Heuristic, Hybrid, and LLM-Assisted Heuristics for Container Yard Strategies Under Incomplete Information: A Simulation-Based Comparison

Abstract

1. Introduction

2. Literature Review

2.1. Stacking Strategies and Optimization Methods

- fail to account for operational variability (e.g., unexpected delays, route changes, load reorganizations);

- rely on full schedule knowledge, which is rarely available in practice;

- do not adapt to real-time yard occupancy levels or predict operational conflicts.

- the requirement for complete input data;

- lack of flexibility in dealing with delays and unplanned events;

- long computation times for large-scale instances.

2.2. Adaptive Strategies and the Application of Artificial Intelligence in Yard Management

2.3. Research Gap and Justification of the Research Approach

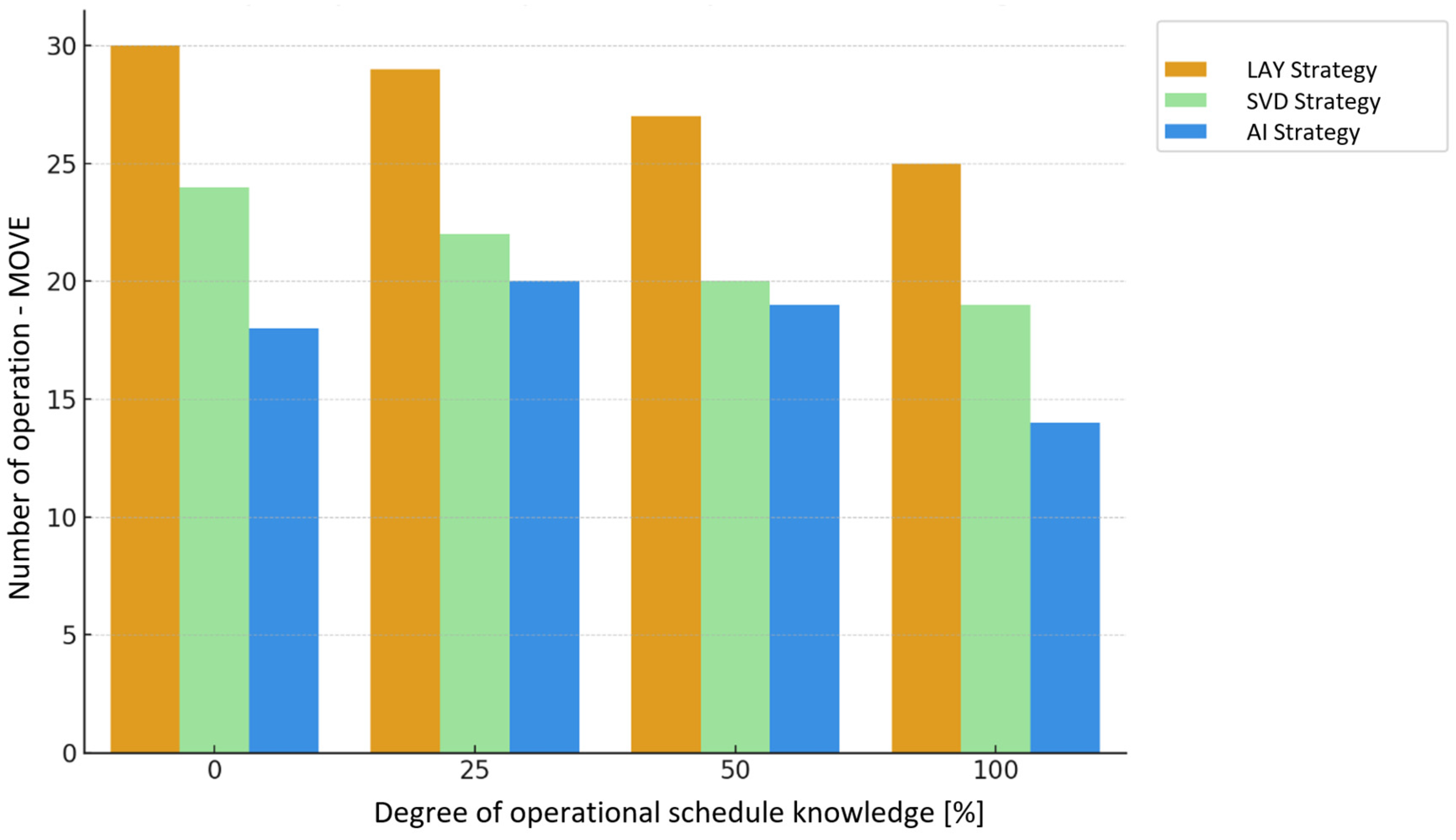

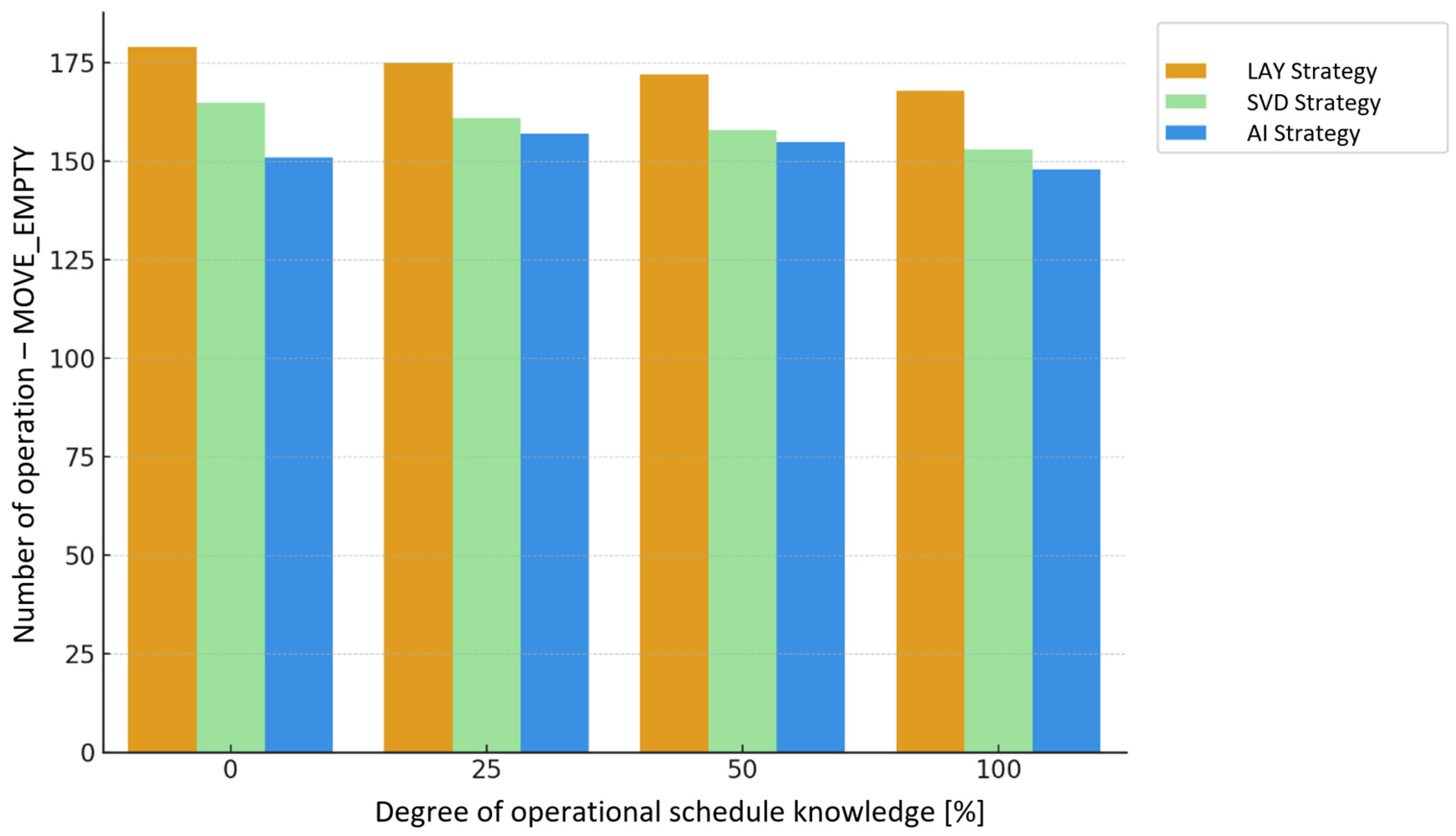

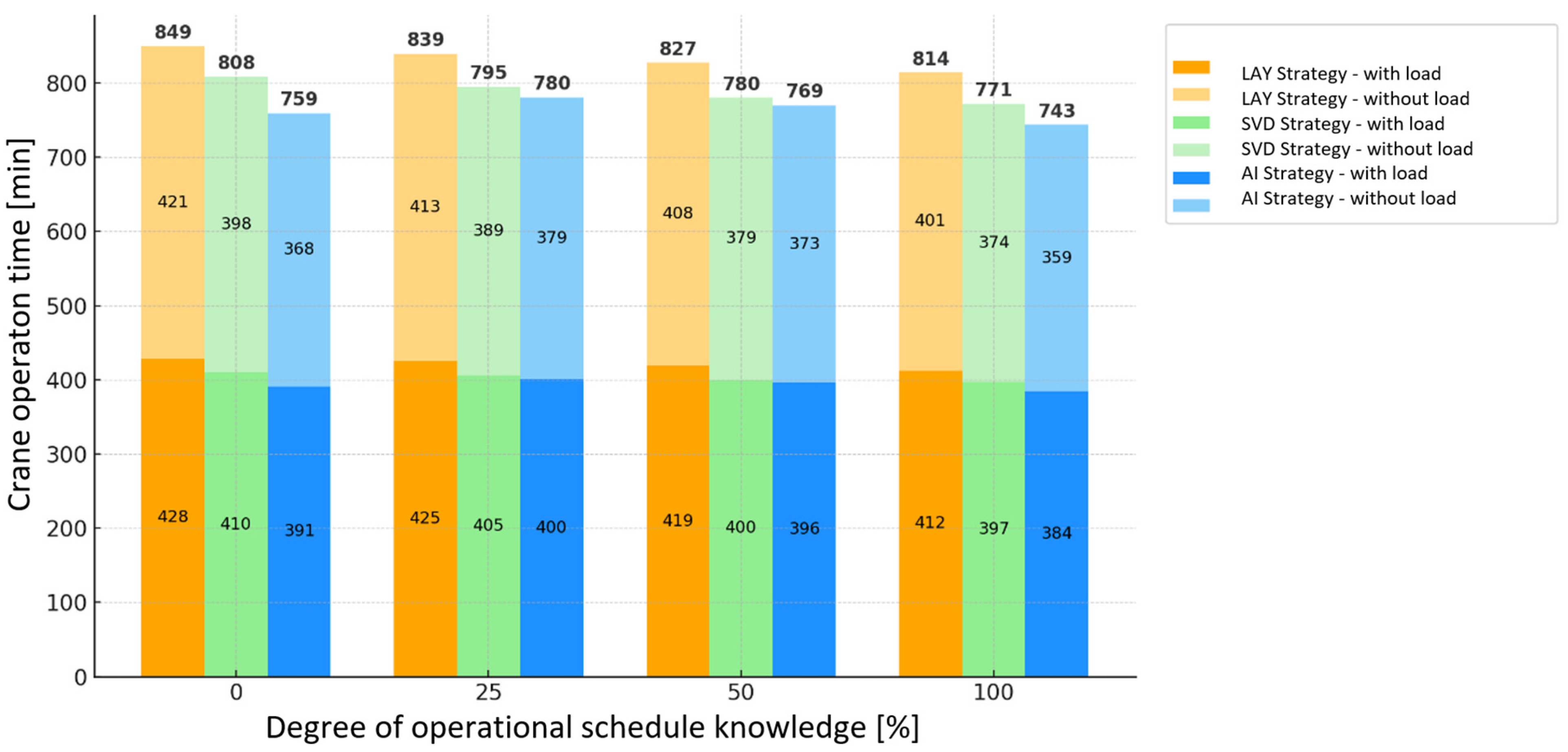

- differentiates levels of schedule information availability (e.g., 0%, 25%, 50%, 100%);

- tests different strategy classes (random, heuristic, adaptive);

- and evaluates their operational robustness under dynamic terminal conditions.

3. Research Methodology

- determine the extent to which adaptive strategies based on artificial intelligence outperform classical and hybrid approaches in information-uncertain environments;

- assess the impact of schedule visibility (0%, 25%, 50%, 100%) on the performance of each strategy;

- identify strategies that are most operationally resilient to disturbances and variability in information.

3.1. Simulation Setup and Procedure

- In the 0% scenario, only current operations were known, and no information about future containers was accessible.

- In the 25% and 50% scenarios, respectively, 25 or 50 out of 100 scheduled container operations were randomly revealed at the beginning of the simulation.

- In the 100% scenario, the system had access to the complete operational schedule, including all arrival and pickup times.

- −

- Unique ID—sequential identifier used for tracking operations.

- −

- hourly distribution reflecting empirical patterns, with inbound peaks in the morning and early afternoon.

- −

- Pickup time—assigned within predefined daily windows, with outbound peaks aligned with dispatch cut-offs.

- −

- Priority class—categorical attribute (high, medium, low) influencing retrieval urgency, generated with probabilities of 0.2, 0.5, and 0.3, respectively.

- −

- Carrier—categorical variable with four classes representing different operators, randomly assigned with equal probability.

- −

- Operation type—inbound (SET) or outbound (GET), fixed at a 50/50 split.

- −

- the number of inbound and outbound containers (50 each),

- −

- time horizon of 24 h,

- −

- required clustering of arrivals (morning) and departures (afternoon/evening),

- −

- assignment of priority classes and carriers.

- Layer-based strategy (LAY),

- Hybrid strategy based on Zając’s model (SVD),

- Adaptive AI-based strategy (AI), featuring predictive and rule-based modules.

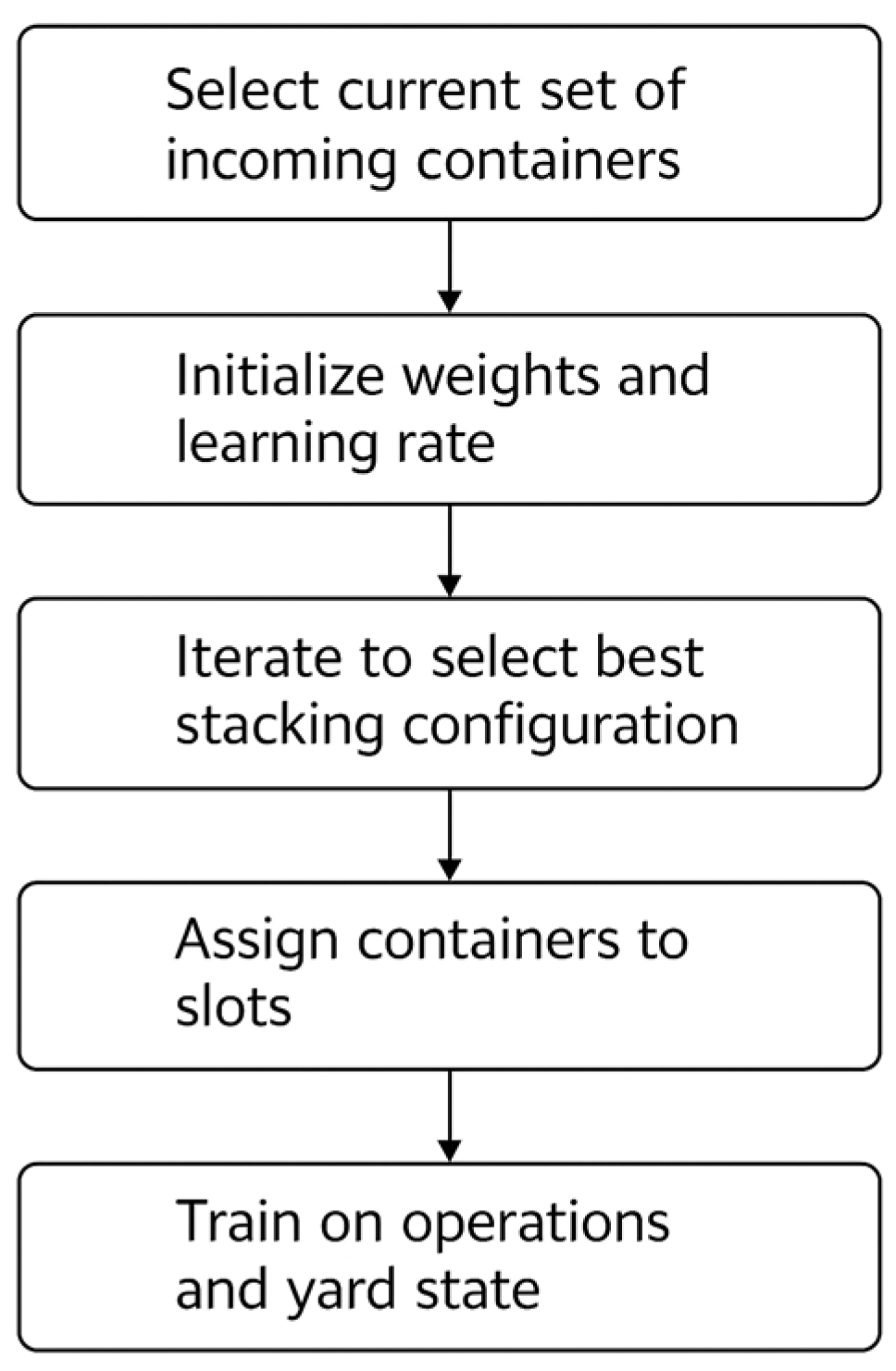

- Setting up the simulation environment: initializing the yard structure and assigning container metadata.

- Schedule generation: producing 100 operations (50 SET, 50 GET) based on realistic timing logic.

- Information scenario setup: determining which data points were hidden or revealed depending on the information level.

- Strategy implementation: executing storage allocation using one of the three defined approaches.

- Crane operation simulation: calculating movement time, vertical operations, and resolving conflicts.

- Multiple experimental runs: performing 10 repetitions for each strategy–information pair (totaling 120 runs).

- Data collection and analysis: aggregating all relevant metrics—operation counts, durations, travel distances, and delays.

- Setting up the simulation environment

- 2.

- Schedule generation

- 3.

- Introducing the information level

- 4.

- Implementation of storage strategies

- 5.

- Crane operation simulation

- 6.

- Multiple experimental runs

- 7.

- Data collection and analysis

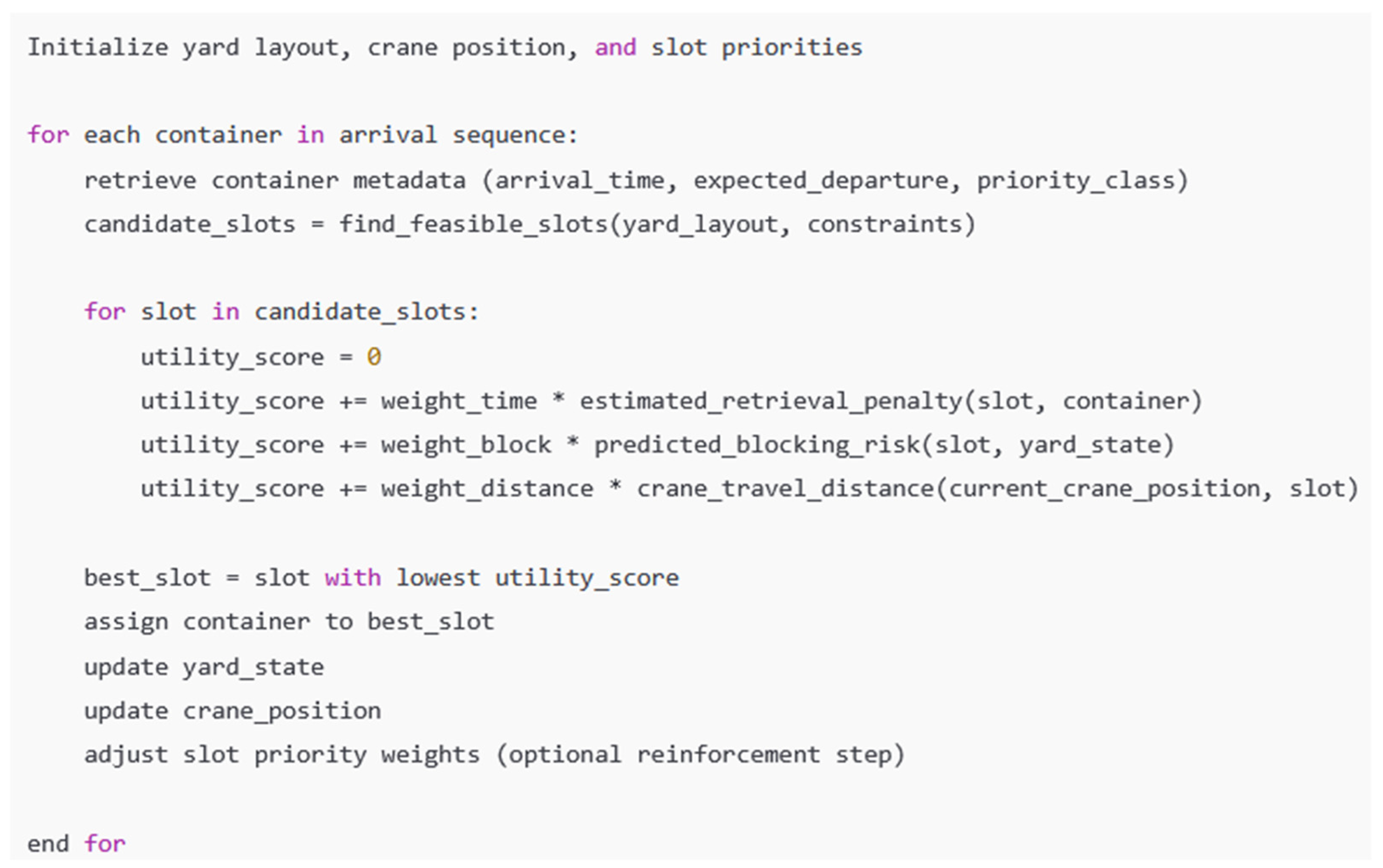

3.2. Storage Strategies

- −

- analyze container movement data in real time;

- −

- forecast future retrieval or relocation operations;

- −

- dynamically assign storage locations to optimize crane routing and minimize empty travel.

3.3. Information Levels and Performance Indicators

- −

- 0%—no knowledge of future events,

- −

- 25%—limited access to the schedule (every fourth container known),

- −

- 50%—partial awareness (every second container known),

- −

- 100%—full knowledge of the entire schedule.

- −

- Numberofoperations:

- SET—placing a container in the yard,

- GET—retrieving a container from the yard,

- MOVE—relocation of a container (non-productive move),

- MOVE_EMPTY—crane movement without a load between tasks,

- −

- Operation duration—average and total,

- −

- Crane travel distance—separately for each type of operation,

- −

- Delays—number and time of operations completed after the scheduled time.

3.4. Formalization of the Decision Problem

- i = 1, 2, …, N: index of container

- : arrival time of container i,

- : departure time of container i,

- x, y, z: coordinates of a yard slot in a 3D grid, where , ,,

- : set of all possible storage slots

- : number of relocations caused by container i,

- : total crane handling time related to container i,

- α, β: weight coefficients (experimentally set or equal).

- estimated departure time of the container,

- slot depth and height (e.g., penalizing deep stacks),

- predicted risk of blocking future operations,

- distance from crane’s current position.

- −

- Random placement—containers are assigned uniformly at random to any available slot, without considering future retrieval times or stack depth. This strategy reflects the absence of planning and provides a lower bound of performance.

- −

- Earliest-Departure-Time (EDT)—each container is placed in a slot minimizing the risk of blocking containers scheduled to depart earlier. This strategy is commonly used in practice to reduce relocations.

- −

- Min-Relocation—each new container is placed to minimize the expected number of future relocations, given the current yard state. This rule is computationally simple and directly targets relocation efficiency.

4. Results

5. Discussion

- validating the proposed model in a real-world environment using data from Terminal Operating Systems (TOS),

- extending the model with additional infrastructure elements, including more than one crane and a larger yard,

- testing AI strategy performance under different levels of noise and errors in the schedule data,

- comparing the strategy with other predictive algorithms, such as LSTM, XGBoost, or Reinforcement Learning models,

- implementing a confidence estimation module to mitigate the risk of overinterpreting incomplete data.

6. Conclusions

- −

- validating the model with operational logs from Terminal Operating Systems,

- −

- benchmarking against classical ML (e.g., Random Forest, XGBoost) and RL/DRL methods,

- −

- integrating explainability mechanisms (XAI) to mitigate the black-box nature of LLM scoring,

- −

- and developing modules for assessing the reliability of incomplete or noisy input data.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Identec Solutions. Container Terminal Yard Operations: What Are Your Blind Spots? Available online: https://www.identecsolutions.com/news/container-terminal-yard-operations (accessed on 30 April 2025).

- ABI Research. What Is a Yard Management System (YMS)? Available online: https://www.abiresearch.com/blog/yard-management-system-yms (accessed on 30 April 2025).

- Danladi, C.; Tuck, S.; Tziogkidis, P.; Tang, L.; Okorie, C. A productivity and efficiency analysis of container ports in lower-middle and upper-middle-income countries. J. Shipp. Trade 2024, 9, 1–24. [Google Scholar] [CrossRef]

- Inter-American Development Bank. The Historical Relationship Between Port Inefficiency and Transport Costs in the Developing World. Available online: https://publications.iadb.org/en/historical-relationship-between-port-inefficiency-and-transport-costs-developing-world (accessed on 30 April 2025).

- McKinsey & Company. How to Rethink Pricing at Container Terminals. Available online: https://www.mckinsey.com/industries/logistics/our-insights/how-to-rethink-pricing-at-container-terminals (accessed on 30 April 2025).

- Carlo, H.J.; Vis, I.F.A.; Roodbergen, K.J. Storage yard operations in container terminals: Literature overview, trends, and research directions. Eur. J. Oper. Res. 2014, 235, 412–430. [Google Scholar] [CrossRef]

- Kim, K.H.; Kim, H.B. Segregating space allocation models for container inventories in port container terminals. Int. J. Prod. Econ. 1999, 59, 415–423. [Google Scholar] [CrossRef]

- Ku, D.; Arthanari, T.S. Container relocation problem with time windows for container departure. Eur. J. Oper. Res. 2016, 252, 1031–1039. [Google Scholar] [CrossRef]

- Vacca, I.; Bierlaire, M.; Salani, M. Yard Optimization at Sea Container Terminals. Available online: https://www.researchgate.net/publication/37456575_Yard_Optimization_at_Sea_Container_Terminals (accessed on 30 April 2025).

- Jo, J.H.; Kim, S. Key performance indicator development for ship-to-shore crane performance assessment in container terminal operations. J. Mar. Sci. Eng. 2019, 8, 6. [Google Scholar] [CrossRef]

- Wu, K.C.; Ting, C.J. A beam search algorithm for minimizing reshuffle operations at container yards. In Proceedings of the International Conference on Logistics and Maritime Systems, Busan, South Korea, 15–17 September 2010; pp. 15–17. [Google Scholar]

- Yu, K.; Yang, J.; Sun, N. MILP model and a rolling horizon algorithm for crane scheduling in a hybrid storage container terminal. Math. Probl. Eng. 2019, 2019, 4739376. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, Q.; Li, X.; Qu, C. A branch-and-price heuristic algorithm for the ART and external truck scheduling problem in an automated container terminal with a parallel layout. Transp. Res. Part E Logist. Transp. Rev. 2024, 184, 103464. [Google Scholar] [CrossRef]

- Zhao, N.; Xia, M.; Mi, C.; Bian, Z.; Jin, J. Simulation-Based Optimization for Storage Allocation Problem of Outbound Containers in Automated Container Terminals. Math. Probl. Eng. 2015, 2015, 548762. [Google Scholar] [CrossRef]

- He, Y.; Wang, Y.; Li, X. Flexible storage yard management in container terminals under uncertainty. Comput. Ind. Eng. 2023, 186, 109753. [Google Scholar] [CrossRef]

- Mili, K. Optimizing Container Terminal Operations: A Comparative Analysis of Hierarchical and Integrated Solution Approaches. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2024, 18, 825–830. [Google Scholar] [CrossRef]

- Kolangiammal, S.; Prabha, S.; Sivalakshmi, P.; Kalaichelvi, S.; Sujatha, S. Transforming yard management for optimizing efficiency through IoT and AI integration. In Proceedings of the 2024 8th International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud)(I-SMAC), Kirtipur, Nepal, 3–5 October 2024; IEEE: New York, NY, USA, 2024; pp. 218–223. [Google Scholar] [CrossRef]

- Maglić, L.; Gulić, M.; Maglić, L. Optimization of container relocation operations in port container terminals. Transport 2020, 35, 37–47. [Google Scholar] [CrossRef]

- Yu, M.; Liang, Z.; Teng, Y.; Zhang, Z.; Cong, X. The inbound container space allocation in the automated container terminals. Expert Syst. Appl. 2021, 179, 115014. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, L.; Yang, X.; Chen, S.; Xie, H. Adaptive Allocation Method of Terminal Container Parameters Based on Evolutionary Game. In Proceedings of the International Conference on Neural Computing for Advanced Applications, Hong Kong, 8–10 July 2014; Singapore Springer Nature: Gateway East, Singapore, 2014; pp. 17–27. Available online: https://link.springer.com/chapter/10.1007/978-981-97-7004-5_2 (accessed on 26 August 2025).

- Wang, X.; Zhao, Q.; Liu, S.; Wang, J.; Qi, L. Robust optimization algorithm for integrated crane assignment and scheduling in slab yard with uncertain arrival time. Int. J. Prod. Res. 2025, 63, 1707–1724. [Google Scholar] [CrossRef]

- Chen, X.; Bai, R.; Qu, R.; Dong, J.; Jin, Y. Deep reinforcement learning assisted genetic programming ensemble hyper-heuristics for dynamic scheduling of container port trucks. IEEE Trans. Evol. Comput. 2024, 29, 1371–1385. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, Z.; Chen, K.; Ding, H.; Voss, S.; Heilig, L.; Chen, Y.; Chen, X.; de Luca, S. Real-Time Monitoring and Optimal Resource Allocation for Automated Container Terminals: A Digital Twin Application at the Yangshan Port. J. Adv. Transp. 2023, 2023, 6909801. [Google Scholar] [CrossRef]

- Van Twiller, J.; Grbic, D.; Jensen, R.M. AI2STOW: End-to-End Deep Reinforcement Learning to Construct Master Stowage Plans under Demand Uncertainty. arXiv 2025, arXiv:2504.04469. [Google Scholar] [CrossRef]

- Chen, X.; Qu, R.; Dong, J.; Bai, R.; Jin, Y. Genetic Programming with Reinforcement Learning Trained Transformer for Real-World Dynamic Scheduling Problems. arXiv 2025, arXiv:2504.07779. [Google Scholar] [CrossRef]

- Jahangard, M.; Xie, Y.; Feng, Y. Leveraging machine learning and optimization models for enhanced seaport efficiency. Marit. Econ. Logist. 2025, 1–42. [Google Scholar] [CrossRef]

- Tideworks Technology. The Future of AI and Machine Learning in Terminal Operations. 2025. Available online: https://tideworks.com/future-ai-machine-learning-terminal-operations/ (accessed on 30 April 2025).

- Lee, W.; Cho, S.W. Reinforcement learning approach for outbound container stacking in container terminals. Comput. Ind. Eng. 2025, 204, 111069. [Google Scholar] [CrossRef]

- Zhang, X.; Jia, N.; Song, D.; Liu, B. Modelling and analyzing the stacking strategies in automated container terminals. Transp. Res. Part E Logist. Transp. Rev. 2024, 187, 103608. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, C.; Zhang, C.; Tang, K.; Zhou, W.; Wang, J. A multi-agent reinforcement learning approach for ART adaptive control in automated container terminals. Comput. Ind. Eng. 2024, 193, 110264. [Google Scholar] [CrossRef]

- Yu, H.; Ning, J.; Wang, Y.; He, J.; Tan, C. Flexible yard management in container terminals for uncertain retrieving sequence. Ocean Coast. Manag. 2021, 212, 105794. [Google Scholar] [CrossRef]

- Lasić, T.; Rožić, T.; Stanković, R. Optimization of transport network using mathematical methods. Transp. Res. Procedia 2023, 73, 5–16. [Google Scholar] [CrossRef]

- Jonker, T.; Duinkerken, M.B.; Yorke-Smith, N.; de Waal, A.; Negenborn, R.R. Coordinated optimization of equipment operations in a container terminal. Flex. Serv. Manuf. J. 2021, 33, 281–311. [Google Scholar] [CrossRef]

- Zając, M. The model of reducing operations time at a container terminal by assigning places and sequence of operations. Appl. Sci. 2021, 11, 12012. [Google Scholar] [CrossRef]

- Turney, D. AI Is Just as Overconfident and Biased as Humans Can Be, Study Shows; Live Science: New York, NY, USA, 2025; Available online: https://www.livescience.com/technology/artificial-intelligence/ai-is-just-as-overconfident-and-biased-as-humans-can-be-study-shows (accessed on 30 April 2025).

- INFORMS. AI thinks like us, flaws and all: New study finds ChatGPT mirrors human decision biases in half the tests. INFORMS. 10 April 2024. Available online: https://www.informs.org/News-Room/INFORMS-Releases/News-Releases/AI-Thinks-Like-Us-Flaws-and-All-New-Study-Finds-ChatGPT-Mirrors-Human-Decision-Biases-in-Half-the-Tests (accessed on 30 April 2025).

| Approach Type | Example Methods | Requires Full Schedule | Adaptability to Uncertainty | Computational Complexity | Reproducibility | Key References |

|---|---|---|---|---|---|---|

| Classical (Rule-Based) | LAY, EET, Min-Relocation | Yes | Low | Low | High | [6,7,10] |

| Heuristic (Hybrid) | SVD, Decision Trees | Partial | Medium | Medium | Medium | [8,12,13] |

| ML-Based | Random Forest, XGBoost | Optional | Medium–High | High | Medium | [16,26] |

| RL/DRL | Q-Learning, PPO, DQN | Optional | High | Very High | Medium | [22,28,30] |

| LLM-Assisted Heuristic | ChatGPT-4 scoring (this study) | Optional | Medium | Low | Low | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zajac, M. Heuristic, Hybrid, and LLM-Assisted Heuristics for Container Yard Strategies Under Incomplete Information: A Simulation-Based Comparison. Appl. Sci. 2025, 15, 10033. https://doi.org/10.3390/app151810033

Zajac M. Heuristic, Hybrid, and LLM-Assisted Heuristics for Container Yard Strategies Under Incomplete Information: A Simulation-Based Comparison. Applied Sciences. 2025; 15(18):10033. https://doi.org/10.3390/app151810033

Chicago/Turabian StyleZajac, Mateusz. 2025. "Heuristic, Hybrid, and LLM-Assisted Heuristics for Container Yard Strategies Under Incomplete Information: A Simulation-Based Comparison" Applied Sciences 15, no. 18: 10033. https://doi.org/10.3390/app151810033

APA StyleZajac, M. (2025). Heuristic, Hybrid, and LLM-Assisted Heuristics for Container Yard Strategies Under Incomplete Information: A Simulation-Based Comparison. Applied Sciences, 15(18), 10033. https://doi.org/10.3390/app151810033