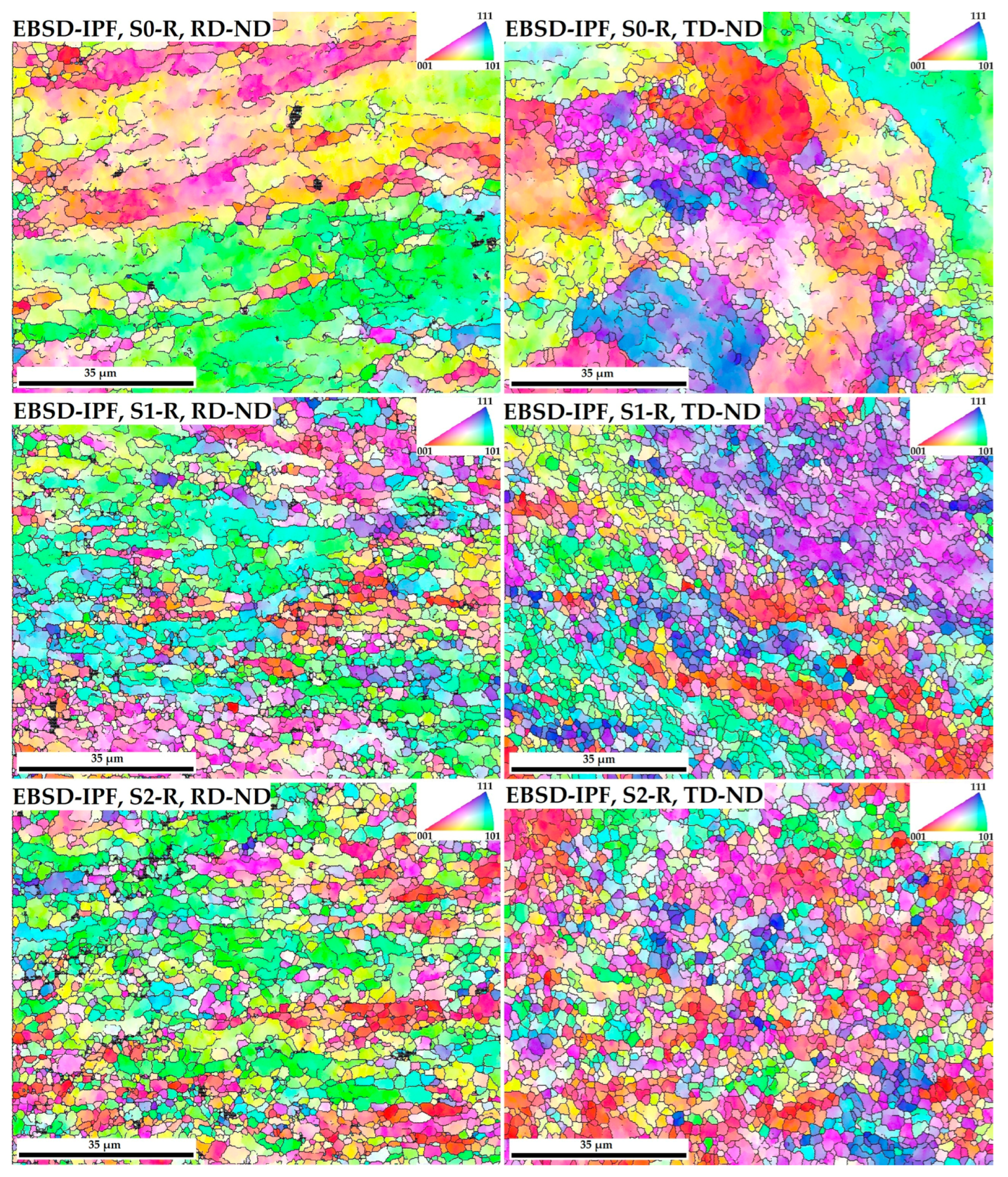

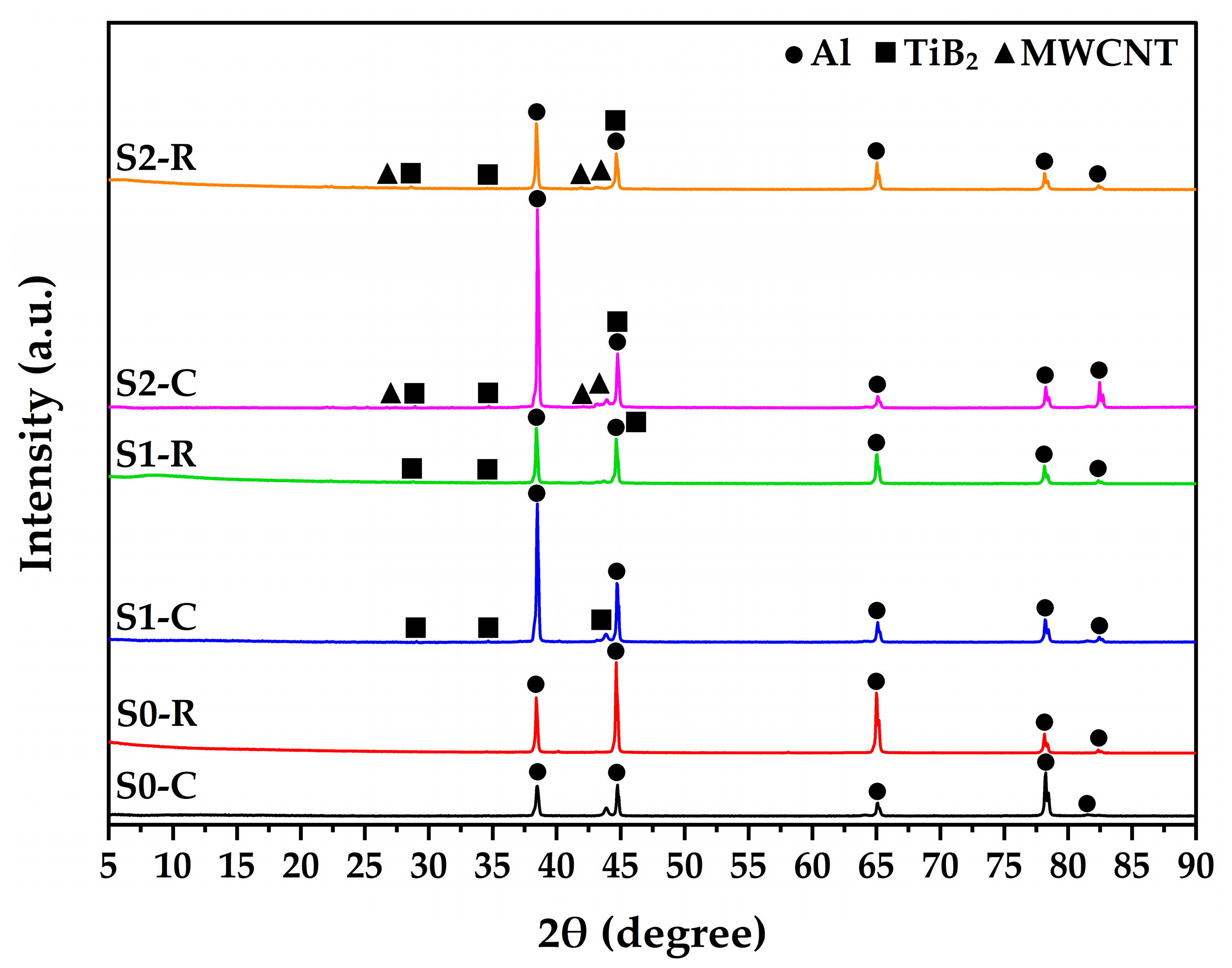

3.1. Microstructural Observations

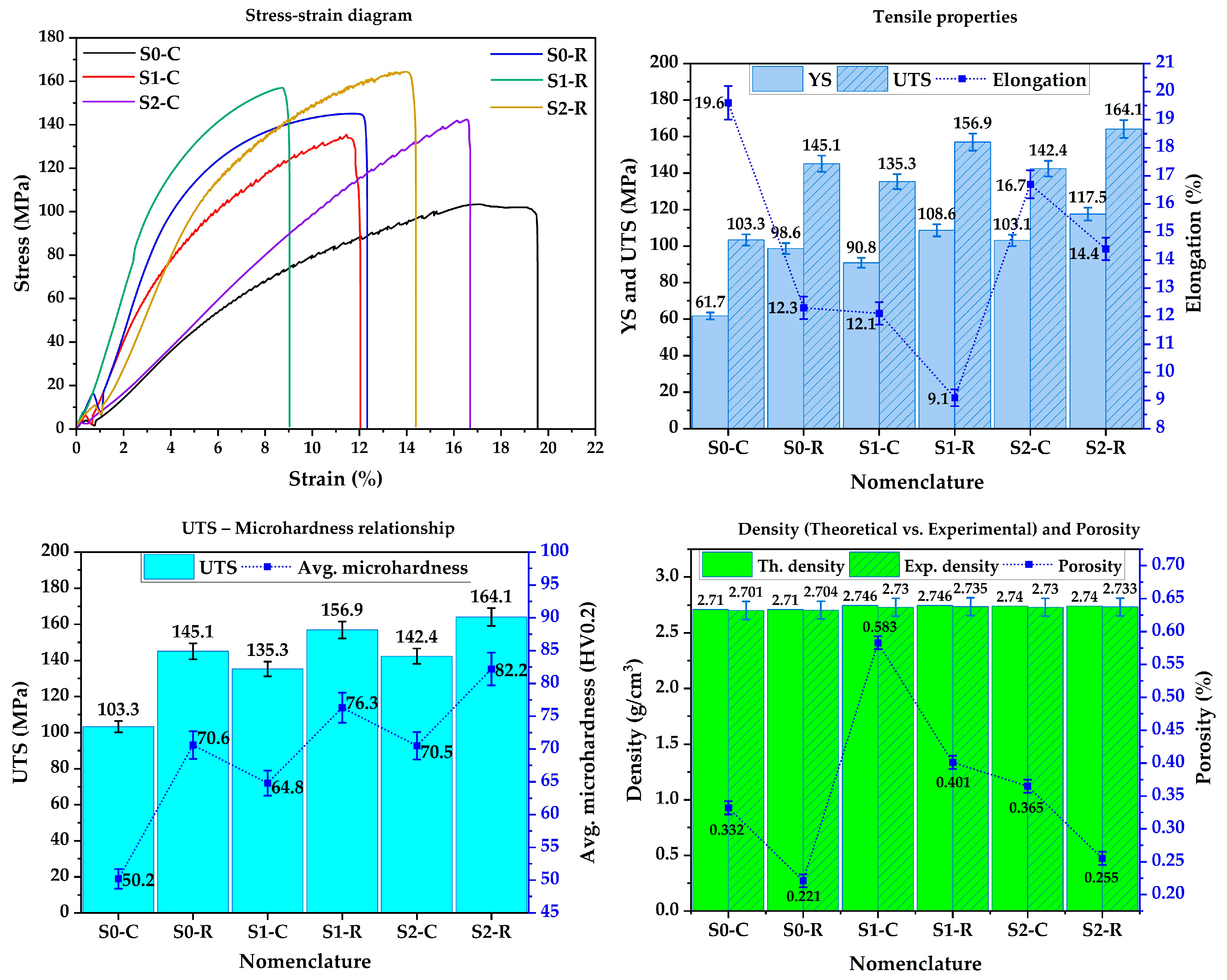

3.2. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Sustainable Processes in Aluminium, Magnesium, and Titanium Alloys Applied to the Transport Sector: A Review. Metals 2022, 12, 9. [Google Scholar] [CrossRef]

- Oyewo, A.T.; Oluwole, O.O.; Ajide, O.O.; Omoniyi, T.E.; Hussain, M. A summary of current advancements in hybrid composites based on aluminium matrix in aerospace applications. Hybrid Adv. 2024, 5, 100117. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Tartibu, L.K. Aluminum Alloy Reinforced with Agro-Waste, and Eggshell as Viable Material for Wind Turbine Blade to Annex Potential Wind Energy: A Review. J. Compos. Sci. 2023, 7, 161. [Google Scholar] [CrossRef]

- Singhal, V.; Shelly, D.; Babbar, A.; Lee, S.-Y.; Park, S.-J. Review of Wear and Mechanical Characteristics of Al-Si Alloy Matrix Composites Reinforced with Natural Minerals. Lubricants 2024, 12, 350. [Google Scholar] [CrossRef]

- Kareem, A.; Qudeiri, J.A.; Abdudeen, A.; Ahammed, T.; Ziout, A. A Review on AA 6061 Metal Matrix Composites Produced by Stir Casting. Materials 2021, 14, 175. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V. Trends in Aluminium Matrix Composite Development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Kar, A.; Sharma, A.; Kumar, S. A Critical Review on Recent Advancements in Aluminium-Based Metal Matrix Composites. Crystals 2024, 14, 412. [Google Scholar] [CrossRef]

- Abishkenov, M.; Tavshanov, I.; Lutchenko, N.; Amanzholov, N.; Kalmyrzayev, D.; Ashkeyev, Z.; Nogaev, K.; Kydyrbayeva, S.; Abdirashit, A. Improving Mechanical Properties of Low-Quality Pure Aluminum by Minor Reinforcement with Fine B4C Particles and T6 Heat Treatment. Appl. Sci. 2024, 14, 10773. [Google Scholar] [CrossRef]

- Mustafa, S.; Haider, J.; Matteis, P.; Murtaza, Q. Synthesis and Wear Behaviour Analysis of SiC- and Rice Husk Ash-Based Aluminium Metal Matrix Composites. J. Compos. Sci. 2023, 7, 394. [Google Scholar] [CrossRef]

- Boppana, S.B.; Dayanand, S.; Murthy, B.V.; Nagaral, M.; Telagu, A.; Kumar, V.; Auradi, V. Development and Mechanical Characterisation of Al6061-Al2O3-Graphene Hybrid Metal Matrix Composites. J. Compos. Sci. 2021, 5, 155. [Google Scholar] [CrossRef]

- Ahmad, S.; Tian, Y.; Hashmi, A.W.; Singh, R.K.; Iqbal, F.; Dangi, S.; Alansari, A.; Prakash, C.; Chan, C.K. Experimental studies on mechanical properties of Al-7075/TiO2 metal matrix composite and its tribological behaviour. J. Mater. Res. Technol. 2024, 30, 8539–8552. [Google Scholar] [CrossRef]

- Subramanian, K.; Murugesan, S.; Mohan, D.G.; Tomków, J. Study on Dry Sliding Wear and Friction Behaviour of Al7068/Si3N4/BN Hybrid Composites. Materials 2021, 14, 6560. [Google Scholar] [CrossRef]

- Rajkumar, G.; Saravanan, M.; Bejaxhin, A.B.H.; Sharma, S.; Dwivedi, S.P.; Kumar, R.; Singh, S. Parametric Optimization of Powder-Mixed EDM of AA2014/Si3N4/Mg/Cenosphere Hybrid Composites Using Fuzzy Logic: Analysis of Mechanical, Machining, Microstructural, and Morphological Characterizations. J. Compos. Sci. 2023, 7, 380. [Google Scholar] [CrossRef]

- Kuppusamy, A.K.; Govindaswamy, S. Influence of ZrB2 on the Tribomechanical Properties of Aluminium Matrix Composites: A Review. Results Eng. 2025, 26, 104943. [Google Scholar] [CrossRef]

- Abishkenov, M.; Tavshanov, I.; Lutchenko, N.; Nogaev, K.; Kalmyrzayev, D.; Abdirashit, A.; Aikenbayeva, N. Effect of Minor Reinforcement with Ultrafine Industrial Microsilica Particles and T6 Heat Treatment on Mechanical Properties of Aluminum Matrix Composites. Appl. Sci. 2025, 15, 1329. [Google Scholar] [CrossRef]

- Mohan, D.; Chinnasamy, B.; Naganathan, S.K.; Nagaraj, N.; Jule, L.; Badassa, B.; Ramaswamy, K.; Kathirvel, P.; Murali, G.; Vatin, N.I. Experimental Investigation and Comparative Analysis of Aluminium Hybrid Metal Matrix Composites Reinforced with Silicon Nitride, Eggshell and Magnesium. Materials 2022, 15, 6098. [Google Scholar] [CrossRef]

- Bhowmik, A.; Sen, B.; Beemkumar, N.; Singh Chohan, J.; Bains, P.S.; Singh, G.; Kumar, A.V.; Santhosh, A.J. Development and wear resistivity performance of SiC and TiB2 particles reinforced novel aluminium matrix composites. Results Eng. 2024, 24, 102981. [Google Scholar] [CrossRef]

- Farooq, S.A.; Mukhtar, S.H.; Raina, A.; Ul Haq, M.I.; Siddiqui, M.I.H.; Naveed, N.; Dobrota, D. Effect of TiB2 on the Mechanical and Tribological Properties of Marine Grade Aluminum Alloy 5052: An Experimental Investigation. J. Mater. Res. Technol. 2024, 29, 3749–3758. [Google Scholar] [CrossRef]

- Alfattani, R.; Yunus, M. Explorations of mechanical and corrosion resistance properties of AA6063/TiB2/Cr2O3 hybrid composites produced by stir casting. J. Sci. Adv. Mater. Devices 2024, 9, 100790. [Google Scholar] [CrossRef]

- Rane, K.; Dhokey, N. On the Formation and Distribution of In Situ Synthesized TiB2 Reinforcements in Cast Aluminium Matrix Composites. J. Compos. Sci. 2018, 2, 52. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, X.; Fang, Y.; Guo, E.; Kang, H.; Hao, Z.; Li, J.; Du, G.; Liu, L.; Chen, Z.; et al. Multiscale microstructures, mechanical properties and electrical conductivity of in-situ dual-size TiB2 particles reinforced 6201 aluminum matrix composites. J. Mater. Res. Technol. 2023, 23, 5459–5473. [Google Scholar] [CrossRef]

- Zhu, J.; Luo, X.; Wang, H.; Hu, R.; Yi, X.; Chen, Y.; Ran, G. High cycle fatigue fracture mechanism of in-situ TiB2/7050Al matrix composite. J. Mater. Res. Technol. 2025, 35, 4071–4085. [Google Scholar] [CrossRef]

- Sharath, B.N.; Madhu, P.; Verma, A. Enhancing tribological performance: A review of ceramic reinforced aluminium hybrid composites for high-temperature engineering applications. Hybrid Adv. 2023, 4, 100094. [Google Scholar] [CrossRef]

- Pole, M.; Mukhopadhyay, S.; Kastamo, S.; Loukus, A.; Choi, J.P.; Olszta, M.; Olszta, M.J.; Herling, D.R.; Grant, G.J.; Devaraj, A.; et al. Tribological Behavior of Hybrid Aluminum-TiB2 Metal Matrix Composites for Brake Rotor Applications. Wear 2025, 562–563, 205639. [Google Scholar] [CrossRef]

- Pazhani, A.; Salman, S.S.; Venkatraman, M.; Patel, A.; Xavior, M.A.; Batako, A.; Paulsamy, J.; Jayaseelan, J. Dynamic FEA Analysis of the Super Lightweight External Cryogenic Fuel Tank (SLWT) Made of Aluminium Alloy 2195–Graphene Nano Composite for Launch Vehicle Aerospace Application. J. Compos. Sci. 2024, 8, 260. [Google Scholar] [CrossRef]

- Md Ali, A.; Omar, M.Z.; Salleh, M.S.; Hashim, H.; Mohamed, I.F.; Wakhi Anuar, N.F.B. Mechanical Behaviour and Morphology of Thixoformed Aluminium Alloy Reinforced by Graphene. Materials 2022, 15, 6791. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Bokaryov, D.V.; Pankratov, S.A.; Elkin, A.I. Increasing the Flow Stress during High-Temperature Deformation of Aluminum Matrix Composites Reinforced with TiC-Coated CNTs. Ceramics 2023, 6, 231–240. [Google Scholar] [CrossRef]

- Popov, V.V.; Pismenny, A.; Larianovsky, N.; Lapteva, A.; Safranchik, D. Corrosion Resistance of Al–CNT Metal Matrix Composites. Materials 2021, 14, 3530. [Google Scholar] [CrossRef]

- Shivalingaiah, K.; Nagarajaiah, V.; Selvan, C.P.; Kariappa, S.T.; Chandrashekarappa, N.G.; Lakshmikanthan, A.; Chandrashekarappa, M.P.G.; Linul, E. Stir Casting Process Analysis and Optimization for Better Properties in Al-MWCNT-GR-Based Hybrid Composites. Metals 2022, 12, 1297. [Google Scholar] [CrossRef]

- Feijoo, I.; Pena, G.; Cristóbal, M.J.; Cabeza, M.; Rey, P. Effect of Carbon Nanotube Content and Mechanical Milling Conditions on the Manufacture of AA7075/MWCNT Composites. Metals 2022, 12, 1020. [Google Scholar] [CrossRef]

- Feijoo, I.; Pena, G.; Cabeza, M.; Cristóbal, M.J.; Rey, P. MWCNT-Reinforced AA7075 Composites: Effect of Reinforcement Percentage on Mechanical Properties. Metals 2021, 11, 969. [Google Scholar] [CrossRef]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting–Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- Bhowmik, A.; Kumar, R.; Beemkumar, N.; Kumar, A.V.; Singh, G.; Kulshreshta, A.; Mann, V.S.; Santhosh, A.J. Casting of particle reinforced metal matrix composite by liquid state fabrication method: A review. Results Eng. 2024, 24, 103152. [Google Scholar] [CrossRef]

- Grilo, J.; Carneiro, V.H.; Teixeira, J.C.; Puga, H. Manufacturing Methodology on Casting-Based Aluminium Matrix Composites: Systematic Review. Metals 2021, 11, 436. [Google Scholar] [CrossRef]

- Yadav, P.; Ranjan, A.; Kumar, H.; Mishra, A.; Yoon, J. A Contemporary Review of Aluminium MMC Developed through Stir-Casting Route. Materials 2021, 14, 6386. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Jiang, R.; Li, X.; Zhang, L.; Li, A.; He, Z. Microstructural evolution and mechanical properties of TiB2/2195 composites fabricated by ultrasonic-assisted in-situ casting. Ultrason. Sonochem. 2022, 90, 106203. [Google Scholar] [CrossRef]

- Venkatesh, V.S.S.; Rao, G.P.; Patnaik, L.; Gupta, N.; Kumar, S.; Saxena, K.K.; Sunil, B.D.Y.; Eldin, S.M.; Kafaji, F.H.K.A. Processing and evaluation of nano SiC reinforced aluminium composite synthesized through ultrasonically assisted stir casting process. J. Mater. Res. Technol. 2023, 24, 7394–7408. [Google Scholar] [CrossRef]

- Gudipudi, S.; Nagamuthu, S.; Subbian, K.S.; Chilakalapalli, S.P.R. Enhanced mechanical properties of AA6061-B4C composites developed by a novel ultra-sonic assisted stir casting. Eng. Sci. Technol. Int. J. 2020, 23, 1233–1243. [Google Scholar] [CrossRef]

- Ashkeyev, Z.; Abishkenov, M.; Nogaev, K. Stress state of workpieces during upsetting with additional shear. Eng. Solid Mech. 2023, 11, 41–46. [Google Scholar] [CrossRef]

- Ashkeyev, Z.; Abishkenov, M.; Mashekov, S.; Kawałek, A. Stress state of workpieces during upsetting with additional shear. Eng. Solid Mech. 2021, 9, 161–176. [Google Scholar] [CrossRef]

- Abishkenov, M.; Ashkeyev, Z.; Mashekov, S.; Akhmetova, G.; Volokitina, I. Investigation of the stress-strain state of balls under deformation in a closed die. Metalurgija 2020, 59, 559–562. [Google Scholar]

- Gronostajski, Z.; Pater, Z.; Madej, L.; Gontarz, A.; Lisiecki, L.; Łukaszek-Sołek, A.; Łuksza, J.; Mróz, S.; Muskalski, Z.; Muzykiewicz, W.; et al. Recent Development Trends in Metal Forming. Arch. Civ. Mech. Eng. 2019, 19, 898–941. [Google Scholar] [CrossRef]

- Abishkenov, M.; Ashkeyev, Z.; Nogaev, K. Investigation of the shape rolling process implementing intense shear strains in special diamond passes. Materialia 2022, 26, 101573. [Google Scholar] [CrossRef]

- Cui, J.; Meng, G.; Zhang, K.; Zuo, Z.; Song, X.; Zhao, Y.; Luo, S. Research Progress on Energy-Saving Technologies and Methods for Steel Metallurgy Process Systems—A Review. Energies 2025, 18, 2473. [Google Scholar] [CrossRef]

- Cho, H.-G.; Kim, Y.D.; Kim, M.-S. Effect of In Situ Al Roll Coating on Strip Surface Quality in Traditional Twin-Roll Casting of Aluminum Alloys. Metals 2025, 15, 377. [Google Scholar] [CrossRef]

- Mashekov, S.; Nurtazaev, E.; Mashekova, A.; Abishkenov, M. Extruding aluminum bars on a new structure radial shear mill. Metalurgija 2021, 60, 427–430. [Google Scholar]

- ELDeeb, I.S.; Hawam, A.A.; Nabhan, A.; Egiza, M. Efficient formability in Radial-Shear Rolling of A2024 aluminum alloy with screw rollers. Mater. Today Commun. 2024, 41, 110241. [Google Scholar] [CrossRef]

- Skripalenko, M.M.; Rogachev, S.O.; Bazhenov, V.E.; Romantsev, B.A.; Skripalenko, M.N.; Karpov, B.V.; Titov, A.Y.; Koltygin, A.V.; Danilin, A.V. Research of Three-High Screw Rolling of Aluminum Billets with Copper Inserts at Different Rolls Feed Angles. Metals 2023, 13, 1671. [Google Scholar] [CrossRef]

- Liu, J.; Chen, X.; Wang, W.; Zhao, Y.; He, N. Effect of TiB2 Nanoparticle Content on the Microstructure and Mechanical Properties of TiB2/Mg-4Al-1.5Si Composites. Materials 2023, 16, 2852. [Google Scholar] [CrossRef]

- Taraborelli, S.; Failla, S.; Sani, E.; Sciti, D. Sintering, Mechanical and Optical Properties of TiB2 Composites with and without High-Energy Milling. Nanomaterials 2023, 13, 2683. [Google Scholar] [CrossRef]

- Soleimani, H.; Baig, M.K.; Yahya, N.; Khodapanah, L.; Sabet, M.; Demiral, B.M.R.; Burda, M. Impact of carbon nanotubes based nanofluid on oil recovery efficiency using core flooding. Results Phys. 2018, 9, 39–48. [Google Scholar] [CrossRef]

- Sakthi, P.; Uma, J.; Balraj, B.; Arulvendhan, K. Improved performance of SnS/MWCNT heterostructures for photocatalytic, energy generation and supercapacitors applications. Sci. Rep. 2025, 15, 22747. [Google Scholar] [CrossRef] [PubMed]

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Prasad, D.S.; Shoba, C.; Ramanaiah, N. Investigations on mechanical properties of aluminum hybrid composites. J. Mater. Res. Technol. 2014, 3, 79–85. [Google Scholar] [CrossRef]

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM E8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Carneiro, Í.; Fernandes, J.V.; Simões, S. Deformation Behaviour of Cold-Rolled Ni/CNT Nanocomposites. Appl. Sci. 2022, 12, 9471. [Google Scholar] [CrossRef]

- Carneiro, Í.; Fernandes, J.V.; Simões, S. Microstructural Characterization of Al/CNTs Nanocomposites after Cold Rolling. Nanomaterials 2023, 13, 1362. [Google Scholar] [CrossRef]

- Doddapaneni, S.; Kumar, S.; Sharma, S.; Shankar, G.; Shettar, M.; Kumar, N.; Aroor, G.; Ahmad, S.M. Advancements in EBSD Techniques: A Comprehensive Review on Characterization of Composites and Metals, Sample Preparation, and Operational Parameters. J. Compos. Sci. 2025, 9, 132. [Google Scholar] [CrossRef]

- Alipour, M.; Keshavamurthy, R.; Koppad, P.G.; Shakiba, A.; Reddy, N.C. Investigation of Microstructure and Mechanical Properties of Cast Al–10Zn–3.5Mg–2.5Cu Nanocomposite Reinforced with Graphene Nano Sheets Produced by Ultrasonic Assisted Stir Casting. Inter. Metalcast. 2023, 17, 935–946. [Google Scholar] [CrossRef]

- Srinivas, V.; Jayaraj, A.; Venkataramana, V.S.N.; Avinash, T.; Dhanyakanth, P. Effect of Ultrasonic Stir Casting Technique on Mechanical and Tribological Properties of Aluminium–Multi-walled Carbon Nanotube Nanocomposites. J. Bio. Tribo. Corros. 2020, 6, 30. [Google Scholar] [CrossRef]

- Que, Z.; Wang, Y.; Mendis, C.L.; Fang, C.; Xia, J.; Zhou, X.; Fan, Z. Understanding Fe-Containing Intermetallic Compounds in Al Alloys: An Overview of Recent Advances from the LiME Research Hub. Metals 2022, 12, 1677. [Google Scholar] [CrossRef]

- Sweet, L.; Zhu, S.M.; Gao, S.X.; Taylor, J.A.; Easton, M.A. The Effect of Iron Content on the Iron-Containing Intermetallic Phases in a Cast 6060 Aluminum Alloy. Metall. Mater. Trans. A 2011, 42, 1737–1749. [Google Scholar] [CrossRef]

- Samuel, A.M.; Samuel, E.; Songmene, V.; Samuel, F.H. A Review on Porosity Formation in Aluminum-Based Alloys. Materials 2023, 16, 2047. [Google Scholar] [CrossRef] [PubMed]

- Tiryakioğlu, M. The Effect of Hydrogen on Pore Formation in Aluminum Alloy Castings: Myth Versus Reality. Metals 2020, 10, 368. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, C.; Song, Y.; Wang, M.; Wang, F. Dual Grain Refinement Effect for Pure Aluminum with the Addition of Micrometer-Sized TiB2 Particles. Materials 2024, 17, 4337. [Google Scholar] [CrossRef] [PubMed]

- Qian, P.; Tang, Z.; Yuan, M.; Xiang, Y.; Wang, L. Microstructure and refinement mechanism of TiB2/TiAl3 in remelted Al-5Ti-1B system. Mater. Sci. Technol. 2019, 35, 1563–1571. [Google Scholar] [CrossRef]

- Ma, T.; Chen, Z.; Nie, Z.; Huang, H. Microstructure of Al-Ti-B-Er refiner and its grain refining performance. J. Rare Earths 2013, 31, 622–627. [Google Scholar] [CrossRef]

- Guan, R.G.; Tie, D. A Review on Grain Refinement of Aluminum Alloys: Progresses, Challenges and Prospects. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 409–432. [Google Scholar] [CrossRef]

- Samal, P.; Raj, H.; Meher, A.; Surekha, B.; Vundavilli, P.R.; Sharma, P. Synergistic Effect of B4C and Multi-Walled CNT on Enhancing the Tribological Performance of Aluminum A383 Hybrid Composites. Lubricants 2024, 12, 213. [Google Scholar] [CrossRef]

- Raju, G.U.; Meti, V.K.V.; Banapurmath, N.R.; Yunus Khan, T.M.; Siddhalingeshwar, I.G.; Vaikunte, V.; Vadlamudi, C.; Krishnappa, S.; Sajjan, A.M.; Patil, A. Effect of Multi-Walled Carbon Nanotubes and Carbon Fiber Reinforcements on the Mechanical and Tribological Behavior of Hybrid Mg-AZ91D Nanocomposites. Materials 2022, 15, 6181. [Google Scholar] [CrossRef]

- Geng, R.; Qiu, F.; Jiang, Q.-C. Reinforcement in Al Matrix Composites: A Review of Strengthening Behavior of Nano-Sized Particles. Adv. Eng. Mater. 2018, 20, 1701089. [Google Scholar] [CrossRef]

- Schwarze, C.; Darvishi Kamachali, R.; Steinbach, I. Phase-field study of zener drag and pinning of cylindrical particles in polycrystalline materials. Acta Mater. 2016, 106, 59–65. [Google Scholar] [CrossRef]

- Sharma, S.K.; Gajević, S.; Sharma, L.K.; Pradhan, R.; Sharma, Y.; Miletić, I.; Stojanović, B. Progress in Aluminum-Based Composites Prepared by Stir Casting: Mechanical and Tribological Properties for Automotive, Aerospace, and Military Applications. Lubricants 2024, 12, 421. [Google Scholar] [CrossRef]

- Sadeghi, B.; Cavaliere, P.D. Reviewing the Integrated Design Approach for Augmenting Strength and Toughness at Macro- and Micro-Scale in High-Performance Advanced Composites. Materials 2023, 16, 5745. [Google Scholar] [CrossRef]

- So, K.P.; Kushima, A.; Park, J.G.; Liu, X.; Keum, D.H.; Jeong, H.Y.; Yao, F.; Joo, S.H.; Kim, H.S.; Kim, H.; et al. Intragranular Dispersion of Carbon Nanotubes Comprehensively Improves Aluminum Alloys. Adv. Sci. 2018, 5, 1800115. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Kondoh, K.; Li, J.S. In-situ observation of interaction between dislocations and carbon nanotubes in aluminum at elevated temperatures. Mater. Lett. 2020, 264, 127323. [Google Scholar] [CrossRef]

- Guo, S.; Yu, H.; Wang, Z.; Yu, W.; Cheng, W.; Huang, L.; Liu, C.; Yin, F.; Zhao, W.; Qin, C. Microstructural Evolution and Mechanical Properties of Pure Aluminum upon Multi-Pass Caliber Rolling. Materials 2022, 15, 1206. [Google Scholar] [CrossRef]

- Kumar, R.; Gupta, A.; Kumar, A.; Chouhan, R.N.; Khatirkar, R.K. Microstructure and texture development during deformation and recrystallisation in strip cast AA8011 aluminum alloy. J. Alloys Compd. 2018, 742, 369–382. [Google Scholar] [CrossRef]

- Snopiński, P.; Hilšer, O. Mechanism of Grain Refinement in 3D-Printed AlSi10Mg Alloy Subjected to Severe Plastic Deformation. Materials 2024, 17, 4098. [Google Scholar] [CrossRef]

- Ye, Z.; Zhou, Z.; Ye, Z.; Wang, Z.; Zhao, Q.; Prashanth, K.G. An Investigation into the Thermomechanical Processing and Dynamic Recrystallization Mechanisms of High-Magnesium Aluminum Alloys. Materials 2025, 18, 2734. [Google Scholar] [CrossRef]

- Kestens, L.A.I.; Pirgazi, H. Texture formation in metal alloys with cubic crystal structures. Mater. Sci. Technol. 2016, 32, 1303–1315. [Google Scholar] [CrossRef]

- Fu, L.; Wu, G.; Zhou, C.; Xiu, Z.; Yang, W.; Qiao, J. Effect of Microstructure on the Dimensional Stability of Extruded Pure Aluminum. Materials 2021, 14, 4797. [Google Scholar] [CrossRef]

- Vincze, G.; Pereira, A.B.; Lopes, D.A.F.; Yánez, J.M.V.; Butuc, M.C. Study on Asymmetric Rolling Process Applied to Aluminum Alloy Sheets. Machines 2022, 10, 641. [Google Scholar] [CrossRef]

- Xia, C.J.; Wang, L.; Zhang, Q.; Zhu, H.F.; Liu, J.; Zhang, F.G.; Chen, Z.; Wang, H.W. An Investigation of Microstructural Evolution, Tensile Properties and Work-Hardening Behavior of Nanosized TiB2/Al-Cu-Mn Composites. Materials 2020, 13, 4250. [Google Scholar] [CrossRef]

- Abishkenov, M.; Tavshanov, I.; Lutchenko, N.; Nogayev, K.; Ashkeyev, Z.; Kulidan, S. Microstructure and Mechanical Properties of Al6060/TiB2 Aluminum Matrix Composites Produced via Ultrasonically Assisted Stir Casting and Radial-Shear Rolling. J. Manuf. Mater. Process. 2025, 9, 309. [Google Scholar] [CrossRef]

- Carneiro, Í.; Simões, S. Strengthening Mechanisms in Carbon Nanotubes Reinforced Metal Matrix Composites: A Review. Metals 2021, 11, 1613. [Google Scholar] [CrossRef]

| Mg | Si | Mn | Fe | Cu | Zn | Ti | Others | Al |

|---|---|---|---|---|---|---|---|---|

| 0.35–0.50 | 0.30–0.60 | ≤0.10 | 0.10–0.30 | ≤0.10 | ≤0.15 | ≤0.10 | ≤0.15 | 97.65–99.35 |

| Nomenclature | Designation | Al6060 (wt.%) | TiB2 (wt.%) | MWCNTs (wt.%) |

|---|---|---|---|---|

| Al6060–Cast | S0-C | 100 | 0 | 0 |

| Al6060–Rolled | S0-R | 100 | 0 | 0 |

| Al6060/TiB2–Cast | S1-C | 98 | 2 | 0 |

| Al6060/TiB2–Rolled | S1-R | 98 | 2 | 0 |

| Al6060/TiB2/MWCNT–Cast | S2-C | 97 | 2 | 1 |

| Al6060/TiB2/MWCNT–Rolled | S2-R | 97 | 2 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abishkenov, M.; Tavshanov, I.; Lutchenko, N.; Nogayev, K.; Ashkeyev, Z.; Kulidan, S. Microstructural Evolution and Mechanical Properties of Hybrid Al6060/TiB2–MWCNT Composites Fabricated by Ultrasonically Assisted Stir Casting and Radial-Shear Rolling. Appl. Sci. 2025, 15, 10427. https://doi.org/10.3390/app151910427

Abishkenov M, Tavshanov I, Lutchenko N, Nogayev K, Ashkeyev Z, Kulidan S. Microstructural Evolution and Mechanical Properties of Hybrid Al6060/TiB2–MWCNT Composites Fabricated by Ultrasonically Assisted Stir Casting and Radial-Shear Rolling. Applied Sciences. 2025; 15(19):10427. https://doi.org/10.3390/app151910427

Chicago/Turabian StyleAbishkenov, Maxat, Ilgar Tavshanov, Nikita Lutchenko, Kairosh Nogayev, Zhassulan Ashkeyev, and Siman Kulidan. 2025. "Microstructural Evolution and Mechanical Properties of Hybrid Al6060/TiB2–MWCNT Composites Fabricated by Ultrasonically Assisted Stir Casting and Radial-Shear Rolling" Applied Sciences 15, no. 19: 10427. https://doi.org/10.3390/app151910427

APA StyleAbishkenov, M., Tavshanov, I., Lutchenko, N., Nogayev, K., Ashkeyev, Z., & Kulidan, S. (2025). Microstructural Evolution and Mechanical Properties of Hybrid Al6060/TiB2–MWCNT Composites Fabricated by Ultrasonically Assisted Stir Casting and Radial-Shear Rolling. Applied Sciences, 15(19), 10427. https://doi.org/10.3390/app151910427