Analytical Method for Temperature Field Distribution of Annular Double-Loop Freezing Pipes in Adjacent Urban Tunnels

Abstract

1. Introduction

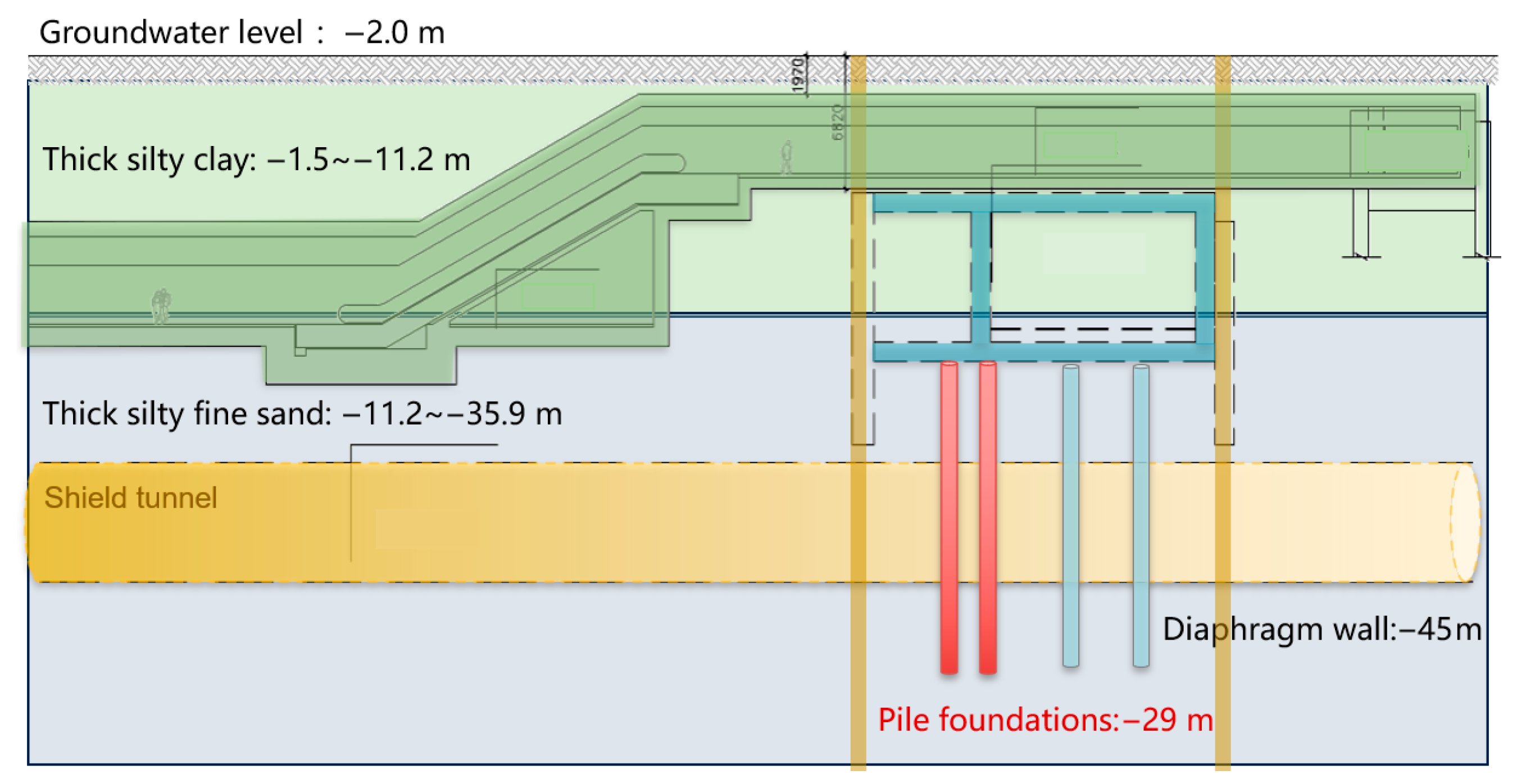

2. Project Overview

2.1. Project Introduction

2.2. Engineering Geological Conditions

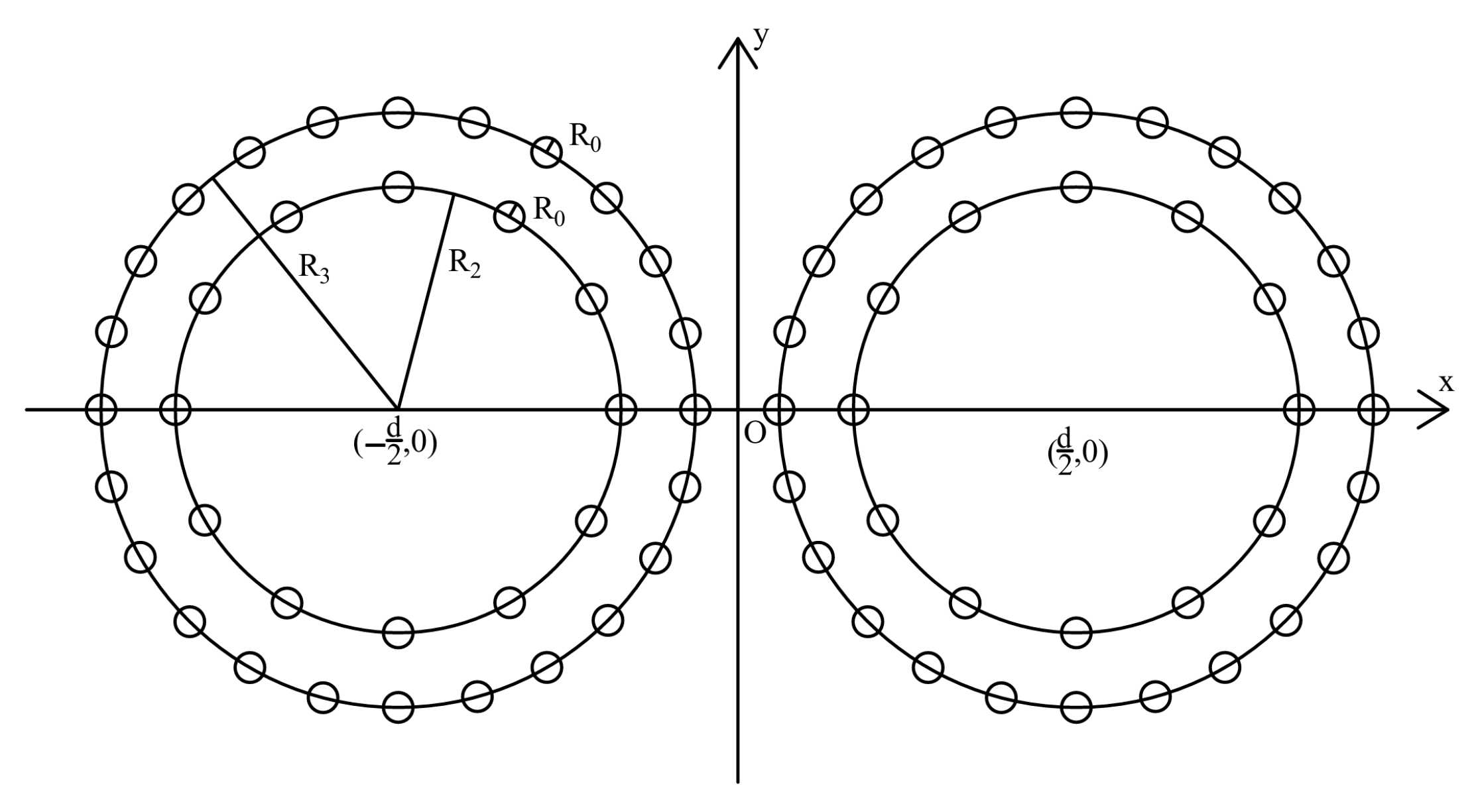

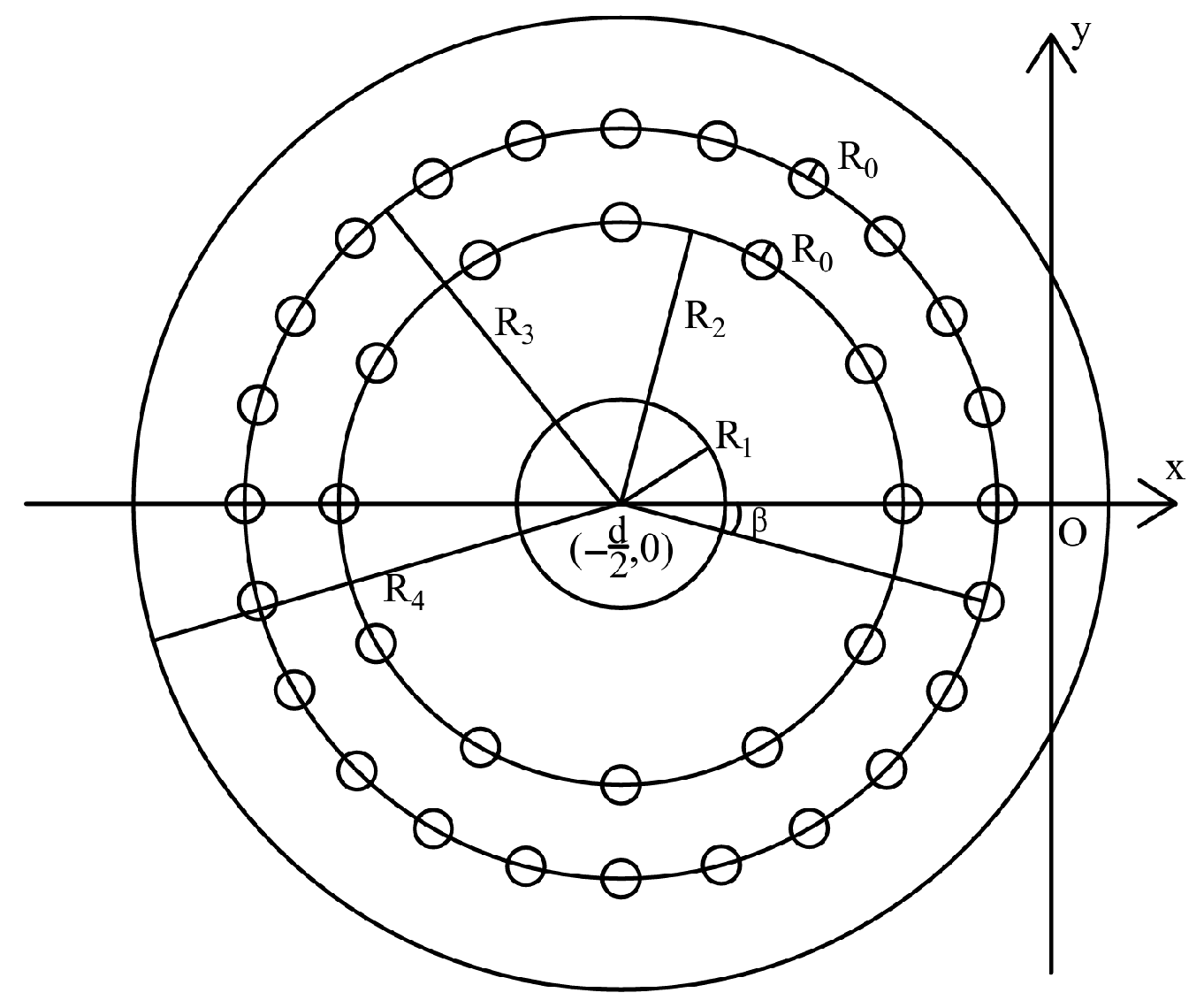

2.3. Freezing Scheme Design

3. Derivation of Analytical Solutions

3.1. Control Equations and Physical Assumptions

- The freezing pipes maintain a constant low temperature , while the external soil temperature remains constant at ;

- The frozen curtain has formed, and the temperature field has stabilized, which can be regarded as quasi-steady state;

- The thermodynamic parameters of the soil are independent of temperature and treated as constants;

- The frozen zone enclosed by the double-loop freezing pipes is circular or approximately circular.

3.2. Double-Loop Pipes Freezing Model of Single Tunnel with Incomplete Freezing

3.3. Transformation from Polar Coordinates to Cartesian Coordinates

3.4. Conformal Transformation

4. The Construction and Solution of Planar Temperature Field Solutions

4.1. Analytical Solution of Image Plane Temperature Field

4.2. Analytical Solution of Object Plane Temperature Field

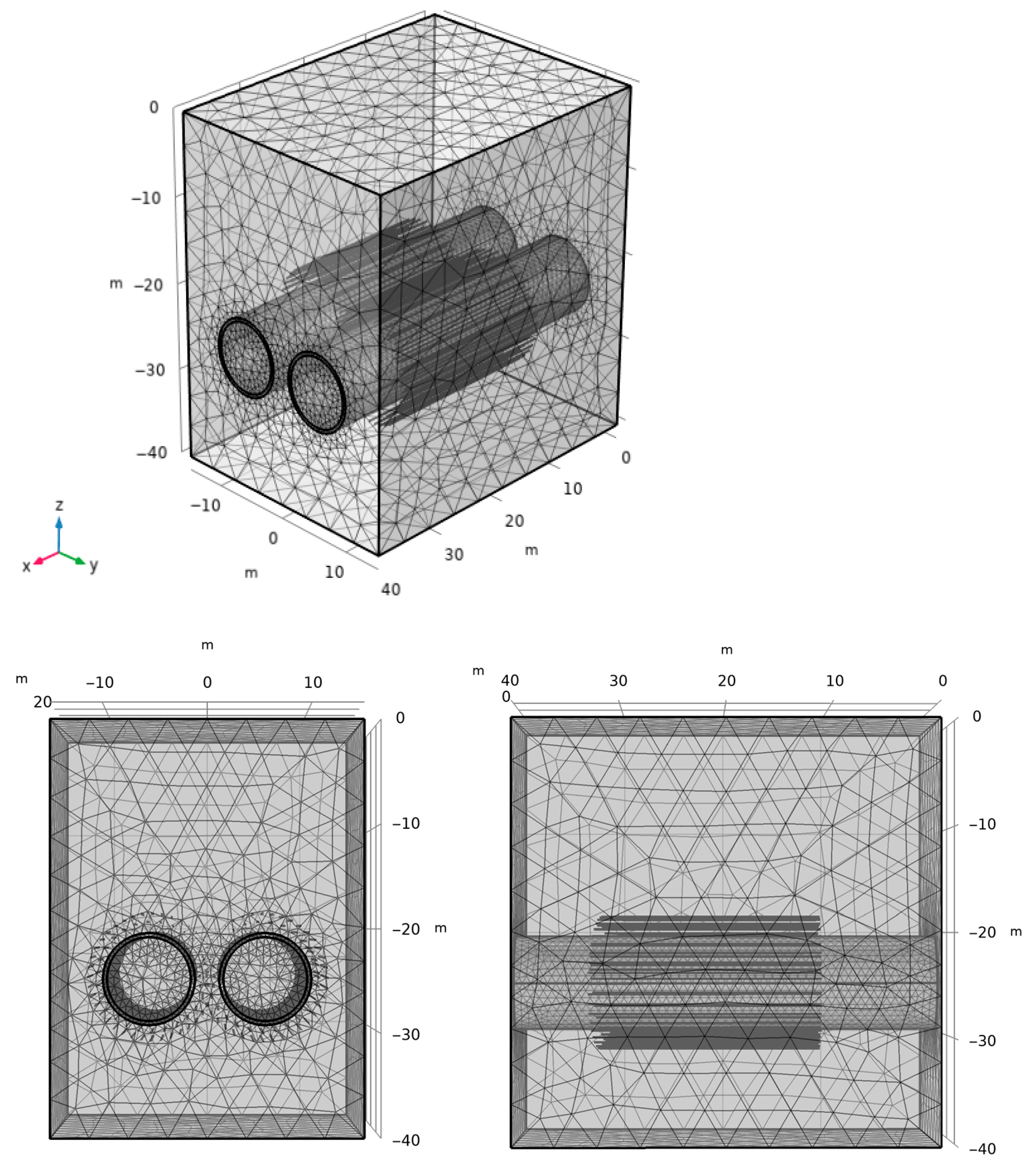

5. Finite Element Numerical Model

5.1. Geometric Modeling

5.2. Material Parameter Setting

5.3. Boundary Condition Setting and Grid Division

5.4. Solution Settings and Two-Dimensional Equivalent Extraction

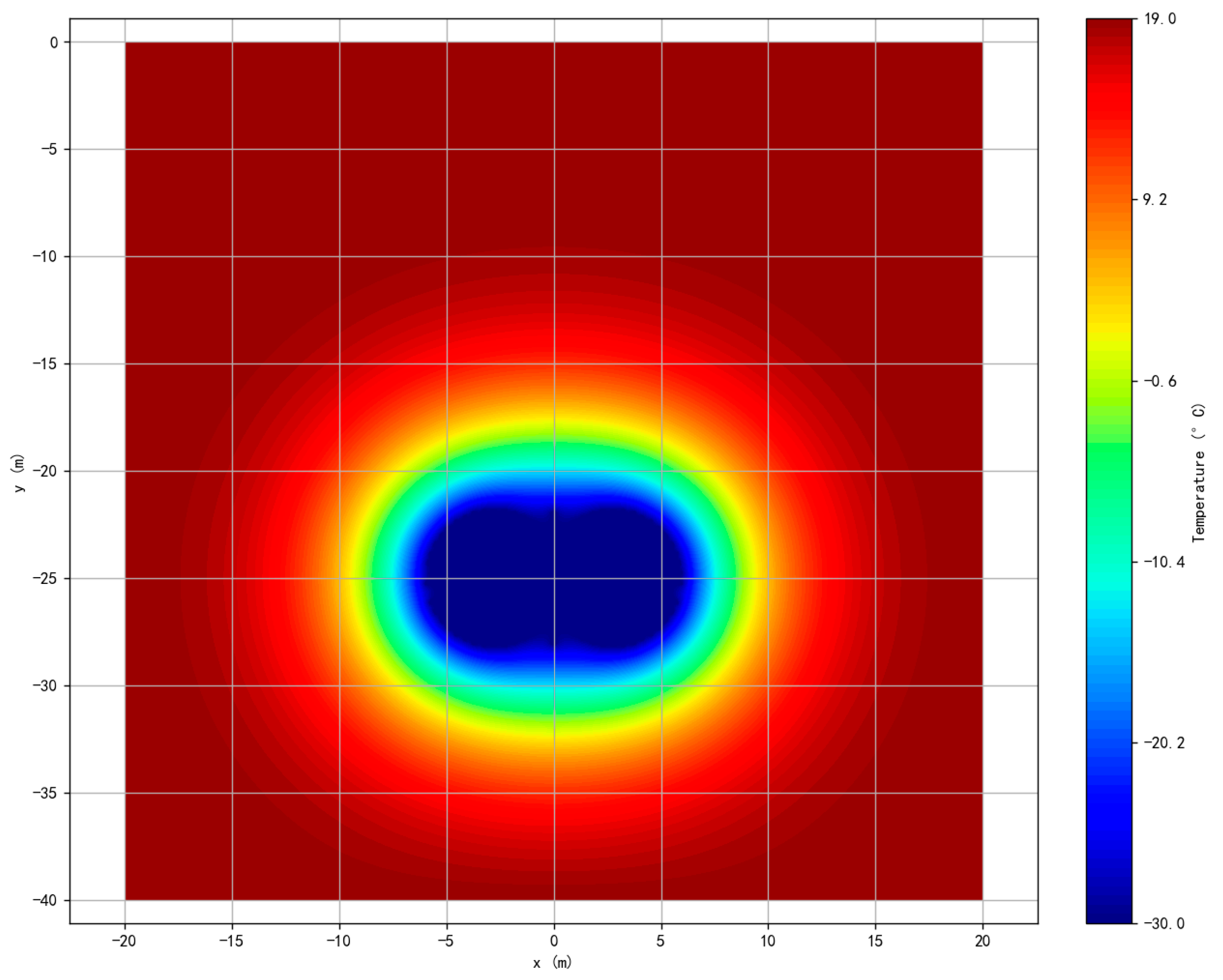

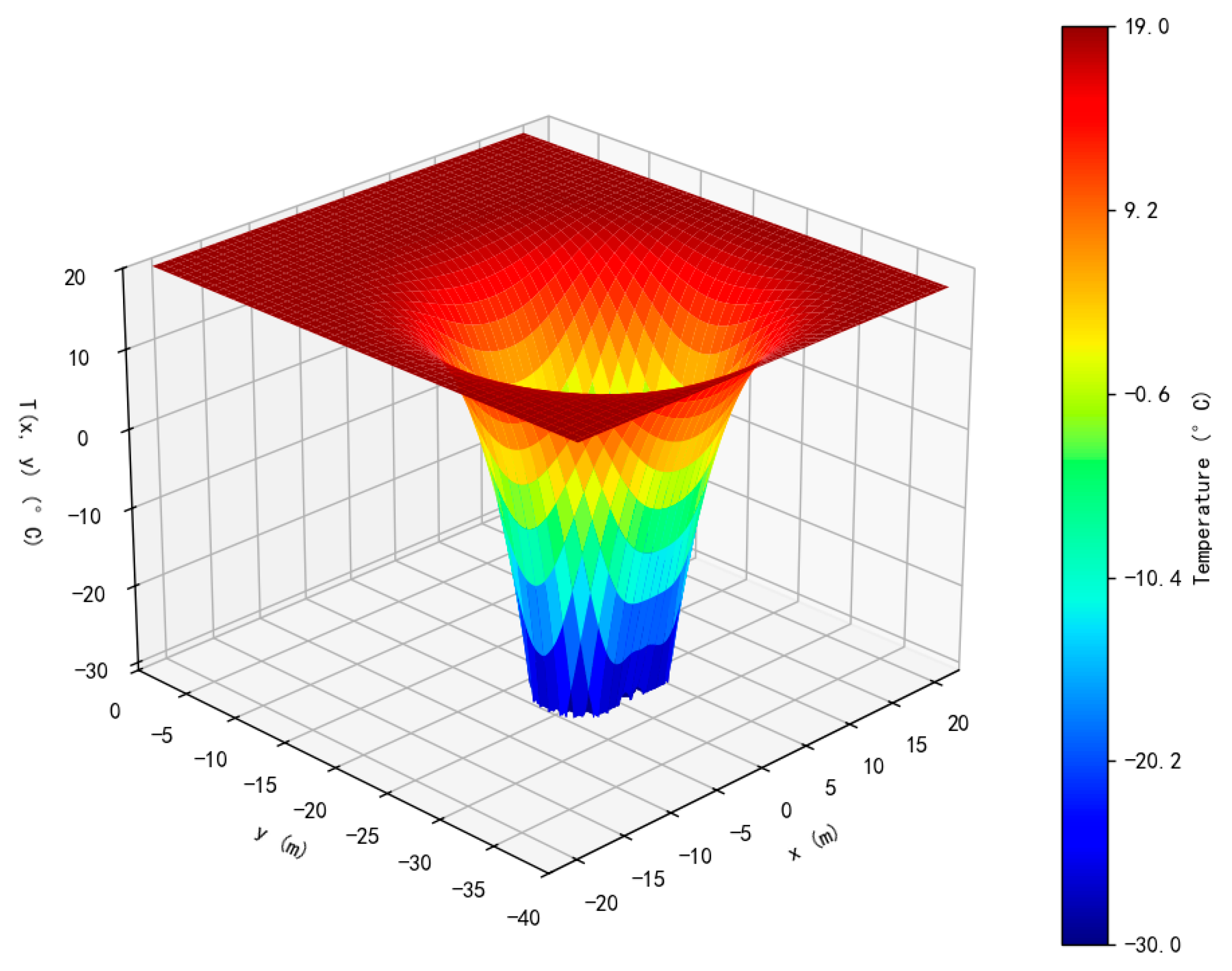

6. Accuracy Test of the Solution

7. Conclusions

- Model development and applicability. The analytical framework successfully transforms the complex double-loop system into a solvable generalized single-row problem through heat source superposition. The proposed model is applicable under steady-state conditions, with assumptions of constant soil thermal parameters and negligible groundwater flow and phase-change effects. It is thus suitable mainly for preliminary design, parameter optimization, and sensitivity studies, but not for final safety assessments under highly dynamic or heterogeneous conditions.

- Accuracy and validation. Quantitative comparisons with COMSOL Multiphysics 6.2 numerical simulations confirm the reliability of the analytical model. At seven representative points, the RMSE between the analytical and numerical results was 1.462 °C, with relative errors of 2.57–6.99% and a correlation coefficient of R = 0.534. These results demonstrate that the analytical solution can reproduce the overall temperature distribution trend, isothermal contour shapes, and frozen core area characterization with sufficient accuracy for engineering applications.

- Sensitivity and robustness. A sensitivity analysis indicates that the analytical solution responds predictably to variations in soil thermal conductivity, freezing pipe radius and spacing, and brine temperature. This highlights its robustness for design parameter evaluation, even though simplifications may limit absolute accuracy.

- Engineering significance. The analytical model provides a rapid and practical tool for early-stage freezing scheme design and optimization, significantly improving computational efficiency. For detailed verification and risk control, particularly under complex geological and hydrogeological conditions, COMSOL numerical simulations remain indispensable. The combination of both approaches offers a comprehensive methodology for freezing design in adjacent tunnels.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Definition | Unit |

| The abscissa of the center of the circle | m | |

| Freezing tube radius | m | |

| The inner boundary of the frozen zone | m | |

| The arrangement radius of the inner ring freezing pipe | m | |

| The arrangement radius of the outer ring freezing pipe | m | |

| The radius of the outer boundary of the frozen zone | m | |

| Soil temperature field function | K | |

| Polar radius | 1 | |

| Polar angle | rad | |

| Freezing tube temperature | K | |

| Natural ground temperature | K | |

| The number of inner ring freezing tubes | / | |

| The number of outer ring freezing tubes | / | |

| Rotate the outer ring of the freezing tube at an angle relative to the inner ring | rad | |

| The distance from the center of the outer freezing pipes to the outer boundary | m | |

| The distance from the center of the inner circle freezing tube to the inner boundary | m | |

| Material density | kg/m3 | |

| Thermal conductivity of material | W/(m·K) | |

| The constant pressure heat capacity of the materia | J/(kg·K) | |

| Young’s modulus | GPa | |

| Poisson’s ratio of material | / | |

| Thermal expansion coefficient of the material | 1/K |

References

- Ding, Z.; Wei, X.-J.; Wei, G. Prediction methods on tunnel-excavation induced surface settlement around adjacent building. Geomech. Eng. 2017, 12, 185–195. [Google Scholar] [CrossRef]

- Liu, C.; Bezuijen, A.; Yang, M.; Cachim, P. Elastic analysis of ground movements around a tunnel considering a buoyant lining moving upwards. Int. J. Numer. Anal. Methods Geomech. 2019, 43, 1562–1575. [Google Scholar] [CrossRef]

- Su, Y.; Su, Y.; Zhao, M.; Vlachopoulos, N. Tunnel Stability Analysis in Weak Rocks Using the Convergence Confinement Method. Rock Mech. Rock Eng. 2020, 54, 559–582. [Google Scholar] [CrossRef]

- Huang, K.; Sun, Y.-W.; Zhou, D.-Q.; Li, Y.-J.; Jiang, M.; Huang, X.-Q. Influence of water-rich tunnel by shield tunneling on existing bridge pile foundation in layered soils. J. Central South Univ. 2021, 28, 2574–2588. [Google Scholar] [CrossRef]

- Chen, H.; Shen, G.Q.; Feng, Z.; Yang, S. Safety risk assessment of shield tunneling under existing tunnels: A hybrid trapezoidal cloud model and Bayesian network approach. Tunn. Undergr. Space Technol. 2024, 152, 105936. [Google Scholar] [CrossRef]

- Gallardo, A.H.; Marui, A. The aftermath of the Fukushima nuclear accident: Measures to contain groundwater contamination. Sci. Total. Environ. 2016, 547, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.-J.; Wang, Y.-Z.; Zhao, X.-D.; Yang, G.-S.; Jia, H.-L.; Rong, T.-L. The influence of temperature and moisture content on sandstone thermal conductivity from a case using the artificial ground freezing(AGF) method. Cold Reg. Sci. Technol. 2018, 155, 149–160. [Google Scholar] [CrossRef]

- Zhelnin, M.; Kostina, A.; Prokhorov, A.; Plekhov, O.; Semin, M.; Levin, L. Coupled thermo-hydro-mechanical modeling of frost heave and water migration during artificial freezing of soils for mineshaft sinking. J. Rock Mech. Geotech. Eng. 2022, 14, 537–559. [Google Scholar] [CrossRef]

- Wallis, S. Freezing Under the Sea Rescues Oslo-Fjord Highway Tunnel. 1999. Available online: https://prokcssmedia.blob.core.windows.net/sys-master-images/h51/h8a/8898431287326/GEOFROST.pdf (accessed on 1 August 2025).

- Hu, X.D.; Zhang, L.Y. Artificial Ground Freezing for Rehabilitation of Tunneling Shield in Subsea Environment. Adv. Mater. Res. 2013, 734–737, 517–521. [Google Scholar] [CrossRef]

- Papakonstantinou, S.; Anagnostou, G.; Pimentel, E. Evaluation of ground freezing data from the Naples subway. Proc. Inst. Civ. Eng.—Geotech. Eng. 2013, 166, 280–298. [Google Scholar] [CrossRef]

- Marwan, A.; Zhou, M.-M.; Abdelrehim, M.Z.; Meschke, G. Optimization of artificial ground freezing in tunneling in the presence of seepage flow. Comput. Geotech. 2016, 75, 112–125. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Sugimoto, M.; Ge, H. Numerical simulation model of artificial ground freezing for tunneling under seepage flow conditions. Tunn. Undergr. Space Technol. 2019, 92, 103035. [Google Scholar] [CrossRef]

- Alzoubi, M.A.; Xu, M.; Hassani, F.P.; Poncet, S.; Sasmito, A.P. Artificial ground freezing: A review of thermal and hydraulic aspects. Tunn. Undergr. Space Technol. 2020, 104, 103534. [Google Scholar] [CrossRef]

- Liu, P.; Hu, J.; Dong, Q.; Chen, Y. Studying the Freezing Law of Reinforcement by Using the Artificial Ground Freezing Method in Shallow Buried Tunnels. Appl. Sci. 2024, 14, 7106. [Google Scholar] [CrossRef]

- Hu, R.; Liu, Q.; Xing, Y. Case Study of Heat Transfer during Artificial Ground Freezing with Groundwater Flow. Water 2018, 10, 1322. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, H.; Wang, C.; Guo, Z.; Pei, W. Analysis of moisture Migration, Temperature, and pore structure characteristics of the muddy clay column subject to artificial ground freezing Based on LF NMR. Tunn. Undergr. Space Technol. 2022, 133, 104948. [Google Scholar] [CrossRef]

- Hu, X.; Fang, T.; Han, Y. Generalized analytical solution of steady-state temperature field of annular double-loop pipes freezing. J. Coal 2017, 42, 2287–2294. (In Chinese) [Google Scholar] [CrossRef]

- Troupak, N.G. Freezing of Rocks During Shaft Sinking (Замoраживание Гoрных Пoрoд При Прo Хoдке Ствoлoв); Ugletekhizdat: Moscow, Russia, 1954. [Google Scholar]

- Hu, X.; Fang, T. Analytical solution of steady-state temperature field of generalized single-row pipes freezing. J. Coal 2019, 44, 535–543. (In Chinese) [Google Scholar] [CrossRef]

- Hu, X.; Han, Y.; Yu, X. Generalized analytical solution of steady-state temperature field of double-row pipes freezing. J. Tongji Univ. (Nat. Sci. Ed.) 2015, 43, 386–391. (In Chinese) [Google Scholar]

- DG/TJ 08-902-2016; Technical Code for Crosspassage Freezing Method. Shanghai Municipal Commission of Housing and Urban-Rural Development: Shanghai, China, 2016.

| Parameters | Numerical Value | Unit |

|---|---|---|

| 0.075 | m | |

| 2.750 | m | |

| 3.150 | m | |

| 30 | / | |

| 40 | / | |

| 19 | °C | |

| −30 | °C | |

| 5.550 | m |

| Material Types | Parameters | Numerical Value | Unit |

|---|---|---|---|

| Groundwater | 1000 | kg/m3 | |

| 0.58 | W/(m·K) | ||

| 4200 | J/(kg·K) | ||

| Tunnel lining (Concrete) | 2300 | kg/m3 | |

| 1.8 | W/(m·K) | ||

| 880 | J/(kg·K) | ||

| 25 | GPa | ||

| 0.20 | / | ||

| 1 × 10−5 | 1/K | ||

| Silty fine sand | 1860 | kg/m3 | |

| 1.7838 | W/(m·K) | ||

| 3653.2 | J/(kg·K) | ||

| 7 × 107 | Pa | ||

| 0.23 | / | ||

| 0 | 1/K |

| Point | Tnum (°C) | Tana (°C) | Abs. Error (°C) | Rel. Error |

|---|---|---|---|---|

| A | −29.987 | −29.215 | 0.772 | 2.57% |

| B | −26.442 | −25.238 | 1.204 | 4.55% |

| C | −26.956 | −28.721 | 1.765 | 6.55% |

| O | −29.997 | −29.124 | 0.873 | 2.91% |

| D | −27.304 | −25.893 | 1.411 | 5.17% |

| E | −27.439 | −29.356 | 1.917 | 6.99% |

| F | −27.267 | −29.102 | 1.835 | 6.73% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Mu, K.; Ban, C.; Liu, C.; Zhou, H.; Shang, X. Analytical Method for Temperature Field Distribution of Annular Double-Loop Freezing Pipes in Adjacent Urban Tunnels. Appl. Sci. 2025, 15, 10149. https://doi.org/10.3390/app151810149

Zhou J, Mu K, Ban C, Liu C, Zhou H, Shang X. Analytical Method for Temperature Field Distribution of Annular Double-Loop Freezing Pipes in Adjacent Urban Tunnels. Applied Sciences. 2025; 15(18):10149. https://doi.org/10.3390/app151810149

Chicago/Turabian StyleZhou, Jie, Kangdi Mu, Chao Ban, Chengjun Liu, Huade Zhou, and Xinmin Shang. 2025. "Analytical Method for Temperature Field Distribution of Annular Double-Loop Freezing Pipes in Adjacent Urban Tunnels" Applied Sciences 15, no. 18: 10149. https://doi.org/10.3390/app151810149

APA StyleZhou, J., Mu, K., Ban, C., Liu, C., Zhou, H., & Shang, X. (2025). Analytical Method for Temperature Field Distribution of Annular Double-Loop Freezing Pipes in Adjacent Urban Tunnels. Applied Sciences, 15(18), 10149. https://doi.org/10.3390/app151810149