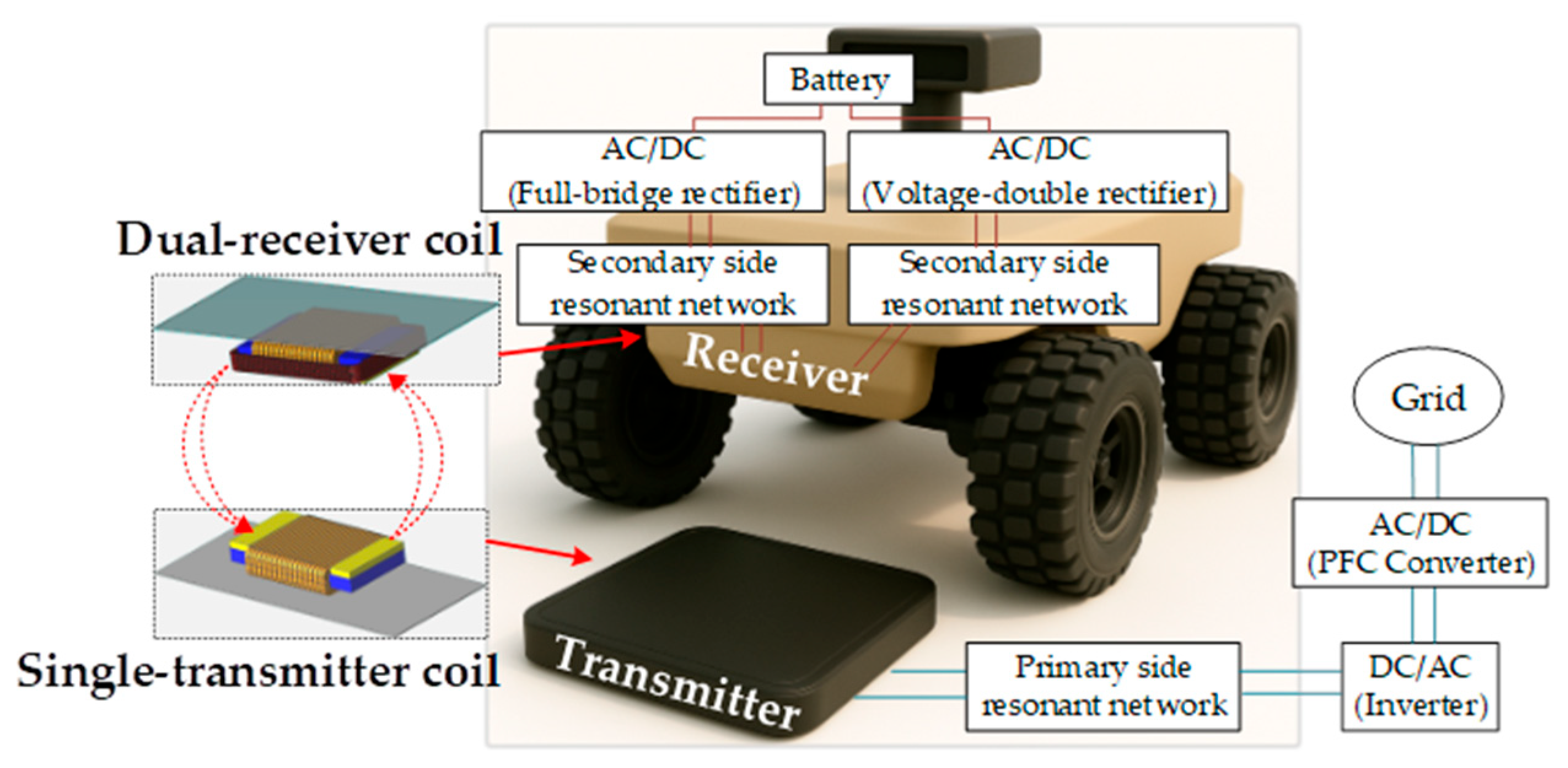

Design of a Compact IPT System for Medium Distance-to-Diameter Ratio AGV Applications with Enhanced Misalignment Tolerance

Abstract

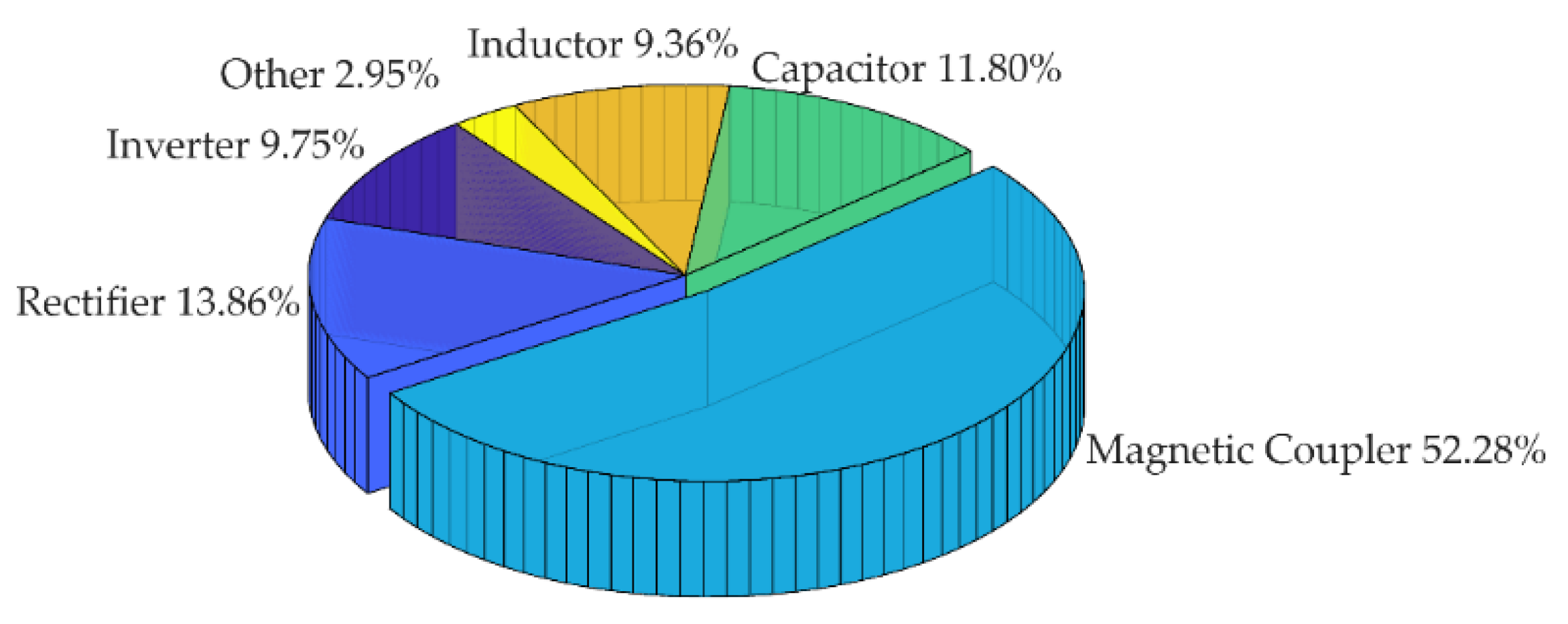

1. Introduction

- (1)

- A flat U-shaped solenoid (FUS) coil is designed through magnetic path optimization. Finite element method (FEM) analysis is adopted to enhance magnetic coupling and improve mutual inductance without increasing copper usage.

- (2)

- A proposed dual-receiver system combining FUS coils and a square solenoid (SS) structure, referred to as FUSS. This structure effectively captures vertical and horizontal magnetic fields to reduce flux variations during the misalignment case.

- (3)

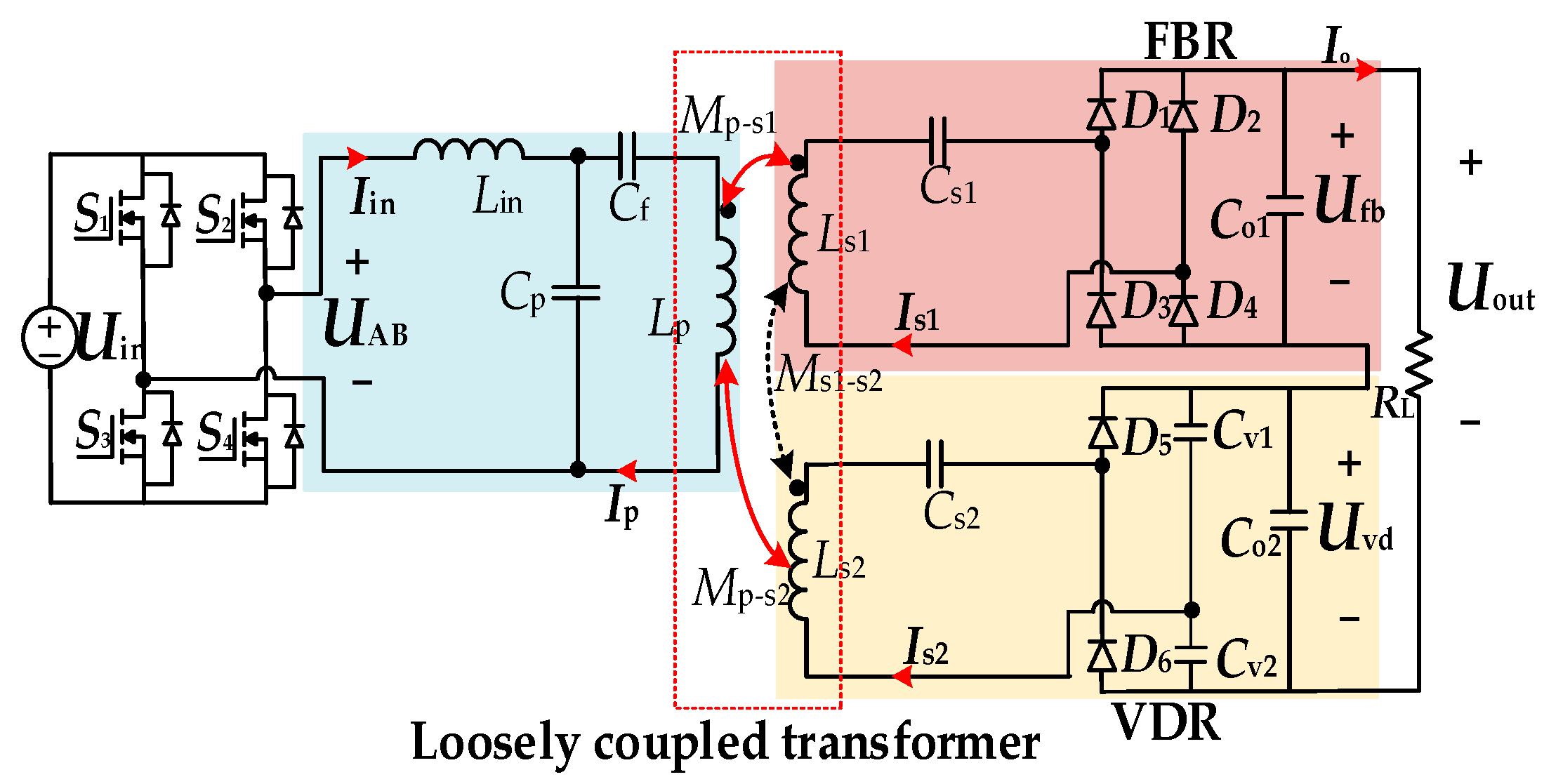

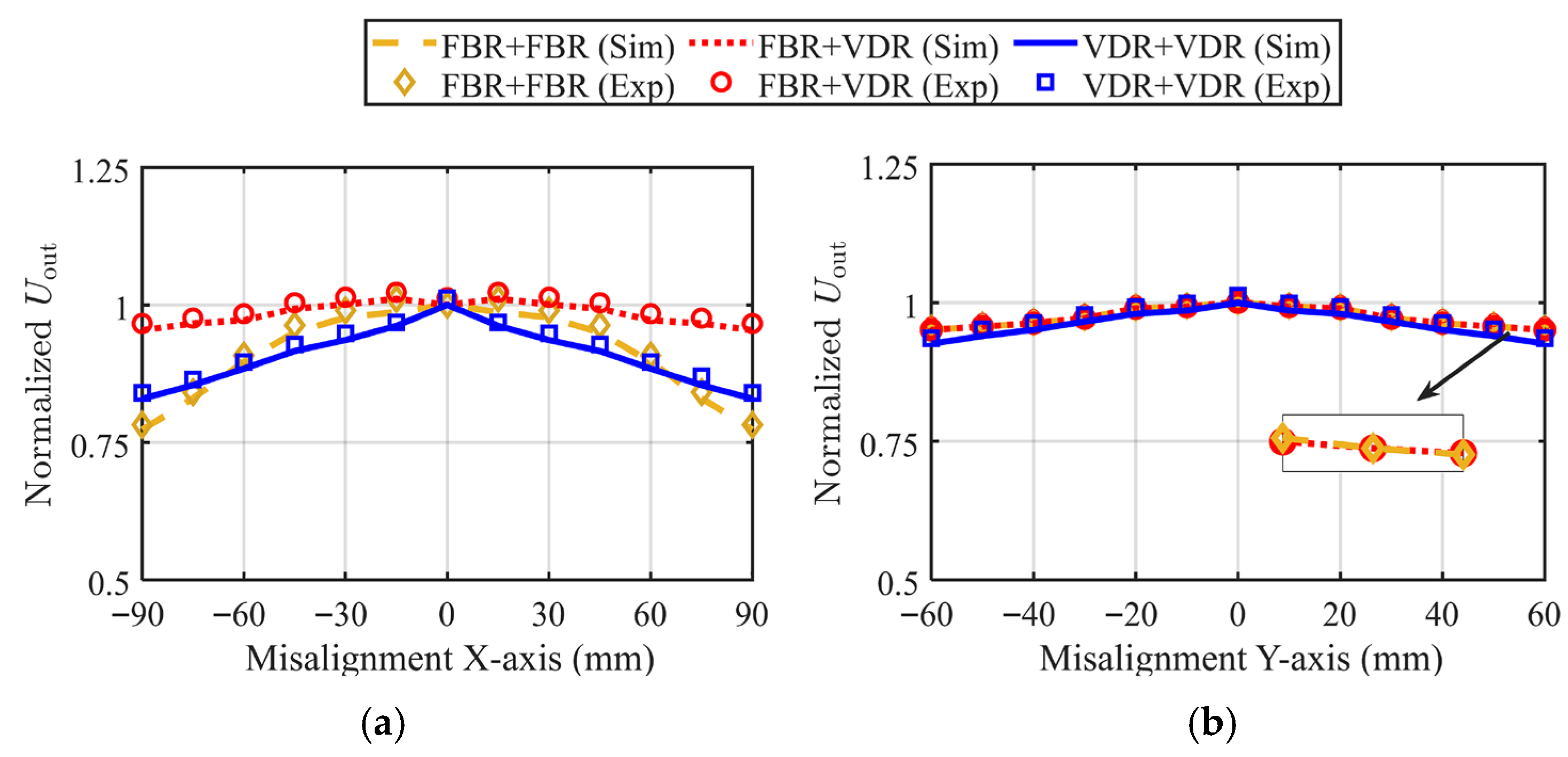

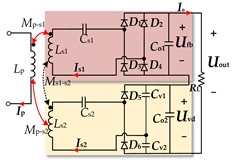

- A hybrid rectifier combining a full-bridge rectifier (FBR). and a voltage-doubler rectifier (VDR) suppresses output voltage fluctuations under misalignment while minimizing coil turns and system size.

- (4)

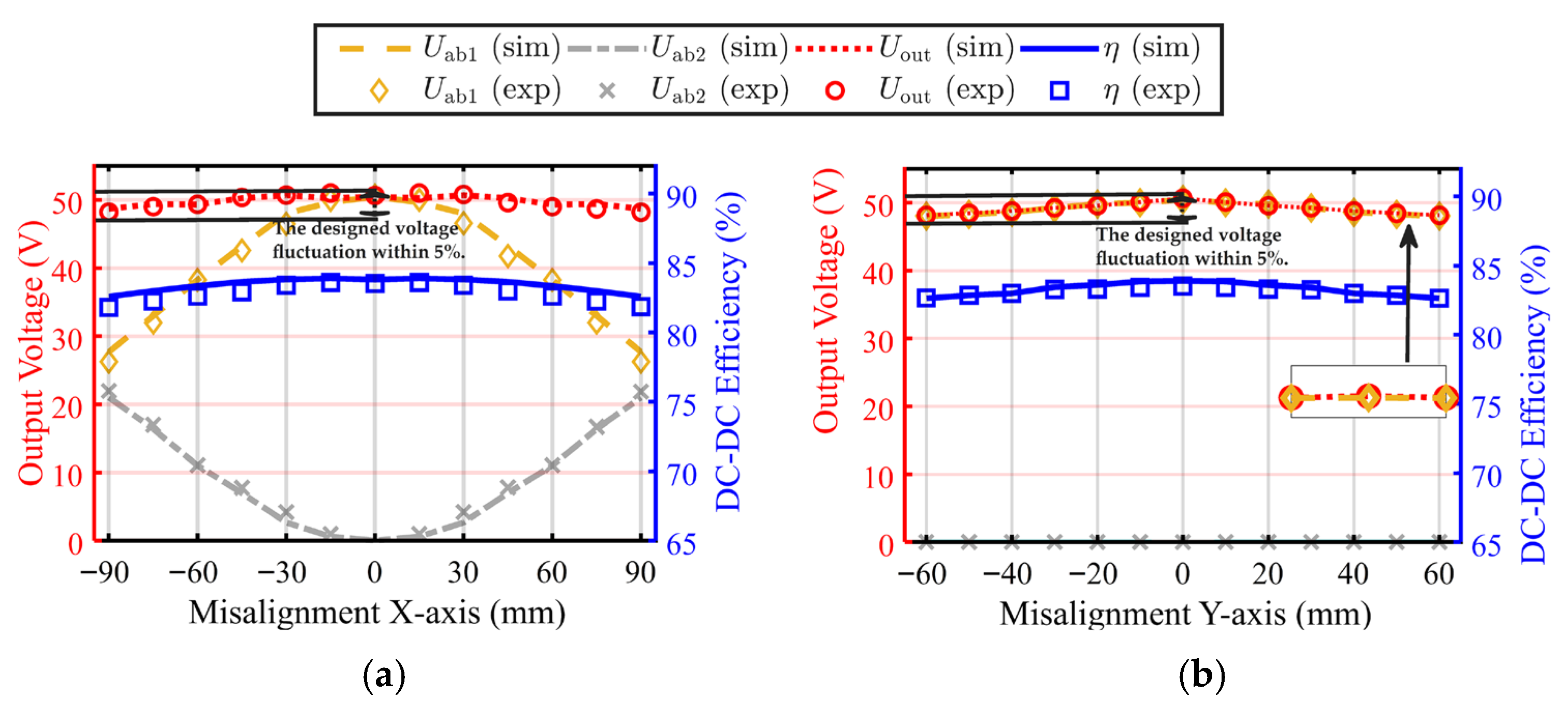

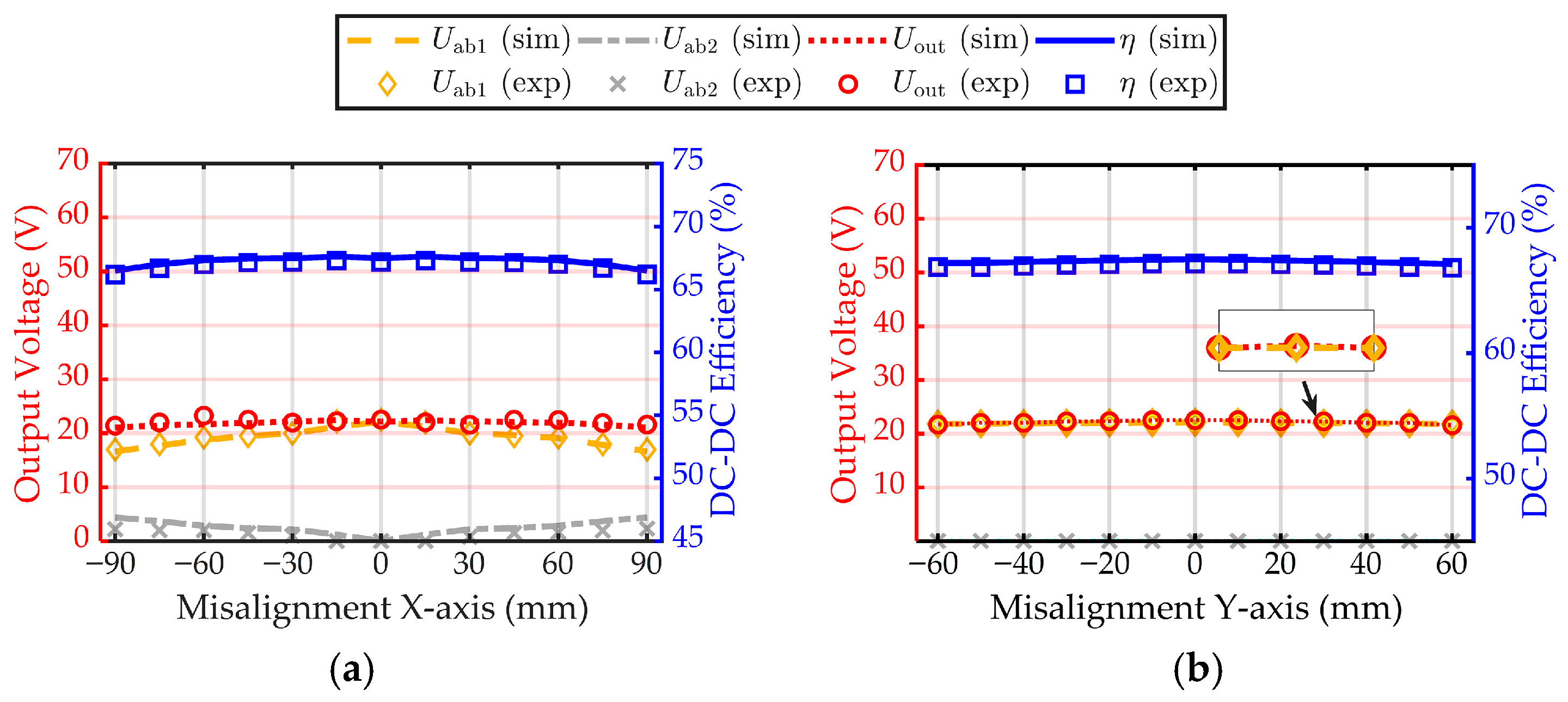

- Experimental results from a 300 W/100 kHz prototype demonstrate 83.51% transmission efficiency under medium DDR conditions. The system maintains voltage fluctuations within 5% under ±51.4% X-axis and ±51.7% Y-axis misalignment.

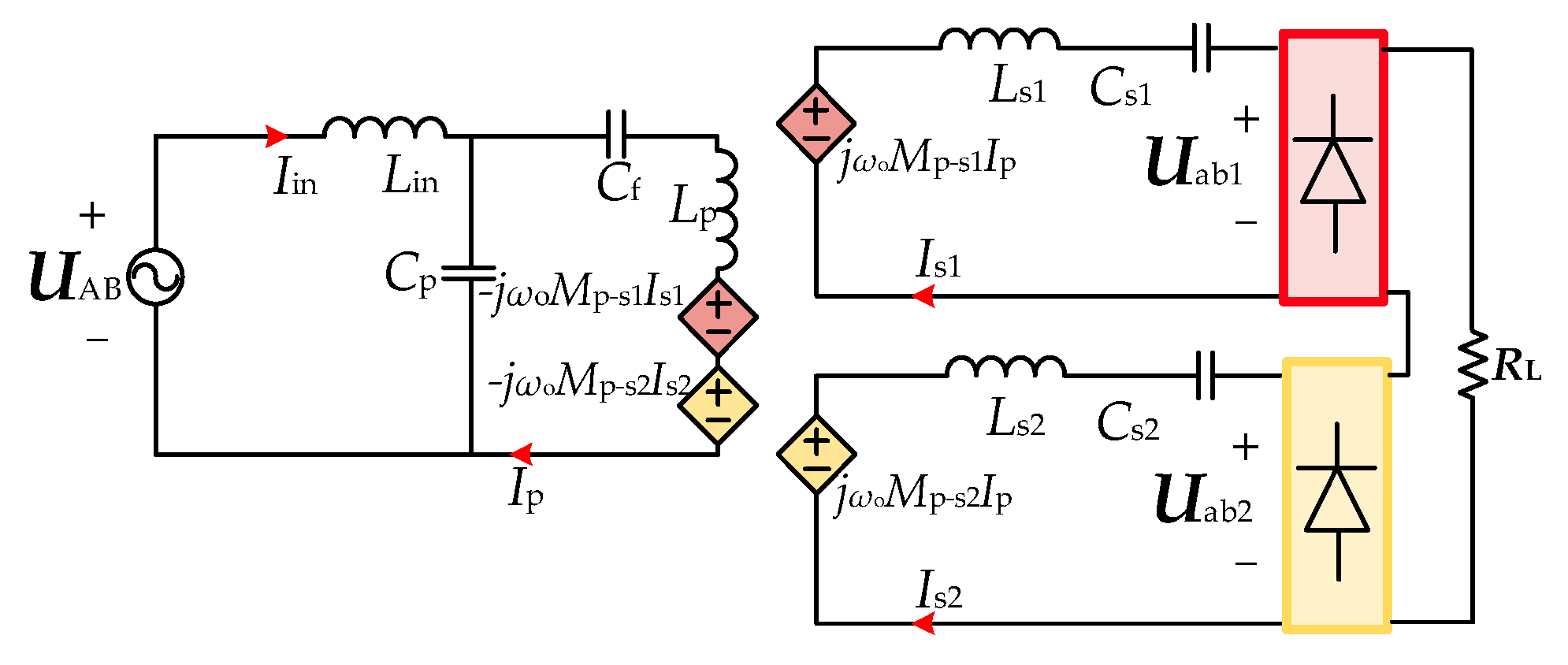

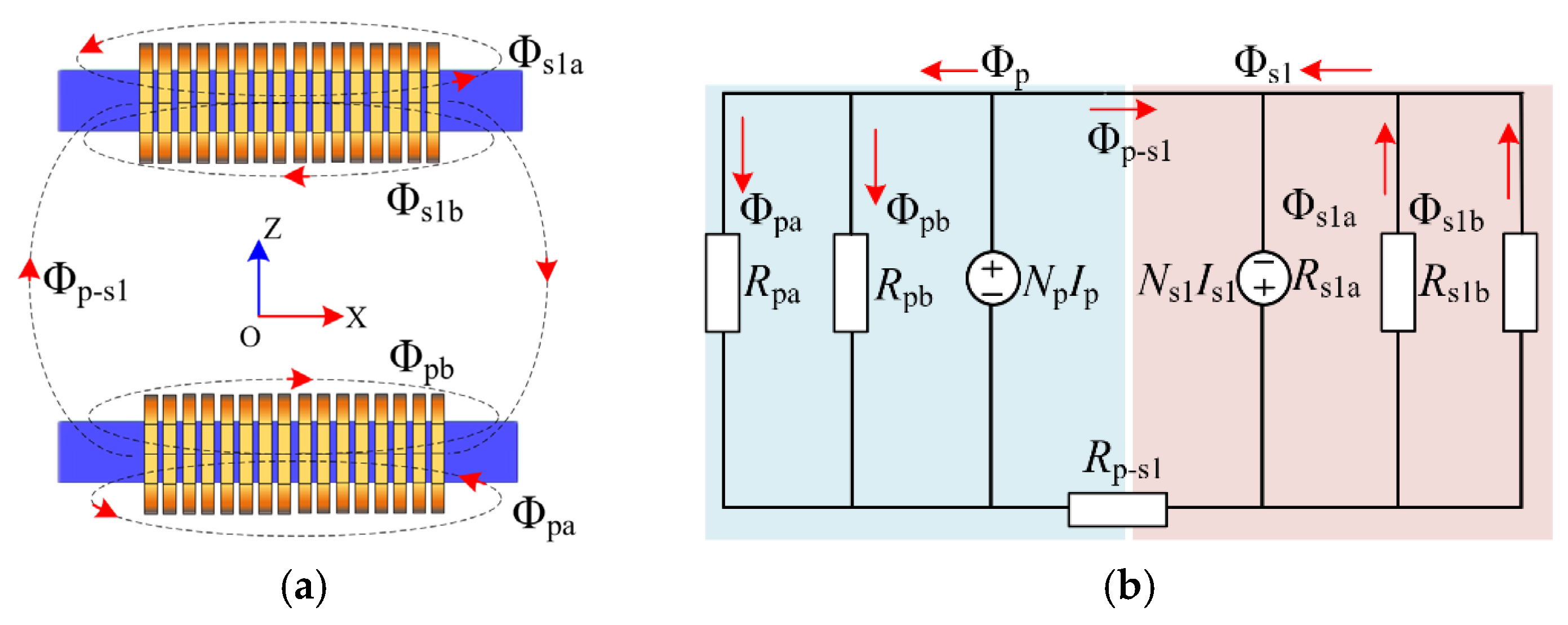

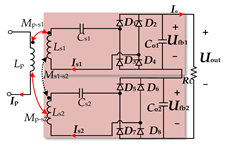

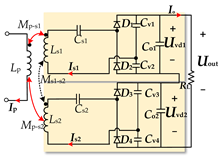

2. Theoretical Analysis for the Proposed Compensation Dual-Receiver IPT System

2.1. System Configuration

2.2. System Analysis

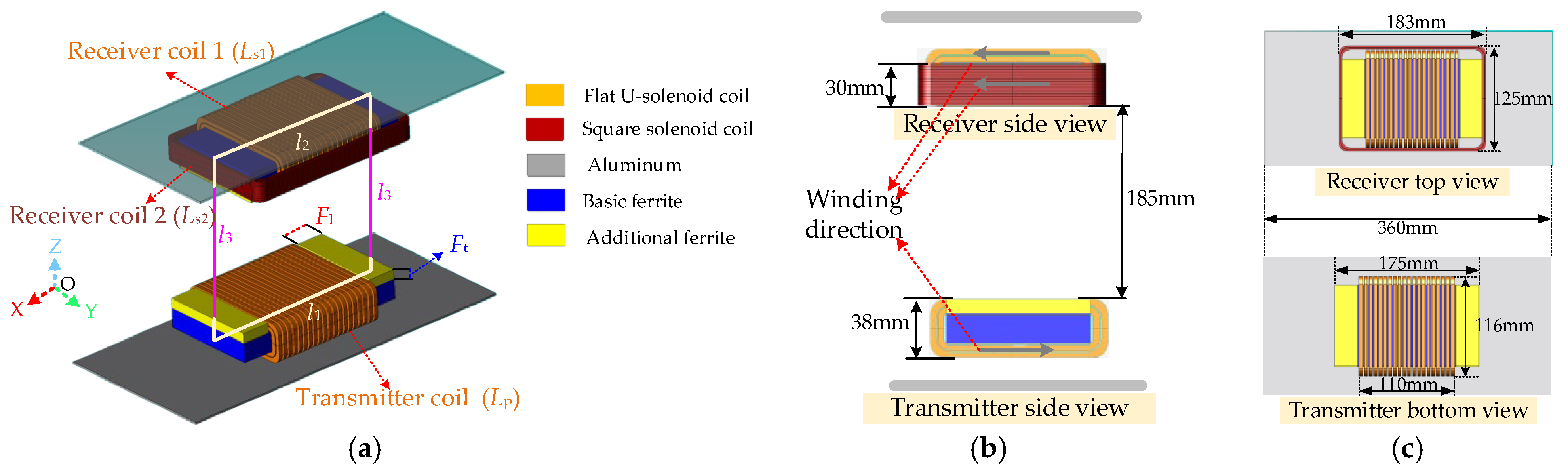

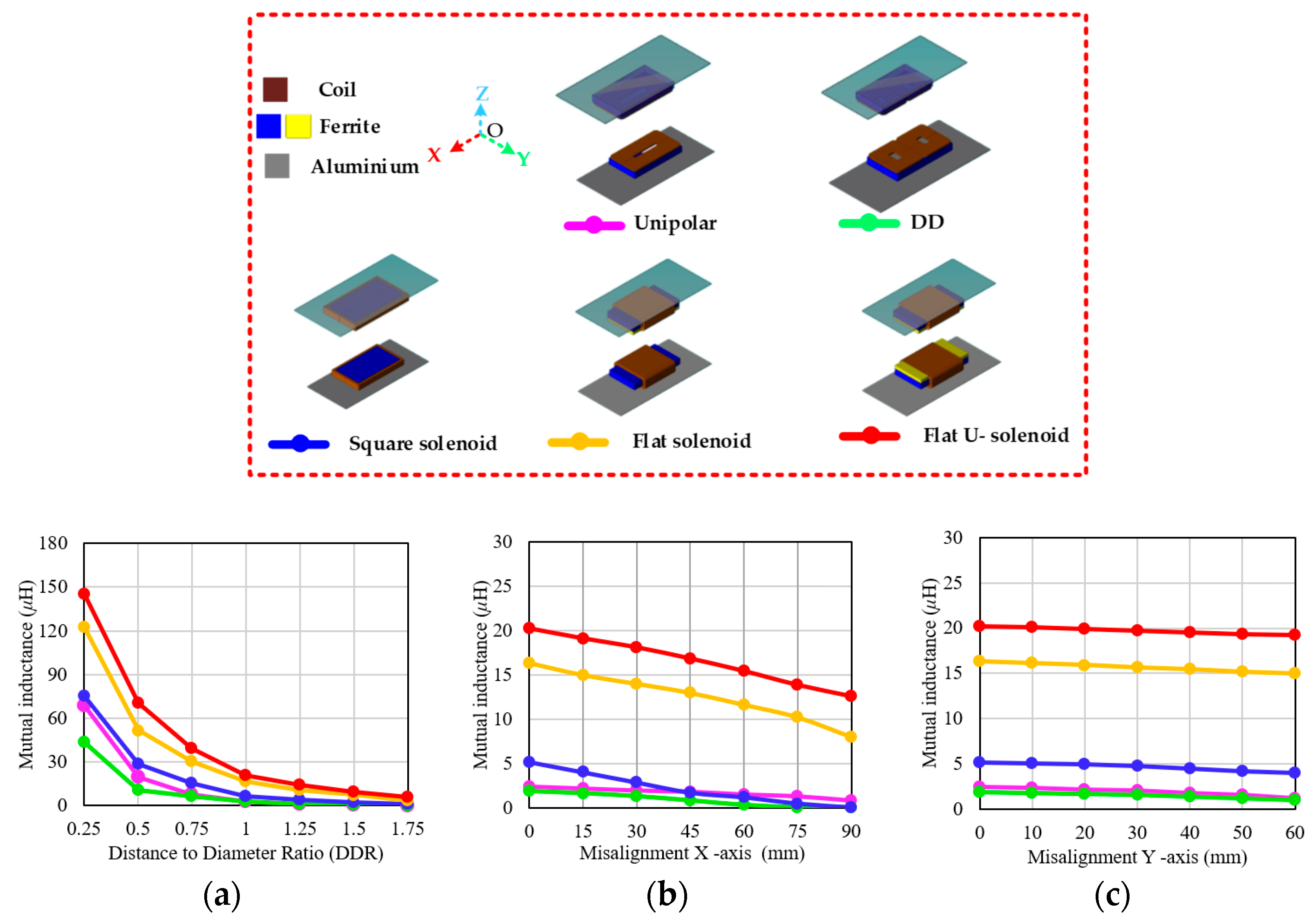

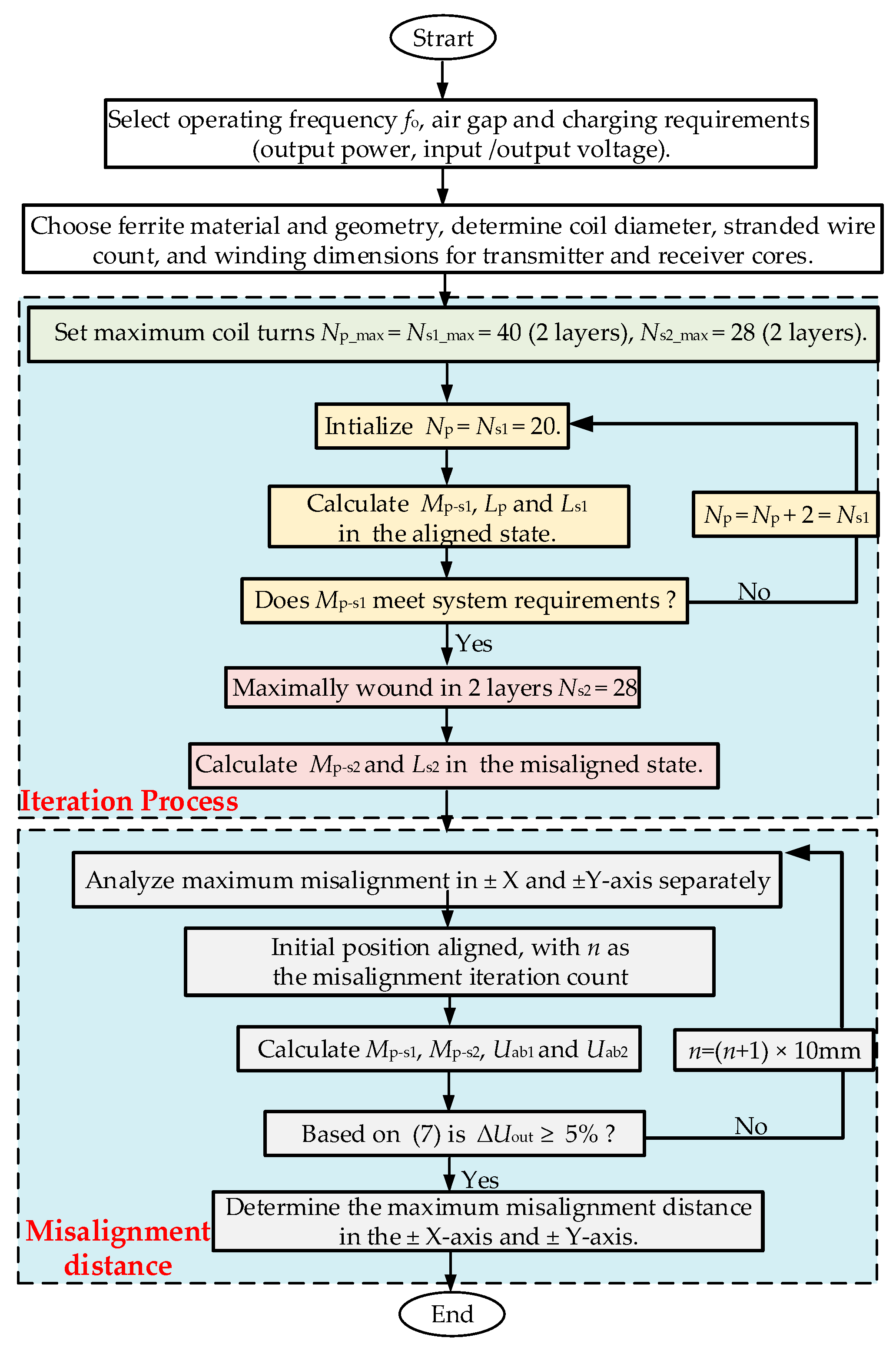

3. Design and Analysis of the Coupler for the Proposed Compensation Dual-Receiver IPT System

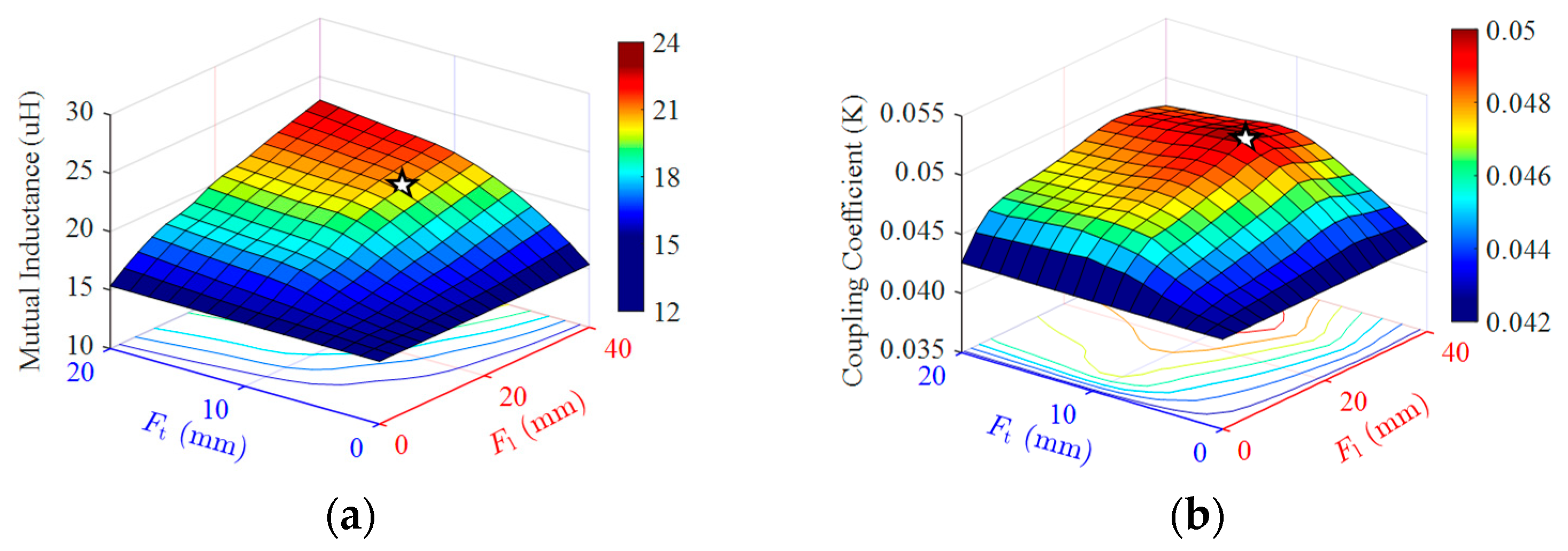

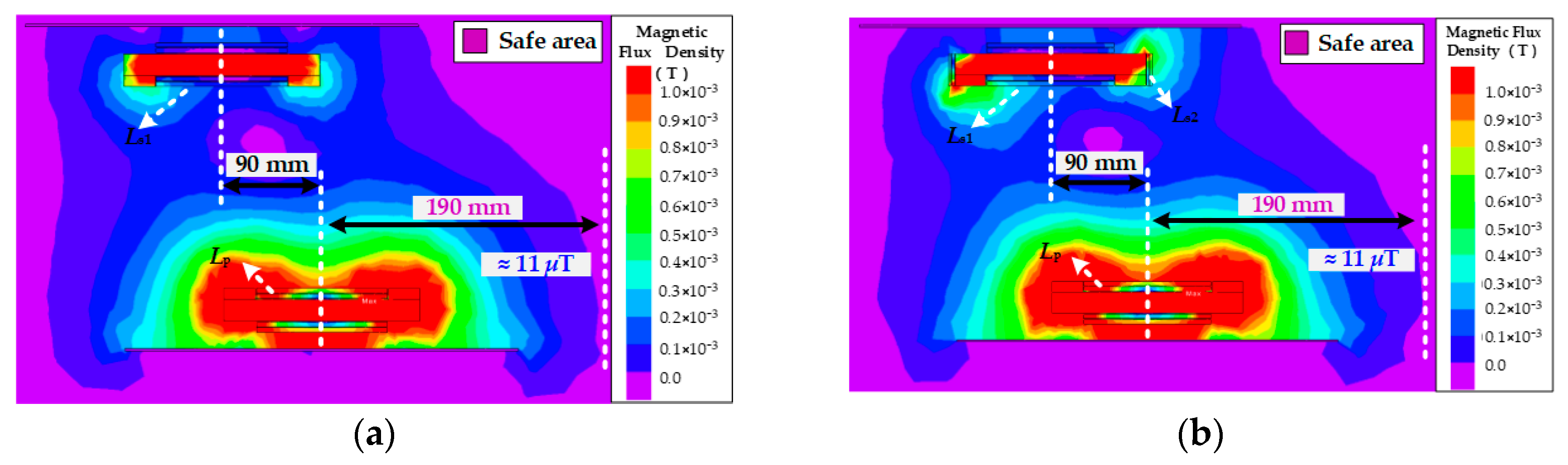

3.1. Analyze the FUS Magnetic Coupling Structure

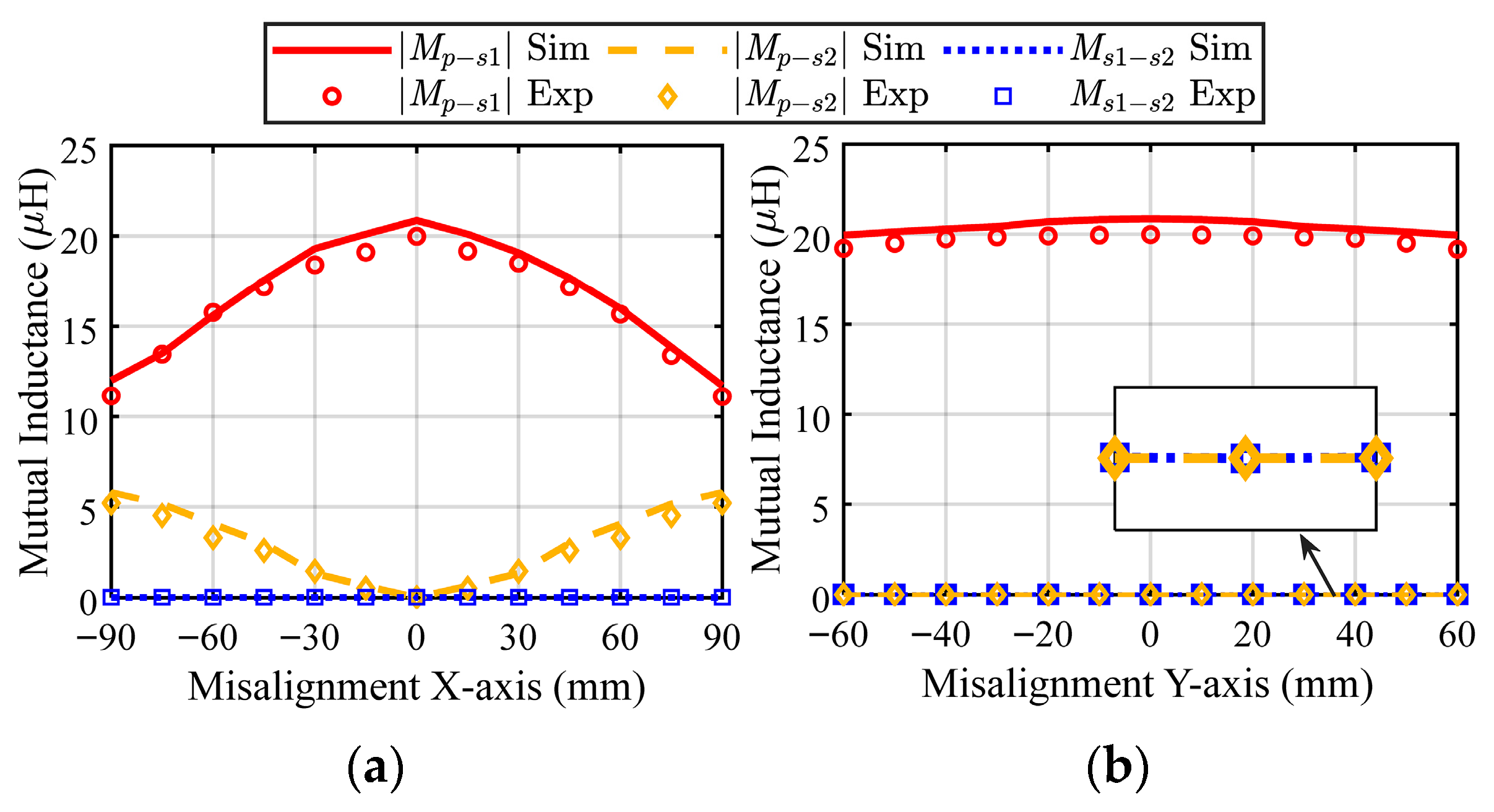

3.2. Analysis of the FUSS Magnetic Coupling Structure

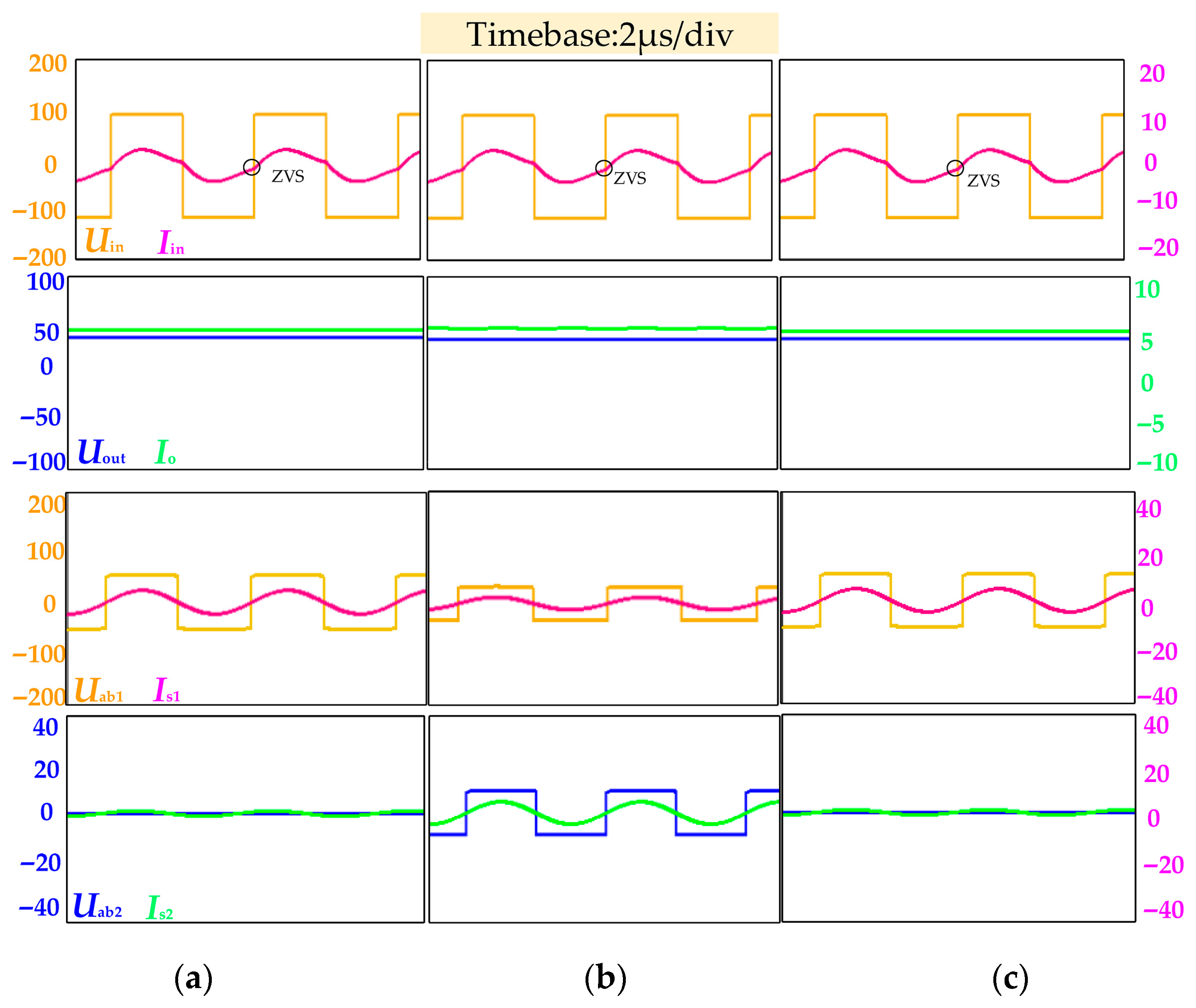

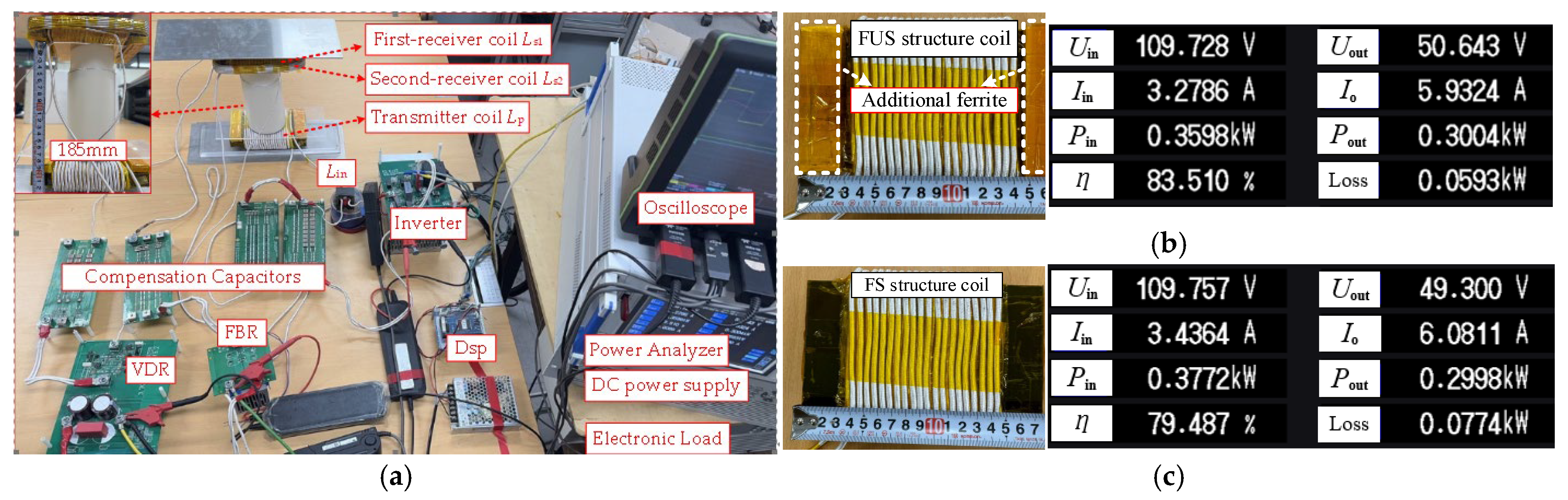

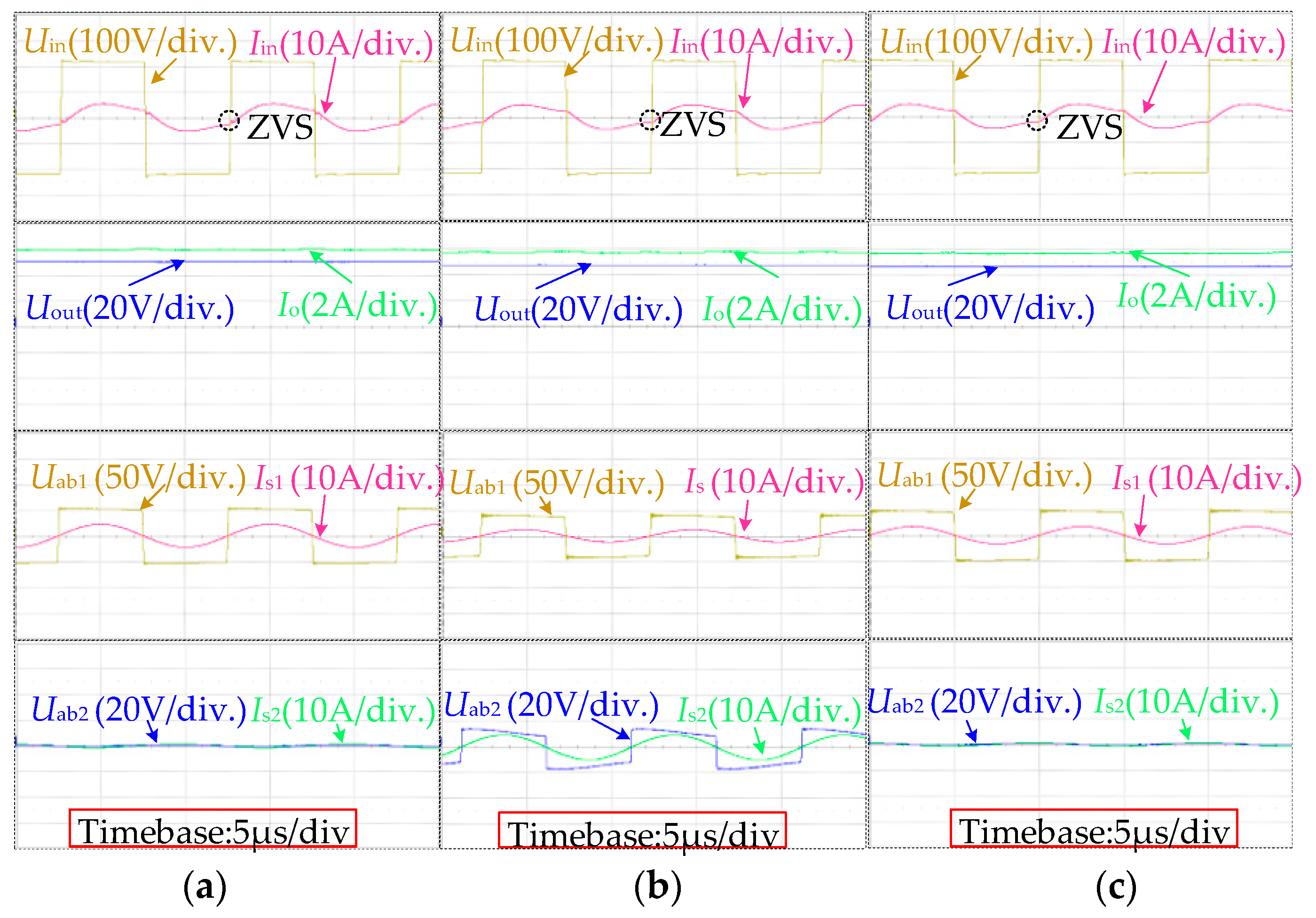

4. Experimental Verification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zeng, Y.; Clerckx, B.; Zhang, R. Communications and signals design for wireless power transmission. IEEE Trans. Commun. 2017, 65, 2264–2290. [Google Scholar] [CrossRef]

- Zhang, Z.; Pang, H.; Georgiadis, A.; Cecati, C. Wireless power transfer—An overview. IEEE Trans. Ind. Electron. 2019, 66, 1044–1058. [Google Scholar] [CrossRef]

- Li, L.; Xu, Y.; Zhang, Z.; Yin, J.; Chen, W.; Han, Z. A prediction-based charging policy and interference mitigation approach in the wireless powered Internet of Things. IEEE J. Sel. Areas Commun. 2019, 37, 439–451. [Google Scholar] [CrossRef]

- Yu, X.; Feng, J.; Zhu, L.; Li, Q. Design and optimization of a planar omnidirectional wireless power transfer system for consumer electronics. IEEE Open J. Power Electron. 2024, 5, 311–322. [Google Scholar] [CrossRef]

- Hoang, H.; Lee, S.; Kim, Y.; Choi, Y.; Bien, F. An adaptive technique to improve wireless power transfer for consumer electronics. IEEE Trans. Consum. Electron. 2012, 58, 327–332. [Google Scholar] [CrossRef]

- Xia, C.; Liu, L.; Liu, Y.; Ma, Z. IPT system for tail-free household appliances in the smart home system. IET Power Electron. 2019, 12, 1002–1010. [Google Scholar] [CrossRef]

- Budhia, M.; Boys, J.T.; Covic, G.A.; Huang, C.-Y. Development of a single-sided flux magnetic coupler for electric vehicle IPT charging systems. IEEE Trans. Ind. Electron. 2013, 60, 318–328. [Google Scholar] [CrossRef]

- Zaheer, A.; Hao, H.; Covic, G.A.; Kacprzak, D. Investigation of multiple decoupled coil primary pad topologies in lumped IPT systems for interoperable electric vehicle charging. IEEE Trans. Power Electron. 2015, 30, 1937–1955. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, Y.; Zhang, H.; Zhu, C.; Diao, L.; Gong, M.; Zhang, W.; Mi, C.C. A low-voltage and high-current inductive power transfer system with low harmonics for automatic guided vehicles. IEEE Trans. Veh. Technol. 2019, 68, 3351–3360. [Google Scholar] [CrossRef]

- Qu, Y.; Zhang, B.; Gu, W.; Shu, X. Wireless power transfer system with high-order compensation network based on parity-time-symmetric principle and relay coil. IEEE Trans. Power Electron. 2023, 38, 1314–1323. [Google Scholar] [CrossRef]

- Liu, X.; Jin, D.; Ji, H.; Liu, L.; Xia, C. Research on mutual inductance identification and efficiency optimization of the three-coil wireless power transfer systems with switchable relay coil. IEEE Trans. Power Electron. 2024, 39, 6492–6503. [Google Scholar] [CrossRef]

- Choi, B.G.; Kim, J.H.; Lee, E.S.; Kim, H.R.; Rim, C.T. Optimal dipole-coil ampere-turns design for maximum power efficiency of IPT. IEEE Trans. Power Electron. 2020, 35, 7317–7327. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, P.; Yao, Y.; Xu, D. Analysis and design of cubic magnetic coupler for high distance-to-diameter ratio IPT systems. IEEE Trans. Ind. Electron. 2022, 69, 409–419. [Google Scholar] [CrossRef]

- Fu, C.; Wang, D.; Zhao, Q. A compact and coupling-smooth magnetic coupler design for AGV wireless charging application. IEEE Access 2023, 11, 11288–11297. [Google Scholar] [CrossRef]

- Ramezani, A.; Narimani, M. A new wireless EV charging system with integrated DC–DC magnetic element. IEEE Trans. Transp. Electrif. 2019, 5, 1112–1123. [Google Scholar] [CrossRef]

- Darvish, P.; Cao, H.; Uddin, M.F.; Wang, H.; Zhao, Y. A generic coupled and/or decoupled integrated inductors optimization for WPT applications. IEEE Trans. Power Electron. 2025, 40, 15976–16003. [Google Scholar] [CrossRef]

- Lin, H.; Cai, C.; Wu, S.; Jiao, Y.; Chai, W.; Yu, J. Compact and misalignment tolerance IPT system based on sine-cosine coupling superposition for autonomous underwater vehicle applications. IEEE Trans. Transp. Electrif. 2025, 11, 6940–6951. [Google Scholar] [CrossRef]

- Mai, J.; Wang, Y.; Yao, Y.; Sun, M.; Xu, D. High-misalignment-tolerant IPT systems with solenoid and double D pads. IEEE Trans. Ind. Electron. 2022, 69, 3527–3535. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, W.; Zhao, J.; Wu, X.; Chen, H.; Xu, D. A novel asymmetric magnetic coupler applied to multiple-receiver wireless charging system for automated guided vehicles. IEEE Trans. Power Electron. 2023, 38, 14761–14775. [Google Scholar] [CrossRef]

- Mai, R.; Luo, Y.; Yang, B.; Song, Y.; Liu, S.; He, Z. Decoupling circuit for automated guided vehicles IPT charging systems with dual receivers. IEEE Trans. Power Electron. 2020, 35, 6652–6657. [Google Scholar] [CrossRef]

- Li, G.; Zhang, H.; Chen, Y.; Xie, J.; Jo, C.-H.; Zhu, C.; Cui, S.; Kim, D.-H. An integrated mutually compensatory dual receiver for AGV misalignment-tolerant IPT charging. IEEE Trans. Circuits Syst. II Express Briefs 2024, 72, 313–317. [Google Scholar] [CrossRef]

- Li, G.; Zhang, H.; Chen, Y.; Yin, Y.; Liu, A.; Li, Z.; Zhang, M. Design and implementation of a coupled complementary IPT system for extensive misalignment tolerance and CC/CV outputs. IEEE Trans. Transp. Electrif. 2025, 11, 8390–8403. [Google Scholar] [CrossRef]

- Shen, Z.; Zhou, H.; Xie, R.; Zhuang, Y.; Mao, X.; Zhang, Y. A strong offset-resistant electric vehicle wireless charging system based on dual decoupled receiving coils. IEEE Trans. Ind. Electron. 2024, 71, 15216–15219. [Google Scholar] [CrossRef]

- Imtiaz, T.; Elsanabary, A.; Mubin, M.; Soon, T.K.; Mekhilef, S. Enhancing misalignment tolerance using naturally decoupled identical dual-transmitter–dual-receiver coils for wireless EV charging system. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 5337–5351. [Google Scholar] [CrossRef]

- Darvish, P.; Hossain, A.; Mekhilef, S.; Tey, K.S.; Mubin, M.B.; Yin, J.; Akhtar, M.M.; Mustafa, A.; Khalid, H.; Imtiaz, T.; et al. Dual-receiver based naturally decoupled coil structure with improved rotational misalignment tolerance for WPT systems. IEEE Trans. Transp. Electrif. 2024, 10, 5412–5423. [Google Scholar] [CrossRef]

- Xu, H.; Huang, Z.; Li, X.L.; Tse, C.K. Misalignment-tolerant IPT coupler with enhanced magnetic flux variation suppression and reduced copper usage. IEEE Trans. Power Electron. 2024, 39, 10506–10517. [Google Scholar] [CrossRef]

| Rectification Combination Type | FBR + FBR | VDR + VDR | FBR + VDR |

|---|---|---|---|

|  |  | |

| Output Voltage | |||

| Uout sensitivity to misalignment | Low | High | Medium |

| Relative Ls2 copper usage | High | Medium | Small |

| Variable | Selected Value |

|---|---|

| Transmitter coil | Size of 110 mm × 116 mm × 38 mm |

| Transmitter coil turns | 40 turns |

| First-receiver coil | Size of 110 mm × 116 mm × 38 mm |

| First-receiver turns | 40 turns |

| Second-receiver coil | Size of 183 mm × 125 mm × 30 mm |

| Second-receiver turns | 28 turns |

| Air gap | 185 mm |

| Ferrite plate | PM12 (TODA ISU) |

| Variable | Selected Value | Variable | Selected Value |

|---|---|---|---|

| Uin | 110 V | Lp | 417.82 μH |

| Uout | 50 V | Ls1 | 415.23 μH |

| Pout | 300 W | Ls2 | 207.66 μH |

| fo | 100 kHZ | Lin | 39.55μH |

| k | 0.047 | Cp | 64.07 nF |

| Mp–s1 | 19.85 μH | Cf | 6.70 nF |

| Mp–s2 | 0.08 μH | Cs1 | 6.10 nF |

| Ms1–s2 | 0.06 μH | Cs2 | 12.20 nF |

| Proposed in | Ref. [18] | Ref. [20] | Ref. [21] | Ref. [26] | This Paper |

|---|---|---|---|---|---|

| Coil structure | SDDP | Coaxial dual receiver | IMCDR | RSP | FUSS |

| Maximum pad size (mm) | 250 × 200 | 100 × 100 | 220 × 180 | 300 × 300 | 183 × 125 |

| Air gap (mm) | 50 | 50 | 45 | 60 | 185 |

| DDR | 0.22 | 0.5 | 0.28 | 0.2 | 1.03 |

| Misalignment X-axis | 44% | N/D | 172% | 50% | 51.4% |

| Misalignment Y-axis | 67% | N/D | N/D | N/D | 51.7% |

| Number of Diodes | 4 | 8 | 8 | 8 | 6 |

| Output fluctuation | <6% | N/D | <5.82% | <10.8% | <5% |

| Maximum power | 0.3 kW | 0.3 kW | 0.54 kW | 1 kW | 0.3 kW |

| Magnetic coupler volume (mm3) | ☆☆ | ☆☆ | ☆☆ | ☆☆ | ☆ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Li, G.; Yang, Z.; Jo, S.; Kim, D.-H. Design of a Compact IPT System for Medium Distance-to-Diameter Ratio AGV Applications with Enhanced Misalignment Tolerance. Appl. Sci. 2025, 15, 9799. https://doi.org/10.3390/app15179799

Xie J, Li G, Yang Z, Jo S, Kim D-H. Design of a Compact IPT System for Medium Distance-to-Diameter Ratio AGV Applications with Enhanced Misalignment Tolerance. Applied Sciences. 2025; 15(17):9799. https://doi.org/10.3390/app15179799

Chicago/Turabian StyleXie, Junchen, Guangyao Li, Zhiliang Yang, Seungjin Jo, and Dong-Hee Kim. 2025. "Design of a Compact IPT System for Medium Distance-to-Diameter Ratio AGV Applications with Enhanced Misalignment Tolerance" Applied Sciences 15, no. 17: 9799. https://doi.org/10.3390/app15179799

APA StyleXie, J., Li, G., Yang, Z., Jo, S., & Kim, D.-H. (2025). Design of a Compact IPT System for Medium Distance-to-Diameter Ratio AGV Applications with Enhanced Misalignment Tolerance. Applied Sciences, 15(17), 9799. https://doi.org/10.3390/app15179799