Energy Consumption Analysis and Thermal Equilibrium Research of High-Voltage Lithium Battery Electric Forklifts

Abstract

Featured Application

Abstract

1. Introduction

2. Advantages and Parameter Selection Design of High-Voltage Lithium Battery Pack

- (1)

- Vehicle Wiring Harness: High current increases wire diameter requirements, complicating connector manufacturing and harness routing and raising overall costs. Moreover, the high current slew rate results in greater resistive heating and elevated temperature rise in conductors.

- (2)

- Motor Controllers: Under the same contact resistance, higher current leads to more severe heating in connectors and internal copper busbars. Since internal power modules are temperature-sensitive components, this increases cooling requirements for the motor controller. In low-voltage, high-current motor controllers, parallel connection of power modules is necessary to meet inverter power demands, but parameter variations affect their reliability.

- (3)

- Motors: A relatively low voltage level reduces their instantaneous power and overload capability, while a high current slew rate under large current conditions makes them more prone to electrical erosion, leading to increased bearing damage.

- (4)

- Battery Charging: Low voltage makes it difficult to achieve fast charging for battery packs. Since public charging stations typically support higher voltages, low-voltage lithium battery forklifts require additional dedicated chargers, increasing the overall purchase cost.

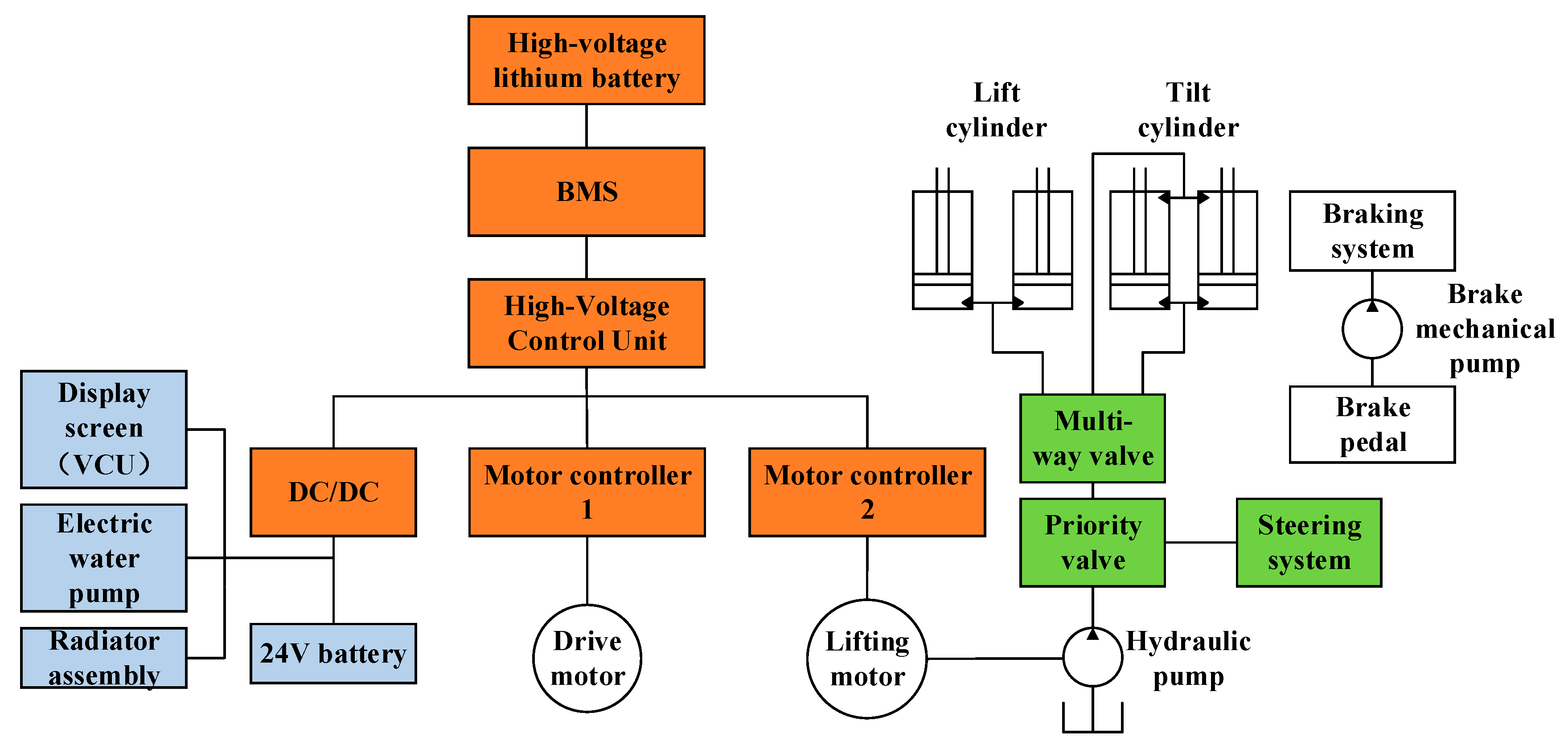

3. Basic Structure of High-Voltage Lithium Battery Forklift Powertrain

3.1. Basic Composition Structure of the Powertrain

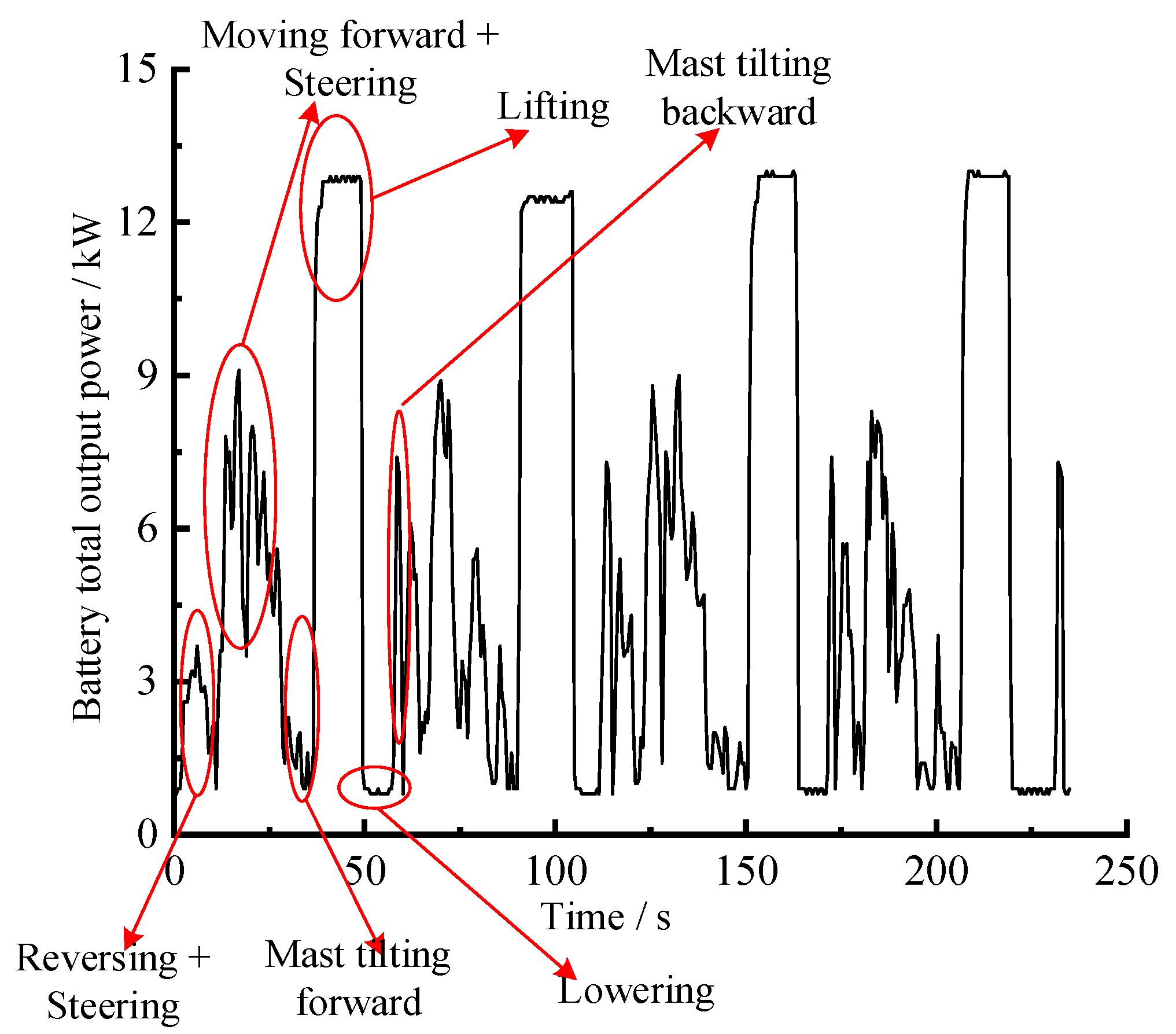

3.2. Forklift Operation Analysis

4. Test Research and Analysis

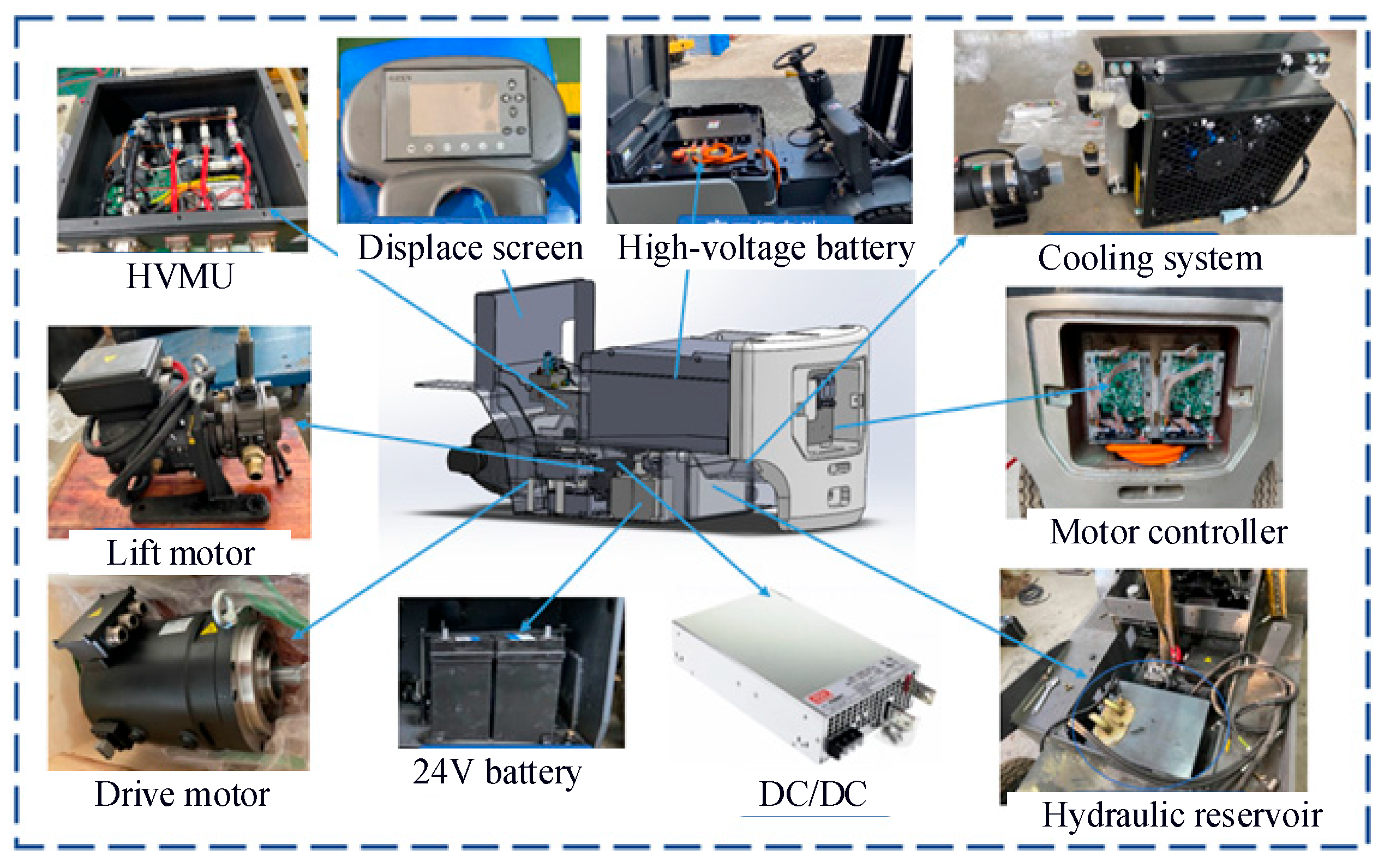

4.1. Prototype Hardware Configuration

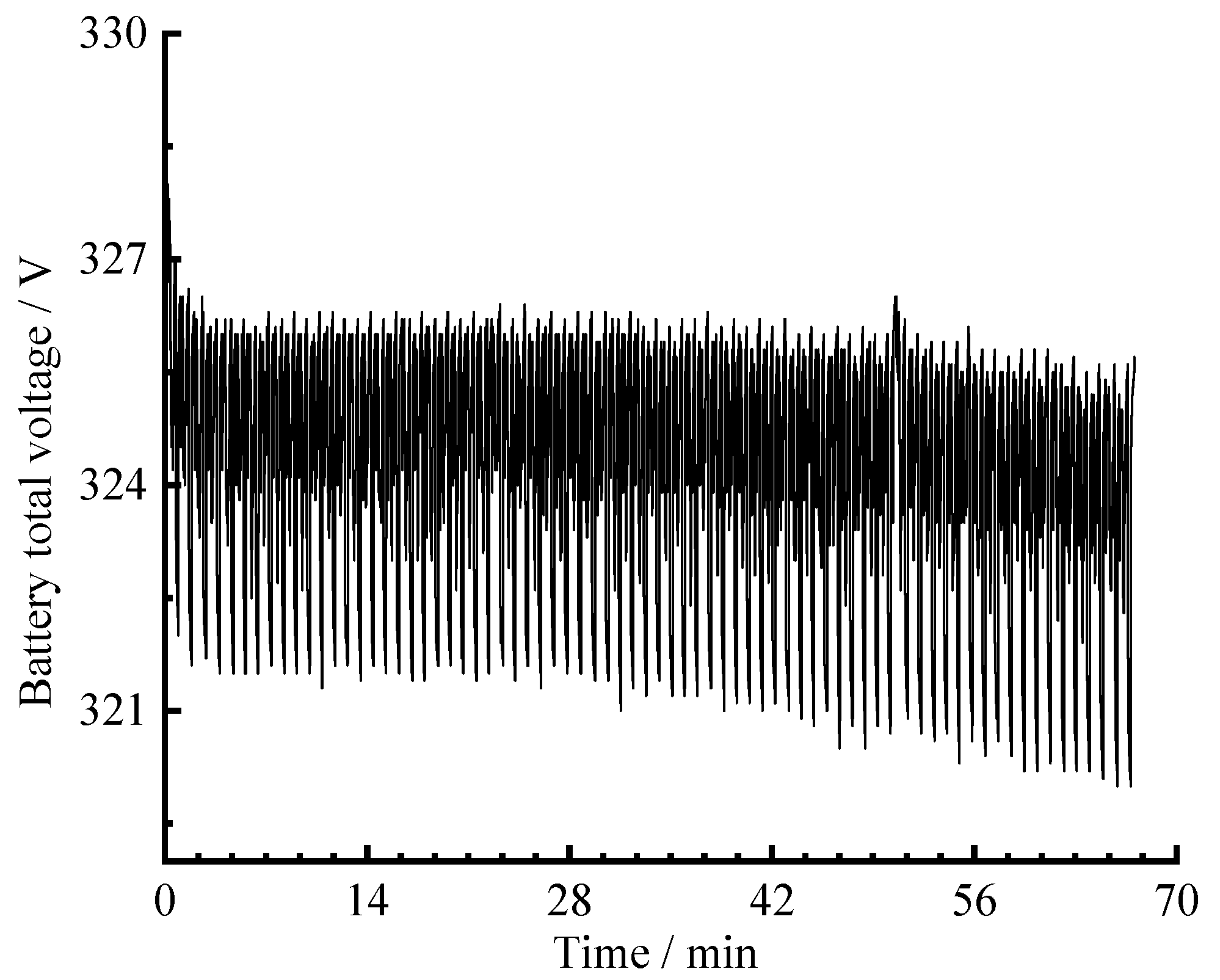

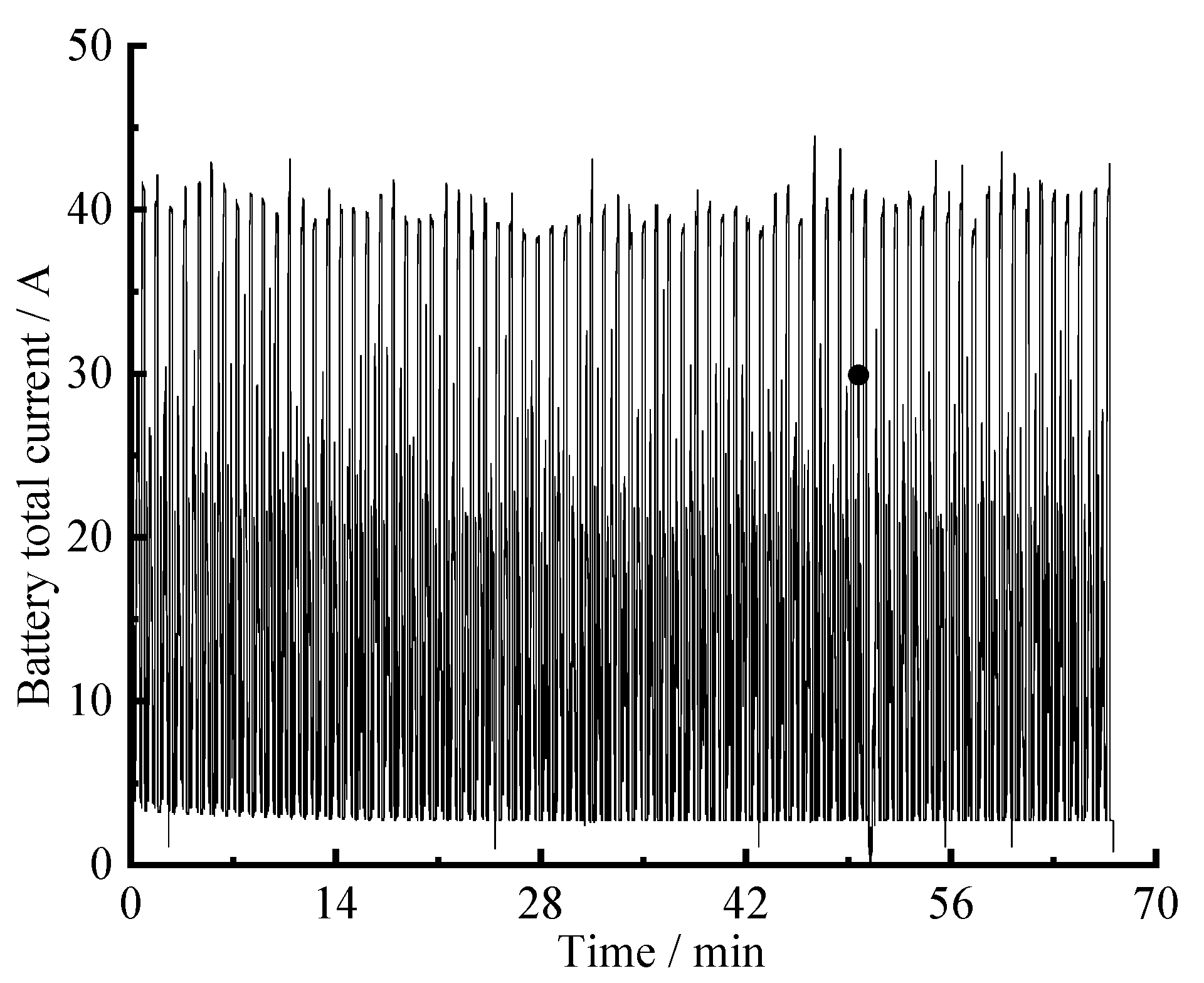

4.2. Analysis of Average Energy Consumption Measurement Results

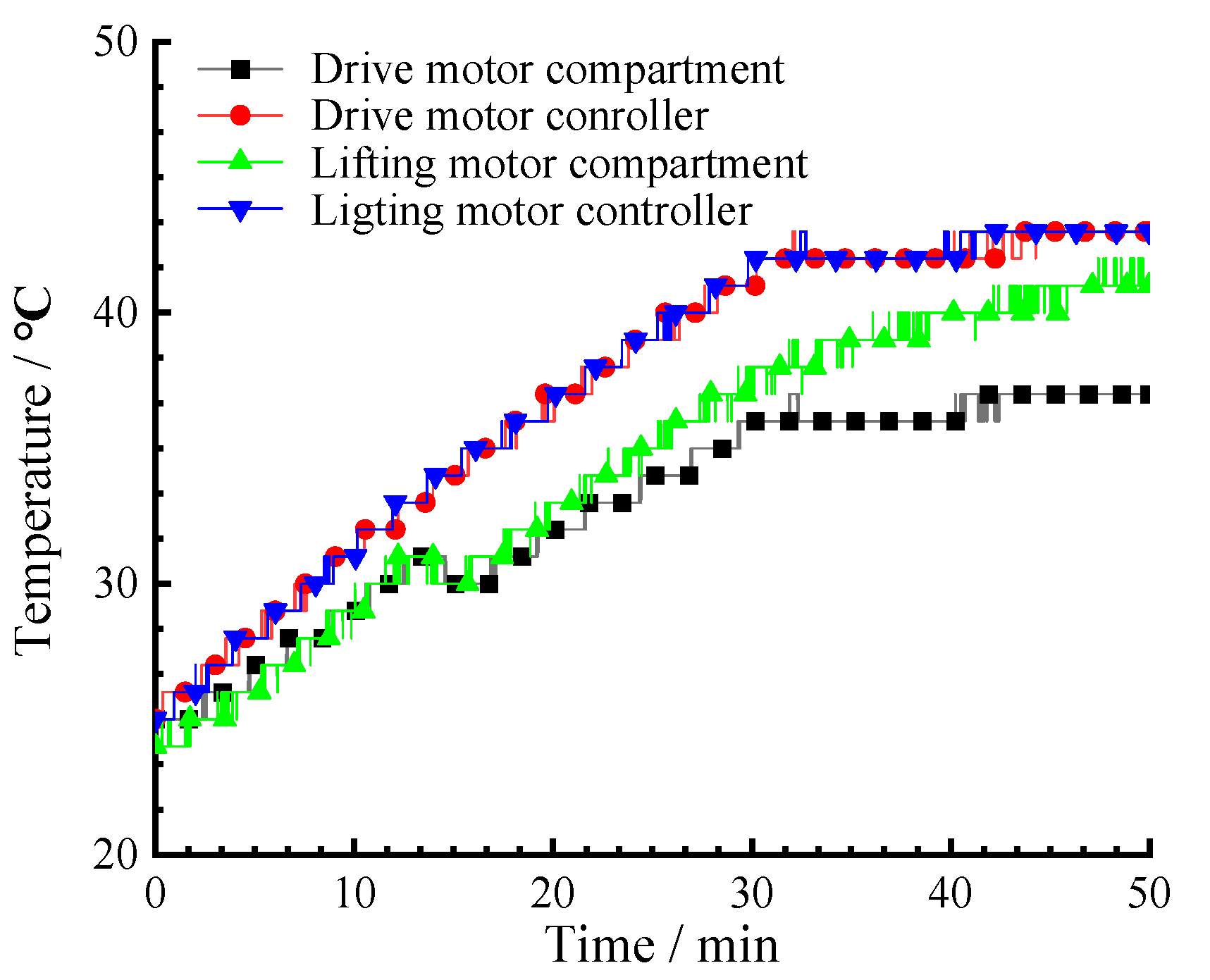

4.3. Thermal Equilibrium Analysis During Normal Forklift Operations

- (1)

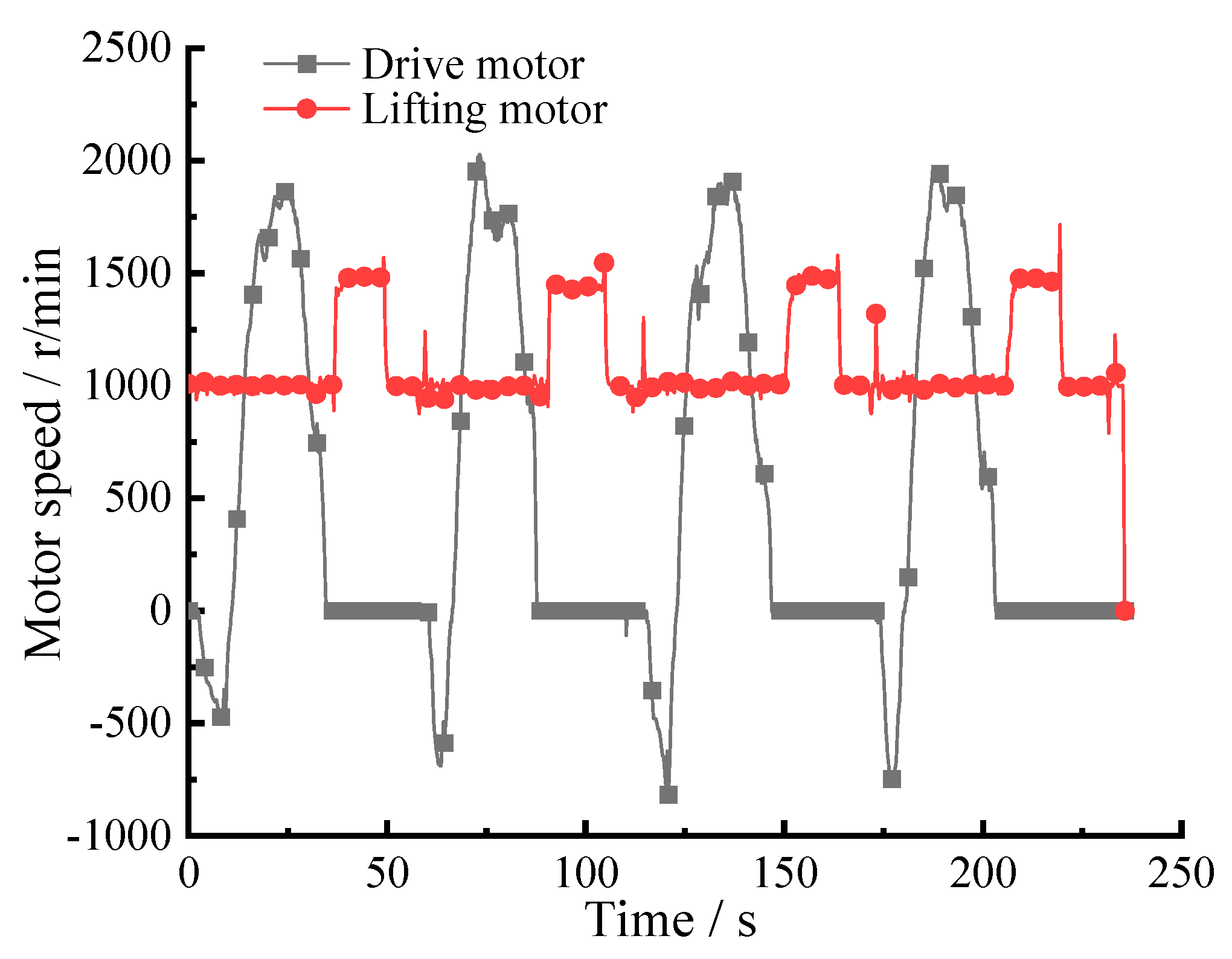

- Motor Operating Modes: As shown in Figure 14, which displays motor speed curves over two test cycles, the lifting motor operated nearly continuously at full-load lifting and 1000 r/min idle speed throughout the test. In contrast, the drive motor followed an intermittent operation pattern, resulting in sustained heat generation in the lifting motor.

- (2)

- Cooling System Configuration: the drive motor employs a dedicated cooling water circuit, whereas the lifting motor’s cooling system is connected in series to the rear ends of both motor controllers. This configuration causes residual heat from the upstream water circuit to further elevate temperatures in the lifting motor compartment.

- (3)

- Thermal Environment Differences: The drive motor is mounted at the rear of the forklift’s front drive axle, allowing natural heat dissipation during vehicle movement. Conversely, the lifting motor is installed beneath the battery pack and adjacent to the hydraulic oil tank, creating a relatively enclosed space that retains heat while also being affected by thermal radiation from the hydraulic system.

5. Conclusions

- (1)

- The construction of the 3-ton high-voltage lithium battery electric forklift test prototype was completed. Based on standardized testing protocols, average energy consumption measurements confirm that the proposed high-voltage system enables 8.89 to 13.34 h of continuous operation, significantly exceeding the 7.5 h service duration achieved by low-voltage lithium battery counterparts.

- (2)

- Based on average energy consumption experiments, the full-load lifting operation represents the highest energy consumption mode for the complete vehicle, accounting for 53.1% of total energy use, followed by the driving power system at 36.7%.

- (3)

- All electronic control units (ECUs) in the vehicle maintain thermal equilibrium temperatures below 43 °C, under the 80 °C shutdown threshold for low-voltage forklifts. This ensures long-term stable operation of the equipment while further demonstrating the lower energy consumption characteristics of the high-voltage lithium battery system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Copetti, D.F.; Canha, L.N.; Botezeli, L.K.; Tolotti, D.; Schmidt, E.; Silva, J.V.D.C.; NeuhausSchneider, A.J.; Da Silva, G.K.; Eggers, D. Electric Forklifts: Technological Advancements and Impacts on Energy Transition and Sustainability. In Proceedings of the 2023 15th Seminar on Power Electronics and Control (SEPOC), Santa Maria, Brazil, 22–25 October 2023; IEEE: New York, NY, USA, 2023; Volume 10, pp. 1–6. [Google Scholar]

- Jiao, M.; Pan, F.; Huang, X.; Yuan, X. Evaluation on Total Cost of Ownership of Electric Forklifts with lithium-ion battery. In Proceedings of the 2021 4th International Electrical and Energy Conference (CIEEC), Wuhan, China, 28–30 May 2021; IEEE: New York, NY, USA, 2021; pp. 1–5. [Google Scholar]

- Yudhistira, R.; Khatiwada, D.; Sanchez, F. A comparative life cycle assessment of lithium-ion and lead-acid batteries for grid energy storage. J. Clean. Prod. 2022, 358, 131999. [Google Scholar] [CrossRef]

- Sadeq, A.M. Hybrid and Electric Vehicles: A Comprehensive Guide, 1st ed.; Routledge: London, UK, 2024; pp. 104–112. [Google Scholar]

- Lin, T.; Lin, Y.; Ren, H.; Chen, H.; Li, Z.; Chen, Q. A double variable control load sensing system for electric hydraulic excavator. Energy 2021, 223, 119999. [Google Scholar] [CrossRef]

- Saeed, B.; Yilma, C.; Kivanc, O.; Tuncay, R.N. Development of a Hybrid Energy Storage System for a Forklift Vehicle. In Proceedings of the 2024 6th Global Power, Energy and Communication Conference (GPECOM), Budapest, Hungary, 4–7 June 2024; IEEE: New York, NY, USA, 2024; Volume 6, pp. 120–125. [Google Scholar]

- Cheng, L.; Zhao, D.; Li, T.; Wang, Y. Modeling and simulation analysis of electric forklift energy prediction management. Energy Rep. 2022, 8, 353–365. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, J. Research on Potential Energy Recovery System Control Strategy for Electric Forklifts. China Mech. Eng. 2015, 26, 844–851. [Google Scholar]

- Yu, C.; Wang, Y.; Zhao, C. Forklift hydraulic system design. Appl. Mech. Mater. 2013, 303–306, 2748–2753. [Google Scholar] [CrossRef]

- Yang, W.; Ke, J.; Yang, Z.; Wang, Y.; Li, L. Design and Simulation of Hydrostatic Transmission System in Electric Forklift. Mach. Tool Hydraul. 2020, 48, 71–75. [Google Scholar]

- Wang, W. Research on Key Technologies of the Drive System for 3T Electric Forklift. Master’s Thesis, Chang’an University, Xi’an, China, 2021. [Google Scholar]

- Li, J.; Lutzemberger, G.; Poli, D.; Scarpelli, C.; Piazza, T. Simulation and experimental validation of a hybrid forklift truck. In Proceedings of the 2019 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Turin, Italy, 2–4 July 2019; IEEE: New York, NY, USA, 2019. [Google Scholar]

- Sayed, K.; Kassem, A.; Saleeb, H.; Alghamdi, A.S.; Abo-Khalil, A.G. Energy-saving of battery electric vehicle powertrain and efficiency improvement during different standard driving cycles. Sustainability 2020, 12, 10466. [Google Scholar] [CrossRef]

- Mazali, I.I.; Daud, Z.H.C.; Hamid, M.K.A.; Tan, V.; Samin, P.M.; Jubair, A.; Ibrahim, K.A.; Kob, M.S.C.; Xinrui, W.; Talib, M.H.A. Review of the methods to optimize power flow in electric vehicle powertrains for efficiency and driving performance. Appl. Sci. 2022, 12, 1735. [Google Scholar] [CrossRef]

- Tong, Z.; Guan, S.; Zhang, Q.; Cao, X.E. Data-driven energy efficient speed planning for battery electric industrial vehicles: Forklift as a case study. J. Clean. Prod. 2024, 443, 140923. [Google Scholar] [CrossRef]

- Tong, Z.; Jiang, Y.; Tong, S.; Zhang, Q.; Wu, J. Hybrid drivetrain with dual energy regeneration and collaborative control of driving and lifting for construction machinery. Autom. Constr. 2023, 150, 104806. [Google Scholar] [CrossRef]

- VDI 2198; Type Sheets for Industrial Trucks. Verein Deutscher Ingenieure (VDI): Düsseldorf, Germany, 2018.

- PN-EN IS0 50001; Energy Management System -Requirements and Recommendations for Use. Polish Committee for Standardization (PKN): Warsaw, Poland, 2012.

- Zajac, P.; Rozic, T. Energy consumption of forklift versus standards, effects of their use and expectations. Energy 2022, 239, 122187. [Google Scholar] [CrossRef]

- Tong, Z.; Guan, S. Developing high-precision battery electric forklift driving cycle with variable cargo weight. Transp. Res. Part D. Transp. Environ. 2024, 136, 104443. [Google Scholar] [CrossRef]

- JB/T 3300-2024; Counterbalance Lift Trucks—Testing Method for Whole Machines. China Machine Press: Beijing, China, 2024.

- ISO 21262:2020; Industrial Trucks—Safety Rules for Application, Operation and Maintenance. The International Organization for Standardization (ISO): Geneva, Switzerland, 2020.

- IEC 62619:2022; Secondary Cells and Batteries Containing Alkaline or Other Non-Acid Electrolytes—Safety Requirements for Secondary Lithium Cells and Batteries, for Use in Industrial Applications. The International Electrotechnical Commission (IEC): Geneva, Switzerland, 2022.

- Shahid, S.; Agelin-Chaab, M. A review of thermal runaway prevention and mitigation strategies for lithium-ion batteries. Energy Convers. Manag. X 2022, 16, 100310. [Google Scholar] [CrossRef]

- Global EV Outlook 2024, IEA. Available online: https://www.iea.org/reports/global-ev-outlook-2024 (accessed on 24 August 2025).

- Fu, S.; Chen, H.; Ren, H.; Lin, T.; Miao, C.; Chen, Q. Potential Energy Recovery System for Electric Heavy Forklift Based on Double Hydraulic Motor-Generators. Appl. Sci. 2020, 10, 10113996. [Google Scholar] [CrossRef]

- Jiang, Y.; Tong, Z.; Tong, S.; Xu, Z.; Li, Y. Hydraulic dual-module hybrid driving system with adjustable waste energy recovery for industrial vehicles. Energy 2024, 307, 132546. [Google Scholar] [CrossRef]

| Parameter Name | Values |

|---|---|

| Battery type | LiFePO4 battery (Lithium Iron Phosphate battery, Anhui Qianhang New Energy Technology Co., Ltd., Bengbu, China) |

| Number of cells in series/parallel | 1P100S |

| Nominal voltage | 320 V |

| Nominal capacity | 100 Ah |

| Total battery capacity | 32 kWh |

| Operating voltage range | 250~365 V |

| Maximum continuous discharge current | 100 A |

| Peak discharge current (10 s) | 200 A |

| Communication method | CAN (Controller Area Network) communication |

| Items | Value |

|---|---|

| Rated load m0 | 3000 kg |

| Moving distance L0 | 30 m |

| Maximum lifting height | 2000 mm |

| Test time tc1 | 4026 s |

| Cycle number | 37 times |

| Environmental Temperature | (25 ± s2 °C) |

| Items | Conditions | Energy Consumption Proportions |

|---|---|---|

| 1 | Reversing + Steering | 7.1% |

| 2 | Moving forward + Steering | 29.6% |

| 3 | Mast tilting forward | 3.7% |

| 4 | Lifting | 53.1% |

| 5 | Lowering | 2.1% |

| 6 | Mast tilting backward | 4.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Chen, J.; Lin, T.; Li, Z.; Miao, C.; Gong, W. Energy Consumption Analysis and Thermal Equilibrium Research of High-Voltage Lithium Battery Electric Forklifts. Appl. Sci. 2025, 15, 9854. https://doi.org/10.3390/app15189854

Wu X, Chen J, Lin T, Li Z, Miao C, Gong W. Energy Consumption Analysis and Thermal Equilibrium Research of High-Voltage Lithium Battery Electric Forklifts. Applied Sciences. 2025; 15(18):9854. https://doi.org/10.3390/app15189854

Chicago/Turabian StyleWu, Xia, Junyi Chen, Tianliang Lin, Zhongshen Li, Cheng Miao, and Wen Gong. 2025. "Energy Consumption Analysis and Thermal Equilibrium Research of High-Voltage Lithium Battery Electric Forklifts" Applied Sciences 15, no. 18: 9854. https://doi.org/10.3390/app15189854

APA StyleWu, X., Chen, J., Lin, T., Li, Z., Miao, C., & Gong, W. (2025). Energy Consumption Analysis and Thermal Equilibrium Research of High-Voltage Lithium Battery Electric Forklifts. Applied Sciences, 15(18), 9854. https://doi.org/10.3390/app15189854