Efficient Representation of Garment Fit with Elastane Fibers Across Yoga Poses in 3D Fashion Design Software: A Preliminary Study Using CLO 3D Software

Abstract

1. Introduction

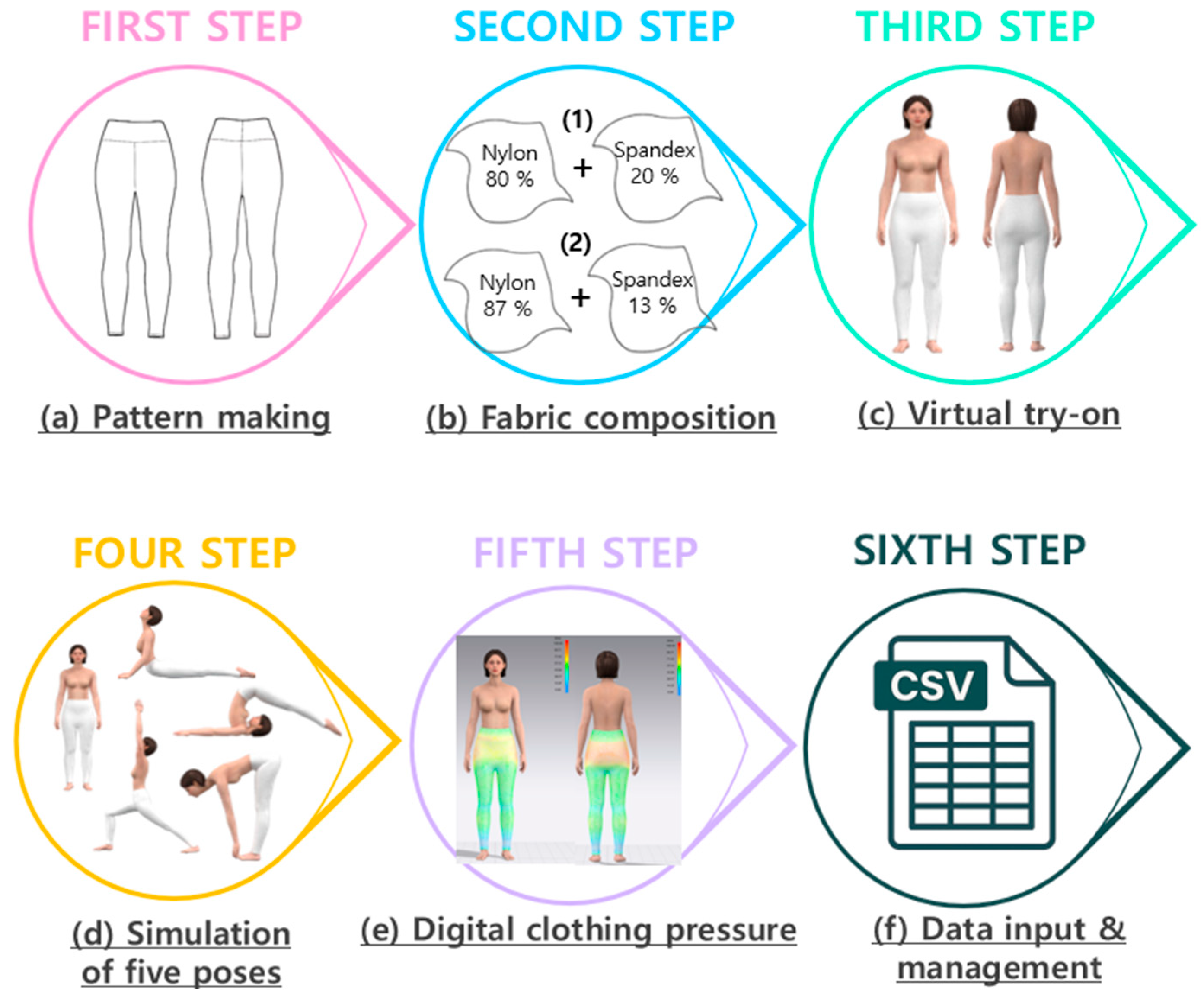

2. Materials and Methods

2.1. Virtual Try-On Garment Creation

2.2. Clothing Pressure Measurement

2.3. Data Analysis

3. Results

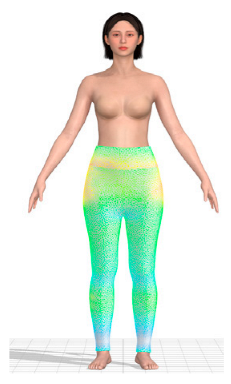

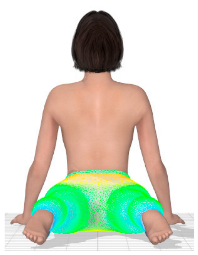

3.1. Qualitative Analysis of Clothing Pressure Differences According to Yoga Poses and Spandex Content

3.2. Quantitative Analysis of Clothing Pressure Differences According to Yoga Poses and Spandex Content

4. Discussion

4.1. Limitations of CLO 3D in Simulating Material Differences

4.2. Posture-Dependent Pressure Distribution and Comparison with Previous Studies

4.3. Suggestions for Optimized Simulation Functions in CLO 3D

4.4. Limitations and Future Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AR | Augmented Reality |

| VR | Virtual Reality |

| kPa | kilopascal |

| CSV | Comma-Separated Values |

References

- Yuan, M.; Chen, Y.; Xu, F.; Zhu, C.; Zhou, K.; Hu, S.; Guo, B. A mixed reality virtual clothes try-on system. IEEE Trans. Multimed. 2013, 15, 1958–1968. [Google Scholar] [CrossRef]

- Huang, S.; Huang, L. CLO3D-based 3D virtual fitting technology of down jacket and simulation research on dynamic effect of cloth. Wirel. Commun. Mob. Comput. 2022, 2022, 5835026. [Google Scholar] [CrossRef]

- Dai, X.; Hong, Y. Fabric mechanical parameters for 3D cloth simulation in apparel CAD: A systematic review. Comput.-Aided Des. 2024, 167, 103638. [Google Scholar] [CrossRef]

- Kim, S.E.; Kim, M.J. Analysis of fashion brand cases using 3D virtual clothing technology—Focusing on green design perspective. J. Korea Fash. Costume Des. Assoc. 2024, 26, 115–127. [Google Scholar]

- Youn, S.; Zhan, S.; Mathur, K. Advanced Virtual Fit Technology for Precision Pressure Application in Medical Compression Waistbands. Appl. Sci. 2024, 14, 10697. [Google Scholar] [CrossRef]

- Nguyen, M.H.T.; Nguyen, M.T. The design, simulation, and adjustment of the Vietnam men’s Ao dai on the CLO3D software. BIJSCIT 2022, 3, 25–31. [Google Scholar] [CrossRef]

- Qi, Y. Study on the digital design of Macau native Portuguese women’s clothing in a metacosmic perspective. Highlights Art Des. 2023, 4, 47–53. [Google Scholar] [CrossRef]

- Yu, Q.; Zhu, G. Virtual simulation design of Mazu clothing based on digital technology. Fibers Polym. 2024, 25, 2773–2787. [Google Scholar] [CrossRef]

- Essa, Y.; Rifai, H.A.M.; Hagag, M.A.H.; Mustafa, A.S.I. The effectiveness of an e-learning program on acquiring some skills of CLO 3D software among clothing students. Int. Des. J. 2024, 14, 249–264. [Google Scholar] [CrossRef]

- Salakhov, R.F.; Salakhova, R.I.; Galiullina, A.G. Perspectives and possibilities of CLO 3D program and artistic design of clothes in the process of teaching students. Vestn. Kazan. Gos. Univ. Kult. Iskusstv 2024, 2, 26–32. [Google Scholar]

- Widiyawati, I.; Putri, S.E.; Hartono, D.; Prasetyo, T. Application of CLO3D technology in fashion vocational education in vocational schools: A systematic literature review. Int. J. Educ. Curric. Appl. 2024, 7, 268–278. [Google Scholar] [CrossRef]

- Nam, Y.R.; Kim, D.E. A study on the comparison of 3D virtual clothing and real clothing by neckline type. Fash. Text. Res. J. 2021, 23, 247–260. [Google Scholar] [CrossRef]

- Choi, K.H. 3D dynamic fashion design development using digital technology and its potential in online platforms. Fash. Text. 2022, 9, 9. [Google Scholar] [CrossRef]

- Mohamed, S.M.; El-Newashy, R.; Bekhet, E.Z.; Mohamed, D. Efficiency of 3D simulation software usage to fit the jacket pattern for obese women. J. Text. Color. Polym. Sci. 2023, 20, 1–9. [Google Scholar] [CrossRef]

- Kim, N.Y.; Lee, H. Influence of clothing pressure on blood flow and subjective sensibility of commercial sports compression wear. Fash. Text. Res. J. 2019, 21, 459–467. [Google Scholar] [CrossRef]

- Kim, H.M.; Choi, J.W. Development of optimal yoga wear design for active senior women. J. Korea Fash. Costume Des. Assoc. 2024, 26, 129–143. [Google Scholar]

- Suh, S.Y.; Lee, J.S. Development of women’s leggings design using floral patterns among the traditional Korean folk paintings. Korean J. Hum. Ecol. 2022, 31, 367–381. [Google Scholar] [CrossRef]

- Park, Y. Analysis of satisfaction and repurchase intention for women’s leggings by demographic characteristics. J. Fash. Bus. 2022, 26, 67–82. [Google Scholar]

- Kim, E.K. A survey on the leggings wearing condition of down-aging women in their 30s and 40s. J. Korea Fash. Costume Des. Assoc. 2022, 24, 41–56. [Google Scholar]

- Lee, J.; Do, W. Clothing pressure analysis of commercial women’s leggings for applying medical compression classes. Fash. Text. 2023, 10, 8. [Google Scholar] [CrossRef]

- Wang, W.; Yu, X.; Cong, H. Pressure evaluation of seamless yoga leggings designed with partition structure. Autex Res. J. 2023, 23, 300–309. [Google Scholar] [CrossRef]

- Kim, Y.; Baytar, F. Product Development of Compression Tops Using 3D Virtual Prototyping Technology and Human Participant Tests. Fash. Pract. 2025, 17, 74–104. [Google Scholar] [CrossRef]

- Kim, N.Y.; Lee, J.; Park, H. Designing Differential Pressure Leggings for Late Middle Age Women. Text. Res. J. 2025; online first. [Google Scholar] [CrossRef]

- ISO 2076:2021; Textiles—Man-Made Fibres—Generic Names. International Organization for Standardization: Geneva, Switzerland, 2021.

- Shi, Y.; Liu, R.; Ye, C. Personalized compression therapeutic textiles: Digital design, development, and biomechanical evaluation. Front. Bioeng. Biotechnol. 2024, 12, 1405576. [Google Scholar] [CrossRef]

- Wang, L.; Felder, M.; Cai, J.Y. Study of properties of medical compression fabrics. J. Fiber Bioeng. Inform. 2011, 4, 15–22. [Google Scholar] [CrossRef]

- Liu, K.; Thomassey, S.; Zeng, X. Garment fit evaluation using machine learning technology. In Artificial Intelligence for Fashion Industry in the Big Data Era; Springer: Singapore, 2018; pp. 273–288. [Google Scholar] [CrossRef]

- Jankoska, M. 3D Virtual Fitting System on Woman’s Garment: Predicting Fit Behavior and Comfort Across Avatar Poses. Tekst. Industrija. 2021, 69, 321–332. [Google Scholar] [CrossRef]

- ISO 8559-1:2017; Textiles—Size Designation of Clothes—Part 1: Anthropometric Definitions for Body Measurement. International Organization for Standardization: Geneva, Switzerland, 2017.

- Liu, A.M.; Chu, I.H.; Lin, H.T.; Liang, J.M.; Hsu, H.T.; Wu, W.L. Training benefits and injury risks of standing yoga applied in musculoskeletal problems: Lower limb biomechanical analysis. Int. J. Environ. Res. Public Health 2021, 18, 8402. [Google Scholar] [CrossRef]

- Pinto, D.P.; Moreira, P.V.S.; Menegaldo, L.L. Postural control adaptations in yoga single-leg support postures: Comparison between practitioners and nonpractitioners. Mot. Control 2022, 26, 412–429. [Google Scholar] [CrossRef]

- Liu, K.; Wang, J.; Hong, Y. Wearing comfort analysis from aspect of numerical garment pressure using 3D virtual-reality and data mining technology. Int. J. Cloth. Sci. Technol. 2017, 29, 166–179. [Google Scholar] [CrossRef]

- Brubacher, K.; Tyler, D.; Apeagyei, P.; Venkatraman, P.; Brownridge, A.M. Evaluation of the accuracy and practicability of predicting compression garment pressure using virtual fit technology. Cloth. Text. Res. J. 2023, 41, 107–124. [Google Scholar] [CrossRef]

- Kweon, S.A. The effect of the skinny pants on the physiological responses and subjective pressure. Korean J. Hum. Ecol. 2012, 21, 567–576. [Google Scholar] [CrossRef][Green Version]

| Measurement Area | Inseam | Waist Circumference | Hip Circumference | Thigh Circumference | Knee Circumference | Calf Circumference | Ankle Circumference | Total Length |

|---|---|---|---|---|---|---|---|---|

| Size (cm) | 65 | 60 | 85 | 45 | 30 | 25 | 18 | 82 |

| Position | Mountain Pose | Cobra Pose | Lunge Pose | Plow Pose | Forward Fold | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | A | B | A | B | A | B | |

| Front |  |  |  |  |  |  |  |  |  |  |

| Side |  |  |  |  |  |  |  |  |  |  |

| Back |  |  |  |  |  |  |  |  |  |  |

| Position | Digital Clothing Pressures (Unit: kPa) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mountain Pose | Cobra Pose | Lunge Pose | Plow Pose | Forward Fold | ||||||

| Fabric a | A | B | A | B | A | B | A | B | A | B |

| P1 (Waist) | 36.02 | 36.02 | 36.11 | 36.11 | 35.48 | 35.48 | 36.18 | 36.18 | 37.55 | 37.55 |

| P2 (Hip) | 63.83 | 63.83 | 66.03 | 66.03 | 65.96 | 65.96 | 68.69 | 68.69 | 70.28 | 70.28 |

| P3 (Thigh) | 38.53 | 38.53 | 39.15 | 39.15 | 68.31 | 68.31 | 36.98 | 36.98 | 40.03 | 40.03 |

| P4 (Knee) | 37.97 | 37.97 | 38.38 | 38.38 | 38.64 | 38.64 | 33.52 | 33.52 | 33.20 | 33.20 |

| P5 (Calf) | 43.93 | 43.93 | 44.81 | 44.81 | 45.30 | 45.30 | 45.04 | 45.04 | 45.61 | 45.61 |

| P6 (Ankle) | 25.51 | 25.51 | 20.95 | 20.95 | 23.33 | 23.33 | 20.96 | 20.96 | 25.81 | 25.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Chae, Y. Efficient Representation of Garment Fit with Elastane Fibers Across Yoga Poses in 3D Fashion Design Software: A Preliminary Study Using CLO 3D Software. Appl. Sci. 2025, 15, 10306. https://doi.org/10.3390/app151910306

Kim J, Chae Y. Efficient Representation of Garment Fit with Elastane Fibers Across Yoga Poses in 3D Fashion Design Software: A Preliminary Study Using CLO 3D Software. Applied Sciences. 2025; 15(19):10306. https://doi.org/10.3390/app151910306

Chicago/Turabian StyleKim, Jisoo, and Youngjoo Chae. 2025. "Efficient Representation of Garment Fit with Elastane Fibers Across Yoga Poses in 3D Fashion Design Software: A Preliminary Study Using CLO 3D Software" Applied Sciences 15, no. 19: 10306. https://doi.org/10.3390/app151910306

APA StyleKim, J., & Chae, Y. (2025). Efficient Representation of Garment Fit with Elastane Fibers Across Yoga Poses in 3D Fashion Design Software: A Preliminary Study Using CLO 3D Software. Applied Sciences, 15(19), 10306. https://doi.org/10.3390/app151910306