Impact Energy Absorption Behavior of Unequal Strength Liquid Storage Structures Under Drop Hammer Impact

Abstract

1. Introduction

2. Experiment and Numerical Analysis

2.1. Experimental Design

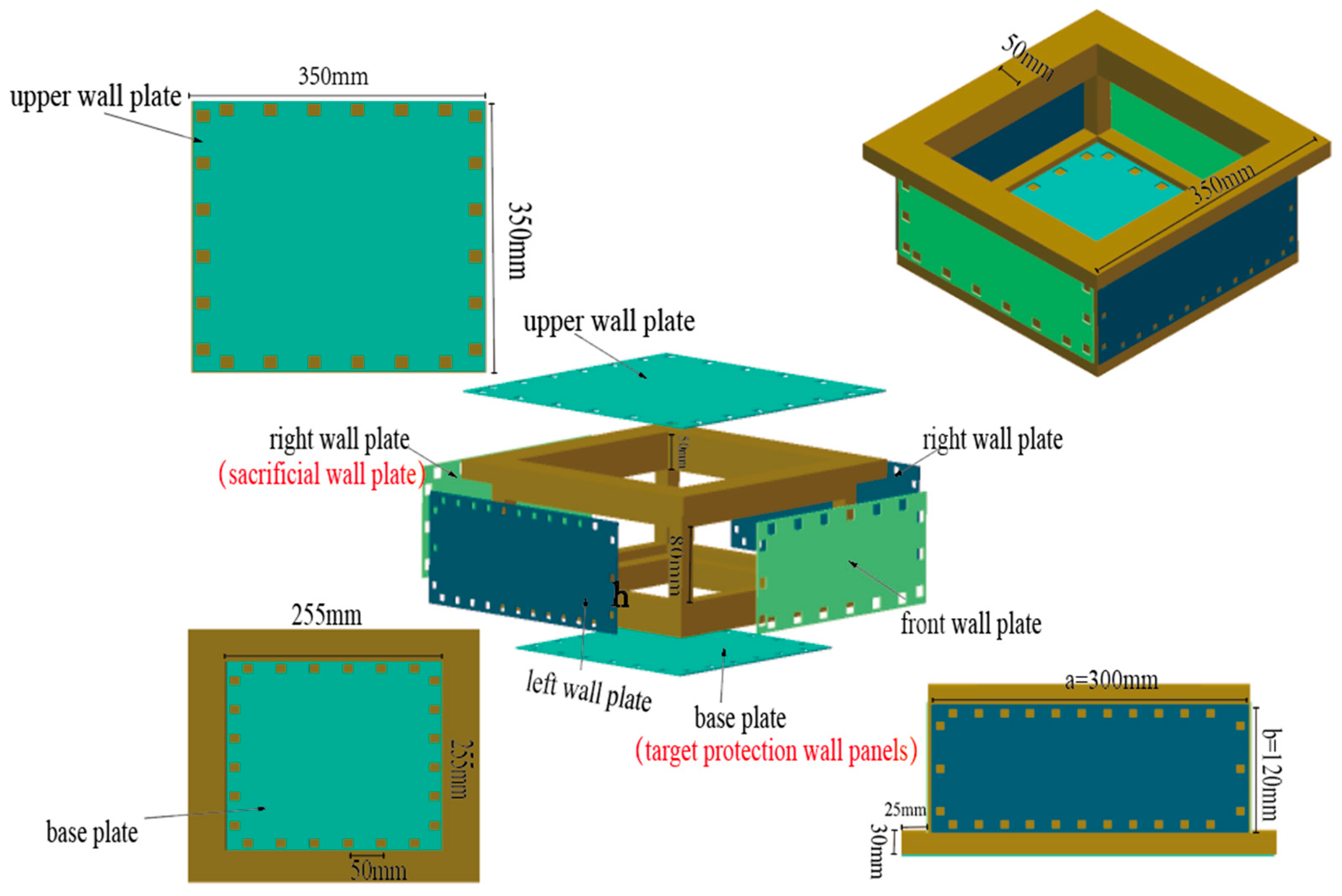

2.1.1. Structural Design

2.1.2. Experimental Setup

2.2. Numerical Analysis Model and Validation

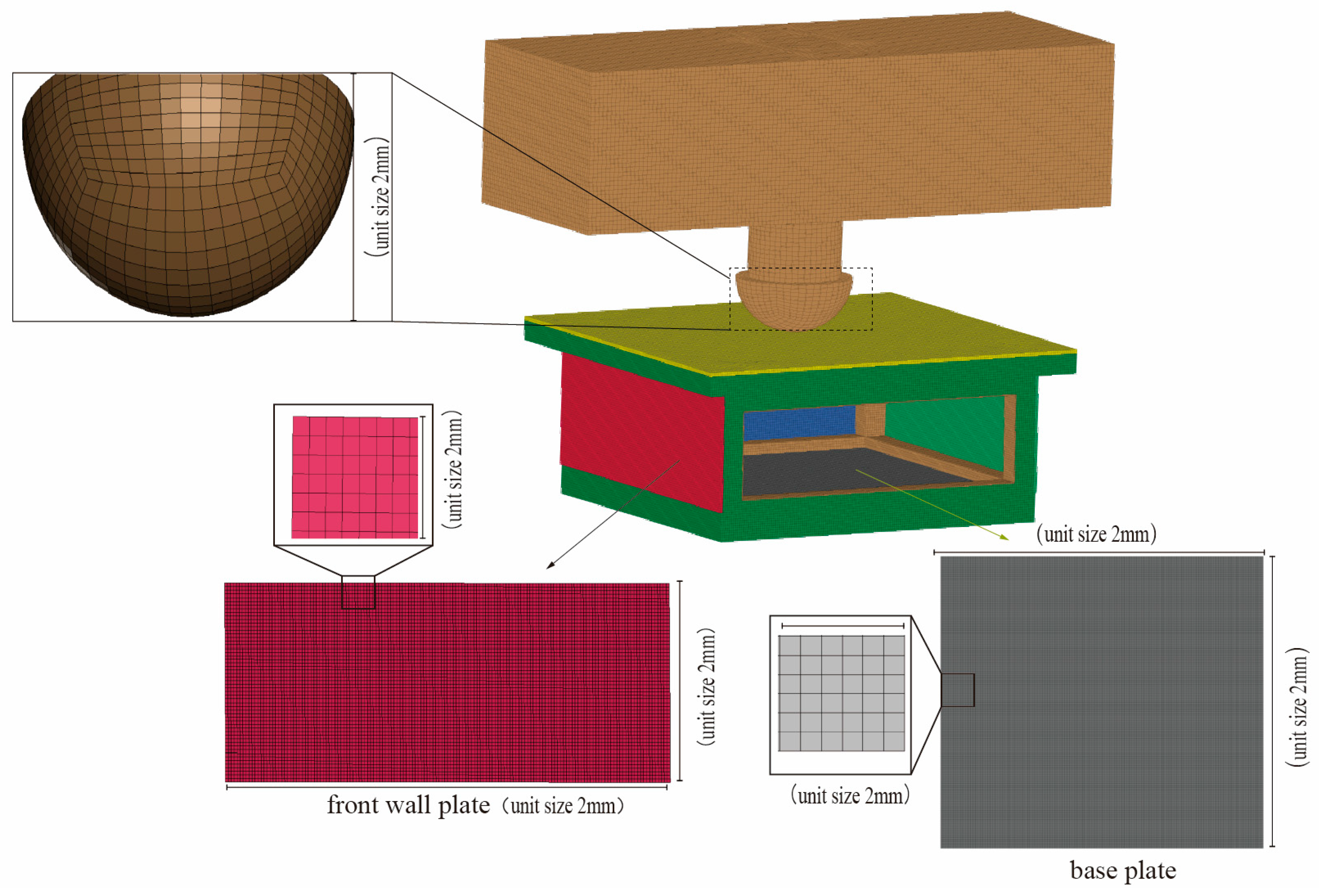

2.2.1. Numerical Analysis Model

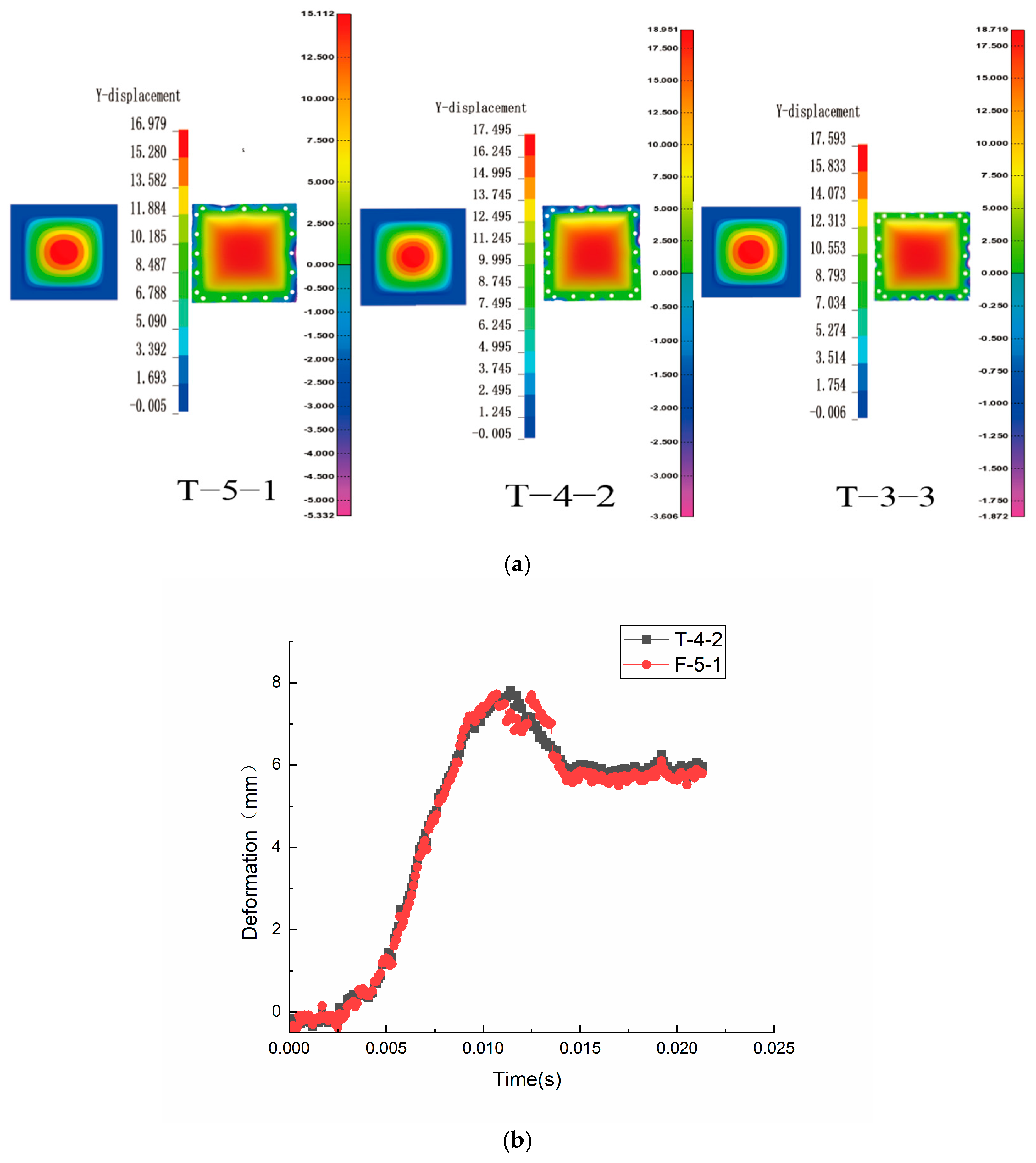

2.2.2. Numerical Model Validation

3. Structural Failure and Dynamic Response Analysis

3.1. Failure Morphology

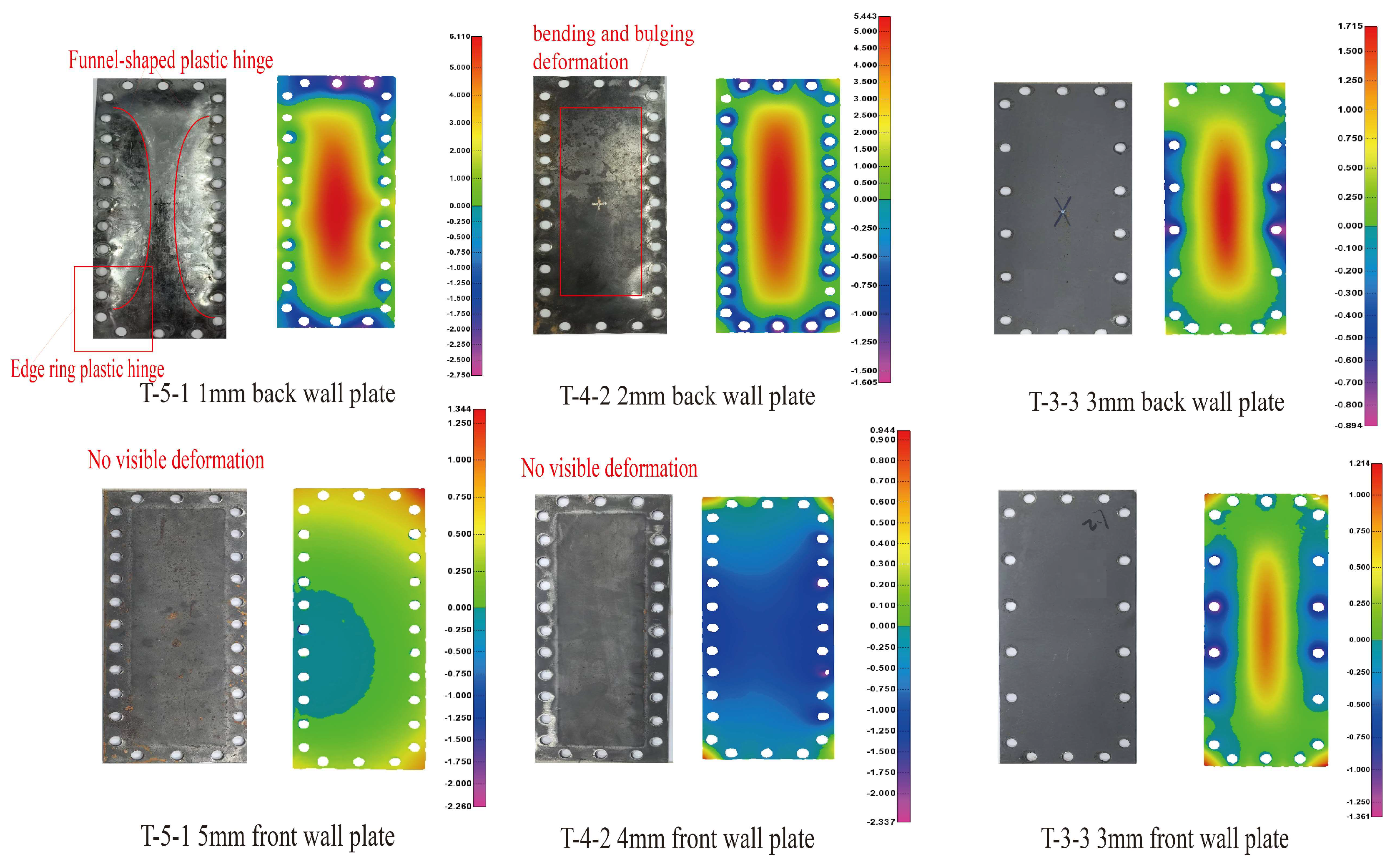

3.1.1. Failure Morphology of Fore and Aft Plates

3.1.2. Failure Morphology of Bottom Plate

3.1.3. Relationship Between Plate Matching Strength and Failure Morphology

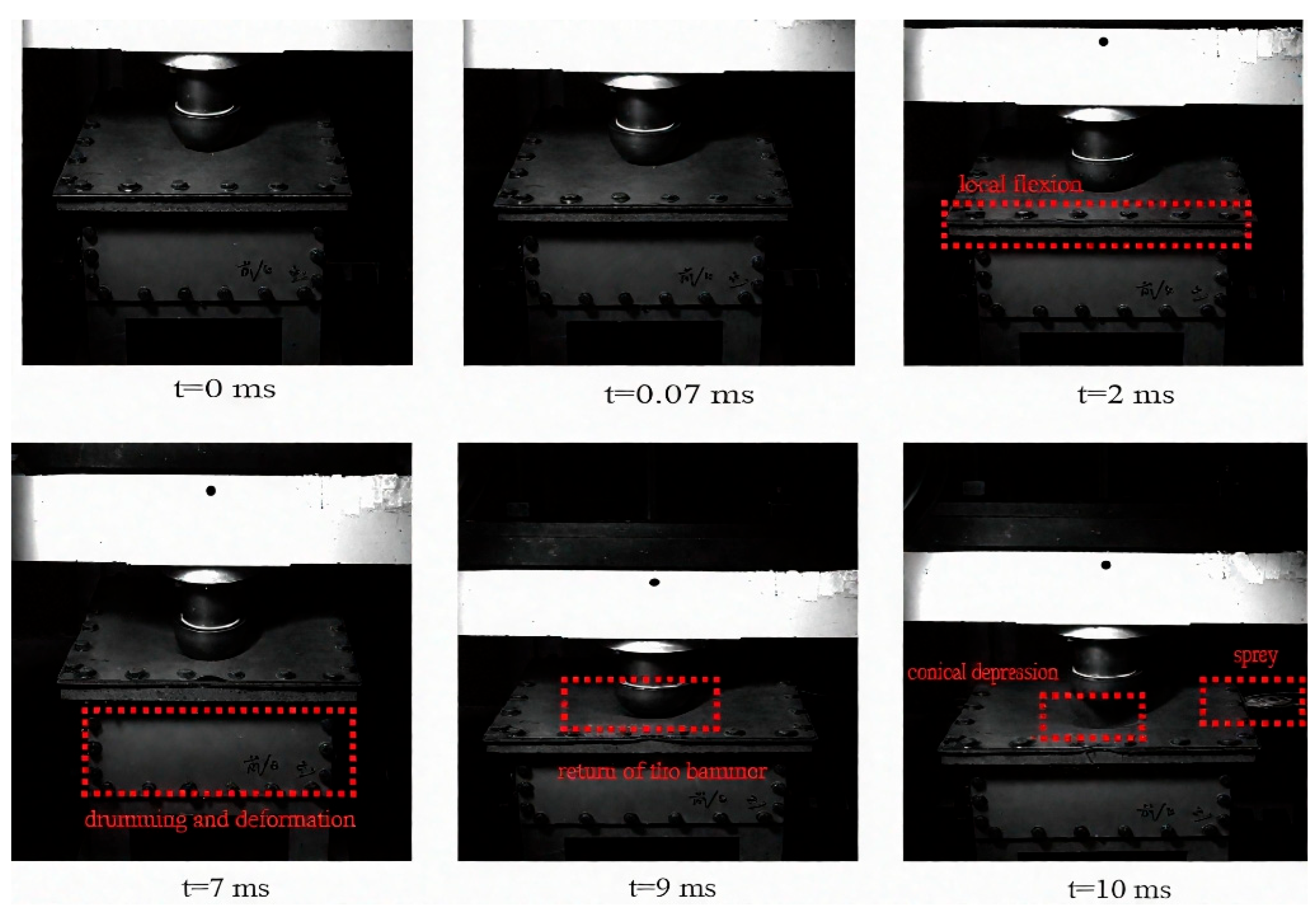

3.2. Dynamic Response Process of the Structure

4. Energy Absorption and Protective Mechanism

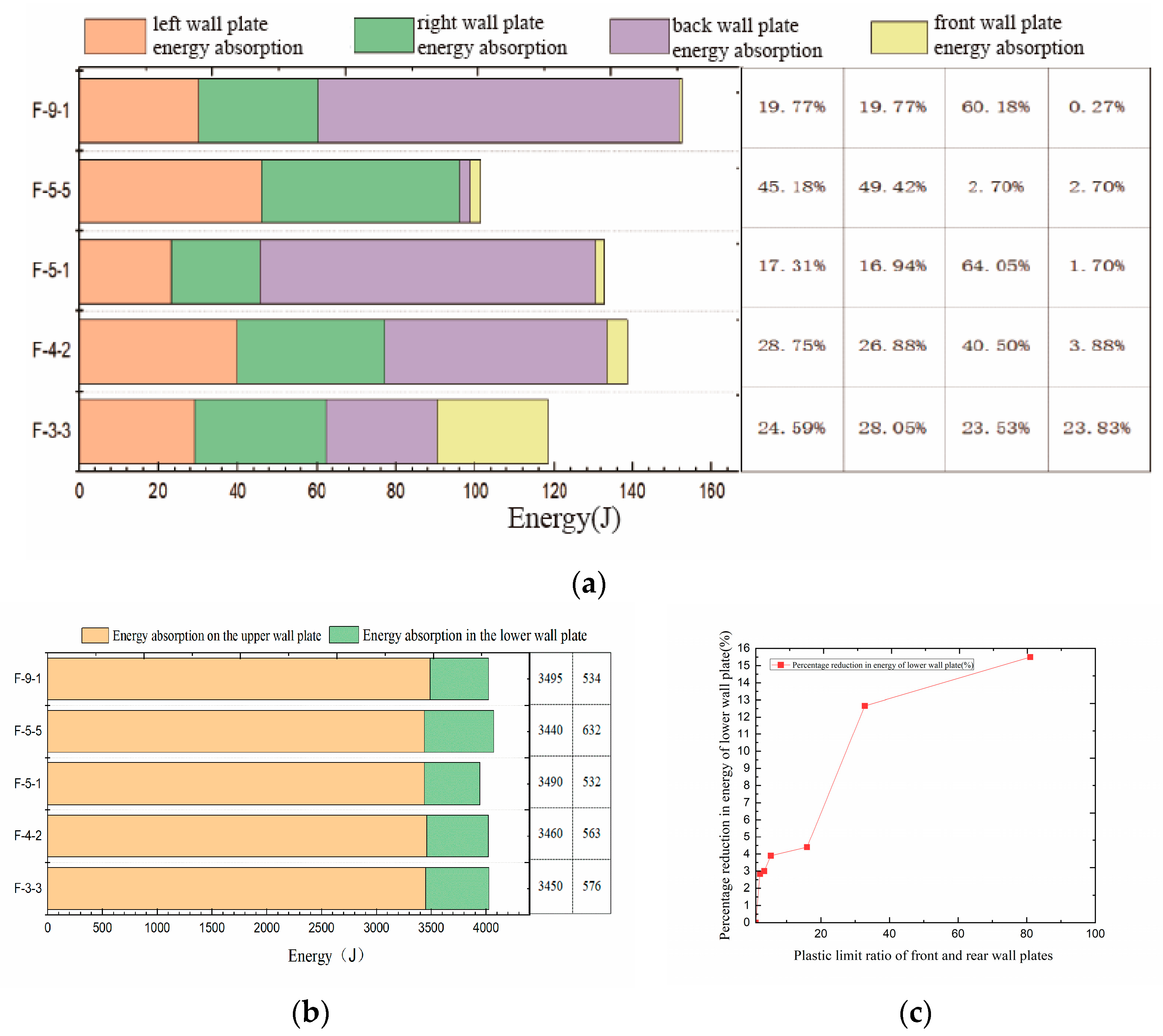

4.1. Energy Absorption Characteristics

4.2. Study on Protective Mechanism

5. Conclusions

- (1)

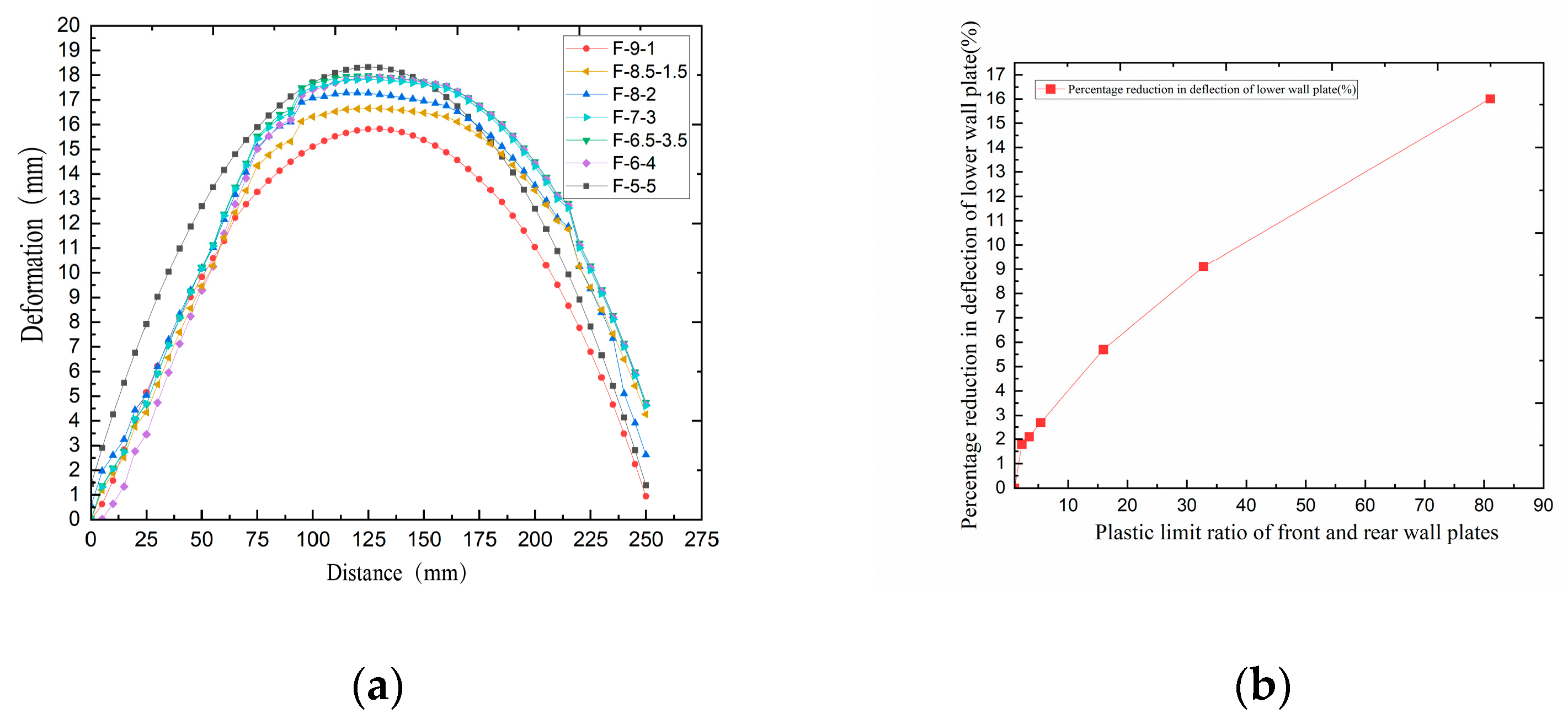

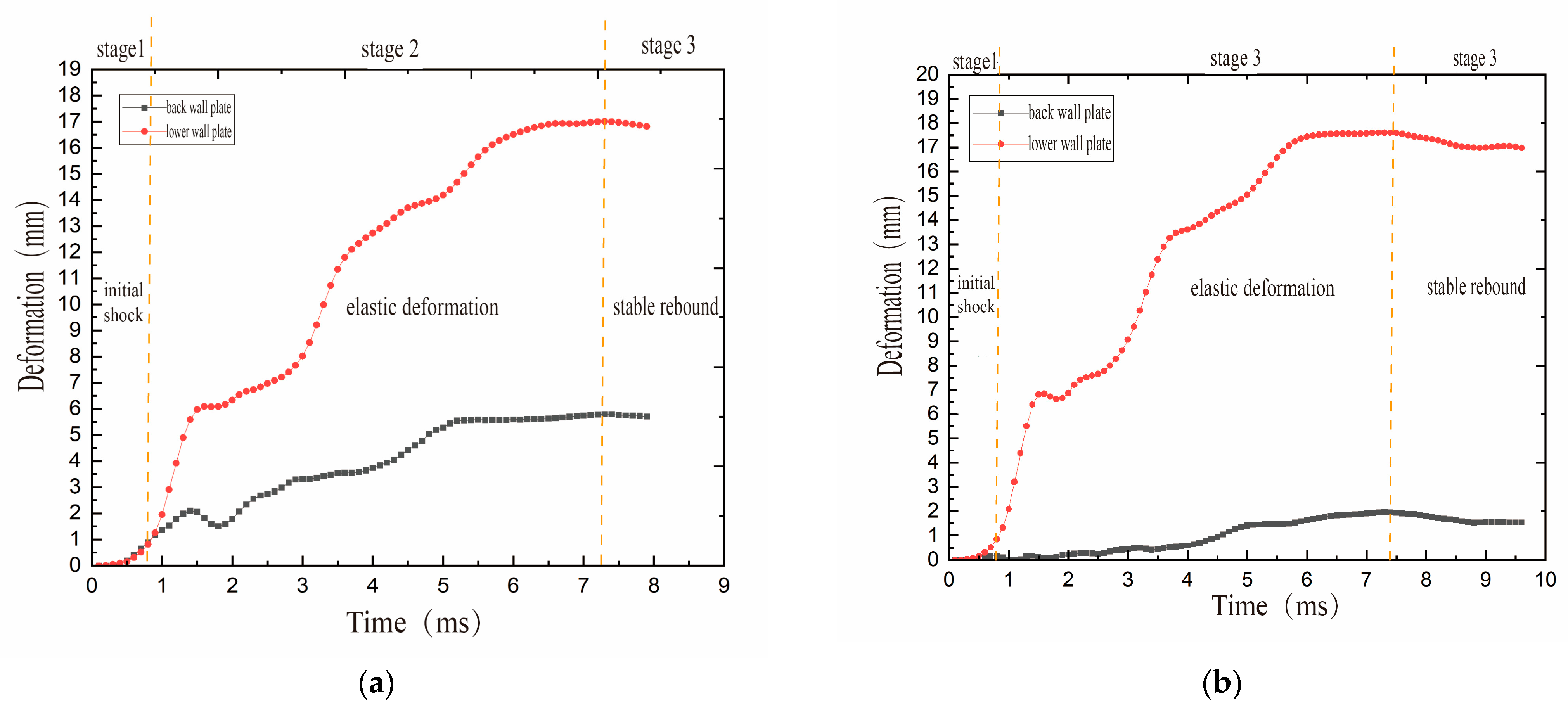

- Effect of aft plate thickness on deformation and load distribution: Reducing the aft plate thickness in the unequal-strength liquid-holding structure lowers its plastic limit strength, causing large-deflection plastic deformation under impact loading and developing an annular and funnel-shaped plastic hinge. The bottom plate also undergoes plastic deformation, forming a cruciform plastic hinge. A smaller aft plate thickness results in a lower final deflection of the bottom plate. Due to the enhanced load-bearing capacity of the fore plate, it can effectively withstand the pressure wave transmitted through the water medium, limiting its deformation to the elastic range and keeping it minimal.

- (2)

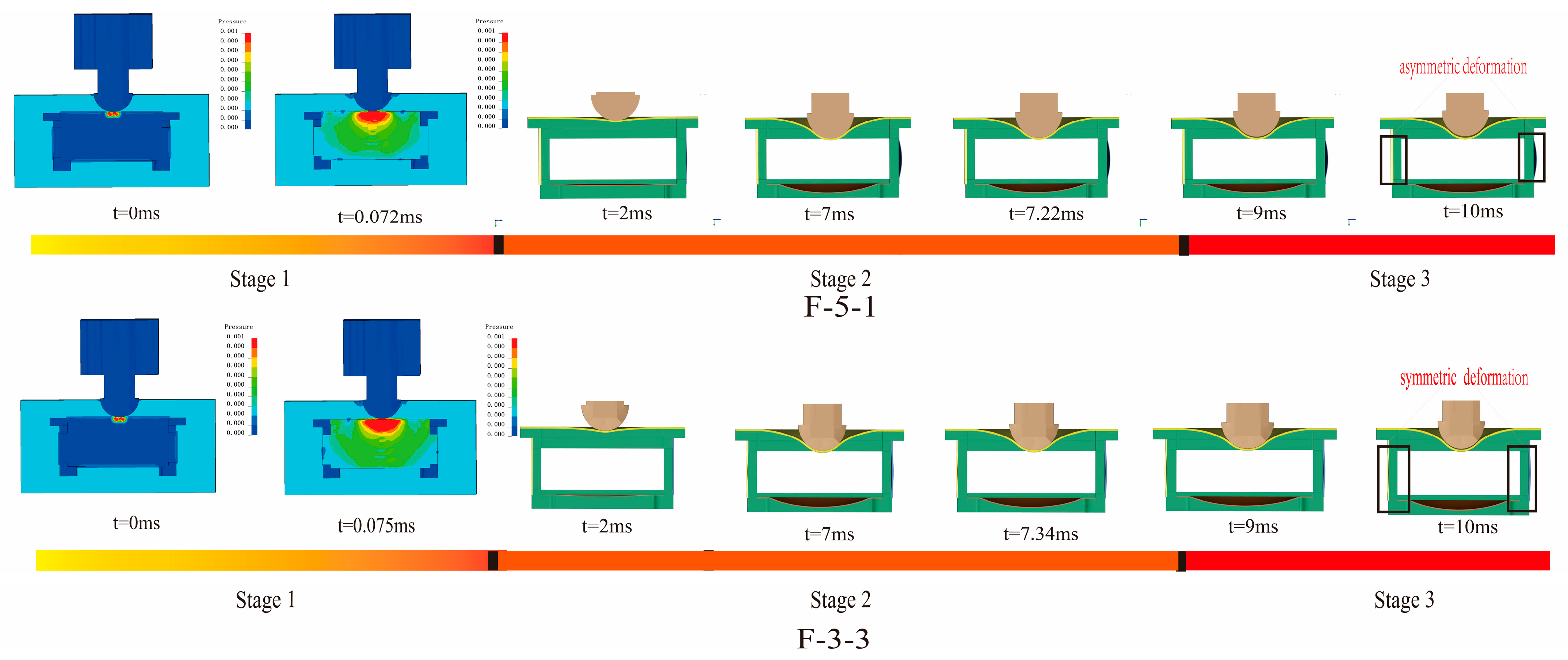

- Dynamic response stages and asymmetry in deformation: Based on the shock wave propagation and structural deformation sequence, the dynamic response can be divided into three stages: initial impact, plate elastic–plastic deformation, and stabilized rebound. Compared with an equal-strength sidewall configuration, the unequal-strength structure directs the pressure wave preferentially toward the low-strength plate. The hammer-induced pressure wave produces asymmetric loading during transmission, leading to asymmetric deformation of the structure.

- (3)

- Influence of fore–aft plate plastic limit ratio on protective performance: As the plastic limit ratio between the fore and aft plates increases, the deflection and energy absorption of the bottom plate decrease more significantly compared to the equal-strength configuration. The maximum efficiency in reducing plate deflection and energy absorption is achieved when the plastic limit ratio is approximately 20–35. Beyond this range, the rate of improvement diminishes, illustrating the “marginal diminishing effect” of plastic deformation. Maintaining a fore–aft plate plastic limit ratio between 20 and 38 ensures structural stability and maximizes energy absorption and protective performance of the unequal-strength liquid-holding structure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.N.; Gao, Z.; Gu, Y.N. Calibration Calculation of Specimen Ultimate Plasticity and Ship Grounding Model Test. Ship Eng. 2002, 6, 13–16. [Google Scholar]

- Nguyen, T.-H.; Amdahl, J.; Leira, B.J.; Garrè, L. Understanding ship-grounding events. Mar. Struct. 2011, 24, 551–569. [Google Scholar] [CrossRef]

- Zhang, L.G. Finite Element Analysis of Ship Collision Process and Emergency Avoidance Suggestions. Pearl River Water Transp. 2024, 20, 134–136. [Google Scholar]

- Prabowo, A.R.; Muttaqie, T.; Sohn, J.M.; Harsritanto, B.I.R. Investigation on structural component behaviours of double bottom arrangement under grounding accidents. Theor. Appl. Mech. Lett. 2019, 9, 50–59. [Google Scholar] [CrossRef]

- Yu, Z.L. Study on the Damage Mechanism of the Main Component Stiffeners of the Double Bottom When the Ship is Grounded on a Platform-Shaped Reef. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2015. [Google Scholar]

- Sun, B. Research on the Structural Damage Mechanism and Ultimate Strength Prediction of Ships in Collision and Grounding Scenarios. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2020. [Google Scholar]

- Guo, J.; Cui, J.; Xiao, W.; Sun, F.; Li, S.M. Dynamic Response of Ship Double-Bottom Liquid Tanks Under Underwater Explosion. Noise Vib. Control 2012, 32, 94–99. [Google Scholar]

- Ma, X.; Zhang, Y.C.; Wang, Z.L. Research on the Anti-impact Performance of Double-bottom Structure Units Under Underwater Non-Contact Explosion Loads. Ship Sci. Technol. 2008, 30, 39–43. [Google Scholar]

- Bornstein, H.; Phillips, P.; Anderson, C. Evaluation of the blast mitigating effects of fluid containers. Int. J. Impact Eng. 2015, 75, 222–228. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, T.; Zhu, W.; Bian, X.; Huang, G. Evaluation of blast mitigation effects of hollow cylindrical barriers based on water and foam. Compos. Struct. 2022, 282, 115016. [Google Scholar] [CrossRef]

- Wang, D.X.; Liu, Z.X.; Hu, H.; Cao, J.; Li, W.J. Special Structure of Cylindrical Explosion Containers. Sichuan Ordnance J. 2012, 33, 70–72. [Google Scholar]

- Zhao, P.D.; Huang, S.; Yin, J.P.; Zhang, L.; Huang, Y.Y.; Xu, Y.X. Numerical Simulation of the Influence of the Thickness of the Explosion Relief Thin Plate on the Damage of the Cabin and the Load in the Cabin. Chin. J. Ship Res. 2019, 14, 58–65+82. [Google Scholar]

- Chen, Y.; Huang, W.; Constantini, S. Blast Shock Wave Mitigation Using the Hydraulic Energy Redirection and Release Technology. PLoS ONE 2012, 7, e39353. [Google Scholar] [CrossRef] [PubMed]

- Shen, W.; Gu, X.; Jiang, P.; Hu, J.; Lv, X.; Qian, L. Crushing analysis and multiobjective optimization design for rectangular unequal triple-cell tubes subjected to axial loading. Thin-Walled Struct. 2017, 117, 190–198. [Google Scholar] [CrossRef]

- Fu, G.; Fu, G.; Yu, C.; Li, S.; Wang, F.; Yang, J. Behaviour of rectangular concrete-filled steel tubular slender column with unequal wall thickness. Eng. Struct. 2021, 236, 112100. [Google Scholar] [CrossRef]

- Kong, X.; Wei, W.; Xiao, L.; Shuang, X.; Tao, H. Numerical simulation of explosion inside ship compartments. Chin. Ship Res. 2009, 4, 7–11. [Google Scholar]

- Li, J.R.; Lu, Y.G.; Feng, X.W.; Wu, H. Analysis of the Loading Characteristics and Dynamic Behavior of RC Box Structures under Internal Explosion. Explos. Shock Waves 2025, 1–18. Available online: https://link.cnki.net/urlid/51.1148.o3.20250116.1650.009 (accessed on 1 September 2025).

- Zhao, Z.J.; Li, D.; Hou, H.L.; Yao, M.; Wuang, K. Study on dynamic response and loading mitigation characteristics of liquid-filled cell under drop-weight impact. Eng. Struct. 2021, 248, 113283. [Google Scholar] [CrossRef]

- Zhou, J.; Qin, R.; Chen, B. Energy absorption properties of multi-cell thin-walled tubes with a double surface gradient. Thin-Walled Struct. 2019, 145, 106386. [Google Scholar] [CrossRef]

- Wang, T.; An, J.; He, H.; Wen, X.; Xi, X. A novel 3D impact energy absorption structure with negative Poisson’s ratio and its application in aircraft crashworthiness. Compos. Struct. 2021, 262, 113663. [Google Scholar] [CrossRef]

- Zhang, Z.Q. Research on the Anti-impact Characteristics of Liquid-filled Double-layer Plate Structures. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2017. [Google Scholar]

- Cui, J.; Zhang, A.M.; Yao, X.L.; Yang, S.T. Influence Analysis of Liquid Cargo in the Cabin on the Collision Performance of Double Sides. J. Ship Mech. 2011, 15, 259–268. (In English) [Google Scholar]

- Lu, G.Y.; Qin, B.; Zhang, G.Q.; Han, Z.J.; Lei, J.P. Dynamic Response of Sandwich Liquid-filled Thin-walled Hemispherical Shell Composite Structure under Impact. Explos. Shock Waves 2012, 32, 561–567. [Google Scholar]

- Guan, W.B.; Yang, H.W.; Hu, J.X.; Han, Z.J.; Lu, G.Y. Experimental and Numerical Analysis of Liquid-filled Hemispherical Shells under Drop Hammer Impact. J. Vib. Shock 2014, 33, 148–154. [Google Scholar]

- Zhang, J.Z.; Zhang, J.L. Research on the Liquid Impact Problem of Energy-absorbing Anti-collision Columns. J. Vib. Shock 2020, 39, 51–57. [Google Scholar]

- Wang, Z.P.; Xu, S.X.; Chen, W.; Le, J.X.; Chai, W.; Li, X.B. Characteristics of shock wave loading inside ship cabin with pressure relief hole. Chin. J. Ship Res. 2023, 18, 155–162. [Google Scholar]

- Held, M. Verification of the equation for radial crater growth by shaped charge jet penetration. Int. J. Impact Eng. 1995, 17, 387–398. [Google Scholar] [CrossRef]

- Gao, S.; Li, D.; Hou, H.; Li, Y.; Bai, X.; Jin, J.; Li, M.; Lin, Y. Investigation on dynamic response of liquid-filled concave cell structures subject to the penetration of high-speed projectiles. Thin-Walled Struct. 2020, 157, 107119. [Google Scholar] [CrossRef]

- Zhao, Z.J.; Hou, H.L.; Li, D. Research Progress on the Dynamic Characteristics and Protection Performance of Filled Multi-cell Anti-impact Protection Structures. Chin. J. Ship Res. 2021, 16, 96–111. [Google Scholar]

- Alavi Nia, A.; Sadeghi, M.Z. An experimental investigation on the effect of strain rate on the behaviour of bare and foam-filled aluminium honeycombs. Mater. Des. 2013, 52, 748–756. [Google Scholar] [CrossRef]

| Serial Number | Test Name | v Drop hammer/m·s−1 | h Front (mm) | ps Before (MPa) | h Back (mm) | ps After (MPa) | h Top, left, right (mm) | h Bottom (mm) | ps Before/ ps After | Research Methods |

|---|---|---|---|---|---|---|---|---|---|---|

| No. 1 | T-5-1 | 9 | 5 | 28.4 | 1 | 1.14 | 3.2 | 1.7 | 24.91 | Test + FEM |

| No. 2 | T-4-2 | 9 | 4 | 18.2 | 2 | 4.57 | 3.2 | 1.7 | 5.69 | Test + FEM |

| No. 3 | T-3-3 | 9 | 3 | 10.3 | 3 | 10.3 | 3.2 | 1.7 | 1 | Test + FEM |

| No. 4 | F-9-1 | 9 | 9 | 92.4 | 1 | 1.14 | 3.2 | 1.7 | 81.05 | FEM |

| No. 5 | F-8.5-1.5 | 9 | 8.5 | 61.36 | 1.5 | 1.87 | 3.2 | 1.7 | 32.8 | FEM |

| No. 6 | F-8-2 | 9 | 8 | 72.9 | 2 | 4.57 | 3.2 | 1.7 | 15.95 | FEM |

| No. 7 | F-7-3 | 9 | 7 | 55.7 | 3 | 10.3 | 3.2 | 1.7 | 5.40 | FEM |

| No. 8 | F-6.5-3.5 | 9 | 6.5 | 35.04 | 3.5 | 10.06 | 3.2 | 1.7 | 3.48 | FEM |

| No. 9 | F-6-4 | 9 | 6 | 40.9 | 4 | 18.2 | 3.2 | 1.7 | 2.24 | FEM |

| No. 10 | F-5-5 | 9 | 5 | 28.4 | 5 | 28.4 | 3.2 | 1.7 | 1 | FEM |

| Symbol | c/m·s−1 | S1 | S2 | S3 | γ0 | A | EW/kJ·s−3 | V0 |

|---|---|---|---|---|---|---|---|---|

| Value | 1450 | 1.98 | 0 | 0 | 0.5 | 3 | 0 | 1 |

| Symbol | c/m·s−1 | S1 | S2 | S3 | γ0 | A | EW/kJ·s−3 | V0 |

|---|---|---|---|---|---|---|---|---|

| Value | 4560 | 1.49 | 0 | 0 | 2.17 | 3 | 0 | 1 |

| Symbol | C0 | C1 | C2 | C3 | C4 | C5 | C6 | EA/kJ·s−3 |

|---|---|---|---|---|---|---|---|---|

| Value | 0 | 0 | 0 | 0 | 0.4 | 0.4 | 0 | 253 |

| Symbol | RO/kg·m−3 | E/GPa | PR | A/MPa | B | N | EPS1 |

|---|---|---|---|---|---|---|---|

| Value | 7850 | 210 | 0.3 | 235 | 0.3 | 0.2 | 0.0 |

| Symbol | ESPO | C | M | EROD | DTF | CP | TM |

| Value | 1.0 | 0.001 | 0.8 | 0.0 | 0.0 | 500 | 1500 |

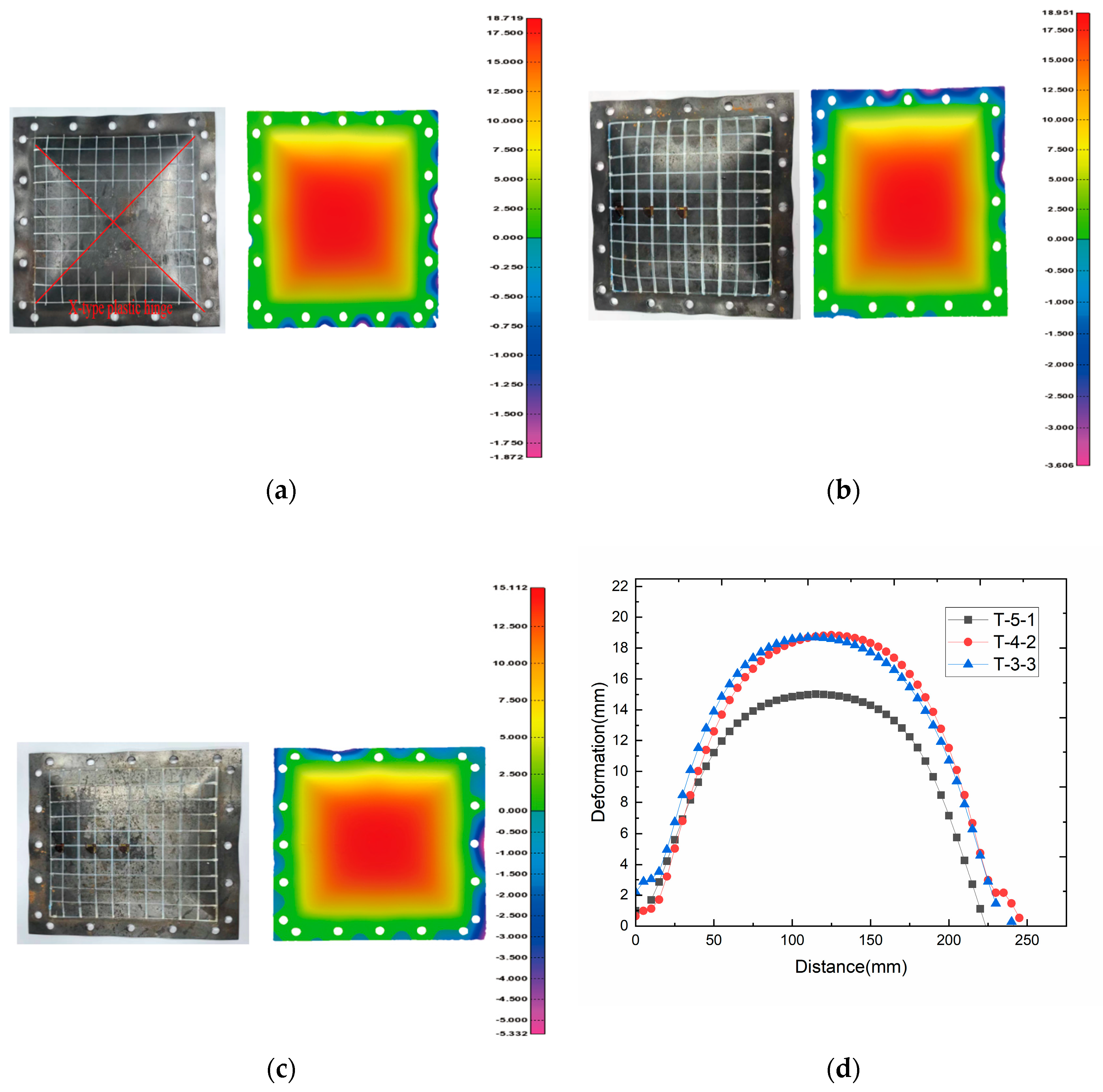

| Serial Number | Experimental Results/mm | Numerical Analysis Results/mm | Deviation |

|---|---|---|---|

| T-3-3 | 18.951 | 17.593 | 7.1% |

| T-4-2 | 18.719 | 17.495 | 6.5% |

| T-5-1 | 15.112 | 15.979 | 5.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Li, Y.; Li, D.; Hou, H. Impact Energy Absorption Behavior of Unequal Strength Liquid Storage Structures Under Drop Hammer Impact. Appl. Sci. 2025, 15, 10211. https://doi.org/10.3390/app151810211

Chen Z, Li Y, Li D, Hou H. Impact Energy Absorption Behavior of Unequal Strength Liquid Storage Structures Under Drop Hammer Impact. Applied Sciences. 2025; 15(18):10211. https://doi.org/10.3390/app151810211

Chicago/Turabian StyleChen, Zhenghan, Yongqing Li, Dian Li, and Hailiang Hou. 2025. "Impact Energy Absorption Behavior of Unequal Strength Liquid Storage Structures Under Drop Hammer Impact" Applied Sciences 15, no. 18: 10211. https://doi.org/10.3390/app151810211

APA StyleChen, Z., Li, Y., Li, D., & Hou, H. (2025). Impact Energy Absorption Behavior of Unequal Strength Liquid Storage Structures Under Drop Hammer Impact. Applied Sciences, 15(18), 10211. https://doi.org/10.3390/app151810211