Silicone Replication Technology Reveals HPWJ Hole Formation Mechanisms

Abstract

1. Introduction

2. Materials and Methods

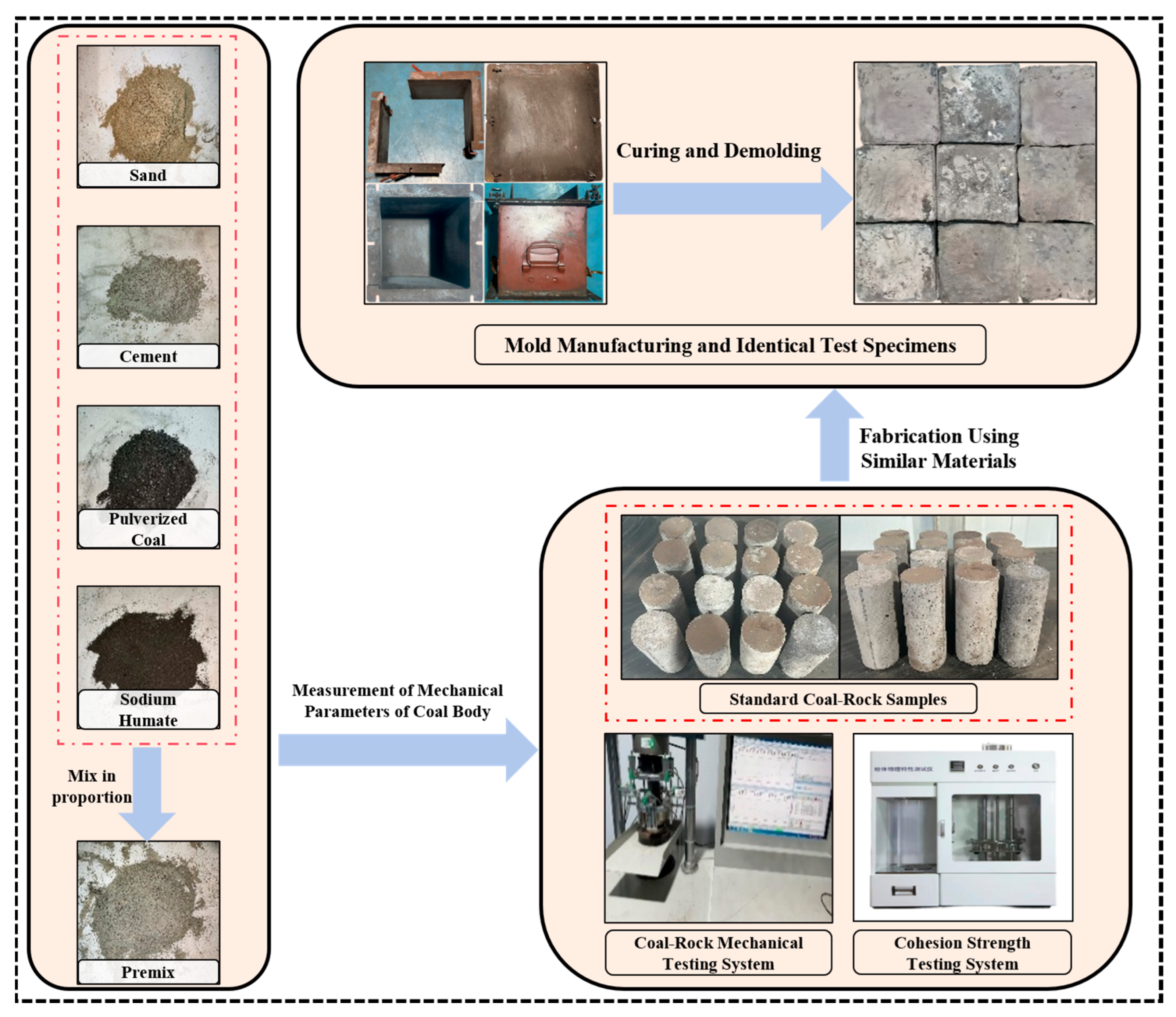

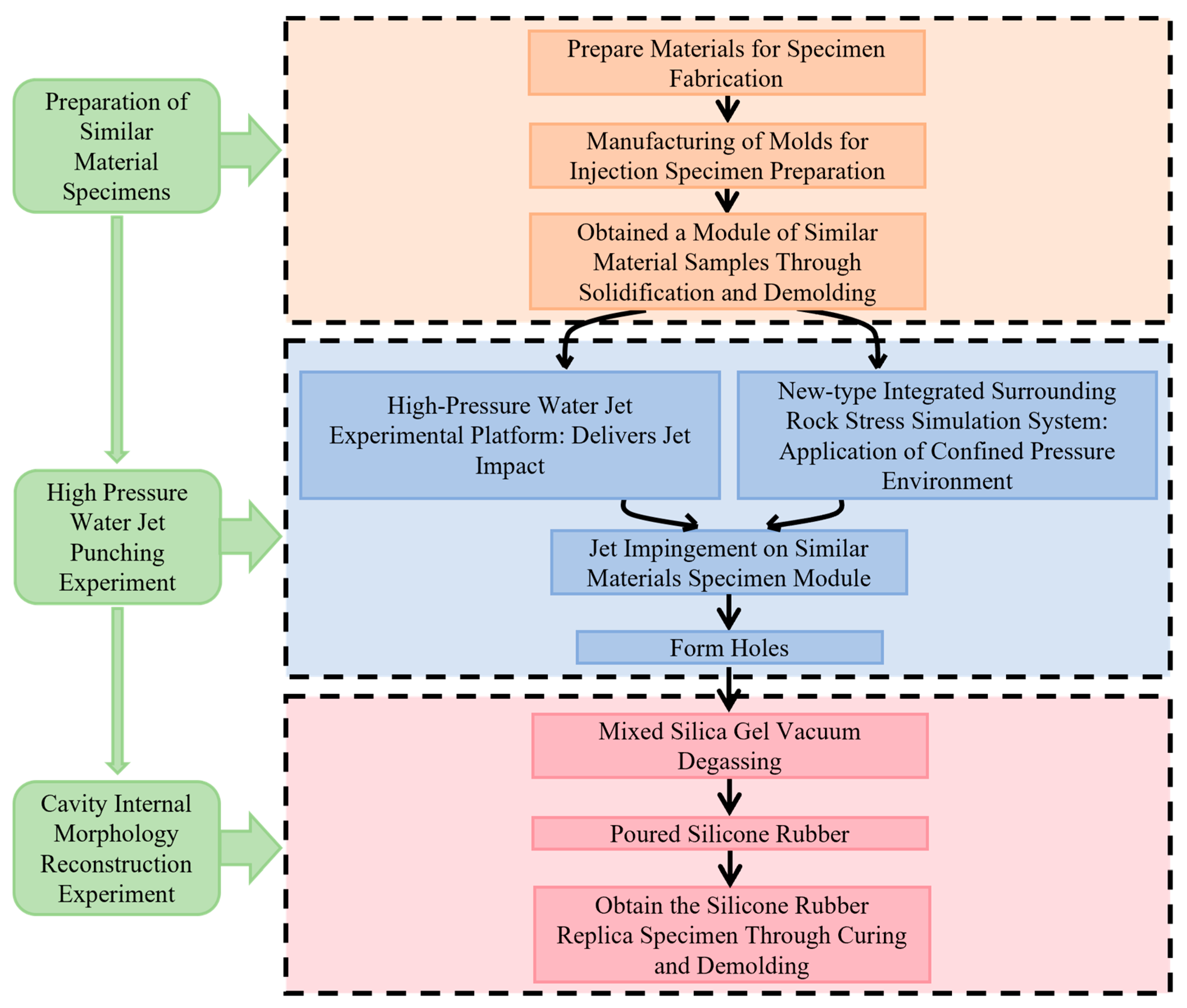

2.1. Similar Material Sample Preparation

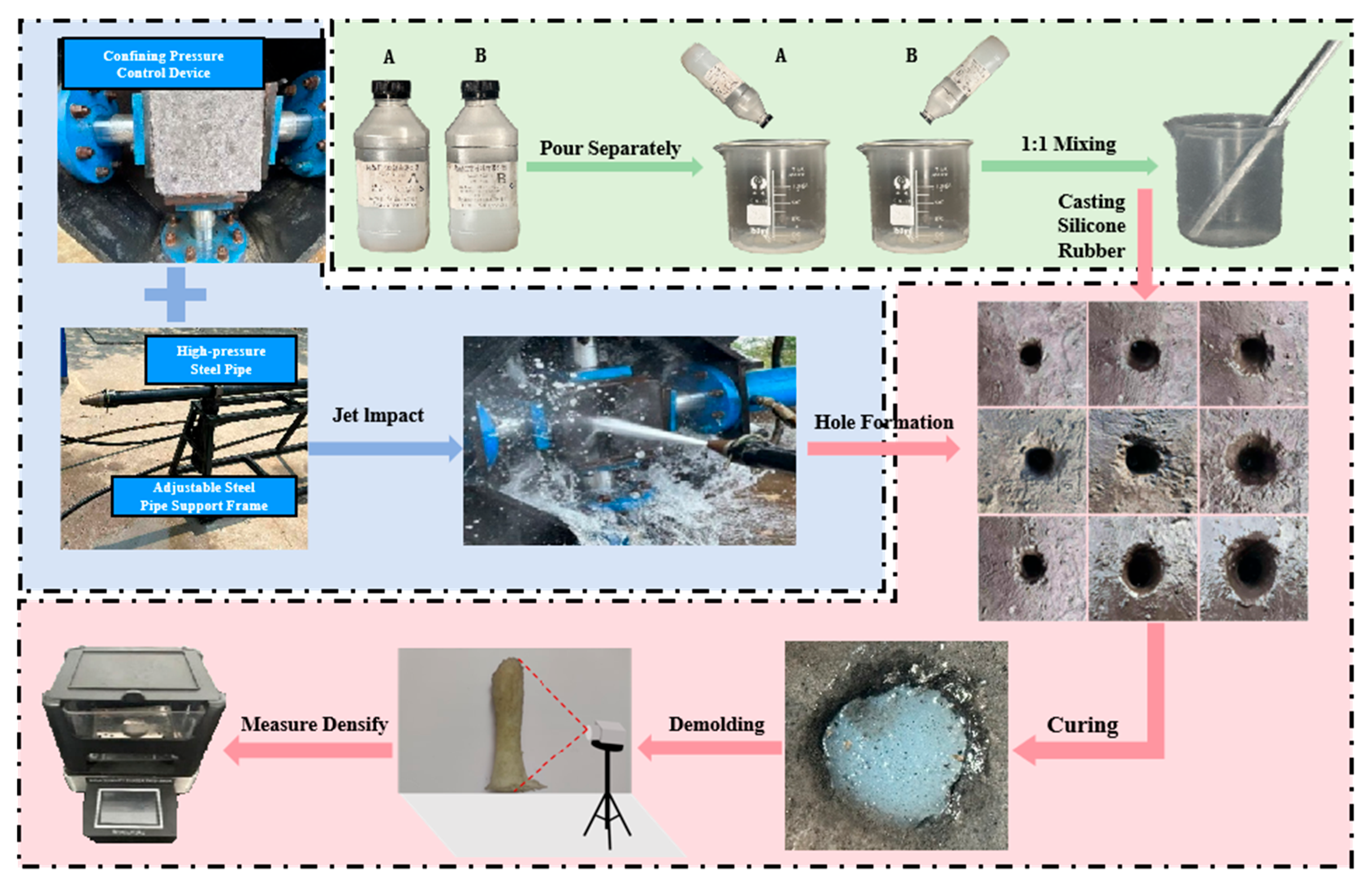

2.2. High-Pressure Water Jet Experimental Platform

2.3. Jet Perforation Experiment

2.4. Silicone Replication Technology Experiment

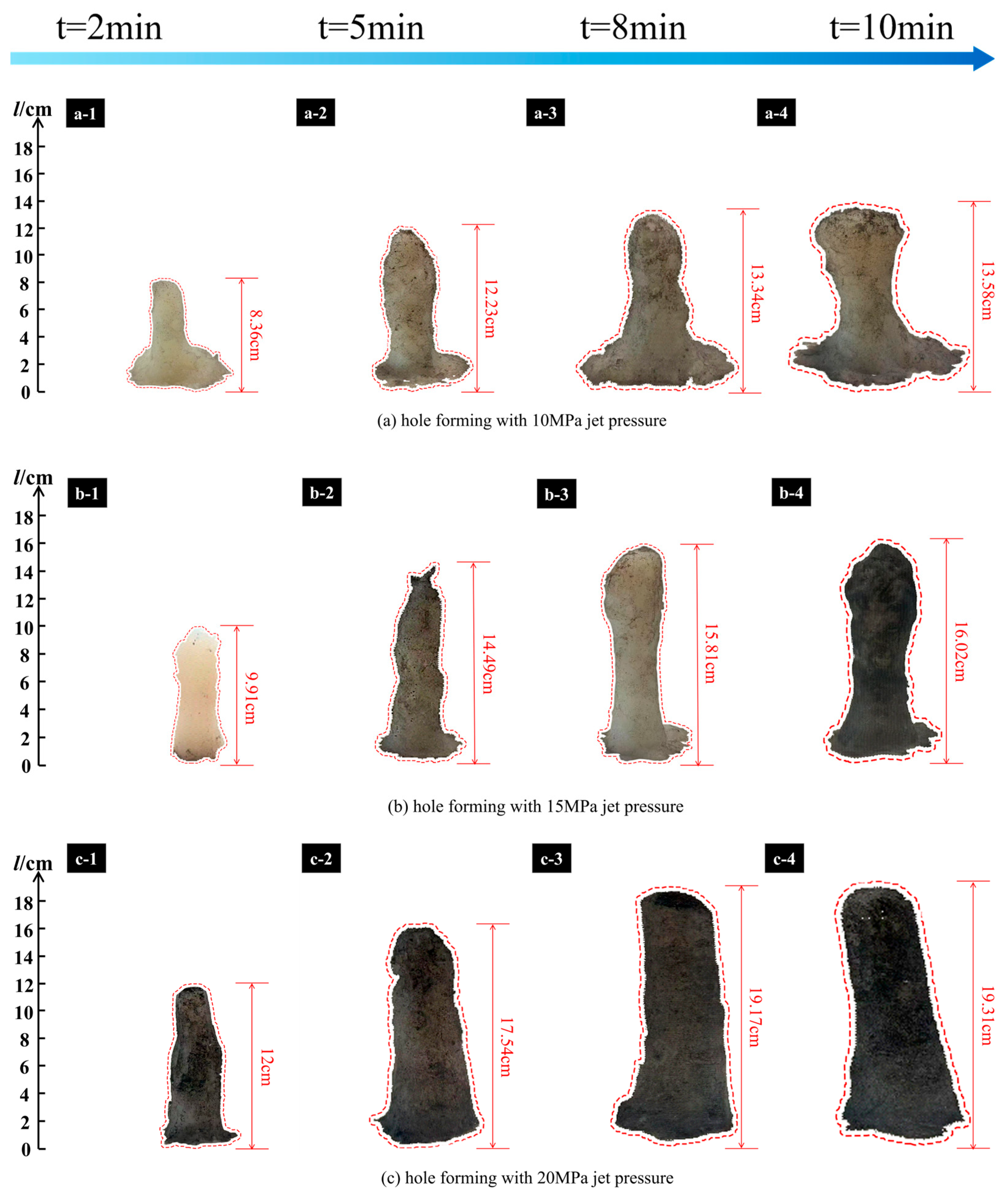

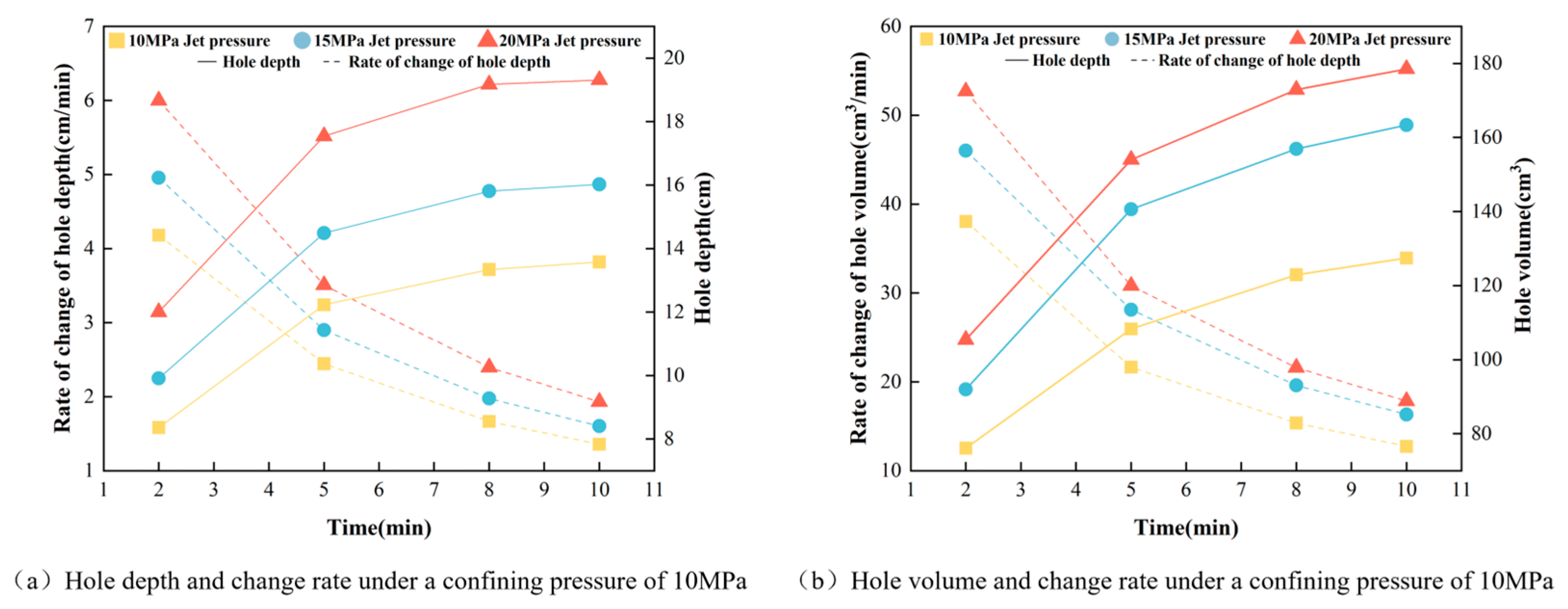

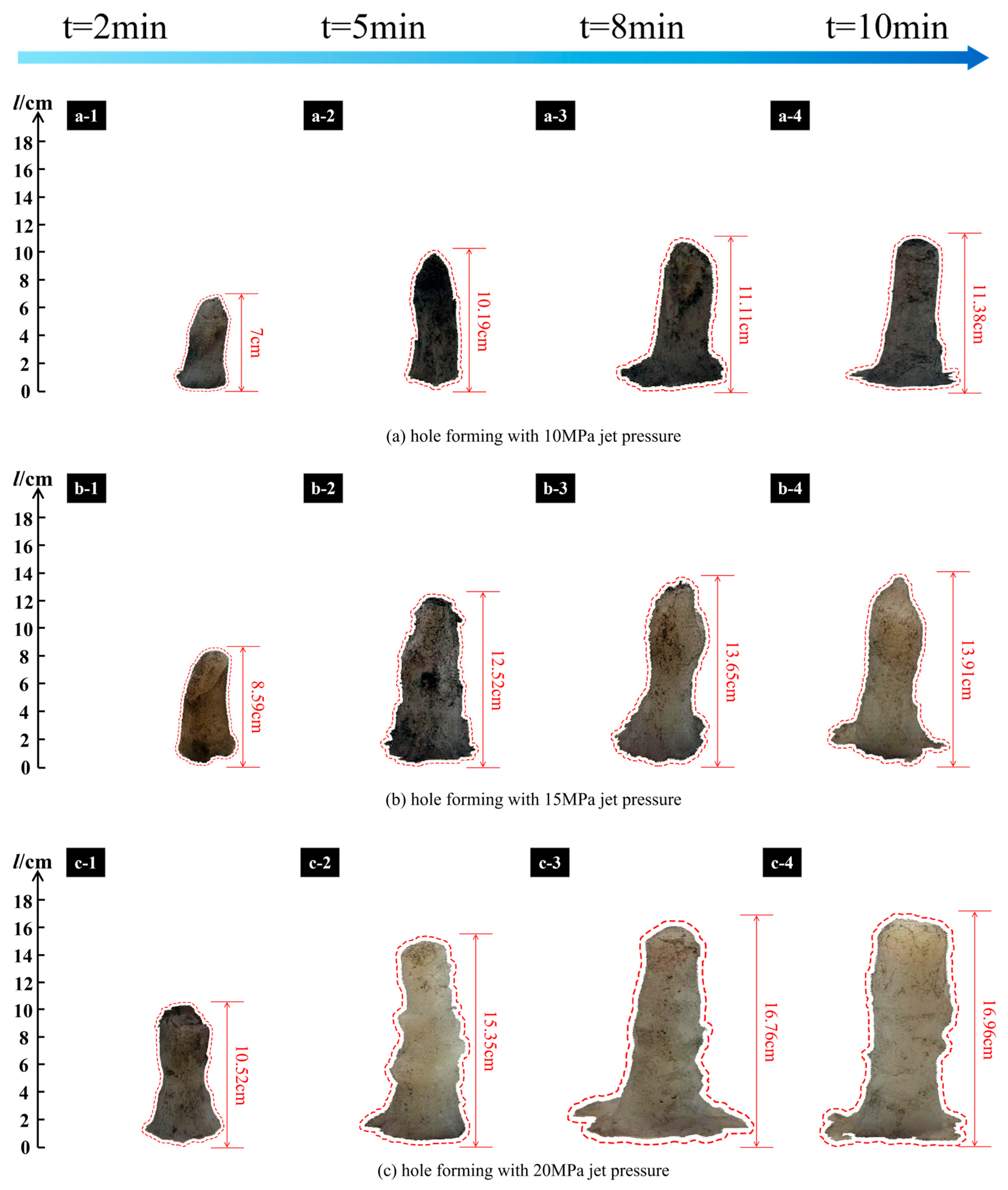

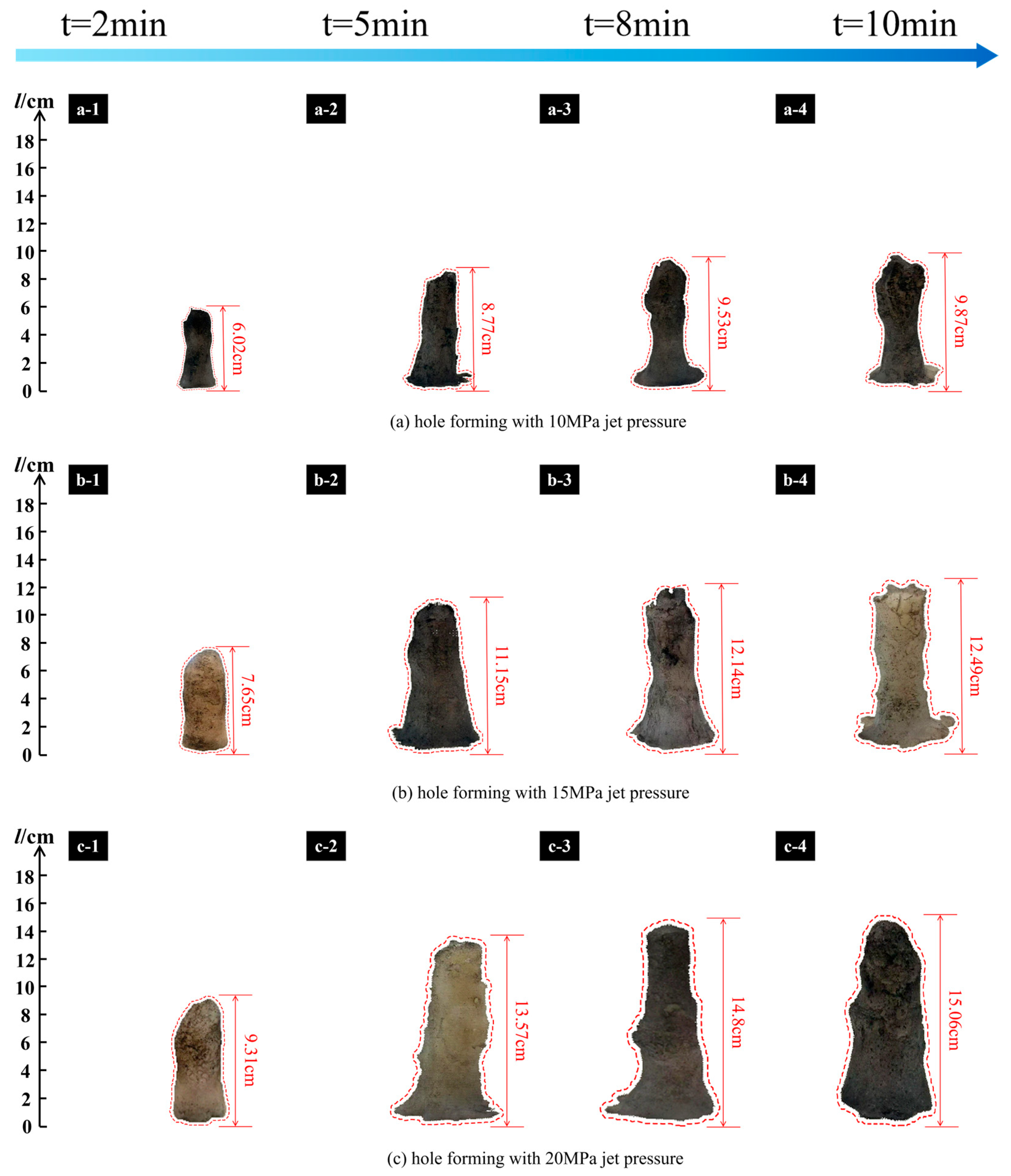

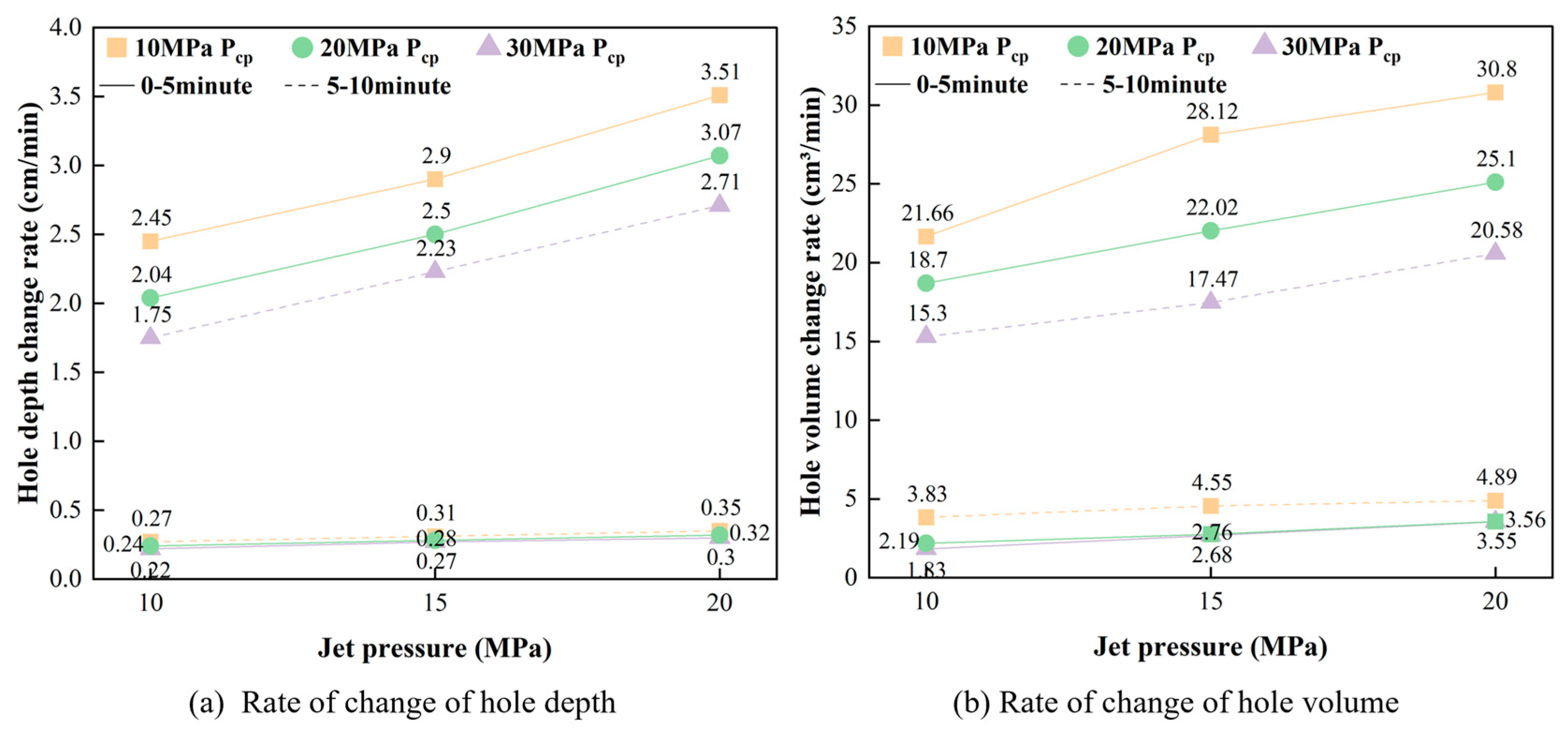

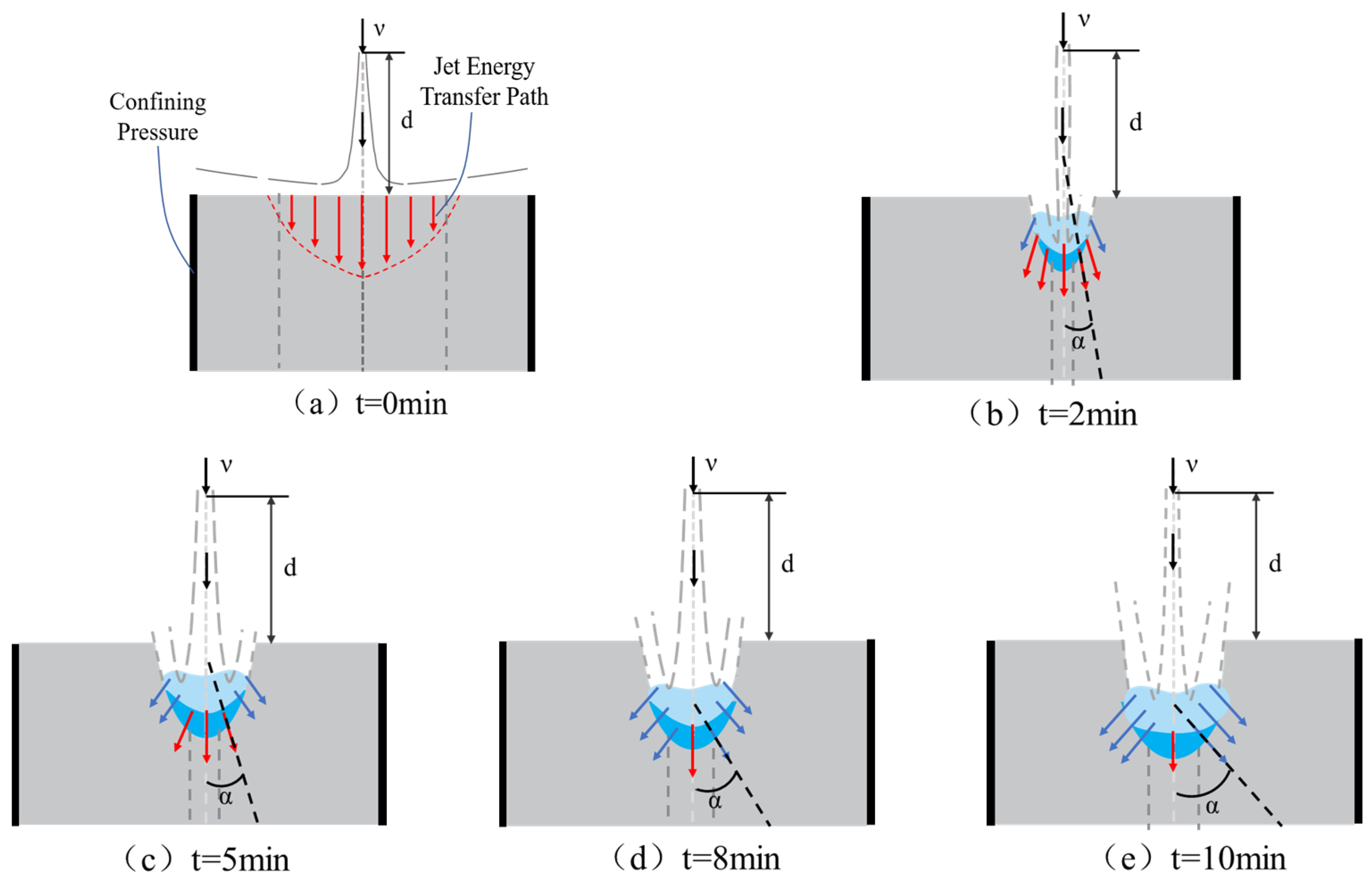

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| HPWJ | High-Pressure Water Jet |

| HPAWJ | High-Pressure Abrasive Water Jet |

| Fbuoy | The buoyancy force acting on the colloid |

| W | The weight of the colloid |

| Wliquid | The weighed value of the colloid in the liquid |

| ρliquid | The density of the liquid |

| Vliquid | The volume of displaced liquid |

| g | The local gravitational acceleration |

| Vcolloid | The colloid volume |

| mliquid | The mass of the colloid |

| Vhole | The hole volume |

| Pjp | The jet pressure |

| l | The hole depth |

| V | The hole volume |

| t | The punching duration |

| Pcp | The confining pressure |

| v | The water jet impact velocity |

| α | The force angle of water jet impact |

References

- Yuan, L.; Zhang, T.; Wang, Y.; Wang, X.; Wang, Y.; Hao, X. Scientific problems and key technologies for safe and efficient mining of deep coal resources. J. China Coal Soc. 2025, 50, 1–12. [Google Scholar]

- Zhang, J.; Bai, X.; Song, Z.; Zhang, Y.; Dong, X.; Wu, S.; Xing, C.; Li, X.; Xu, W.; Zhang, S. Research Progress and Perspectives on Prevention and Control Technologies for Coal–Rock–Gas Composite Dynamic Disasters: New Types of Induced Classifications, Discriminant Criteria, and Structural Control Schemes. Rock Mech. Rock Eng. 2025, 58, 10143–10181. [Google Scholar] [CrossRef]

- Xu, F.; Hou, W.; Xiong, X.; Xu, B.; Wu, P.; Wang, H.; Feng, K.; Yun, J.; Li, S.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Niu, X.; Zhao, Y.; Li, K.; Zhang, Y.; Abu-Jdayil, B. Ultra-High-Pressure Hydraulic Slitting Pressure Relief and Penetration Enhancement Technology and Equipment for Soft Coal Seams. Geofluids 2022, 2022, 1895836. [Google Scholar] [CrossRef]

- Cao, S.; Ge, Z.; Zhang, D.; Zhou, Z.; Lu, Y.; Zhao, H. An experimental study of ultra-high pressure water jet-induced fracture mechanisms and pore size evolution in reservoir rocks. Int. J. Rock Mech. Min. Sci. 2022, 150, 104995. [Google Scholar] [CrossRef]

- Yiyu, L.U.; Shan, H.; Zhaolong, G.E.; Zhe, Z.H.O.U.; Wenchuan, L.I.U.; Yarui, G.U.A.N. Research progress and strategic thinking of coal mine water jet technology to enhance coal permeability in China. J. China Coal Soc. 2022, 47, 3189–3211. [Google Scholar]

- Tomassi, A.; de Franco, R.; Trippetta, F. High-resolution synthetic seismic modelling: Elucidating facies heterogeneity in carbonate ramp systems. Pet. Geosci. 2025, 31, petgeo2024–petgeo2047. [Google Scholar] [CrossRef]

- Ge, Z.; Zhang, H.; Zhou, Z.; Cao, S.; Zhang, D.; Liu, X.; Tian, C. Experimental study on the characteristics and mechanism of high-pressure water jet fracturing in high-temperature hard rocks. Energy 2023, 270, 126848. [Google Scholar] [CrossRef]

- Sun, H.; Yang, H.; Guo, H.; Ma, S. Study on the Effect of Hydraulic Flushing on the Stress and Permeability Variations of Loaded Coal. ACS Omega 2025, 10, 8292–8302. [Google Scholar] [CrossRef] [PubMed]

- Ge, Z.; Cao, S.; Lu, Y.; Gao, F. Fracture mechanism and damage characteristics of coal subjected to a water jet under different triaxial stress conditions. J. Pet. Sci. Eng. 2022, 208, 109157. [Google Scholar] [CrossRef]

- Shang, Y.; Wang, Y.; Zhang, L.; Wu, G.; Kong, D.; Zhang, P.; Jia, T. Impact of lower protective coal seam mining on overlying strata: Deformation, pressure relief, and permeability enhancement. Int. J. Geomech. 2024, 24, 04024178. [Google Scholar] [CrossRef]

- Ge, Z.L.; Zhao, H.Y.; Lu, Y.Y.; Xiao, S.Q.; Zhou, Z.; Bo, T. Damage and fracture characteristics of coal sandstone shale under high pressure water jet impact. J. Vib. Shock. 2021, 40, 174–181. [Google Scholar]

- Lei, Z.; Yan, P.U.; Yu, P.; Binwei, X.; Liulin, F. Mechanism and influencing factors of rock breaking and pore-forming by water jet in deep coal seam based on the MPM. J. China Coal Soc. 2024, 49, 3845–3858. [Google Scholar]

- Xiao, S.; Xiao, J.; Ren, Q.; Cheng, Y.; Li, W.; Zhang, W.; Meng, X.; Qin, H. Damage evolution and fracture characteristics of heterogeneous concrete with coarse aggregate impacted by high-velocity water jet. Constr. Build. Mater. 2024, 416, 135128. [Google Scholar] [CrossRef]

- Xiao, S.; Qin, H.; Zhang, W.; Ren, Q.; Xiao, J.; Li, W.; Cheng, Y. On the concrete breakage by pulsed water jet impact: Fracture characteristic, stress and damage evolution laws. Case Stud. Constr. Mater. 2023, 19, e02634. [Google Scholar] [CrossRef]

- Xue, Y.; Si, H.; Chen, G. The fragmentation mechanism of coal impacted by water jets and abrasive jets. Powder Technol. 2020, 361, 849–859. [Google Scholar] [CrossRef]

- Zhang, X.; Wiśniewski, P.; Dykas, S.; Zhang, G. Permeability enhancement properties of high-pressure abrasive water jet flushing and its application in a soft coal seam. Front. Energy Res. 2021, 9, 679623. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, M.; Liu, J.; Yang, L.; Hao, H.; Yang, B.; He, Z.; Wang, X. Mechanism and Feasibility Evaluation of Laser-Assisted Rock-Breaking in Drilling Fluid Environment. Rock Mech. Rock Eng. 2025, 1–22. [Google Scholar] [CrossRef]

- Peel, B.; Lee, W.; Hussein, N.; Yoo, S.-J. State-of-the-art silicone molded models for simulation of arterial switch operation: Innovation with parting-and-assembly strategy. JTCVS Tech. 2022, 12, 132–142. [Google Scholar] [CrossRef]

- Bell, M.A.; Becker, K.P.; Wood, R.J. Injection molding of soft robots. Adv. Mater. Technol. 2022, 7, 2100605. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Z. Study and application of evaluation method for fracability of deep CBM reservoir-taking the Daning-Jixian block in the Ordos Basin as an example. Int. J. Oil Gas Coal Technol. 2024, 35, 407–441. [Google Scholar] [CrossRef]

- Wen, H.; Fan, C.; Jiang, X.; Luo, M.; Xiao, B.; Zhou, L.; Yang, Z. Experimental investigations on enhanced coal seam methane extraction by injecting gas: A review. Energy Fuels 2024, 38, 3517–3538. [Google Scholar] [CrossRef]

- Wang, H.; Yang, S.; Zhang, L.; Xiao, Y.; Su, X.; Yu, W.; Zhou, D. Experimental analysis of the mechanical properties and failure behavior of deep coalbed methane reservoir rocks. Processes 2024, 12, 1125. [Google Scholar] [CrossRef]

- Cao, S.; Wang, X.; Ge, Z.; Guo, Z.; Zhang, L. Experimental study on the damage and fracture mechanism of deep coal beds impacted by water jets at different temperatures. Fuel 2024, 371, 132121. [Google Scholar] [CrossRef]

- Li, H.; Xu, P.; Zhang, L.; Jiang, H.; Chen, Y.; Sun, D. Numerical and experimental investigation on rock breaking mechanism and performance of high-pressure energy-gathering water jet. Eng. Fract. Mech. 2025, 320, 111050. [Google Scholar] [CrossRef]

- Lei, Y.; Cheng, Y.; Wang, L.; Ren, T.; Tu, Q. Mechanisms of coal and gas outburst experiments: Implications for the energy principle of natural outbursts. Rock Mech. Rock Eng. 2023, 56, 363–377. [Google Scholar] [CrossRef]

- Qiao, G.; Liu, Z.; Zhang, Y.; Yi, C.; Gao, K.; Fu, S.; Zhao, Y. Theoretical analysis and engineering application of controllable shock wave technology for enhancing coalbed methane in soft and low-permeability coal seams. Int. J. Coal Sci. Technol. 2024, 11, 25. [Google Scholar] [CrossRef]

- Li, J.-Q.; Wang, Z.-F.; Wang, Y.-Q.; Chang, H.-T. Analysis and countermeasures of large deformation of deep-buried tunnel excavated in layered rock strata: A case study. Eng. Fail. Anal. 2023, 146, 107057. [Google Scholar] [CrossRef]

- Wu, D.; Luo, C.; Gao, Z.; Li, D.; Xu, C. Effect of different reinforced load transfer platforms on geosynthetic-reinforced pile-supported embankment: Centrifuge model test. KSCE J. Civ. Eng. 2022, 26, 630–649. [Google Scholar] [CrossRef]

- Wan, F.; Jiang, Z.; Tian, X.; Konietzky, H.; Xiao, Z. A thermo-hydro-mechanical damage model for lined rock cavern for compressed air energy storage. J. Energy Storage 2024, 78, 110186. [Google Scholar] [CrossRef]

- Yuan, M.; Liu, Y.; Niu, Y.; Yang, T.; Yu, B.; Yin, L.; Wen, X.; Long, Z.; Jiang, M. Crushing mechanism and influencing factors of gas-containing coal under water jet impact loading. Powder Technol. 2025, 465, 121350. [Google Scholar] [CrossRef]

- Jiang, M.; Sun, B.; Niu, Y.; Liu, Y.; Long, Z.; Bu, X. Insights and simulation models for long-distance water jet mining: Evolution of breaking depth and mass. Process Saf. Environ. Prot. 2025, 195, 106761. [Google Scholar] [CrossRef]

- Narushin, V.G.; Volkova, N.A.; Vetokh, A.N.; Dzhagaev, A.Y.; Sotnikov, D.A.; Volkova, L.A.; Orszulik, S.T.; Griffin, D.K.; Romanov, M.N.; Zinovieva, N.A. Reimagining Archimedes: An innovative and accurate calculation of volumes and asserting another standard method for defining the surface area of quail and any avian eggs. Food Bioprod. Process. 2024, 147, 327–334. [Google Scholar] [CrossRef]

- Liu, W.; Hu, Z.; Liu, C.; Huang, X.; Hou, J. Mechanical properties under triaxial compression of coal gangue-fly ash cemented backfill after cured at different temperatures. Constr. Build. Mater. 2024, 411, 134268. [Google Scholar] [CrossRef]

| Representative Coal Seam | Compressive Strength (MPa) | Elastic Modulus (MPa) | Cohesion (MPa) | Poisson’s Ratio |

|---|---|---|---|---|

| Deep Coal Seam 1# | 23.2 | 4.96 | 5.92 | 0.34 |

| Deep Coal Seam 2# | 24.15 | 5 | 3.2 | 0.32 |

| Deep Coal Seam 3# | 23.73 | 4.51 | 3.4 | 0.39 |

| Average | 23.693 | 4.823 | 4.17 | 0.343 |

| Serial Number | Cement | Coal Powder | Sand | Sodium Humate | Compressive Strength (MPa) | Elastic Modulus (MPa) | Cohesion (MPa) | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|---|

| 1 | 30.00% | 50.00% | 18.50% | 1.50% | 2.39 | 4.88 | 0.42 | 0.34 |

| 2 | 30.00% | 40.00% | 28.10% | 1.90% | 2.56 | 4.93 | 0.29 | 0.2 |

| 3 | 40.00% | 40.00% | 17.70% | 2.30% | 4.37 | 5.21 | 0.32 | 0.25 |

| 4 | 40.00% | 30.00% | 28.20% | 1.80% | 3.03 | 5.07 | 0.71 | 0.45 |

| 5 | 50.00% | 30.00% | 17.50% | 2.50% | 3.29 | 5.16 | 0.35 | 0.28 |

| Name | Specification | Basic Parameters |

|---|---|---|

| Water Tank | Dimensions (m) | 2.5 × 2.5 × 1.5 |

| Electric Motor | Power (kW) | 160 |

| High-Pressure Steel Pipe | Length (m) | 10 |

| Inner Diameter (cm) | 8 | |

| Outer Diameter (cm) | 10 | |

| High-Pressure Water Pump | Flow Rate (m3·h−1) | 180–240 |

| Jet | Pressure (MPa) | 10–30 |

| Hydraulic Control Module | Pressure (MPa) | 0–40 |

| Parameter | Value |

|---|---|

| Jet Pressure (MPa) | 10, 15, 20 |

| Confining Pressure Conditions (MPa) | 10, 20, 30 |

| Perforation Duration (min) | 2, 5, 8, 10 |

| Nozzle Diameter (mm) | 8 |

| Target Distance (m) | 1.2, 1.5, 1.8 |

| Similar Material Specimen Dimensions (mm) | 250 × 250 × 250 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Zhang, X.; Zhou, X.; Guo, L.; Zhang, J.; Yang, H.; Xin, Y.; Zhu, Y.; Hu, Z. Silicone Replication Technology Reveals HPWJ Hole Formation Mechanisms. Appl. Sci. 2025, 15, 10132. https://doi.org/10.3390/app151810132

Xu S, Zhang X, Zhou X, Guo L, Zhang J, Yang H, Xin Y, Zhu Y, Hu Z. Silicone Replication Technology Reveals HPWJ Hole Formation Mechanisms. Applied Sciences. 2025; 15(18):10132. https://doi.org/10.3390/app151810132

Chicago/Turabian StyleXu, Shen, Xinrui Zhang, Xu Zhou, Liwen Guo, Jiayong Zhang, Haikun Yang, Yu Xin, Yaoyuan Zhu, and Zelin Hu. 2025. "Silicone Replication Technology Reveals HPWJ Hole Formation Mechanisms" Applied Sciences 15, no. 18: 10132. https://doi.org/10.3390/app151810132

APA StyleXu, S., Zhang, X., Zhou, X., Guo, L., Zhang, J., Yang, H., Xin, Y., Zhu, Y., & Hu, Z. (2025). Silicone Replication Technology Reveals HPWJ Hole Formation Mechanisms. Applied Sciences, 15(18), 10132. https://doi.org/10.3390/app151810132