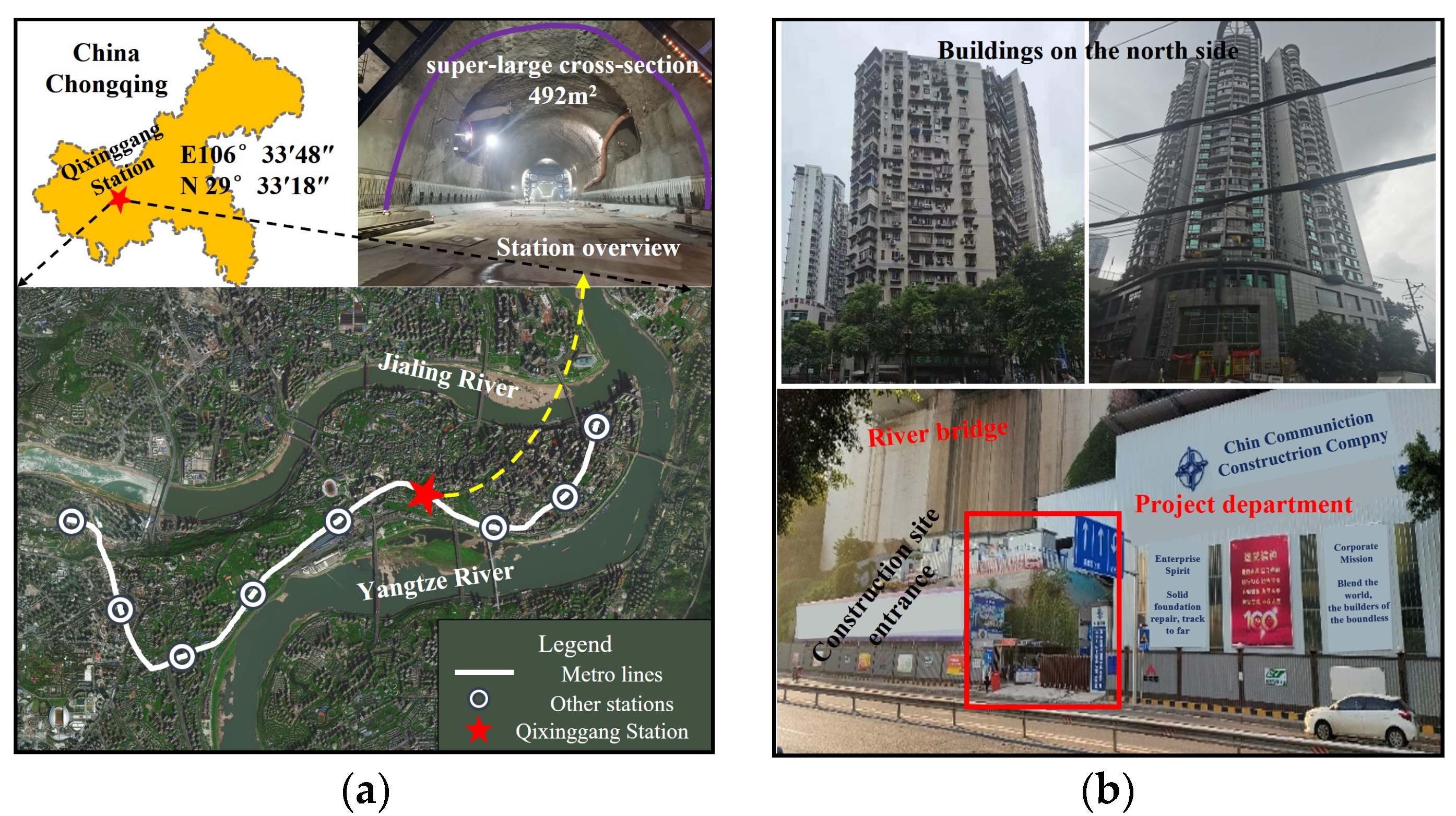

With the implementation of China’s new round of the “Western Development” strategy and the “Transportation Powerhouse” initiative, the construction of transportation infrastructure in the southwest region has advanced rapidly, leading to an increased focus on urban infrastructure development in underground spaces. The construction of large-section tunnels in complex environments has become an essential component of many projects, albeit with significant engineering challenges. On one hand, the busy surface traffic and densely packed buildings make traditional blasting techniques likely to induce ground vibrations, collapses, and other safety incidents, thereby necessitating the adoption of non-blasting construction technologies [

1,

2]. On the other hand, the construction of large-section tunnels using underground excavation methods presents inherent technical challenges, such as the complex distribution of surrounding rock stress and the uneven loading of support structures. Ensuring the safe and efficient completion of tunnel construction is a critical issue that engineers must address.

At present, many scholars at home and abroad have achieved fruitful research results in the construction of metro stations. Some scholars believe that the cut-and-cover method and the cover-and-excavate method are the most widely used construction methods in metro station construction [

3,

4,

5]. However, with the progression of urbanization and the increasing difficulty of ignoring the impact of the surrounding environment, underground excavation techniques for metro stations are expected to develop and be applied rapidly [

6]. Wei Xu et al. [

7], through analyzing various station structures in terms of evacuation convenience, construction safety, and cost rationality, explored the reasonable excavation methods for deep-buried stations in loess regions. Guojun Diao et al. [

8], based on a cut-and-cover metro station in Chengdu, proposed a scientific method for determining the boundary between cut-and-cover and underground excavation methods and conducted an in-depth study on key construction parameters such as settlement control and initial support for underground excavation. Zhiren Dai et al. [

9] investigated the issues related to the construction of shallow-buried metro stations in water-rich strata using the underground excavation method. They identified key processes such as the arrangement and excavation sequence of pilot tunnels, pre-reinforcement methods for strata, initial support types, combined steel pipe columns, and arched cover plates.

Some scholars believe that research on the construction of subway stations primarily focuses on the control of surrounding rock deformation. One of the most critical tasks in urban deep excavation is to control the deformation of surrounding rock and surface settlement caused by excavation, so as to avoid potential damage to adjacent facilities [

10,

11,

12,

13]. Liu et al. [

14] studied the interaction between a newly constructed station on Beijing Metro Line 12 and the existing Metro Line 5. They analyzed the construction parameters affecting the internal forces of the existing tunnel, including the distance between the excavation face and the existing tunnel, the face area, and the number of excavation steps in the pilot tunnel. Liu et al. [

15] proposed a simplified method for evaluating tunnel heave, which was compared with traditional modeling methods based on field measurements of longitudinal deformation in subway tunnels. The results showed little difference between the two approaches. Wang et al. [

16], using a station on the Nanjing Metro as a case study, conducted inverse analysis with the finite element method to determine key parameters of the excavation model. The displacement distribution of the model matched well with field measurements. Li et al. [

17] analyzed the settlement characteristics of corner buildings near Daliang Station in Foshan, China, and proposed that partition walls can significantly reduce the horizontal deformation of diaphragm walls and the settlement of corner buildings. Giardina et al. [

18] evaluated the effectiveness of tunnel excavation models under varying levels of geological complexity in predicting surface displacement and building deformation during tunnel construction. Xu et al. [

19], based on the foundation excavation of a subway station in Fuzhou, proposed a new method for assessing the reliability of support structure deformation, which was successfully applied for the reliability evaluation of support structures. Chen et al. [

20] argued that surface settlement is one of the primary concerns in deep excavation design and construction. They proposed a new least-squares-based algorithm to convert scattered data of sidewall displacement into a continuous function and studied the displacement response of tunnel excavation. Morovatdar et al. [

21] used finite element software to model the tunnel excavation process and calculated the settlement induced by excavation. Their post-processing results confirmed that the deployment of pipe roofing could reduce the settlement of the tunnel crown and the ground surface by 76% and 42%, respectively. Some scholars believe that in urban environments, predicting potential damage factors to existing structures induced by subway station excavation is critical. This should be followed by the optimization of support parameters and subsequent inverse analysis for verification [

22,

23,

24]. Other scholars have proposed that for large-span subway stations in urban areas, it is essential to innovate excavation methods by developing new tunneling approaches compatible with local conditions and large-scale machinery. This is necessary to meet the complex demands of urban rail transit construction in challenging environments [

25,

26,

27]. Yeow et al. [

28] argued that temporary supports are not always essential during excavation. They conducted a 13 m unsupported excavation at the bottom of a 30 m deep foundation pit. Zeng et al. [

29] proposed the use of buttressed retaining walls to limit wall movements and associated ground settlement caused by earthworks. They noted that the efficiency of deformation constraints decreases as the length of the buttress increases. Zhang et al. [

30] proposed a hybrid simulation method to further analyze the impact of station foundation excavation on the surrounding environment, taking the Wuhan Metro Line 2 as an example. They also provided relevant control measures. Guo et al. [

31], based on the underground space development of Shenzhen Metro’s Dayun Hub, addressed the technical challenges of ultra-deep foundation pit excavation and top-down construction with traffic cover. By adopting grouting reinforcement and top-down methods, they achieved effective deformation control of the existing station structure. Li et al. [

32] proposed and applied the 0-theta method for the first time, addressing key technologies such as tunneling mode switching and tunnel process control in complex construction environments.

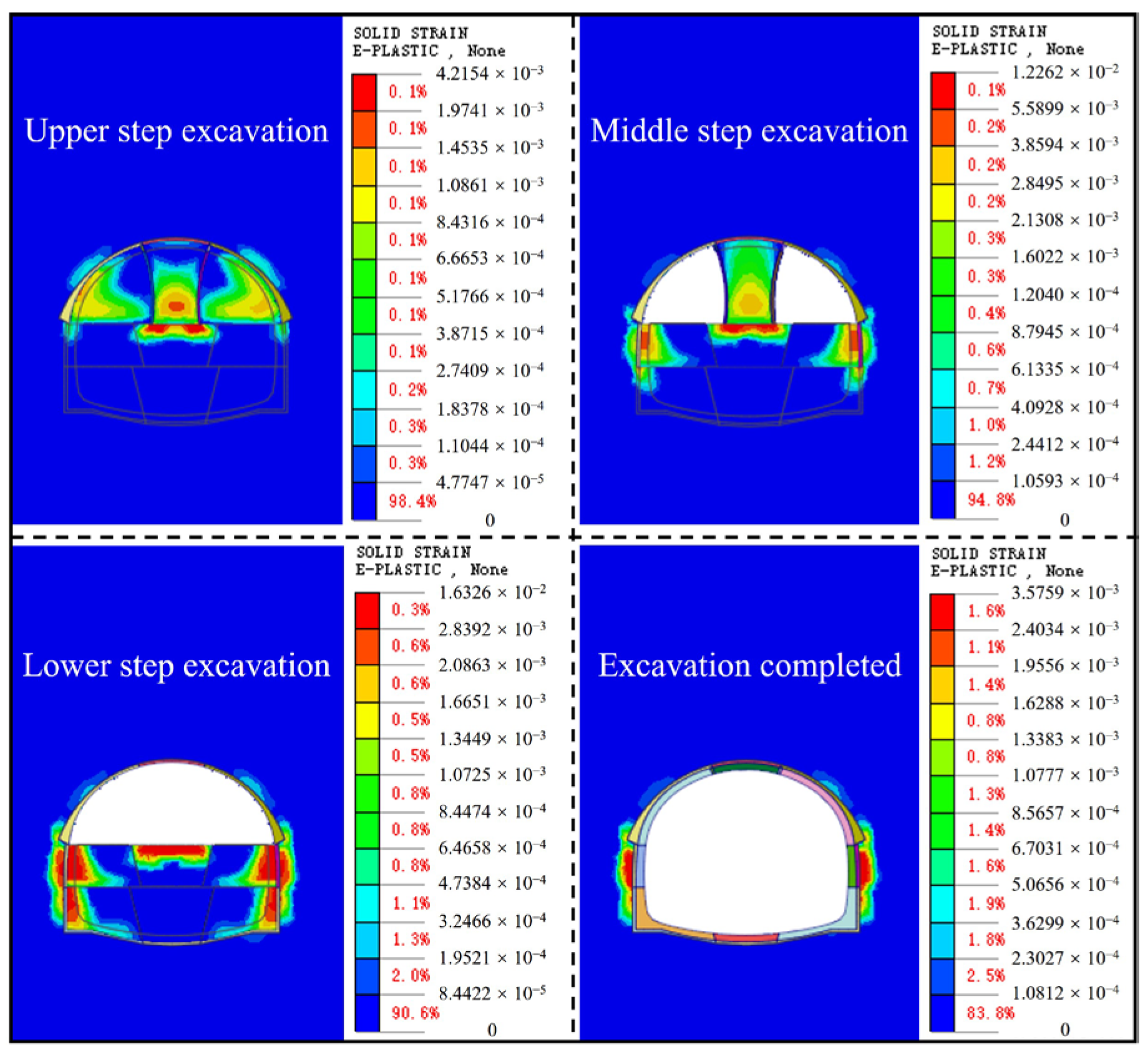

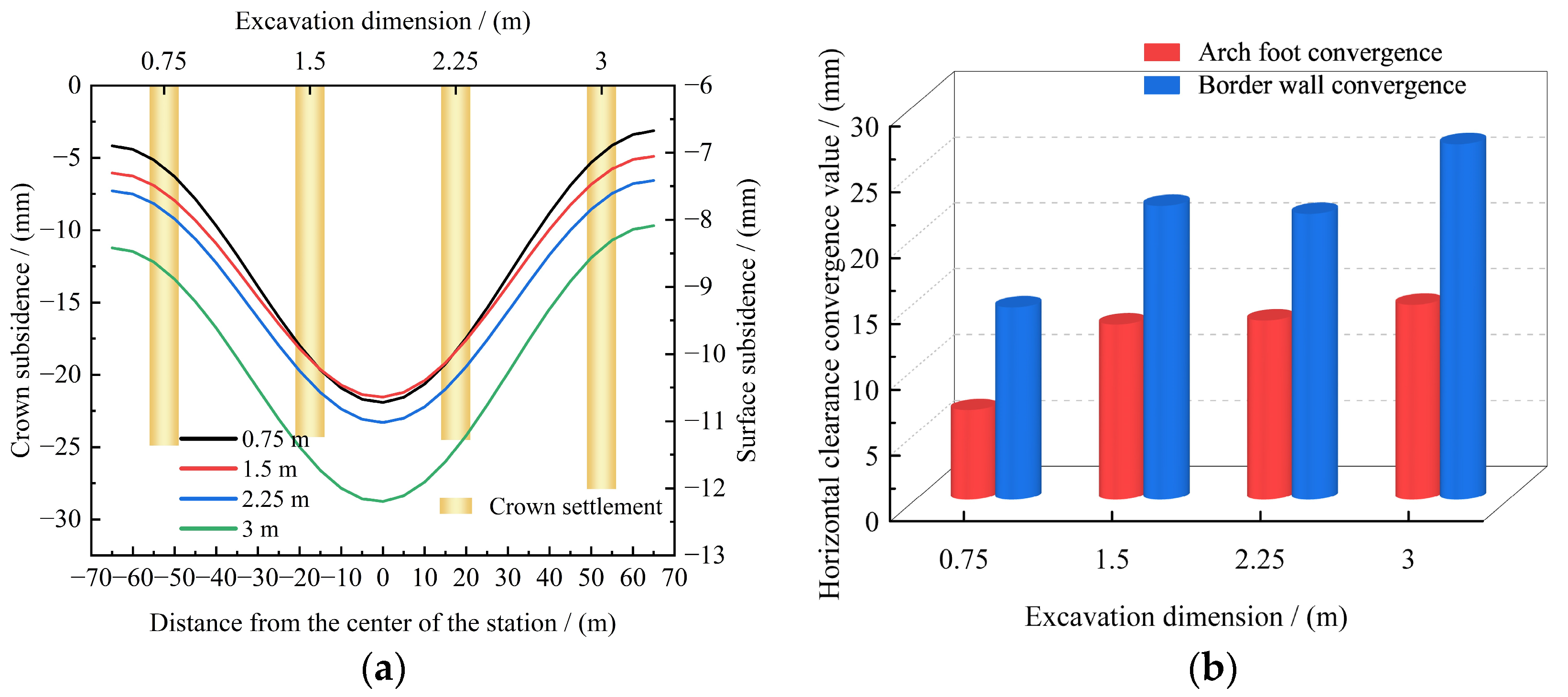

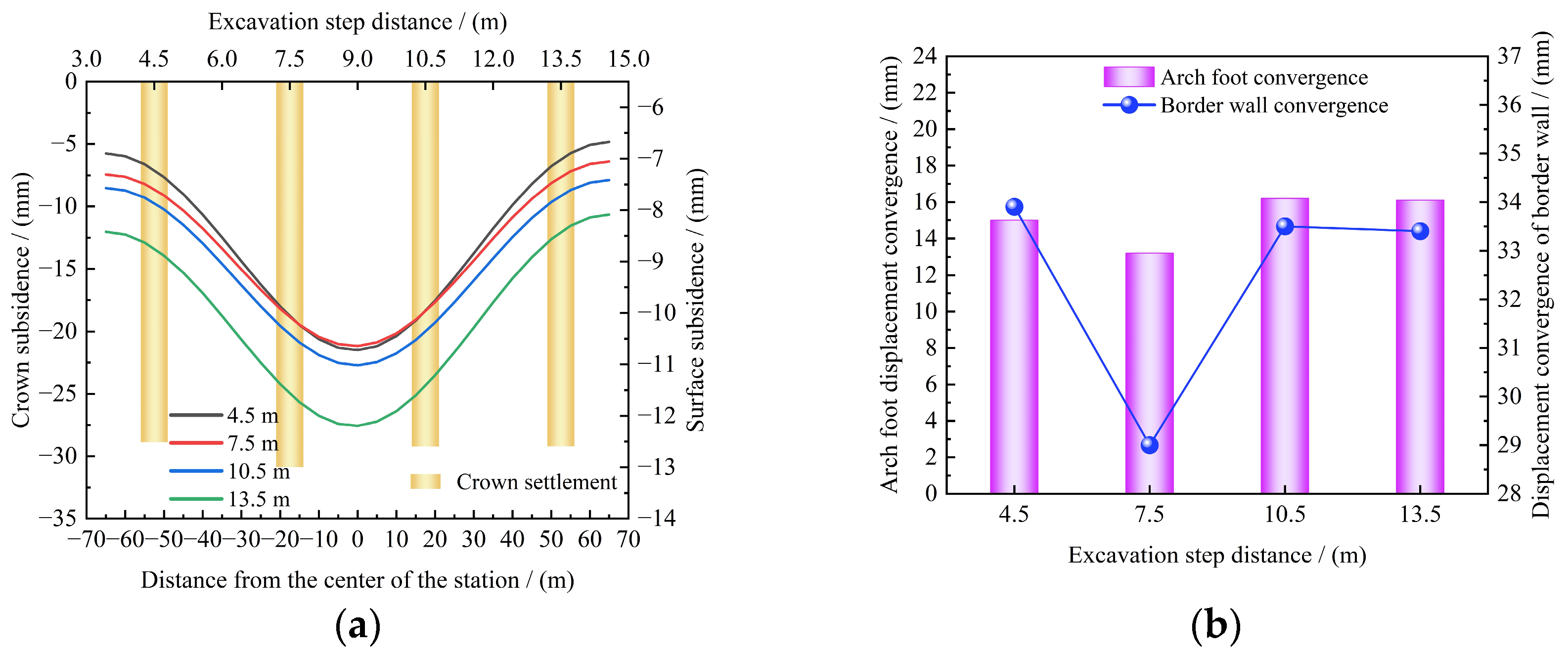

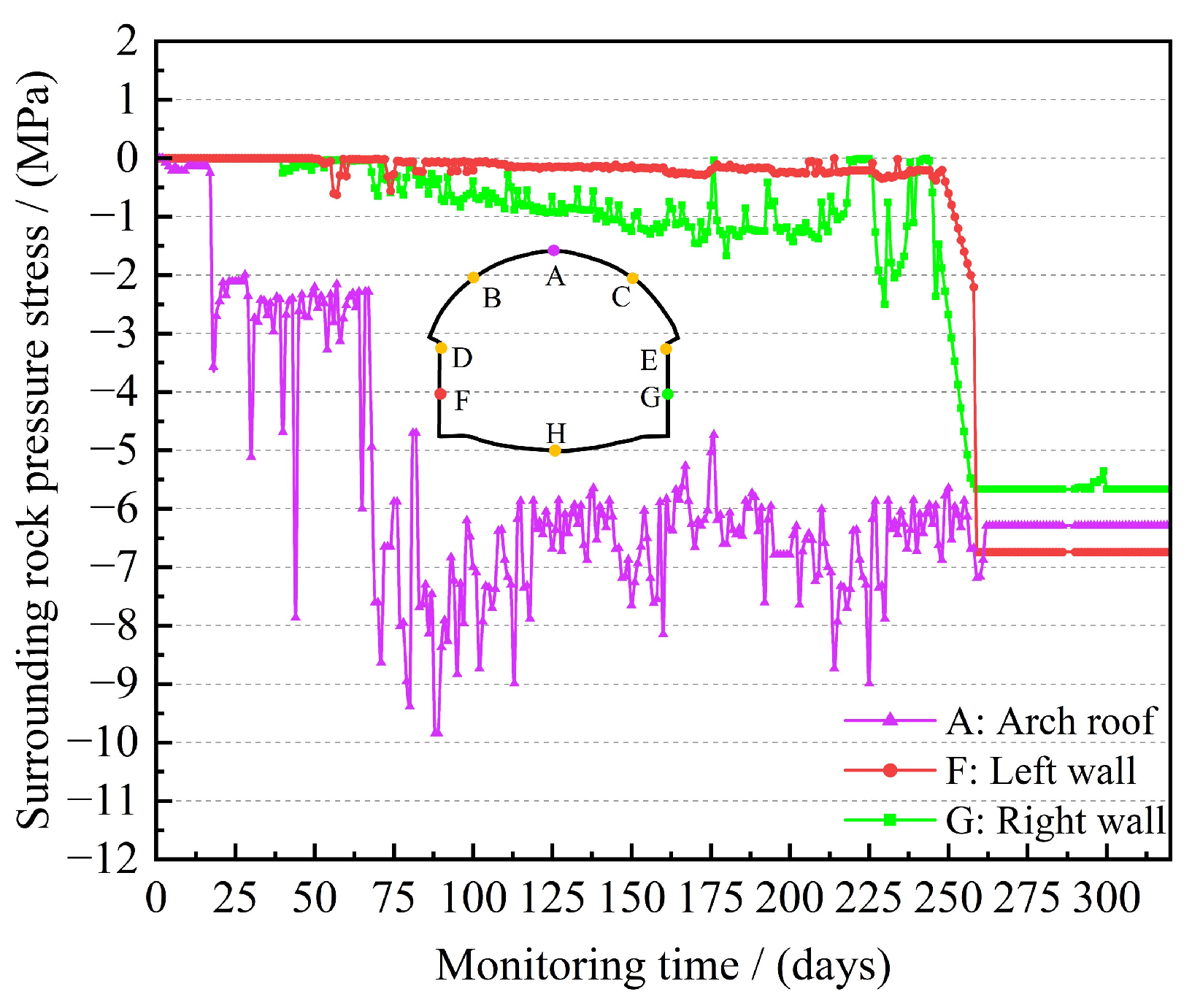

In summary, open-cut construction methods still account for a large proportion of subway station construction, while studies on the construction of mined subway stations primarily focus on shallow-buried stations. The construction methods most frequently employed on-site are the pile-beam-arch (PBA) method or the pipe-jacking method. Thus, research on the construction of deep-buried, large-section mined subway stations remains relatively limited, with more attention given to the optimization of support structures rather than excavation parameters. This is particularly true for large-span subway stations with significant burial depths, for which there are few relevant references available either domestically or internationally. In particular, studies on the optimization of mechanical excavation parameters for such stations are evidently insufficient. Although the enlarged footing bench method, as a highly adaptable mined construction technique, can effectively control surrounding rock deformation and surface settlement to a certain extent, its application in complex urban environments still faces many technical challenges, such as the rational design and optimization of excavation parameters. This paper aims to address the optimization of key technical parameters for mechanical excavation in large-section mined subway stations under complex urban conditions. Through numerical simulation analysis of various working conditions and the integration of advanced automated monitoring technologies in the field, we achieved an accurate analysis of the rock mass deformation process. We determined the safety of the structure based on whether the convergence values of the surrounding rock’s horizontal displacement exceeded the regulatory limits, ultimately identifying the optimal key construction parameters. This study holds significant reference value for the construction of deep-buried, large-section subway stations in the southwestern region of China.