Study on Surrounding Rock Failure Analysis and Novel Stability Control Approach for High-Stress Gob-Side Roadway Retaining

Abstract

1. Introduction

2. Engineering Overview

2.1. Geological Conditions of the Engineering

2.2. Engineering Problems

3. Key Technology and Control Principle

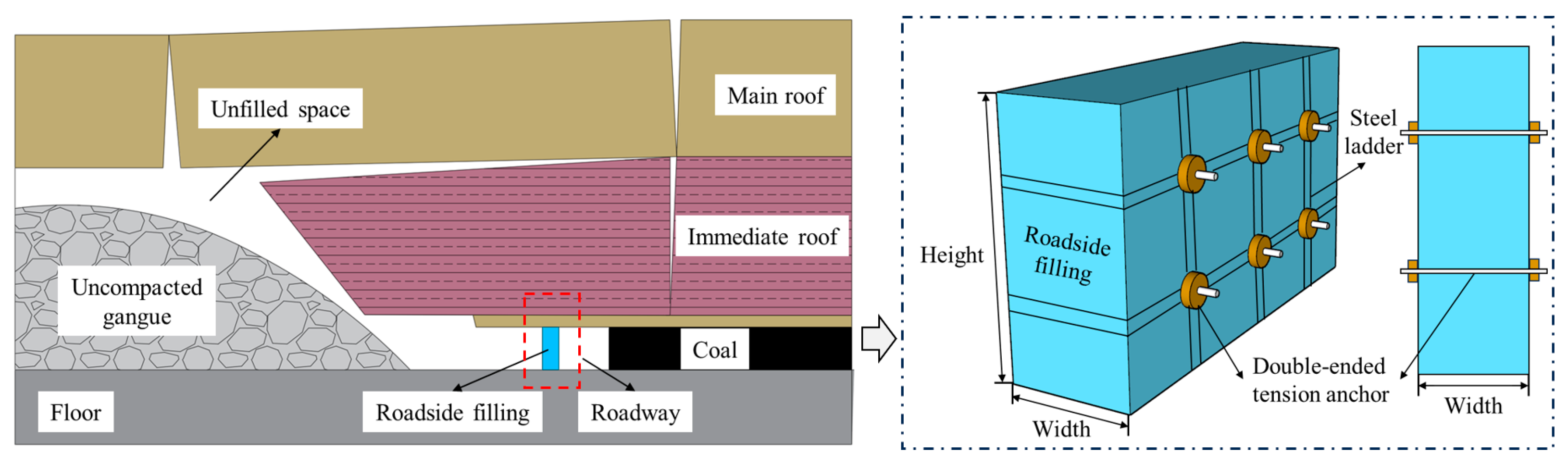

3.1. Roadside Filling Technology

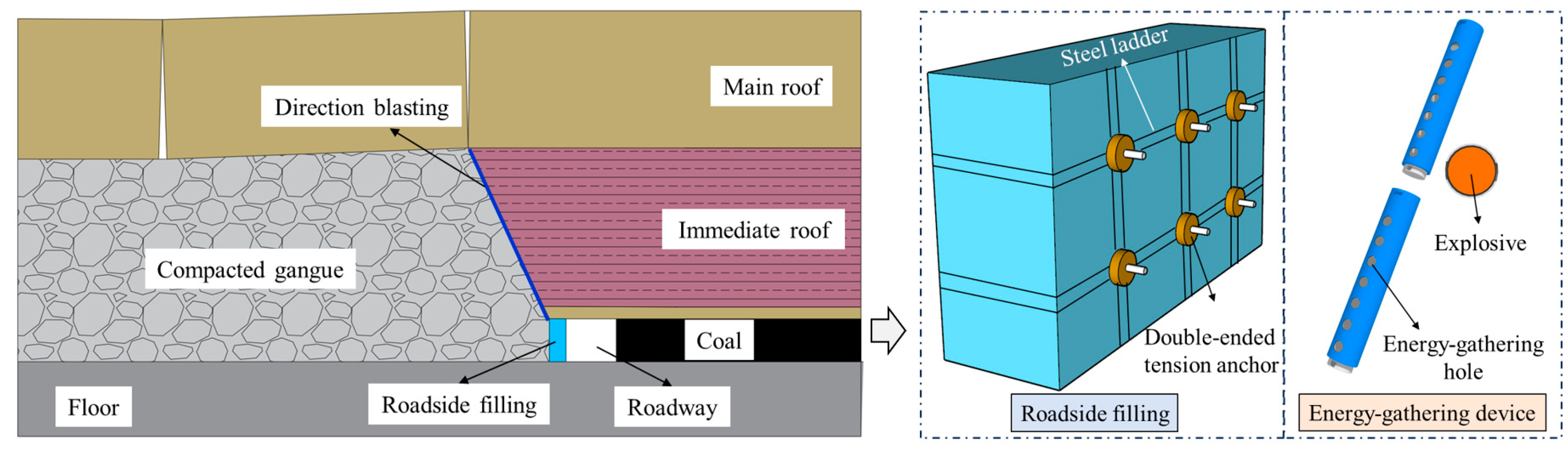

3.2. Roof Cutting and Pressure Relief Technology

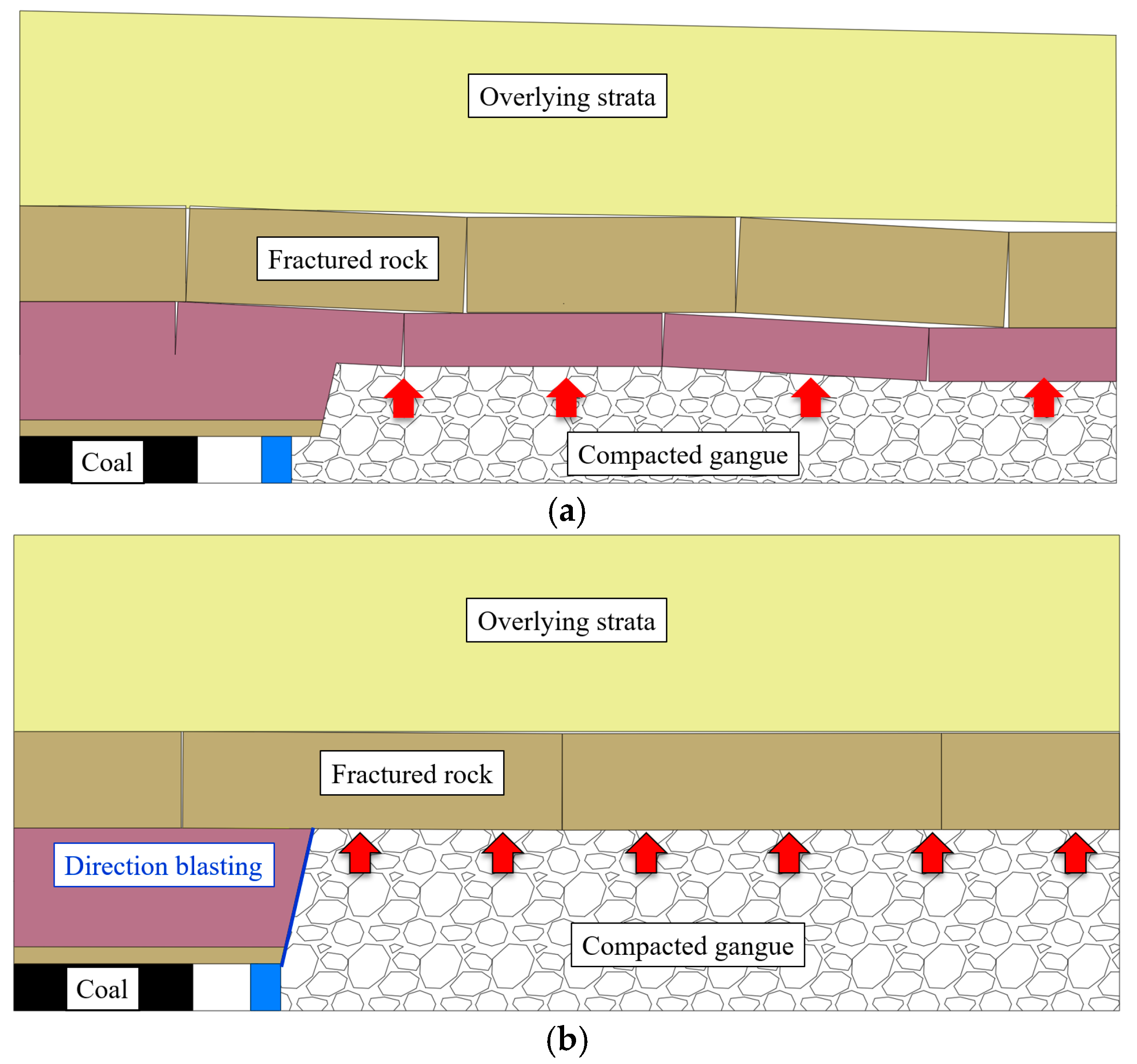

3.3. Synergistic Control Method and Principle

4. Control Effects

4.1. Model Established

4.2. Effect Analysis

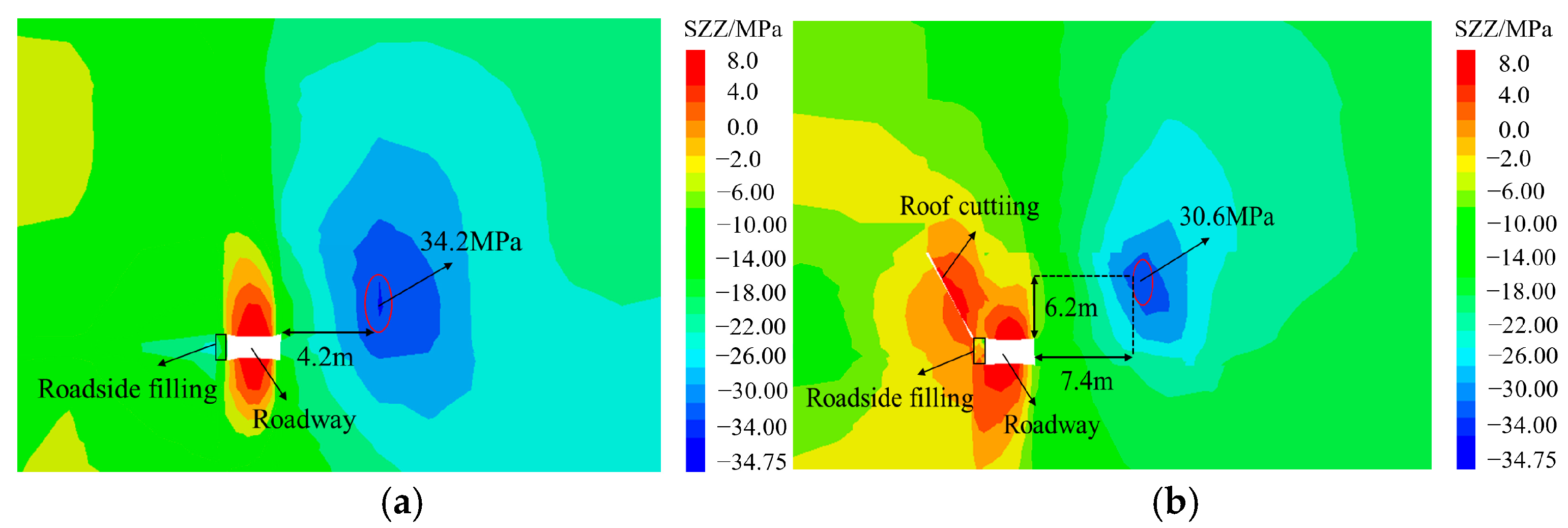

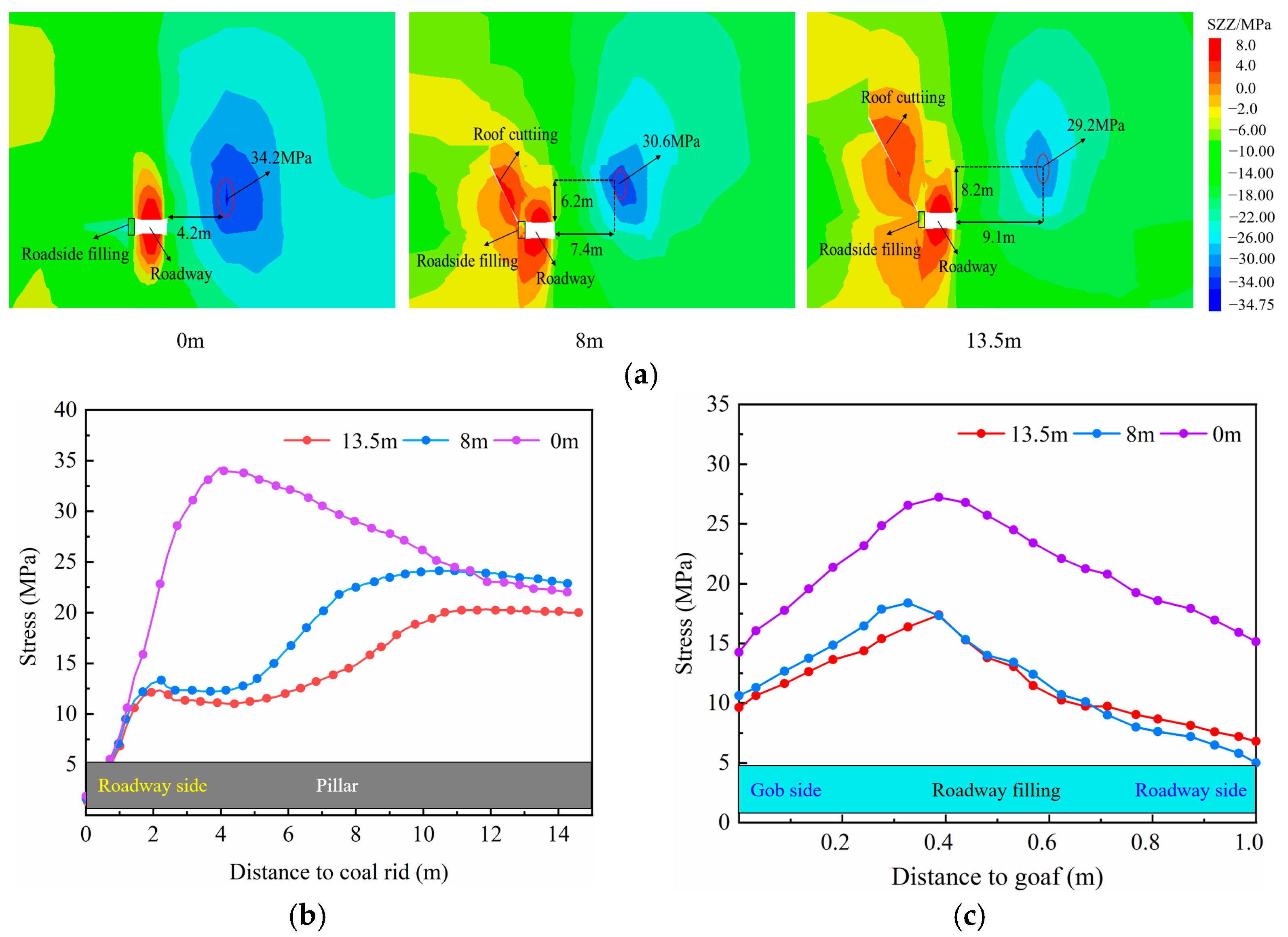

4.2.1. Analysis of Surrounding Rock Stress

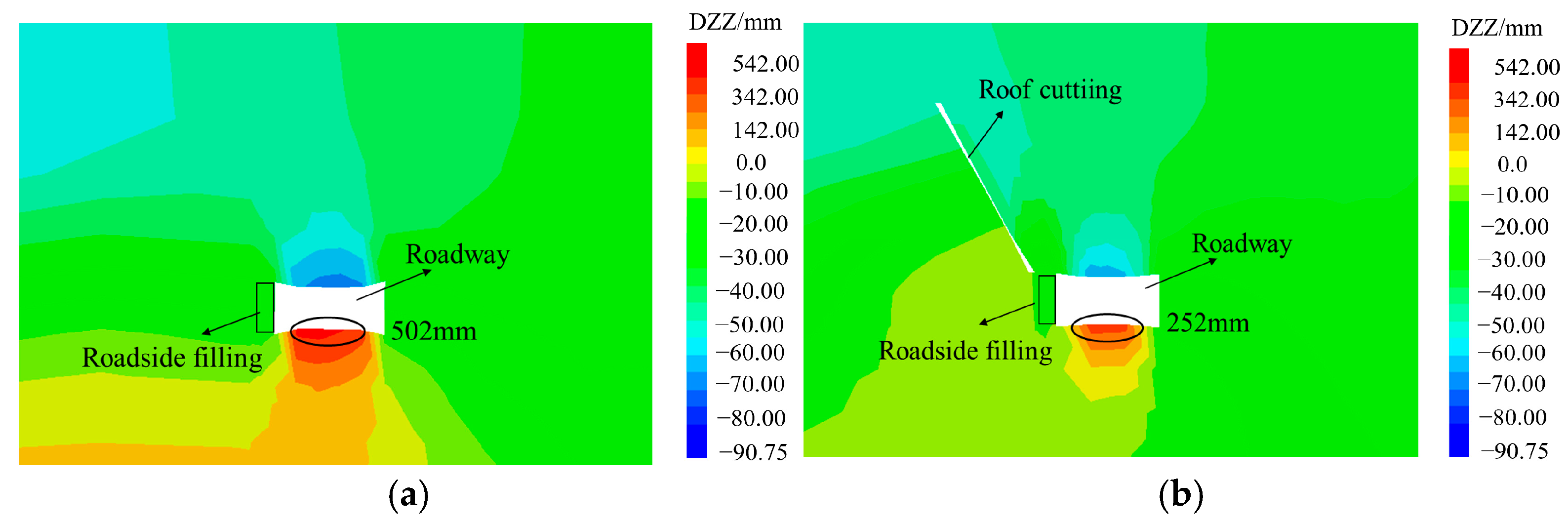

4.2.2. Analysis of Surrounding Rock Deformation

4.2.3. Analysis of the Surrounding Rock Plastic Zone

4.3. Analysis of Key Parameters

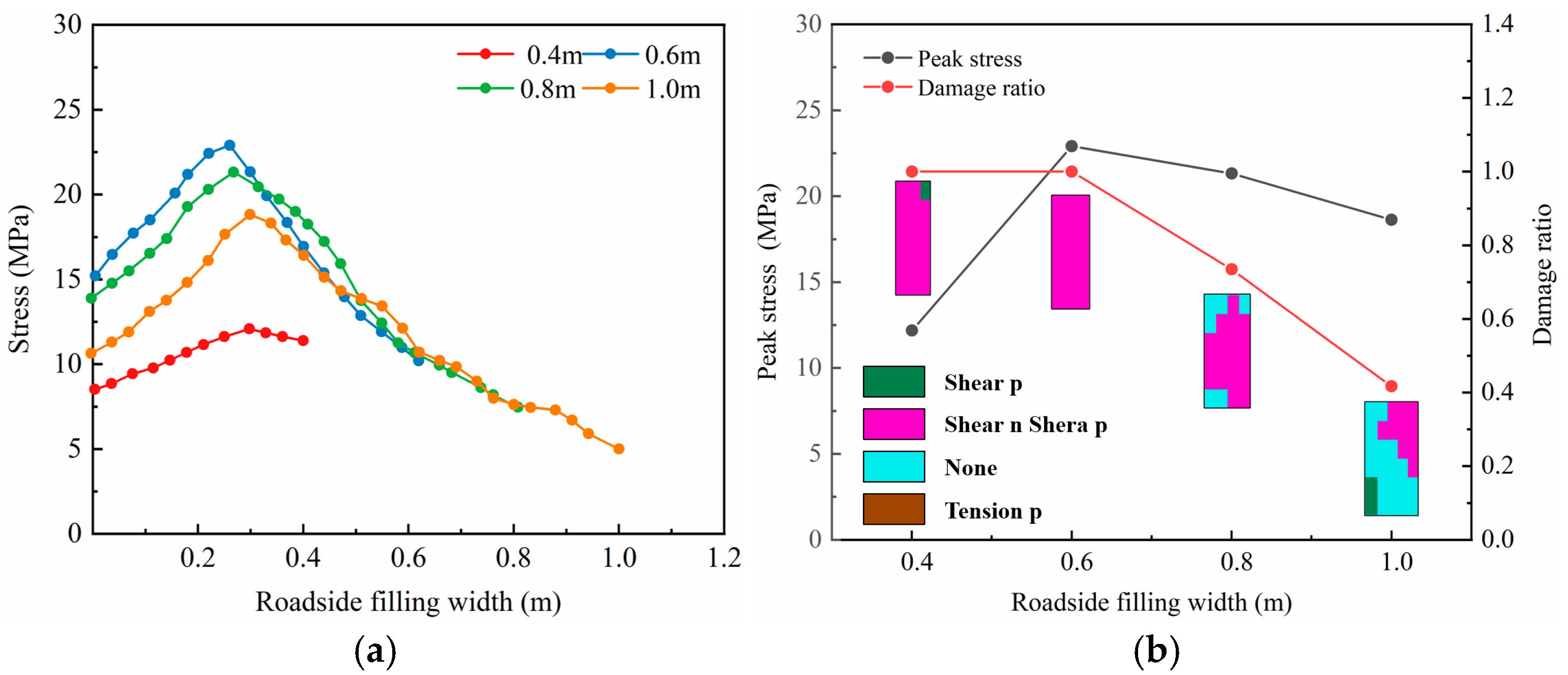

4.3.1. Analysis of Filling Body Parameters

4.3.2. Analysis of Roof Cutting Parameters

5. Engineering Application

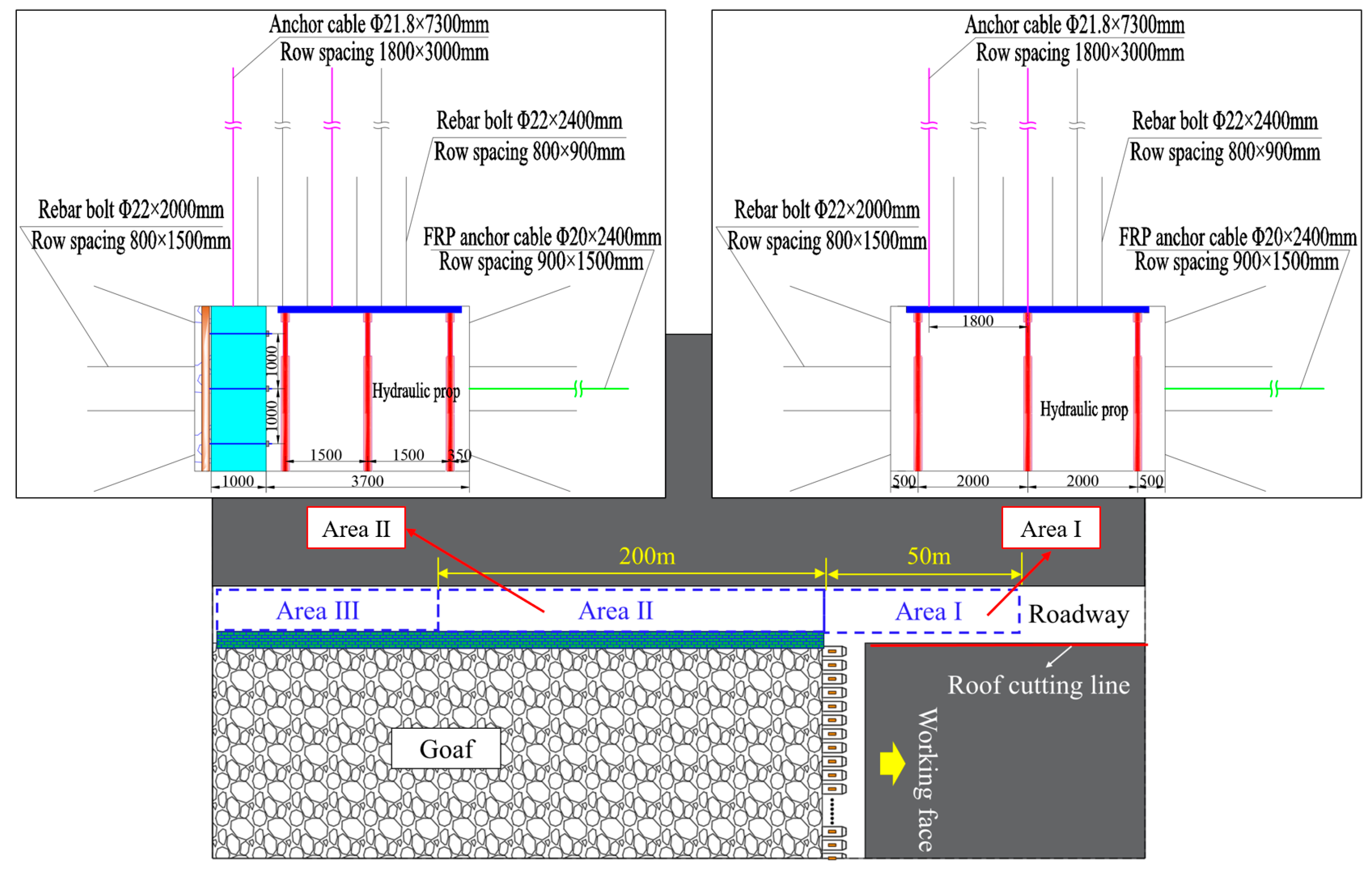

5.1. Scheme Design

5.1.1. Roof Cutting Design

5.1.2. Support Design

5.2. Analysis of Application Effects

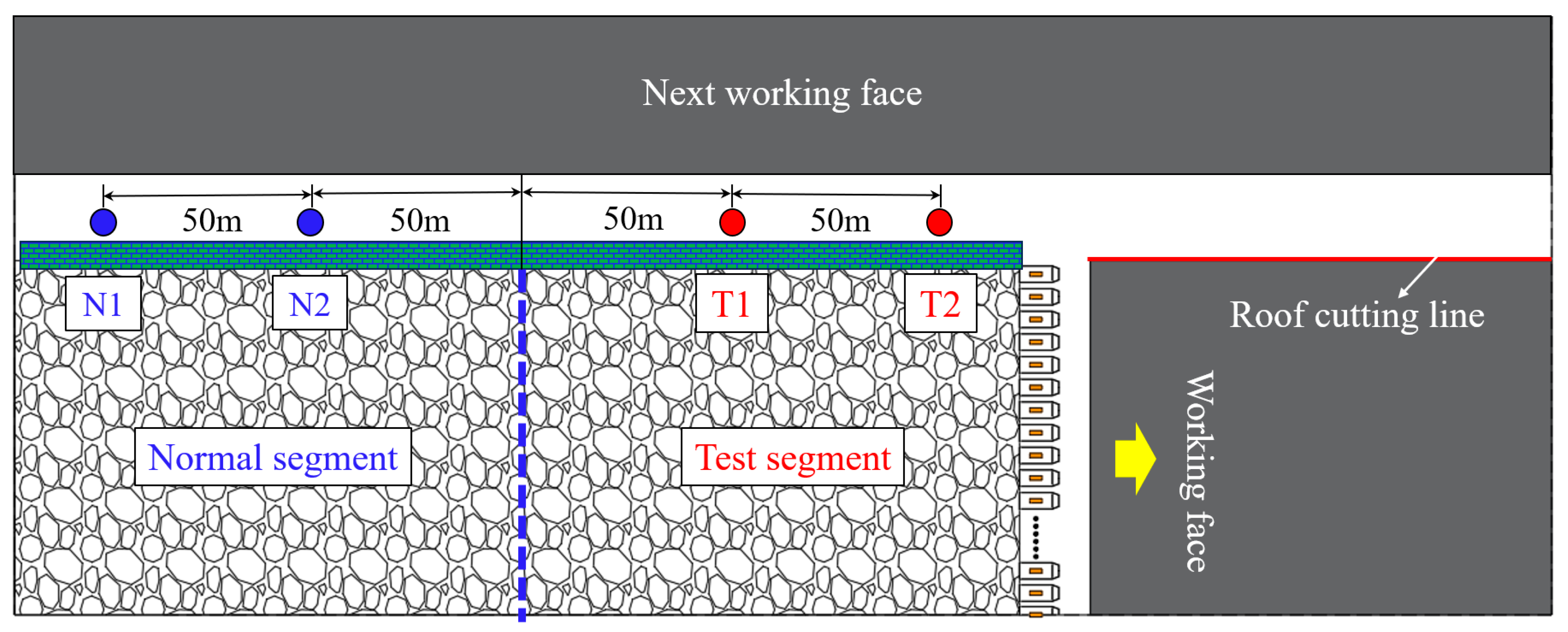

5.2.1. Monitoring Scheme

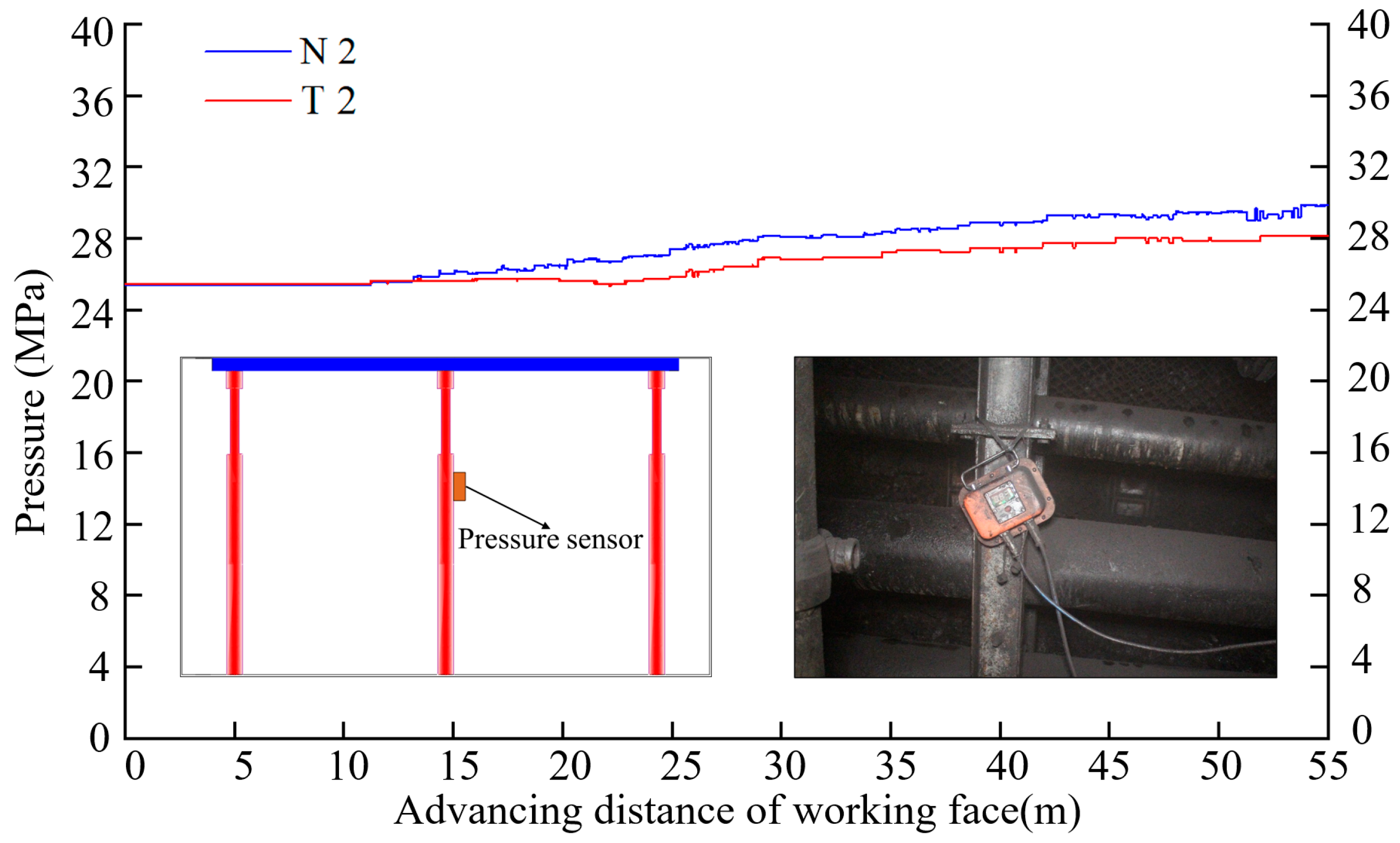

5.2.2. Hydraulic Prop Stress

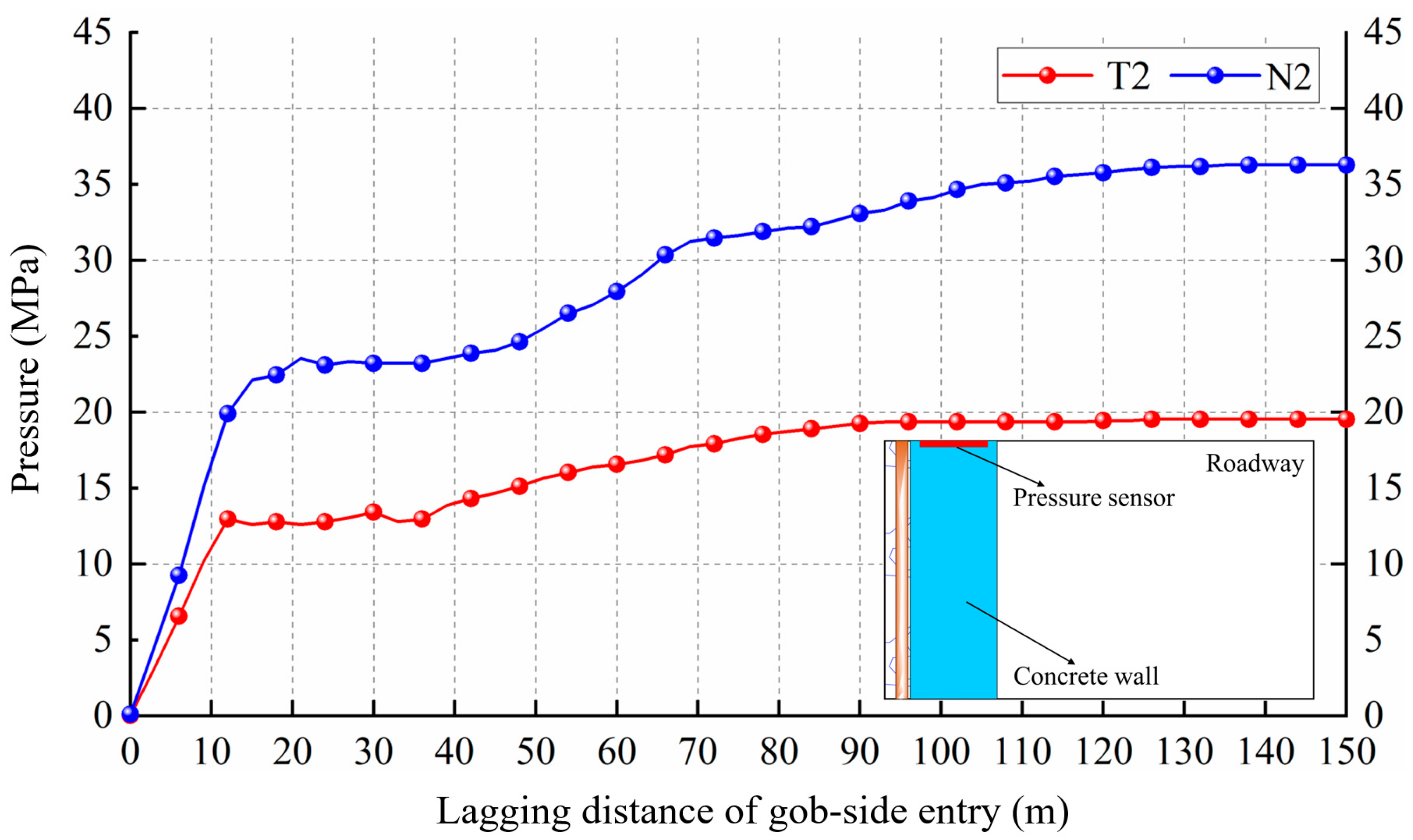

5.2.3. Filling Body Stress

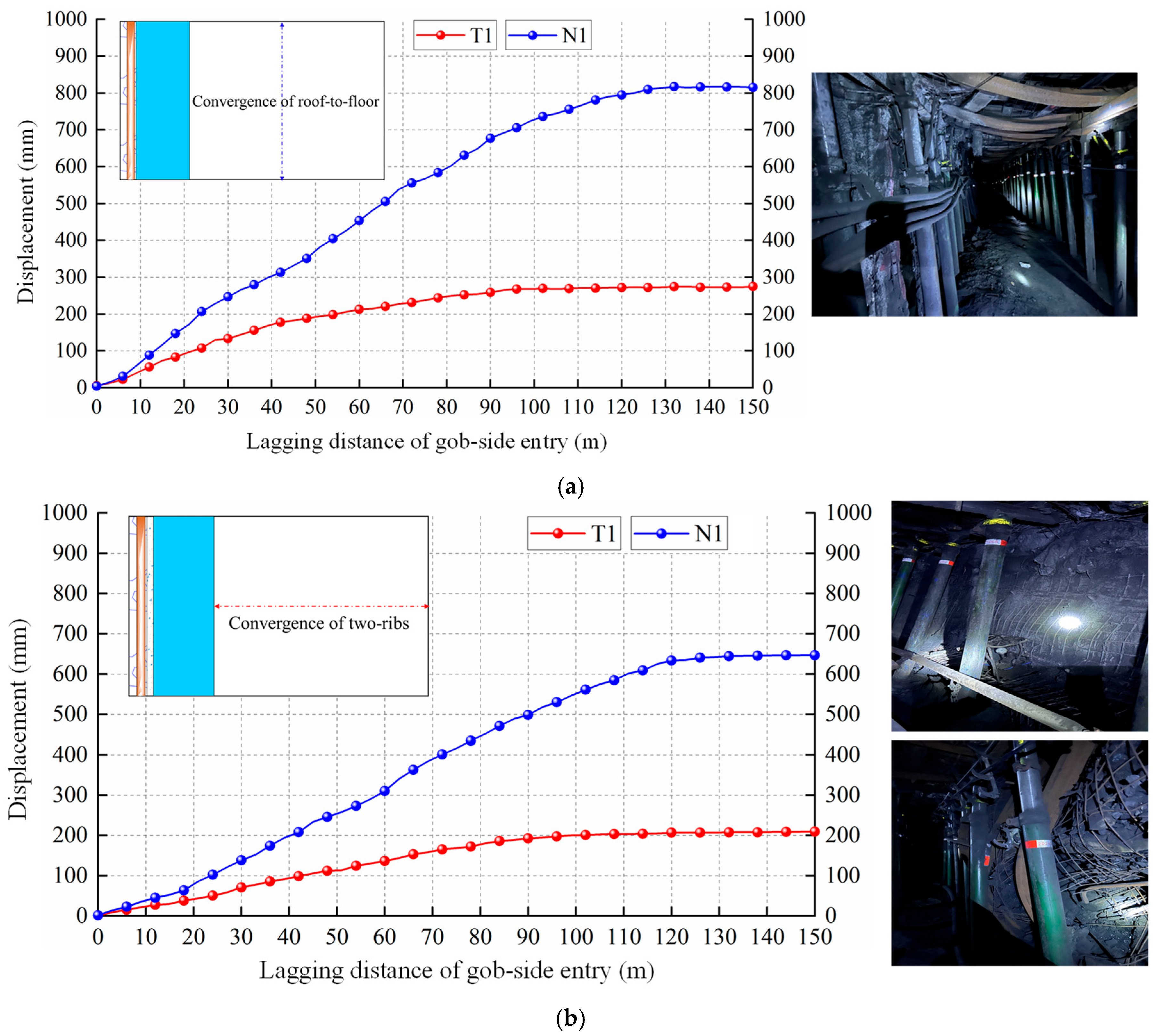

5.2.4. Roadway Surrounding Rock Deformation

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.L.; Feng, L.Y.; Davidsson, S.; Hook, M. Chinese coal supply and future production outlooks. Energy 2013, 60, 204–214. [Google Scholar] [CrossRef]

- Xue, G.; Yilmaz, E.; Feng, G.; Cao, S. Analysis of tensile mechanical characteristics of fibre reinforced backfill through splitting tensile and three-point bending tests. Int. J. Min. Reclam. Environ. 2022, 36, 218–234. [Google Scholar] [CrossRef]

- Akinbinu, V.A. Relationship of brittleness and fragmentation in brittle compression. Eng. Geol. 2017, 221, 82–90. [Google Scholar] [CrossRef]

- Chen, S.M.; Wu, A.X.; Wang, Y.M.; Chen, X.; Yan, R.F.; Ma, H.J. Study on repair control technology of soft surrounding rock roadway and its application. Eng. Fail. Anal. 2018, 92, 443–455. [Google Scholar] [CrossRef]

- Zhang, C.L.; Wang, P.Z.; Wang, E.Y.; Chen, D.P.; Li, C. Characteristics of coal resources in China and statistical analysis and preventive measures for coal mine accidents. Int. J. Coal Sci. Techn. 2023, 10, 1–16. [Google Scholar] [CrossRef]

- Afrouz, A.; Hassani, F.P.; Scoble, M.J. Geotechnical assessment of the bearing capacity of coal mine floors. Int. J. Mining Geol. Eng. 1988, 6, 297–312. [Google Scholar] [CrossRef]

- Sun, X.M.; Jiang, M.; Zhang, T.; Miao, C.Y. A novel method of deep and shallow combined roof cutting and constant resistance support for enhancing deep mining roadway stability. Min. Metall. Explor. 2025, 42, 1421–1440. [Google Scholar] [CrossRef]

- Yuriy, G.; Vayenas, N. Discrete-event simulation of mine equipment systems combined with a reliability assessment model based on genetic algorithms. Int. J. Min. Reclam. Environ. 2008, 22, 70–83. [Google Scholar] [CrossRef]

- Khandelwal, M.; Faradonbeh, R.S.; Monjezi, M.; Armaghani, D.J.; Yagiz, S. Function development for appraising brittleness of intact rocks using genetic programming and nonlinear multiple regression models. Eng. Comput. 2016, 32, 13–21. [Google Scholar] [CrossRef]

- Jiang, L.S.; Wu, Q.S.; Wu, Q.L.; Wang, P.; Xue, Y.C.; Kong, P.; Gong, B. Fracture failure analysis of hard and thick key layer and its dynamic response characteristics. Eng. Fail. Anal. 2019, 98, 118–130. [Google Scholar] [CrossRef]

- Shabanimashcool, M.; Li, C.C. A numerical study of stress changes in barrier pillars and a border area in a longwall coal mine. Int. J. Coal Geol. 2013, 106, 39–47. [Google Scholar] [CrossRef]

- Wang, H.W.; Wang, Y.P.; Jiang, J.Q.; Chen, P.P. Stability mechanism and control technology for fully mechanized caving mining of steeply inclined extra-thick seams with variable angles. Min. Metall. Explor. 2021, 38, 1047–1057. [Google Scholar]

- Ozfirat, M.K.; Yenice, H.; Simir, F.; Yarali, O. A new approach to rock brittleness and its usability at prediction of drillability. J. Afr. Earth. Sci. 2016, 119, 94–101. [Google Scholar] [CrossRef]

- Xie, P.; Luo, Y.; Wu, Y.; Gao, X.; Luo, S.; Zeng, Y. Roof deformation associated with mining of two panels in steeply dipping coal seam using subsurface subsidence prediction model and physical simulation experiment. Min. Metall. Explor. 2020, 37, 581–591. [Google Scholar] [CrossRef]

- Li, T.; Chen, G.B.; Qin, Z.C.; Li, Q.H.; Cao, B.; Liu, Y.L. The gob-side entry retaining with the high-water filling material in Xin’an Coal Mine. Geomech. Eng. 2020, 22, 541–552. [Google Scholar]

- Kang, Y.S.; Liu, Q.S.; Xi, H.L.; Gong, G.Q. Improved compound support system for coal mine tunnels in densely faulted zones: A case study of China’s Huainan coal field. Eng. Geol. 2018, 240, 10–20. [Google Scholar] [CrossRef]

- Liu, X.S.; Ning, J.G.; Tan, Y.L.; Xu, Q.; Fan, D.Y. Coordinated supporting method of gob-side entry retaining in coal mines and a case study with hard roof. Geomech. Eng. 2018, 15, 1173–1182. [Google Scholar]

- Wang, J.; Liu, P.; He, M.C.; Yu, G.Y.; Tian, H.Z. Floor heave mechanism for gob-side entry retaining with concrete blocks and control method: A case study. Undergr. Space 2024, 15, 244–259. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, C.; Zheng, P.Q.; Li, N.; Zhan, Y.B. Deformation and failure mechanism of surrounding rocks in crossed-roadway and its support strategy. Eng. Fail. Anal. 2020, 116, 104743. [Google Scholar] [CrossRef]

- Deng, G.Z.; Li, H.J. Study on the technology and application of cooperative roadway protection with roof cutting pressure relief and CO2 mineralization and filling. Sci. Rep. 2025, 15, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Pu, S.J.; Wu, G.Y.; Liu, Q.Z.; Wang, Y.L.; Li, Q.; Xiong, Y. Determination of reasonable width of filling body for gob-side entry retaining in mining face with large cutting height. Geofluids 2022, 2022, 1–12. [Google Scholar] [CrossRef]

- Zhu, Y.H.; Tian, Y.; Gong, P.L.; Wen, G.; Yi, K. Predictive model for the instability of flexible formwork concrete wall in secondary mining of non-pillar coal mining. Sci. Rep. 2024, 14, 1–17. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, Z.H.; Jiang, B.; He, M.C.; Yang, J.; Xue, H.J. Ground control method of using roof cutting pressure release and energy-absorbing reinforcement for roadway with extra-thick hard roof. Rock Mech. Rock Eng. 2023, 56, 7197–7215. [Google Scholar] [CrossRef]

- Gao, Y.B.; Gai, Q.K.; Zhang, K.D.; Fu, Q.; Zhang, X.X. Strata behaviour and stability control of the automatic roadway formation by roof cutting below a fault influenced longwall goaf. Sci. Rep. 2022, 12, 1–18. [Google Scholar] [CrossRef]

- Yang, J.; He, M.C.; Cao, C. Design principles and key technologies of gob side entry retaining by roof pre-fracturing. Tunn. Undergr. Space Tech. 2019, 90, 309–318. [Google Scholar] [CrossRef]

- Wang, Y.J.; He, M.C.; Yang, J.; Wang, Q.; Liu, J.N.; Tian, X.C.; Gao, Y.B. Case study on pressure-relief mining technology without advance tunneling and coal pillars in longwall mining. Tunn. Undergr. Space Tech. 2020, 97, 103236. [Google Scholar] [CrossRef]

- Du, Z.W.; Chen, S.J.; Ma, J.B.; Guo, Z.P.; Yin, D.W. Gob-side entry retaining involving bag filling material for support wall construction. Sustainability 2020, 12, 6681. [Google Scholar] [CrossRef]

- Yang, J.; Fu, Q.; Gao, Y.B.; Wu, X.; Chang, X.; Li, C.J. A novel method of combined deep hole blasting for gob-side roadway protection. Rock Mech. Rock Eng. 2023, 56, 3551–3571. [Google Scholar] [CrossRef]

- Chen, D.C.; Wang, X.Y.; Wu, S.; Zhang, F.T.; Fan, Z.Z.; Wang, X.D.; Li, M.L. Study on stability mechanism and control techniques of surrounding rock in gob-side entry retaining with flexible formwork concrete wall. J. Cent. South Univ. 2023, 30, 2966–2982. [Google Scholar] [CrossRef]

- Xie, S.R.; Pan, H.; Chen, D.D.; Zeng, J.C.; Song, H.Z.; Cheng, Q.; Xiao, H.B.; Yan, Z.Q.; Li, Y.H. Stability analysis of integral load-bearing structure of surrounding rock of gob-side entry retention with flexible concrete formwork. Tunn. Undergr. Space Tech. 2020, 103, 103464. [Google Scholar] [CrossRef]

- Gao, Y.B.; Wang, Y.J.; Yang, J.; Zhang, X.Y.; He, M.C. Meso- and macroeffects of roof split blasting on the stability of gateroad surroundings in an innovative nonpillar mining method. Tunn. Undergr. Space Tech. 2019, 90, 99–118. [Google Scholar] [CrossRef]

- Fu, Q.; Yang, J.; Song, H.X.; Wu, X.; Liu, Y.X.; Wei, X.J. Study on the method of pressure relief and energy absorption for protecting roadway under thick and hard roof. Rock Mech. Rock Eng. 2023, 56, 7177–7196. [Google Scholar] [CrossRef]

- Wang, Y.J.; Gao, Y.B.; Wang, E.Y.; He, M.C.; Yang, J. Roof deformation characteristics and preventive techniques using a novel non-pillar mining method of gob-side entry retaining by roof cutting. Energies 2018, 11, 627. [Google Scholar] [CrossRef]

| Parameter Values | Sensitivity Coefficient | |

|---|---|---|

| Rotation angle θ | θ = 1.5°~5.0° | 5.689~9.887 |

| Roof length L | L = 4.7~7.5 m | 38.659~12.563 |

| Roof thickness b | b = 10~14 m | 1.589~2.697 |

| Lithology | Density (kg/m3) | Bulk Modulus /GPa | Shear Modulus /GPa | Cohesion /MPa | Tensile Strength /MPa | Friction Angle /(°) |

|---|---|---|---|---|---|---|

| Overlying rock strata | 2500 | 12.9 | 9.6 | 1.5 | 1.41 | 30 |

| Fine-grained sandstone | 2560 | 7.4 | 5.4 | 1.8 | 0.79 | 30 |

| Limestone | 2360 | 10.2 | 3.9 | 1.5 | 1.41 | 30 |

| Siltstone | 1890 | 5.2 | 4.2 | 1.5 | 0.89 | 24 |

| Coal | 2430 | 5.04 | 4.1 | 2.3 | 0.4 | 26 |

| Roadside filling | 2300 | 10.5 | 6.2 | 3.2 | 1.5 | 34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Zhao, S.; Shi, Y.; Li, Y.; Lv, K.; Fu, Q.; Ren, W.; Zhou, Z. Study on Surrounding Rock Failure Analysis and Novel Stability Control Approach for High-Stress Gob-Side Roadway Retaining. Appl. Sci. 2025, 15, 10119. https://doi.org/10.3390/app151810119

Gao H, Zhao S, Shi Y, Li Y, Lv K, Fu Q, Ren W, Zhou Z. Study on Surrounding Rock Failure Analysis and Novel Stability Control Approach for High-Stress Gob-Side Roadway Retaining. Applied Sciences. 2025; 15(18):10119. https://doi.org/10.3390/app151810119

Chicago/Turabian StyleGao, Hainan, Shankun Zhao, Yue Shi, Yunpeng Li, Kun Lv, Qiang Fu, Weiguang Ren, and Zhibin Zhou. 2025. "Study on Surrounding Rock Failure Analysis and Novel Stability Control Approach for High-Stress Gob-Side Roadway Retaining" Applied Sciences 15, no. 18: 10119. https://doi.org/10.3390/app151810119

APA StyleGao, H., Zhao, S., Shi, Y., Li, Y., Lv, K., Fu, Q., Ren, W., & Zhou, Z. (2025). Study on Surrounding Rock Failure Analysis and Novel Stability Control Approach for High-Stress Gob-Side Roadway Retaining. Applied Sciences, 15(18), 10119. https://doi.org/10.3390/app151810119