1. Introduction

Reactor pressure vessels (RPV) [

1], aerospace propulsion chambers [

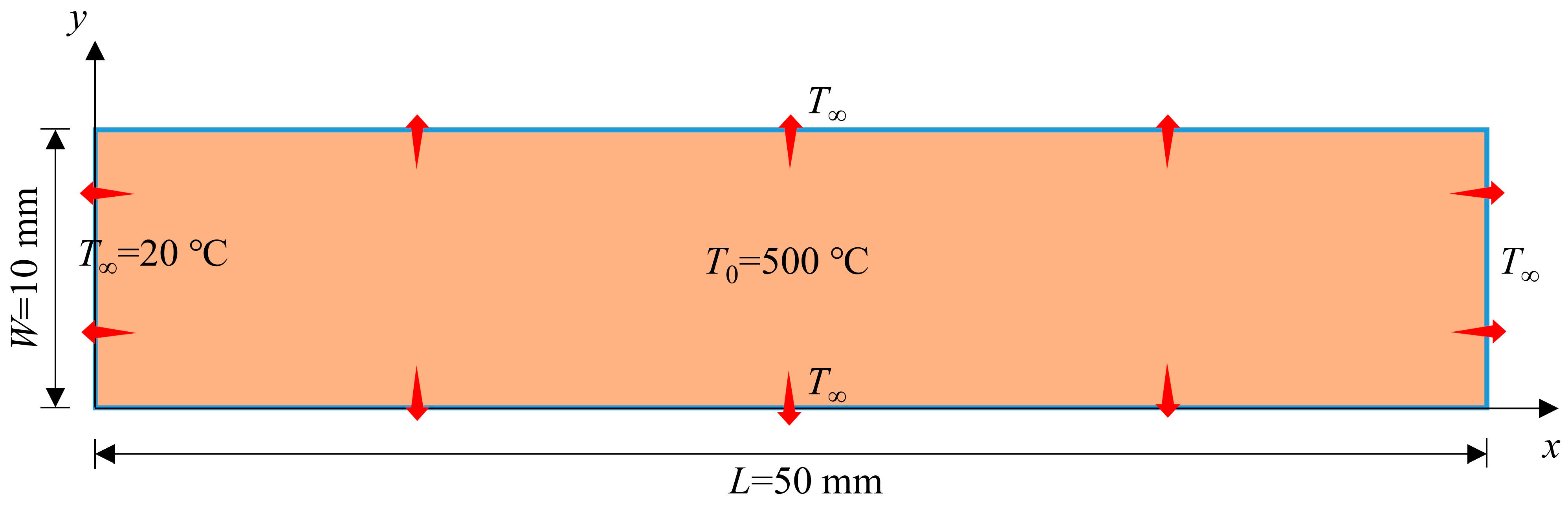

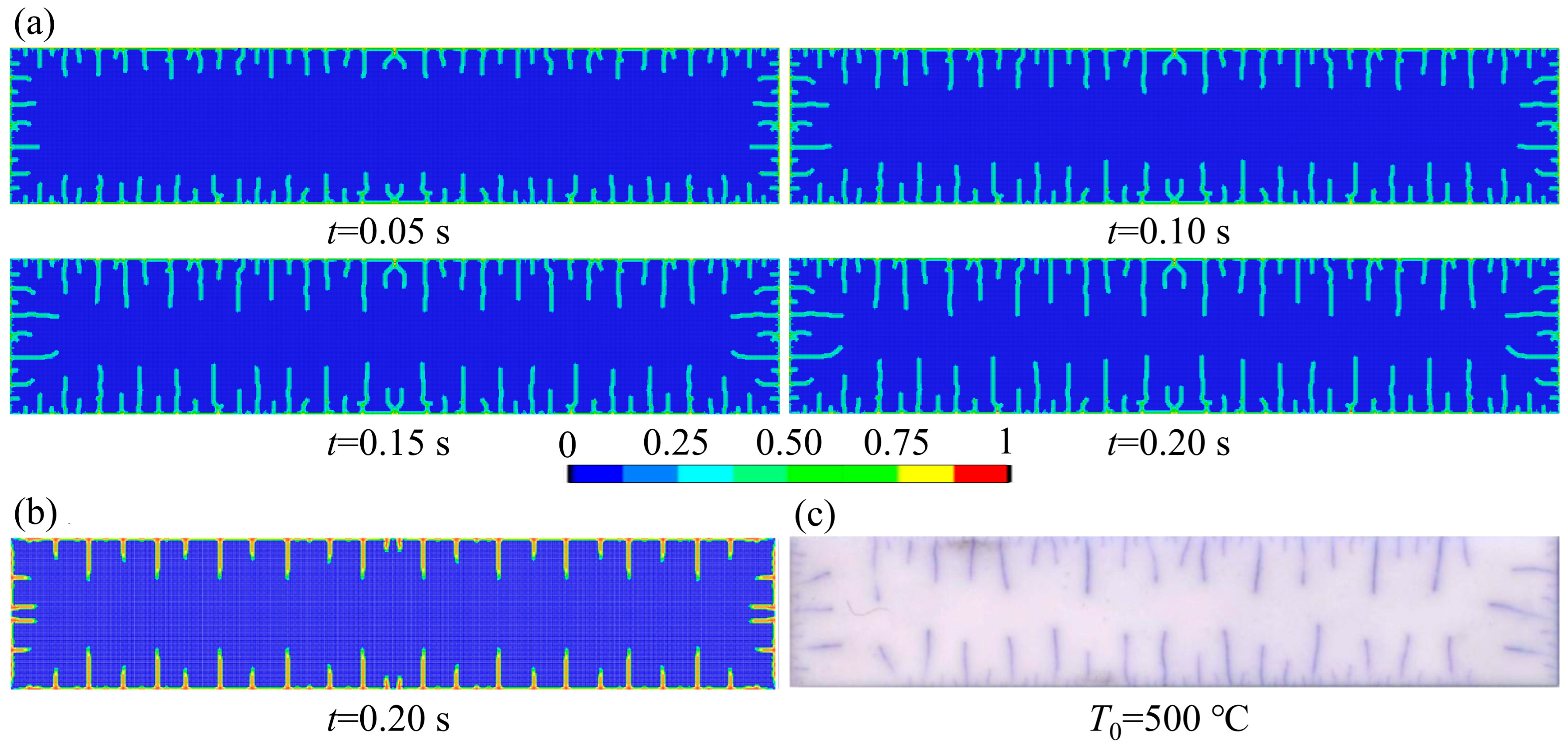

2], and other critical pressure-bearing structures play a crucial role in the energy and aerospace sectors. During normal operation, these structures are subjected to high temperatures, high pressures, and other complex loading conditions for prolonged periods. This exposure can lead to thermal stress concentration, thermal cracking, and other deformation-related damage [

3]. Such phenomena can result in localized failure or even complete structural collapse, which poses a significant risk to the safety and operational lifespan of engineering equipment. Therefore, it is essential to develop efficient and accurate computational methods for analyzing the deformation and damage behavior of these structures under thermomechanical coupling.

Over the past few decades, numerical methods based on classical continuum mechanics theory, such as the finite element method (FEM) [

4] and finite difference method [

5], have been the mainstream tools in thermomechanical coupling analysis. However, these methods are limited by their continuity assumptions when dealing with discontinuous deformation problems, such as damage, fracture, and crack propagation, making it difficult to describe crack initiation and evolution naturally. In complex scenarios involving large deformations, strong nonlinearity, and multiphysics coupling, these methods often encounter difficulties with convergence and exhibit strong mesh dependency, limiting their applicability in simulating complex failure behaviors [

6]. Therefore, in recent years, methods such as the smoothed particle hydrodynamics [

7,

8], the moving least square method [

9,

10], the phase-field method [

11,

12], and peridynamics (PD) [

13,

14], which are based on meshless or particle-based numerical methods, have gradually been introduced.

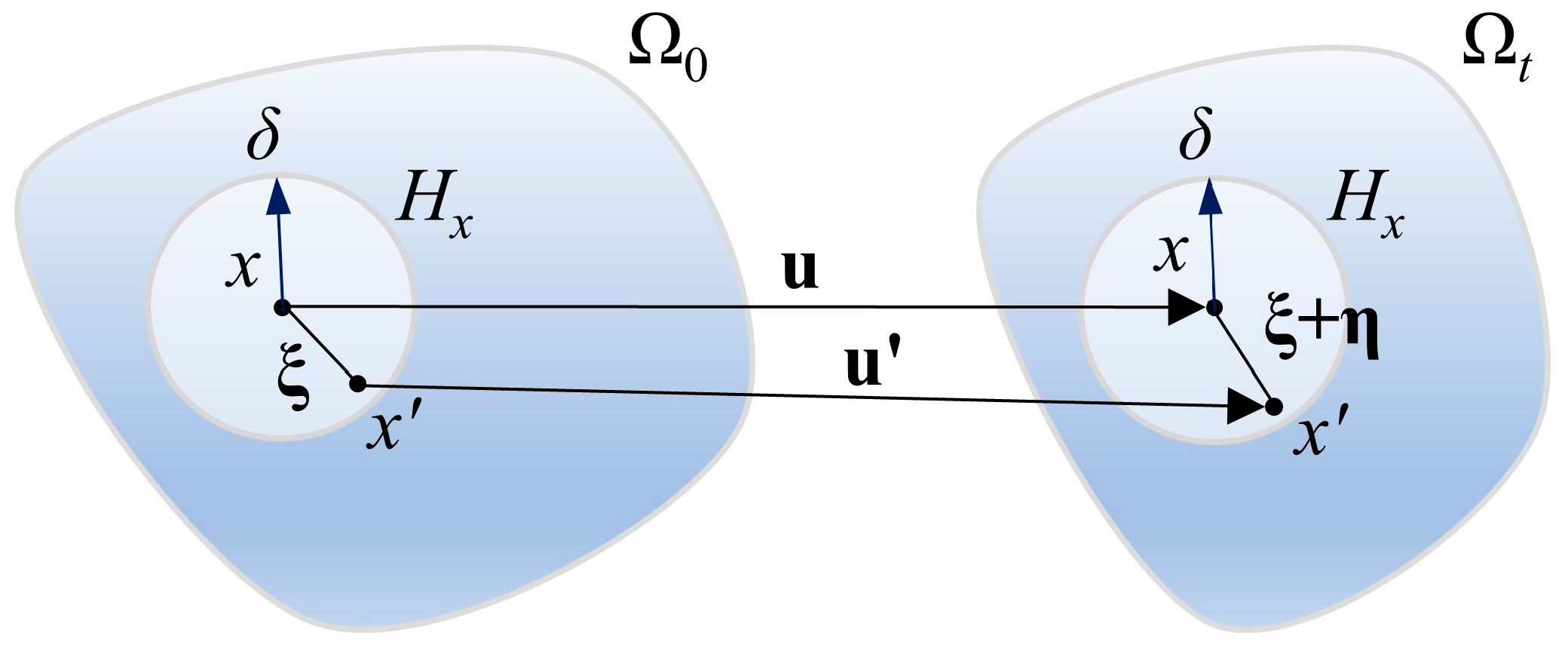

The PD theory, proposed by Silling in 2000 [

15], is a nonlocal continuum mechanics theory based on spatial integral equations. It replaces partial differential equations with integral equations, enabling the consideration of nonlocal effects, which is particularly useful for simulating crack propagation and material damage [

16,

17,

18]. Recently, some researchers have attempted to introduce the PD method into thermomechanical coupling models. Oterkus et al. [

19] derived a fully coupled PD thermodynamic equation based on thermodynamic principles, proposing a generalized model combining energy conservation and free energy functions to solve complex thermomechanical coupling problems. Wang et al. [

20,

21] proposed a bond-based peridynamic (BBPD) thermomechanical coupling PD model and validated its accuracy through benchmark problems. To study thermal failure in functionally graded materials, He et al. [

22] proposed an improved fully coupled thermomechanical ordinary state-based PD model to study thermal failure in functionally graded materials, and analyzed the effect of material gradient changes on the thermal response by introducing an exothermic term due to irreversible damage. Yang et al. [

23] proposed a fully coupled thermomechanical PD model for simulating the thermomechanical response and thermal-induced fracture of solids. Additionally, PD-based thermomechanical coupling models have been used to address issues such as thermal damage to railway rails [

24], high temperature fractures of alloys [

25], and frost heaving in rocks [

26]. In summary, the PD method demonstrates unique advantages in handling nonlocal effects under thermomechanical loads, particularly in simulating complex thermomechanical coupling processes, such as local damage and crack propagation.

Despite the substantial promise of PD and related nonlocal formulations for characterizing thermomechanically coupled damage evolution, their intrinsic nonlocality makes them significantly more computationally expensive than classical local continuum approaches. The response of each material point must be evaluated by integrating over its neighborhood, which renders PD simulations—particularly those involving long-duration physical evolution—computationally intensive and time-consuming [

27,

28]. This high computational cost severely constrains the use of PD in real-time engineering analysis and rapid prediction, for example in the fast diagnosis of sudden failures, large-scale parametric screening, and online feedback within digital-twin systems. It is therefore imperative to develop a computational framework that preserves the high accuracy of PD while satisfying real-time performance requirements. Deep learning (DL) offers a transformative pathway to address this tension [

29,

30].

Through training, DL models can learn highly nonlinear mappings from input parameters to complex physical responses, thereby serving as efficient surrogate models [

31]. Once trained, neural networks deliver extremely fast forward predictions, typically within milliseconds to seconds, accomplishing tasks that would require hours or even days with traditional numerical solvers, thus resolving the timeliness bottleneck. Building on this insight, the present work integrates the high-fidelity modeling capability of PD with the rapid inference of DL to construct a PD–DL hybrid framework. High-fidelity data generated by PD simulations are used to train the neural networks, which are then employed for fast prediction. This approach not only remedies the computational inefficiency of pure PD, but also mitigates the potential distortions of purely data-driven methods by embedding physics-based information, thereby enabling the accurate, real-time analysis of thermomechanically coupled damage processes.

The remainder of this paper is organized as follows.

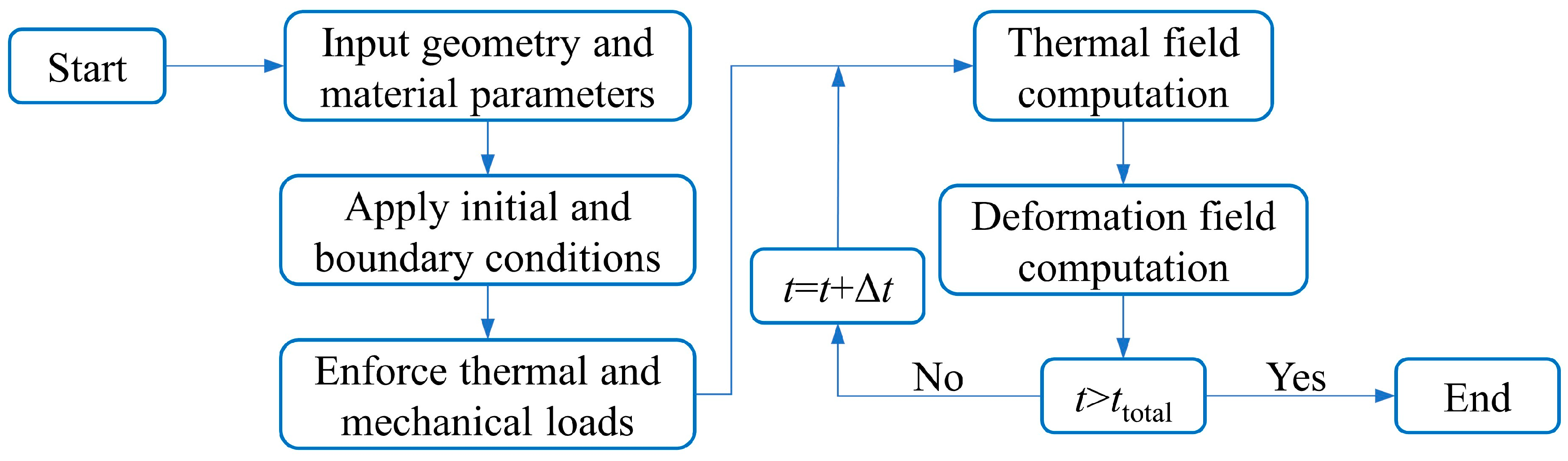

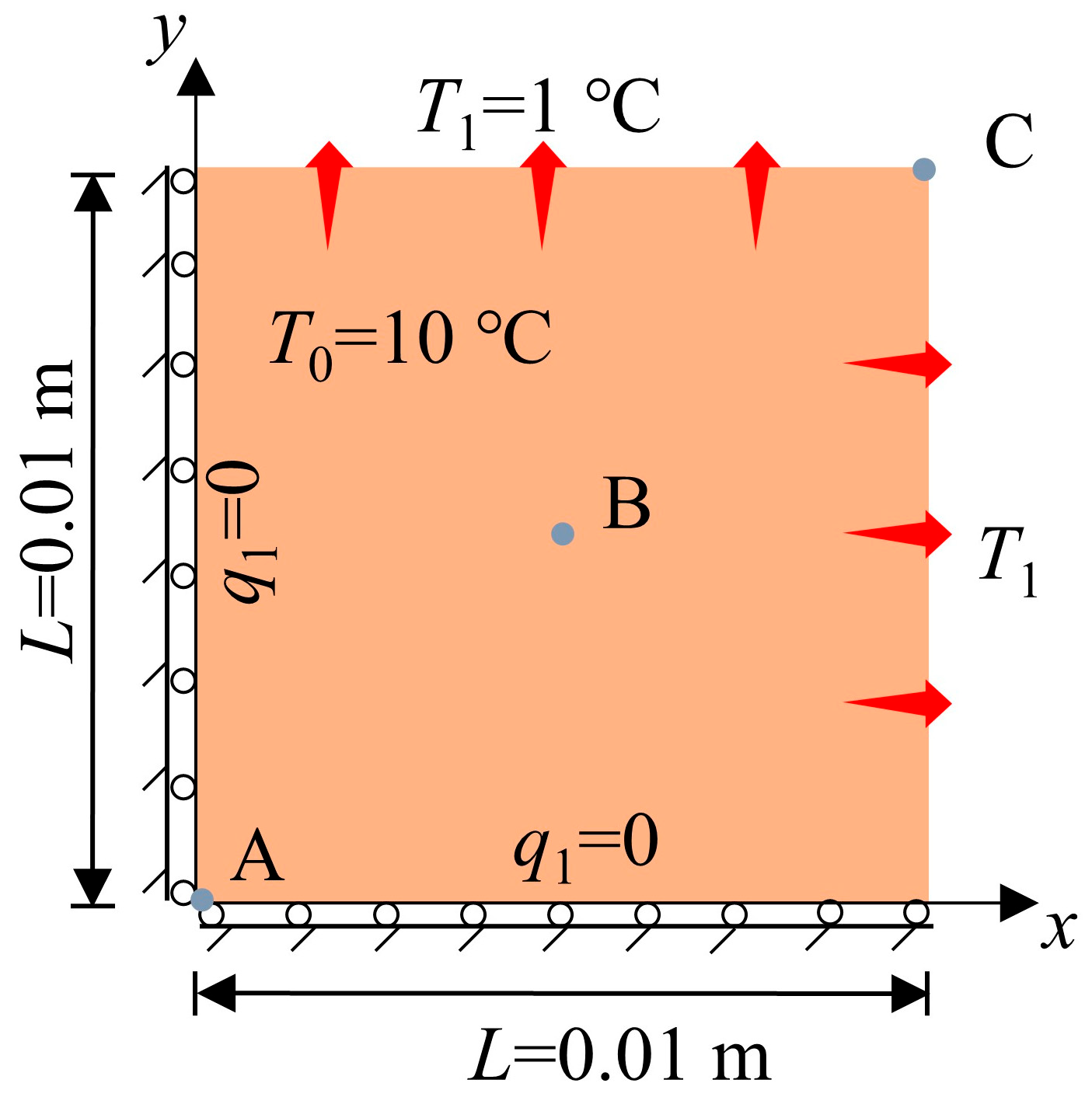

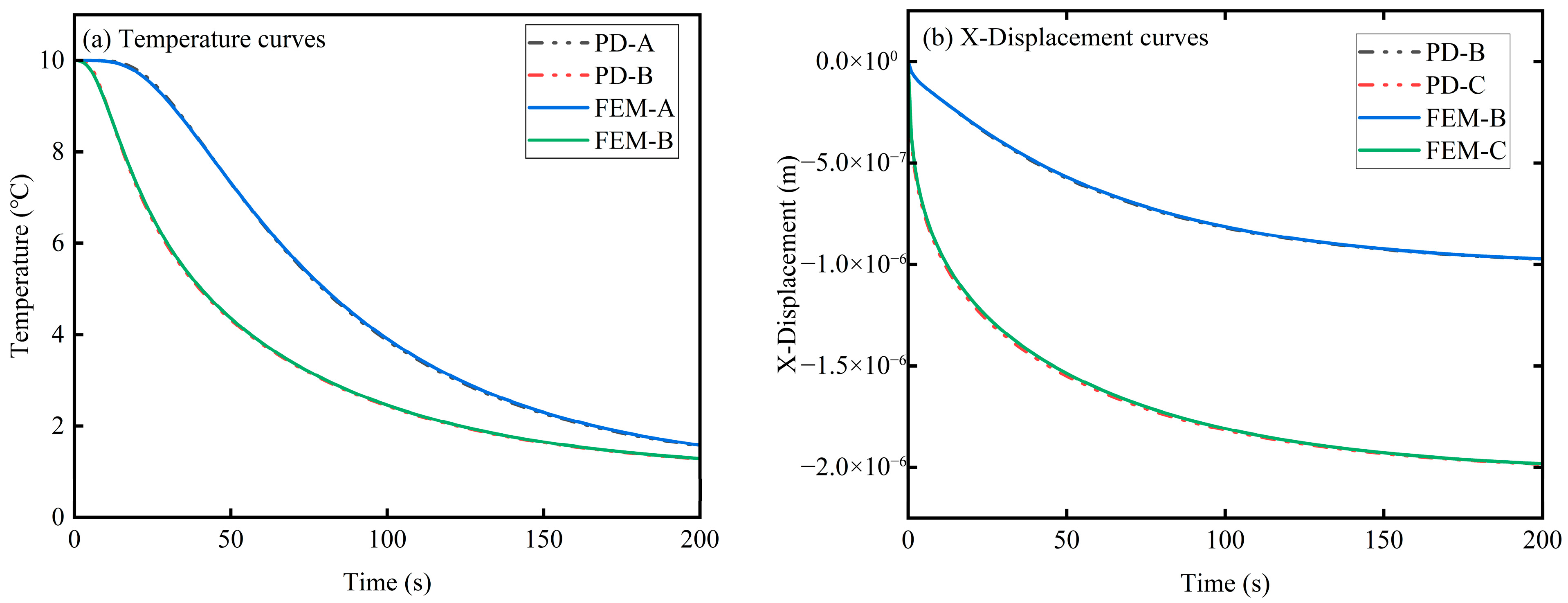

Section 2 presents a sequential thermomechanical coupling model based on PD.

Section 3 validates the accuracy of the proposed thermomechanical coupling model for damage and deformation response calculations using two typical examples.

Section 4 discusses the method of constructing a neural network model based on PD simulation data and establishes an efficient neural network model for fast prediction in thermomechanical coupling analysis.

4. Construction and Validation of the Deep Learning Model

As the complexity of thermodynamic problems increases, traditional computational methods face limitations, including high computational costs and complex solution processes, when handling dynamic loads and large-scale problems. To overcome these challenges, this section discusses the method of constructing a deep neural network (DNN) based on PD simulation data. By generating large amounts of simulation data through extensive computations and training a DL model on these data, a DNN is developed for fast prediction in thermomechanical coupling analysis.

4.1. Problem Description

The structural integrity of the RPV is a critical issue in the operation and life extension of nuclear power plants. In particular, verifying the RPV’s structural integrity under pressurized thermal shock conditions is crucial for ensuring the safe operation of the plant. In this context, the development of rapid analysis methods is essential for improving the efficiency of safety assessments, aiding in operational decision-making, and reducing the significant time and economic costs associated with more detailed analyses.

The plane strain model effectively simplifies the problem and significantly improves the computational efficiency. Taking the cylindrical section of a pressure vessel as an example, the model can be simplified as a 2D ring model. This section focuses on a 2D ring model, applying stable temperature boundary conditions, temperature boundary conditions with varying temperature, and pressure boundary conditions to analyze its thermomechanical coupling deformation behavior.

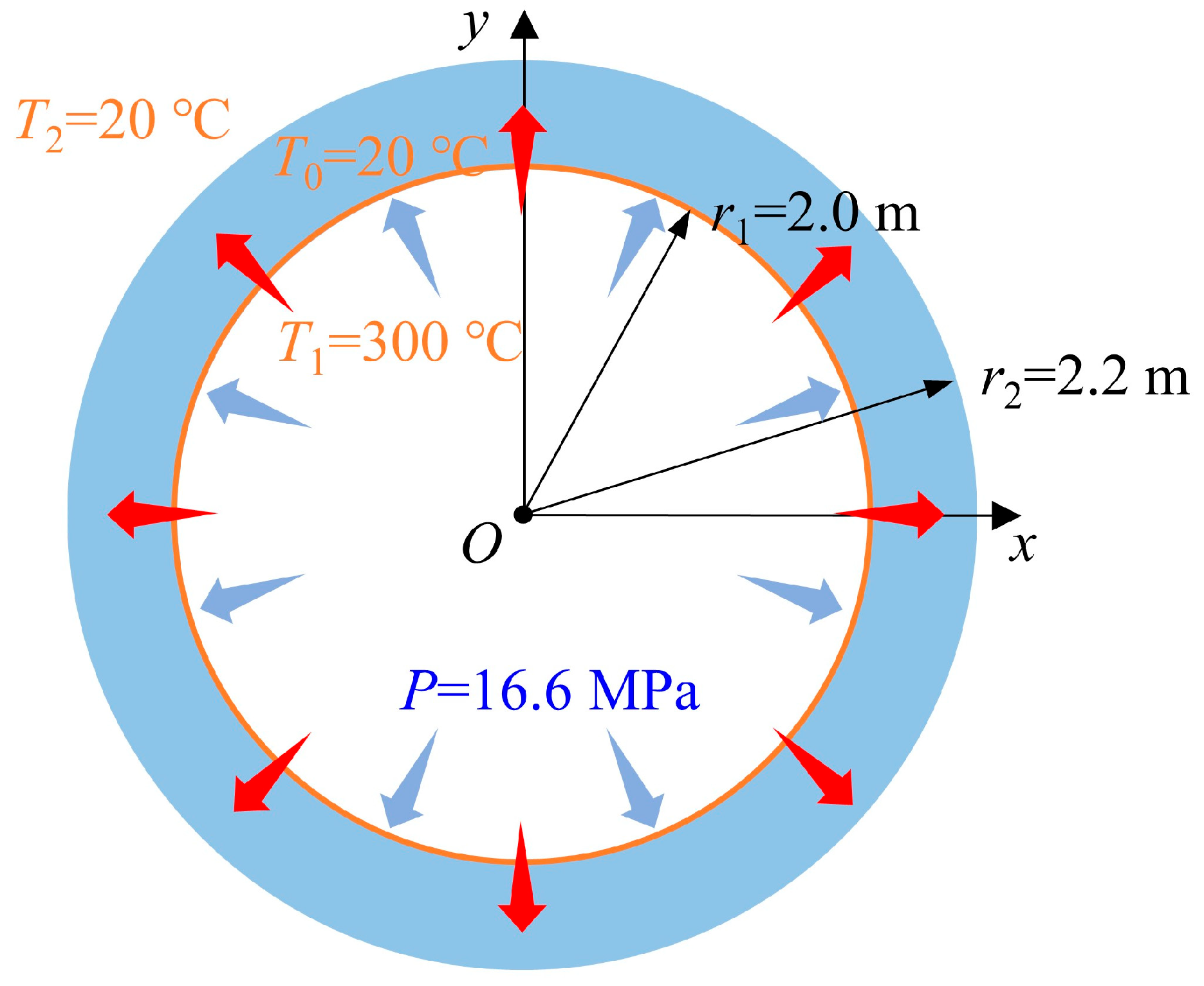

The geometric model of the 2D ring is shown in

Figure 8, with an inner radius of 2.0 m and an outer radius of 2.2 m. In the PD model, the 2D ring was discretized into material points with the same radial length but varying widths. The material points were spaced radially at Δ

x = 6.25 × 10

−3 m (with 32 layers of material points in the radial direction), and the PD range was

δ = 3.015Δ

x. A temperature boundary condition of 320 °C was applied to the inner wall, and 20 °C was applied to the outer wall. The internal pressure was 16.6 MPa, with an initial temperature of 20 °C. A pressure boundary condition of 16.6 MPa was applied to the inner wall. The thermodynamic parameters of the 2D ring material are as follows: elastic modulus

E = 191 GPa, Poisson’s ratio

ν = 0.25, density

ρ = 7769 kg/m

3, specific heat

cv = 565.32 J/(kg·°C), thermal conductivity

kT = 39.246 J/(s·m·°C), and thermal expansion coefficient

α = 1.34 × 10

−5/°C.

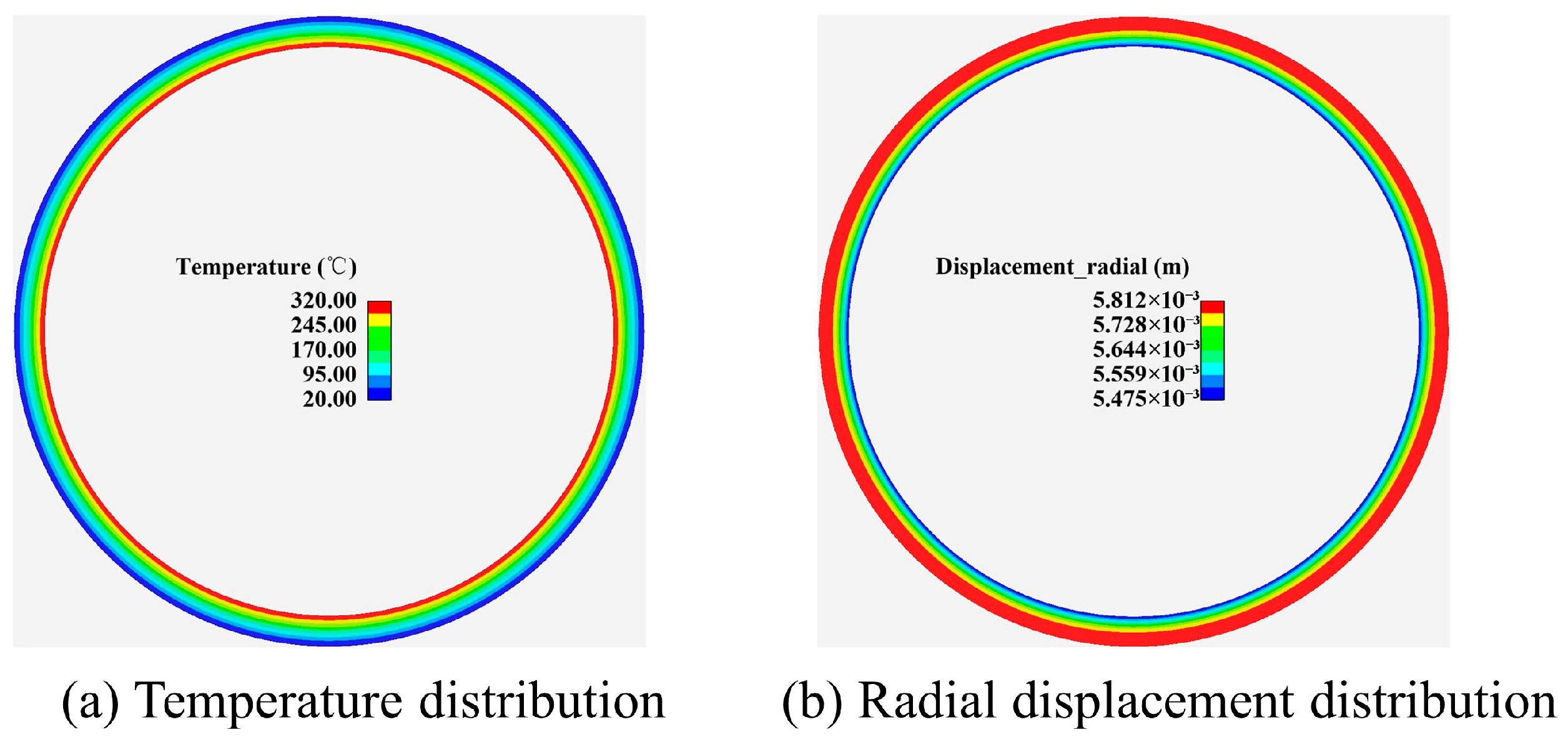

Figure 9 shows the temperature and radial displacement distributions of the 2D ring in the steady state. As shown in the figure, when the inner wall of the 2D ring is subjected to internal pressure and heating loads, both the temperature and radial displacement distributions exhibit a layered pattern. The temperature of the 2D ring decreases gradually from the inner wall to the outer wall, whereas the radial displacement increases from the inner wall to the outer wall. Under thermomechanical coupling loads, the inner wall experiences significant deformation due to thermal expansion and internal pressure. However, its proximity to the center and the strong geometric constraints cause the material points in the inner circle to be surrounded by more material, which greatly limits the deformation. The outer wall, being relatively “free”, responds more easily to the accumulated thermal expansion driving force from the interior. As heat is conducted from the inner wall to the outer wall, the entire structure undergoes gradient expansion. During this process, owing to material continuity, deformation in the inner layers is transferred to the outer layers; therefore, even when the inner layers experience higher stress, their displacement is overcome by the outer layers. Under the influence of the plane strain assumption and the symmetric geometric structure of the 2D ring, both the axial and circumferential displacements are zero, and the deformation of the 2D ring occurs along the radial direction.

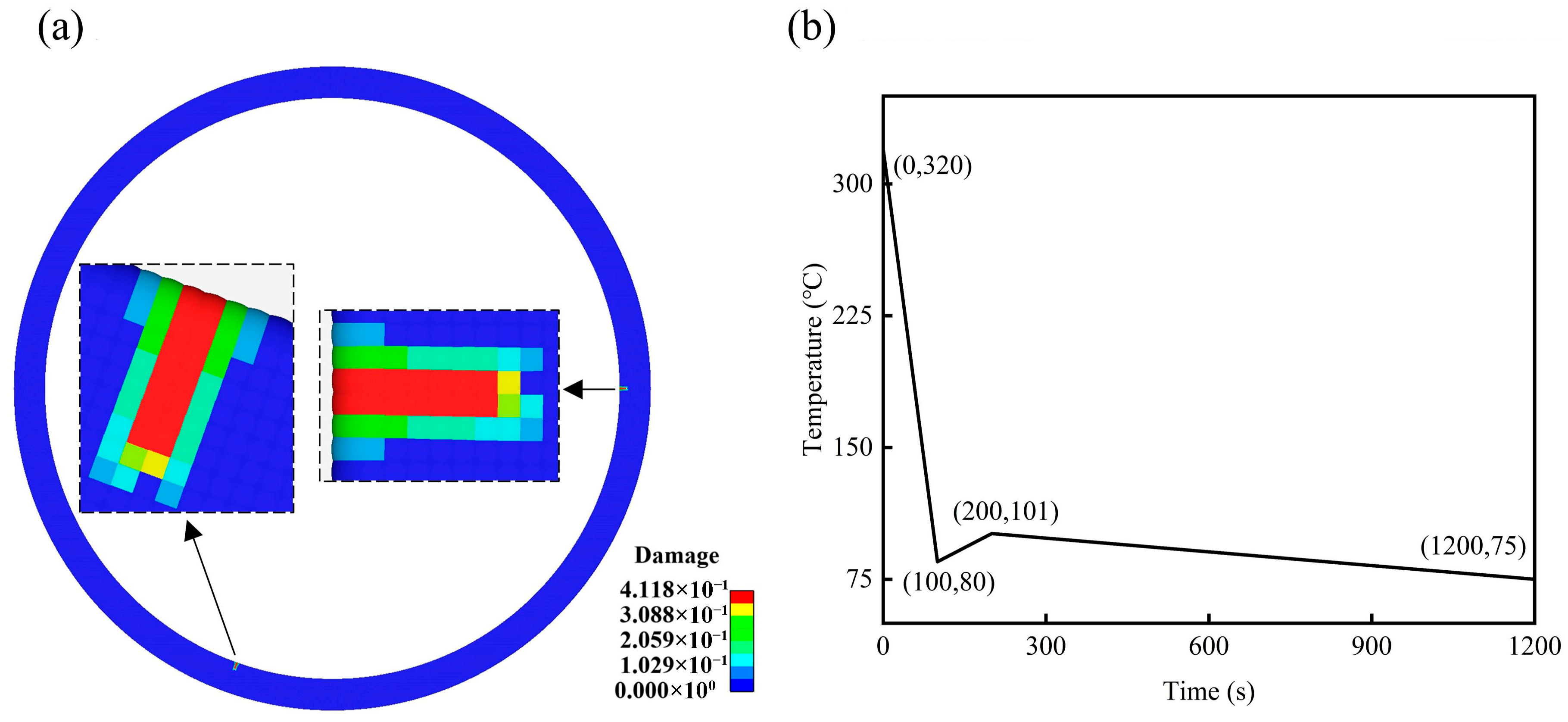

Under long-term thermomechanical loading, cracks can form on the surface of the cylindrical section of the pressure vessel. The initiation and propagation of these cracks affect the safety of the vessel. To simulate the deformation response of a pressure vessel under varying temperature loads after crack formation during service, two randomly generated cracks are introduced into the 2D ring geometry, as shown in

Figure 10a, and the calculation formula for damage is given by Equation (6). The lengths of the two cracks are both 0.04375 m, with an angle of 141.25°. The temperature field distribution and deformation field distribution of the 2D ring in steady state from

Figure 9 are selected, upon which varying temperature conditions [

37] and an internal wall pressure of 16.6 MPa, as shown in

Figure 10b, are applied.

After introducing cracks into the steady-state 2D ring shown in

Figure 9, some bonds between the material points in the PD model break. Although the mechanical response of individual bonds remains unchanged, the disruption of local interactions reduces the number of effective bonds, disturbing the original equilibrium state. The introduction of cracks causes the structure to transition from a stable state to a non-equilibrium state. Therefore, before applying varying temperature conditions to the cracked 2D ring (at

t = 0 s in

Figure 10b), further calculations are performed to obtain the stable state of the cracked 2D ring.

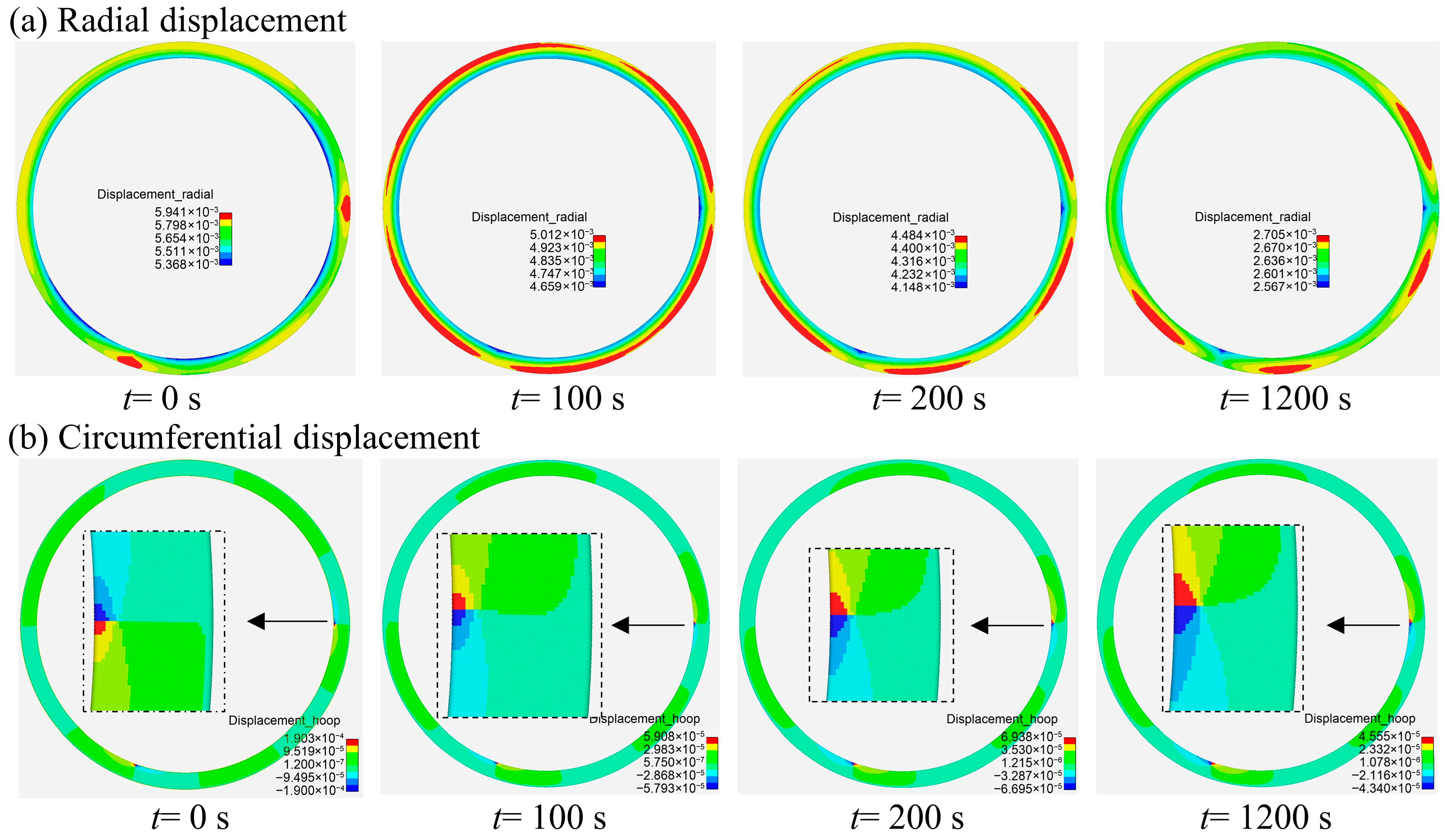

Figure 11a shows that the radial displacement of the ring gradually decreases over time. At the initial state (

t = 0 s), the radial displacement is concentrated at the crack tips. However, as the varying temperature condition progresses, the displacement at the crack tips decreases, while larger radial displacements appear in the surrounding region. After the introduction of cracks, some material points near the cracks experience bond breakage, leading to a redistribution of circumferential stress and resulting in a noticeable circumferential displacement in the surrounding region. As shown in

Figure 11b, the circumferential displacement distribution near the crack tip indicates that the inner wall transitions from a compressive to a tensile state. This is because during the cooling process, the inner wall experiences a rapid temperature drop and thermal contraction, resulting in tensile stress.

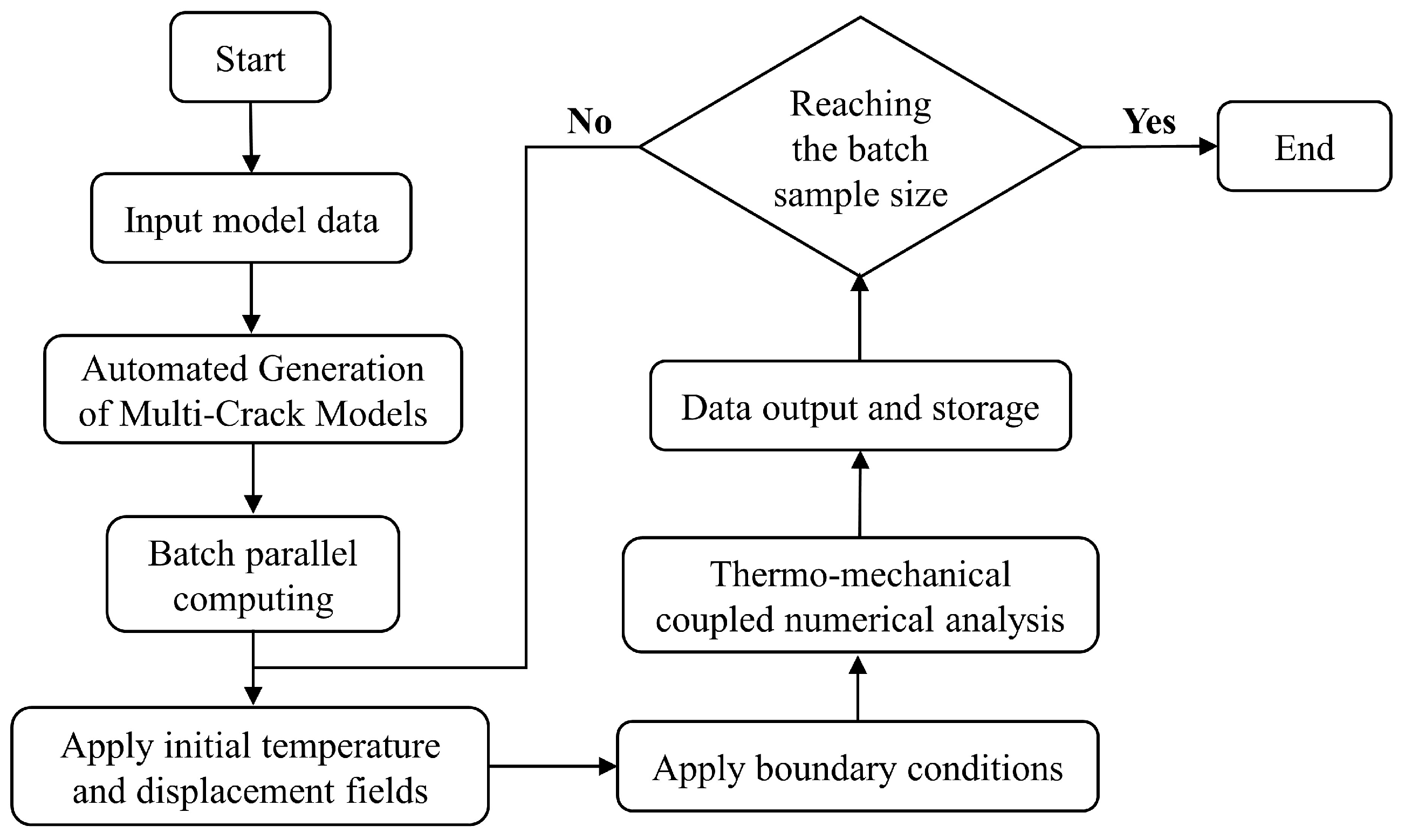

4.2. Large-Scale Computation

Large-scale numerical calculations were performed on a multiple-cracked 2D ring under varying temperature conditions to generate the necessary database for constructing a data-driven offline prediction model based on a DNN. To achieve this, a large-scale, high-throughput, concurrent numerical method was employed for damage and fracture analysis. Efficient parallel computing techniques were combined to simulate the deformation response of a multi-cracked 2D ring under varying temperature conditions. The high-throughput numerical analysis process is shown in

Figure 12.

First, the temperature and deformation field distributions of the crack-free 2D ring in the steady state under the initial loading conditions were simulated, as shown in

Figure 9. The number of material points, point IDs, temperature values, displacements, coordinates, damage index, bond force densities, and other properties of each bond in the steady-state 2D ring are stored as the initial conditions for subsequent calculations.

Next, to study the temperature and displacement distributions within the pressure vessel after a crack suddenly forms on the inner wall due to thermomechanical loading, a geometrical model of a multi-cracked 2D ring with different crack distributions was randomly generated for nearly 1000 sets using the code. Among them, there were two radial cracks in the ring; their lengths were less than or equal to one-quarter of the ring thickness (5 cm), with one crack fixed in position, ensuring that the angle between the two cracks was less than π. Nearly 1000 sets of geometrical models were divided into several groups and computed using different computational resources. At the start of the computation, the physical quantities of the steady-state 2D ring stored previously are used as the initial conditions. The temperature field, deformation field, and damage state distribution at the initial time (t = 0 s) under varying temperature conditions are then computed, without changing the steady-state temperature and pressure boundary conditions.

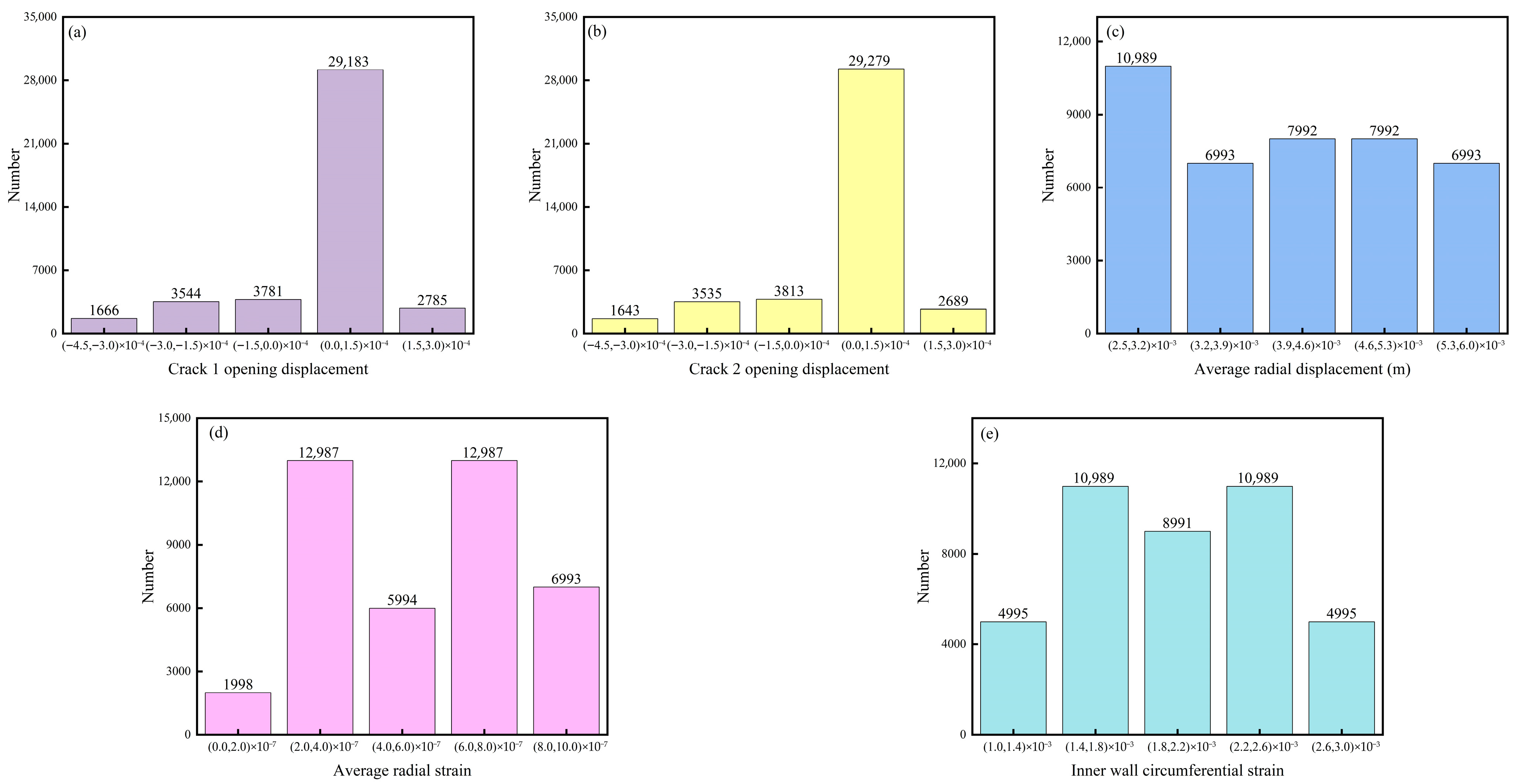

Finally, varying temperature boundary conditions, as shown in

Figure 10b, are initially applied to the multi-cracked 2D ring under varying temperature conditions. The computations for nearly 1000 sets of multi-cracked 2D rings under varying temperature conditions result in a total of 40,959 datasets. The output variables include the inner wall temperature, inner wall pressure, crack 1 length, crack 2 length, angular difference between the cracks, crack tip opening displacement, average radial displacement, average radial strain, and inner wall circumference change rate of the 2D ring at different times under varying temperature conditions, providing reliable data for subsequent large-scale data analysis and model training. The crack tip opening displacement of the two cracks is calculated by the difference in the circumferential displacement between the material points at both ends of the radial crack on the inner wall of the 2D ring. The average radial displacement is the mean radial displacement of all material points in the 2D ring. The average radial strain is the mean radial strain at various locations on the ring. The rate of change in the inner wall circumference is calculated by dividing the change in the inner wall circumference after the deformation by the original inner wall circumference. The distribution of the output variables from the large-scale computations across different value ranges is shown in

Figure 13.

4.3. Deep Learning Model Construction and Network Training

To approximate the nonlinear relationship between input parameters and mechanical responses under thermomechanical coupling, a DNN was constructed. The input for this problem is a six-dimensional vector consisting of the lengths of the first crack L1, the second crack L2, the angle between the two cracks θ, the inner wall temperature T, the time under varying temperature conditions t, and the inner wall pressure P. The outputs are the crack tip opening displacement D1 for crack 1, the crack tip opening displacement D2 for crack 2, the average radial displacement Dr of the 2D ring, the average radial strain Ds, and the change rate of the inner wall circumference C.

The DNN is trained using the large-scale PD simulation results presented in

Section 4.2 as ground truth data, enabling it to serve as an efficient surrogate model for rapid mechanical response prediction. Considering the significant differences in the magnitude of the input and output variables, such as the fact that the average radial displacement and the average radial strain differ by up to four orders of magnitude, all input data are non-dimensionalized as shown in Equation (13) and all output data are normalized as shown in Equation (14).

Here, represents the non-dimensionalized data, represents the normalized data, max(x) is the maximum value, and min(x) is the minimum value.

The network is trained by minimizing the mean squared error between predicted and true values, defined as

where

n is the number of samples,

represents the predicted values from the neural network,

yi represents the true values, and

is the mean of the true values. To evaluate the predictive accuracy of the model, the coefficient of determination (

R2) is employed:

The model training cost is measured in terms of wall-clock time.

To determine an appropriate network structure, a series of comparative experiments are carried out by varying the number of neurons per hidden layer, while keeping the number of hidden layers fixed at two. As summarized in

Table 2, the training time remains nearly constant (between 28 and 29 min), whereas the prediction accuracy initially increases and then declines as the number of neurons increases. The highest goodness of fit on the test set (

R2 = 0.987) is achieved when each hidden layer contained nine neurons. This indicates that insufficient neurons limit the model’s learning capacity, while excessive neurons introduce overfitting and impair generalization. Therefore, a neuron count of nine per layer is selected as the optimal choice.

Further experiments are conducted by fixing the number of neurons per layer at nine and varying the number of hidden layers. As shown in

Table 3, using two hidden layers achieves the best goodness-of-fit. This confirms that increasing the depth of the network beyond two layers does not lead to better generalization, but rather increases computational cost and potential overfitting. Thus, the final DNN architecture is determined to consist of two hidden layers, each containing nine neurons.

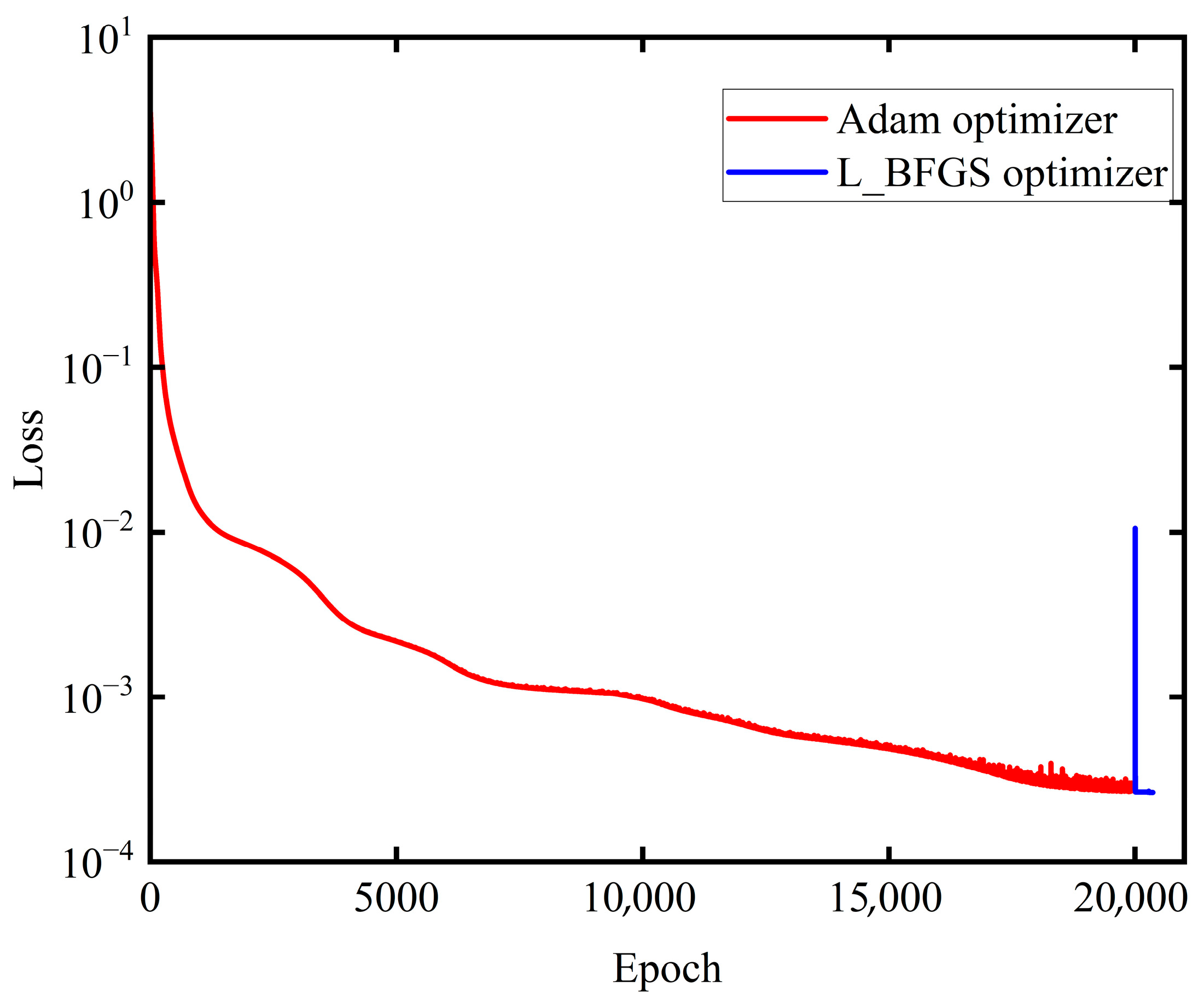

For the selected structure, the training process consists of two stages. Initially, the Adam optimizer is used for 20,000 iterations to achieve preliminary convergence. Subsequently, the L-BFGS optimizer is applied for an additional 300 iterations to further refine the model and reduce residual loss. The convergence behavior of the loss function is depicted in

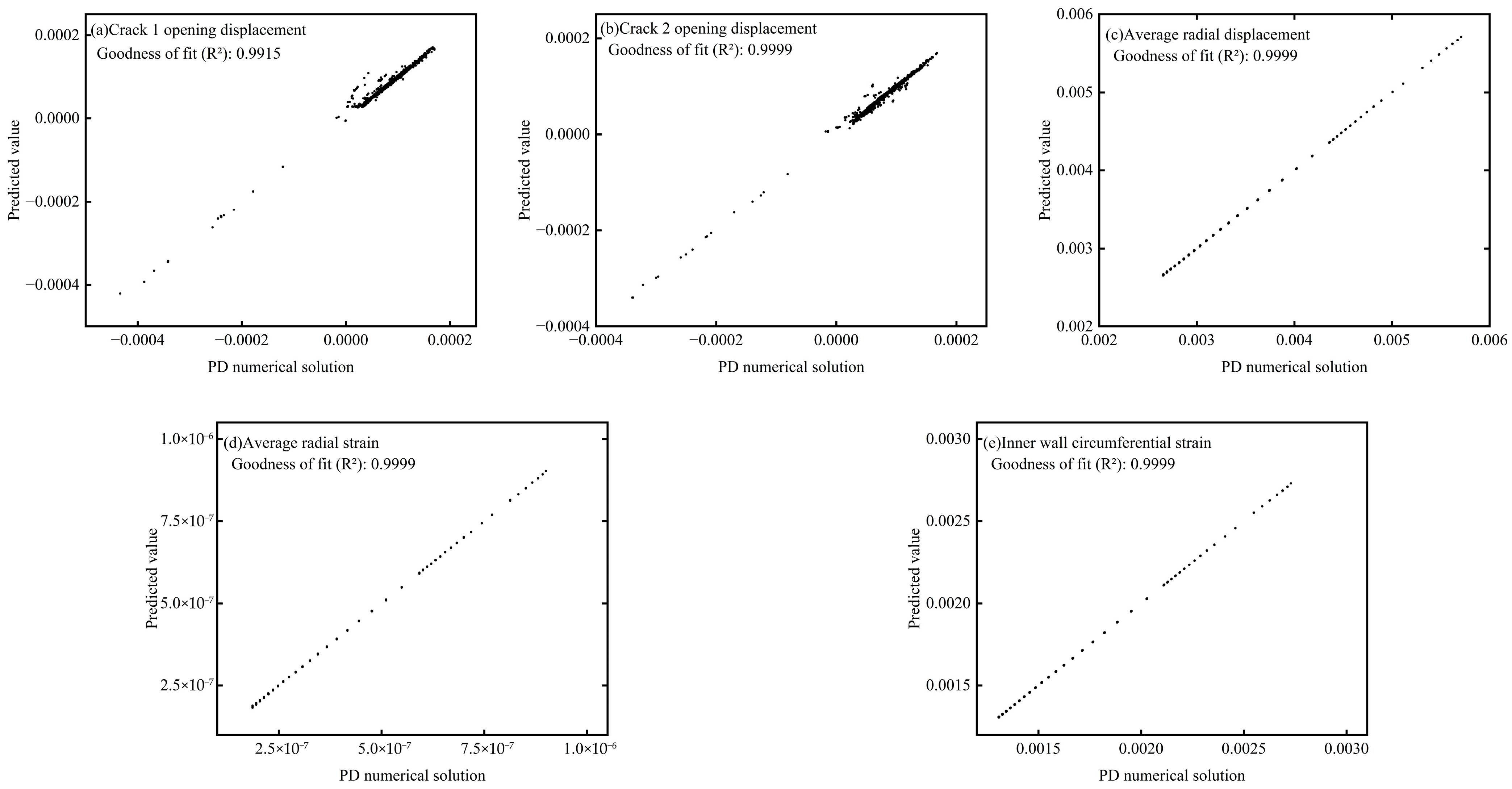

Figure 14. Finally, the trained model is evaluated on the test set. As shown in

Figure 15, the predicted mechanical responses closely match the PD reference solutions, with most outputs achieving

R2 > 0.99, confirming that the trained DNN exhibits excellent accuracy and generalization capability for multi-output mechanical prediction tasks.

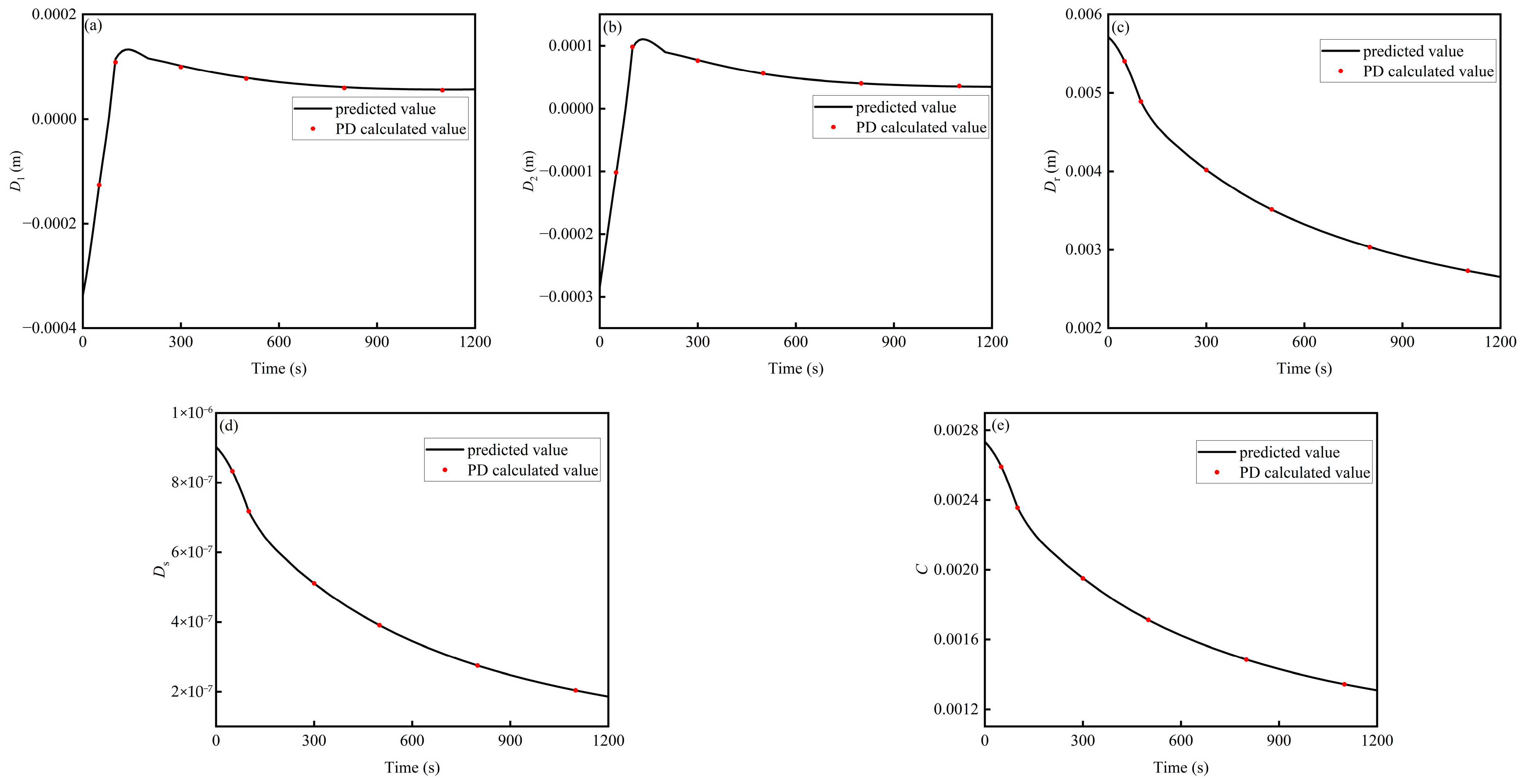

4.4. Thermomechanical Coupling Deformation Behavior Prediction

Two cracks are randomly generated in a two-dimensional circular ring, with the first crack having a length of

L1 = 0.0375 m and the second crack having a length of

L2 = 0.03125 m. The angle between the two cracks is

θ = 119.41°. The crack distribution, along with the temperature conditions under varying temperatures (as shown in

Figure 10b), including the corresponding time, temperature, and pressure, are input into the network trained in

Section 4.3. The network is capable of predicting the opening displacements of the two cracks (

D1 and

D2), the average radial displacement

Dr of the two-dimensional ring, the average radial strain

Ds, and the change rate of the inner wall circumference

C at different time instances. To further validate the efficiency and accuracy of the neural network predictions, the deformation characteristics of the two-dimensional ring during the temperature variation process under the given crack distribution are calculated using PD.

Figure 16a–e present the results of five output variables at different times, obtained from both the neural network predictions and the PD calculations. The results show good agreement between the two methods. However, it is noteworthy that the neural network prediction takes only approximately 0.5 s, while the PD calculation requires approximately 10 min. This demonstrates that the neural-network-based prediction method achieves a computational efficiency improvement of approximately 1200 times, highlighting its significant advantage in handling similar problems.

5. Conclusions

This study introduces an innovative approach for modeling thermomechanical failure in critical structures under extreme conditions by combining peridynamics (PD) with deep learning (DL). The proposed PD thermomechanical coupling model, utilizing the BBPD for structural deformation and the peridynamic differential operator for thermal diffusion, successfully captures the nonlocal interactions associated with crack propagation and thermal stresses. Through comprehensive validation, including simulations of a 2D plate under cooling and the quenching process of an Al2O3 ceramic, the model demonstrates excellent accuracy compared to the conventional FEM and experimental data. Furthermore, the integration of DL, specifically a deep neural network, trained on large datasets generated by PD simulations, offers a significant enhancement in computational efficiency, achieving prediction speeds approximately 1200 times faster than those of direct PD simulations without compromising accuracy.

The PD-DL framework provides a promising direction for real-time analysis and fault prediction in thermomechanical coupling problems, particularly in engineering applications involving critical structures, such as pressure vessels. Future research could focus on extending the framework to complex materials, like composites, and improving the DL surrogate model to handle larger datasets and enhance generalization. Additionally, integrating this framework with structural health monitoring systems could offer a comprehensive solution for real-time damage detection and predictive maintenance in critical infrastructure.