Digital Twin and Computer Vision Combination for Manufacturing and Operations: A Systematic Literature Review

Abstract

1. Introduction

2. Background

2.1. Digital Twins in Manufacturing and Operations

2.2. Computer Vision in Manufacturing and Operations

2.3. Digital Twin with Computer Vision in Manufacturing and Operations

3. Materials and Methods

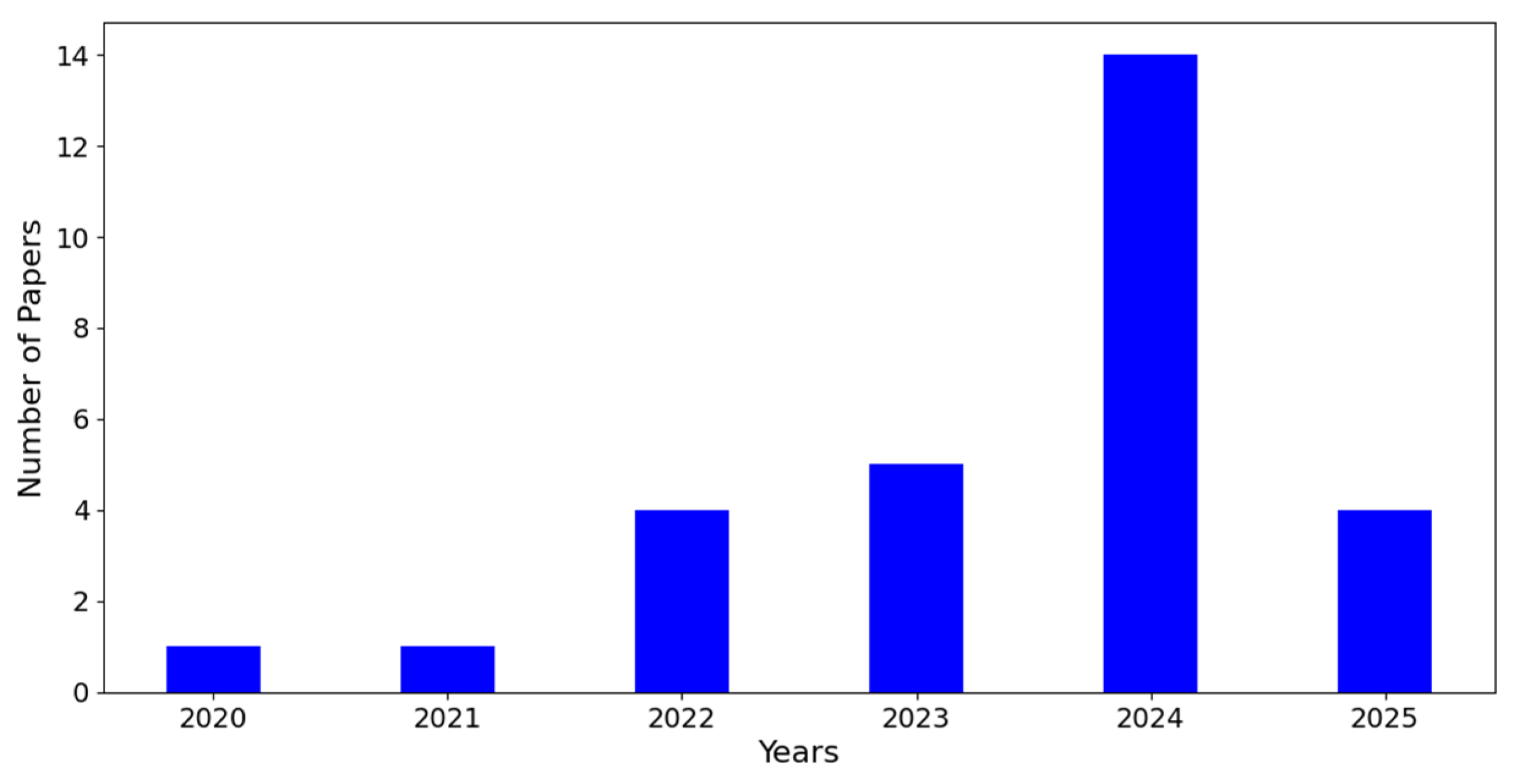

4. Results

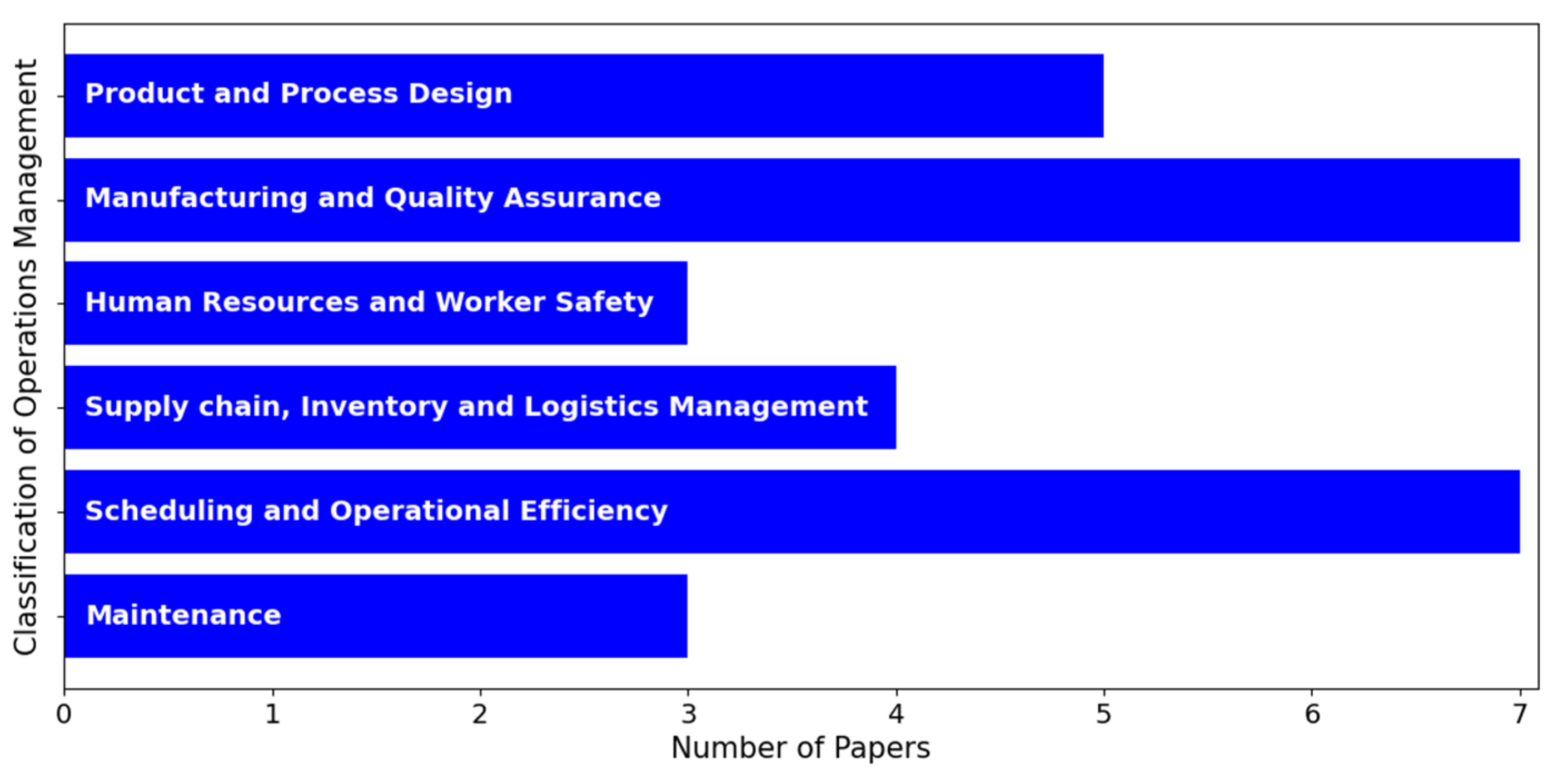

4.1. Application of DT-CV Combo in Industrial Operations and Management

4.1.1. Product and Process Design

4.1.2. Manufacturing and Quality Assurance

4.1.3. Human Resources and Worker Safety

4.1.4. Supply Chain, Inventory, and Logistics Management

4.1.5. Scheduling and Operational Efficiency

4.1.6. Maintenance

4.2. Summary of DT-CV Combo Research and Real-World Industrial Applications

4.3. Overcoming Barriers to DT-CV Combo Implementation in Industry

4.3.1. Implementation Barriers

4.3.2. Emerging Trends in Industry

4.4. Identified Gaps in the Literature

4.4.1. Case Studies

- What are the strategic financial costs and potential savings associated with deploying DT-CV combo solutions in manufacturing and operations?

- Which industries or operational areas offer the most immediate opportunities (“low-hanging fruit”) for achieving cost competitiveness relative to conventional approaches?

- What are the long-term sustainability implications of adopting DT-CV combinations in operations management?

4.4.2. Context and Method

- What are the real-world use cases of DT-CV combo solutions for industrial maintenance operations?

- How can worker safety benefit from DT-CV combo adoption while simultaneously improving efficiency and ensuring that both employers and employees maintain trust in the computer vision aspects of these solutions?

- How can logistics operations and supply chains—occurring outside factory boundaries and embedded in the physical world—deploy DT-CV solutions to strengthen resilience and mitigate challenges such as the bullwhip effect or supplier shocks during exogenous disruptions (e.g., pandemics, natural disasters)?

- In the context of the Internet of Digital Twins, how do DT-CV and DT-VLM combos impact operational efficiency, resilience, and sustainability in manufacturing networks?

- How do DT-CV combo-enabled solutions quantitatively impact cost and efficiency in OM?

4.4.3. Ethical and Regulatory Aspects

- How can worker privacy be ensured when deploying DT-CV combo-based solutions in an operational setting? And what are the different regulatory/ethical frameworks governing such deployment in different countries?

- What governance models can effectively balance the need for collaborative data sharing and federated learning with the protection of manufacturers’ intellectual property rights (IPR)?

- How can regulatory frameworks ensure compliance while enabling innovation in DT-CV combo applications in OM?

5. Discussion

5.1. The DT-CV Combo for Actionable Outputs in Operations Safety

5.2. Integration with Vision Language Models for Manufacturing and Quality Assurance

5.3. Dynamic Remodeling (Online Semantic 3D Mapping) of Factory DT for Operational Accuracy and Efficiency

5.4. Future Research Directions and Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yousif, I.; Burns, L.; El Kalach, F.; Harik, R. Leveraging computer vision towards high-efficiency autonomous industrial facilities. J. Intell. Manuf. 2024, 36, 2983–3008. [Google Scholar] [CrossRef]

- Albukhitan, S. Developing digital transformation strategy for manufacturing. Procedia Comput. Sci. 2020, 170, 664–671. [Google Scholar] [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital twin: Values, challenges and enablers from a modeling perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Qamar, R.; Zardari, B.A. Application of computer vision in manufacturing. In Machine Vision and Industrial Robotics in Manufacturing; CRC Press: Boca Raton, FL, USA, 2025; pp. 36–56. [Google Scholar]

- Omri, S.; Mehta, D.; Neuhüttler, J. Leveraging computer vision for sustainable manufacturing: Potentials, challenges and future perspectives. Adv. Emerg. Technol. 2023, 115, 115. [Google Scholar] [CrossRef]

- Li, J.; Zhou, G.; Zhang, C.; Hu, J.; Chang, F.; Matta, A. Defining a feature-level digital twin process model by extracting machining features from MBD models for intelligent process planning. J. Intell. Manuf. 2025, 36, 3227–3248. [Google Scholar] [CrossRef]

- NASA. Why Does the World (and NASA) Need Digital Twins? 2025. Available online: https://science.nasa.gov/biological-physical/why-does-the-world-and-nasa-need-digital-twins/ (accessed on 27 August 2025).

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, use cases, challenges, and opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.D.J. Digital twin technology challenges and applications: A comprehensive review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Mihai, S.; Yaqoob, M.; Hung, D.V.; Davis, W.; Towakel, P.; Raza, M.; Karamanoglu, M.; Barn, B.; Shetve, D.; Prasad, R.V.; et al. Digital twins: A survey on enabling technologies, challenges, trends and future prospects. IEEE Commun. Surv. Tutor. 2022, 24, 2255–2291. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Wan, X.; Zhou, S.; Gao, Z. Digital twin-driven surface roughness prediction and process parameter adaptive optimization. Adv. Eng. Inform. 2022, 51, 101470. [Google Scholar] [CrossRef]

- Zhang, K.; Zhou, H.-Y.; Baptista-Hon, D.T.; Gao, Y.; Liu, X.; Oermann, E.; Xu, S.; Jin, S.; Zhang, J.; Sun, Z.; et al. Concepts and applications of digital twins in healthcare and medicine. Patterns 2024, 5, 101028. [Google Scholar] [CrossRef] [PubMed]

- Vallée, A. Envisioning the future of personalized medicine: Role and realities of digital twins. J. Med. Internet Res. 2024, 26, e50204. [Google Scholar] [CrossRef]

- Asciak, L.; Kyeremeh, J.; Luo, X.; Kazakidi, A.; Connolly, P.; Picard, F.; O’nEill, K.; Tsaftaris, S.A.; Stewart, G.D.; Shu, W. Digital twin assisted surgery, concept, opportunities, and challenges. NPJ Digit. Med. 2025, 8, 32. [Google Scholar] [CrossRef] [PubMed]

- Deng, S.; Ling, L.; Zhang, C.Z.; Li, C.; Zeng, T.; Zhang, K.; Guo, G. A systematic review on the current research of digital twin in automotive application. Internet Things Cyber-Phys. Syst. 2023, 3, 180–191. [Google Scholar] [CrossRef]

- Yang, Z.; Zhao, X. Design and simulation of automotive digital instruments based on digital twin technology. In Proceedings of the 2024 4th International Symposium on Computer Technology and Information Science (ISCTIS), Xi’an, China, 12–14 July 2024; IEEE: New York, NY, USA, 2024; pp. 800–803. [Google Scholar]

- Kim, S.; Heo, S. An agricultural digital twin for mandarins demonstrates the potential for individualized agriculture. Nat. Commun. 2024, 15, 1561. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, M.H.; Yoe, H. Research on the design and application of digital twin-based smart agricultural systems. In Proceedings of the 2023 Congress in Computer Science, Computer Engineering & Applied Computing (CSCE), Las Vegas, NV, USA, 24–27 July 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Chernyshev, D.; Dolhopolov, S.; Honcharenko, T.; Haman, H.; Ivanova, T.; Zinchenko, M. Integration of building information modeling and artificial intelligence systems to create a digital twin of the construction site. In Proceedings of the 2022 IEEE 17th International Conference on Computer Sciences and Information Technologies (CSIT), Lviv, Ukraine, 10–12 November 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Nie, X. Design of building construction quality supervision system based on digital twin. In Proceedings of the 2023 International Conference on Telecommunications, Electronics and Informatics (ICTEI), Lisbon, Portugal, 11–13 September 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Xiong, T.; Cheng, Q.; Yang, C.; Yang, X.; Lin, S. Application of digital twin technology in intelligent building energy efficiency management system. In Proceedings of the 2021 International Conference on E-Commerce and E-Management (ICECEM), Dalian, China, 24–26 September 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Khan, M.S.; Chinnaiyan, R.; Balachandar, S.; Ibrahim, S.J.A.; Chakravarthy, N.K.; Kalaiarasan, C.; Divya, R. Centralized and reliable digital twin models for smart city’s buildings protection during disaster. In Proceedings of the 2022 International Conference on Computational Modelling, Simulation and Optimization (ICCMSO), Pathum Thani, Thailand, 23–25 December 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Liu, Z.; Li, M.; Ji, W. Development and application of a digital twin model for Net zero energy building operation and maintenance utilizing BIM-IoT integration. Energy Build. 2024, 328, 115170. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Hossein Motlagh, N.; Jaribion, A.; Werner, L.C.; Holmström, J. Digital twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Zhao, X. A novel digital-twin approach based on transformer for photovoltaic power prediction. Sci. Rep. 2024, 14, 26661. [Google Scholar] [CrossRef]

- Deakin, M.; Vanin, M.; Fan, Z.; Van Hertem, D. Smart energy network digital twins: Findings from a UK-based demonstrator project. arXiv 2023, arXiv:2311.11997. [Google Scholar] [CrossRef]

- Lei, Z.; Zhou, H.; Dai, X.; Hu, W.; Liu, G.P. Digital twin based monitoring and control for DC-DC converters. Nat. Commun. 2023, 14, 5604. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.; Niu, H.; Guan, M.; Chen, W.; Wang, Q.; Zheng, D.; He, P. Digital Twin Civil Aviation Research Airport for Aircraft Security and Environment Protection. In Proceedings of the 2022 IEEE 4th International Conference on Civil Aviation Safety and Information Technology (ICCASIT), Dali, China, 12–14 October 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Starostin, I.E.; Khalyutin, S.P.; Druzhinin, A.A.; Gavrilenkov, S.I. Development of an Information System of Digital Twins of Aviation Electrical Equipment as a Software Module of the Local Load Control Center. In Proceedings of the 2023 XX Technical Scientific Conference on Aviation Dedicated to the Memory of N.E. Zhukovsky (TSCZh), Moscow, Russia, 13–14 April 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Conde, J.; Munoz-Arcentales, A.; Romero, M.; Rojo, J.; Salvachúa, J.; Huecas, G.; Alonso, Á. Applying digital twins for the management of information in turnaround event operations in commercial airports. Adv. Eng. Inform. 2022, 54, 101723. [Google Scholar] [CrossRef]

- Kong, Q.; Zhou, H.; Du, Y.; Liu, N. Design of logistics distribution scheduling system based on computer digital twin. In Proceedings of the 2023 IEEE 3rd International Conference on Data Science and Computer Application (ICDSCA), Dalian, China, 27–29 October 2023; IEEE: New York, NY, USA, 2023; pp. 1161–1165. [Google Scholar]

- Hu, B.; Guo, H.; Tao, X.; Zhang, Y. Construction of digital twin system for cold chain logistics stereo warehouse. IEEE Access 2023, 11, 73850–73862. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, S.; Ballot, E. Unveiling the potential of digital twins in logistics and supply chain management: Services, capabilities, and research opportunities. Digit. Eng. 2024, 3, 100025. [Google Scholar] [CrossRef]

- Grand View Research. Digital Twin Market Size & Trends. Grand View Research Report. 2023. Available online: https://www.grandviewresearch.com/horizon/outlook/digital-twin-market-size/global (accessed on 15 April 2025).

- Szeliski, R. Computer Vision: Algorithms and Applications, 2nd ed.; Springer: Cham, Switzerland, 2022. [Google Scholar]

- GlobalData. Computer Vision Market Size, Share, Trends and Analysis by Region, Industry Vertical and Segment Forecasts to 2026. GlobalData Report. 2023. Available online: https://www.globaldata.com/store/report/computer-vision-market-analysis/ (accessed on 15 April 2025).

- Kaushal, S.; Tammineni, D.K.; Rana, P.; Sharma, M.; Kandi, S.; Chen, H.H. Computer vision and deep learning-based approaches for detection of food nutrients/nutrition: New insights and advances. Trends Food Sci. Technol. 2024, 146, 104408. [Google Scholar] [CrossRef]

- Almazán-Lázaro, J.A.; López-Alba, E.; Díaz-Garrido, F.A. Applied computer vision for composite material manufacturing by optimizing the impregnation velocity: An experimental approach. J. Manuf. Process. 2022, 74, 52–62. [Google Scholar] [CrossRef]

- Mezher, A.M.; Marble, A.E. Computer vision defect detection on unseen backgrounds for manufacturing inspection. Expert. Syst. Appl. 2024, 243, 122749. [Google Scholar] [CrossRef]

- Kabir, M.M.; Rahman, A.; Hasan, M.N.; Mridha, M.F. Computer vision algorithms in healthcare: Recent advancements and future challenges. Comput. Biol. Med. 2025, 185, 109531. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Computer vision to enhance healthcare domain: An overview of features, implementation, and opportunities. Sens. Int. 2024, 5, 100234. [Google Scholar] [CrossRef]

- Ghazal, S.; Munir, A.; Qureshi, W.S. Computer vision in smart agriculture and precision farming: Techniques and applications. Artif. Intell. Agric. 2024, 13, 64–83. [Google Scholar] [CrossRef]

- Lin, S.; Qi, X. Development of intelligent agricultural automation based on computer vision. In Proceedings of the 2023 International Conference on Integrated Intelligence and Communication Systems (ICIICS), Kalaburagi, India, 24–25 November 2023; IEEE: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Carbon Robotics. Laserweeding Technology. 2025. Available online: https://carbonrobotics.com/laserweeding-technology (accessed on 27 August 2025).

- Hou, X.; Li, C.; Fang, Q. Computer vision-based safety risk computing and visualization on construction sites. Autom. Constr. 2023, 156, 105129. [Google Scholar] [CrossRef]

- Jayaram, M.A. Computer vision applications in construction material and structural health monitoring: A scoping review. Mater. Today Proc. 2023, 74, 52–62. [Google Scholar] [CrossRef]

- Li, J.; Miao, Q.; Zou, Z.; Gao, H.; Zhang, L.; Li, Z.; Wang, N. A review of computer vision-based monitoring approaches for construction workers’ work-related behaviors. IEEE Access 2024, 12, 7134–7155. [Google Scholar] [CrossRef]

- Bajaj, S.; Yemula, P.K. Computer vision based energy monitoring system using Meter Image Capturing System (MICAPS). In Proceedings of the 2020 First International Conference on Power, Control and Computing Technologies (ICPC2T), Raipur, India, 3–5 January 2020; IEEE: New York, NY, USA, 2020. [Google Scholar]

- Liu, X.; Xia, H.; Li, K.; Lu, Y.; Lv, S.; Zhao, Q.; Song, W.; Wang, L. The real-time shadow detection of the PV module by computer vision based on histogram matching and gamma transformation method. Sci. Rep. 2024, 14, 21781. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, C.; Liu, S.; Zhao, Y.; Zhang, Y.; Wang, L. Multi-robot collaborative manufacturing driven by digital twins: Advancements, challenges, and future directions. J. Manuf. Syst. 2025, 82, 333–361. [Google Scholar] [CrossRef]

- Man, D.; Olchawa, R. The possibilities of using BCI technology in biomedical engineering. In Proceedings of the International Scientific Conference BCI 2018 Opole, Opole, Poland, 13–14 March 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 30–37. [Google Scholar]

- Stark, A.; Ferm, K.; Hanson, R.; Johansson, M.; Khajavi, S.; Medbo, L.; Holmström, J. Hybrid digital manufacturing: Capturing the value of digitalization. J. Oper. Manag. 2023, 69, 890–910. [Google Scholar] [CrossRef]

- Lu, Q.; Zhu, D.; Wang, M.; Li, M. Digital twin-driven thermal error prediction for CNC machine tool spindle. Lubricants 2023, 11, 219. [Google Scholar] [CrossRef]

- Kaur, N. Intelligent manufacturing in Industry 4.0. In Intelligent Manufacturing: Exploring AI, Blockchain, and Smart Technologies in Industry 4.0; CRC Press: Boca Raton, FL, USA, 2025; pp. 5–25. [Google Scholar]

- Soori, M.; Arezoo, B.; Dastres, R. Digital twin for smart manufacturing: A review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar] [CrossRef]

- Vetrivel, S.; Sowmiya, K.C.; Sabareeshwari, V. Digital Twins: Revolutionizing Business in the Age of AI. In Harnessing AI and Digital Twin Technologies in Businesses; IGI Global: Hershey, PA, USA, 2024; pp. 111–131. [Google Scholar]

- Yazdi, M. Digital twins and virtual prototyping for industrial systems. In Advances in Computational Mathematics for Industrial System Reliability and Maintainability; Springer: Cham, Switzerland, 2024; pp. 155–168. [Google Scholar]

- Sahal, R.; Alsamhi, S.H.; Breslin, J.G.; Brown, K.N.; Ali, M.I. Digital twins collaboration for automatic erratic operational data detection in Industry 4.0. Appl. Sci. 2021, 11, 3186. [Google Scholar] [CrossRef]

- Onaji, I.; Tiwari, D.; Soulatiantork, P.; Song, B.; Tiwari, A. Digital twin in manufacturing: Conceptual framework and case studies. Int. J. Comput. Integr. Manuf. 2022, 35, 831–858. [Google Scholar] [CrossRef]

- Leng, J.; Chen, Z.; Sha, W.; Lin, Z.; Lin, J.; Liu, Q. Digital twins-based flexible operating of open architecture production line for individualized manufacturing. Adv. Eng. Inform. 2022, 53, 101676. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, D.; Pham, D.T. Digital twin-enabled reconfigurable modeling for smart manufacturing systems. Int. J. Comput. Integr. Manuf. 2021, 34, 709–733. [Google Scholar] [CrossRef]

- Jiang, Y.; Ding, Y.; Zhang, Y.; Wang, Y.; Wang, J. Industrial applications of digital twins. Philos. Trans. A Math. Phys. Eng. Sci. 2021, 379, 20200360. [Google Scholar] [CrossRef] [PubMed]

- Vinci-Carlavan, G.; Rossit, D.; Toncovich, A. A digital twin for operations management in manufacturing engineering-to-order environments. J. Manuf. Syst. 2024, 42, 100679. [Google Scholar] [CrossRef]

- Lugaresi, G.; Gangemi, S.; Gazzoni, G.; Matta, A. Online validation of digital twins for manufacturing systems. Comput. Ind. 2023, 150, 103942. [Google Scholar] [CrossRef]

- Friederich, J.; Francis, D.P.; Lazarova-Molnar, S.; Mohamed, N. A framework for data-driven digital twins for smart manufacturing. Comput. Ind. 2022, 136, 103586. [Google Scholar] [CrossRef]

- Leng, J.; Zhou, M.; Xiao, Y.; Zhang, H.; Liu, Q.; Shen, W.; Su, Q.; Li, L. Digital twins-based remote semi-physical commissioning of flow-type smart manufacturing systems. J. Clean. Prod. 2021, 306, 127278. [Google Scholar] [CrossRef] [PubMed]

- Balakrishna, K.; Tiwari, V.; Deshpande, A.V.; Patil, S.R.; Garg, A.K.; Geetha, B.T. Computer vision for automated quality inspection in manufacturing. In Proceedings of the 2024 International Conference on Advances in Computing, Communication and Applied Informatics (ACCAI), Chennai, India, 9–10 May 2024; IEEE: New York, NY, USA, 2024. [Google Scholar]

- Yu, H.Z.; Li, W.; Li, D.; Wang, L.J.; Wang, Y. Enhancing additive manufacturing with computer vision: A comprehensive review. Int. J. Adv. Manuf. Technol. 2024, 132, 5211–5229. [Google Scholar] [CrossRef]

- Nascimento, R.; Martins, I.; Dutra, T.A.; Moreira, L. Computer vision based quality control for additive manufacturing parts. Int. J. Adv. Manuf. Technol. 2023, 124, 3241–3256. [Google Scholar] [CrossRef]

- O’Donovan, C.; Giannetti, C.; Pleydell-Pearce, C.J. Revolutionising the sustainability of steel manufacturing using computer vision. Procedia Comput. Sci. 2024, 232, 1729–1738. [Google Scholar] [CrossRef]

- Akhtar, S.; Martha, F. Quality Control in Retail and Manufacturing: Computer Vision Innovations for SME Operations. ResGate Preprint. 2024. Available online: https://www.researchgate.net/publication/386397839_Quality_Control_in_Retail_and_Manufacturing_Computer_Vision_Innovations_for_SME_Operations (accessed on 28 April 2025).

- Ji, J.; Pannakkong, W.; Buddhakulsomsiri, J. A computer vision-based system for metal sheet pick counting. Comput. Mater. Contin. 2023, 75, 3643–3656. [Google Scholar] [CrossRef]

- Deshpande, A.M.; Telikicherla, A.K.; Jakkali, V.; Wickelhaus, D.A.; Kumar, M.; Anand, S. Computer vision toolkit for non-invasive monitoring of factory floor artifacts. Procedia Manuf. 2020, 48, 1020–1028. [Google Scholar] [CrossRef]

- Yousif, I.; Samaha, J.; Ryu, J.; Harik, R. Safety 4.0: Harnessing computer vision for advanced industrial protection. Manuf. Lett. 2024, 41, 1342–1356. [Google Scholar] [CrossRef]

- Pivkin, P.; Nazarenko, E.; Grechishnikov, V.; Kuznetsov, V.; Uvarova, L.; Ershov, A.; Yazev, A.; Nadykto, A.; Onyusheva, I.; Markovich, D.; et al. Digital cyber-physical system for designing and manufacturing of conical end mill. E3S Web Conf. 2024, 592, 05024. [Google Scholar] [CrossRef]

- Moretti, M.; Rossi, A.; Senin, N. In-process monitoring of part geometry in fused filament fabrication using computer vision and digital twins. Addit. Manuf. 2021, 37, 101609. [Google Scholar] [CrossRef]

- Mahdi, M.M.; Sadeqi Bajestani, M.; Noh, S.D.; Kim, D.B. Digital twin-based architecture for wire arc additive manufacturing using OPC UA. Robot. Comput. Integr. Manuf. 2025, 94, 102944. [Google Scholar] [CrossRef]

- Humphries, J.; Van de Ven, P.; Amer, N.; Nandeshwar, N.; Ryan, A. Managing safety of the human on the factory floor: A computer vision fusion approach. Technol Sustain. 2024, 3, 309–331. [Google Scholar] [CrossRef]

- Jakhotiya, Y.; Rahul, M.R.; Chiddarwar, S.S. Integrating digital twin and computer vision system for efficient pick-and-place operation using Tecnomatix Process Simulate. Int. J. Interact. Des. Manuf. 2024, 18, 7429–7443. [Google Scholar] [CrossRef]

- Xiang, T.; Li, B.; Zhang, Q.; Leach, M.; Lim, E.G. A novel approach to grasping control of soft robotic grippers based on digital twin. In Proceedings of the 29th International Conference on Automation and Computing (ICAC), Sunderland, UK, 28–30 August 2024. [Google Scholar]

- Haponik, A. Digital Twin—Computer Vision Use Case. Addepto Blog. 2024. Available online: https://addepto.com/blog/digital-twin-computer-vision-use-case/ (accessed on 27 August 2025).

- Touhid, M.T.B.; Zhu, E.; Ehteshamfara, M.V.; Yang, S. Evaluation of digital twin synchronization in robotic assembly using YOLOv8. Int. J. Adv. Manuf. Technol. 2024, 134, 871–885. [Google Scholar] [CrossRef]

- Sow, M.C.; Assila, A.; Garcia, D.; Martinez, S.; Zghal, M.; Baudry, D. Towards the development of a digital twin for micro learning factory: A proof of concept. In Extended Reality: International Conference, XR Salento 2023, Lecce, Italy, 6–9 September 2023, Proceedings, Part I; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2023; Volume 14218, pp. 284–298. [Google Scholar]

- Busch, R. Explore Digital Twins Accelerated by NVIDIA Omniverse. NVIDIA. 2024. Available online: https://www.nvidia.com/en-us/learn/learning-path/digital-twins/ (accessed on 27 August 2025).

- Hohenstein, J. BMW to Work Globally on Vehicle Virtual Twins with Data-Driven Approach. Metrology and Quality News. 2024. Available online: https://metrology.news/bmw-to-work-globally-on-vehicle-virtual-twins-with-data-driven-approach/ (accessed on 27 August 2025).

- Sauerwein, D.; Winterholer, M.; Boehmer, S.; Perez Hallerbach, I. Using Computer Vision to Enable Digital Building Twins with NavVis and AWS. AWS Partner Network Blog. 2023. Available online: https://aws.amazon.com/blogs/apn/using-computer-vision-to-enable-digital-building-twins-with-navvis-and-aws/ (accessed on 27 August 2025).

- Akkila, J. Production and Maintenance Operations in Real Time on the 3D Digital Twin Platform. Process Genius/Konecranes. 2021. Available online: https://processgenius.eu/konecranes/ (accessed on 27 August 2025).

- Detectium. Leveraging Digital Twins and Artificial Intelligence. Detectium.io. 2023. Available online: https://next.detectium.io/ (accessed on 27 August 2025).

- Koerte, P. Siemens Unveils Breakthrough Innovations in Industrial AI and Digital Twin Technology. Siemens Press Release. 2025. Available online: https://press.siemens.com/global/en/pressrelease/siemens-unveils-breakthrough-innovations-industrial-ai-and-digital-twin-technology-ces (accessed on 27 August 2025).

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and identification of current research trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Heizer, J.; Render, B. Operations Management, 7th ed.; Pearson Prentice Hall: Saddle River, NJ, USA, 2003; p. 29. [Google Scholar]

- Cristofoletti, M.; Emrith, K.; Elsaddik, A.; Karray, F. Towards a computer vision-based approach for digital twin implementation. In Proceedings of the 2023 International Conference on Intelligent Metaverse Technologies & Applications (iMETA), Tartu, Estonia, 18–20 September 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Liu, J.; Huang, I.; Anand, A.; Chang, P.-H.; Huang, Y. Digital twin in retail: An AI-driven multi-modal approach for real-time product recognition and 3D store reconstruction. In Proceedings of the 2024 IEEE Conference on Virtual Reality and 3D User Interfaces Abstracts and Workshops (VRW), Orlando, FL, USA, 16–21 March 2024; IEEE: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Urgo, M.; Terkaj, W.; Simonetti, G. Monitoring manufacturing systems using AI: A method based on a digital factory twin to train CNNs on synthetic data. CIRP J. Manuf. Sci. Technol. 2024, 50, 249–268. [Google Scholar] [CrossRef]

- Çapunaman, Ö.B.; Farrokhsiar, P.; Bilén, S.G.; Duarte, J.P.; Gürsoy, B. Vision-based sensing and digital twin technologies in conformal 3D concrete printing. Constr. Robot. 2025, 9, 4. [Google Scholar] [CrossRef]

- Stürmer, J.M.; Graumann, M.; Koch, T. Demonstrating automated generation of simulation models from engineering diagrams. In Proceedings of the 2023 IEEE International Conference on Machine Learning and Applications (ICMLA), Jacksonville, FL, USA, 15–17 December 2023; IEEE: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Oyekan, J.; Farnsworth, M.; Hutabarat, W.; Miller, D.; Tiwari, A. Applying a 6 DoF robotic arm and digital twin to automate fan-blade reconditioning for aerospace maintenance, repair, and overhaul. Sensors 2020, 20, 4637. [Google Scholar] [CrossRef]

- Sousa, T.; Ibusuki, U.; Del Conte, E. Development of a digital twin for spot welding quality inspection in an Industry 4.0 testbed of a Brazilian university. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022. [Google Scholar]

- Doroszuk, B.; Bortnowski, P.; Ozdoba, M.; Król, R. Calibrating the Digital Twin of a Laboratory Ball Mill for Copper Ore Milling: Integrating Computer Vision and Discrete Element Method and Smoothed Particle Hydrodynamics (DEM-SPH) Simulations. Minerals 2024, 14, 407. [Google Scholar] [CrossRef]

- Döbrich, O.; Brauner, C.J.F. Machine vision system for digital twin modeling of composite structures. Front. Mater. 2023, 10, 1154655. [Google Scholar] [CrossRef]

- Weckx, S.; Meyers, B.; Jordens, J.; Robyns, S.; Baake, J.; Lietaert, P.; De Geest, R.; Maes, D. Development and deployment of a digital twin for monitoring of an adaptive clamping mechanism, used for high performance composite machining. IET Collab. Intell. Manuf. 2022, 4, 112–122. [Google Scholar] [CrossRef]

- Aiken, W.; Carden, L.; Bhabhrawala, A.; Branco, P.; Jourdan, G.V.; Berg, A. Strategic digitalization in oil and gas: A case study on mixed reality and digital twins. IEEE Access 2024, 12, 87248–87267. [Google Scholar] [CrossRef]

- Yi, S.; Wu, Y.; Li, J.; Zhang, C.; Zhou, H. A vision-based human–robot collaborative system for digital twin. Procedia CIRP 2022, 107, 552–557. [Google Scholar] [CrossRef]

- Arbabian, A.; Pezeshk, A.; Yang, K. Productivity enhancement in semiconductor manufacturing with AI-enabled operations digital twin platform. In Proceedings of the 2024 19th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IM-PACT), Taipei, Taiwan, 22–25 October 2024; IEEE: New York, NY, USA, 2024. [Google Scholar]

- Rivera-Calderón, S.; Pérez-San Lázaro, R.; Vazquez-Hurtado, C. Online assessment of computer vision and robotics skills based on a digital twin. In Proceedings of the 2022 IEEE Global Engineering Education Conference (EDUCON), Tunis, Tunisia, 28–31 March 2022; IEEE: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Cheng, D.; Liu, Y.; Zhang, Y.; Han, J.; Zhang, W. A digital twin-driven guidance method for human–machine collaborative assembly operations based on machine learning and computer vision. In Proceedings of the 2024 International Conference on Networking, Sensing and Control (ICNSC), Hangzhou, China, 18–20 October 2024; IEEE: New York, NY, USA, 2024. [Google Scholar] [CrossRef]

- Kovari, A.J. A framework for integrating vision transformers with digital twins in Industry 5.0 context. Machines 2025, 13, 36. [Google Scholar] [CrossRef]

- Legaz, M.J.G.; Gaspar, H.M. Computer vision for reverse engineering in the design, simulation and operation of maritime systems. In Proceedings of the 38th ECMS International Conference on Modelling and Simulation (ECMS 2024), Cracow, Poland, 4–7 June 2024; European Council for Modelling and Simulation: Ostend, Belgium, 2024. [Google Scholar] [CrossRef]

- Ward, R.; Soulatiantork, P.; Finneran, S.; Hughes, R.; Tiwari, A. Real-time vision-based multiple object tracking of a production process: Industrial digital twin case study. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1861–1872. [Google Scholar] [CrossRef]

- Ullah, A.; Younas, M.; Saharudin, M.S. Digital twin framework using real-time asset tracking for smart flexible manufacturing system. Machines 2025, 13, 37. [Google Scholar] [CrossRef]

- Zhang, S. Application of computer vision 3D imaging sensing technology in GIS high-voltage power bushing gas composition detection and its device development. In Proceedings of the 2023 8th International Conference on Image, Vision and Computing (ICIVC), Dalian, China, 27–29 July 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Pila, L.D. Image processing in digital twin solutions: A technical overview. Int. J. Comput. Eng. Technol. 2025, 16, 339–350. [Google Scholar] [CrossRef]

- Kozin, E. Operational management of production for car maintenance and repair using digital twin technology. In The Future of Industry: Human-Centric Approaches in Digital Transformation; Springer: Cham, Switzerland, 2024; pp. 205–218. [Google Scholar]

- Pavlosky, S. How Can Smart Factories Use Digital Twins to Learn and Test Before Deploying in a Real-World Environment. GE Vernova Blog. 2025. Available online: https://www.gevernova.com/software/blog/how-digital-twin-simulation-software-improves-manufacturing-operations (accessed on 27 August 2025).

- Nvidia. Amazon Robotics Deploys First Fully Autonomous Robot with NVIDIA Isaac Sim. YouTube. 2023. Available online: https://www.youtube.com/watch?v=LUnZXBL_lqA (accessed on 27 August 2025).

- Vimaan. The Role of Computer Vision in a Warehouse Digital Twin. Vimaan Blog. 2025. Available online: https://vimaan.ai/resources/blog/warehouse-digital-twin-explained/ (accessed on 27 August 2025).

- Shyalika, C.; Prasad, R.; Jaimini, U.; Henson, C.; El Kalach, F.; Sheth, A. Multiagent CoPilot in industrial AI applications. In Proceedings of the 24th Int Conf Autonomous Agents and Multiagent Systems (AAMAS), Detroit, MI, USA, 19–23 May 2025. [Google Scholar]

- National Ocean Channel. Industrial Digital Twins for Simulating Robot Fleets. YouTube. 2022. Available online: https://www.youtube.com/watch?v=IuWk0C3MzBQ (accessed on 27 August 2025).

- Zheng, O.; Abdel-Aty, M.; Yue, L.; Abdelraouf, A.; Wang, Z.; Mahmoud, N. CitySim: A drone-based vehicle trajectory dataset for safety-oriented research and digital twins. Transp. Res. Rec. 2024, 2678, 606–621. [Google Scholar] [CrossRef]

- Ghosh, A.; Acharya, A.; Saha, S.; Jain, V.; Chadha, A. Exploring the frontier of vision–language models: A survey of current methodologies and future directions. arXiv 2024, arXiv:2404.07214. [Google Scholar]

- ISO 9001:2015; Quality Management Systems—Requirements. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2015.

- Heras-Saizarbitoria, I.; Boiral, O. ISO 9001 and ISO 14001: Towards a research agenda on management system standards. Int. J. Manag. Rev. 2013, 15, 47–65. [Google Scholar] [CrossRef]

- Kandie, C.J. Effect of ISO 9001:2008 Standard Certifications on Sustainable Performance of Kenyan Public Universities. Master’s Thesis, University of Eldoret, Eldoret, Kenya, 2019. [Google Scholar]

- Sundby, T.; Graham, J.M.; Rasheed, A.; Tabib, M.; San, O. Geometric change detection in digital twins using 3D machine learning. Digital 2021, 1, 111–129. [Google Scholar] [CrossRef]

- Webb, A.M.; Brown, G.; Luján, M. ORB-SLAM-CNN: Lessons in adding semantic map construction to feature-based SLAM. In Proceedings of the Annual Conference Towards Autonomous Robotic Systems, London, UK, 3–5 July 2019; Springer: Cham, Switzerland, 2019; pp. 221–235. [Google Scholar]

| OM Aspect | Conventional Approach | New Approach/Emerging Technologies |

|---|---|---|

| Planning & control | MRP-based fixed, step-by-step planning [53] | ERP with flexible, real-time decision-making using data [53] |

| Process optimization | Optimizing individual processes in isolation [55] | Coordinating multiple workflows dynamically [55] |

| Maintenance | Manual inspection and scheduled maintenance | DT for synchronized monitoring, automation, anomaly detection, and predictive maintenance [56,57,58,59] |

| Simulation & process design | Limited physical trials, reliance on expert knowledge | DT-based multi-physics simulations, adaptive decision-making, worker training via simulations [60,61,62,63,64,65,66] |

| Operational stability | Rigid control systems with limited adaptability | DT ensuring stability under uncertain conditions [63] |

| Operational coordination | Separate silos (engineering, planning, shop-floor operations) | DTs enhancing coordination across functions, supporting agility in engineer-to-order environments [64] |

| Risk management | Reactive fault detection | DT-based real-time validation, improved fault detection, and system reliability [65] |

| Commissioning & sustainability | Longer system validation, more material waste | DT-based commissioning reduces validation time, minimizes waste, and supports sustainability [67] |

| OM Aspect | Traditional Approach | New Approach/Emerging Technologies |

|---|---|---|

| Inspection & quality control | Manual inspection, human-dependent, lower efficiency | CV automating QC inspection, defect detection, quality monitoring, potential for higher efficiency [68,72,73] |

| Process design in additive manufacturing | Limited monitoring of print jobs | CV for real-time defect detection during 3D printing [69,70] |

| Quality assurance in heavy industry (e.g., steel) | Manual surface defect checks | CV for automated defect detection and consistent quality control [71] |

| Supply chain management | Manual inventory tracking and logistics management | CV-driven toolkits for real-time inventory tracking, automated logistics [74] |

| Sustainable manufacturing | Higher waste, reactive maintenance | CV and DT for predictive maintenance, resource optimization, waste reduction [5] |

| Workforce safety | Manual compliance tracking, reliance on supervisors | CV automating PPE detection, compliance tracking, and safety monitoring [1,75] |

| Classification | Scope | Outlet | Applications |

|---|---|---|---|

| Product and Process Design | 1. DT-CV combo for optimized 3D printing material selection [6] | J. Intell. Manuf. | Material Optimization |

| 2. Digital Cyber-Physical System for Tool Design & Machining Process [76] | E3S Web Conf. | Virtual Prototyping & Simulation | |

| 3. Digitization of Engineering Diagrams for Hydraulic System Model Creation [96] | Constr. Robot. J. | 3D printing optimization | |

| 4. Feature-Level Digital Twin Process Model (FL-DTPM) for Aerospace Manufacturing Optimization [97] | IEEE International Conference on Machine Learning and Applications | Automated Design Validation | |

| 5. The design prototype utilizes a DT-CV combo, a 6-DoF industrial robot, and an end-effector grinder for optimizing the grinding process [98] | Sensors | Real-time monitoring & performance analysis | |

| Manufacturing & Quality Assurance | 1. A Novel Object Recognition Approach with DT-CV combo for Autonomous Robot Correction [1] | J. Intell. Manuf. | Minimizes human interaction and reduces disruption of manufacturing operations. |

| 2. Vision-Guided Micro adjustments framework for fused filament Fabrication [77] | Addit. Manuf. | Defect Detection, Quality Controls | |

| 3. DT-CV combo for Adaptive Quality Control of Industrial Robot Grippers [81] | 29th International Conference on Automation and Computing | Robot Performance Analytics | |

| 4. Quality Inspection for Automotive Welding with DT-CV combo [99] | 12th Conference on Learning Factories | Quality inspection | |

| 5. DT-CV combo for Process Synchronization in Grinding Mill Operations [100] | Minerals | Energy Consumption Monitoring | |

| 6. Digitalization of the composite production Process chain [101] | Front. Mater. | Optimization of the manufacturing of Composite Material. | |

| 7. A Cloud-Based DT-CV combo Model for Monitoring the Machining of Composite Parts in Manufacturing [102] | IET Collab. Intell. Manuf. | Visual Anomaly Detection | |

| Human resources and worker safety | 1. A DT-CV combo Approach for Managing Human Safety on the Factory Floor [79] | Technol. Sustain. | Hazard monitoring |

| 2. DT-CV combo Framework for Route Planning to Train Robots to Interact with Objects [93] | International Conference on Intelligent Metaverse Technologies & Applications | Anomaly detection | |

| 3. DT-CV combo Framework with Adaptive Architectures for Employee Training in the Oil and Gas Industry [103] | IEEE Access | Mixed reality safety training | |

| 4. A Novel DT-Based Approach for Developing a Human–robot Collaborative Assembly System [104] | Procedia CIRP | Robotic safety enhancement, Emergency Response Simulation | |

| Supply chain, inventory, and logistics management | 1. AI-driven multi-modal approach with DT for real-time in-store product recognition and reconstruction [94] | IEEE Conference on Virtual Reality and 3D User Interfaces Abstracts and Workshops | Package Integrity Verification, Warehouse/Retail automation |

| 2. A DT-CV-Based Human–machine Collaboration Model with Indoor Tracking for Electronics Manufacturing [105] | 19th International Microsystems, Packaging, Assembly and Circuits Technology Conference | Route Optimization, Smart Inventory Tracking | |

| 3. A Bin Picker Using Mono and Stereo Vision with DT-CV for Classifying and Arranging Cylinders by Color and Size [106] | 2022 IEEE Global Engineering Education Conference | Robotic Bin Picking, Autonomous Robots Coordination | |

| Scheduling and operational efficiency | 1. A Cobot Optimizing Pick-and-Place Operations with DT-CV combo in Tecnomatix Process Simulate [80] | Int. J. Interact. Des. Manuf. | Enhance Cobot Efficiency, Resource Optimization, Process Automation |

| 2. A DT-CV-Enabled Model for Advanced Real-Time Monitoring in Manufacturing Systems [95] | CIRP Annals—Manufacturing Technology | Historical Failure Analysis, Downtime Reduction | |

| 3. The Human–machine Collaborative Method Using DT-CV combo for Assembly Operations in the Automotive Industry [107] | 2024 International Conference on Networking, Sensing and Control | Human–machine Collaboration Analytics, PPE Compliance Monitoring | |

| 4. A DT-CV combo Framework for Analyzing Multidimensional Data, Integrating Operational and Visual Streams for Real-Time Tracking and Decision-Making in Industry [108] | Machines | Workflow Visualization and Optimization, | |

| 5. A DT-CV combo Framework for Reverse Engineering in Maritime Systems [109] | 38th ECMS International Conference on Modelling and Simulation | Recreation of the model/system | |

| 6. A design model for real-time vision-based multi-object tracking in production processes [110] | Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. | Dynamic Demand-Response Scheduling | |

| 7. A DT- CV combo framework integrating real-time asset tracking for smart flexible manufacturing systems [111] | Machines | AI-Driven Resource Allocation | |

| Maintenance | 1. A DV-CV combo Method for High-Precision Gas Composition Detection in High-Voltage Equipment Using 3D Imaging for Insulation Monitoring [112] | 8th International Conference on Image, Vision and Computing | Insulation Monitoring, Gas linkage |

| 2. Enhancing Industrial Operations with DT by Integrating Image Processing for Real-Time Monitoring [113] | Int. J. Comput. Eng. Technol. | Automated Repair Planning | |

| 3. A DT-CV combo Simulation Model for the Predictive Maintenance of Car Service Stations [114] | The Future of Industry Book | Condition-Based Simulations |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faqeer, H.A.; Khajavi, S.H. Digital Twin and Computer Vision Combination for Manufacturing and Operations: A Systematic Literature Review. Appl. Sci. 2025, 15, 10157. https://doi.org/10.3390/app151810157

Faqeer HA, Khajavi SH. Digital Twin and Computer Vision Combination for Manufacturing and Operations: A Systematic Literature Review. Applied Sciences. 2025; 15(18):10157. https://doi.org/10.3390/app151810157

Chicago/Turabian StyleFaqeer, Haji Ahmed, and Siavash H. Khajavi. 2025. "Digital Twin and Computer Vision Combination for Manufacturing and Operations: A Systematic Literature Review" Applied Sciences 15, no. 18: 10157. https://doi.org/10.3390/app151810157

APA StyleFaqeer, H. A., & Khajavi, S. H. (2025). Digital Twin and Computer Vision Combination for Manufacturing and Operations: A Systematic Literature Review. Applied Sciences, 15(18), 10157. https://doi.org/10.3390/app151810157