Recycled Plastics in Asphalt Mixtures: A Systematic Review of Mechanical Performance, Environmental Impact and Practical Implementation

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Sources and Search Strategies

2.2. Inclusion and Exclusion Criteria

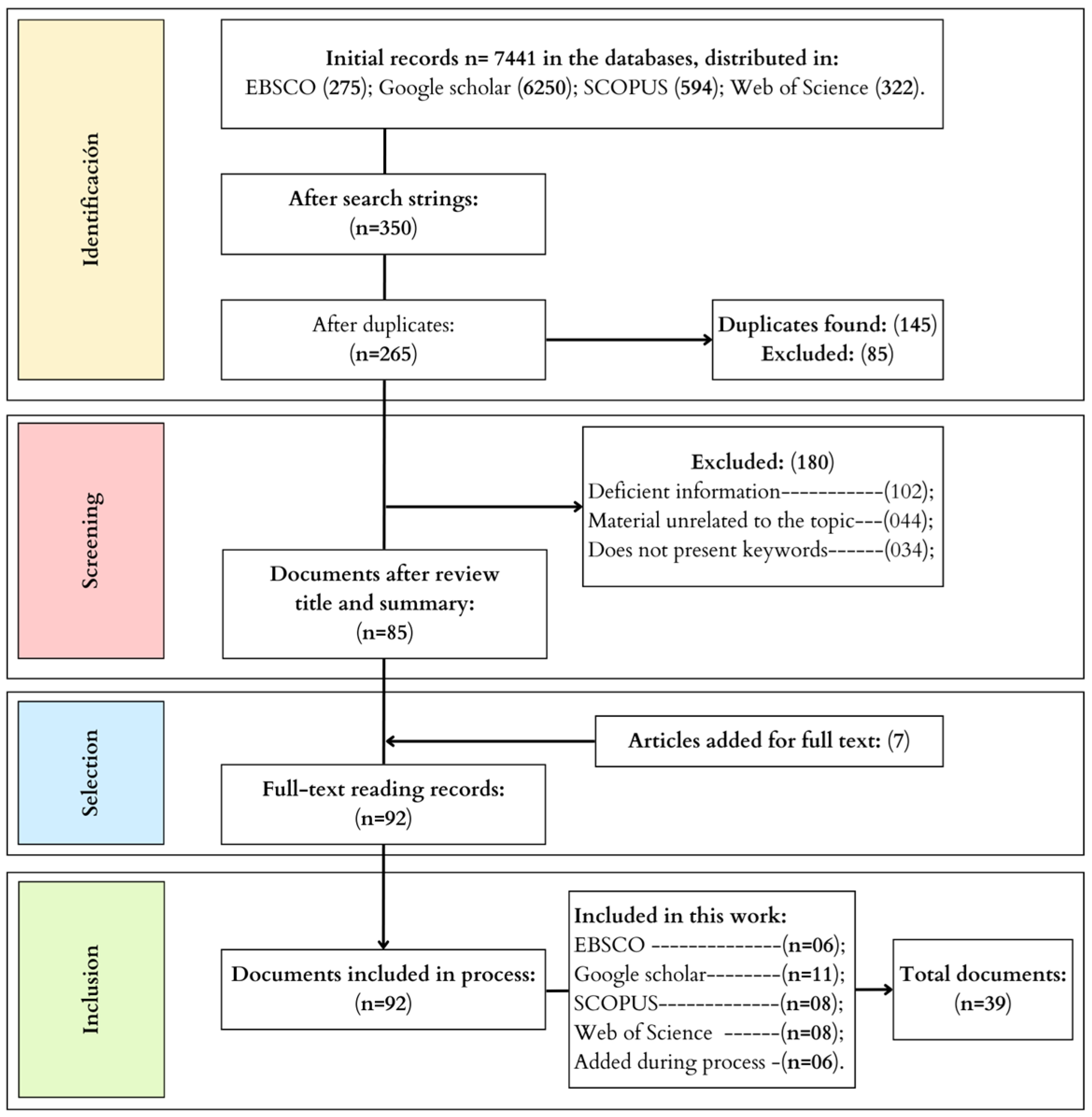

2.3. Article Selection Process

2.4. Risk of Bias Assessment

3. Results

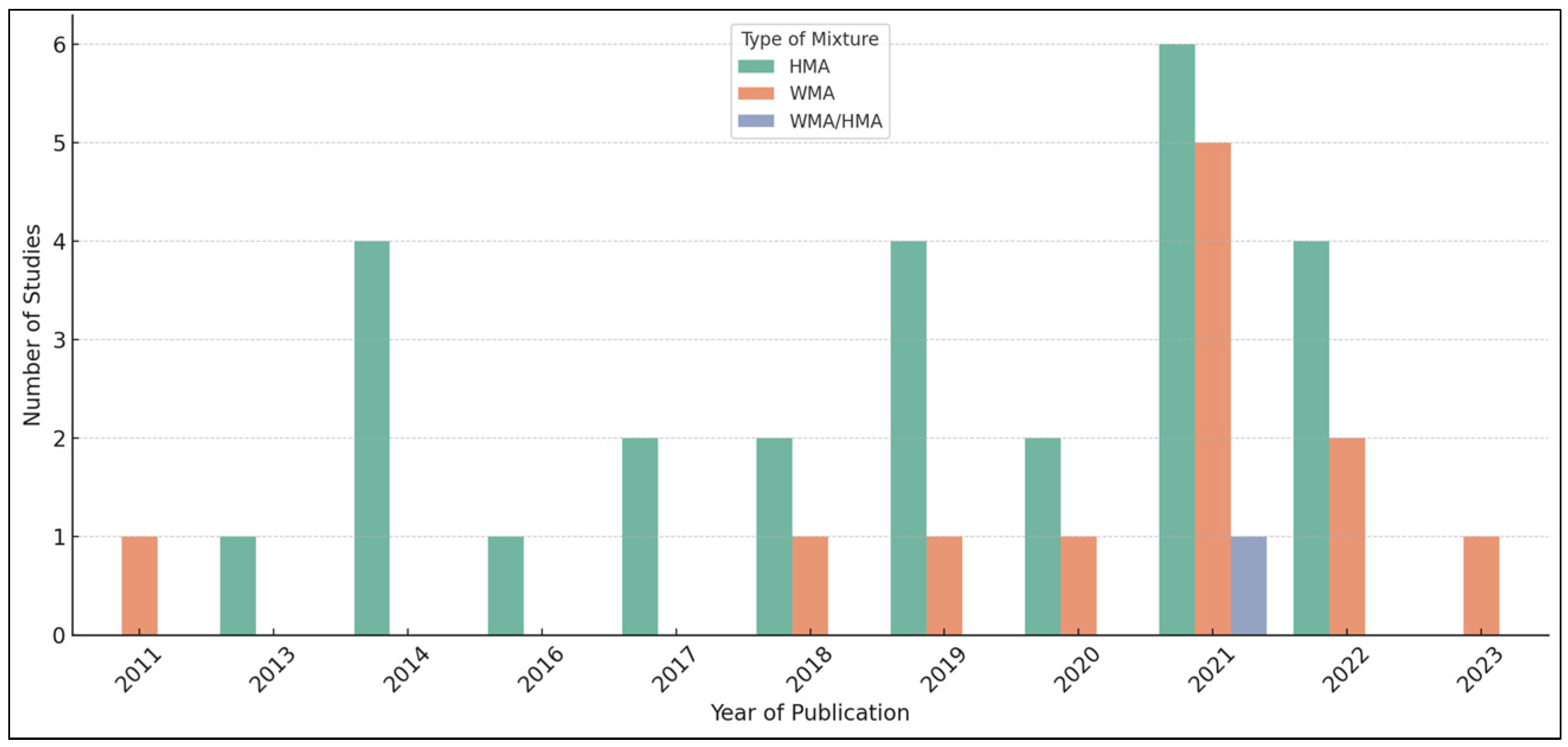

3.1. Characteristics of the Included Studies

3.2. Data Extraction

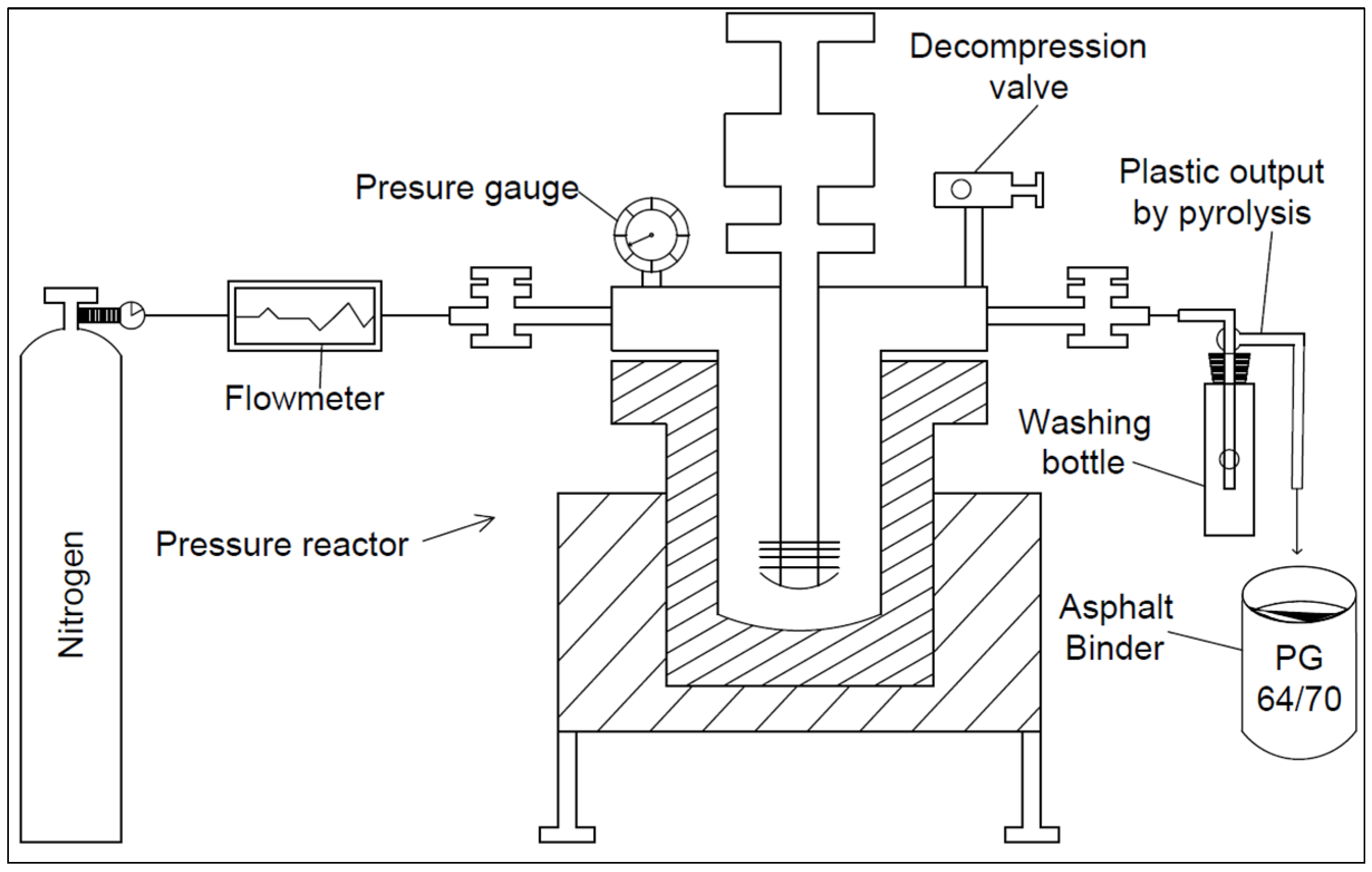

3.3. Ways of Incorporating Plastic into Asphalt Mixtures

3.4. Plastic in Asphalt Mixture Results

3.4.1. Polyethylene Terephthalate (PET)

3.4.2. Low-Density Polyethylene (LDPE)

3.4.3. Polypropylene (PP)

3.4.4. Other Plastics

3.4.5. Studies with More than 1 Type of Plastics

3.5. Structural Properties and Environmental Impact

3.6. Challenges of High Melting Point Plastics in WMA Blends

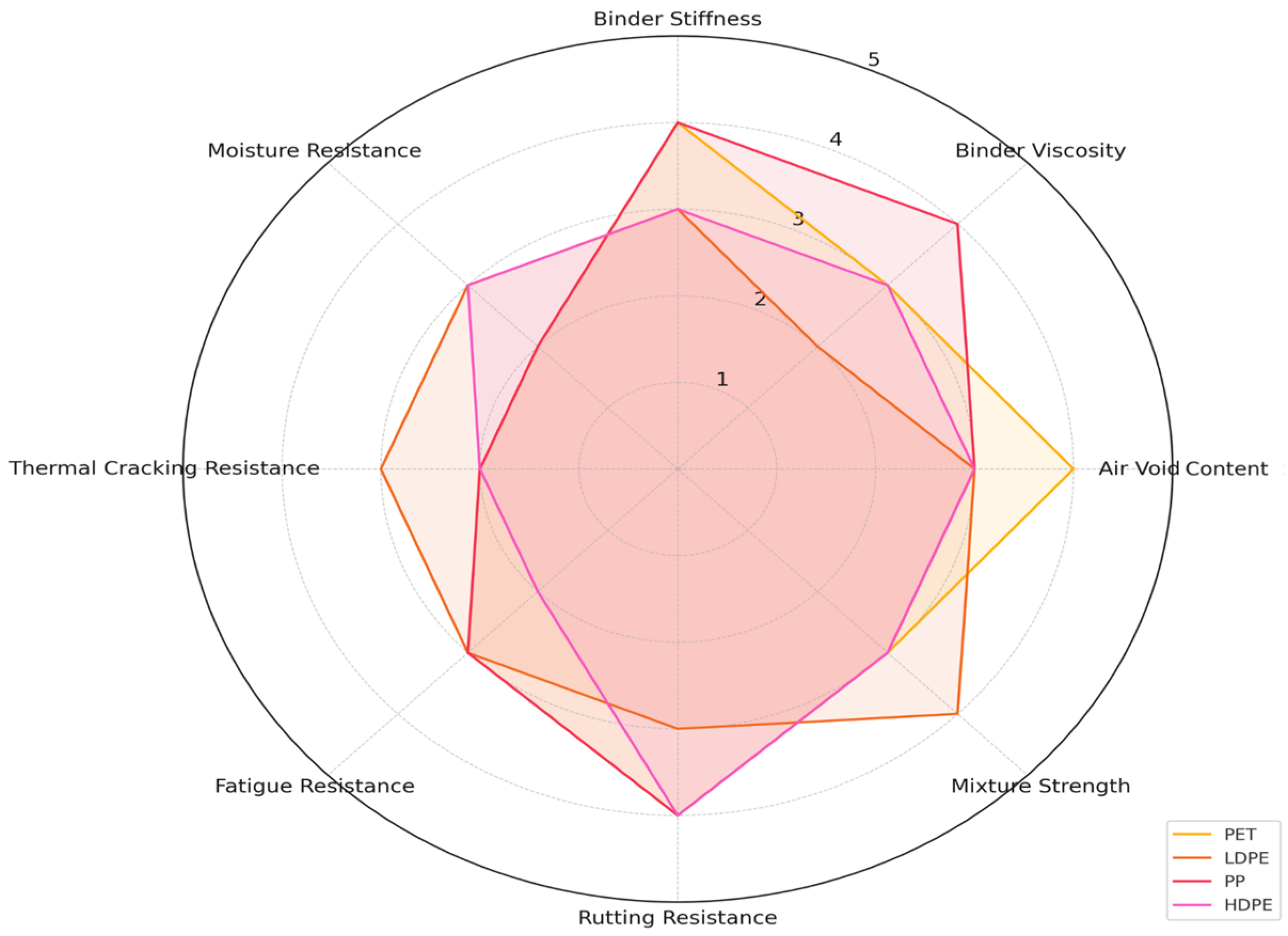

3.7. Summary and Comparison of Results

4. Discussion

5. Conclusions

- PET increases binder stiffness and fatigue life while contributing to the valorization of large volumes of post-consumer beverage containers, thereby reducing environmental contamination.

- LDPE enhances ductility, workability, and moisture resistance, enabling the reuse of common single-use plastics such as bags and packaging materials, which are among the most persistent pollutants in urban and marine environments.

- PP offers improved stiffness and high-temperature performance, allowing the recycling of packaging and industrial plastics, but requires careful control in WMA to avoid dispersion issues.

- HMA ensures maximum mechanical durability for heavy traffic roads, whereas WMA delivers substantial environmental gains, such as reduced energy demand and lower CO2 emissions, making it ideal for projects in environmentally sensitive zones.

- Dry methods provide a scalable pathway for integrating PET and LDPE with minimal adaptation costs, while wet and pyrolysis methods allow for more uniform binder modification and the incorporation of high-melting-point plastics.

- The use of recycled plastics in pavements directly reduces landfill pressure, marine litter, and microplastic release by immobilizing plastics within a durable road matrix.

- This technology supports social benefits by promoting waste-to-resource initiatives, creating local jobs in plastic collection and processing, and enabling municipalities to demonstrate visible sustainability actions.

- The integration of plastics into asphalt aligns with global sustainability goals, linking infrastructure development with climate change mitigation and responsible resource management.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Secretariat of the United Nations Convention to Combat Desertification (UNCCD). The Land in Numbers: Livelihoods at a Tipping Point. Bonn, 2014. Available online: https://www.unccd.int/resources/publications/land-numbers-livelihoods-tipping-point (accessed on 30 November 2023).

- Las Carreteras ya Cruzan el 20% de la Tierra. ABC Ciencia, Madrid, el 15 de Diciembre de 2016. Available online: https://www.abc.es/ciencia/abci-20-ciento-tierra-esta-totalmente-cubierto-carreteras-201612152031_noticia.html (accessed on 30 November 2023).

- Gkyrtis, K.; Kokkalis, A. Toward the Inclusion of Waste Materials at Road Upper Layers: Integrative Exploration of Critical Aspects. Futur. Transp. 2025, 5, 67. [Google Scholar] [CrossRef]

- United Nations Development Programme (UNDP). El ABC de los Plásticos: Una Guía Sobre las negociaciones mundiales sobre plásticos. UNDP, 2023. Available online: https://www.undp.org/es/el-abc-de-los-plasticos (accessed on 2 July 2025).

- d’Ambrières, W. Plastics recycling worldwide: Current overview and desirable changes. Field Actions Sci. Rep. 2019, 19, 12–21. [Google Scholar]

- Leal Filho, W.; Saari, U.; Fedoruk, M.; Iital, A.; Moora, H.; Klöga, M.; Voronova, V. An overview of the problems posed by plastic products and the role of extended producer responsibility in Europe. J. Clean. Prod. 2019, 214, 550–558. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing waste plastics into cleaner asphalt pavement materials: A critical literature review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Biber, N.F.; Foggo, A.; Thompson, R.C. Characterising the deterioration of different plastics in air and seawater. Mar. Pollut. Bull. 2019, 141, 595–602. [Google Scholar] [CrossRef]

- Rojas, T. Todo Sobre el Polietileno de Alta Densidad (HDPE): Usos, Ventajas y Mercado Actual. Tecnología del Plástico, 2023. Available online: https://www.plastico.com/es/noticias/todo-sobre-el-polietileno-de-alta-densidad-hdpe-usos-ventajas-y-mercado-actual (accessed on 30 November 2023).

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a recycled polymer modified binder for use in stone mastic asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Singh, B.; Gupta, M.; Tarannum, H. Mastic of polymer-modified bitumen and poly(vinyl chloride) wastes. J. Appl. Polym. Sci. 2003, 90, 1347–1356. [Google Scholar] [CrossRef]

- Sintac. Propiedades del Polietileno de Baja Densidad (PEBD). SINTAC Recycling, 2022. Available online: https://sintac.es/propiedades-del-polietileno-de-baja-densidad/ (accessed on 30 November 2023).

- Zhang, F.; Hu, C. The research for crumb rubber/waste plastic compound modified asphalt. J. Therm. Anal. Calorim. 2016, 124, 729–741. [Google Scholar] [CrossRef]

- Yan, K.; Xu, H.; You, L. Rheological properties of asphalts modified by waste tire rubber and reclaimed low density polyethylene. Constr. Build. Mater. 2015, 83, 143–149. [Google Scholar] [CrossRef]

- Jmal, H.; Bahlouli, N.; Wagner-Kocher, C.; Leray, D.; Ruch, F.; Munsch, J.N.; Nardin, M. Influence of the grade on the variability of the mechanical properties of polypropylene waste. Waste Manag. 2018, 75, 160–173. [Google Scholar] [CrossRef] [PubMed]

- SyBridge Technologies. Know Your Materials: Polystyrene (PS)—SyBridge Technologies. SyBridge Technologies, 2021. Available online: https://sybridge.com/know-your-materials-polystyrene/ (accessed on 30 November 2023).

- Makri, C.; Hahladakis, J.N.; Gidarakos, E. Use and assessment of ‘e-plastics’ as recycled aggregates in cement mortar. J. Hazard. Mater. 2019, 379, 120776. [Google Scholar] [CrossRef]

- Lopes, D.; Ferreira, M.J.; Russo, R.; Dias, J.M. Natural and synthetic rubber/waste—Ethylene-Vinyl Acetate composites for sustainable application in the footwear industry. J. Clean. Prod. 2015, 92, 230–236. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Evaluation of the properties and microstructure of SBS and EVA polymer modified bitumen. Constr. Build. Mater. 2008, 22, 1897–1905. [Google Scholar] [CrossRef]

- Gad, Y.H.; Magida, M.M.; El-Nahas, H.H. Effect of ionizing irradiation on the thermal blend of waste low density polyethylene/ethylene vinyl acetate/bitumen for some industrial applications. J. Ind. Eng. Chem. 2010, 16, 1019–1024. [Google Scholar] [CrossRef]

- Tarantili, P.A.; Mitsakaki, A.N.; Petoussi, M.A. Processing and properties of engineering plastics recycled from waste electrical and electronic equipment (WEEE). Polym. Degrad. Stab. 2010, 95, 405–410. [Google Scholar] [CrossRef]

- De la Colina Martínez, A.L.; Barrera, G.M.; Díaz, C.E.B.; Córdoba, L.I.Á.; Núñez, F.U.; Hernández, D.J.D. Recycled polycarbonate from electronic waste and its use in concrete: Effect of irradiation. Constr. Build. Mater. 2019, 201, 778–785. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rubio-de-Hita, P. Influence of polycarbonate waste on gypsum composites: Mechanical and environmental study. J. Clean. Prod. 2019, 218, 21–37. [Google Scholar] [CrossRef]

- Jin, X.; Guo, N.; You, Z.; Wang, L.; Wen, Y.; Tan, Y. Rheological properties and micro-characteristics of polyurethane composite modified asphalt. Constr. Build. Mater. 2020, 234, 117395. [Google Scholar] [CrossRef]

- Khoo, H.H. LCA of plastic waste recovery into recycled materials, energy and fuels in Singapore. Resour. Conserv. Recycl. 2019, 145, 67–77. [Google Scholar] [CrossRef]

- Napper, I.E.; Thompson, R.C. Plastic Debris in the Marine Environment: History and Future Challenges. Glob. Chall. 2020, 4, 1900081. [Google Scholar] [CrossRef]

- Walker, T.R.; Xanthos, D. A call for Canada to move toward zero plastic waste by reducing and recycling single-use plastics. Resour. Conserv. Recycl. 2018, 133, 99–100. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Assefa, N. Evaluation of the effect of recycled waste plastic bags on mechanical properties of hot mix asphalt mixtures for road construction. Sustain. Environ. 2021, 7, 1957649. [Google Scholar] [CrossRef]

- Mazouz, M.; Merbouh, M. The Effect of Low-Density Polyethylene Addition and Temperature on Creep-recovery Behavior of Hot Mix Asphalt. Civ. Eng. J. 2019, 5, 597–607. [Google Scholar] [CrossRef]

- Yung Vargas, Y.W.; Cordoba Maquilón, J.E.; Rondón Quintana, H.A. Evaluación del desgaste por abrasión de una mezcla drenante modificada con residuo de llanta triturada (GCR). Tecnura 2016, 20, 106–118. [Google Scholar]

- C. y T. (SICT); D. G. de S. T. (CMT) Secretaría de Infraestructura. Características de los Materiales N·CMT·4·05·001/05. 4. Materiales Para Pavimentos. Ciudad de México, 2005. Available online: https://normas.imt.mx/storage/normativa/N-CMT-4-05-001-05.pdf (accessed on 2 July 2025).

- You, L.; Long, Z.; You, Z.; Ge, D.; Yang, X.; Xu, F.; Hashemi, M.; Diab, A. Review of recycling waste plastics in asphalt paving materials. J. Traffic Transp. Eng. 2022, 9, 742–764. [Google Scholar] [CrossRef]

- Harmon, J.; D’Angelo, J.; Bukowski, J. Superpave Asphalt Mixture Design Workshop Workbook. McLean, VA (FHWA Headquarters), 1999. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/asphalt/mixdsgn.pdf (accessed on 2 July 2025).

- Ma, J.; Hesp, S.A.M. Effect of recycled polyethylene terephthalate (PET) fiber on the fracture resistance of asphalt mixtures. Constr. Build. Mater. 2022, 342, 127944. [Google Scholar] [CrossRef]

- López, C.; Thenoux, G.; Sandoval, G.; Armijos, V.; Ramírez, A.; Guisado, F.; Moreno, E. Estudio de mezclas asfálticas templadas con emulsión super-estabilizada. Rev. Ing. Construcción 2017, 32, 57–64. [Google Scholar] [CrossRef]

- Raza, S.A.; Shah, N.; Sharif, A. Time frequency relationship between energy consumption, economic growth and environmental degradation in the United States: Evidence from transportation sector. Energy 2019, 173, 706–720. [Google Scholar] [CrossRef]

- Franesqui, M.A.; Yepes, J.; Valencia-Díaz, S. Sustainable Pavement Construction in Sensitive Environments: Low-Energy Asphalt with Local Waste Materials and Geomaterials. Buildings 2024, 14, 530. [Google Scholar] [CrossRef]

- Shamseer, L.; Moher, D.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015: Elaboration and explanation. BMJ 2015, 349, g7647. [Google Scholar] [CrossRef]

- Ouzzani, M.; Hammady, H.; Fedorowicz, Z.; Elmagarmid, A. Rayyan—A web and mobile app for systematic reviews. Syst. Rev. 2016, 5, 210. [Google Scholar] [CrossRef]

- Moussa, G.; Sallam, I.; Younis, H. Performance Investigation of Hot- and Warm- Asphalt Mixtures Modified with Superplast. JES. J. Eng. Sci. 2021, 49, 679–703. [Google Scholar] [CrossRef]

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffness and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Awad, A. Utilization of Waste Plastics to Enhance the Performance of Modified Hot Mix Asphalt. Int. J. GEOMATE 2017, 13, 132–139. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I.; Jamal; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- Hong, Z.; Yan, K.; Wang, M.; You, L.; Ge, D. Low-density polyethylene/ethylene–vinyl acetate compound modified asphalt: Optimal preparation process and high-temperature rheological properties. Constr. Build. Mater. 2022, 314, 125688. [Google Scholar] [CrossRef]

- Ling, T.; Lu, Y.; Zhang, Z.; Li, C.; Oeser, M. Value-Added Application of Waste Rubber and Waste Plastic in Asphalt Binder as a Multifunctional Additive. Materials 2019, 12, 1280. [Google Scholar] [CrossRef]

- Singh, P.; Swamy, A.K. Effect of aging level on viscoelastic properties of asphalt binder containing waste polyethylene. Int. J. Sustain. Eng. 2019, 12, 141–148. [Google Scholar] [CrossRef]

- Marquez, K.P.; Arizala, C.V.; Soriano, V.J.; Barron, J.M.; Florece, A.E.; Caday, J.H.; Calibo, J.A.; Aguila, M.J.; Razal, R.A.; Migo, V.P. Recycled Polyethylene Terephthalate as Reinforcement Additive of Asphalt Mixture for Pavement Application. Philipp. J. Sci. 2021, 150, 1061–1068. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R. Evaluation of permanent deformation characteristics of unmodified and Polyethylene Terephthalate modified asphalt mixtures using dynamic creep test. Mater. Des. 2014, 53, 317–324. [Google Scholar] [CrossRef]

- Bekhedda, A.; Merbouh, M. Recycling of plastic waste polyethylene terephthalate (PET) as a modifier in asphalt mixture: Study of Creep-Recovery at Low, Medium, and Hot Temperatures. Frat. Integrità Strutt. 2022, 16, 438–450. [Google Scholar] [CrossRef]

- Movilla-Quesada, D.; Raposeiras, A.C.; Olavarría, J. Effects of Recycled Polyethylene Terephthalate (PET) on Stiffness of Hot Asphalt Mixtures. Adv. Civ. Eng. 2019, 2019, 6969826. [Google Scholar] [CrossRef]

- Ghabchi, R.; Dharmarathna, C.P.; Mihandoust, M. Feasibility of using micronized recycled Polyethylene Terephthalate (PET) as an asphalt binder additive: A laboratory study. Constr. Build. Mater. 2021, 292, 100085. [Google Scholar] [CrossRef]

- Singh, G.D.; Sharma, V.K.; Sangma, B.; Kumar, R.; Senthil, K.; Singh, A.P. Experimental study on bituminous concrete pavement using low density polyethylene and sasobit. Mater. Today Proc. 2022, 52, 2109–2114. [Google Scholar] [CrossRef]

- Radeef, H.R.; Abdul Hassan, N.; Abidin, A.R.; Mahmud, M.Z.; Yusoffa, N.I.; Idham Mohd Satar, M.K.; Warid, M.N. Enhanced Dry Process Method for Modified Asphalt Containing Plastic Waste. Front. Mater. 2021, 8, 700231. [Google Scholar] [CrossRef]

- Li, C.; Wang, H.; Fu, C.; Shi, S.; Li, G.; Liu, Q.; Zhou, D.; Jiang, L.; Cheng, Y. Evaluation of modified bitumen properties using waste plastic pyrolysis wax as warm mix additives. J. Clean. Prod. 2023, 405, 136910. [Google Scholar] [CrossRef]

- Jafar, J.J. Utilisation of waste plastic in bituminous mix for improved performance of roads. KSCE J. Civ. Eng. 2016, 20, 243–249. [Google Scholar] [CrossRef]

- Hall, F.; White, G. The Effect of Waste Plastics on the Ageing Phenomenon of Bituminous Binders and Asphalt Mixtures. Materials 2021, 14, 6176. [Google Scholar] [CrossRef] [PubMed]

- Cardone, F.; Spadoni, S.; Ferrotti, G.; Canestrari, F. Asphalt mixture modification with a plastomeric compound containing recycled plastic: Laboratory and field investigation. Mater. Struct. 2022, 55, 109. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I. A step toward smart city and green transportation: Eco-friendly waste PET management to enhance adhesion properties of asphalt mixture. Constr. Build. Mater. 2021, 304, 124702. [Google Scholar] [CrossRef]

- Abduljabbar, N.; Al-Busaltan, S.; Dulaimi, A.; Al-Yasari, R.; Sadique, M.; Al Nageim, H. The effect of waste low-density polyethylene on the mechanical properties of thin asphalt overlay. Constr. Build. Mater. 2022, 315, 125722. [Google Scholar] [CrossRef]

- Zhou, G.; Li, C.; Wang, H.; Zeng, W.; Ling, T.; Jiang, L.; Li, R.; Liu, Q.; Cheng, Y.; Zhou, D. Preparation of Wax-Based Warm Mixture Additives from Waste Polypropylene (PP) Plastic and Their Effects on the Properties of Modified Asphalt. Materials 2022, 15, 4346. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Li, Y.; Zhang, W.; Zhang, D.; Liu, S.; Shi, S.; Li, C. Study on Performance of Wax Warm Mix Asphalt Cracked by Mixed Polyethylene Waste Plastics. Sci. Soc. Res. 2021, 3, 170–174. [Google Scholar] [CrossRef]

- MGürü; Çubuk, M.K.; Arslan, D.; Farzanian, S.A.; Bilici, İ. An approach to the usage of polyethylene terephthalate (PET) waste as roadway pavement material. J. Hazard. Mater. 2014, 279, 302–310. [Google Scholar] [CrossRef]

- Shang, L.; Wang, S. Pyrolysed Wax from Recycled Crosslinked Polyethylene as a Warm-Mix Asphalt (WMA) Additive for Crumb-Rubber-Modified Asphalt. Prog. Rubber Plast. Recycl. Technol. 2011, 27, 133–144. [Google Scholar] [CrossRef]

- Mosa, A.; Jawad, I.T.; Salem, L.A. Modification of the Properties of Warm Mix Asphalt Using Recycled Plastic Bottles. Int. J. Eng. 2018, 31, 1514–1520. Available online: https://www.ije.ir/article_73287.html (accessed on 2 July 2025). [CrossRef]

- Jassim, H.M.; Mahmood, O.T.; Ahmed, S.A. Optimum Use of Plastic Waste to Enhance the Marshall Properties and Moisture Resistance of Hot Mix Asphalt. Int. J. Eng. Trends Technol. 2014, 7, 18–25. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Pirbasti, M.H.; Pirbasti, Z.R. Investigating the Effect of Using Waste Ultra-high-molecular-weight Polyethylene on the Fatigue Life of Asphalt Mixture. Period. Polytech. Civ. Eng. 2020, 64, 1170–1180. [Google Scholar] [CrossRef]

- Almeida, A.; Capitão, S.; Estanqueiro, C.; Picado-Santosc, L. Possibility of incorporating waste plastic film flakes into warm-mix asphalt as a bitumen extender. Constr. Build. Mater. 2021, 291, 123384. [Google Scholar] [CrossRef]

- Costa, L.; Peralta, J.; Oliveira, J.; Silva, H. A New Life for Cross-Linked Plastic Waste as Aggregates and Binder Modifier for Asphalt Mixtures. Appl. Sci. 2017, 7, 603. [Google Scholar] [CrossRef]

- Abdo, A.M.A.; Jung, S.J. Investigation of reinforcing flexible pavements with waste plastic fibers in Ras Al Khaimah, UAE. Road Mater. Pavement Des. 2020, 21, 1753–1762. [Google Scholar] [CrossRef]

- White, G.; Reid, G. Recycled Waste Plastic for Extending and Modifying Asphalt Binders. In Proceedings of the 8th Symposium on Pavement Surface Characteristics (SURF 2018), Brisbane, Australia, 2–4 May 2018; p. 12. Available online: https://www.researchgate.net/publication/324908837 (accessed on 2 July 2025).

- Suaryana, N.; Nirwan, E.; Ronny, Y. Plastic Bag Waste on Hotmixture Asphalt as Modifier. Key Eng. Mater. 2018, 789, 20–25. [Google Scholar] [CrossRef]

- Demirbas, A.; Arin, G. An Overview of Biomass Pyrolysis. Energy Sources 2002, 24, 471–482. [Google Scholar] [CrossRef]

- Akinleye, M.T.; Jimoh, Y.A.; Salami, L.O. Marshall Properties Evaluation of Hot and Warm Asphalt Mixes Incorporating Dissolved Plastic Bottle Modified Bitumen. J. Mater. Eng. Struct. 2020, 7, 439–450. Available online: https://revue.ummto.dz/index.php/JMES/article/view/2399 (accessed on 2 July 2025).

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Obaid, H.A. Characteristics of warm mixed asphalt modified by waste polymer and nano-silica. Int. J. Pavement Res. Technol. 2021, 14, 397–401. [Google Scholar] [CrossRef]

- Ullah, S.; Raheel, M.; Khan, R.; Khan, M.T. Characterization of physical & mechanical properties of asphalt concrete containing low- & high-density polyethylene waste as aggregates. Constr. Build. Mater. 2021, 301, 124127. [Google Scholar] [CrossRef]

- Nejad, F.M.; Arabani, M.; Hamedi, G.H.; Azarhoosh, A.R. Influence of using polymeric aggregate treatment on moisture damage in hot mix asphalt. Constr. Build. Mater. 2013, 47, 1523–1527. [Google Scholar] [CrossRef]

- Ohm, B.S.; Kim, K.; Kim, Y.M.; Le, T.H. Assessing the Viability of Waste Plastic Aggregate in Stone-Modified Asphalt Concrete Mix for Bus Rapid Transit Pavement Maintenance. Buildings 2023, 13, 3069. [Google Scholar] [CrossRef]

- RKovács; Czímerová, A.; Fonód, A.; Mandula, J. The Use of Waste Low-Density Polyethylene for the Modification of Asphalt Mixture. Buildings 2024, 14, 3109. [Google Scholar] [CrossRef]

| Plastic | Symbol | Major Products | Major Physical Property and Biodegradability |

|---|---|---|---|

| Polyethylene terephthalate (PET) |  | Beverage bottles, food bottles/jars (salad dressing, peanut butter, honey, etc.), and clothing or polyester rope. |

|

| High-density polyethylene (HDPE) |  | Milk cartons, detergent bottles, cereal box liners, toys, buckets, park benches and rigid tubes. | |

| Polyvinyl Chloride (PVC) |  | Plumbing pipes, credit cards, human and pet toys, rain gutters, teethers, IV fluid bags, medical tubing, and oxygen masks. |

|

| Low-density polyethylene (LDPE) |  | Plastic/Cling Wrap, Sandwich and Bread Bags, Bubble Wrap, Garbage Bags, Grocery Bags, and Drink Cups. | |

| Polypropylene (PP) |  | Straws, bottle caps, prescription bottles, hot food containers, packing tape and DVD/CD cases |

|

| Polystyrene (PS) |  | Cups, takeaway containers, product and shipping packaging, egg cartons, cutlery and building insulation. | |

| Other |  | Acrylonitrile Butadiene Styrene (ABS) Used for electronic devices, Legos, personal protective equipment and helmets [17]. |

|

| Ethylene Vinyl Acetate (EVA) Footwear industry, including soles and insoles [18]. |

| ||

| Polycarbonate (PC) CD and DVD. |

| ||

| Polyurethane (PU) This is used in the food cold chain, in upholstered furniture and mattresses, shoes, automobiles, medical devices, as well as for thermal insulation of buildings and technical equipment. |

| PG | Maximum Performance Grade Temperature | ||||||

| 46 °C | 52 °C | 58 °C | 64 °C | 70 °C | 76 °C | 76 °C + n6 °C | |

| Minimum Performance Grade Temperature | |||||||

| +2 °C | −4 °C | −10 °C | −16 °C | −22 °C | −28 °C | −28 °C − n6 °C | |

| PEN | Penetration Ranges | ||||||

| 40–50 | 60–70 | 80–100 | 120–150 | ||||

| Study Group (IEEE Reference) | Clear Design | Control of Variables | Risk of Bias |

|---|---|---|---|

| [30,31,36,42,43] | Yes | Partial | Moderate |

| [44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59] | Yes | Yes | Low |

| [60,61,62,63,64,65,66,67,68,69,70] | Partial | Partial/No | Moderate |

| [67,71,72,73] | No | No | High |

| [74,75] | Yes | Yes | Low |

| Aspect | Dry Method | Wet Method |

|---|---|---|

| Procedure | Shredded or granulated plastic is mixed with aggregates before adding the binder. | Molten plastic is blended with the binder before mixing with aggregates. |

| Type of plastics | Plastics with high melting points (HDPE, PET). | Plastics with low melting points (LDPE, PP). |

| Advantages | Simple, low cost, maintains plastic integrity. | Improves rheological properties and binder durability. |

| Limitations | Risk of non-uniform distribution, weaker interaction with binder. | Requires higher temperature control and specialized equipment. |

| Mixture Type and Binder | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|

| WMA, PEN 70 | 1, 3, 5, 7%, Through a pyrolysis sintering process for PET. |

| China, [65]. |

| WMA, PEN 60/70 | 3, 6, 9, 12%, Through particles with measurements of 3.5 mm and 1.75 mm. |

| Pakistan, [60]. |

| HMA, PEN 60/70 | 2, 4, 6, 8, 10%, With size of 0.425, 1.18 mm. |

| Iran, [43]. |

| HMA, PEN 40/50 | 3, 5, 7%, With size of 2.5–1.25 mm and 0.315–0.160 mm. |

| Algeria, [51]. |

| HMA, PEN 45 | 1, 2, 3, 5, 10%, Crushed into flakes under a 10 mm sieve |

| Turkey, [64]. |

| Mixture Type and Binder | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|

| WMA | 0.1, 0.3, 0.5, 0.7, 0.9, 1.1% of the weight of aggregate, 2.36 mm size PET. |

| Iraq, [66]. |

| HMA, VG-30 | 0, 2, 4, 6%, With size grinding of 0.5 × 0.5 cm. |

| India, [48]. |

| HMA, PG 64-28 | 10%, With size of 18 and 6.5 mm. |

| Canada, [36]. |

| HMA, AC-24 | 6, 10, 18, 22%, With size of 10, 5, 2.36 mm. |

| Chile, [52]. |

| HMA, PEN 80/100 | Plastic particles of 0, 0.2, 0.4, 0.6, 0.8, 1% to 2.36 mm were crushed and used. |

| Malaysia, [50]. |

| HMA, PG 58-28 | PET from 2 water bottles (0–20%) was cut, dried at 45 °C for 2 h, conditioned at 18 °C for 4 h, and then crushed. |

| USA, [53]. |

| HMA, PEN 60/70 | 0, 10, 15, 20, 25, 30%, With size of 2.36 mm (Crushed and cut). |

| Philippines, [49]. |

| HMA, PG 64-22, AC 60-70 | 0.5, 1%, (Shredded and cut into fibers). |

| United Arab Emirates (UAE), [71]. |

| HMA, PEN 40/60 | 6%. |

| United Kingdom, [72]. |

| HMA, PEN 40/50 | 5–25% plastic with thicknesses of 0.2–1 mm, passing 19.0 mm to No. 50 (0.3 mm) sieves. |

| Iraq, [67]. |

| Mixture Type and Binder | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|

| WMA, VG-10 | 4.2, 4.7, 5.2, 5.7%. |

| India, [54]. |

| WMA, PEN 40/50 | 2, 4, 6%, HDPE is used in powder form. |

| Iraq, [61]. |

| HMA, PEN 60/70 | 7, 13,17%, With size of 2.36 and 4.75 mm. |

| Ethiopia, [30]. |

| HMA, PEN 60/70 | 0.5, 1%, With size of 5–10 mm. |

| Malaysia, [55]. |

| Mixture Type and Binder | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|

| HMA, PEN 60/80 | 0, 2, 4, 6%. |

| China, [46]. |

| HMA, PEN 60 | 0, 5, 10%. With size grinding of 9.5 mm and 0.6 mm. |

| Indonesia, [73]. |

| HMA, PEN 40/50 | 5%. Shredded plastic bags of 1 and 3 mm2. |

| Algeria, [31]. |

| Mixture Type and Binder | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|

| WMA, PEN 70 | 6%. Through a pyrolysis sintering process for PP. |

| China, [62]. |

| WMA, PEN 40/50 | 3%. |

| Iraq, [77]. |

| HMA, PEN 60/70 | 2, 2.5, 3, 3.5, 4, 4.5%. |

| Jordania, [44]. |

| HMA, PEN 70 | 5%. Through a pyrolysis sintering process for PP. |

| China, [47]. |

| Plastic Explanation | Mixture Type and Binder | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|---|

| Superplast | WMA, PEN 60/70 | 3, 4, 5%. |

| Egypt, [42]. |

| WPP, PW | WMA, PEN 60/80 | 6%, via pyrolysis sintering of landfill-sourced WPP, crushed to 0.177–0.25 mm red granules. |

| China, [56]. |

| Plastic and rubber mix | HMA, PEN 125 | 8%. With size of 1–4 mm. |

| United Kingdom, [57]. |

| Commercial plastic waste MR6 and MR10 | HMA, PEN 100/150 | 6%. |

| Australia, [58]. |

| UHMWPE | HMA, PG 64/16 | 2%. It comes in the form of very fine solid particles between 150 and 120 μm. |

| Iran, [68]. |

| Plastic Explanation | Mixture Type and Binder | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|---|

| Waste plastic film flakes | WMA/HMA, PEN 35/50 | 6%, plastic film flakes |

| Portugal, [69]. |

| PEX mostly made of HDPE. | HMA, PEN 50/70 | 5% PEX, with laminar flakes (Øₑq: 0.5–10 mm) and crushed plastic (Øₑq: 0.5–4.0 mm). |

| Portugal, [70]. |

| Plastic | Mixture Type and Binder | Method | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|---|---|

| HDPE/LDPE | WMA, PEN 50/70 | Wet/Dry | 3, 6, 9 and 12% in Wet process using HDPE/LDPE, 9% in dry process using HDPE/LDPE |

| Australia, [45]. |

| Plastic | Mixture Type and Binder | Method | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|---|---|

| HDPE/LDPE | WMA, Asphalt Hard (AH), AH-70 = PEN 60/70 | Wet | Through a pyrolysis sintering process for HDPE and LDPE. |

| China, [63]. |

| PET/HDPE | WMA, VG 30 = PEN 60/70 | Wet | 1, 3, 5, 7, 9, 11, 13, 15, 17%, Through a pyrolysis sintering process for PET/HDPE. |

| Nigeria, [75]. |

| Plastic | Mixture Type and Binder | Method | Dosage and Size | Main Results | Country, Reference |

|---|---|---|---|---|---|

| HDPE/LDPE | HMA, PEN 60/70 | Dry | 5, 15, 25%. |

| Pakistan, [78] |

| HDPE/LDPE | HMA, PEN 60/70 | Dry | 0.43, 0.48%. With melted plastic and incorporated into the aggregate at temperatures of 180 to 190 degrees. |

| Iraq, [79]. |

| PP/PE | HMA, PEN 50/70 | Dry | 3.8% SBS (bitumen), 5.2% (binder), Ø 5 mm. |

| Italy, [59]. |

| Plastic Type | Parameters of Interest (As Compared to Conventional Asphalt Binder/Mixtures) | |||||||

|---|---|---|---|---|---|---|---|---|

| Binders’ Stiffness | Binders’ Viscosity | Mixtures’ Air Voids Content | Mixtures’ Strength | Mixtures’ Rutting Resistance | Mixtures’ Fatigue Resistance | Thermal Cracking Resistance | Mixtures’ Moisture Resistance | |

| PET | N/A | |||||||

| LDPE | ||||||||

| PP | N/A | |||||||

| Other Plastics | N/A | |||||||

| Plastic Type | Incorporation Method | Asphalt Type (HMA/WMA) | Improved Properties | Limitations | References |

|---|---|---|---|---|---|

| PET | Dry | HMA | Stiffness, fatigue resistance, rutting resistance | May reduce moisture resistance; limited performance in WMA | [44,45,50] |

| LDPE | Wet | WMA | Workability, moisture resistance, ductility | Requires optimized mixing; poor high-temp performance | [44,48,63] |

| PP | Wet/Pyrolysis | HMA/WMA | Stiffness, temperature stability | Incomplete melting in WMA; reduced flexibility | [44,61,63] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calderón-Ramírez, J.; Sepúlveda-Valdez, D.; García, L.; Lomeli-Banda, M.A.; Salazar-Briones, C.; Montoya-Alcaraz, M. Recycled Plastics in Asphalt Mixtures: A Systematic Review of Mechanical Performance, Environmental Impact and Practical Implementation. Appl. Sci. 2025, 15, 9901. https://doi.org/10.3390/app15189901

Calderón-Ramírez J, Sepúlveda-Valdez D, García L, Lomeli-Banda MA, Salazar-Briones C, Montoya-Alcaraz M. Recycled Plastics in Asphalt Mixtures: A Systematic Review of Mechanical Performance, Environmental Impact and Practical Implementation. Applied Sciences. 2025; 15(18):9901. https://doi.org/10.3390/app15189901

Chicago/Turabian StyleCalderón-Ramírez, Julio, David Sepúlveda-Valdez, Leonel García, Marcelo A. Lomeli-Banda, Carlos Salazar-Briones, and Marco Montoya-Alcaraz. 2025. "Recycled Plastics in Asphalt Mixtures: A Systematic Review of Mechanical Performance, Environmental Impact and Practical Implementation" Applied Sciences 15, no. 18: 9901. https://doi.org/10.3390/app15189901

APA StyleCalderón-Ramírez, J., Sepúlveda-Valdez, D., García, L., Lomeli-Banda, M. A., Salazar-Briones, C., & Montoya-Alcaraz, M. (2025). Recycled Plastics in Asphalt Mixtures: A Systematic Review of Mechanical Performance, Environmental Impact and Practical Implementation. Applied Sciences, 15(18), 9901. https://doi.org/10.3390/app15189901