Abstract

This review covers the current state, challenges, and future directions of catalytic combustion technologies for mitigating fugitive methane emissions from the fossil fuel industry. Methane, a potent greenhouse gas, is released from diverse sources, including natural gas production, oil operations, coal mining, and natural gas engines. The paper details the primary emission sources, and addresses the technical difficulties associated with dilute and variable methane streams such as ventilation air methane (VAM) from underground coal mines and low-concentration leaks from oil and gas infrastructure. Catalytic combustion is a useful abatement solution due to its ability to destruct methane in lean and challenging conditions at lower temperatures than conventional combustion, thereby minimizing secondary pollutant formation such as NOX. The review surveys the key catalyst classes, including precious metals, transition metal oxides, hexa-aluminates, and perovskites, and underscores the crucial role of reactor internals, comparing packed beds, monoliths, and open-cell foams in terms of activity, mass transfer, and pressure drop. The paper discusses advanced reactor designs, including flow-reversal and other recuperative systems, modelling approaches, and the promise of advanced manufacturing for next-generation catalytic devices. The review highlights the research needs for catalyst durability, reactor integration, and real-world deployment to enable reliable methane abatement.

1. Introduction

Modern industrial society produces and uses a vast range of materials, many of which are made using chemical processes. This modern society also consumes large amounts of energy to maintain its existence. Undesired side effects from this societal model are the many concomitant environmental problems that are created. These problems often have serious effects on both human health and the natural habitat. The primary focus of this review is the emission of fugitive methane, but we also discuss a related topic, the emission of oxides of nitrogen, the so-called NOX compounds.

The majority of the energy used today is obtained through the combustion of the so-called fossil fuels, namely, coal, crude oil and its refined products, and natural gas. The products of the complete combustion of hydrocarbons are water and carbon dioxide, with some nitrogen- and sulphur-rich compounds if those elements were present in the fuel. Nitrogen oxide compounds can also be formed from the nitrogen present in the combustion air, especially when the combustion occurs at a high temperature. Emissions of oxides of sulphur and nitrogen are associated with significant health problems in humans.

One of the biggest environmental challenges that the world faces today is the rapidly changing climate, the cause of which is widely attributed to the constantly increasing levels of the so-called greenhouse gases (GHGs). Greenhouse gases contribute to global warming by absorbing and re-emitting infrared radiation, thereby trapping heat in the Earth’s atmosphere. This absorption slows the escape of heat into space, creating an energy imbalance that increases the planet’s thermal energy. Water vapour, a feedback amplifier, further intensifies warming by increasing in response to rising temperatures.

Carbon dioxide is the most abundant GHG in the atmosphere, followed by methane. Methane has a global warming potential (GWP) of between 25 and 30 times that of carbon dioxide on the 100-year time scale, or about 80 times on the 20-year time scale [1,2]. Because methane has a shorter life span in the atmosphere than carbon dioxide, its mitigation offers a much greater short-term mitigation result. Many countries have agreed to reduce methane emissions under the auspices of the Global Methane Pledge [3].

Methane is a colourless, odourless gas that is the simplest hydrocarbon molecule, comprising one atom of carbon and four of hydrogen. Methane is the principal component of natural gas. Its main direct use is as a fuel, either for space heating or electricity generation, and it is also used as a transportation fuel in the form of compressed natural gas (CNG) or liquefied natural gas (LNG). Methane is a key feedstock for the chemical process industries, especially in the manufacture of hydrogen via steam reforming or dry reforming. In addition to hydrogen, many other chemical products can be made from syngas produced by reforming. These include methanol, gasoline, methyl-tert-butyl-ether (MTBE), and formaldehyde, to mention a few [4].

This paper reviews mitigation strategies for fugitive methane emissions from the fossil fuel industry using catalytic combustion. The focus is on lower-temperature systems. In addition to the focus on fugitive methane mitigation, we also briefly discuss some other, usually high-temperature, applications, because those applications played a fundamental role in the advancement of the field of catalytic combustion. While it is not possible to provide an in-depth study of all aspects of this broad field, it is our objective to provide an overview of the key concepts, which the reader can use as a stepping-stone to achieving a greater insight of this fascinating area.

2. Sources of Fugitive Methane

2.1. Overview of Emission Sources

Recent estimates of global methane emissions from all sources give a value of approximately 610 million tonnes, or about 854 billion cubic metres per annum. This figure includes emissions from natural and anthropogenic sources. Effective mitigation strategies depend on the methane source, whether the emissions can be easily captured, and the methane concentration in the emission stream. Natural sources account for about 40% of global methane emissions. The remaining 60% are anthropogenic, of which agriculture accounts for about 50%, the energy sector 22%, and other sources such as landfills and wastewater treatment the remaining 28%. Energy sector emissions are divided amongst oil operations, including production and use, coal mining, and the natural gas supply chain [5,6].

In the following sections, we expand on emissions sources that originate in the production, transportation, and use of the three fossil fuels, coal, oil, and natural gas.

2.2. Natural Gas Production and Transportation

Global natural gas production has trended higher recently, and achieved a record high of approximately 4.19 trillion cubic metres in 2024. The United States is the world’s largest producer, accounting for about a quarter of the world’s supply. Russia is the second-largest producer, followed by Iran, China, and Canada. This continuous production growth reflects the robust global demand, particularly in the Asia-Pacific region, and is supported by the expanding infrastructure for both the pipeline and liquefied natural gas (LNG) trade. About 1% of the global natural gas production is lost to fugitive emissions. Methane is emitted at every stage, including production, storage, shipping, and use [7].

During the production stage, methane escapes for several reasons. These include some intentional venting, flaring, and loss through leakage. Leaks can occur at wellheads, piping connections, valves, and pneumatic devices that use pressurized gas for control. Completion and well flowback operations, particularly for unconventional resources like shale gas, can produce intermittent but sometimes very large emissions. After natural gas is extracted, it may be stored in underground facilities, which are also a source of emissions through leaks.

Natural gas is processed to remove impurities and separate valuable hydrocarbons, especially ethane. This stage can produce emissions from dehydrators, separation equipment, venting, pneumatic controllers, and leaks at facility components. Methane emissions at processing plants are often due to routine operations or equipment malfunction.

There can be a considerable loss of methane during shipping. This category includes the extensive pipeline networks that are used as basic transportation, as well as the large-scale movement by ship in the form of LNG.

In the pipeline network, leakage occurs throughout the chain of activities, from leaky seals, valves, pipe joints, compressors, etc. As natural gas flows through the pipelines, it requires periodic recompression to counteract the pressure loss resulting from flow, which is accomplished by periodic compressor stations. These can contribute significant emissions from several sources.

Either turbines or natural gas internal combustion (IC) engines are used to drive the compressors. While the emissions from gas turbines are fairly low, the IC engine emissions are significantly higher. These engines are operated in either lean-burn (excess oxygen) or with a stoichiometric air/fuel ratio. The IC engines in compressor stations are much larger than those used in road transportation applications, and, therefore, produce much more methane emissions. A typical 115 litre displacement natural gas lean-burn engine running at 1200 rpm produces about 61 tonnes per year of methane (1400 tonnes of CO2 equivalent), which increases as the engines age [8].

Another emission source is instrument vents. Natural gas actuates the pneumatic instruments used to control, for example, the temperature and pressure. These devices, however, bleed natural gas into the atmosphere during normal operation. This gas may be collected as a concentrated stream and vented outside of the building.

Leaking equipment is another emission source, which tends to be higher in older facilities. Methane losses through the compressor seal can range up to the tens of tonnes per year, and a single leaking valve can yield up to 1000 tonnes a year. The leaking methane is pure; however, it is rapidly diluted as it moves into the building and mixes with air [8].

Natural gas contains water vapour that must be removed to prevent pipeline corrosion and solid hydrate formation. Water is removed using triethylene glycol in a dehydration unit. The dehydration process absorbs water, methane, and other volatile organic compounds, including hazardous air pollutants such as benzene, toluene, ethyl benzene, and xylene (collectively called BTEX). When the glycol is regenerated, these emissions are released. Natural gas dehydration effluent is the third-largest methane emission source in the natural gas production industry [9].

2.3. Oil Production, Storage, and Transportation

In spite of the efforts to transition away from fossil fuels, oil production also continues at near-record rates, and is likely to do so for the foreseeable future. Methane emissions originate from numerous sources during the production and shipping of oil. They comprise intentional and unintentional releases, including operational venting, flaring, leakages, and tank/storage handling. Many of the streams are mainly methane, but can contain other light hydrocarbons. These leaks may be individually small, but there are also super-emitting cases, and, collectively, they are significant. Some of the main sources are given in the following paragraphs.

In most oil reservoirs, methane is dissolved in the oil, and is referred to as solution gas. Oil production comes from a wide variety of oil field types. Some of these fields contain a large number of highly productive wells, which, together, produce a large amount of methane. In this case, the methane might be collected and used as a fuel, or added to the pipeline. In other cases, the oil production rate is small, or there is a lack of infrastructure, so the gas is flared. On the smallest scale, flaring is not viable and the gas is simply vented. While a properly functioning flare should emit minimal methane, there are many cases of malfunctioning flares that emit significant amounts of methane. Venting and flaring have been estimated to account for about 75% of methane emissions from oil and gas operations, with venting alone responsible for 64%, and flaring for about 11% [5]. The remaining 25% of methane emissions come from a variety of sources. Methane can escape through equipment leaks at virtually every stage, from wellheads and pipelines to storage tanks and valves. Many control instruments, such as pneumatic controllers and chemical injection pumps, are powered by pressurized natural gas and intentionally release small amounts during operation. Methane is emitted from oil storage tanks (through breathing, flashing, or venting events), especially when pressure relief valves open or tanks are offloaded. Separators, used to separate oil, gas, and water, can also be major sources.

Many of these streams have a high percentage of methane, often more than 80%, especially those from leaks. Storage tank emissions can often contain significant amounts of higher hydrocarbons. Finally, a significant source of methane emissions is abandoned oil wells that have not been properly capped.

2.4. Ventilation Air Methane (VAM)

Underground coal mining presents a challenge in controlling methane emissions, a priority both for the protection of mine workers and the mitigation of environmental impacts. Methane is naturally adsorbed within coal seams and the surrounding rock strata. As coal is extracted, substantial quantities of this methane are liberated into underground mine workings. The presence of methane is a major safety hazard: in concentrations between 5 and 15% in air, it forms an explosive mixture, necessitating stringent safety protocols and continuous monitoring. To prevent hazardous accumulations, underground mines depend on powerful ventilation systems that continuously dilute and remove methane, along with other gases, by supplying large volumes of fresh air and exhausting contaminated air from the mines.

The exhaust air from these systems, known as Ventilation Air Methane (VAM), is characterized by highly dilute concentrations of methane, generally well below 1%, and frequently lower than 0.5% by volume. The enormous airflows required result in massive overall emissions. As a consequence, VAM represents the single largest source of methane emissions from most active underground coal mines. Annual methane emissions from a large coal mine ventilation shaft may reach approximately 50,000 tonnes. Considering the latest estimates of total methane emissions from mines, amounting to 41 Mt per year, and the estimated share of VAM in these emissions at 60%, the total VAM emissions are approximately 25 Mt per year [5,10,11,12].

Mitigating VAM emissions poses substantial technical challenges. The low methane concentration inhibits the use of conventional methane utilization technologies, such as flares or gas engines, which typically require higher methane contents to operate efficiently. Additionally, the variable nature of VAM, driven by factors such as the changes in coal production rates, periodic mine sealing, and atmospheric pressure fluctuations [12], complicates the implementation of consistent abatement strategies. Methane concentrations in VAM can exhibit both short-term and long-term fluctuations, and sudden changes may occur due to the operational events or geological conditions within the mine.

VAM is usually available at close to ambient temperature and may contain some water vapour. The water content may be around 2% by volume, and typically corresponds to saturated air at the local temperature. The low temperature and water content provide additional challenges for mitigation.

2.5. Natural Gas Engines

Natural gas may be used to power the engines in natural gas compressor stations. There is also an interest in the use of methane as an alternative fuel in internal combustion engines (ICEs) as a replacement for diesel or gasoline, especially in larger trucks used for the long-distance transportation of goods. Changing the fuel from diesel to natural gas results in a large reduction in the emission of greenhouse gases, provided that the methane that is not burned in the engine is successfully destroyed in a catalytic converter.

Natural gas easily forms homogeneous air–fuel mixtures which can be ignited and burned over a wide flammability range [13,14]. This pre-mixed combustion produces much lower nitrogen oxide (NOX) emissions and soot emissions compared to diesel engines. The fuel itself is chemically inert with a low photochemical reactivity and low global toxicity of the exhaust gases compared to those from diesel engines [15]. The low carbon/hydrogen ratio also permits reduced carbon dioxide emissions for a given engine efficiency [16]. Natural gas has excellent knock resistance which, when combined with the lean mixtures, permits diesel-like compression ratios for optimum engine efficiencies.

The composition and temperature of the exhaust stream from a natural gas engine vary significantly depending on whether the engine operates in a lean-burn or stoichiometric mode, each presenting distinct emissions challenges and opportunities for emission control. The excess oxygen present in lean-burn mode encourages the more complete combustion of the methane fuel, which reduces carbon monoxide emissions. The emission of nitrogen oxides (NOX) is also very low compared to traditional diesel engines. Because of the excess oxygen present in the feed, the exhaust also has excess oxygen, and, thus, a three-way converter (TWC) cannot be used. The stoichiometric natural gas engine operates with an air-to-fuel ratio close to the value required to ensure the complete combustion of the fuel, and, thus, there is little to no oxygen in the effluent. Stoichiometric engines are less fuel-efficient than lean-burn ones, and, thus, emit more carbon dioxide per unit of usable energy produced—in other words, per vehicle mile travelled.

Water is a major component of the exhaust from the engine, about 18 to 20% by volume. The value for the lean-burn operation is slightly lower than for the stoichiometric one, but is still a significant amount. Water has a strong effect on the catalyst activity for emission control. Lean-burn engines typically operate at much lower temperatures than stoichiometric ones. Stoichiometric natural gas engines typically have higher exhaust temperatures, often in the range of 450–600 °C and occasionally higher depending on the load and engine configuration. Lean-burn natural gas engines, on the other hand, produce cooler exhaust streams, with typical temperatures ranging from about 350 to 500 °C. At lower loads, the exhaust temperatures can fall below these ranges. The amount of methane emitted in the exhaust depends significantly on the engine type and operating conditions. Lean-burn engines tend toward higher emissions, in the range of 600 to 3000 ppm, with higher values at low engine loads. The methane emissions from stoichiometric engines are lower.

2.6. Summary of Emission Sources

The broad range of emission sources implies many possible compositions. Generally speaking, the composition can be divided into those containing significant quantities of water (wet) and those that do not (dry). There might also be other species present, such as sulphur compounds, BTEX, etc. The emissions of biogas might also contain a variety of species. It is often the case that the methane concentration is low, and there is an excess of oxygen (lean). As the oxygen content is reduced, the mixture becomes methane-rich. Furthermore, the temperature can be at ambient temperature or significantly higher. The composition and temperature of the emission stream, along with the ability to capture it, affects the mitigation technique that can be used.

3. Mitigation Strategies for Fugitive Methane

The mitigation strategies for methane emissions are many and varied. They can be as simple as decreasing emissions from natural gas transmission facilities by reducing leaks from valves and other equipment [17]. It has been shown that the actual leakage rate can be much higher than official inventory estimates [18]. Methane emissions from cattle are a significant agricultural source, which can be reduced by modifying their feed [19,20,21,22]. Both of these mitigation efforts rely on emissions reduction from the source, which would be the best solution; however, in many cases, anthropogenic emissions are inevitable, and, therefore, should be destroyed rather than be released into the atmosphere.

Methane is commonly burned as a fuel, and combustion technology can be used as a mitigation method for methane. Although the combustion of methane produces carbon dioxide, another greenhouse gas, it, nevertheless, results in the reduction in the greenhouse effect because of the high global warming potential of methane. Indeed, if the GWP of methane is taken as 27 times that of carbon dioxide, then the complete combustion of methane reduces the overall GWP by 90% on a mass basis, if the effects of water vapour are ignored. The combustion of fugitive methane emissions poses challenges, largely because of the conditions at which they exist, which often consist of dilute streams and relatively low temperatures. A solution, in some cases, is to use catalytic combustion, and, in the next section, we provide an overview of this methodology.

4. Combustion of Methane

Combustion is the complete oxidation of a substance (fuel) that is accompanied by a release of thermal energy. Fuels may be solids, liquids, or gases. Although many chemical species undergo combustion reactions, they are most commonly associated with fuels that are composed mainly of hydrocarbons or, for solid fuels, carbon alone. Fuels may contain other species, such as nitrogen, sulphur, or oxygen. Combustion is typically performed to provide thermal energy for heating, to generate electricity, or to produce mechanical work. Combustion may also be used to destroy unwanted material such as garbage or waste streams that should not be allowed to enter the environment.

4.1. Conventional and Catalytic Combustion

Combustion is a broad field that, because of its prevalence, has been widely researched. There are many classifications of combustion. We use the term conventional combustion to refer to the oxidation reaction that takes place between oxygen and the fuel, usually in the presence of a flame, which may or may not be visible to the naked eye. Conventional combustion is subject to a number of conditions, which constrain when it may occur. First and foremost are the flammability limits, which state that combustion can only occur over a well-defined composition. For example, for a mixture of methane in air, the lower flammability limit is about 4.4% methane and the upper limit is about 16% methane. Within this range, the mixture will burn if it is exposed to an ignition source. Conventional combustion typically requires temperatures in the range of 1300 to 2000 °C, which can lead to the formation of undesirable byproducts such as oxides of nitrogen. Finally, because of the presence of the flame, consideration must be given to the firebox design, which is often large and must be designed to accommodate the flow patterns of the fuel/air mixture. It is important to prevent flame impingement on the combustor walls.

Catalytic combustion, in contrast, is a flameless combustion process that uses a catalyst to promote the oxidation reaction. Detailed descriptions of catalytic combustion can be found in references [23,24,25]. The advantages of catalytic combustion compared to conventional combustion are many. Catalytic combustion is not constrained by flammability limits, and, thus, streams with a low fuel concentration can often be combusted without using support fuel, although very low concentrations of methane (less than 0.3% by volume) remain a challenge. Inlet reactor temperatures around 300 °C can be used for the catalytic combustion of methane, although the temperature depends on the catalyst activity and the space velocity (throughput) in the reactor. These lower reactor temperatures decrease the possibility of nitrogen oxide production.

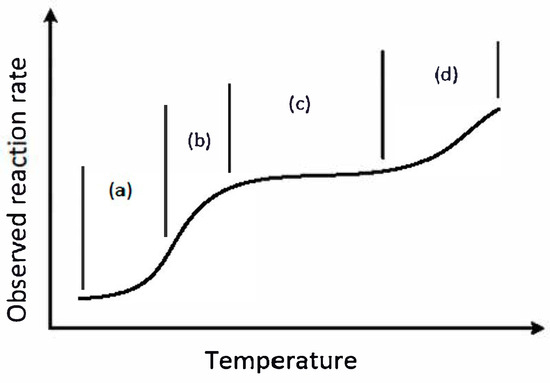

Catalytic combustion can be divided, perhaps somewhat arbitrarily, into regions based on temperature. These temperature regions determine the dominant forces that control the reaction rate, and, critically, determine the type of catalyst and support system that is used. The temperature used in the catalytic combustion system is also a strong function of the application. There is a classical plot commonly used in the catalytic combustion literature that shows a stylized representation of the observed reaction rate expressed as a function of temperature, as shown in Figure 1. In effect, this plot can be used to illustrate and explain the roles of kinetics and heat and mass transfer in the system.

Figure 1.

Representation of the variation in observed reaction rate with temperature. The rate varies depending on the controlling factors, as the rate moves from kinetic to mass transfer control, and then as homogeneous reaction becomes important. Region (a) corresponds to kinetic control, (b) to the onset of mass transfer limitation, (c) to complete control by mass transfer and (d) the onset of catalytically supported homogeneous reaction.

In a heterogeneous catalytic system, the reaction occurs at the catalyst surface. For a porous catalyst, the bulk of the active catalyst surface lies within the bulk catalyst, that is, on the surface of the porous network. To achieve the reaction, the reactants are first transferred from the bulk gas phase to the external surface of the catalyst, through the concentration boundary layer. The reactants must then diffuse into the pores, where the reaction occurs on the surface. Both of these mass transfer steps depend on either diffusion or convection. The intrinsic reaction rate on the catalyst is controlled by the reaction kinetics. The observed rate of reaction, therefore, depends on both the rates of mass transfer and the kinetics. At relatively low temperatures, corresponding to Zone (a) in Figure 1, the reaction is intrinsically slow, and the reaction kinetics determine the rate. In this region, the rate increases exponentially with temperature, and the rate of mass transfer from the bulk becomes increasingly important. Zone (b) in Figure 1 corresponds to the region where both the reaction kinetics and the mass transfer rate control the observed rate. As the temperature increases further, and we move into Zone (c), the surface concentration becomes very small, and the mass transfer from the bulk gas phase controls the reaction. Because mass transfer coefficients are not a strong function of temperature, the observed reaction rate also only increases slowly. In this region, the kinetic expression is not important. As the temperature increases beyond this range and into Zone (d), homogeneous reactions start to occur. These homogeneous reactions are promoted by the surface catalytic reaction, and, thus, can occur outside of the standard flammability range for the fuel in question. This latter region is referred to as Catalytically Stabilized Thermal combustion, or CST [26]. It should perhaps be emphasized that, at high-temperature and -pressure operation such as that found in catalytic gas turbines, the gas phase, or homogeneous, chemistry makes a significant contribution to the overall methane conversion, and without a flame necessarily being present. We also point out that, in some turbine designs, there is a small homogeneous reaction section placed after the catalytic section [23].

The temperatures that govern the limits of the zones depicted in Figure 1 depend on the intrinsic catalyst activity, as well as the mass transfer coefficients. The latter depends on such things as the reactor geometry and the bulk gas flow regime. Although the zone limits depend on these factors, it is always important to be aware of these factors when designing a catalytic combustion system.

4.2. History and Applications of Catalytic Combustion

The development of catalytic combustion processes has been application-driven, and a brief history and the major applications are given as follows. The discovery of catalytic combustion dates to the safety lamp experiments of Sir Humphry Davy in 1818, where he observed platinum wires enabling flameless methane combustion [27]. As discussed in various publications [23,26,28], this fundamental discovery and the subsequent research into the catalysis of combustion formed the basis of the modern field of catalysis.

Catalytic combustion applications can be divided into those where the objective is to generate energy in the form of work or heat, and those in which the desire is to control fugitive emissions. While the main focus of this overview paper is on the latter application, we mention briefly some of the primary applications, because they have been important in the development of the catalytic combustion field. It is important also to realize that the two application areas often have quite different requirements, and materials that are useful in one area are not necessarily useful in others.

Some of the early work reported on catalytic combustions focuses on the applications of radiant heaters, where a catalytic active surface at high temperature supplies radiant energy. These devices ranged from large-scale process heaters to small-scale consumer products [23,26]. There was interest in the United States about using catalytic combustion for space heating during the decades of the 1950s to the 1970s.

Radiant heaters have been used with many fuels [29], and often use a metal fibre type of catalyst [21]. More recent developments in the use of porous radiant heaters based on catalytic combustion use multiple-stage designs of increasing sophistication [30,31].

There was a large increase in the interest in catalytic combustion starting in the early 1970s, with the objective of developing gas turbines that operated at relatively low temperature, compared to conventional gas turbines, as a means of reducing the production of NOX compounds in the combustion chamber. Most of these devices tended to operate in the CST region discussed earlier. There are many summary reference papers that provide details of this branch of catalytic combustion and discuss the theory of operation [23,26]. There have been numerous papers published that describe various designs at different scales, e.g., [32,33,34]. Several articles provide general discussions of the state of the technology and the remaining challenges [35,36].

A common feature of these primary combustion applications is the need for a catalyst able to withstand high temperatures for extended periods of time.

Another significant motivation for catalytic combustion came with the need to reduce atmospheric pollution from road vehicles, with catalytic converters becoming mandatory in the USA in the 1970s. This requirement led to the development of the automotive catalytic converter. Early catalytic converters destroyed carbon monoxide and hydrocarbons in vehicular exhaust, with the later appearance of the so-called three-way converter (TWC) that also reduced NOX emissions. This last technology was developed for engines operating on a stoichiometric air/fuel ratio, and purely oxidizing converters were used for lean-burn engines. An excellent review of this topic can be found in [37]. The main focus of this aspect of catalytic combustion was catalyst development, as well as the widespread adoption of monolith reactor technology, which will be discussed in more detail shortly. Although the reactions in the automotive catalytic converter for gasoline and diesel engines are quite different from the combustion of methane, there is a lot of commonality in the catalyst materials, and the associated reactor development, especially for monolith supports.

With the advent of vehicles that used natural gas as a fuel, a requirement developed for a more active catalyst that would destroy the methane present in the exhaust [38]. The remainder of the technology was similar to other automotive exhaust gas applications.

Finally, a third major area of application relates to the desire to destroy emissions from other sources. As discussed in the introduction, methane emissions from a number of sources exist, including the oil and gas sector, coal mining, agriculture, and others. In addition to methane, species such as formaldehyde, benzene, toluene, ethanol, etc. can all be readily oxidized using catalytic combustion [9]. The wide variety of properties of the emissions from these sources makes their destruction a challenge.

5. Catalysts for Methane Combustion

5.1. Overview of Catalysts Used

Catalytic combustion catalysts have been extensively studied over the past seventy years, including a large number for the combustion of methane [39]. Methane is the most stable hydrocarbon with a symmetry that makes it difficult to rupture the carbon–hydrogen bonds. The practical result is reflected in the high activation energy of the reaction, and the fact that the options for a viable catalyst are limited.

Several factors influence the catalyst performance. These include the ratio of oxygen to methane in the feed, the method of catalyst loading on the support, the nature of the support itself, the sensitivity to the catalyst structure and composition, the extent and nature of the catalyst pretreatment, the presence of other components in the feed (especially water), and the reaction conditions. The basic requirement for any combustion catalyst is that it has sufficient activity at the operating temperature desired, combined with an ignition temperature consistent with the feed properties. The operating temperature is determined by the application. For example, gas turbines and radiant heaters would normally have higher temperatures than reactors designed to destroy low-concentration emission streams. In many practical cases, there are physical constraints on the size of the reactor, and, in such cases, it is important to have high-activity catalysts. The cost can be a factor in the catalyst choice.

Although many materials have been tested in catalytic combustion applications, they can be divided into four general groups. The first group, which is considered the most active, is based on precious group metals, notably platinum and palladium. The second group consist of the metal oxide catalysts that use earth common metals. For the destruction of fugitive methane emissions, these two groups of catalysts are the most widely used.

For higher-temperature applications such as turbines and radiant heaters, research has focused on hexa-aluminate-type catalysts and those based on perovskite materials [39]. We briefly describe these four classes of catalysts. It is not the intention here to give a detailed literature review of each type, but, rather, to present an idea of the characteristics of each with some relevant references. The established literature on the catalytic combustion of methane is vast.

5.2. Catalysts Based on the Precious Group Metals (PGMs)

It is generally accepted that precious metals in either pure or oxide form are the most active catalysts for catalytic combustion [40]. These catalysts are preferred for lower-temperature applications where a highly active catalyst is required [41,42]. Palladium is the most widely used PGM catalyst for methane combustion, and research on this metal is plentiful. Two useful reviews are found in references [43,44].

Some applications of the catalytic combustion of methane, especially some low-concentration emission streams, have a feed stream that contains a large amount of water. Palladium is quite susceptible to activity loss and permanent deactivation by the presence of water. Activity loss is especially noticeable at temperatures below about 450 °C, which is attributed to the formation of Pd(OH)2 species on the surface [40,45,46]. Another suggestion is that surface hydroxyls inhibit the exchange of oxygen between the PdO, support, and the gas phase [47,48].

Platinum has also been widely used in catalytic combustion applications, especially as a key ingredient of the automotive catalytic converter. Platinum is considered to be very effective for the combustion of non-methane hydrocarbons; however, there are many references to the use of platinum for the catalytic combustion of methane. Various supports have been used [49,50,51,52,53,54].

The use of palladium or platinum alone is widespread, especially in the older literature. Combinations of different PGMs have also been presented, and typical combinations include rhodium [55,56,57,58,59,60] and gold [61,62,63]. The most recent trend today for the PGM catalysts is to use a mixture of palladium and platinum, and there is copious literature extant for this combination [63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78]. The Pd:Pt combination is considered to be advantageous in the presence of water and this combination may also be more resistant to sintering. The ratio of Pd to Pt is considered to be an important factor [63,65]. It should be noted that it has been shown that, while a Pt addition enhances the catalytic activity under wet conditions, the activity can be decreased under dry feed conditions, compared to the pure Pd catalyst [76].

5.3. Deactivation of PGM-Based Catalysts

It is important that the catalyst does not suffer from excessive deactivation at the operating temperature of the system, nor from any compounds present in the feed, such as impurities or water. The inhibition of the activity of the Pd-based catalyst is discussed in Section 5.2. The presence of water can also cause long-term catalyst deactivation, especially at higher temperatures, as a result of sintering. High temperatures can also cause activity loss, even in the absence of water in the feed. Platinum catalysts are generally less susceptible to deactivation by water, but sintering and support interactions can also cause activity loss over time. The presence of even small amounts of sulphur compounds can also cause activity loss because of the irreversible adsorption on active sites.

In the case of palladium catalysts, there is an additional factor to consider. The most active surface form of palladium is PdO. At higher temperatures, even in the presence of oxygen, there is a transition to the less active Pd form. The transition temperature depends on the oxygen partial pressure [23], and is a reversible process. However, it should be considered for the case of feeds with low oxygen concentrations.

5.4. Catalysts Based on Transition Metal Oxides

Transition metal oxides represent a promising and economically attractive alternative to PGM catalysts for methane combustion, owing to the abundance and lower cost of their constituent elements. Notable oxides, such as those based on cobalt, nickel, iron, copper, and manganese, have demonstrated significant activity, selectivity, and thermal stability [79,80,81,82,83,84,85]. Among these, cobalt oxide (Co3O4) and its composites with ceria or alumina supports are particularly effective, achieving high methane conversion rates at moderate reaction temperatures and displaying an enhanced tolerance to common catalyst poisons and thermal cycling. Recent advances have focused on fine-tuning the morphological and electronic properties of these oxides via doping, surface functionalization, and nanostructuring, resulting in improved low-temperature activity, durability, and resistance to water inhibition. A recent review by [86] summarizes the current developments and emerging strategies for this family of catalysts.

5.5. Catalysts Based on Hexa-Aluminates

The third group of combustion catalysts are the hexa-aluminates and substituted hexa-aluminates, introduced for methane combustion in the 1990s [87]. Barium hexa-aluminates are especially effective [88]. As with other catalysts, the activity depends strongly on the preparation method. These materials have a very high thermal stability, although their activity is generally lower than that of the transition metal oxides.

5.6. Catalysts Based on Perovskites

For high-temperature applications, an interesting alternative to the hexa-aluminate catalysts is those made from perovskites. Perovskites are mixed oxides with a structure of the general formula ABO3. Lanthanide elements usually are at the site A position and the first-row transition metals at the site B position. Perovskites have a good thermal stability, and offer a lower-cost alternative to precious metals with acceptable high-temperature activity [89,90,91,92]. Their activity is also affected by the preparation method [93,94].

5.7. Catalyst Supports and Promotors

Catalyst systems, especially those based on PGM and metal oxide, generally consist of the active component and a support. Many permutations and combinations exist, and the situation is further complicated because components which are themselves active catalysts may be used as supports. The support can affect the catalytic mechanism, the activity, and the resulting rate equation; see references [95,96,97,98,99]. Supports include alumina [100,101,102,103,104,105,106,107], zirconia [108,109,110,111,112], silica [113,114,115], aluminosilicates [116], cobalt oxide [117,118], ceria [119,120], nickel compounds [121], and tin [122,123]. In addition to the choice of support, the preparation method [93,94,124] and the use of promoters [125,126,127] can also have a significant impact on the catalytic activity.

6. Reactor Internal Support Systems

All reactors used in catalytic combustion are multi-phase, consisting of the gaseous reacting stream and the solid catalyst system. Reactors can be divided into two categories, fixed bed and fluidized bed. In the fixed bed system, the catalyst is fixed in some manner within the reactor, and the reacting fluid flows through it. In the fluidized bed, small particles of the catalyst are placed in a bed over a distributor plate. High-speed gas is passed through the bed, causing it to move and behave like a fluid. Fluidized beds have been used for combustion applications, and a good review is available [128]. In this work, we focus exclusively on fixed bed systems.

Fixed bed reactors can be considered as a porous medium, and, in the terminology of porous media, the bed can be either consolidated or unconsolidated. In an unconsolidated porous medium, the solid phase consists of particles that are dumped into the vessel and are only constrained be the walls of the vessel. In a consolidated bed, the catalyst is typically placed on the surface of a well-defined support structure. The two most common support structures are monoliths and foams, although wires can also be used.

6.1. Unconsolidated Packed Beds

The majority of industrial chemical reactors use a fixed bed with catalyst particles in an unconsolidated bed. They have been the subject of countless publications and reviews, and all of the theory of individual catalyst particles and the packed bed is well-covered in standard chemical reaction engineering textbooks [23,129,130,131]. Their use in catalytic combustion has been reported [132]. As with all systems, there are advantages and disadvantages to using a packed bed of particles. Because of their widespread use, there is an extensive knowledge base and operational experience associated with them. Compared with the alternatives, they offer the largest bulk density possible, that is, the highest amount of catalyst per unit volume.

One of the main disadvantages is the pressure drop associated with the flow through the bed. In many commercial applications of catalytic combustion, the pressure drop is critical, and the use of packed beds is problematic. One of the consequences of the pressure drop is also the size of the catalyst particles. The pressure drop increases as the particle size decreases, and, therefore, relatively large particles, of the order of 6 mm in size, are used in industrial units. Because of this size, and considering the fast combustion reaction, the mass and heat transport effects can be significant, which significantly reduces the effectiveness of the catalyst. Finally, a packed bed of particles is prone to fouling or clogging, especially if there are particles in the feed.

6.2. Monoliths

The need for an efficient automotive catalytic converter, among other applications, led to the extensive development of the honeycomb monolith substrate [37]. This support system consists of a single block containing a series of straight, uniformly sized, and non-connected channels through which the reacting gas flows. The design maximizes the geometric surface area while maintaining a low flow resistance, making it ideal for high-throughput catalytic processes.

Monolith channels can have a variety of cross-sectional shapes, including circular, hexagonal, square, triangular, or more elaborate sinusoidal forms, chosen to balance the surface area, pressure drop, and ease of manufacture. The cross-sectional geometry, along with the channel density and wall thickness, dictates the percentage of open frontal area and the effective hydraulic diameter, which, in turn, influences the mass transfer rates and thermal response. Monolith structures are routinely manufactured with well-controlled specifications for the channel size, cell density, and wall thickness, enabling engineers to optimize for both the reaction and transport performance. Cell density is normally expressed in cells per square inch (CPSI), with commercial units ranging from around 100 to 1200 CPSI. Lower densities (100–400 CPSI) are favoured in applications requiring a very low pressure drop and high gas throughput, while high densities increase the available surface area for catalyst deposition but at the expense of a higher flow resistance. Cordierite remains the most common ceramic composition as a result of its low thermal expansion and excellent thermal shock resistance, although alternative materials such as silicon carbide (SiC) are increasingly applied in demanding, high-temperature catalytic combustion duties where a higher thermal conductivity and robustness are desirable.

The active surface of the monolith is provided by applying a high-surface-area coating, called a washcoat, onto the channel walls. This porous oxide layer, often γ-alumina or a composite oxide, hosts the catalytically active phase, typically finely dispersed precious metals or transition metal oxides. Washcoat thicknesses can range from ~10 to 150 μm, depending on the application, although deposition uniformity is challenging in non-circular geometries such as square or triangular channels [23,133]. Thicker washcoats increase catalyst loading but also risk introducing mass transfer resistance within the porous layer, which can be significant for fast, highly exothermic reactions like methane combustion. In operation, the reacting gas flows axially down each channel, with reactants transported across a diffusion boundary layer to the washcoat surface, after which molecular diffusion and the heterogeneous reaction proceed within the porous washcoat.

The heat and mass transfer characteristics of monoliths are excellent, particularly in high-pressure service where the gas flow may be in the turbulent regime within the narrow channels. At atmospheric pressure, the flow is typically laminar even at relatively high velocities; nonetheless, the high surface-to-volume ratio offsets some limitations in turbulent transport, and thermal conduction through the solid walls can help smooth temperature gradients. This is beneficial in exothermic reactions like catalytic combustion, where minimizing localized hot spots reduces catalyst sintering and structural degradation. Metal monoliths, in particular, can offer superior thermal conductivity, aiding in heat spreading and thermal cycling durability.

Mechanically, monoliths are robust, resistant to vibration, and capable of withstanding large thermal shocks, particularly when made from cordierite or suitably stabilized ceramics. Their modular form factors allow for the easy scaling from laboratory test pieces to large industrial units, and they can be assembled in stacks or arrays to treat very large flow rates. They also lend themselves well to the integration into heat exchanger/reactor hybrids, counter-diffusive configurations, or recuperative combustors, as the open-channel geometry is amenable to embedding into multi-functional reactor designs.

The properties of a low pressure drop, high geometric surface area, scalability, and good mechanical and thermal performance have seen monoliths become the dominant support system for many catalytic combustion applications, including gas turbines, automotive and stationary engine emission control, and industrial lean-methane abatement systems.

6.3. Foams

Foam materials, both regular (engineered open-cell foams) and irregular (random cellular structures), have become increasingly important as structured catalyst supports in catalytic combustion reactors, particularly for applications such as fugitive methane abatement. These porous substrates offer an innovative alternative to traditional pelletized or monolithic supports, facilitating significant improvements in reactor performance and process intensification. They have a high thermal stability and porosity. The flow patterns are typically more tortuous than monolith honeycombs, although less so than particle beds [134]. A fundamental understanding of how the geometrical and material properties of metallic and ceramic foams can optimize the catalytic reaction environments, reduce energy consumption, and enhance the overall process performance, and can be found in [135]. These properties have established foams as promising candidates for sustainable and intensified chemical engineering applications.

This new class of structured supports emerged in the 1990s [136,137,138,139,140]. These materials, available in metallic, ceramic, and composite variants, are characterized by their high porosity, large specific surface area, and interconnected open-cell structures. Metal foams, typically made from stainless steel, nickel, or FeCr alloys, offer excellent mechanical and thermal stability. Their properties can be enhanced via surface treatments and coating techniques. Ceramic foams, made from materials such as cordierite, mullite, and alumina, are noted for their superior thermal stability and resistance to mechanical stress. In addition, novel composite materials, including metal–ceramic hybrids and additively manufactured structures, further expand the range of design possibilities for catalyst supports.

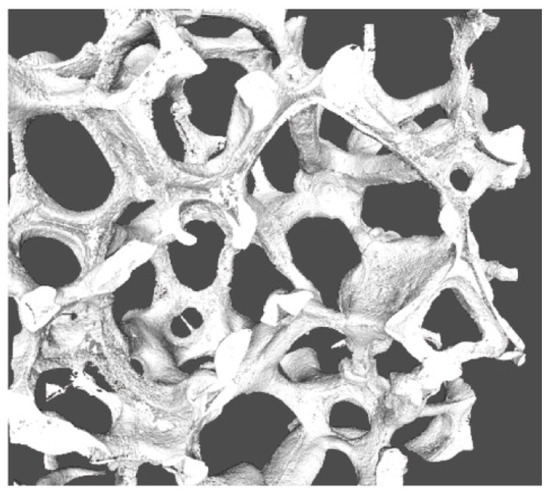

A typical foam structure geometry is shown in Figure 2. Solid foams can be described as three-dimensional networks of struts and pores, forming cells (approximately spherical voids enclosed by struts) and windows (openings connecting neighbouring cells). The geometry can be expressed by overall statistical parameters, usually provided by manufacturers, such as the following: the pore density (often called grade), given as the number of pores per linear inch (PPI) and typically ranging from 5 to 100 PPI; total density; porosity; and specific internal surface area (SISA, m2/m3). Describing these parameters for irregular structures in sufficient detail for fluid-dynamic modelling is a challenge. X-ray tomographic methods have proven effective for this purpose [140].

Figure 2.

Typical appearance of a foam.

An interesting observation for metal foams (e.g., nickel- or FeCr-based ones) is that many of their mechanical and physical properties are directly influenced by the density, the porosity, the pore size, and the thickness of trigonal-structured struts. These factors collectively determine the foam performance in catalytic reactions. The SISA is, thus, closely linked to the foam grade and pore size.

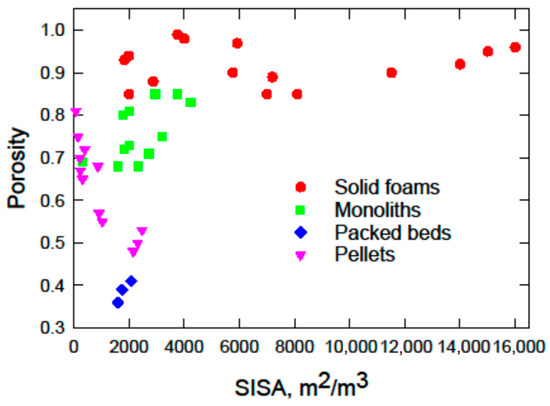

The relationship between the porosity and surface area illustrates how foams differ from other reactor internals; see Figure 3. Solid foams occupy most of the available parameter space, with SISA values reaching up to 16,000 m2/m3, combined with a very high porosity. A high porosity translates into a low flow resistance when foams are used as internals in catalytic reactors. In terms of both the flow resistance and mass-transfer coefficients, foams are positioned between packed beds and monoliths with similar SISA values [141,142]. A comparison of foam carriers with standard monoliths and randomly packed beds of similar geometric surface area shows that reactors filled with solid foams can achieve the same level of methane conversion with shorter reactor lengths and a lower flow resistance [140,143]. This makes metal foam packings an attractive option for efficient reactor design by reducing the pressure drop and reactor volume requirements.

Figure 3.

Porosity and SISA for solid foams and most typical reactor packings.

Solid foams as catalytic layer carriers have been successfully tested in numerous reactions, for example, CO oxidation [141,142,144,145], Fischer–Tropsch synthesis [146,147], the abatement of vehicle exhaust emissions [137], and methane reforming [148,149].

Both open-cell ceramic and metallic foams are recognized as high-performance supports for catalytic methane combustion because of their unique structure and transport properties, particularly under conditions requiring rapid conversion and process intensification. Metal and ceramic foams (e.g., Al2O3, Fe–Ni alloys, and ZrO2) coated or impregnated with catalysts such as PdO, Co3O4, and perovskites achieve faster methane conversion rates and lower ignition temperatures than conventional supports. For example, Pd/Co3O4/Al2O3 foams achieve complete methane conversion below 400 °C at a moderate space velocity, outperforming monoliths under similar conditions [150,151,152]. Experimental studies have shown that metal foams based on FeCr or NiCr alloys exhibit Nusselt and Sherwood numbers comparable to packed beds and far exceeding those of monolithic structures [140,143,153]. Reactor modelling confirms that, for fast kinetics processes such as palladium-catalyzed methane oxidation, mass transfer in foams becomes the limiting factor that allows for shorter reactor lengths at high conversion levels [140,150,153].

For catalytic methane combustion, foams are typically coated with a thin, uniform catalyst layer such as Pd/γ-Al2O3. The effective integration of catalysts with foam carriers depends on coating methods that ensure a uniform coverage, strong adhesion, and easy access to active sites. While traditional techniques such as washcoating and sol–gel deposition are still common, electrophoretic deposition (EPD) has recently emerged as a promising and innovative alternative [154]. Unlike conventional slurry or solution-based approaches, EPD employs an electric field to drive charged catalyst particles from a stable colloidal suspension directly inside the metallic foam structure. Studies indicate that EPD offers exceptional control over the film thickness, deep penetration into the foam’s porous structure, and remarkably uniform coverage.

In summary, open-cell ceramic and metallic foams bridge the performance gap between monolithic honeycombs and randomly packed beds, combining a high specific surface area and excellent heat and mass transfer with a moderate pressure drop. Their unique 3D interconnected architecture, high porosity, and tunable pore geometry allow engineers to tailor reactor internals for both low-resistance flow and intense gas–solid contact. Compared with monoliths of an equivalent geometric surface area, foams typically deliver superior mass transfer rates, enabling shorter reactor lengths for the same conversion, while retaining mechanical robustness and good thermal conductivity, particularly in metallic variants. These traits, coupled with advances in precision coating methods such as electrophoretic deposition, make foams especially attractive for catalytic methane combustion under lean and dilute conditions, where rapid light-off, uniform temperature profiles, and compact reactor footprints are critical. While the cost, coating durability, and scale-up of fabrication remain practical considerations, the balance of the transport performance, design flexibility, and operational robustness suggests that foams will continue to gain importance as structured catalyst carriers in future catalytic combustion systems.

6.4. Comparison of Packed Beds, Monoliths, and Foams

Packed particle beds, monoliths, and foams each offer distinct performance characteristics, and their suitability depends on the balance of the pressure drop, mass and heat transfer, mechanical robustness, and fouling tolerance required by the application. Packed beds provide the highest catalyst bulk density, enabling a high active surface area per unit reactor volume. They are mechanically simple and benefit from decades of operating experience, but have a relatively high pressure drop, which limits the allowable particle size, leading to significant intraparticle diffusion and heat transfer limitations, which are particularly problematic for fast, highly exothermic reactions like methane combustion. They are also more prone to plugging or fouling when particulates are present in the feed. Monoliths overcome many of these drawbacks by providing straight, non-connected channels that combine a high geometric surface area with a low pressure drop, making them ideal for high-throughput and particulate-tolerant systems. Their geometry offers a predictable flow distribution, good heat and mass transfer (especially in turbulent, high-pressure operation), and excellent mechanical durability under vibration and thermal cycling. However, monoliths offer lower bulk catalyst loading than packed beds and can be limited by the laminar flow transport at atmospheric pressure, requiring careful washcoat optimization to avoid internal diffusion resistances. Foams occupy an intermediate position: their open, interconnected 3D structure yields a higher porosity and lower flow resistance than packed beds, with higher mass and heat transfer rates than monoliths of an equivalent surface area, especially under laminar flow. Their pore geometry can be tailored for performance, and metallic foams, in particular, offer a high thermal conductivity for temperature uniformity. Nonetheless, foams generally have a lower geometric regularity than monoliths, making precise modelling more challenging, and fabrication plus coating processes can be more costly or complex to scale. In practice, the selection between these support types hinges on the required compromise between catalyst loading, pressure loss, transport performance, fouling tolerance, thermal management, and economic factors, with packed beds favoured for the maximum catalyst density, monoliths for low-pressure-drop high-flow applications, and foams for high-intensity heat/mass transfer with a moderate flow resistance.

7. Autogenous Reactor Operation

Although there might be exceptions, it is usually desired to run the catalytic combustion reactor adiabatically, and, once the reaction has been initiated, the reactor should ideally operate in an autogenous manner. The energy provided by the combustion reaction should be sufficient to maintain the reaction, without needing an external energy supply. We distinguish autogenous operation from the broader, more general term, autothermal operation, which includes cases where the energy provided by an exothermic reaction is used to drive an endothermic one. We do not consider the latter case, although some authors use the term autothermal in a broad sense that includes autogenous operation.

7.1. Steady-State Systems with Unidirectional Flow

The first choice for reactor design is usually a single-pass unidirectional flow system, with minimum complications for construction and operation. There are many systems where design simplicity is the overwhelming criterion, and, in this case, the only option may be to select a sufficiently large reactor, with a catalyst of the appropriate activity to achieve the desired combustion efficiency. There are many cases where this method is quite feasible. For example, for the combustion of methane emissions from a natural gas vehicle operating under stoichiometric conditions, the engine exhaust gas temperature is usually sufficiently high to allow for acceptable conversion. The exhaust from a lean-burn natural gas engine has a significantly lower temperature; however, there are currently catalysts that will operate at these conditions, although it remains a challenge.

7.2. Steady-State Systems with Internal Recuperation

On the other hand, there are also many fugitive methane streams that are available at ambient temperatures, in the range of 0–30 °C. Some of these streams also have low concentrations of methane, and, thus, are difficult to combust. For these cases, some form of combined reactor and heat exchanger is needed. The obvious solution for the case of a highly exothermic reaction is to use the thermal energy generated by the combustion to heat the feed. A good overview of the broader concept of autothermal operation, including the combination of endo- and exothermic reactions, can be found in [155,156,157].

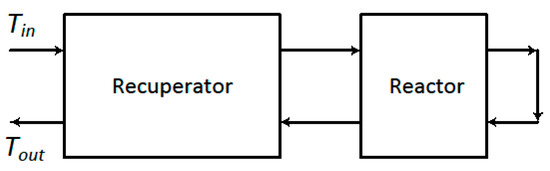

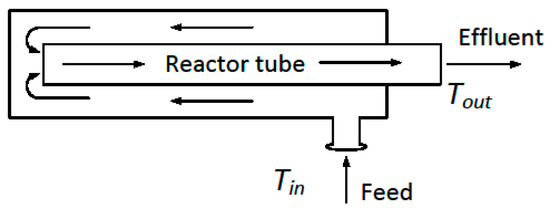

Using the hot effluent to heat the feed requires some form of heat exchanger. Conceptually, the simplest and most straightforward method of integrating heat exchange with the reactor is to add a heat exchanger as a separate unit, in which the feed and effluent exchange heat, as shown in Figure 4. If one assumes constant physical properties, and, furthermore, the use of a simple counter-current-flow single-pass heat exchanger, then the heat transferred in the exchanger is given by the following:

Figure 4.

Simple configuration for a combined reactor and heat exchanger. The arrows indicate the direction of flow.

The temperature driving force is the adiabatic temperature rise for the reaction, assuming 100% conversion. Thus, provided that the overall heat transfer coefficient, U, is known, then the heat exchanger area can be calculated to achieve any desired reactor inlet temperature. This design has an advantage in that one can independently control the heat transfer parameters such as the heat transfer area, and the construction may be easier.

If we move beyond the simple concept shown in Figure 4, there are more integrated systems of the reaction and heat exchange reported in the literature. Although these designs may offer an abundance of subtle variations, in a sense, they are all variations on the theme shown in Figure 5, where the heat transfer area is incorporated along the reactor surface.

Figure 5.

Simple integrated concept of reactor and heat exchanger. The arrows indicate the direction of flow.

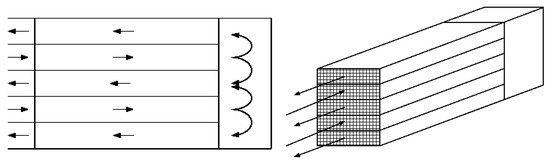

The design shown in Figure 5 is similar in principle to a double-pipe heat exchanger operated in counter-current flow. The cold feed that enters the system is in contact with the hot end of the reactor, and is pre-heated as it flows along the reactor wall. There have been many variations of this integrated theme. For example, there could be multiple reaction and heat transfer layers, as in the small-scale unit proposed for natural gas engines [158], as shown in Figure 6. This design was, in turn, inspired by a design from the literature [159,160]. Other examples of this arrangement have been reported, for example, [161,162]. Another variation on the theme used three parallel channels per unit, with separate reaction and recuperation sections [163].

Figure 6.

Multiple channel reactor recuperator, after [158]. The arrows indicate the direction of flow.

In the application shown in Figure 6, the reactor layers were blocks of washcoated monolith, through which the reacting stream flowed. This work used highly conductive silicon carbide monoliths, and showed that efficient conversion could be achieved, with maximum temperatures larger than the adiabatic temperature rise. The concept can be used with the monoliths being replaced by any suitable reactor internal catalyst support.

Another interesting adaptation of heat exchanger technology was the incorporation of a catalytic washcoat on the walls of a double-spiral heat exchanger [164]. A spiral-design heat exchanger was also used recently as part of an integrated unit for the combustion of VAM directly in the coal mine workings, as shown in Figure 7 [165]. The spiral design for heat exchangers is well-known, and has many advantages over other heat exchanger configurations. They are generally space-efficient and offer a high heat transfer area per unit volume. The spiral design also induces turbulence which, although it increases pressure drop, also enhances the heat transfer rate. The smooth spiral shape also helps to avoid dead zones, and also sharp changes in the flow direction, thus reducing erosion–corrosion. They may, however, be more complex to construct, which can increase the cost.

Figure 7.

An integrated reactor/recuperator system. The central catalyst section is surrounded by a spiral-type heat exchanger [165].

In the design shown in Figure 7, the catalyst was contained in a cartridge in the centre of the system. The catalyst was a series of washcoated monoliths with a state-of-the-art methane combustion catalyst. High central temperatures were achieved, which resulted in complete conversion at high values of the space velocity. Complete details are found in [165].

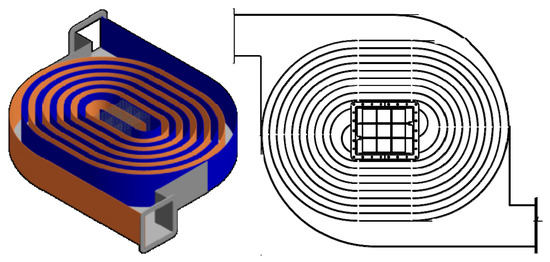

7.3. The Catalytic Flow-Reversal Reactor

Catalytic reactors are commonly operated at steady state, where the temperatures and concentrations are constant at any spatial position as a function of time. The advantages of running at steady state include ease of control and simplicity of operation. However, there are cases where unsteady operation is inevitable, and, over the past decades, some advantages of imposing a transient behaviour have been observed. Changes in the reaction selectivity and conversion can result from the dynamics of the adsorbed surface concentrations of reactive intermediates. There are many publications about forcing unsteady flow with a unidirectional flow; however, a reactor type of significant interest is called the catalytic flow-reversal reactor (CFRR). In this case, the feed is periodically switched between either end of the reactor using the appropriate valves, as illustrated in Figure 8.

Figure 8.

Illustration of the reverse-flow reactor concept. The arrows indicate the direction of flow. Pattern (a) corresponds to forward flow and (b) corresponds to reverse flow.

We refer to Figure 8a and follow the path of the process stream. Valves 1 and 4 are open, whilst valves 2 and 3 are closed. The feed flows to the reactor from left to right (which we can call forward flow). After some time, valves 1 and 4 are closed, and valves 2 and 3 are opened, and the flow then traverses the reactor from right to left, as shown in Figure 8b. A complete cycle consists of these two operations. The elapsed time for each half-cycle is referred to as the switch time. If the forward- and reverse-flow times are the same, the operation is called symmetric reverse flow, and, if the times are different, the operating mode is called asymmetric operation. The sum of the times for forward and reverse flow is the cycle duration.

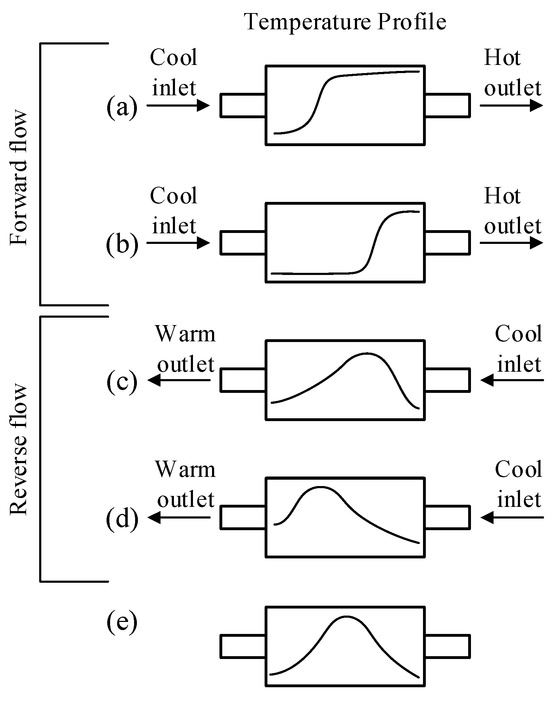

The operating principle for the CFRR can be understood by considering some temperature profiles during operation. For an exothermic reaction, the CFRR has a behaviour referred to as a heat sink [166] and a heat trap [167], which allows for an elevated temperature within the system. The principle of the heat trap effect is illustrated in Figure 9.

Figure 9.

Illustration of the heat trap effect for reverse-flow operation. (a) shows a possible temperature profile for unidirectional flow. (b) shows the progression of the profile towards the reactor exit. (c) shows how switching the flow prevents the hot zone from leaving the reactor, and then (d) shows the reverse progression of the temperature profile. Finally, (e) shows a possible stationary state profile that may finally be achieved.

Consider first the axial temperature profile that might be obtained in a tubular reactor with an exothermic reaction. If the reactor feed temperature is sufficient to allow for the reaction to start, then, at some point, in the reactor, the temperature will rise rapidly as the reaction rate increases exponentially, and then becomes constant as the reactants are consumed and the reaction rate decreases. Such a profile is shown in Figure 9a. Once initiated, the reactor will operate at steady state with a constant profile. However, if the feed temperature were, for example, lowered, then the reaction conditions would be insufficient to maintain autothermal operation, and the steep reaction front would progress towards the reactor exit and the reaction would extinguish. The principle behind the CFRR concept is to reverse the flow before the reaction front can leave the reactor, and the incoming cold feed now encounters a hot catalyst. The energy stored in the hot catalyst bed heats the incoming feed, and, thus, the reaction is allowed to continue, and the reaction front now moves in the opposite direction. The feed is switched back to the other end before the reaction front can exit. Provided that the reactor is initially at a sufficiently high temperature (which may require some auxiliary heat source) and the cycle duration is carefully chosen, it is possible to achieve autothermal reactor operation at feed temperatures well below those required for autothermal operation with unidirectional flow. A quasi-steady-state operation may be achieved in which the reactor temperature profile has a maximum value near the centre of the reactor, which slowly oscillates as the feed is switched between the two ends of the reactor, as shown in Figure 9c–e. Because this stored energy is added to the feed stream, it is possible to achieve temperatures higher than the adiabatic temperature rise based on the fresh feed inlet temperature. A reverse-flow operation in which the solid-phase temperature rise was as high as 13 times the adiabatic temperature rise has been reported [168].

The concept of reverse-flow operation (RFO) originated with its use in packed beds of solids [169,170]. The extension to catalytic reactors (CFRRs) was discussed by Frank-Kamenetski [171]. RFO has been applied to many processes [156]. An early commercial implementation was the oxidation of SO2 [172,173,174], and the technology has since been adapted for methanol synthesis [175,176] and NOX reduction [177,178,179,180]. Periodic flow reversal in packed bed reactors has also been shown to achieve high conversions in the catalytic decontamination of waste gases [181], with 99.5% conversion being reported. In that work, a central heat exchanger was incorporated to remove the excess heat, preventing catalyst deactivation or reactor damage, and allowing the recovered heat to be used for building heating or to drive turbines. The management of heat removal in reverse-flow reactors is further discussed in [166,181,182]. Mass extraction from the central region of the reactor as a means to withdraw energy and control temperature has also been studied [183].

The “heat trap” effect, which leads to elevated temperatures at the reactor centre, makes the process particularly suitable for the catalytic combustion of lean hydrocarbon mixtures at standard conditions. Numerous studies have explored CFRRs for catalytic combustion [181,182,184,185,186,187,188]. Many of these applications target large volumetric flow rates and employ relatively long cycle times. The technology is well-established for the combustion of VAM in underground coal mining, with large-scale units being used in, for example, China [189]. These large-scale units used for coal mines are typically located on the surface. There has been interest in small-scale units that can be used in situ, or for other applications in, for example, the oil and gas industries [183,190,191,192,193].

At a much smaller scale than these mentioned reactors, the CFRR has been used for lean methane combustion in automotive applications. The use of reverse-flow catalytic converters for natural gas and dual-fuel engines has been reported [167,194,195,196,197,198].

The CFRR often uses inert sections to allow for additional storage, and many configurations are possible [192]. Catalysts that have been reported for the catalytic combustion of methane include both fixed beds of particles [132] and monoliths [195,196,197,198]. The choice of catalyst material depends on size constraints on the unit, catalyst activity and cost, and operating variables such as the maximum allowable pressure drop.

Computational modelling can provide much needed insight into the reactor design and operation. Some basic discussion of the mathematics of the CFRR can be found in [156], and typical modelling studies can be found in [177,190,191,193,199,200]. The control of a CFRR can also be complicated, and various strategies have been proposed [201,202,203,204].

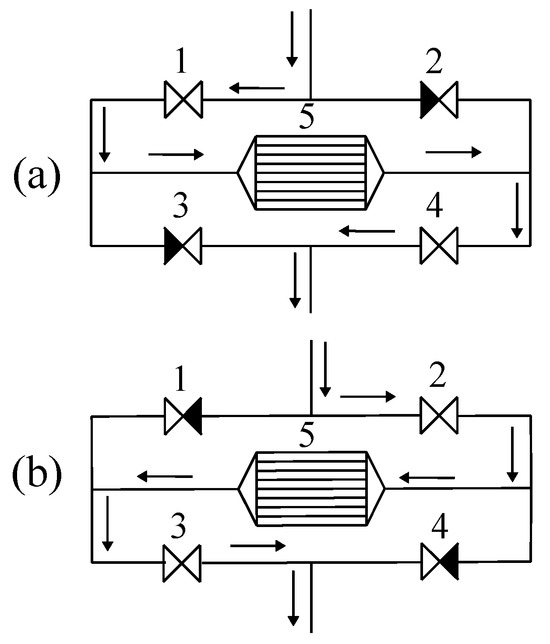

7.4. Counter-Diffusion Reactors

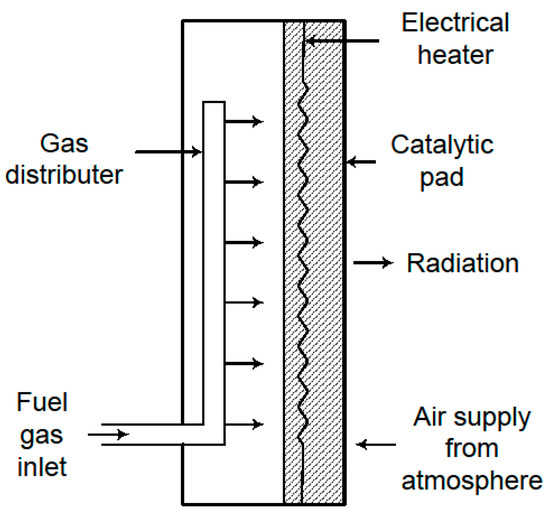

We have noted the challenge of achieving autothermal operation for the low-temperature feed. In the case where a fuel-rich stream is used, an interesting reactor that has seen considerable use in industry is the counter-diffusive reactor. These reactors have been used for radiant heating applications for many years [205,206]. The cross-section of a typical unit is shown in Figure 10.

Figure 10.

Schematic of the cross-section of a counter-diffusion catalytic reactor. The arrows indicate the direction of the flow.

The reactor inlet is located at the back of the unit. Pure fuel is admitted to a plenum chamber through a fuel distributor, and is usually controlled through the use of flow and pressure regulators. The fuel then flows by convection through, first, a porous insulation blanket, and then a porous pad containing the catalyst. The porous insulation blanket reduces energy loss through the back. The catalyst pad is positioned immediately after the insulation blanket. This pad is composed of a fibrous, porous structure that incorporates the active catalytic material. Platinum is the most common catalyst used in commercial systems [207,208], though alternatives such as palladium [209] and various non-noble metals have also been documented [210]. To secure the catalyst pad, a wire mesh is typically placed at its front face. An electric heating element is generally installed between the insulation blanket and the catalyst pad; its function is to elevate the pad’s temperature to a level sufficient to trigger the combustion reaction. Once ignition occurs, the heater is turned off and the reactor operates in an auto-thermal mode.

Oxygen necessary for combustion is supplied by diffusion from the surrounding air. It must first traverse the natural convection boundary layer at the pad’s surface before diffusing into the pad itself, moving counter to the direction of the fuel flow. The principal mode of heat transfer from the reactor is via radiation emitted from the front of the catalyst pad. Additional, though lesser, heat losses occur through convection from the heater’s body and by the bulk gas flow through the system. Key experimental and modelling studies on these reactors are discussed in the following paragraphs.

The early experimental and modelling work was reported by [207,208], whose work was based on a Pt catalyst in the fibre pad. They studied the effect of the methane flow rate on the temperature distribution across and through the catalyst pad. As the methane flow rate increased, the maximum temperature moved toward the front of the pad and the combustion efficiency decreased. Their model predictions were compared to the experimental results and some agreement was obtained. The model predicted that the maximum temperature moved closer to the front of the pad as the flow rate increased. Moreover, as the flow rate increased, a higher fuel slippage was observed; that is, the combustion efficiency decreased and more methane was emitted by the system.

A counter-flow reactor model for methane combustion was proposed [211] and the modelling data were compared with the experimental results from [205] and showed good agreement. The study also reported that the combustion takes place in a thin layer near the front surface of the catalyst panel and that the oxygen diffusion into the catalyst panel is the controlling factor in the conversion efficiency.

These older observations were confirmed in a detailed experimental and modelling study of the counter-diffusive-flow reactor applied to the combustion of methane streams that contained significant amounts of impurities, such as higher hydrocarbons, water, and BTEX compounds (benzene, toluene, ethylbenzene, and xylene) [9,212]. Those investigations confirmed that the diffusion of oxygen from the surrounding air was the rate-limiting step that controlled methane conversion. Fuel slippage was dramatically reduced by enhancing the rate of mass transfer to the front surface using enhanced convection. BTEX and other hydrocarbons were preferentially converted compared to methane, and no slippage of these molecules was observed. Provided that high temperatures could be attained, no effects of large amounts of water were observed.

Radiant heaters are widely used in industry simply for their heating function, but have been increasingly used as emission control devices. They are ideally suited to situations where there are relatively low flow rate streams of the fuel-rich feed. The devices are easily portable and can be started using batteries, for example.

8. Mathematical Modelling of Catalytic Combustion Systems

8.1. Modelling Overview

The early development work in combustion systems was performed essentially on a trial-and-error basis, but the use of computational models became more prevalent as time went on. The advent and increasing availability of low-cost and powerful computational tools have allowed for more fundamental designs. In the context of the advanced computational modelling of catalytic combustion system, we discuss models that are based on the solution of the conservation equations of momentum, mass, and energy, which are represented as partial differential equations (PDEs). Today, there exist a plethora of commercial software products that can be used to solve PDE, which, in many cases, are very user-friendly.

Modelling any system is always a compromise between the computational complexity and desired model accuracy. In this section, we provide some general overview and thoughts about the future directions. We consider the variations on the fixed bed models with packed beds, monoliths, and foams as the internal structure.

8.2. Continuum Reactor Model