Abstract

Enzyme-induced carbonate precipitation (EICP), an environmentally friendly geotechnical reinforcement method, is commonly adopted in water conservancy infrastructure, like reservoir bank slopes. Currently, limited studies have been performed on the mechanical and structural properties of EICP-solidified soil (ES) under freeze–thaw (F-T) cycles. In this study, a series of unconfined compressive strength (UCS) tests were performed to investigate the strength degradation characteristics and failure modes of ES and untreated soil (US) under a various number of F-T cycles. The “freeze–thaw structural parameter Mσ” and “initial freeze–thaw structural parameter Mp” were established to study the structural evolution laws of ES with strain and number of F-T cycles. Finally, the effect of F-T cycles on the microscopic pore structure of soil was investigated. The results indicated that the ES exhibited good strength retention capabilities subjected to F-T cycles. After one F-T cycle, the strength loss rate of the US was as high as 69.33%, while that of the ES was only 64.69% after 15 F-T cycles. The “freeze–thaw structural parameter Mσ” and the “initial freeze–thaw structural parameter Mp” presented the enhancement degree of structural strength and stabilization of ES under F-T cycles. The Mσ with strain could be divided into three stages. The nonlinear fitting results regarding the Mp showed a negative logarithmic relationship with the number of F-T cycles. With various F-T cycles, the pore area ratio of ES increased by an average of 0.603%, lower than that of US, 1.19%. After 10 to 15 F-T cycles, the Feret diameter reduction in ES was only 0.015 μm, which was 7% of the US, verifying the macroscopic test results. In the design of the reservoir slope, Mp and Mσ can be used to evaluate the deterioration of mechanical and structural properties after freeze–thaw disturbance, and to predict the stress and deformation response.

1. Introduction

In the seasonal frozen region, the stability of the reservoir bank slope has become a critical issue in the construction and operation of hydraulic engineering [1,2]. Clay is widely adopted in various hydraulic engineering constructions, like dams [3,4], and bank slopes [5,6], because they have excellent engineering characteristics, such as widespread distribution, low cost, and simple construction [7]. Clay is highly susceptible to plastic deformation and even instability failure under the influence of external factors such as water level fluctuations and loads, due to its fine particle size, large specific surface area, and strong hydrophilicity [8]. Therefore, combined with the characteristics of clay, it is of great significance to explore solidified measures to enhance the mechanical properties and engineering applicability of clay [9,10]. Enzyme-Induced Carbonate Precipitation (EICP) technology, an emerging environmentally friendly method for geotechnical engineering reinforcement, utilized enzymes to catalyze the hydrolysis of urea to produce carbonate ions [11,12]. Calcium carbonate precipitates were generated by the reacting of carbonate ions and calcium ions, which fill the pores and enhance the cementation between soil particles, thereby improving the strength and stability of the soil.

To further expand the engineering application of EICP-solidified technology, numerous laboratory tests have been performed on EICP-solidified soil to reveal the reinforcement mechanisms by several authors. Peng [13] performed triaxial tests and unconfined compression tests to study the mechanical properties of the EICP combined with lignin-solidified clay at room temperature, and demonstrated that the EICP technology noticeably improved the strength. Lignin with a content of 0.75% can mitigate the brittle characteristics of EICP-solidified soil. Wang [14] conducted comparative tests and concluded that the unconfined compressive strength of the EICP-solidified silt soil was 954 kPa, which was higher than that of MICP-solidified soil, 675 kPa. Mehmood [15] proposed that the EICP-solidified expansive soil decreased the expansive force by five times, and the strength increased to 247 kPa after 14 days of curing.

The aforementioned studies primarily focus on the strength characteristics and reinforcement mechanisms of EICP-solidified soil at room temperature conditions. In seasonal frozen soil regions, the calcium carbonate cementation structure formed by EICP can be damaged through periodic frost heave and thaw settlement, affecting the mechanical properties of solidified soil [16]. At present, some scholars have studied the strength degradation characteristics and failure mode of EICP-solidified soil under freeze–thaw cycles. Yuan [17] studied the freeze–thaw durability and environmental risk assessment of silty sand improved by EICP combined with magnesite tailings powder, and analyzed the unconfined compressive strength and secant modulus of EICP-solidified soil. Ahenkorah [18] analyzed the unconfined compressive strength of the EICP-solidified soil under freeze–thaw or dry–wet conditions. All of them verified the good effect of EICP-solidified soil. However, uncertainties regarding their structural properties have impeded the wide application and the economic benefits of EICP-solidified technology in water conservancy infrastructure such as bank slopes.

The essence of soil mechanical properties is the macroscopic response of its internal structure. Therefore, structural damage inevitably leads to the degradation of soil mechanical properties. Several scholars have found that the macroscopic mechanical behavior, compressibility, and strength, were directly affected by cementation characteristics and the arrangement of soil particles [19,20]. To determine the microstructural and damage evolution laws of soil during the loading process [21], existing studies primarily focused on comparing the mechanical properties of undisturbed soil and remolded soil, such as strength and compressibility. Wu [22] investigated the effects of water content and dry density on the deformation characteristics and strength variation laws of undisturbed loess through conventional triaxial shear tests and concluded that water content exhibited the greatest impact on loess structure using redefined structural parameters. Wu [23] proposed the structural parameters for undisturbed loess, which was defined based on the shear strength of undisturbed loess and remolded saturated loess, reflecting the strength characteristics and essential properties of the soil. Structural performance decreased as the ratio of dry density to porosity increased, and increased as the plastic limit increased. Yao [24] proposed a new structural parameter, stress ratio sensitivity (Sη), based on the mechanical sensitivity of undisturbed and remolded loess. The validity of the parameter was verified by conducting triaxial shear tests on specimens with different water contents. Tremblay [25] studied the compression characteristics of silt-stabilized soil by introducing the concept of the inherent compression curve to predict the yield stress of artificially structured soil.

The above authors had conducted quantitative studies on different types of structural soils. However, structural parameters should be able to describe the special properties of a soil, such as, the collapsibility for collapsible loess, the expansivity for expansive soil. Therefore, the structural quantitative indicators for EICP-solidified soil (ES) should be able to describe the improvement effects of strength and structural properties. Currently, Shao [21] defined the structural property parameter of loess based on the unconfined compressive strength of the undisturbed, remolded, and undisturbed saturated soils, and conducted quantitative research on the structural strength of undisturbed soils under immersion saturation and loading conditions. However, the structural property parameter had the following limitations. Firstly, the existing structural property parameter failed to characterize the structural reinforcement effect of ES. Secondly, the structural property parameter could not exhibit the evolution process of soil structural property with increasing strain under loading conditions. Thirdly, the structural parameters could not reflect the influence of freeze–thaw (F-T) cycles on soil structure. Finally, the parameter could not reveal the coupled evolution laws on soil strength and structural characteristics during F-T cycles.

Based on the above analyses, a series of laboratory unconfined compressive strength tests were conducted on EICP-solidified soil (ES) under freeze–thaw (F-T) cycles to establish the mechanical properties and structural evolution patterns. The predictive function between structural parameter and mechanical index was established. The evolution laws of micro pore parameters of the ES under F-T cycles were analyzed by scanning electron microscopy (SEM). The experimental results of this study can provide a reference for the design and application of EICP technology in seasonal frozen soil regions.

2. Materials and Methods

2.1. Test Materials

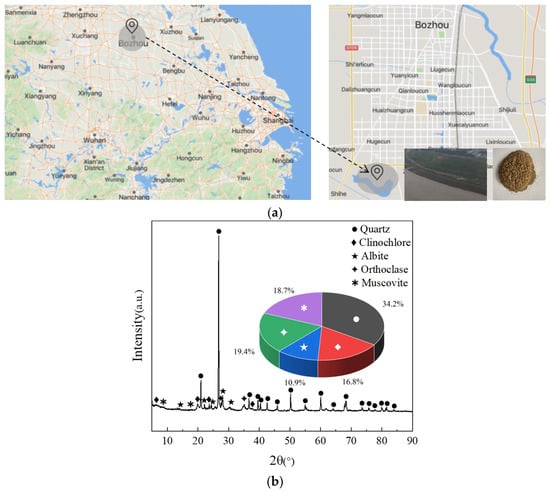

The soil used in this study was taken from the reservoir bank slope in the Bozhou area of Anhui Province, China, with a sampling depth of 0.5 m below the slope surface, as shown in Figure 1a. The main mineral components of the soil were quartz, chlorite, sodium feldspar, orthoclase, muscovite, and other hydrophilic minerals, through XRD, as shown in Figure 1b. The fundamental physical indicators of the soil were shown in Table 1. The test soil was classified as low liquid limit clay according to the Unified Soil Classification System (USCS) (ASTM D2487-17) [26].

Figure 1.

The geographical location and composition of soil used in the experiment: (a) the location of the soil used in this study; (b) the composition of the soil.

Table 1.

Basic physical indicators of soil.

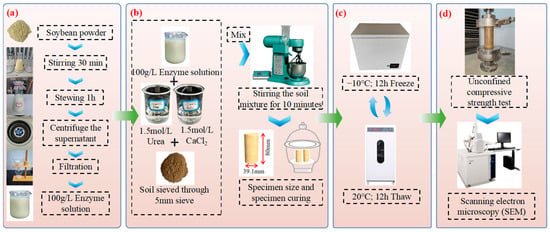

The EICP solution used in the test was composed of an enzyme solution and a cementing solution mixed in a 1:1 volume ratio. The enzyme was derived from raw soybeans, and the production process is shown in Figure 2a. The concentration of the enzyme solution was 100 g/L [27]. The cementing solution consisted of a urea solution and calcium chloride solution, both with a concentration of 1.5 mol/L, mixed in a volume ratio of 1:1. The function of the cementing solution is to provide carbon and calcium sources for the EICP. According to the conductivity method [28], the enzyme had an average activity level of about 12 mmol/min. The formula of enzyme activity (EA) is shown in Equation (1).

where 10 is the dilution multiple of enzyme solution, ΔU is the change value of conductivity within 5 min, 11.1 is the conductivity change of 1 mS/min corresponding to the enzyme activity of 11.1 U (1.0 U = 1.0 mmol/(L·min)).

Figure 2.

Flow chart of test process: (a) production process of enzyme solution; (b) specimen preparation; (c) freeze–thaw cycling tests; (d) unconfined compressive strength and SEM tests.

2.2. Experimental Program

2.2.1. Specimen Preparation

This study included three types of soil specimens, EICP-solidified soil (ES), untreated soil (US), and EICP-solidified saturated soil (ES_Sr), for the purpose of investigating the strength and structural properties of the ES. The specimens of ES were obtained by mixing prepared EICP solution with dry clay. The specimens of US were obtained by mixing water with dry clay. The specimens of ES_Sr were obtained by saturating ES through the vacuum saturation method referred to in the Standard for geotechnical testing method (GB/T 50123-2019) [29]. All soil specimens were prepared using the optimum moisture content. The preparation process of soil specimens was shown in Figure 2b. The dimensions of the soil specimens were 39.1 mm in diameter and 80 mm in height [29]. It should be noted that the specimens were sealed and placed into a constant temperature and humidity curing box. The curing conditions were controlled at 25 °C and 95% humidity for curing 14d to ensure that the enzyme-catalyzed hydrolysis of urea proceeded adequately.

2.2.2. Freeze–Thaw (F-T) Cycling Tests

Freeze–thaw (F-T) cycling tests were conducted in low-temperature freezers and constant-temperature test chambers, as shown in Figure 2c, to simulate the freeze–thaw process of soil. Based on the daily temperature variation range in winter of the Bozhou area (2020–2025) of Anhui, China, the freezing and thawing temperatures were set as −10 °C and 20 °C, respectively. According to the research of Yang [30] and Yuan [17,31], F-T cycling tests were conducted in this temperature range with the number of F-T cycles (N) being 0, 1, 3, 6, 10, 15. Based on the work of Yuan [31] and ASTM D560M-24 [32], the duration of 12 h were selected for both freezing and thawing to simulate the freeze–thaw process of soil. To prevent moisture loss during the freeze–thaw cycle, the soil specimens were wrapped in plastic wrap during the testing process.

2.2.3. Unconfined Compressive Strength Test (UCS Test)

The unconfined compressive strength test, which can obtain the unconfined compressive strength and stress–strain curve of soil, is a commonly used method for testing the mechanical properties of soil. The tests were conducted on soil specimens subjected to a various number of F-T cycles using an electronic universal testing machine, as shown in Figure 2d. The test conditions controlled the compression rate to 1% strain per minute until the cumulative strain reached 15% referred to in the Standard Test Method for Unconfined Compressive Strength of Cohesive Soil (ASTM D2166-16) [33]. The EICP-solidified soil and untreated soil showed the stress “σ” -strain “ε” curves, peak stress “qu” and failure modes to characterize their mechanical properties. To ensure the accuracy of the test data, the unconfined compressive strength of the specimens was determined by taking the average value of three parallel specimens.

2.2.4. Structural Analysis of EICP-Solidified Soil

Shao [34] established a structural parameter to describe the initial structure of loess based on the unconfined compressive strength of the undisturbed loess, remolded loess, and saturated loess. This structural parameter reflected the stability and variability of the loess structure by releasing the water sensitivity potential and disturbance potential of loess. In this study, following the idea of comprehensive structural potential, EICP-solidified soil (ES) was regarded as structural undisturbed soil, EICP-solidified saturated soil (ES_Sr) as saturated undisturbed soil, and untreated soil (US) as remolded soil to investigate the structural properties of the ES.

2.2.5. Scanning Electron Microscopy (SEM)

The specimens of ES and US subjected to 0, 1, 3, 6, 10, and 15 F-T cycles were analyzed using scanning electron microscopy (SEM) to investigate their microscopic pore structures. Firstly, specimens were selected from natural cross-sections for testing, with sample dimensions of 5 mm × 5 mm × 5 mm (length × width × height). Secondly, the specimens were dried in a vacuum freeze dryer to prevent changes in their microstructure. Subsequently, the dried specimens were affixed to the specimen stage using conductive adhesive. Finally, the microstructure of the specimens was observed and photographed using SEM by selecting the appropriate magnification (2000×).

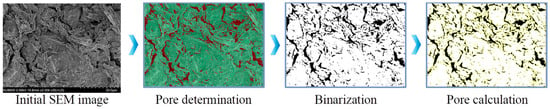

The parameters of pore area ratio and Feret diameter were obtained using image processing software, and the calculation process is shown in Figure 3. Five positions were selected for each specimen for photography. To ensure the accuracy of the experimental data, the mean values of pore parameters at five locations were analyzed under the same operation method. The Feret diameter is used to describe the diameter of irregularly shaped pores. The diameter is measured at every 10° from the center of the pore, and the average of the measured values is taken as the Feret diameter [35,36]. The formula of pore area ratio “F” is shown in Equation (2).

where F is the pore area ratio, Av is the total pore area, and A0 is the total area.

Figure 3.

The process of calculating pore parameters.

3. Results and Discussion

This section presents a summary of the experimental results and analyses obtained from the unconfined compressive strength test of EICP-solidified soil (ES) under freeze–thaw (F-T) cycling conditions. Firstly, a comparative study was conducted on the stress–strain curves, strength degradation patterns, and failure modes of ES and untreated soil (US) before and after F-T cycles. Then, by constructing the “Freeze–thaw structural parameter Mσ” and “Initial freeze–thaw structural parameter Mp”, the evolution laws of the structural properties were studied by the ES with strain and the number of F-T cycles, respectively. Meanwhile, a strength prediction model for the ES was established. Finally, the impact of F-T cycles on the microscopic pore structure of the soil was investigated using SEM.

3.1. Analysis of Mechanical Properties and Failure Modes of EICP-Solidified Soil Under Freeze–Thaw Cycles

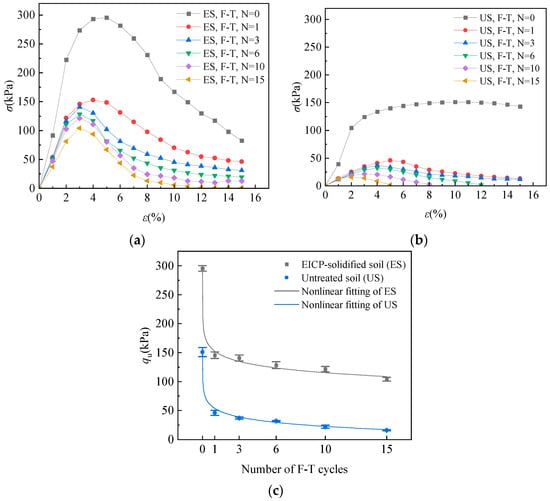

Figure 4 shows the stress (σ)–strain (ε) curves of ES and US obtained from the unconfined compressive strength tests under various numbers of F-T cycles. As can be seen from Figure 4a, the stress–strain curves of the ES remained basically consistent before and after F-T cycles, and showed a strain softening behavior. From Figure 4b, the stress–strain curve of the US showed a strain hardening behavior before the F-T cycle, which was similar to the experimental results of Peng [13]. It should be noted that the stress–strain curves of US showed a softening behavior after F-T cycles, owing to the fact the US could not support greater loads to maintain the process of plastic deformation, resulting in failure at the initial stage of loading.

Figure 4.

Results of unconfined compression strength tests on ES and US: (a) ES; (b) US; (c) nonlinear fitting results.

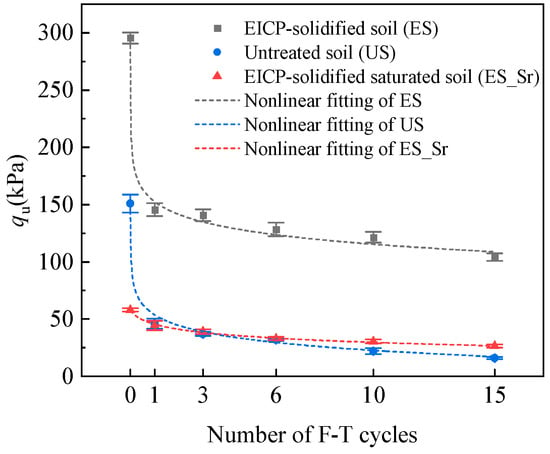

The unconfined compressive strength of the US was 150 kPa before F-T cycles, as shown in Figure 4c. The unconfined compressive strength of the US decreased to 46 kPa after one F-T cycle, with a strength loss rate of 69.33%. The strength further decreased to 36 kPa after three F-T cycles, and the strength loss rate reached 76%. After 15 F-T cycles, the strength was only 16 kPa, and the strength loss rate reached as high as 89.33%. The results showed that the strength and damage resistance of the US decreased significantly.

The unconfined compressive strength of the ES was 295 kPa before the F-T cycle, which was 96.67% higher than that of the US, indicating that EICP technology can significantly improve the strength characteristics of clay. The unconfined compressive strength of the ES decreased, which was relatively small, with an increase in the number of F-T cycles. After one F-T cycle, the unconfined compressive strength of the ES decreased to 146 kPa, with a strength loss rate of 50.51%; after 3 F-T cycles, the strength decreased to 141 kPa, with a strength loss rate of 52.2%; After 15 F-T cycles, the strength was 104.15 kPa, with a strength loss rate of 64.69%.

Based on the above analysis, the unconfined compressive strength of the soil decreased significantly due to the stage characteristics of the evolution process in microscopic pores. During the initial freezing stage, owing to the rapid crystallization and expansion of free water and weakly bound water, the soil skeleton was concentratedly destroyed by frost heave stress, causing irreversible expansion of the original pores, and transforming closed pores into connected pores. The soil skeleton was damaged after thawing, losing the elastic recovery, which cannot shrink back to the initial state, resulting in permanent pore expansion damage. The connectedness of soil pores was consistently strengthened with an increase in the number of freeze–thaw cycles. However, the rate of the increasing pore area slowed down, and the marginal effect significantly weakened. It was indicated that, in the early F-T cycle, the damage for soil was dominated by the expansion of pore size, while subsequent stages were dominated by soil particle rearrangement.

The unconfined compressive strength of the ES, although with a decrease, remained higher than that of US subjected to the same number of F-T cycles. After three F-T cycles, the unconfined compressive strength of the ES increased by 291.67% as compared to US, indicating that the ES had better strength retention capabilities under F-T cycles and could effectively resist the negative impacts. The nonlinear fitting plot of the number of F-T cycles versus the unconfined compressive strength qu are shown in Figure 4c. It can be seen that the nonlinear fitting results of the specimens showed good agreement with the experimental data, and the fitting correlation coefficients were all above 0.99. As shown in Figure 4c, the unconfined compressive strength of the soil under the freeze–thaw cycles had a certain discreteness. The error bars of EICP-solidified soil were generally short, and the standard deviations were lower than 6% of the average. The data dispersion was small, which reflected the good uniformity of EICP-solidified soil. The error bars of the untreated soil were relatively longer. The standard deviations were less than 8% of the average. Compared to the EICP-solidified soil, the qu of the untreated soil had a larger discreteness, which reflected the poorer uniformity and more uneven pore distribution of the untreated soil. However, the overall data error of soil specimens was relatively small, showing high reliability and reproducibility [37,38].

Based on the above analysis, the freezing and thawing of water within the soil pore was an important physical factor on the variations in soil pore structure. When the temperature dropped, the water in the soil pores was frozen and expanded in volume, generating frost heave. For the US, owing to frost heaving, the pore area ratio increased, causing the loose structure. These changes were attributed to the weakening of cementation (organic cementation and weak water cementation) and the rearrangement of soil particles. As for the ES, part of the soil pores were filled and cemented by calcium carbonate precipitates to maintain the relative integration of the soil structure. However, the enhancement effect of calcium carbonate precipitates in the soil particles was still damaged by frost heave, leading to the detachment and fracture of calcium carbonate precipitates. Some studies have mentioned that freeze–thaw and wet–dry cycles can damage the internal structure of soil and increase the deterioration of the pore structure of biocemented soil [17,39], which is consistent with the mechanism of freeze–thaw induced increase in soil porosity and strength degradation in this study.

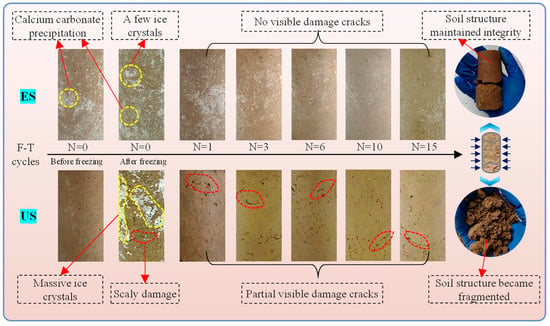

Figure 5 shows the surface morphology of the ES and US with various numbers of F-T cycles. From Figure 5, the following experimental phenomena are observed. Before freezing (N = 0), the surface of the ES showed white calcium carbonate precipitates while the US had no precipitates. After the first freeze (N = 0), the surface of ES presented a few ice crystals with few visible cracks. After thawing (N = 1), the surface of the ES presented no visible cracks after the ice crystals melted. In contrast, the surface of the US, after the first freeze (N = 0), presented a large amount of ice crystals with scaly damage. After thawing (N = 1), damaging cracks occurred on the surface of the US. After 15 F-T cycles, the surface of the ES still exhibited no obvious damaging cracks, maintaining the integrity of the structure even under forceful extrusion, while the structure of the US appeared loose and fragmented upon slight extrusion.

Figure 5.

Comparison of the surface morphology of the ES and US under the F-T cycles.

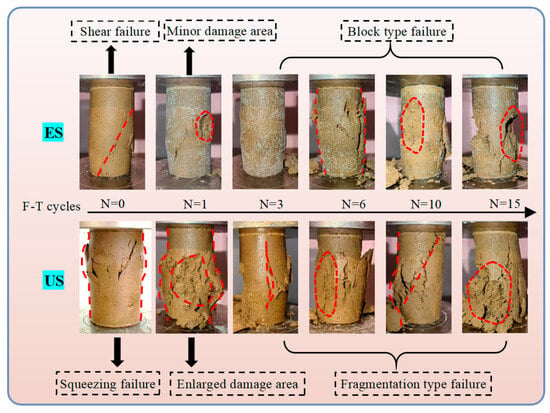

Figure 6 shows the failure mode of the ES and US at the strain of 10%, after various F-T cycles. Firstly, before freezing (N = 0), the ES showed shear failure, while the US presented extrusion failure with drum deformation. Subsequently, after one F-T cycle, the ES showed relatively good structural integrity after compression, with only minor damage to the surface, while the surface of the US presented extensive damage. Finally, with increasing F-T cycles, the ES showed block type failure, and the US presented fragmentation type failure. It was indicated that the strength of the soil was enhanced by EICP-solidified technology, which enabled the reduction in deformation and the formation of damaging cracks in soils after the F-T cycles, and significantly decreased the damaged area of soil after compression. However, the peak strength of the ES decreased, indicating that the structure of the soil was still damaged after the F-T cycles.

Figure 6.

Failure modes of the ES and US at a strain of 10%.

3.2. Analysis of Structural Evolution of EICP-Solidified Soil Under Freeze–Thaw Cycles

Based on the analysis in Section 3.1, the surface of the ES showed no visible damage after F-T cycles (Figure 5). However, the unconfined compressive strength degraded significantly (Figure 4c). This suggested that the freeze–thaw-induced damage to the soil was primarily attributed to the deterioration of the internal structure.

To further analyze the effect of freeze–thaw on the soil structural properties, the unconfined compressive strength test results of EICP-solidified saturated soil (ES_Sr) were introduced. The plot of unconfined compressive strength versus the number of F-T cycles for ES, US, and ES_Sr is shown in Figure 7. As can be seen in Figure 7, the curve of the ES showed a similar structural potential to the undisturbed soil with a high strength. The unconfined compressive strength of the ES_Sr showed a gradually decreasing trend with increasing F-T cycles, which was similar to that of the US. It was indicated that after saturation, the ability of the ES to resist partial F-T damage was basically lost, which was similar to the destruction of soil particle cementation and arrangement in the undisturbed soil after saturation. Therefore, it was valid to apply the theory of comprehensive structural potential of undisturbed soil to the structural properties study of ES, based on the test results.

Figure 7.

Unconfined compressive strength “qu” vs. number of F-T cycles.

Based on the reinforcement mechanism of structural properties in ES, the “structural enhancement coefficient m1” was defined as the ratio of the stress σES_N of ES after N freeze–thaw cycles to the stress σUS of US (N = 0) with the same strains. The “structural enhancement coefficient m1” represented the ability of ES to enhance soil strength under external loads. The greater the m1, the better the soil structural strength was enhanced, and vice versa. The “immersion disturbance coefficient m2” was defined as the ratio of the stress σES_Sr of EICP-solidified saturated soil (N = 0) to the stress σES of ES (N = 0) with the same strains. The “immersion disturbance coefficient m2” represented the resist ability of the ES to degrade soil strength under a saturated state. The smaller the m2, the greater the soil structural strength was disturbed, and vice versa. The “freeze–thaw structural parameter Mσ” was established to investigate the evolution laws of the structural properties for ES with increasing strain under F-T cycles. The newly established structural quantitative parameters can reflect the structural characteristics of ES under F-T conditions, which reflected the structural reinforcement capability and resistance to water immersion disturbance of the ES through structural reinforcement potential and released water sensitivity potential. The “freeze–thaw structural parameter Mσ” was defined as the product of the “m1”and “m2”. The greater the Mσ, the higher the structural strength and stabilization of ES presented. The formula of “freeze–thaw structural parameter Mσ” was shown in Equation (3).

where Mσ was the freeze–thaw structural parameter, m1 was the structural enhancement coefficient, m2 was the immersion disturbance coefficient; σES_N was the stress of ES after N freeze–thaw cycles (N = 0, 1, 3, 6, 10, 15), σUS was the stress of US (N = 0), σES_Sr was the stress of ES_Sr (N = 0), σES was the stress of ES (N = 0), kPa.

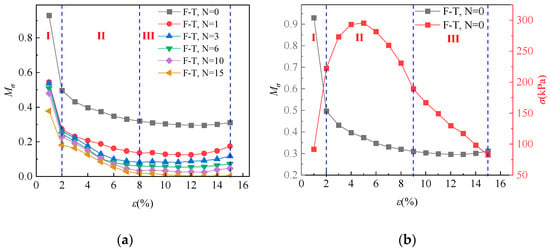

The plot of “freeze–thaw structural parameter Mσ” versus the strain with various F-T cycles was shown in Figure 8. From Figure 8, with the increase in number of F-T cycles, the plot of “Mσ” gradually shifted down, indicating that the structural strength and stabilization of ES degraded. In addition, the curves exhibited a decreased trend with increasing strain.

Figure 8.

The evolution laws of “freeze–thaw structural parameter Mσ”. (a) the plot of Mσ vs. Strain; (b) the comparison with Mσ and σ in various stages.

Observing the evolution process of “freeze–thaw structural parameter Mσ” of ES before F-T cycles (N = 0), the process of the curve could be divided into three stages, namely stage I, stage II, and stage III, as shown in Figure 8a,b. Stage I showed the significant drop of Mσ. In this stage, the soil structure was gradually compacted with minimal plastic deformation, and was less susceptible to damage, owing to the cementing and filling effects of calcium carbonate precipitates between soil particles. Stage II represented the transition of Mσ degradation. In this stage, with the increase in strain, the soil structure strength gradually decreased with larger plastic deformation, due to partial cementation damage and rearrangement between soil particles. Stage III was the stable process of soil structure. In this stage, the soil structural arrangement was gradually stabilized owing to the destruction of the cementation and densification effects in the soil particles, resulting in the significant decrease in unconfined compressive strength.

The above analyses focused on the structural evolution laws of ES with the strain. In order to reveal the structural evolution law of ES with increasing the number of F-T cycles, the “initial freeze–thaw structural parameter Mp” was proposed. The “initial structural enhancement coefficient n1” was defined as the ratio of unconfined compressive strength of ES after N freeze–thaw cycles (qES_N) to unconfined compressive strength of US before F-T cycles (qUS) (N = 0). The greater the n1, the better the soil structural strength was enhanced. The “initial immersion disturbance coefficient n2” was defined as the ratio of the unconfined compressive strength of the ES_Sr (qES_Sr) (N = 0) to the unconfined compressive strength of the ES (qES) (N = 0). The smaller the n2, the greater the soil structural strength was disturbed. The “initial freeze–thaw structural parameter Mp” was defined as the product of “n1” and “n2”. The greater the Mp, the higher the structural strength and stabilization of the ES presented. The formula of “initial freeze–thaw structural parameter Mp” is shown in Equation (4).

where Mp is the initial freeze–thaw structural parameter, n1 is the initial structural enhancement coefficient, n2 is the initial immersion disturbance coefficient; qES_N is the unconfined compressive strength of ES after N freeze–thaw cycles (N = 0, 1, 3, 6, 10, 15), qUS is the unconfined compressive strength of US (N = 0), qES_Sr is the unconfined compressive strength of saturated ES_Sr (N = 0), qES is the unconfined compressive strength of ES (N = 0), kPa.

The comprehensive structural potential parameter was proposed by Xie [19]. The structure index reflecting the initial structure of undisturbed loess was proposed by Shao [21,34]. The above two parameters reflect the sensitivity of undisturbed soil after being disturbed. The stronger the structure of undisturbed soil, the more vulnerable it is to disturbance. Different from the above two structural parameters, EICP-solidified soil needs to use the strength advantage of strong structural soil, and to weaken the instability characteristics of strong structural soil. The structural parameters Mσ and Mp proposed in this study reflect the stability of the EICP-solidified soil after being disturbed. The greater the Mσ and Mp, the stronger the ability of EICP-solidified soil to enhance structural strength and maintain structural stability. The Mσ, defined as the product of m1 and m2, is a parameter describing the process evolution, which can reflect the ability of EICP-solidified soil to enhance structural strength and maintain structural stability during loading. The Mp, defined as the product of n1 and n2, is a parameter reflecting the initial structural strength enhancement and the ability to maintain the initial structural stability of EICP-solidified soil after immersion disturbance.

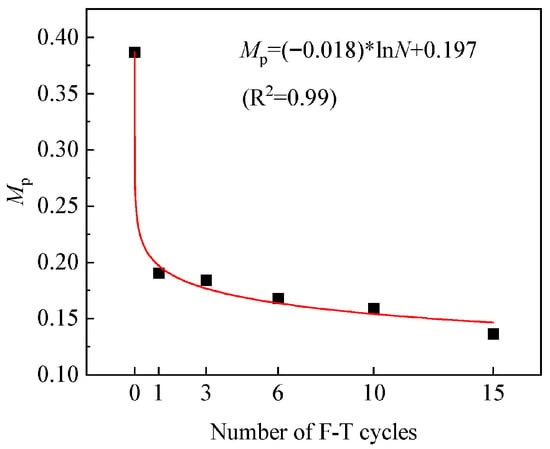

The plot of the nonlinear fitting results regarding the “initial freeze–thaw structural parameter Mp” with the number of F-T cycles is shown in Figure 9. From Figure 9, it can be seen that the nonlinear fitting results had a negative logarithmic relationship, showing good agreement with the experimental data. Before F-T cycles, the Mp was the largest, at 0.39, indicating the greatest structural strength and stabilization of ES. After the first F-T cycle, the Mp decreased most significantly, by 51%, indicating that the soil structural strength and stabilization decreased significantly. The reason was that, in the early F-T cycle stage, the freezing and migration of water molecules caused the irreversible destruction of the cementation and arrangement of soil particles. The Mp decreased by 65% after 15 F-T cycles, which is only a 14% decrease as compared to the first F-T cycle, indicating that the variability of the soil structure decreased. The reason was that the expansion of soil pores was gradually weakened with the increasing number of F-T cycles. However, some of the structural strength and stabilization were preserved due to the cementation and densification of the EICP-solidified technology.

Figure 9.

Nonlinear fitting results of “initial freeze–thaw structural parameter Mp”.

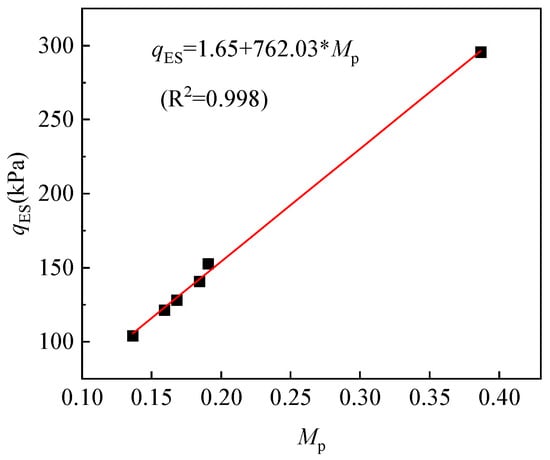

Based on the above “freeze–thaw initial structural parameter Mp”, a freeze–thaw strength prediction model of the ES was established. The qES and Mp exhibited a linear normalization relationship. The linear fitting results are shown in Figure 10 and Equation (5).

where qES is the unconfined compressive strength of ES, Mp is the initial freeze–thaw structural parameter, and the fitting correlation coefficient is 0.99.

Figure 10.

“Initial freeze–thaw structural parameter Mp” vs. unconfined compressive strength qES.

By comparing the linear fitting results with the experimental data, the prediction error was found to be less than 2%. These results indicated that the freeze–thaw strength prediction for ES exhibited satisfactory fitting and prediction accuracy.

3.3. Analysis of Microscopic Pore Structure Evolution of EICP-Solidified Soil Under Freeze–Thaw Cycles

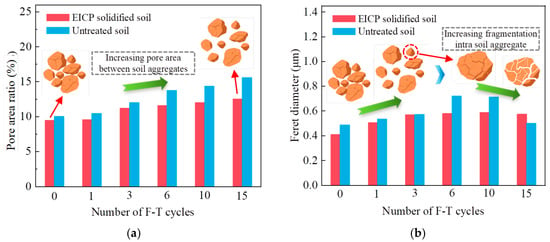

Based on the above analyses, the pore structure of soil exerted a significant influence on soil mechanical characteristics and structural properties. Therefore, typical SEM images were selected to analyze the evolution laws of the microscopic pore structure of the ES. The pore area ratio and Feret diameter of the ES and US with a different number of F-T cycles were obtained through image processing of SEM, as shown in Figure 11a. From Figure 11a, with an increasing number of F-T cycles, the pore area ratio of ES and US was gradually increased. Compared to the US, the pore area ratio of the ES increased by an average of 0.603%, which was lower than that of US, 1.19%. The increasing pore area ratio of ES was less evident as the number of F-T cycles increased. The reason was that the damage of the pore structure was alleviated by the calcium carbonate cementation and densification. Meanwhile, the enhancement effect of EICP-solidified technology was demonstrated via macroscopic mechanical tests.

Figure 11.

The evolution patterns of pore area ratio and Feret diameter under F-T cycles. (a) Pore area ratio; (b) Feret diameter.

The plot of the Feret diameter with the number of F-T cycles is shown in Figure 11b. From Figure 11b, the trend of the Feret diameter in the ES and US with the increase in the number of F-T cycles was first increased and then decreased. The evolution pattern showed that the numerous soil aggregates were separated by the freezing-induced expansion of pore water in the early F-T cycles, causing the increase in Feret diameter. However, in the later F-T cycles, changes in pore structure shifted from separation between soil aggregates to fragmentation intra soil aggregate, resulting in a decrease in Feret diameter [36].

After 10 to 15 F-T cycles, the Feret diameter reduction in ES was only 0.015 μm, while the US was 0.213 μm, which was 14.2 times larger than ES, due to the availability of more cemented compounds to cement the soil particles together, and densification. It should be noted that the diameter of the US increased significantly between 6–10 cycles, owing to the separation of large soil aggregates. After 10 F-T cycles, the large diameter pores increase gradually slowed down, while the number of micro-pores inside soil aggregates increased significantly. Hence, a significant decrease in diameter was observed on the US due to fragmentation within soil aggregates, while there was a slight decrease on the ES. It can also be verified from Figure 5 that, after 15 F-T cycles, the structure of the ES still maintained a block state under forceful extrusion, whereas the US was broken down into smaller fragments under slight extrusion.

Based on the above research, the following ideas are summarized so that the research may contribute to sustainability. On the one hand, from the perspective of micro-scale mechanisms, EICP-solidified technology enhances cementation and optimizes the structural arrangement of soil particles, thereby effectively increasing mechanical strength and improving structural stabilization. On the other hand, from the perspective of macro-scale reinforcement approaches, recommendations include increasing the concentration of the cementation solution and employing the surface spraying of the EICP-solidified solution to reduce moisture content in the pore structure, thus enhancing the F-T durability of the ES on reservoir bank slopes.

4. Conclusions

- (1)

- The unconfined compressive strength of the EICP-solidified soil (ES) and untreated soil (US) showed strength degradation with the increase in number of freeze–thaw (F-T) cycles, especially significantly after one F-T cycle. The reason was that the microscopic pore damage of soil showed stage characteristics with the increase in the number of F-T cycles. In the early stage, irreversible expansion damage of pores was observed, and the damage slowed down due to the buffering of residual pores in the later stage.

- (2)

- The strength degradation of soil subjected to F-T cycles was improved effectively by EICP-solidified technology. After 15 F-T cycles, the strength loss rate of ES was only 64.69% with no visible damage cracks, exhibiting block type failure. Compared to the ES, the US was as high as 69.33% after one F-T cycle, and after 15 cycles, was increased to 89.33%, presenting fragmentation type failure.

- (3)

- The “freeze–thaw structural parameter Mσ” exhibited the evolution law of the ES structural strength and stabilization with increasing strain under F-T cycles. The evolution laws of the curves, first increased and then decreased, could be divided into three stages, namely the significant drop of Mσ, the transition period of Mσ degradation, and the stable process of Mσ.

- (4)

- The “initial freeze–thaw structural parameter Mp” showed the evolution law of the ES structural strength and stabilization with increasing the number of F-T cycles. The fitting results had a negative logarithmic relationship with the number of F-T cycles. Moreover, the qES (unconfined compressive strength of ES) and Mp exhibited a linear normalization relationship.

- (5)

- The pore area ratio of ES and US increased with the increase in the number of F-T cycles. The pore area ratio of the ES was smaller than the US, indicating that the increase in pore area was alleviated by the effect of calcium carbonate precipitates’ cementation and densification. The evolution laws of the Feret diameter showed a trend of first of increase and then decrease, indicating that the failure process shifted from between soil aggregates to intra aggregate with increasing the number of F-T cycles.

In the design of the reservoir slope, Mp and Mσ can be used to evaluate the deterioration of the mechanical and structural properties after freeze–thaw disturbance, and to predict the stress and deformation response. Meanwhile, the ammonium by-products produced by EICP technology may cause potential hazards such as water eutrophication and soil acidification [40]. In the follow-up work, the use of bionic hydrogels [41,42], environmentally friendly urea sources, and extraction of ammonia by-products near water bodies [43] can be further considered to alleviate the above hazards.

Author Contributions

Writing—original draft preparation: F.Y.; Writing—review and editing: F.Y. and W.Z.; Validation: W.Z.; Funding acquisition: W.Z.; Methodology: F.Y. and W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Key Research and Development Program of China (2019YFC1509800), Research project of Yangtze-to-Huaihe water diversion (YJJH-ZT-ZX-20221130515).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Acknowledgments

Thank you to Qibing Zhang for providing financial and on-site support. He has provided significant assistance with on-site investigation and soil sampling testing, as well as guidance and supervision for the verification of experimental results. Additionally, Junwei Shang provided guidance in experimental design and methodology, optimizing the process and characterization methods for micropore testing. We extend our warm and heartfelt thanks to the aforementioned two authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, Y.R.; Gao, C.F.; Zhuang, W.Y.; Wei, C.Y.; Qi, Z.L.; Zhang, K.; Hou, S.K. Prediction and early warning analysis of reservoir bank slopes based on anti-sliding stability evolution. Geosci. Front. 2025, 16, 102113. [Google Scholar] [CrossRef]

- Yang, Z.; Mou, X.Y.; Ji, H.L.; Liang, Z.H.; Zhang, J.H. Effects of freeze–thaw on bank soil mechanical properties and bank stability. Sci. Rep. 2024, 14, 9808. [Google Scholar] [CrossRef]

- Moro, K.; Hoth, N.; Roscher, M.; Kaulfuss, F.; Vianney, J.M.; Drebenstedt, C. Characterization of Historical Tailings Dam Materials for Li-Sn Recovery and Potential Use in Silicate Products—A Case Study of the Bielatal Tailings Dam, Eastern Erzgebirge, Saxony, Germany. Sustainability 2025, 17, 4469. [Google Scholar] [CrossRef]

- Günay, A.; Akbas, S.O. AI-Supported probabilistic steady-state and transient seepage analysis of an embankment dam with clay core: A case study on Büyükcekmece Dam. Eng. Geol. 2025, 351, 108029. [Google Scholar] [CrossRef]

- Zhou, C.Y.; Zhang, Q.X.; Liao, J.; Lai, H.Q.; Liu, Z. Experiment and Mechanism of Ecological Restoration of Water Level Fluctuation Zone Based on Redbed Composite Polymer Materials. Polymers 2025, 17, 306. [Google Scholar] [CrossRef]

- Islam, S.; Chowdhury, A.S.; Hasnat, N.; Alam, M.J.B.; Islam, J. Mitigating Desiccation Cracking in Embankment Soil Using Polyester Fiber and Fly Ash. Geotech. Geol. Eng. 2025, 43, 277. [Google Scholar] [CrossRef]

- Gao, Z.A.; Kong, L.W.; Yan, J.B.; Wang, S.J. Effects of drying–wetting cycles on small-strain stiffness characteristics of fissured clay. J. Rock Mech. Geotech. Eng. 2025, 17, 4618–4631. [Google Scholar] [CrossRef]

- Zhao, S.; Su, X.J.; Xu, C.; Gao, X.; Lu, S.Y. Microbial adaptation and genetic modifications for enhanced remediation in low-permeability soils. Sci. Total Environ. 2025, 958, 177916. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.T.; Sun, Y.L.; Sun, C.; Gu, H.Y. Experimental study on shear strength and deterioration behavior of silty clay under dry-wet-freeze-thaw cycles. Sci. Rep. 2025, 15, 17907. [Google Scholar] [CrossRef]

- Peng, W. Analysis of Quantitative Structural Parameters and Elastoplastic Constitutive Model of Saline Soil Under Freeze-Thaw Cycle. Ph.D. Thesis, Jilin University, Changchun, China, 2022. [Google Scholar]

- Liu, J.; Zhu, Q.C.; Li, G.; Qu, J.; Zhang, J.L. Research on the Anti-Erosion Capacity of Aeolian Sand Solidified with Enzyme Mineralization and Fiber Reinforcement Under Ultraviolet Erosion and Freeze–Thaw Erosion. Sustainability 2025, 17, 5053. [Google Scholar] [CrossRef]

- Xu, K.; Huang, M.; Cui, M.J.; Li, S. Effect of crystal morphology on cementability and micromechanical properties of calcium carbonate precipitate induced by crude soybean enzyme. J. Rock Mech. Geotech. Eng. 2024, 16, 5095–5108. [Google Scholar] [CrossRef]

- Peng, C.; Zhou, H.Y.; Deng, B.; Wang, D.X.; Zhu, J.R. Mechanical Properties Test and Microscopic Mechanism of Lignin Combined with EICP to Improve Silty Clay. Sustainability 2025, 17, 975. [Google Scholar] [CrossRef]

- Wang, Y.K.; Jiang, R.; Jiao, M.J.; Cao, T.C.; Yu, X. Macro and micro experimental study on solidification of Yellow River silt based on different biomineralization technologies. Environ. Earth Sci. 2023, 82, 86. [Google Scholar] [CrossRef]

- Mehmood, M.; Guo, Y.C.; Wang, L.; Liu, Y.L.; Uge, B.U.; Ali, S. Influence of Enzyme Induced Carbonate Precipitation (EICP) on the Engineering Characteristics of Expansive soil. Arab. J. Sci. Eng. 2024, 49, 14101–14116. [Google Scholar] [CrossRef]

- Qin, Z.P.; Lai, Y.M.; Tian, Y.; Zhang, M.Y. Effect of freeze-thaw cycles on soil engineering properties of reservoir bank slopes at the northern foot of Tianshan Mountain. J. Mt. Sci. 2021, 18, 541–557. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, S.Q.; Zhu, Z.Q.; Ru, M.Y.; Wan, A.C.; Zhu, X. Freeze-thaw durability and environmental risk assessment of silty soil improved using EICP combined with magnesite tailings powder. Environ. Res. 2025, 285, 122350. [Google Scholar] [CrossRef]

- Ahenkorah, I.; Rahman, M.M.; Karim, M.R.; Beecham, S. Unconfined compressive strength of MICP and EICP treated sands subjected to cycles of wetting-drying, freezing-thawing and elevated temperature: Experimental and EPR modelling. J. Rock. Mech. Geotech. Eng. 2023, 15, 1226–1247. [Google Scholar] [CrossRef]

- Xie, D.Y. Exploration of some new tendencies in research of loess mechanics. Chin. J. Geotech. Eng. 2001, 23, 3–13. [Google Scholar]

- Shen, Z.J. Mathematical model of soil structure the core problem of soil mechanics in the 21st century. Chin. J. Geotech. Eng. 1996, 18, 95–97. [Google Scholar]

- Shao, S.J.; Wang, L.Q.; Tao, H.; Wang, Q.; Wang, S. Structural index of loess and its relation with granularity, density and humidity. Chin. J. Geotech. Eng. 2014, 36, 1387–1393. [Google Scholar]

- Wu, X.J.; Dang, F.N.; Li, J.Y. Research on structural parameters of loess and its experimental determination method. Front. Built Environ. 2025, 11, 1529204. [Google Scholar] [CrossRef]

- Wu, X.J.; Dang, F.N.; Li, J.Y. The Parameter of Soil Structural Properties and Their Relationship to Grain Size, Density, and Moisture Content. Appl. Sci. 2025, 15, 1872. [Google Scholar] [CrossRef]

- Yao, M.; Chen, H.; Li, H.; Wang, Q.; Han, Y.; Yu, Q.B.; Liu, Y.B. Stress ratio sensitivity—A novel parameter for evaluating the shearing-based structural characteristic of loess. Bull. Eng. Geol. Environ. 2023, 83, 18. [Google Scholar] [CrossRef]

- Tremblay, H.; Leroueil, S.; Locat, J. Mechanical improvement and vertical yield stress prediction of clayey soils from eastern Canada treated with lime or cement. Can. Geotech. J. 2001, 38, 567–579. [Google Scholar] [CrossRef]

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM: West Conshohocken, PA, USA, 2017.

- Guan, D.W.; Zhou, Y.Z.; Mohamed, A.S.; Hamed, K.T.; Cheng, L. Assessment of urease enzyme extraction for superior and economic bio-cementation of granular materials using enzyme-induced carbonate precipitation. Acta Geotech. 2023, 18, 2263–2279. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO: Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, Western Australia, 2004. [Google Scholar]

- GB/T 50123; Standard for Geotechnical Testing Method. GB: Beijing, China, 2019.

- Yang, X.; Hu, Z.Q.; Li, H.R.; Wang, Y.; Zhang, Y.; She, H.C.; Wang, X.L. Effect of freeze-thaw cycles on mechanical properties and microstructure of artificially prepared site soil. Constr. Build. Mater. 2025, 485, 141878. [Google Scholar] [CrossRef]

- Yuan, H.; Shi, Q.S.; Li, J.; Zhao, Z.L. Effect of freeze–thaw cycling on mechanical properties of Na-montmorillonite modified EICP-treated silty sand. Case Stud. Constr. Mat. 2023, 19, 02641. [Google Scholar]

- ASTM D560; Standard Test Methods for Freezing and Thawing Compacted Soil-Cement Mixtures. ASTM: West Conshohocken, PA, USA, 2024.

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: West Conshohocken, PA, USA, 2016.

- Shao, S.J.; Zheng, W.; Wang, Z.H.; Wang, S. Structural index of loess and its testing method. Rock Soil Mech. 2010, 31, 15–19+38. [Google Scholar]

- Xu, D.L.; Yuan, C.; Dai, L.; Zeng, L.; Li, L.; Guan, X.W.; Wang, H.L. A method for measuring the critical pore diameter of a homogeneous microchannel separator based on image analysis and a simulation comparison of CFD-DEM. Sep. Purif. Technol. 2025, 360, 130896. [Google Scholar] [CrossRef]

- Watson, O.; Bruce, R.A.; Essex, R.; Valter, K. Experimental and statistical study on sound absorption coefficient of porous asphalt concrete considering mesoscopic pore parameters. Constr. Build. Mater. 2024, 434, 136767. [Google Scholar] [CrossRef]

- Folorunso, O.; Ojo, O.; Busari, M.; Adebayo, M.; Joshua, A.; Folorunso, D.; Ugwunna, C.O.; Olabanjo, O.; Olabanjo, O. Exploring machine learning models for soil nutrient properties prediction: A systematic review. Big Data Cogn. Comput. 2023, 7, 113. [Google Scholar] [CrossRef]

- Attom, M.F.; Vandanapu, R.; Khan, Z.; Yamin, M.; Astillo, P.V.; Eltayeb, A.; Khalil, A. Prediction of internal erosion parameters of clay soils using initial physical properties. Water 2024, 16, 232. [Google Scholar] [CrossRef]

- Sun, L.; Liu, E.L.; Luo, F. Micromechanics-based strength criterion for tailings silty clay considering the influence of freeze-thaw cycles. Cold. Reg. Sci. Technol. 2025, 237, 104536. [Google Scholar] [CrossRef]

- Hu, Y.K.; Long, J.W.; Feng, L.G.; Chen, C.; Luo, Q.L. Biomineralization techniques and its engineering application: A systematic review and meta-analysis. J. Build. Eng. 2025, 100, 111739. [Google Scholar] [CrossRef]

- Zhao, Z.; Hamdan, N.; Shen, L.; Nan, H.Q.; Almajed, A. Biomimetic hydrogel composites for soil stabilization and contaminant mitigation. Environ. Sci. Technol. 2016, 50, 12401–12410. [Google Scholar] [CrossRef]

- Yan, Z.; Gowthaman, S.; Nakashima, K.; Kawasaki, S. Polymer-assisted enzyme induced carbonate precipitation for non-ammonia emission soil stabilization. Sci. Rep. 2022, 12, 8821. [Google Scholar] [CrossRef] [PubMed]

- Gowthaman, S.; Mohsenzadeh, A.; Nakashima, K.; Kawasaki, S. Removal of ammonium by-products from the effluent of bio-cementation system through struvite precipitation. Mater. Today Proc. 2022, 61, 243–249. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).