Abstract

Enhanced oil recovery (EOR) can significantly contribute to sustainable energy by improving oil recovery efficiency, integrating renewable technologies, and reducing the environmental impact of extraction. This study builds on previous work involving polyfraction nanoemulsions by introducing more realistic experimental conditions using live crude oil and undiluted reservoir water. The base fluid, modified with nanoemulsion and polymer additives, was injected using an alternating strategy with varying concentrations. The most effective sequence involved reservoir water with 2 wt% nanoemulsion and 0.5 wt% polymer, followed by injections with 0.3% and 0.1% polymer. This method achieved a displacement efficiency of 68.2%, with oil recovery 21.2% higher than that obtained when using reservoir water with 0.2% of polymer with nanoemulsion. These results highlight the potential of polyfraction nanoemulsions to enhance EOR efficiency while supporting sustainable development goals.

1. Introduction

1.1. Background and Motivation

The global energy landscape is undergoing rapid transformation, driven by increasing energy demand and the declining productivity of conventional oil fields. With many mature reservoirs entering late stages of production, there remains a substantial volume of unrecovered hydrocarbons that cannot be economically extracted using primary and secondary recovery methods. In this context, enhanced oil recovery (EOR) techniques are gaining renewed interest. EOR methods aim to maximize extraction from depleted or challenging reservoirs by applying advanced physical and chemical approaches that improve displacement efficiency and fluid mobility.

Despite significant technological progress, conventional recovery methods still leave behind up to 70% of the original oil in place (OOIP) in many reservoirs [1,2]. Among these, carbonate reservoirs, especially those composed of dolomite, present unique challenges for oil recovery due to their complex mineralogy, heterogeneity, low permeability, and adverse wettability [3,4]. Conventional chemical methods often perform poorly in these systems, primarily because of high temperature, salinity, and the presence of hydrogen sulfide (H2S). These conditions accelerate surfactant degradation, polymer precipitation, and adsorption losses, reducing the efficiency of EOR treatments [5,6].

Consequently, there is a growing interest in developing tailored chemical formulations, including robust polymers and nanoemulsions, that can operate effectively under such extreme reservoir conditions. The application of these advanced materials may significantly increase recovery efficiency while also reducing the environmental footprint of fossil fuel production.

1.2. Role of Nanotechnology and Alternating Injection in EOR

Among the advanced chemical methods, nanotechnology-enhanced fluids—such as nanoemulsions—offer several advantages in terms of interfacial tension reduction, wettability alteration, and mobility control. Nanoemulsions are thermodynamically stable systems typically composed of oil, water, surfactants, and nanoparticles. Their small droplet size allows for better penetration into porous media and interaction with reservoir rock surfaces [7,8]. Recent research has focused on integrating nanotechnology into EOR, particularly through the use of nanoemulsions—stable colloidal dispersions of oil, water, and surfactants stabilized by nanoparticles [7,8,9]. These systems have been shown to reduce interfacial tension (IFT), alter rock wettability, and improve oil displacement in porous media [10]. Carbonate reservoirs, especially those dominated by dolomite, require formulations that are chemically stable in the presence of divalent cations (Ca2+, Mg2+), H2S, and high temperatures [11,12]. Traditional anionic surfactants tend to precipitate or degrade in such environments. For this reason, the nanoemulsion D66 was specifically designed to maintain stability under high-salinity and H2S-rich conditions [13,14,15]. In parallel, polymers like hydrolyzed polyacrylamide (HPAM) have long been used to improve mobility control in EOR by increasing the viscosity of injected fluids and reducing viscous fingering [16,17]. However, standard HPAM is susceptible to thermal degradation and sulfide attack, leading to performance loss [18,19]. To overcome this, new polymer types such as TN-16988, engineered for high thermal stability and chemical resistance, are being investigated for carbonate EOR applications. The synergistic effect of combining nanoemulsions with polymers has received growing attention. Studies show that polymer-stabilized nanoemulsions exhibit improved rheological behavior, IFT reduction, and resistance to adsorption [20,21,22]. Alternating injection strategies using formation brine, nanoemulsion slugs, and polymer solutions have been proposed to leverage the unique benefits of each component [23,24,25]. In laboratory settings, such formulations have demonstrated incremental recovery gains of 10–25% OOIP over conventional methods. The combination of brine compatibility, IFT reduction, and mobility control improves both sweep and displacement efficiency [26,27,28]. However, field application remains limited, and pilot studies are essential to verify performance under reservoir-specific conditions [29].

1.3. Objectives and Scope of the Study

This study focuses on the experimental evaluation of alternating polymer–nanoemulsion injection in dolomite carbonate reservoirs under high-temperature, high-salinity, and H2S-rich conditions. It builds on previous screening work where 23 nanoemulsions and 7 polymer suspensions were initially tested for basic performance parameters (e.g., viscosity, CMC, stability). From these, five promising polymer–nanoemulsion systems were selected for in-depth evaluation under simulated reservoir conditions.

Laboratory tests included wettability and IFT measurements; thermal and chemical stability assessments; adsorption dynamics on carbonate rock; core-flooding experiments using live recombined crude oil under PVT conditions; and an evaluation of oil recovery efficiency under alternating injection schemes. In this study, an attempt was made to answer the following question: Which injection strategies provide the highest oil recovery while maintaining acceptable injection pressures?

A distinctive aspect of this study is its strong focus on realistic reservoir conditions. Experiments were conducted using actual dolomite core samples, formation brine, and recombined live oil, with the selected materials evaluated not only for their performance but also for their resistance to H2S degradation and long-term stability. The application of undiluted formation brine significantly reduces operational costs by minimizing the need for additional water treatment and transportation, offering a notable economic advantage for the proposed method.

The importance of this research lies in:

- Demonstrating the practical viability of polymer–nanoemulsion systems under authentic dolomite reservoir conditions;

- Providing valuable insights into adsorption mechanisms and injection strategies;

- Guiding future EOR field designs and reservoir simulations for carbonate formations characterized by complex geochemistry.

The findings provide a solid foundation for subsequent reservoir simulations and potential pilot-scale EOR applications. The proposed alternating injection strategy, supported by laboratory evidence, showcases both technical feasibility and environmental benefits, particularly through reduced chemical consumption and lower requirements for produced water treatment.

2. Materials and Methods

2.1. Materials

Experiments were carried out on natural carbonate cores using crude oil, natural gas, and reservoir water as the foundational components for both injection and chemically modified solutions, including polymer-based systems and nanoemulsion formulations. The core samples, consisting of 3.81 cm (1.5-inch) plugs, were supplied by Kocurek Industries, Hard Rock Division (Caldwell, TX, USA). The core plug sample analyzed in this study was obtained from the Guelph Dolomite, a carbonate reservoir rock from the Silurian formation. Mineralogical analysis confirmed a high dolomite content of 99.4%, with only minor quartz content at 0.6%, indicating a nearly pure dolostone lithology. The high mineralogical purity indicates homogenous rock properties, which is beneficial for laboratory-scale core-flooding experiments and provides consistent conditions for enhanced oil recovery (EOR) simulation studies. Core UCS values between 9000 and 12,000 psi suggest a competent lithology capable of maintaining structural stability under reservoir conditions and injection-induced stress regimes typical of EOR applications. These characteristics make the Guelph Dolomite a representative and reliable medium for evaluating fluid–rock interactions and displacement efficiency in carbonate EOR studies.

In this investigation, live oil was prepared by blending dead light crude oil with separator gas at reservoir-representative conditions of 120 °C and 38 MPa, utilizing a PVT apparatus supplied by Chandler Engineering (Tulsa, OK, USA). This procedure was employed to accurately simulate the in situ fluid characteristics. A comprehensive compositional analysis of dead oil from the well was conducted to assess its suitability for enhanced oil recovery (EOR) applications. The oil sample demonstrated a density of 0.841 g/cm3 and a comparatively high viscosity of 82.1 mPa·s under ambient conditions, categorizing it as light-to-medium crude oil. Higher viscosity levels may lead to increased flow impedance during reservoir production. The asphaltene content was low (0.21%), which is advantageous for EOR operations, as it reduces the risk of asphaltene precipitation and formation damage during injection processes. With 4.86% resin content, the oil benefits from enhanced colloidal stability and maintained asphaltene solubility, supporting better flow properties. A dominant fraction of 42.10% saturated hydrocarbons suggests a paraffin-rich composition, which tends to enhance the mobility of the crude oil. In contrast, aromatic hydrocarbons made up 5.93% of the oil, reflecting a moderate level of polarity, which can influence oil–water interfacial interactions, particularly in chemically assisted EOR methods. These physicochemical characteristics suggest that the crude is a viable candidate for EOR strategies, including low-salinity waterflooding, surfactant injection, or polymer-assisted recovery.

The reservoir gas analyzed in this study was separated from the associated crude oil phase and characterized to determine its compositional profile, which is relevant for understanding gas–oil interactions and evaluating EOR strategies. The gas was predominantly composed of light hydrocarbons (C1–C6), which accounted for 60.234 mol%, indicating a high proportion of methane and other low-molecular-weight alkanes, typical of associated gases in mature reservoirs. The C7–C12 hydrocarbon fraction was present at low concentrations, contributing only 1.013 mol% to the total gas phase. Notably, the gas also contained 30.295 mol% nitrogen (N2), reflecting a significant presence of non-hydrocarbon inert gases, which can impact the compressibility and thermal properties of the gas phase. Hydrogen (H2) was present at 0.406 mol%, and carbon dioxide (CO2) at 0.077 mol%, both of which may influence the gas’s corrosivity and reactivity under reservoir conditions. A considerable concentration of hydrogen sulfide (H2S), measured at 7.975 mol%, indicates sour gas characteristics, necessitating careful handling and consideration in any EOR operation due to its corrosive and toxic nature. This gas composition data provides essential input for thermodynamic modeling and simulation of gas injection scenarios within the reservoir.

Reservoir water was used as the base for preparing the displacement solutions. A detailed physicochemical analysis of the reservoir water is presented in Table 1.

Table 1.

Analysis of reservoir formation water at 22 °C.

The polymer TN-16988 and nanoemulsion D66 were selected based on previous research and screening studies, particularly those presented in our earlier publication [19], where both materials demonstrated favorable properties under high-temperature and high-H2S conditions characteristic of deep reservoirs. TN-16988 is a synthetic, high-molecular-weight polymer specifically designed for enhanced thermal stability and resistance to salinity and H2S degradation. It outperformed conventional partially hydrolyzed polyacrylamides (HPAM) in terms of viscosity retention and injectivity under harsh conditions. Similarly, D66 nanoemulsion brine compatibility, which is essential for maintaining effective mobility control during chemical flooding.

Although other types of polymers, including cationic and zwitterionic variants, were initially considered during the formulation phase, they did not meet the required performance criteria under reservoir-representative environments. TN-16988 offered the best combination of thermal and chemical stability, injectivity, and cost-efficiency, making it a suitable candidate for further core flooding and performance testing.

Polymer solutions (trade name TN-16988) and the nanoemulsion D66 were supplied by a chemical additive manufacturer specializing in the petroleum industry. The polymer used in this study was a copolymer of AMPS (2-acrylamido-2-methyl-1-propanesulfonic acid) and acrylamide, known for its good water solubility, compatibility with anionic additives, and resistance to high salinity and elevated temperatures. The nanoemulsion consisted of terpenes, propan-2-ol, and a surfactant. These specific formulations were selected based on prior research focused on developing EOR agents optimized for high-temperature, high-salinity reservoir conditions. The manufacturer aimed to ensure the polymer suspension remained stable and the nanoemulsion components exhibited effective dispersion under test conditions. A key requirement was the ability to form a stable polymer–nanoemulsion system. After evaluating various formulations, TN-16988 and D66 were recommended for laboratory displacement tests using natural carbonate cores under simulated reservoir conditions. TN-16988, as a copolymer of AMPS and acrylamide, contains sulfonic acid groups that provide enhanced chemical resistance, thermal stability, and reduced adsorption on carbonate rocks [19]. These findings confirm that our material selection is supported not only by the literature, but also by verified laboratory tests under reservoir-representative conditions.

2.2. Methods

The research began with preparatory work, which involved selecting the polymer and nanoemulsion based on previous studies. Following this, an appropriate amount of core material was prepared and tested, along with the evaluation of reservoir fluids such as brine and live oil. The next phase consisted of cyclical procedures that included saturating the cores, preparing the displacement solution, conducting core-flooding experiments, and performing final evaluations. Key formulations, especially those demonstrating the highest displacement efficiencies, were subjected to repeated tests to ensure the reliability and consistency of the results. The repeated tests showed consistent outcomes within an acceptable range of variability. After each cycle, the composition of the displacement solution was adjusted accordingly.

- Preparatory Phase

- –

- Select polymer and nanoemulsion (based on prior research);

- –

- Prepare core material (quantified amount);

- –

- Test core material;

- –

- Analyze reservoir fluids (brine and live oil).

- Cyclical Process (Repeat for each cycle)

- Saturate cores;

- Prepare displacement solution;

- Conduct core-flooding experiment;

- Evaluate results;

- Modify displacement solution.

2.2.1. Permeability and Porosity Analysis of Core Samples

Absolute permeability was assessed using a DGP-100 gas permeability meter (EPS, Aberdeen, UK) on cylindrical core samples with a diameter of 3.81 cm. Each sample was positioned in a Hassler-type core holder and enclosed in a rubber sleeve, with external pressure applied to ensure sealing. Once secured, nitrogen gas was introduced through the core. After reaching steady-state flow, measurements of flow rate and pressure drop across the sample were taken. These measurements, combined with the sample’s dimensions, ambient temperature, and atmospheric pressure, were used to compute the permeability coefficient.

Effective porosity was evaluated using an HPG-100 helium porosimeter and a BVMS 1000 system—both produced by EPS (Aberdeen, UK)—to determine the total sample volume. The same 3.81 cm cylindrical cores were used. The method involved placing each rock specimen into a sealed chamber with a known volume, then introducing a predetermined volume of helium under stable temperature and pressure conditions. By comparing the helium pressure before and after expansion, the volume of the solid rock matrix excluding closed pores was calculated. With the total volume of the core known, the porosity coefficient was then derived.

2.2.2. Preparation Procedure for Core Samples

The core material was provided as core plugs with a diameter of 3.81 cm and an approximate length of 51 mm. These plugs served as specimens for both contact angle measurements of the nanoemulsion and core-flooding experiments. Contact-angle analyses were performed on disks, several millimeters in height, sectioned from the core plugs. The exposed surfaces of these disks were meticulously ground and polished to achieve a smooth finish. Following mechanical preparation, the core plugs underwent solvent extraction using a Soxhlet apparatus with a sequential solvent regimen, followed by rinsing in deionized water [30,31]. Post-cleaning, the cores were dried at 115 °C until reaching constant mass. Cores prepared via this protocol were allocated either for core flooding or wettability assessment. For core flooding, saturation with reservoir fluids—specifically reservoir brine and dead oil—was performed using a vacuum pump and chamber (for brine) and the Core Lab AFS-300 core-flooding system (Tulsa, OK, USA) for fluid injection and flow testing.

After saturating the cores in a vacuum chamber, they were mounted in a Hassler core holder, connected to the flow system, and securely sealed. Reservoir water was then injected through the core assembly, while the temperature and pressure were gradually increased to 120 °C and 38 MPa, respectively. Upon reaching stable test conditions, reservoir water was pumped at a constant flow rate of 0.3 mL/min for a volume equivalent to three pore volumes (PV). Following this, dead oil was injected continuously at a fixed rate. Once a clean oil effluent—free from formation water—was observed, an additional three pore volumes (PV) of oil were introduced to establish the equilibrium distribution between oil and reservoir water. The core holder was then sealed and left undisturbed for several hours to allow for adsorption equilibrium to be reached. Subsequently, the temperature and pressure were gradually decreased before the cores were extracted from the core holder and transferred into a pressure vessel containing dead oil. The vessel was then sealed and pressurized to approximately 38 MPa, followed by incubation in a heating chamber at 120 °C for a duration of two weeks. Following this procedure, the cores were conditioned and prepared for subsequent core-flooding experiments.

2.2.3. Surface-Tension Analysis

Surface-tension measurements of the test solutions were performed using a precision goniometer (OCA 15EC, DataPhysics, Filderstadt, Germany). To assess surface tension, a series of D66 solution concentrations were prepared. The liquid was introduced via a needle-equipped syringe installed in the goniometer’s dosing unit, which dispensed droplets at a controlled rate of 0.1 µL/s in ambient air. Each measurement was conducted 20 times to ensure statistical reliability. The resultant droplet geometry was governed by the balance between gravitational forces, which tend to elongate the droplet, and surface-tension forces, which promote a spherical morphology to minimize surface area. The equilibrium droplet profile, characterized by its curvature, was quantitatively analyzed using the Young–Laplace equation.

2.2.4. Core-Flooding Analysis: Core Saturation Procedure with Live Oil

Dead crude oil–presaturated core plugs were mounted in a Hassler-type core holder, which was integrated with the flow lines and control modules of the AFS-300 core-flooding system. Once positioned, the cores were securely sealed to ensure confinement under test conditions. Initial injection of dead crude oil was conducted at a constant flow rate of 0.3 mL/min, while system pressure and temperature were gradually elevated to match the conditions required for live oil saturation. Following system stabilization, recombined live oil was introduced from a high-pressure vessel under reservoir PVT conditions. At the core outlet, the produced fluids were separated into oil and gas phases, and their volumes were continuously measured to calculate the instantaneous gas-to-oil ratio (GOR).

Injection proceeded until the measured GOR aligned with the target value obtained from PVT analysis, indicating stable saturation conditions. Subsequently, an additional three pore volumes (3 PV) of live oil were injected, while maintaining continuous monitoring of system pressure, temperature, differential pressure across the core, and the cumulative volumes of produced oil and gas. Upon completion of the injection phase, both the inlet and outlet valves of the core holder were closed, and the system was left static under reservoir conditions for several hours (overnight) to ensure equilibrium.

This saturation protocol enabled validation and correction of the fluid saturation levels within the core, including oil and formation water content, based on the analysis of the effluent. Cores prepared using this method were deemed representative of reservoir conditions and were subsequently used in EOR core-flooding experiments, employing various injection fluids and displacement strategies.

3. Experimental Results

3.1. Measuring Porosity, Permeability, and Fluid Saturation in Reservoir Rocks

Laboratory investigations commenced with the determination of permeability and porosity of dolomite core samples using DGP-100, HPG-100, and BVMS-1000 instrumentation. Following characterization, a physical core model was assembled for enhanced oil recovery (EOR) experiments, comprising three cores exhibiting distinct permeability values. The cores were subsequently saturated with reservoir brine and dead crude oil employing the AFS-300 core-flooding system. A summary of the key measurement results is presented in Table 2.

Table 2.

Data of Guelph Dolomite core plugs used in core-flooding tests.

Table 2 summarizes the measurements of Guelph Dolomite cores employed to evaluate the efficiency of enhanced oil recovery (EOR) processes using nanoemulsions. Effective porosity values ranged from 9.44% to 35.79%. Permeability measurements exhibited considerable variability across dozens of cores tested, ranging from a few millidarcies to over 200 mD.

To capture this heterogeneity, each physical model for EOR testing was constructed using three cores with significantly different permeabilities. The core with higher permeability was positioned at the inlet side, followed by the lower permeability core. The cores possessed comparable physical dimensions, ensuring similar pore volumes and thus facilitating consistent porosity models. Total pore volumes for the physical models ranged narrowly between 17.42 and 24.22 cm3.

Each core set was saturated with reservoir brine and dead oil following the established procedure. Final saturations ranged from 62.01% to 72.51% for oil and 27.49% to 37.99% for water, respectively.

3.2. Measuring the Surface Tension of Fluid Flowing out of the Cores

The displacing fluids were prepared using undiluted reservoir water. The nanoemulsion and polymer were incorporated into the reservoir water to achieve the target concentrations. Surface-tension measurements were performed for each prepared solution to serve as a reference. For each test, the surface tension of the effluent displacing fluid—collected post-core flooding—was measured to assess surfactant retention and potential adsorption onto the rock pore surfaces. The complete set of results is shown in Table 3 and Table 4.

Table 3.

Surface tension of fluids used during flow experiments at 22 °C.

Table 4.

Surface tension of outflowing solution from tests at 22 °C.

Experimental results demonstrated that the D66 nanoemulsion effectively reduced the surface tension of undiluted reservoir water. However, an increase in concentration from 2 wt% to 5 wt% did not yield a further measurable decrease in surface tension, indicating a plateau in interfacial activity at higher concentrations. The unexpected increase in surface tension for the “reservoir water + 5% D66 + 0.02% TN-16988” system compared to “reservoir water + 2% D66” is attributed to polymer–surfactant interactions. Polymers like TN-16988 can form complexes with surfactant molecules via hydrophobic and electrostatic forces, reducing the number of free surfactant molecules available at the interface. At higher surfactant concentrations, polymer-induced micelle aggregation may also occur, altering interfacial properties and increasing surface tension. Similar effects have been reported in the literature [32]. Thus, the observed surface-tension increase is consistent with known polymer–surfactant interaction mechanisms, limiting surfactant efficiency.

Effluent fluid analysis revealed that surface-tension values measured after core flooding were consistently higher—by up to twofold—than those of the corresponding injected fluids. This observation indicates significant adsorption of surfactant molecules onto the rock surfaces during the displacement process. Therefore, to maintain effective interfacial modification within the porous medium, an excess of nanoemulsion may be required to offset losses due to surfactant retention. This phenomenon became apparent only after the full completion of the EOR tests and analysis of the effluent compositions.

3.3. Nanoemulsion Oil Displacement Using Solutions Containing the Novel Nanoemulsion

This phase of the experimental study was carried out using physical models constructed from natural core samples saturated with reservoir fluids under conditions representative of the reservoir environment. The objective was to evaluate the effectiveness of the newly developed D66 nanoemulsion in combination with a polymer for enhanced oil recovery (EOR) applications.

A series of core-flooding experiments—several dozen in total—were performed during the research project. However, only a selection of representative results is presented in this paper. Four displacement tests were conducted under varying formulation conditions:

Test 1: Injection of reservoir water then reservoir water + 5% D66 + 0.02% TN-16988 and then reservoir water + 2% D66.

Test 2: Reservoir water then reservoir water + 2% D66 + 0.5% TN-16988 and then reservoir water + 2% D66.

Test 3: Reservoir water then reservoir water + 1% D66 and then reservoir water + 1% D66 + 0.5% TN-16988.

Test 4: Reservoir water then reservoir water + 2% D66 + 0.5% TN-16988 and then reservoir water + 2% D66 + 0.3% TN-16988 and then reservoir water + 2% D66 + 0.1% TN-16988.

Each experiment continued until a total of 12 PV of the test fluid had been injected. Both the oil recovery factor and differential pressure across the core were continuously monitored. The core-flooding experiment was conducted at a temperature of 120 °C and a confining pressure of 420 bar. The injection flow rate of the tested medium was maintained at 0.20 mL/min. The total volume of injected fluid corresponded to 12 pore volumes (PV) of the core sample. Results of displacement efficiency are presented in Table 5 and Figure 1, Figure 2, Figure 3 and Figure 4.

Table 5.

Displacement efficiency results.

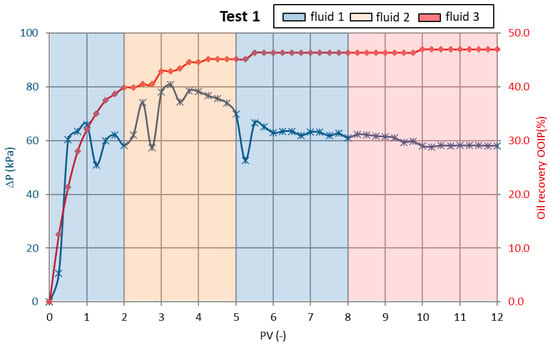

Figure 1.

Recovery factor for reservoir water with the addition of polymer and nanoemulsion for the fluid combinations according to Table 5; Test number 1.

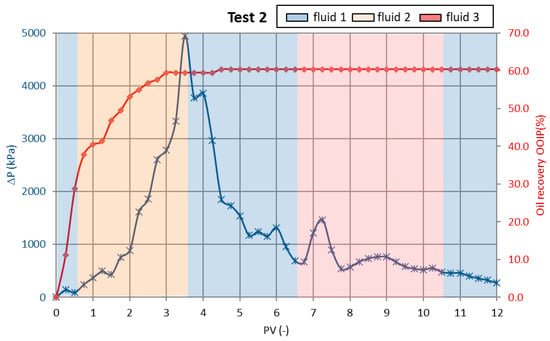

Figure 2.

Recovery factor for reservoir water with the addition of polymer and nanoemulsion for the fluid combinations according to Table 5; Test number 2.

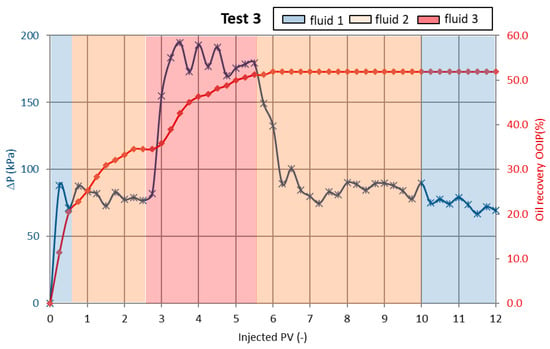

Figure 3.

Recovery factor for reservoir water with the addition of polymer and nanoemulsion for the fluid combinations according to Table 5; Test number 3.

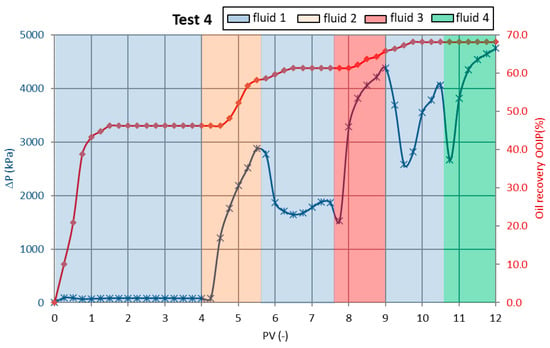

Figure 4.

Recovery factor for reservoir water with the addition of polymer and nanoemulsion for the fluid combinations according to Table 5; Test number 4.

In the first test, the polymer concentration was 0.02 wt%, while the nanoemulsion concentration was 5 and 2 wt%. As shown in Figure 1, this led to 47% of recovery factor, representing a 13.4 percentage point reduction compared to the next test. However, the system exhibited a significantly lower resistance to flow compare to other tests, with the differential pressure peaking at 80 kPa with final differential pressure of only 58 kPa.

In the second test, the injection fluid was prepared by adding 0.5 wt% TN-16988 polymer and 2 wt% D66 nanoemulsion to reservoir water. This formulation resulted in a significant improvement in oil recovery, reaching 60.4% of the original oil in place (OOIP). Simultaneously, a reduction in differential pressure was observed, with an initial value of 4949 kPa and a final value of 270 kPa at the end of the injection process.

In the third test, the nanoemulsion concentration was reduced to 1 wt%, while maintaining the polymer concentration at 0.5 wt%. As shown in Figure 3, this led to a decrease in the oil recovery factor to 51.9%, representing a 8.5 percentage point reduction compared to the previous test. These results suggest that lower concentrations of active components can extend the duration of the displacement process, allowing for more effective oil mobilization and sweep efficiency.

The fourth and final test in the presented series yielded the highest oil recovery of all formulations tested. The displacement fluid contained 0.1–0.5 wt% polymer and 2 wt% nanoemulsion. This combination achieved an oil recovery factor of 68.2% OOIP. The displacement occurred more gradually compared to earlier tests, with peak recovery reached after injecting more than 9 pore volumes of solution. The improvement in recovery was substantial—an increase of 21.2 percentage points compared to the first test with low polymer concentration. Because the polymer was added to three fluids, there was also a significant increase in differential pressure to a maximum value of 4752 kPa at the end of the test. Such high pressures could pose challenges in field applications, especially in formations with lower fracture gradients. Careful pressure monitoring and stepwise injection strategies would be necessary to mitigate potential injectivity issues or formation damage in the field.

The proposed alternating injection strategy employing a gradient polymer concentration (0.5% → 0.3% → 0.1%) represents a significant advancement over conventional fixed-concentration polymer flooding methods. This approach optimizes displacement efficiency by dynamically adjusting the polymer content during the injection process, which balances enhanced mobility control with the mitigation of polymer retention and formation damage. Specifically, the initial higher polymer concentration (0.5%) improves sweep efficiency by effectively reducing water mobility and improving conformance, while subsequent lower concentrations (0.3% and 0.1%) maintain displacement effectiveness but reduce the risk of excessive polymer adsorption and plugging in the reservoir.

4. Discussion

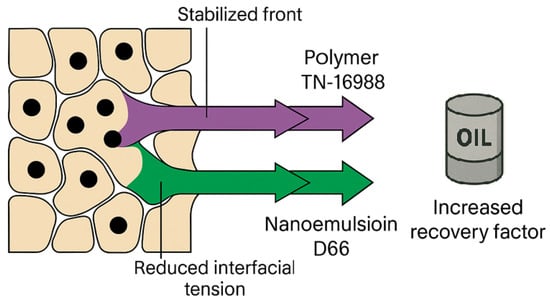

We conducted a series of laboratory studies to evaluate the effectiveness of enhanced oil recovery (EOR) using polymer–nanoemulsion solutions. This formulation benefits from the synergy between components: the polymer (TN-16988) increases the viscosity of the displacing fluid and stabilizes the displacement front, while the nanoemulsion (D66) reduces interfacial tension and alters pore surface wettability. These mechanisms work together to improve both microscopic and macroscopic sweep efficiencies, leading to more effective oil displacement (see Figure 5).

Figure 5.

Schematic illustration of the enhanced oil recovery mechanism using polymer TN-16988 and nanoemulsion D66 with an alternating injection strategy.

Experiments on Guelph Dolomite cores used live crude oil, reservoir brine, polymer TN-16988, and nanoemulsion D66. Our preliminary findings contribute to optimizing these novel EOR agents.

- Optimal nanoemulsion concentration: Surface-tension measurements showed that adding 2 wt% D66 to undiluted reservoir water significantly reduced interfacial tension, while increasing to 5 wt% had no further effect, indicating a saturation point. Thus, 2 wt% is optimal for efficient interfacial tension reduction without excess surfactant use.

- Surfactant adsorption and its impact: Effluent fluids from core flooding showed increased surface tension relative to injected fluids, often nearly doubling, indicating surfactant adsorption onto rock surfaces. This reduces active surfactant concentration in the flowing phase, necessitating consideration of surfactant loss and potentially higher initial doses or overdosage to maintain effectiveness in porous media.

- Mitigation strategies for surfactant loss: Two complementary approaches are recommended for field applications: (1) pre-flushing with brine of higher salinity than optimum to create a negative salinity gradient, reducing adsorption and maintaining microemulsion conditions; (2) injecting a polymer slug before surfactant slug to block adsorption sites on rock surfaces, protecting surfactant from early loss. These highlight the importance of core-scale retention studies, as bulk fluid surface activity does not directly predict reservoir performance.

- Oil recovery and injection pressure trade-offs: The highest oil recovery factor (68.2% OOIP) was achieved in Test 4, with an alternating injection of reservoir water and fluids containing 2 wt% nanoemulsion and decreasing polymer concentrations (0.5, 0.3, 0.1 wt%). However, this was accompanied by a continuous rise in differential pressure up to 4752 kPa, posing challenges for field-scale implementation. Test 2 (0.5 wt% polymer, 2 wt% nanoemulsion) gave 60.4% OOIP but with even higher pressure (4949 kPa). Test 3 balanced oil recovery (51.9% OOIP) and operational feasibility best, using 2 PV of fluid with 1 wt% nanoemulsion and 0.5 wt% polymer, followed by reservoir water with 1 wt% nanoemulsion, achieving low peak differential pressure (194 kPa).

- Importance of optimizing fluid concentration and injection sequence: These results underscore that carefully tuning additive concentrations and injection sequences is crucial for maximizing oil recovery while maintaining manageable pressures suitable for reservoir conditions.

Although our experiments demonstrated enhanced displacement efficiency, sweep efficiency and residual oil saturation mapping remain to be evaluated in future work using multi-plug testing, imaging, and reservoir modeling.

- Field validation: Following lab tests, a pilot field test was conducted using the same polymer–nanoemulsion formulations at concentrations of 0.5% and 1% for nanoemulsion and 0.2% and 0.5% for polymer. No injectivity or pressure buildup issues occurred, and the entire planned injection volume was delivered uninterrupted. This confirms that laboratory pressure increases are transient and specific to lab conditions, not due to polymer degradation or permanent flow restriction.

- Advantages of using undiluted reservoir brine: Incorporating undiluted formation brine into EOR can reduce costs, provide environmental benefits, and improve oil recovery efficiency. However, the specific benefits depend on reservoir and brine characteristics, requiring thorough reservoir studies for optimization.

Author Contributions

Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Investigation, Writing—original draft, Writing—review and editing, K.W.-Z.; Conceptualization, Supervision, Data curation, Formal analysis, Methodology, Project administration, Visualization, Writing—review and editing, P.K.; Conceptualization, Supervision, Data curation, Formal analysis, Investigation, Project administration, Validation, Writing—review and editing, M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was co-funded by the National Centre for Research and Development (Project No. POIR.01.02.00-00-0033/16) under the Smart Growth 2014–2020 programme, focused on enhanced oil recovery technology using polyfraction nanoemulsion.

Data Availability Statement

The data presented in this study are openly available at [https://doi.org/10.3390/en13164175], reference number [20].

Acknowledgments

We would like to thank Łukasz Leśniak and Brenntag Polska for enabling our participation in the project, their technical involvement, and organizational support. We also thank the management of the Oil and Gas Institute–National Research Institute for their assistance and support during the research.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| HPHT | High-pressure–high-temperature |

| CMC | Critical micelle concentration |

| UCS | Uniaxial compressive strength |

| GOR | Gas–oil ratio |

| PV | Pore volume |

| OOIP | Original oil in place |

| Q | Flow |

| So | Oil saturation |

| Sw | Water saturation |

References

- Li, K.; Zhang, X.; Liu, Y. Review on enhanced oil recovery by nanofluids. Energies 2018, 11, 43. [Google Scholar] [CrossRef]

- Zhang, T.; Xue, H. Nanoemulsions in EOR: A critical review. J. Pet. Sci. Eng. 2021, 187, 106871. [Google Scholar]

- Al-Anazi, B.D.; El-Desouky, A. Enhanced oil recovery in carbonate reservoirs: Current status and future challenges. Energies 2020, 13, 4819. [Google Scholar] [CrossRef]

- Alvarado, V.; Manrique, E. Enhanced oil recovery: A review. J. Pet. Sci. Eng. 2019, 172, 291–315. [Google Scholar]

- Patel, A.A.; Shah, M. Polymer flooding in enhanced oil recovery. Pet. Sci. Technol. 2019, 37, 552–567. [Google Scholar]

- Ahmed, T. Reservoir Engineering Handbook, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- El-Masry, J.F.; Bou-Hamdan, K.F.; Abbas, A.H.; Martyushev, D.A. A Comprehensive Review on Utilizing Nanomaterials in Enhanced Oil Recovery Applications. Energies 2023, 16, 691. [Google Scholar]

- Dantas, T.N.C.; Santanna, V.C.; Souza, T.T.C.; Lucas, C.R.S.; Dantas Neto, A.A.; Aum, P.T.P. Microemulsions and Nanoemulsions Applied to Well Stimulation and Enhanced Oil Recovery (EOR). Braz. J. Pet. Gas 2018, 12, 251–265. [Google Scholar] [CrossRef]

- Wilk, K.; Kasza, P.; Czupski, M. Zastosowanie nanocieczy jako dodatków wspomagających proces wypierania ropy naftowej. Nafta-Gaz 2014, 1, 14–20. [Google Scholar]

- Abdelgawad, K.Z.; Mahmoud, M.A. High-Performance EOR System in Carbonate Reservoirs. In Proceedings of the SPE Saudi Arabia Section Annual Technical Symposium and Exhibition, Al Khobar, Saudi Arabia, 21–24 April 2014. SPE-172182. [Google Scholar]

- Manrique, E.J.; Muci, V.E.; Gurfinkel, M.E. EOR Field Experience in Carbonate Reservoir in United States. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2006. SPE-100063. [Google Scholar]

- Alvarez, J.M.; Sawatzky, R.P. Waterflooding: Same Old, Same Old? In Proceedings of the SPE Heavy Oil Conference Canada, Calgary, AB, Canada, 11–13 June 2013. SPE-165406.

- Hamouda, A.A.; Gomari, K.A.R. Influence of Temperature Wettability Alteration of Carbonate Reservoir. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2008. SPE-99848. [Google Scholar]

- Zhang, Y.; Xie, X.; Morrow, N.R. Waterflood Performance by Injection of Brine with Different Salinity for Reservoir Cores. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. SPE-109849. [Google Scholar]

- Panthi, K.; Mohanty, K.K. Development of surfactant formulation for high-temperature offshore carbonate reservoirs. Front. Chem. 2024, 12, 1408115. [Google Scholar] [CrossRef] [PubMed]

- Nur, H.A.; Nurul, A.G.; Tengku, A.T.M.; Sitinoor, A.I.; Effah, Y.; Noorsuhana, M.Y. Nanoemulsion Applications in Enhanced Oil Recovery and Wellbore Cleaning: An Overview. Appl. Mech. Mater. 2015, 754, 1161–1168. [Google Scholar] [CrossRef]

- Hirasaki, G.J.; Miller, C.A. Recent Advances in Surfactan EOR. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. SPE-115386. [Google Scholar]

- Abdel-Fattah, A.I.; Moshat, A.; Alsakar, M.; Gizzatov, A. NanoSurfactant for EOR in Carbonate Reservoirs. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 24–27 April 2017. SPE-188046. [Google Scholar]

- Teletzke, G.F.; Aattenbarger, R.C.; Wilkinson, J.R. Enhanced Oil Recovery PilotTesting Best Practice. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, UAE, 3–6 November 2008. SPE-118055. [Google Scholar]

- Kasza, P.; Czupski, M.; Wilk, K.; Masłowski, M.; Moska, R.; Leśniak, Ł. Laboratory Testing of Novel Polyfraction Nanoemulsion for EOR Processes in Carbonate Formations. Energies 2020, 13, 4175. [Google Scholar] [CrossRef]

- Manrique, E.; Thomas, C.; Ravikiran, R.; Izadi, M.; Lantz, M.; Romero, J.; Alvardo, V. EOR: Current Status and Opportunieties. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. SPE-130113. [Google Scholar]

- Sheng, J.J. Enhanced Oil Recovery Field Case Studies; Gulf Professional Publishing: Houston, TX, USA, 2015. [Google Scholar]

- Thomas, S. Enhanced oil recovery—An overview. Oil Gas Sci. Technol. 2008, 63, 9–19. [Google Scholar] [CrossRef]

- Pal, N.; Mandal, A. Enhanced oil recovery performance of gemini surfactant-stabilized nanoemulsions functionalized with partially hydrolyzed polymer/silica nanoparticles. Chem. Eng. Sci. 2020, 226, 115887. [Google Scholar] [CrossRef]

- Goswami, A.S.; Rawat, R.; Pillai, P.; Saw, R.K.; Joshi, D.; Mandal, A. Formulation and Characterization of Nanoemulsions Stabilized by Nonionic Surfactant and Their Application in Enhanced Oil Recovery. Petrol. Sci. Technol. 2023, 42, 2990–3008. [Google Scholar] [CrossRef]

- Hu, J.; Fu, M.; Zhou, Y.; Wu, F.; Li, M. Experimental Study on SiO2 Nanoparticles-Assisted Alpha-Olefin Sulfonate Sodium (AOS) and Hydrolyzed Polyacrylamide (HPAM) Synergistically Enhanced Oil Recovery. Energies 2023, 16, 7523. [Google Scholar] [CrossRef]

- Khalaf, G.S.; Tantawy, M.A.; Gawish, A.A.; Salem, A.M.; Gomaa, S.; El-hoshoudy, A.N. Key Aspects of Polymeric Nanofluids as a New Enhanced Oil Recovery Approach: A Comprehensive Review. Fuel 2024, 368, 131515. [Google Scholar] [CrossRef]

- Fan, J.C.; Wang, F.C.; Chen, J.; Zhu, Y.B.; Lu, D.T.; Liu, H.; Wu, H.A. Molecular Mechanism of Viscoelastic Polymer Enhanced Oil Recovery in Nanopores. R. Soc. Open Sci. 2018, 5, 180076. [Google Scholar] [CrossRef] [PubMed]

- Bai, B.; Liu, Y.; Coste, J.P.; Li, L. Preformed particle gel for conformance control: Transport mechanism through porous media. SPE Reserv. Eval. Eng. 2007, 10, 176–184. [Google Scholar] [CrossRef]

- Vijapurapu, C.S.; Rao, D.N.; Lian, K. The E_ect of Rock Surface Characteristics on Reservoir Wettability. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 13–17 April 2002. SPE-75211. [Google Scholar]

- Gant, P.L.; Anderson, W.G. Core Cleaning for Restoration of Native Wettability. SPE Form. Eval. 1988, 3, 131–138. [Google Scholar]

- Apicella, B.; Russo, C.; Tregrossi, A.; Ciajolo, A. Thermophoretic sampling of large PAH (C ≥ 22–24) formed in flames. Fuel 2020, 263, 116722. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).