Safety Risk Identification of the Freezing Method for the Construction of a Subway Contact Channel Based on Bayesian Network

Abstract

1. Introduction

2. Methodology

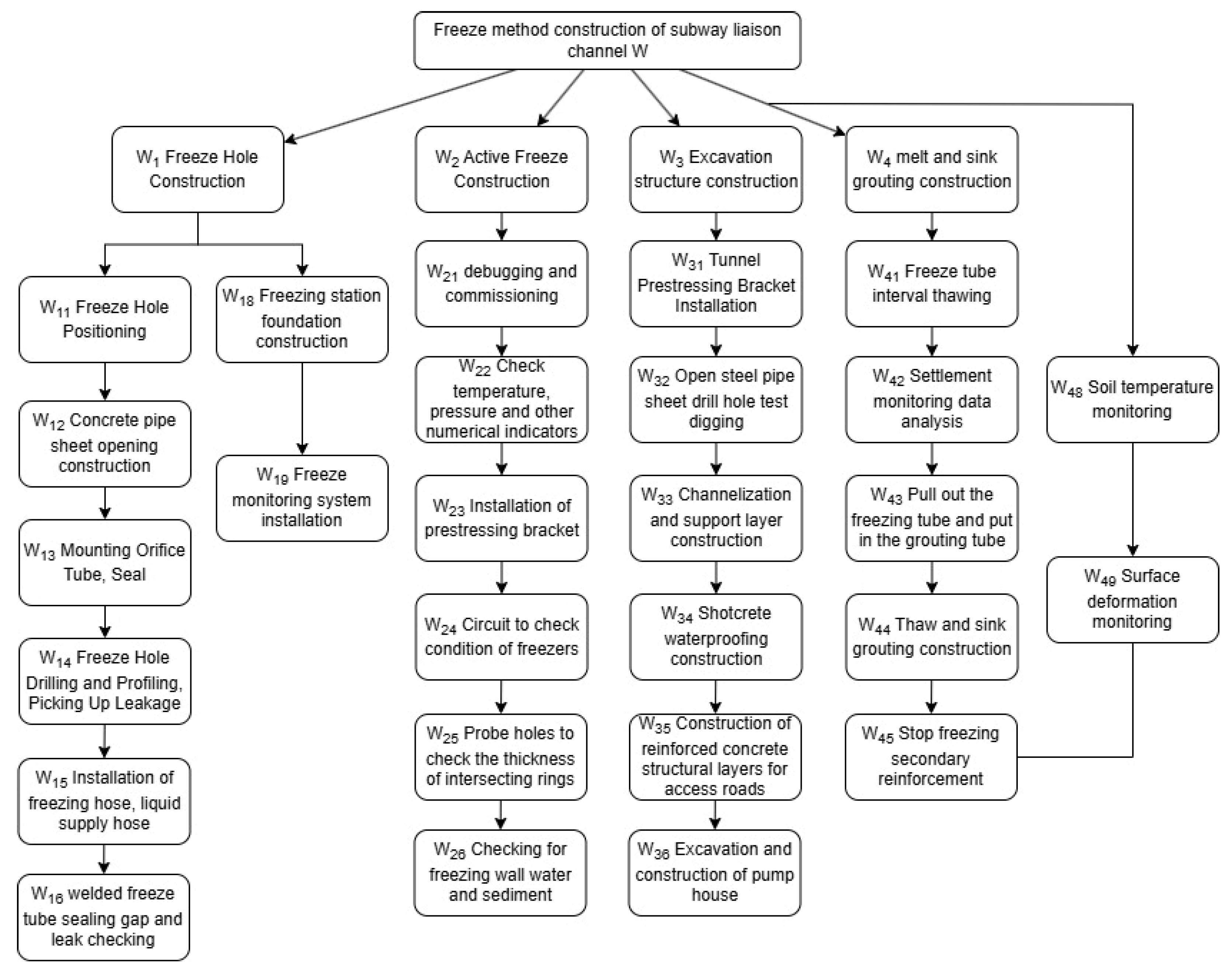

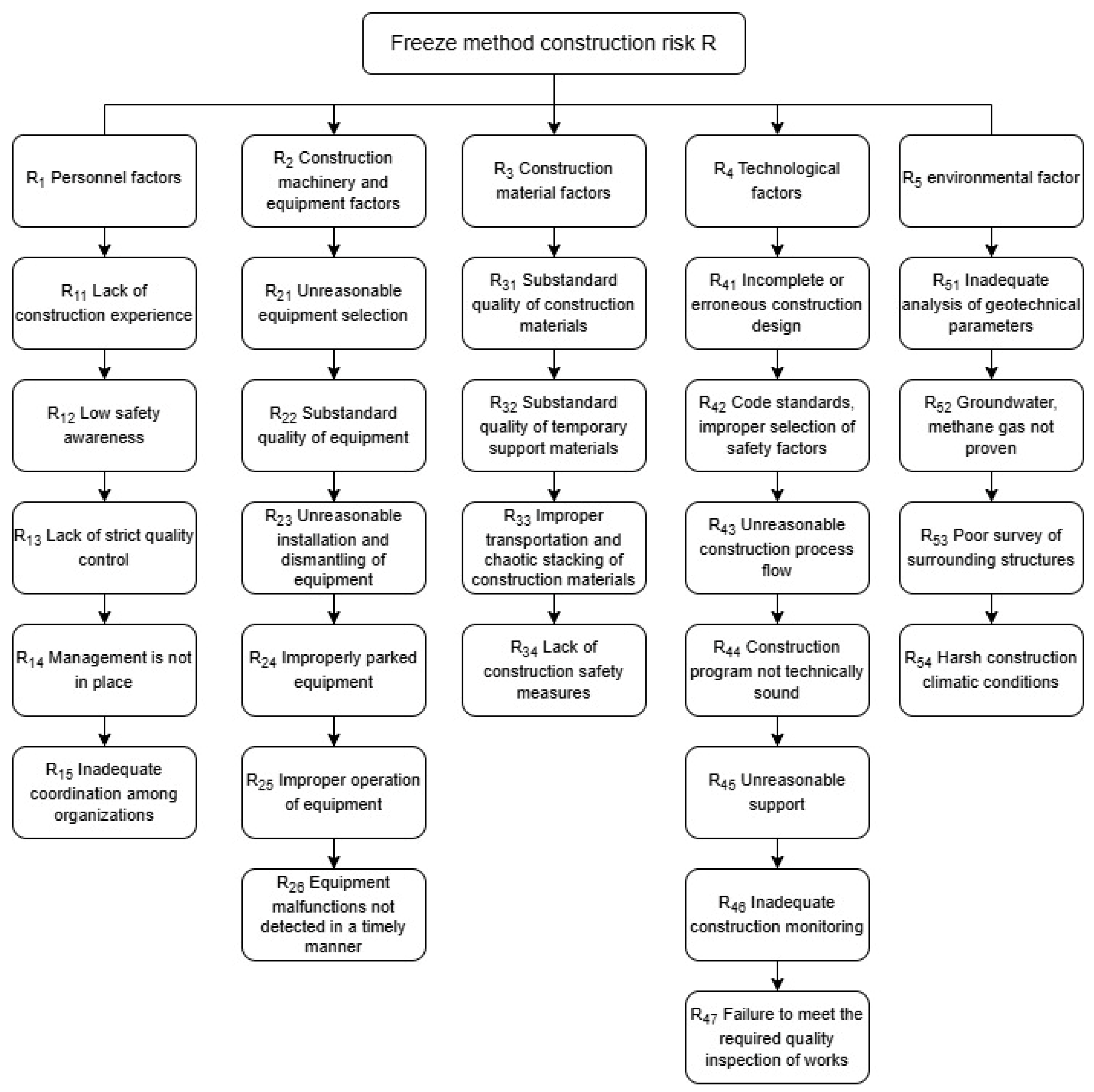

2.1. Identification of Causes of Safety Accidents and WBS-RBS Matrix Construction

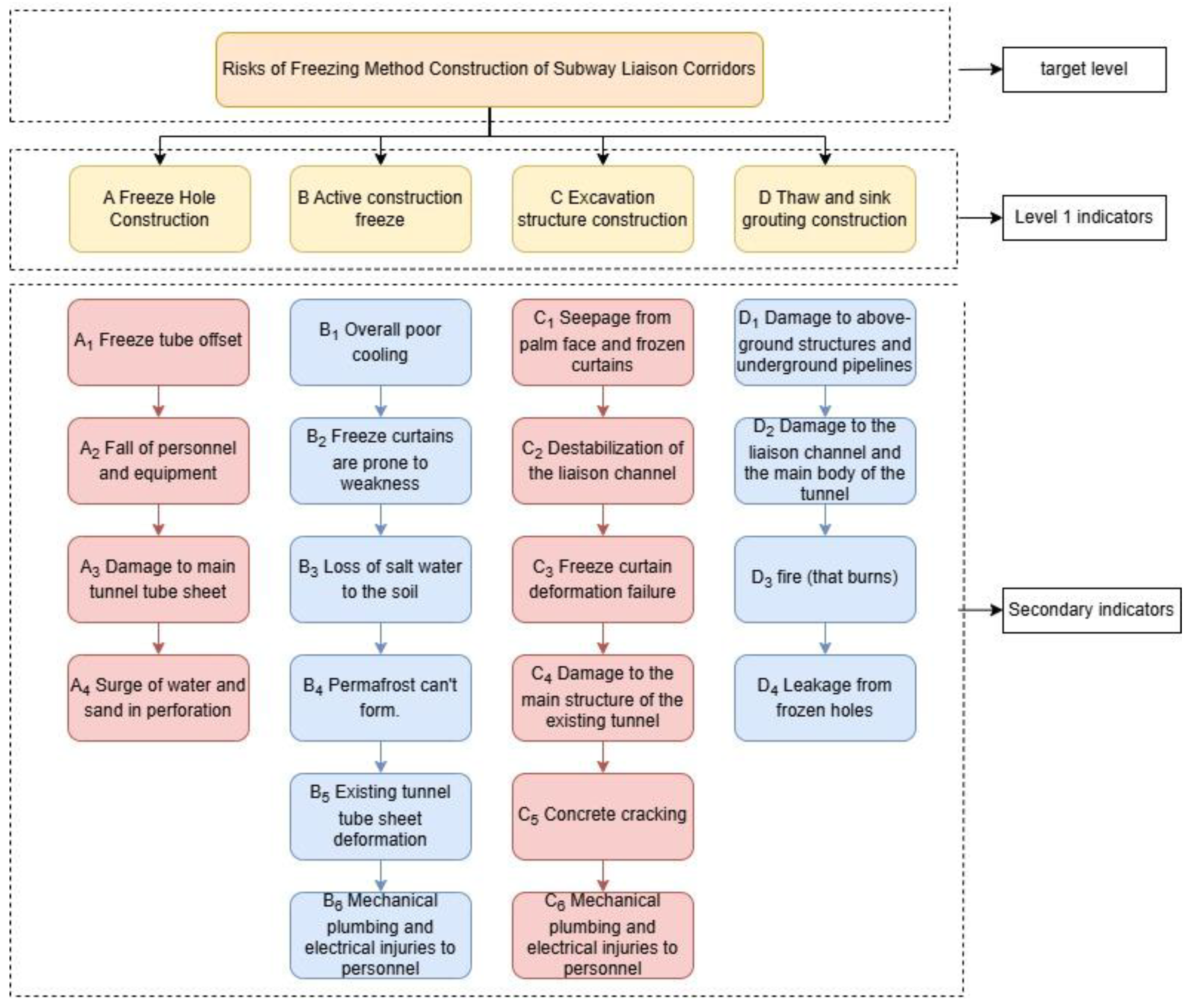

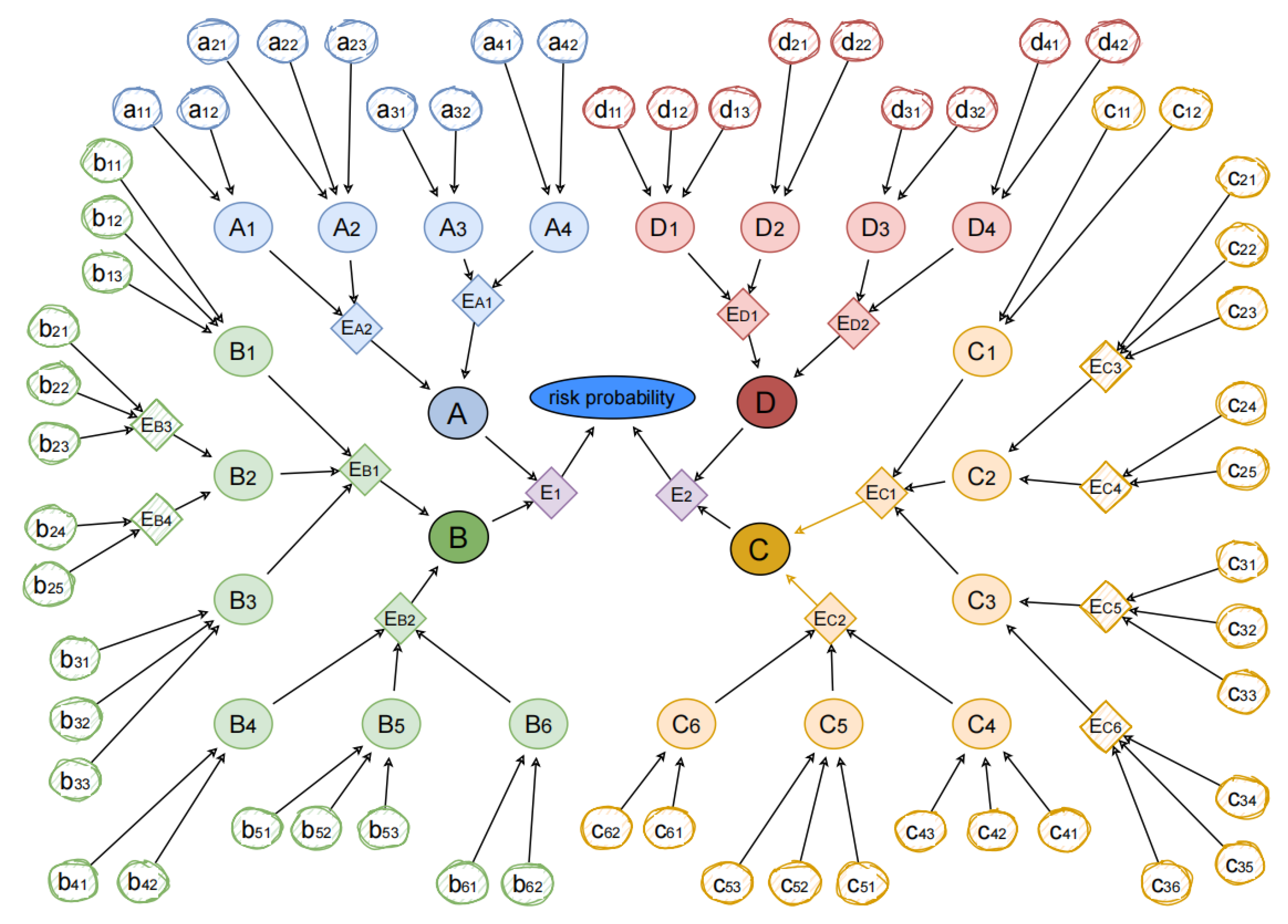

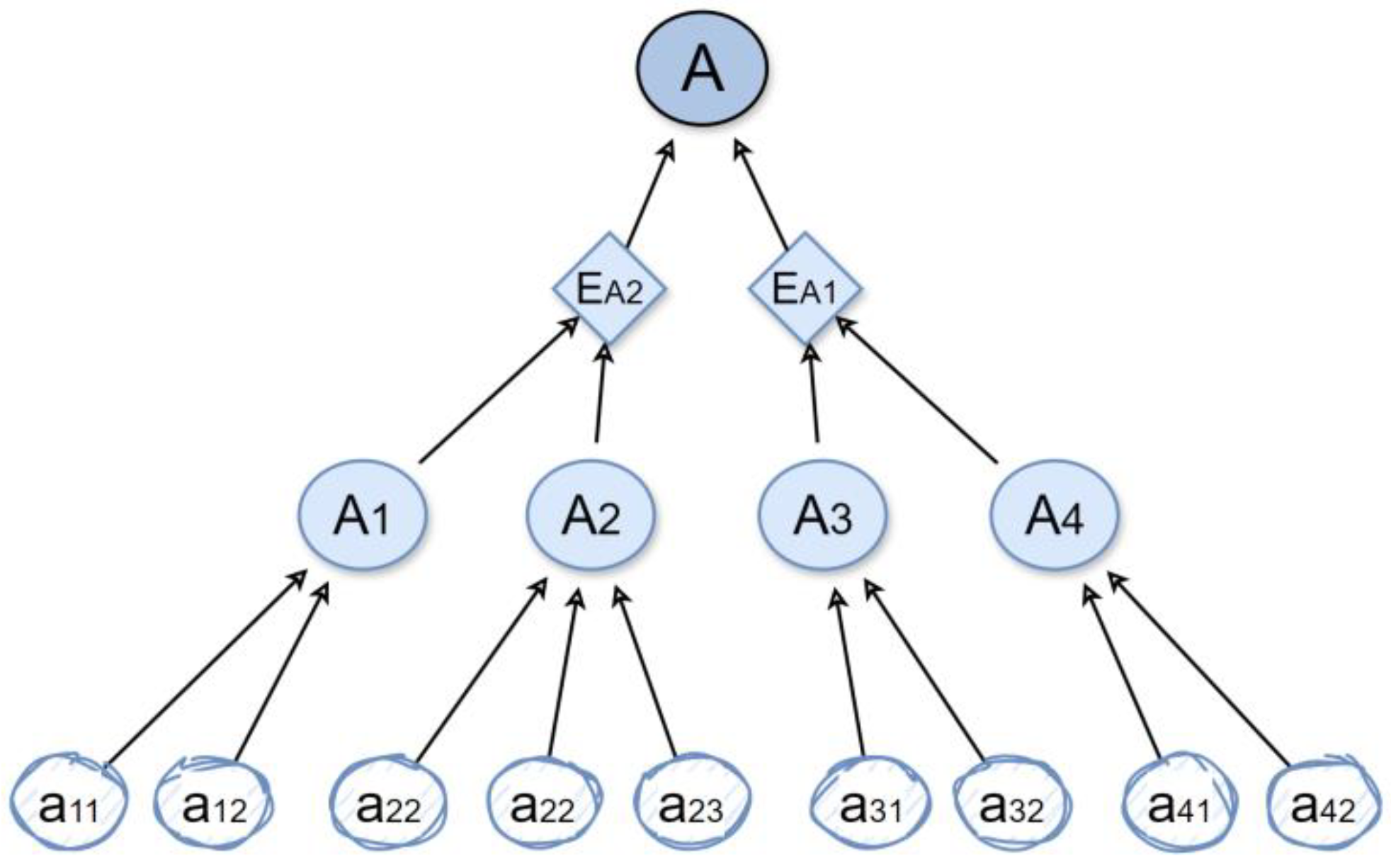

2.2. Establishment of Construction Risk Index of Freezing Method

2.3. Determination of Indicator Weights Using AHP

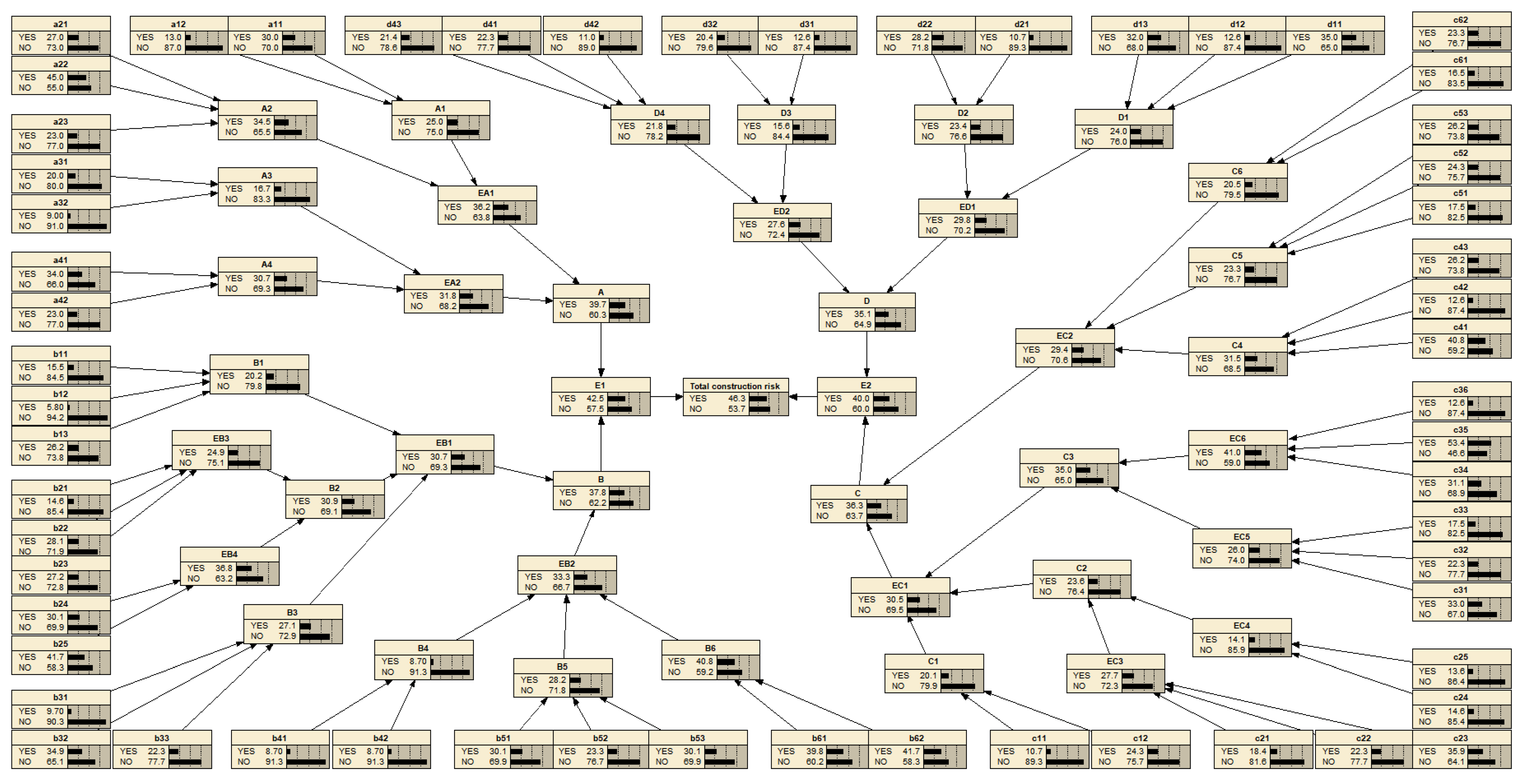

2.4. Bayesian Network Based Risk Assessment Model

3. Case Study and Results

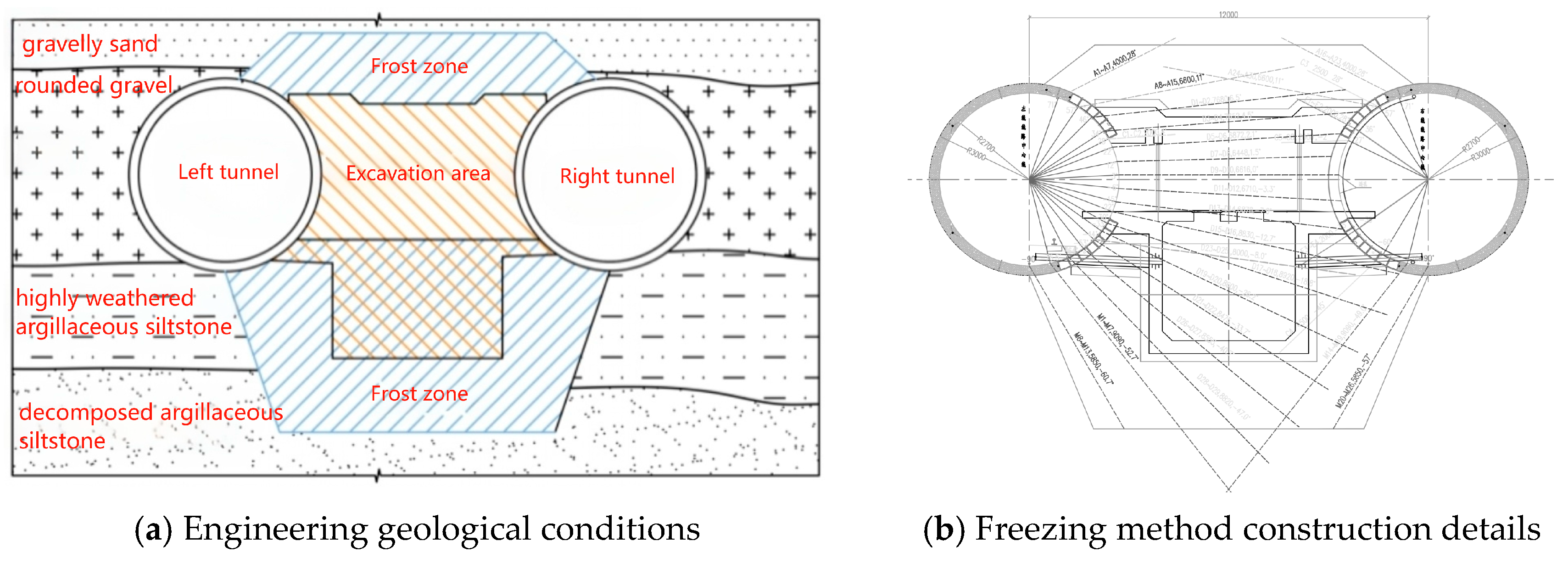

3.1. Case Background

3.2. Risk Probability and Sensitivity Analysis

4. Discussion

4.1. Key Risk Factors and Comparative Analysis

4.2. Methodological Advantages and Comparisons

4.3. Practical Implications for Risk Management

4.4. Limitations and Future Research

5. Conclusions

- (1)

- A risk evaluation system encompassing four construction stages and twenty secondary indicators was developed through integrated WBS-RBS decomposition of construction processes and risk factors.

- (2)

- Using the Analytic Hierarchy Process (AHP), risk weights were quantified, revealing that the excavation support stage (52.94%) and thawing-grouting stage (31.48%) exerted the most significant influence on overall risk.

- (3)

- A Bayesian network-based risk assessment model was constructed, with risk probabilities calculated through expert surveys and accident data. Results demonstrated an overall construction risk probability of 46.3%, with the excavation stage exhibiting the highest sensitivity index (3.97%)—identifying it as the core risk control link. Key contributing factors included freezing pipe fracture, insufficient support strength, and groundwater seepage. Real-time probability updating through construction monitoring data demonstrated the model’s capability for dynamic risk early warning.

- (4)

- Contrary to silty clay strata, where thaw settlement dominates [14], excavation stability emerged as the primary risk in sandy strata, highlighting geological dependencies in risk prioritization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Chen, H.; Lei, Y.; Xia, L.; Deveci, M.; Chen, Z.-S.; Liu, Y. Dynamic evaluation of the safety risk during shield construction near existing tunnels via a pair-copula Bayesian network. Appl. Soft Comput. 2025, 169, 112583. [Google Scholar] [CrossRef]

- Liu, P.; Jin, X.; Shang, Y.; Zhu, J. Analysis of collapse risks under cut and cover method based on multi-state fuzzy Bayesian network. PLoS ONE 2025, 20, e0321382. [Google Scholar] [CrossRef] [PubMed]

- China Urban Rail Transit Association. Overview of Urban Rail Transit Lines in Mainland China in the First Half of 2024. Available online: https://www.camet.org.cn/xytj/xxfb/589415181037637.shtml (accessed on 18 June 2025).

- Yu, P.; Liu, H.; Wang, Z.; Fu, J.; Zhang, H.; Wang, J.; Yang, Q. Development of urban underground space in coastal cities in China: A review. Deep Earth Sci. 2023, 2, 148–172. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, S.; Qi, H. Mitigating subway construction collapse risk using Bayesian network modeling. Autom. Constr. 2022, 143, 104541. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, Y.; Lian, N.; Peng, L.; Hao, Y.; Wang, W.; Tian, R.; Qin, G. Analysis of urban subway construction collapse disaster chain and research on chain breaking and disaster reduction. PLoS ONE 2025, 20, e0318269. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Xu, J.; Xie, X.; Zeng, H.; Xu, W.; Niu, G.; Xiao, Z. Disaster mechanism analysis for segments floating of large-diameter shield tunnel construction in the water-rich strata: A case study. Eng. Fail. Anal. 2024, 157, 107953. [Google Scholar] [CrossRef]

- Zhang, S.; Yue, Z.; Lu, X.; Zhang, Q.; Sun, T.; Qi, Y. Model test and numerical simulation of foundation pit constructions using the combined artificial ground freezing method. Cold Reg. Sci. Technol. 2023, 205, 103700. [Google Scholar] [CrossRef]

- Fu, Y.; Hu, J.; Wu, Y. Finite element study on temperature field of subway connection aisle construction via artificial ground freezing method. Cold Reg. Sci. Technol. 2021, 189, 103327. [Google Scholar] [CrossRef]

- Sai, H. Study on Risk Management of XTC Metro Construction Project. Master’s Thesis, China University of Petroleum, Qingdao, China, 2025. [Google Scholar] [CrossRef]

- Huang, Y. Research on Construction Risk Assessment of Subway Foundation Pit Engineering. Master’s Thesis, Guangxi University, Nanning, China, 2023. [Google Scholar] [CrossRef]

- Lu, X.-Y.; Xu, C.-S.; Hou, B.-W.; Du, X.-L.; Li, L.-Y. Risk assessment of metro construction based on dynamic Bayesian network. Chin. J. Geotech. Eng. 2022, 44, 10. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Chen, C. Fuzzy comprehensive Bayesian network-based safety risk assessment for metro construction projects. Tunn. Undergr. Space Technol. 2017, 70, 330–342. [Google Scholar] [CrossRef]

- Zhai, Q.; Gu, W.H.; Jing, Z.Q. Safety Risk Assessment for a Subway Connecting Passage Constructed by Freezing Method. Mod. Tunn. Technol. 2021, 58, 10. [Google Scholar]

- Ma, L.; Zhang, R.K. Case study on construction risk management and control of contact channel freezing method. J. Highw. Transp. Res. Dev. Appl. Technol. Ed. 2016, 12, 273–274. [Google Scholar]

- Zheng, G.P. Study on Construction Safety Risk Control of Connecting Passage of Metro Tunnel in Rich Water Sand Layer. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2022. [Google Scholar] [CrossRef]

- Du, P. Research on Safety Management of Assembled Concrete Building Construction on WBS-RBS Method. Master’s Thesis, Anhui University of Science and Technology, Huainan, China, 2020. [Google Scholar] [CrossRef]

- Xu, N.; Guo, C.; Wang, L.; Zhou, X.; Xie, Y. A three-stage dynamic risk model for metro shield tunnel construction. KSCE J. Civil Eng. 2024, 28, 503–516. [Google Scholar] [CrossRef]

- Hong, R.; Cai, H.; Li, M. Integrated prediction model of ground surface deformation during tunnel construction using local horizontal freezing technology. Arab. J. Sci. Eng. 2022, 47, 4657–4679. [Google Scholar] [CrossRef]

- Go, G.-H.; Le, V.D. Optimization study on artificial ground freezing in elliptical tunnel construction: A comprehensive analysis of groundwater flow and thermodynamic parameters of soil. Tunn. Undergr. Space Technol. 2025, 163, 106774. [Google Scholar] [CrossRef]

- Zhou, H.; Zhao, Y.; Shen, Q.; Yang, L.; Cai, H. Risk assessment and management via multi-source information fusion for undersea tunnel construction. Autom. Constr. 2020, 111, 103050. [Google Scholar] [CrossRef]

- Zhou, H.; Gao, B.; Zhao, X.; Peng, L.; Bai, S. Developing a cloud evidence method for dynamic early warning of tunnel construction safety risk in undersea environment. Dev. Built Environ. 2023, 16, 100225. [Google Scholar] [CrossRef]

| Risk Category | Sign | Reasons for Formation | Coupling Factor |

|---|---|---|---|

| A1 Freeze tube offset | a11 | ① Incorrect positioning of freeze holes | ① W11—R11/R14 |

| a12 | ② Insufficient drilling accuracy | ② W14—R25/R43 | |

| A2 Fall of personnel and equipment | a21 | ① Low safety awareness among construction workers | ① R12 |

| a22 | ② Lack of construction safety materials | ② R34 | |

| a23 | ③ Poorly designed construction scaffolding | ③ W11—R41 | |

| A3 Main tunnel tube sheet damage | a31 | ① Drilling holes without avoiding the location of main bars, and bolts, etc. | ① W12—R11/R14 |

| a32 | ② Excessive ground settlement due to drilling | ② W14—R11/R15/R52 | |

| A4 Water and sand gushing occurred when drilling holes | a41 | ① Hole seals are dislodged and failing drill holes lead to excessive ground settlement | ① W13 R12/R13/R14/R31 |

| a42 | ② Excessive ground settlement due to pressurized water being knocked through the borehole during drilling | ② W14—R52/R13 | |

| B1 The overall cooling effect is not good | b11 | ① Insufficient design cooling capacity drilled holes resulting in excessive ground settlement | ① W21—R21/R22/R44 |

| b12 | ② Improper operation of freezing equipment | ② W21—R25/R14 | |

| b13 | ③ Failure of freezing equipment to be detected in a timely manner | ③ W24—R26/R14 | |

| B2 Freeze curtain appears weak | b21 | ① Loss of brine due to breakage of freezing pipes | ① B3 |

| b22 | ② Skewed freezing tube position | ② A1, W25—R46 | |

| b23 | ③ Imbalance of series cooling supply for freezing equipment | ③ W25—R23, W15—R44 | |

| b24 | ④ Equipment outage time is too long | ④ W21—R15 | |

| b25 | ⑤ Decrease in strength of rock and soil after many freeze–thaw cycles | ⑤ W22—R14 | |

| B3 Loss of salt water to the soil | b31 | ① Rupture of freezing pipe due to poor quality | ① W21—R31/R33 |

| b32 | ② The clogging of freezing pipe leads to swelling and cracking | ② W15—R23 | |

| b33 | ③ Freezing pipe breakage due to different mechanical parameters of geotechnical soil | ③ W22—R51 | |

| B4 Frozen soil cannot be formed | b41 | ② Excessive seepage rate of groundwater flow | ① W26—R52 |

| b42 | ① Leakage of salt water | ② B3 | |

| b43 | ③ Strong external heat source exists in the soil layer | ③ W22—R54 | |

| B5 Deformation of existing tunnel tube sheets | b51 | ① Discrepancy of geotechnical parameters | ① W23—R51 |

| b52 | ② Insufficient number of pressure relief holes, untimely pressure relief | ② W22—R41 | |

| b53 | ③ Insufficient strength of supporting structure in the tunnel | ③ W23—R42 | |

| B6 Mechanical and electrical injuries to personnel | b61 | ① Poor safety awareness of construction personnel | ① W23/W25—R12/R34 |

| b62 | ② Equipment aging, faults are not found in time | ② R22 | |

| C1 Seepage from palm face and freezing curtains | c11 | ① Exposure time of excavation surface is too long | ① W33—R11/R14 |

| c12 | ① The support is not completed in time | ② W33—R15/R45 | |

| C2 Destabilization and damage of contact channel | c21 | ① The strength of frozen soil is not up to the standard for construction | ① W32—R13/R26 |

| c22 | ② over-excavation of the soil body of the contact channel, support is not timely | ② W33—R15/R43 | |

| c23 | ③ Insufficient support strength | ③ W33—R45/R31 | |

| c24 | ③ Insufficient support strength | ④ R14 | |

| c25 | ⑤ Existence of groundwater flow with excessive seepage rate | ⑤ W32—R52 | |

| C3 Deformation and failure of freezing curtain | c31 | ① Equipment failure not detected in time | ① R26 |

| c32 | ② Improper operation of freezing equipment | ② R25 | |

| c33 | ③ The freezing curtain design parameters are wrong | ③ R42 | |

| c34 | ④ Exposure time of excavation surface is too long | ④ W33—R15/R43 | |

| c35 | ⑤ Rupture of frozen pipe due to irregular construction | ⑤ W33—R11/R13 | |

| c36 | ⑥ Rupture of freezing pipe due to unqualified quality | ⑥ R31/R33 | |

| C4 Deformation of existing tunnel tubes | c41 | ① The geotechnical parameters are too inconsistent | ① W33—R51 |

| c42 | ② Unqualified welding quality of tunnel metal tube sheet | ② R13 | |

| c43 | ③ Insufficient support strength of the existing tunnel | ③ W31—R42/R32/R45 | |

| C5 Cracking of concrete | c51 | ① Early demolding of soil mix during lining | ① W36—R13/R14 |

| c52 | ② Quality defects in construction | ② W36—R47/R13/R31 | |

| c53 | ③ Weakening of freezing curtain strength when strength is not reached | ③ C3 | |

| C6 Mechanical hydroelectricity injury to personnel | c61 | ① Poor safety awareness of construction personnel | ① R12R34 |

| c62 | ② Equipment aging, faults are not found in time | ② R22 | |

| D1 Damage to underground structures and pipelines | d11 | ① The soil freezes and thaws too fast | ① R51/R15/R46 |

| d12 | ② Not timely grouting | ② W44—R14/R15 | |

| d13 | ③ Failure of grouting quality control | ③ W44—R53 | |

| D2 Damage to contact channel and tunnel body | d21 | ① Soil freezing and thawing too quickly | ① R51/R15/R46 |

| d22 | ② Insufficient strength or quality defects of passages and tunnels | ② R13/R45 | |

| D3 Leakage from frozen holes | d31 | ① Soil freezing and thawing too quickly | ① R51/R15/R46 |

| d32 | ② Failure to cut frozen pipes in time | ② R11/R14/R52 | |

| D4 Fire | d41 | ① Methane gas in the soil layer | ① R52 |

| d42 | ② Lack of construction safety measures | ② R34 |

| Serial No. | Overall Risk (Target Level) | Construction Phase (Guideline Level) | Risk Factors (Program Level) |

|---|---|---|---|

| 1 | Risks of Freezing Method Construction of Subway Liaison Corridors | Freeze hole construction phase risk A | A1 Frozen Pipe Offset |

| 2 | A2 Fall of Personnel and Machinery | ||

| 3 | A3 Damage to main tunnel tubes | ||

| 4 | A4 Surge of water and sand | ||

| 5 | Active freezing construction phase risk B | B1 Overall cooling effect is not good | |

| 6 | B2 Weakness of freezing curtain | ||

| 7 | B3 Freezing pipe breakage leading to saltwater loss | ||

| 8 | B4 Frozen soil could not be formed | ||

| 9 | B5 Damage to existing tunnel structure | ||

| 10 | B6 Injury to personnel by mechanical hydroelectricity | ||

| 11 | Excavation structure construction risk C | C1 Water seepage from palm face and freezing curtains | |

| 12 | C2 Destabilization of contact tunnel excavation face | ||

| 13 | C3 Deformation and failure of freezing curtain | ||

| 14 | C4 Deformation of existing tunnel | ||

| 15 | C5 Cracking of concrete | ||

| 16 | C6 Mechanical and hydraulic injuries to personnel | ||

| 17 | Thawing and grouting construction risk D | D1 Damage to neighboring structures (buildings) | |

| 18 | D2 Contact channel and tunnel body destabilization | ||

| 19 | D3 Leakage from frozen holes | ||

| 20 | D4 Fire |

| Risks of Freeze Hole Construction | A Freeze Hole Construction | B Active Freezing Construction | C Excavation Structure Construction | D Thaw and Sink Grouting Construction |

|---|---|---|---|---|

| A Freeze Hole Construction | 1 | 3 | 1/3 | 1/5 |

| B Active Freezing Construction | 1/3 | 1 | 1/3 | 1/5 |

| C Excavation structure construction | 3 | 3 | 1 | 1/3 |

| D Thaw and sink grouting construction | 5 | 5 | 3 | 1 |

| Weighting Calculation | A | B | C | D | Eigenvector (Math.) | Weights (N) | Maximum Characteristic Root |

|---|---|---|---|---|---|---|---|

| A | 0.1071 | 0.2500 | 0.0714 | 0.1154 | 0.5440 | 0.1360 | 4.2045 |

| B | 0.0357 | 0.0833 | 0.0714 | 0.1154 | 0.3059 | 0.0765 | CR = CI/RI |

| C | 0.3214 | 0.2500 | 0.2143 | 0.1923 | 0.9780 | 0.2445 | 0.0763 < 0.1 |

| D | 0.5357 | 0.4167 | 0.6429 | 0.5769 | 2.1722 | 0.5430 |

| Freezing Method Construction | Expert 1 | Expert 2 | Expert 3 | Expert 4 | Expert 5 | Expert 6 | Average Weights |

|---|---|---|---|---|---|---|---|

| A Freeze hole construction | 0.1360 | 0.2729 | 0.0768 | 0.0768 | 0.2311 | 0.1360 | 0.1549 |

| B Active freezing construction | 0.0765 | 0.5329 | 0.5011 | 0.5011 | 0.0735 | 0.0765 | 0.2936 |

| C Excavation structure construction | 0.2445 | 0.1276 | 0.2630 | 0.2630 | 0.5430 | 0.5430 | 0.3307 |

| D Thawing and sinking grouting construction | 0.5430 | 0.0667 | 0.1591 | 0.1591 | 0.5382 | 0.2445 | 0.2851 |

| Class I Indicators | Weights | Secondary Indicators | Weights for Level 1 Indicators | For the Weight of the Target Layer | Arrange in Order |

|---|---|---|---|---|---|

| A Freeze-hole construction stage | 0.1051 | A1 Frozen pipe offset | 0.1581 | 0.0166 | 13 |

| A2 Fall of personnel and machinery | 0.0956 | 0.0100 | 15 | ||

| A3 Damage to tube sheet in main tunnel | 0.0518 | 0.0054 | 17 | ||

| A4 Surge of water and sand in perforation | 0.6944 | 0.0730 | 6 | ||

| B Active freezing construction stage | 0.0508 | B1 Overall cooling effect is not good | 0.0296 | 0.0015 | 20 |

| B2 Weakness of freezing curtain | 0.2869 | 0.0146 | 14 | ||

| B3 Saltwater loss to soil layer | 0.1252 | 0.0064 | 16 | ||

| B4 Frozen soil could not be formed | 0.0512 | 0.0026 | 19 | ||

| B5 Deformation of tube sheet of existing tunnel | 0.4259 | 0.0216 | 10 | ||

| B6 Injury to personnel by mechanical hydroelectricity | 0.0812 | 0.0041 | 18 | ||

| C Excavation structure construction stage | 0.5294 | C1 Water seepage from palm face and freezing curtains | 0.0570 | 0.0302 | 9 |

| C2 Destabilization and damage of contact channel | 0.3157 | 0.1671 | 3 | ||

| C3 Deformation and failure of freezing curtain | 0.1387 | 0.0734 | 5 | ||

| C4 Deformation of existing tunnel tubes | 0.4532 | 0.2399 | 1 | ||

| C5 Cracking of concrete | 0.0354 | 0.0187 | 11 | ||

| C6 Mechanical hydroelectricity injury to personnel | 0.0869 | 0.0460 | 7 | ||

| D Thawing and sinking grouting construction stage | 0.3148 | D1 Damage to underground structures and pipelines | 0.5579 | 0.1756 | 2 |

| D2 Damage to contact channel and tunnel body | 0.2633 | 0.0829 | 4 | ||

| D3 Leakage from frozen holes | 0.0569 | 0.0179 | 12 | ||

| D4 Fire | 0.1219 | 0.0384 | 8 |

| Point | Risk Incident | Number | Nicknames | Node Name | Number of Occurrences | Number of Occurrences | Number of Accidents |

|---|---|---|---|---|---|---|---|

| Freeze-hole construction phase | A1 Freeze pipe deflection | 1 | a11 | ① Freeze hole positioning error | 31 | 44 | 220 |

| 2 | a12 | ② Insufficient accuracy of freezing hole deflection measurement | 13 | ||||

| A2 Fall of personnel and equipment | 3 | a21 | ① Lack of safety awareness of construction personnel | 28 | 88 | ||

| 4 | a22 | ② Lack of construction safety protection materials | 46 | ||||

| 5 | a23 | ③ Irrational design of construction scaffolding | 24 | ||||

| A3 Damage to main tunnel tube sheet | 6 | a31 | ① Drilling holes without avoiding the location of main reinforcement, bolts, etc. | 21 | 30 | ||

| 7 | a32 | ② Drilling ground settlement is too large | 9 | ||||

| A4 Water and sand gushing | 8 | a41 | ① Hole sealing device off, failure | 35 | 58 | ||

| 9 | a42 | ② Pressurized water is penetrated during drilling | 23 |

| Grade | Parent Node | B1 | B2 | … | Bj | … | Bn |

|---|---|---|---|---|---|---|---|

| A1 | F1 | a11 | a12 | … | a1j | … | a1n |

| A2 | F2 | a21 | a13 | … | a2j | … | a2n |

| … | … | … | … | … | … | … | … |

| Ai | Fi | ai1 | ai2 | … | aij | … | ain |

| … | … | … | … | … | … | … | … |

| Am | Fm | am1 | am2 | … | amj | … | amn |

| child node | no | 1—P1 | 1—P2 | … | 1—Pj | … | 1—Pn |

| probability | yes | P1 | P2 | … | Pj | … | Pn |

| Grade | Root Node | 0 | 28 | 29 | 57 | 15 | 43 | 44 | 72 |

|---|---|---|---|---|---|---|---|---|---|

| 15 | b21 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 |

| 29 | b22 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 1 |

| 28 | b23 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 |

| B2 | No (0) | 1.000 | 0.611 | 0.597 | 0.208 | 0.792 | 0.403 | 0.389 | 0.000 |

| Yes (1) | 0.000 | 0.389 | 0.403 | 0.792 | 0.208 | 0.597 | 0.611 | 1.000 |

| Grade | Parent Node | 0 | 43 | 31 | 74 |

|---|---|---|---|---|---|

| 31 | b24 | 0 | 0 | 1 | 1 |

| 43 | b25 | 0 | 1 | 0 | 1 |

| B2 | No (0) | 1.000 | 0.419 | 0.581 | 0.000 |

| Yes (1) | 0.000 | 0.581 | 0.419 | 1.000 |

| Arrange in Order | Risk Factor | Percentage (%) | Arrange in Order | Risk Factor | Percentage |

|---|---|---|---|---|---|

| 1 | C | 3.97 | 7 | C4 | 0.0672 |

| 2 | B | 3.62 | 8 | B2 | 0.207 |

| 3 | D | 0.714 | 9 | D1 | 0.049 |

| 4 | A | 0.953 | 10 | A1 | 0.0144 |

| 5 | C2 | 0.103 | 11 | B1 | 0.0175 |

| 6 | C3 | 0.195 | 12 | B4 | 0.00125 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Lei, L.; Wang, Z.; Huang, S. Safety Risk Identification of the Freezing Method for the Construction of a Subway Contact Channel Based on Bayesian Network. Appl. Sci. 2025, 15, 9959. https://doi.org/10.3390/app15189959

Guo X, Lei L, Wang Z, Huang S. Safety Risk Identification of the Freezing Method for the Construction of a Subway Contact Channel Based on Bayesian Network. Applied Sciences. 2025; 15(18):9959. https://doi.org/10.3390/app15189959

Chicago/Turabian StyleGuo, Xu, Lele Lei, Zhenhua Wang, and Susu Huang. 2025. "Safety Risk Identification of the Freezing Method for the Construction of a Subway Contact Channel Based on Bayesian Network" Applied Sciences 15, no. 18: 9959. https://doi.org/10.3390/app15189959

APA StyleGuo, X., Lei, L., Wang, Z., & Huang, S. (2025). Safety Risk Identification of the Freezing Method for the Construction of a Subway Contact Channel Based on Bayesian Network. Applied Sciences, 15(18), 9959. https://doi.org/10.3390/app15189959